Page 1

C

Specifications

ST 3000 Series

SX 3000 Series

Stackers

ST/SX 3000

Series

Page 2

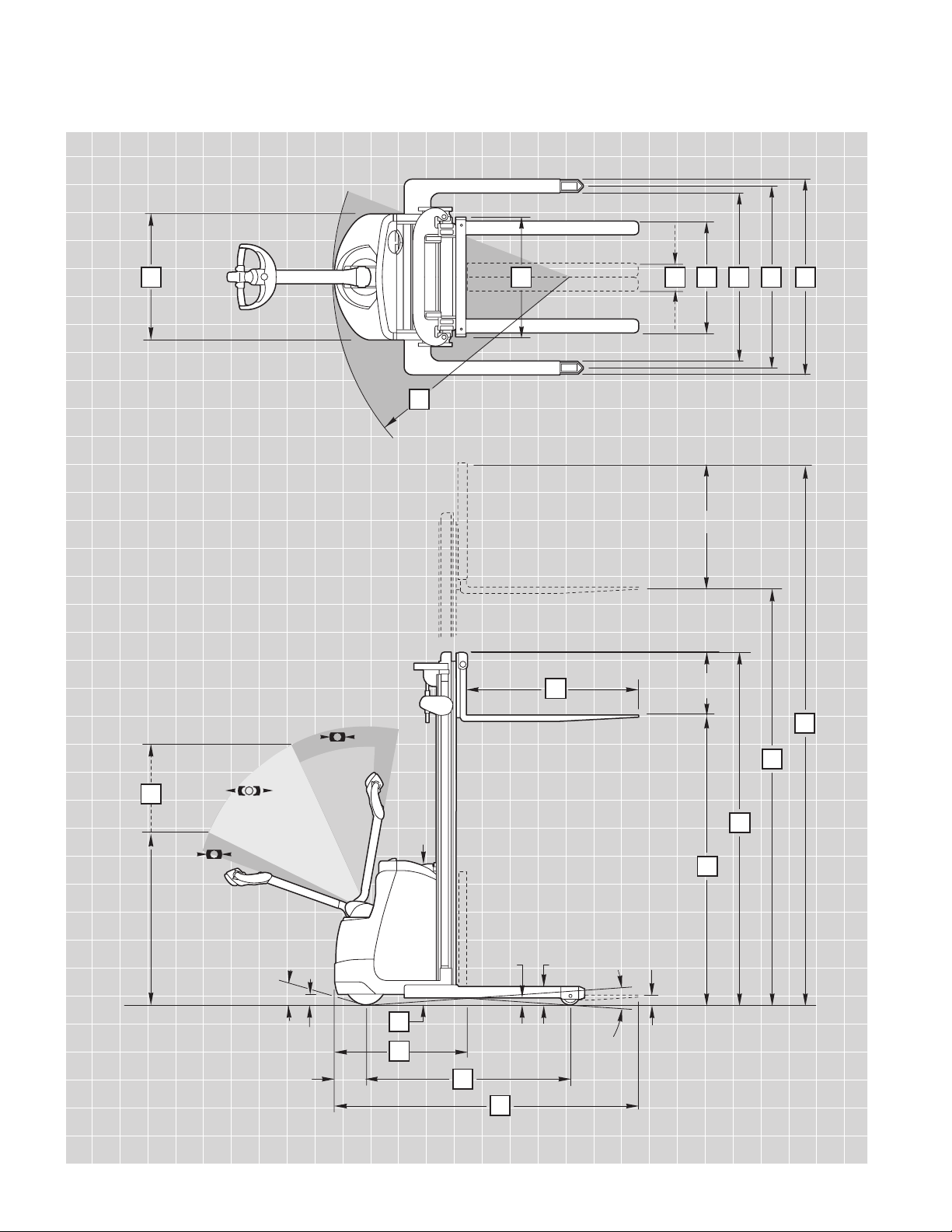

21

4"

12.8%

1.57"

31

7

32

7.5"

18

20

19

42.4%

2.36"

27

2"

28

38

17 34333034 30

23

35

17.2

"

BRAKE

DRIVE

BRAKE

OVERRIDE

BRAKE

36

"

C

ST 3000 Series

Stackers

Page 3

1 Manufacturer Crown Equipment Corporation

2 Model ST 3000N-20 ST 3000-20 ST 3000-20 ST 3000-20

Mast Type in (mm) TL-128 (3236) TL-128 (3236) TT-154 (3912) TT-168 (4267)

3 Power Electric

4 Operator Type Walkie

5 Load Capacity Max lb (kg) 2000 (907)

6 Load Center in (mm) 24 (600)

7 Wheelbase in (mm) 49 (1255)

8 Weight Less Battery lb (kg) 1775 (805) 1828 (829) 2004 (909) 2004 (909)

13 Wheel Size Front (d x w) Vulkollan in (mm) 10 x 3.35 (254 x 85)

Rubber in (mm) 10 x 4 (254 x 100)

14 Wheel Size Rear (d x w) Vulkollan in (mm) 4 x 2 (102 x 50)

Steel in (mm) 4 x 2 (102 x 50)

15 Additional Wheels

Caster Wheel (d x w)

Poly in (mm) 3.54 x 2 (90 x 50)

16 Wheels Number (x=driven) Front/Rear 1x / 2

17 Track Width Rear in (mm) Inside Straddle + 3 (76)

18 Lift Height in (mm) 127.4 (3236) 127.4 (3236) 154 (3912) 168 (4267)

18a Capacity at Lift Height 24" Load Center lb (kg) 2000 (907) 2000 (907) 2000 (907) 2000 (907)

26" Load Center lb (kg) 1850 (840) 1850 (840) 1850 (840) 1850 (840)

28" Load Center lb (kg) 1720 (780) 1720 (780) 1720 (780) 1720 (780)

30" Load Center lb (kg) 1600 (725) 1600 (725) 1600 (725) 1600 (725)

19 Free Lift w/o Load Backrest in (mm) 6 (152) 6 (152) 56 (1422) 56 (1422)

20 Collapsed Height in (mm) 83 (2108) 83 (2108) 73 (1858) 73 (1858)

21 Extended Height w/o Load Backrest in (mm) Lift Height + 17.2 (436)

w/Load Backrest in (mm) Lift Height + 36 (914)

22 Load Backrest Width Load Backrest Height

in (mm) 36 (914) / 42 (1067) / 48 (1219)

36" (914) High

23

Tiller Arm Ht in Drive Position

Min/Max in (mm) 31.1 (790) / 47.5 (1206)

24 Outrigger Height in (mm) 4 (100)

25 Lowered Fork Height in (mm) 2 (51)

27 Power Unit Height in (mm) 32.28 (820)

28 Fork Lengths in (mm) 36 (914) / 42 (1067) / 48 (1219)

29 Fork Dimensions Thickness x Width in (mm) 1.5 x 3 (38 x 76)

30 Width Across Forks Adjustable Min/Max in (mm) 6.57 - 24.8 (167 - 630)

31 Headlength in (mm) 32.24 (819) 32.24 (819) 32.95 (837) 32.95 (837)

32 Overall Length Headlength + Fork Length

33 Inside Straddle in (mm)

29.3-36 (744-914) 38-50 (965-1270) 38-50 (965-1270) 38-50 (965-1270)

34 Overall Width Front in (mm) 28.03 (712)

Rear in (mm) Inside Straddle + 6 (152)

35 Fork Carriage Width in (mm) 26.57 (675)

36 Ground Clearance w/Load below Mast in (mm) 1.57 (40)

37 Center Wheelbase in (mm) 1.57 (40)

38 Turning Radius in (mm) 56.73 (1446)

39 Length w/Outriggers in (mm) 60.28 (1536)

40 Travel Speed

w/wo Load

mph (km/h) 3.11 / 3.42 (5.0 / 5.5)

41 Lift Speed

w/wo Load

fpm (m/s) 25.59 / 39.37 (.13 / .20)

42 Lowering Speed 1

w/wo Load

fpm (m/s) 49.21 / 49.21 (.25 / .25)

Lowering Speed 2

w/wo Load

fpm (m/s) 19.69 / 11.81 (.10 / .06)

43 Gradeability

w/wo Load, 60 min Rating

% 2.4 / 4.5

w/wo Load, 30 min Rating

% 4.9 / 9.1

44 Max Gradeability

w/wo Load, 5 min Rating

% 8.4 / 15.7

45 Service Brake Electric

46 Maximum Battery Box L x W x H in (mm) 7.28 x 25.55 x 24.13 (185 x 649 x 613) (w/No Clearance)

47 Battery Voltage (Nominal 4x Automotive Starter V/Ah 24 / 87

Capacity 6 Hour Rating) 2x 12v MF V/Ah 24 / 95

4x Semi-industrial V/Ah 24 / 156

4x 6v MF V/Ah 24 / 195

48 Type of Controller Drive Transistor

49 Battery Weight 4x Automotive Starter lb (kg) 128 (58)

2x 12v MF lb (kg) 132 (60)

4x Semi-industrial lb (kg) 220 (100)

4x 6v MF lb (kg) 267 (121)

ST 3000 Series

Specifications

General Information

Tires

Dimensions

Performance

Battery

English conversions are approximations. Metric conversions should be done to find true values.

Page 4

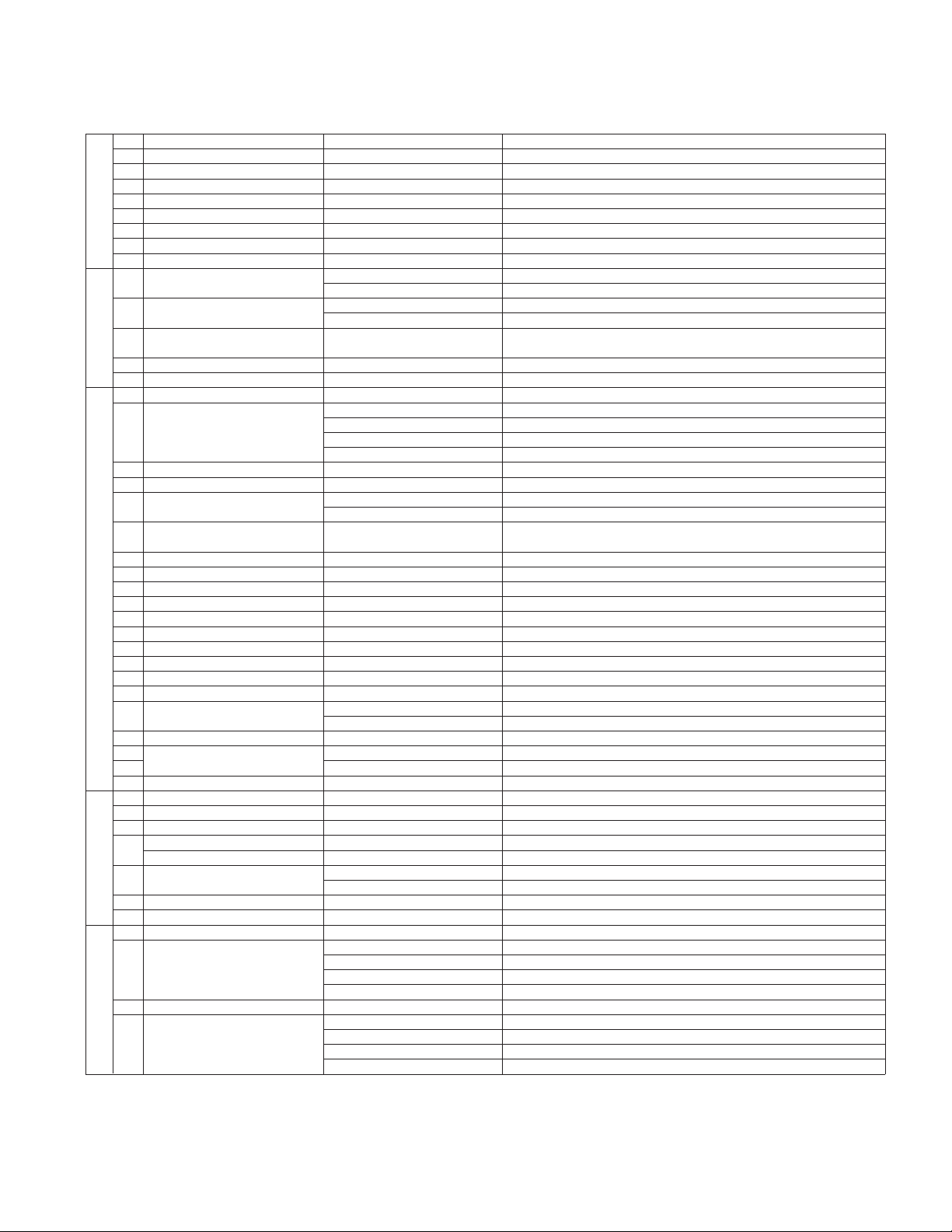

21

18

20

19

42.4%

2.36"

27

1.57"

31

7

32

7.5"

4"

11. 9%

28

47.3

"

30 17 3433

38

34

2"

20

"

30

23

BRAKE

DRIVE

BRAKE

OVERRIDE

BRAKE

35

C

SX 3000 Series

Stackers

Page 5

1 Manufacturer Crown Equipment Corporation

2 Model SX 3000-30 SX 3000-30 SX 3000-30

Mast Type in (mm) TL-128 (3236) TT-154 (3912) TT-168 (4267)

3 Power Electric

4 Operator Type Walkie

5 Load Capacity Max lb (kg) 3000 (1361)

6 Load Center in (mm) 24 (600)

7 Wheelbase in (mm) 53.6 (1362)

8 Weight Less Battery Auxiliary lb (kg) 2247 (1019) 2423 (1099) 2423 (1099)

No Auxiliary lb (kg) 2143 (972) 2319 (1052) 2319 (1052)

13 Wheel Size Front (d x w) Vulkollan in (mm) 10 x 3.35 (254 x 85)

Rubber in (mm) 10 x 4 (254 x 100)

14 Wheel Size Rear (d x w) Vulkollan in (mm) 4 x 3 (102 x 73)

15 Additional Wheels

Caster Wheel (d x w)

Poly in (mm) 3.54 x 2 (90 x 50)

16 Wheels Number (x=driven) Front/Rear 1x / 2

17 Track Width Rear in (mm) Inside Straddle + 4 (102)

18 Lift Height in (mm) 127.4 (3236) 154 (3912) 168 (4267)

18a Capacity at Lift Height** 24" Load Center lb (kg) 3000 (1361) 3000 (1361) 2500 (1134)

26" Load Center lb (kg) 2700 (1225) 2700 (1225) 2200 (998)

28" Load Center lb (kg) 2500 (1134) 2500 (1134) 2000 (907)

30" Load Center lb (kg) 2250 (1020) 2250 (1020) 1750 (795)

19 Free Lift w/o Load Backrest in (mm) 6 (152) 53 (1347) 53 (1347)

20 Collapsed Height in (mm) 83 (2108) 73 (1858) 73 (1858)

21 Extended Height w/o Load Backrest in (mm) Lift Height + 20 (510)

w/Load Backrest in (mm) Lift Height + 47.3 (1202)

22 Load Backrest Size in (mm) 47.3 (1202) H x 32.7 (832) W

23

Tiller Arm Ht in Drive Position

Min/Max in (mm) 31.1 (790) / 47.5 (1206)

24 Outrigger Height in (mm) 4 (100)

25 Lowered Fork Height in (mm) 2 (50)

27 Power Unit Height in (mm) 32.28 (820)

28 Fork Lengths in (mm) 36 (914) / 42 (1067) / 48 (1219)

29 Fork Dimensions Thickness x Width in (mm) 1.5 x 4 (38 x 102)

30 Width Across Forks Adjustable Min/Max in (mm) 10 - 30.93 (253.6 - 785.6)

31 Headlength* in (mm) 34.02* (869*) 34.72* (887*) 34.72* (887*)

32 Overall Length Headlength + Fork Length

33 Inside Straddle in (mm) 38-50 (965-1270)

34 Overall Width Front in (mm) 28.03 (712)

Rear in (mm) Inside Straddle + 8 (204)

35 Fork Carriage Width in (mm) 31.89 (810)

36 Ground Clearance w/Load below Mast in (mm) 1.57 (40)

37 Center Wheelbase in (mm) 1.57 (40)

38 Turning Radius in (mm) 61.14 (1553)

39 Length with Outriggers in (mm) 65 (1651)

40 Travel Speed

w/wo Load

mph (km/h) 3.42 / 3.73 (5.5 / 6.0)

41 Lift Speed

w/wo Load

fpm (m/s) 31.50 / 49.21 (.16 / .25)

42 Lowering Speed 1

w/wo Load

fpm (m/s) 51.18 / 41.34 (.26 / .21)

Lowering Speed 2

w/wo Load

fpm (m/s) 11.81 / 5.91 (.06 / .03)

43 Gradeability

w/wo Load, 60 min Rating

% 2.6 / 5.2

w/wo Load, 30 min Rating

% 4.4 / 8.7

44 Max Gradeability

w/wo Load, 5 min Rating

% 9.5 / 19.4

45 Service Brake Electric

46 Maximum Battery Box L x W x H in (mm) 9.1 x 26.4 x 23.62 (230 x 670 x 600) (w/No Clearance)

47 Battery Voltage (Nominal 4x 6v MF V/Ah 24 / 195

Capacity 6 Hour Rating) 300 Industrial V/Ah 24 / 300

48 Type of Controller Drive Transistor

49 Battery Weight 4x 6v MF lb (kg) 267 (121)

300 amp hour Industrial

lb (kg) 360-710 (163-322)

SX 3000 Series

Specifications

* Add 2.24" (57 mm) for Sideshift Option.

**Deduct 300 lb for Sideshift Option.

English conversions are approximations. Metric conversions should be done to find true values.

General Information

Tires

Dimensions

Performance

Battery

Page 6

ST/SX 3000 Series

Technical Information

Standard Equipment

1. 24 volt fused electrical

system

2. MOSFET transistorized

traction control system

3. Separately excited drive

motor (SEM)

4. Wet-cell starter battery

pack, four 6-volt batteries at

87 amp hour (ST)

5. Maintenance-free battery

pack, four 6-volt batteries at

195 amp hour (SX)

6. 30 amp fully automatic

charger

7. Electric brake

8. Brake override

9. Anti-roll down

10. Regenerative motor braking

11. Heavy-duty drive unit

12. Drive unit enclosed in high

ductile strength steel frame

13. Stamped steel power

unit cover

14. Safety reversing button

15. 175 amp connector with

disconnect handle

16. Color-coded wiring

17. High speed cut-out at

lift height

18. Two pre-programmed

performance levels

19. 10" x 3.35" wide Vulkollan

drive tire

20. Vulkollan load wheels

4" x 2" wide (ST)

4" x 3" wide (SX)

21. Adjustable outriggers

22. Battery compartment

storage tray

23. Plexiglas mast guard

24. One-speed lift, two-speed

lower – soft start hydraulics

(SX only)

25. Horn

26. Key switch

27. Discharge indicator with

hour meter and lift lockout

28. Hydraulic thermal protection

switch (SX only)

Optional Equipment

1. Rubber drive tire

2. Non-marking rubber

drive tire

3. Diamond siped rubber

drive tire

4. Spring loaded poly casters

5. Handset analyzer for

calibration or fault analyzing

6. 36" high load backrest (ST),

48" high load backrest (SX)

7. Maintenance-free, semiindustrial or starter battery

package (ST)

9. Freezer/corrosion

conditioning (SX only)

10. Keyless on/off toggle switch

in lieu of key switch

11. Steel load wheels (ST only)

12. Wire mesh mast guard

13. Sideshift (SX only)

14. Soft start hydraulic control

(ST only)

15. Work Assist™ Accessories:

• Clip pad and hook

• Operator fan

• Storage pocket

• Remote raise/lower

control

16. Work Assist Options:

• Load backrest tray

• Work platform

Platform options:

- Work lights

- Operator fan

- Clip pad and hook

- Adjustable load tray

- Remote raise/lower

control

- Casters

• Snap-on platform

(ST only)

Battery and Charger

ST 3000-20

Battery package options are as

follows:

• Maintenance-free battery

pack, two 12-volt batteries at

95 amp hour

four 6-volt batteries at 195

amp hour

• Semi-industrial deep cycle

battery pack, four 6-volt

batteries at 156 amp hour

• Wet-cell starter battery pack,

four 6-volt batteries at 87

amp hour

Flooded battery packs have a

slide-out feature to check water

level of bottom batteries.

SX 3000-20

Battery options are as follows:

• Maintenance-free battery

pack, four 6-volt batteries at

195 amp hour

• Industrial battery - The 9.1"

battery compartment will

accept an industrial storage

battery up to 300 amp hour

capacity.

A built-in 30-amp charger is

standard with all battery packs.

This premium fan-cooled, solidstate charger is durable and

efficient. It has an advanced

memory feature to allow for

opportunity charging. The

charger can be set for either

maintenance free, wet cell or

industrial batteries. An extension

cord is included with any truck

equipped with the built-in

battery charger.

Add 6" to all aisle dimensions for maximum maneuverability.

Add 6" to all aisle dimensions for maximum maneuverability.

Add 2" if sideshift option is used.

ST/SX 3000 Series

Aisle Planning Guide

ST 3000 – Right Angle and Intersecting Aisle

Pallet Length

Pallet 30 36 40 42 48

Width

ABABAB ABAB

36

in 57.6 62.9 57.6 62.9 57.6 62.9 57.6 62.9 57.6 68.4

mm 1463 1599 1463 1599 1463 1599 1463 1599 1463 1738

40

in 60.9 64.0 60.9 64.0 60.9 64.0 60.9 64.0 60.9 68.6

mm 1546 1625 1546 1625 1546 1625 1546 1625 1546 1625

42

in 62.5 64.5 62.5 64.5 62.5 64.5 62.5 64.5 62.5 68.7

mm 1588 1638 1588 1638 1588 1638 1588 1638 1588 1746

48

in 67.5 69.0 67.5 69.0 67.5 69.0 67.5 69.0 67.5 72.0

mm 1715 1752 1715 1752 1715 1752 1715 1752 1715 1829

SX 3000 – Right Angle and Intersecting Aisle

Pallet Length

Pallet 30 36 40 42 48

Width

ABABAB ABAB

36

in 61.2 67.1 61.2 67.1 61.2 67.1 61.2 67.1 61.2 67.8

mm 1554 1704 1554 1704 1554 1704 1554 1704 1554 1722

40

in 64.5 68.1 64.5 68.1 64.5 68.1 64.5 68.1 64.5 68.1

mm 1638 1730 1638 1730 1638 1730 1638 1730 1638 1730

42

in 66.1 68.6 66.1 68.6 66.1 68.6 66.1 68.6 66.1 68.6

mm 1680 1743 1680 1743 1680 1743 1680 1743 1680 1743

48

in 71.1 72.9 71.1 72.9 71.1 72.9 71.1 72.9 71.1 72.9

mm 1807 1851 1807 1851 1807 1851 1807 1851 1807 1851

B

Right Angle Aisles

Pallet

Width

Pallet

Length

A

Equal Intersecting Aisles

Page 7

ST/SX 3000 Series

Technical Information

Operator Controls

The control hand grips are

urethane covered for insulation

from cold and vibration. Full

function control handle includes

travel direction, raise, lower and

reversing switch.

The physical efforts to hold the

handle at a comfortable height

was minimized to reduce fatigue

a distinct advantage. The

operator is positioned to

maximize the steer effort and

maintain excellent visibility.

The rabbit/turtle switch

incorporates two levels of

programmable travel performance

to match operator experience

and application environment.

Exclusive brake override allows

slow speed travel with the

handle near vertical. This feature

improves maneuverability in

tight areas.

Performance

The ST/SX 3000 Series benefits

from Crown’s design and

engineering excellence.

The transistor control module

works in conjunction with a new

separately excited (SEM) drive

motor to provide excellent acceleration and top travel speed

loaded or empty. Transistor

control is programmable for

specific tasks or operator

skill levels.

Smooth travel and lift combine

with excellent controls to reduce

product damage and increase

productivity.

Electrical System

A heavy-duty 24-volt fused

electrical system provides good

travel and lift speeds.

Separately excited motor control

eliminates directional contactors

reducing maintenance and

downtime.

The transistor control is sealed

from dirt, dust and moisture for

trouble-free operation. Transistor

control features include overtemperature protection, polarity

protection, self-test and visible

diagnostics.

Regenerative motor braking is

activated under a downhill condition, during plugging or when

the directional control is returned

to neutral. “Regen” reduces heat

build-up and extends motor

brush life.

An anti-roll down feature will

apply the brakes if the truck rolls

without a travel command.

175-amp battery connector with

standard disconnect handle.

Hydraulic System

Heavy-duty hydraulic motor

(ST–2.2 kw, SX–3.0 kw) with

integral pump and reservoir for

maximum efficiency and

durability.

Single-speed lift and two-speed

lowering is available to the

operator.

Cylinder rods are hard-plated

chrome with polyurethane seals.

Relief valve tuned to capacity

protects all components in the

hydraulic system.

Drive Unit and Brakes

Heavy-duty gearbox with spur

gears for low noise emission.

Drive unit is equipped with an

electromagnetic disc brake that

is spring applied and electrically

released. Brake is activated by

the control handle position.

Brake rotor and disc are easily

accessed for inspection and

replacement. Regenerative motor

braking assists brake effort and

improves component life.

Drive unit mounts in truck frame

with a permanently lubricated,

twin-conical roller bearing that

disperses load forces evenly,

reducing maintenance and

downtime.

Mast

High visibility two- and threestage mast design features

nested I-beams and canted

rollers. Lift cylinders are positioned in outer I-beam profile for

best visibility through the mast

and clear view onto fork tips

during load handling. Mast

cushioning between stages

ensures smooth operation.

Heavy-duty mast and chain

rollers are sealed and lubricated

for life. Mast design allows for

easy access to carriage rollers.

Fork Carriage

ST 3000 Series feature 25" wide

pin-type fork carriage. Forks are

adjustable from 6.5" to 24.8".

Standard fork lengths are 36",

42" and 48".

SX 3000 Series feature a standard 32" wide ITA Class II fork

carriage. Forks are adjustable

from 10" to 31". Standard fork

lengths are 36", 42" and 48".

Ser viceability

One-piece steel power unit

cover is removed easily for

access to all major components.

Brake rotor and disc inspection

and replacement are easy.

Drive motor brush access is

excellent.

Color-coded wiring speeds

troubleshooting and the transistor control module uses visible

LED flashes for fault communication. Optional plug-in hand

set analyzer for servicing and

programming capability.

Control handle switch cap is

easily removed to expose

components.

Wheels and Tires

• Drive tire – Vulkollan

10" dia x 3.35" wide

• Load wheels – Vulkollan

4" dia x 2" wide (ST)

4" dia x 3" wide (SX)

• Optional poly casters are

3.5" dia x 2" wide

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Other Options Available

Contact your local Crown dealer.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifications are subject to change

without notice.

Page 8

C

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Te l 419-629-2311

Fax 419-629-3796

crown.com

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Momentum symbol and Work Assist are

trademarks of Crown Equipment Corporation.

Copyright 2004 Crown Equipment Corporation

SF14388 5/04

Printed in U.S.A.

Loading...

Loading...