Page 1

C

SR 5285H

Specifications

SR 5285H Series

Reach Truck

Series

Page 2

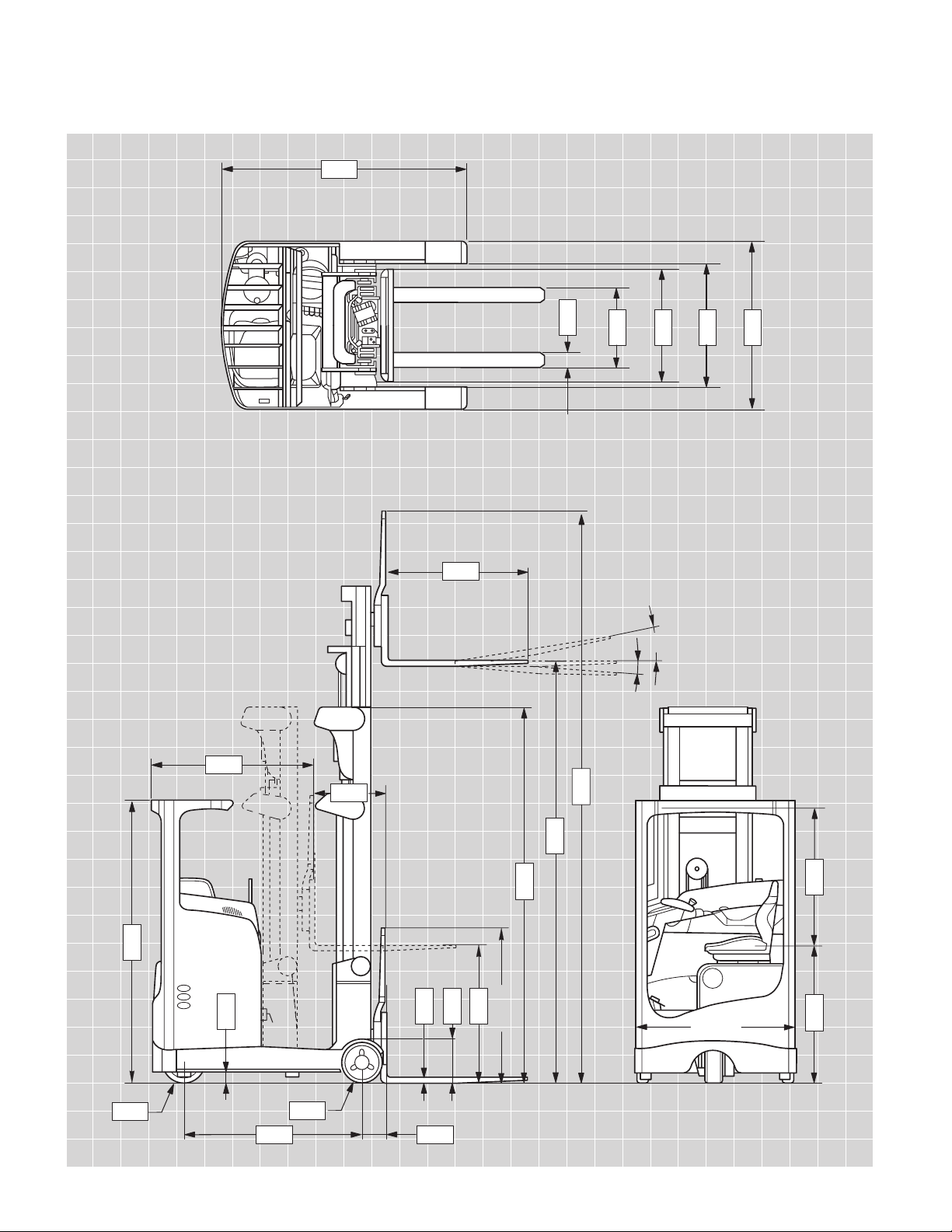

4.37

4.22

4.20

4.28

4.32

3.3

4.22

4.10

47.24"

4.3

4.2

4.4

4.5

2°

4°

4.21

1.8

49.80"

1.9

4.22

4.7

4.164.8

4.26

4.24

4.25

3.2

C

SR 5285H Series

Reach Truck

Page 3

SR 5285H Series

1.1 Manufacturer Crown Equipment Corporation

1.2 Model SR 5285H

1.3 Power Electric

1.4 Operator Type Rider / Seat

1.5 Load Capacity lb 4500

1.6 Load Center in 24

1.8 Load Distance Mast Extended in 8.54

General Information

1.9 Wheelbase in 58.07

2.1 Weight Less Battery lb 8110** (Option 1 Straddle)

3.1 Tire Type D / L in Vulkollan

3.2 Tires Front in 13.50 x 5.51

3.3 Tires Rear in 13.00 x 3.94

Tires

3.5 Wheels Number (x = driven) Front / Rear 1x / 2

4.1 Forkcarriage Tilt Forward / Backward º 2 / 4

4.2 Mast Collapsed Height in See Table 3

4.3 Free Lift* Load Backrest in See Table 3

4.4 Lift in See Table 3

4.5 Mast* (Extended Height) With Load Backrest in See Table 3

4.7 Overhead Guard Height in 84

4.8 Seat Height Compressed in 40.55

4.10 Outrigger Height in 13.62

4.15 Lowered Fork Height in 1.77

4.16 Head Room - Overhead Guard Not Compressed / Compressed in 39.49 / 40.20

4.20 Headlength in 58.03

4.21 Overall Width in See Table 1

4.22 Forks Standard H x W x L in 1.77 x 3.94 x 39.37

Dimensions

4.23 Fork Carriage ISO Class 2 A

4.24 Fork Carriage Width With Load Backrest in See Table 1

Fork Carriage Height in 45.67

Optional Fork Carriage Height in 31.50, 35.43, 39.37, 43.31, 47.24

4.25 Width Across Forks in See Table 1

4.26 Inside Straddle in See Table 1

4.28 Reach in 18.70

4.32 Ground Clearance Center Wheelbase in 2.99

4.37 Length over Outriggers in 74.92

5.1 Travel Speed With / Without Load mph 7.45 / 7.45

5.2 Lift Speed With / Without Load fpm 63 / 106

5.3 Lower Speed With / Without Load fpm 112 / 98

5.4 Reach Speed With / Without Load fpm 37 / 37

Performance

5.10 Service Brake Hydraulic

6.3 Max Battery Box Size in See Table 2

6.4 Battery Voltage Max Capacity 6h Rating V/Ah 48 / 1085

Battery

6.5 Battery Weight Minimum lb 2736

Optional Lengths in 42.01, 45.28, 48.03

Specifications

* With 47.24" Backrest

** With lift height 426"

Page 4

Table 1 - Straddle Options

Option 1 Option 2

4.21 Overall width in 56.10 62.01

4.24 Fork carriage width in 30.71 39.76

4.25 Width across forks, max in 29.52 38.58

4.26 Width inside straddle in 43.50 49.41

Sideshift movement in each direction in 2.75 3.94

Table 2 - Battery Size

6.3 Battery Size 46.97 x 30.56 x 19.64

L x H x W

* Remove standard spacer

*48.15 x 30.56 x 19.64

Table 3

SR 5285H Series

Specifications

4.4 4.2 4.3 4.5

Lift Height Overall Collapsed Height Free Lift** Overall Extended Height**

in in in in

360 145.4 99.8 406.10

378 151.3 105.7 423.81

391 155.6 110.0 436.81

426 167.4 121.8 472.24

450 175.3 129.7 495.87

** With 47.24" backrest

Page 5

SR 5285H Series

Technical Information

Capacity

Model SR 5285H: 4500 lb at

24" load center

Batteries/Electrical

System

The battery is pulled out of the

chassis with the reach carriage.

The battery can be removed

vertically or by rollers provided

allowing horizontal removal of

the battery from either side.

Standard Equipment

1. Crown Integrated Control

System with Access 1 2 3

2. Virtually maintenance free

three-phase (AC) motors

for traction, hydraulics

and steering

3. Motor controllers for traction, hydraulics and steering

4. CAN-Bus technology

5. Speed-sensitive electric

steering with programmable

turning ratios

6. Tilting steer column

7. Proportional fingertip control

for all hydraulic functions incorporating soft-lift/soft-stop

for smooth load movement

8. Information display:

• Access 1 2 3 on-board

diagnostics with real

time troubleshooting

capabilities

• Two-line LCD display with

16 characters per line

• Hour meters for

monitoring various truck

operating components

• Travel direction indicator

• Input for operator PIN

• Real-time clock and date

• Three selectable

performance profiles

• Battery discharge

indicator with lift lockout

• Steer wheel position

indicator

9. Integrated lift height and

load weight indicator with

truck performance linked

to fork height

10. Rack Height Select with

automatic laden/unladen

fork positioning starting

19.7" above secondary

mast staging

11. Tilt position assist

12. Free lift indicator, warning of

fork heights above free lift.

Can be programmed to

reduce top travel speed.

®

13. Thumb-operated travel

direction switch

14. Automotive type accelerator

and brake pedal

15. All-wheel braking

16. Braking systems:

• Parking brake

• Mechanical service brake

• Regenerative direction

reversal

• Regenerative coast

braking

17. Electric switch for parking

brake activation

18. Truck-Hold automatic

braking for slopes or

pushback racking

19. Electric power disconnect

switch

20. Vulkollan load wheels and

drive tire

21. Four easy-access storage

compartments

22. Comfortable knee and

hip padding within the

driver’s compartment

23. Comfortable suspension

seat with multiple

adjustment possibilities

24. Unique offset, wide

visibility mast

25. Clear view overhead guard

and load backrest

26. Lift slowdown prior to

reaching full mast extension

27. Reach-out battery system

28. Reach carriage slowdown

prior to reaching full extend

or retract position

29. Integrated sideshift with

tilting fork carriage

30. ISO Class 2A Forks

31. Battery plug SB 350

32. Battery rollers for horizontal

battery extraction

33. Strobe light

Optional Equipment

1. Lift cutout with/without

override switch

2. Mast mounted camera with

color or B&W monitor

3. Work lights 12-volt

4. Audible travel alarm

5. Dual-axis controls

6. Heated seat

7. Cloth seat

8. OHG covers

9. Work Assist™ Accessories

• Accessory pad clip

and hook

• Accessory clamp

• Accessory RF

mounting plate

• Accessory RF

mounting bracket

• Accessory clip pad

• Accessory hook

• Accessory pocket

• Accessory tube

10. Cold storage conditioning

for applications to -30° C

11. English/French/Spanish

labels

Driver’s Compartment

and Controls

A comfortable step height,

well-positioned grab handle and

non-slip floor mat ensure safe

and comfortable footing during

entry and exit.

Once seated, the operator has

the ability to tailor the compartment to “fit”. A high quality

comfortable seat can be

adjusted for the operator’s

weight. In addition, the seat can

be adjusted laterally, as well as

for the angle of the seatpad and

backrest. These adjustments,

coupled with a tilting steer

column, ensure a comfortable

position for any operator.

The left foot rests on the

operator “presence” pedal.

The right foot operates an

automotive style accelerator and

brake pedal arrangement, while

the right leg is supported by

ergonomically positioned

padding for the knee and hip

areas. The direction switch is

actuated with the right thumb

leaving the fingers of the right

hand free to operate all the

hydraulic controls. The fingertip

control levers allow for easy

blending of hydraulic functions

and are easily understood by

new or inexperienced operators.

There are four easily accessible

storage compartments. The

ergonomically formed armrest

is well padded and is designed

particularly with wrist support

in mind.

The display contains information

on the truck’s operating status,

a battery discharge indicator, a

travel direction indicator, steer

wheel position indicator, hour

meters for various truck operations, performance profile selection, and service information

for planned maintenance scheduling, fault finding and testing.

Coupled with a traditional

keyswitch, the information

display also serves as the PIN

input for those choosing to

employ the on-board user code

system thereby preventing

unauthorized use. The two-line

LCD display with 16 characters

per line is well illuminated for

excellent visibility. These standard features are complimented

by information such as fork

height and load weight indicators

should these options be chosen.

A further panel is integrated into

the chassis column and incorporates optional accessories such

as light switches.

Access 1 2 3

Integrated Control System

Crown’s Integrated Control

System provides unmatched

truck control for all primary

truck systems:

• Traction motor control

• Hydraulic valve and

motor control

• Steer motor control

• Braking

• Information/diagnostic display

Dedicated motor controllers are

employed to simplify troubleshooting and minimize replacement cost. All systems are linked

through CAN-Bus, which greatly

simplifies wiring while improving

diagnostic communication.

On ramps, or when interfacing

with push back racking, the

selectable Truck-Hold feature

electronically brakes the truck

when the accelerator is

released. The operator does

not have to apply the brake,

improving comfort and control

in these applications.

Selected travel speed remains

constant regardless of surfaces,

load weight or grades. The travel

speed, acceleration, and electric

braking ratio can be set via the

display, facilitating the best

possible productivity and energy

consumption for each application. Regenerative motor braking

helps save energy.

The control system for the

hydraulic pump motor and all

proportional hydraulics facilitates

precise and sensitive execution

of all hydraulic functions. All

hydraulic parameters such as lift,

lower, tilt, sideshift and reach

speeds are fully adjustable and

can therefore be adapted to

different applications.

®

Page 6

SR 5285H Series

Technical Information

Access 1 2 3

Integrated Control System

(continued)

Crown’s Access 1 2 3 Diagnostics is the most comprehensive

fault detection system in the

industry. A properly trained

technician can actively view

inputs and outputs during truck

operation thereby significantly

reducing search and downtime.

The information display is the

first point for troubleshooting.

All operator information such as

travel and hydraulic parameters,

truck monitors, etc. can be

obtained and adjusted via the

display. No handset or laptop

is required – all functions are

onboard and easy to use.

Performance Profiling

Three pre-set performance

profiles can be selected on the

display. The pre-set parameters

can be changed to a multitude

of other traction and hydraulic

parameters allowing adaptation

to each customer’s requirements.

Hydraulic System

Proportional control ensures all

hydraulic functions can be individually and precisely actuated

regardless of load. Four hydraulic

functions (lift/lower, tilt, sideshift,

reach) are standard. All hydraulic

hoses are internally reeved

through the mast.

The utilization of an internal

gear pump reduces the noise

level and ensures high efficiency

in all applications. The hydraulic

oil is filtered twice. The return

and suction filters can be

exchanged without draining

the hydraulic tank.

Mast and Reach Carriage

Crown’s unique offset, wide view

mast delivers excellent visibility at

height as well as for low-level

operations. Mast cross-bracing

and overhead guard bracing

have been angled and hose and

chain rollers have been canted to

further enhance visibility. A load

backrest designed for maximum

visibility is also standard. The

standard three-stage full-free lift

mast incorporates integrated

sideshift with tilting carriage,

hence reducing head length.

Mast channels are reinforced

to minimize static and

dynamic deflection.

Spring dampers are located on

the fork carriage to reduce noise

while staging and the lifting

speed is slowed before reaching

the lift limit. Elastomer dampers

between the mast stages and

hydraulic dampening in the

free-lift cylinder reduce noise

while lowering.

The anti-friction mast rollers are

canted to reduce energy consumption and ensure longer life.

The heavy-duty reach carriage

moves on four main roller

bearings. Two adjustable

backing rollers minimize

dynamic mast rocking while

four adjustable side rollers

ensure very smooth movement

and precise positioning.

Drive Unit

A highly efficient drive unit with

helical gears, integrated pinion

and vertically mounted threephase (AC) traction motor

provides quiet, powerful traction

performance. A large Vulkollan

drive wheel (13.50" x 5.51")

offers high load capacity, long

life and excellent travel comfort.

Steering

The electric steering system

is travel speed sensitive. It

provides fast direct response

with light effort for controlled

maneuverability. Variable steering

ratio can be programmed to suit

specific needs. A fail-safe control

circuit applies motor braking and

parking brake if a fault is detected.

Brakes

The foot pedal applies the

service brake. The brake pressure is distributed to the load

wheels and the drive wheel by a

master cylinder in combination

with regenerative motor braking.

This ensures the truck brakes

smoothly and efficiently.

The parking brake is activated by

a switch in the operator compartment. The spring-applied / electro-magnetically released brake

is applied on the drive wheel. The

parking brake is automatically

applied when the operator exits

the truck.

The truck can also be brought to

a stop by reversing the travel

direction using the electric

regenerative plugging function.

Furthermore, the truck is

equipped with an electric autobrake function, which stops the

truck as the accelerator pedal is

released (controlled coasting).

Both electric braking functions

can be set via the display.

Motors

All motors are highly efficient

three-phase (AC) which provide

high available torque and seamless reversal. Traction and

hydraulic motors are oversized

for superior thermal capability

and are especially suitable for

high loads and high ambient

temperature applications.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with

audible travel alarms and

flashing lights include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Other Options Available

Contact your local Crown dealer.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifications are subject to change

without notice.

C

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Momentum symbol, Access 1 2 3

and Work Assist are trademarks of

Crown Equipment Corporation.

Copyright 2005 Crown Equipment Corporation

SF14484 6/05

Printed in U.S.A.

Loading...

Loading...