Page 1

C

SHR 5500

Specifications

SHR 5500 Series

Heavy-Duty Walkie

Reach Stacker

Series

Page 2

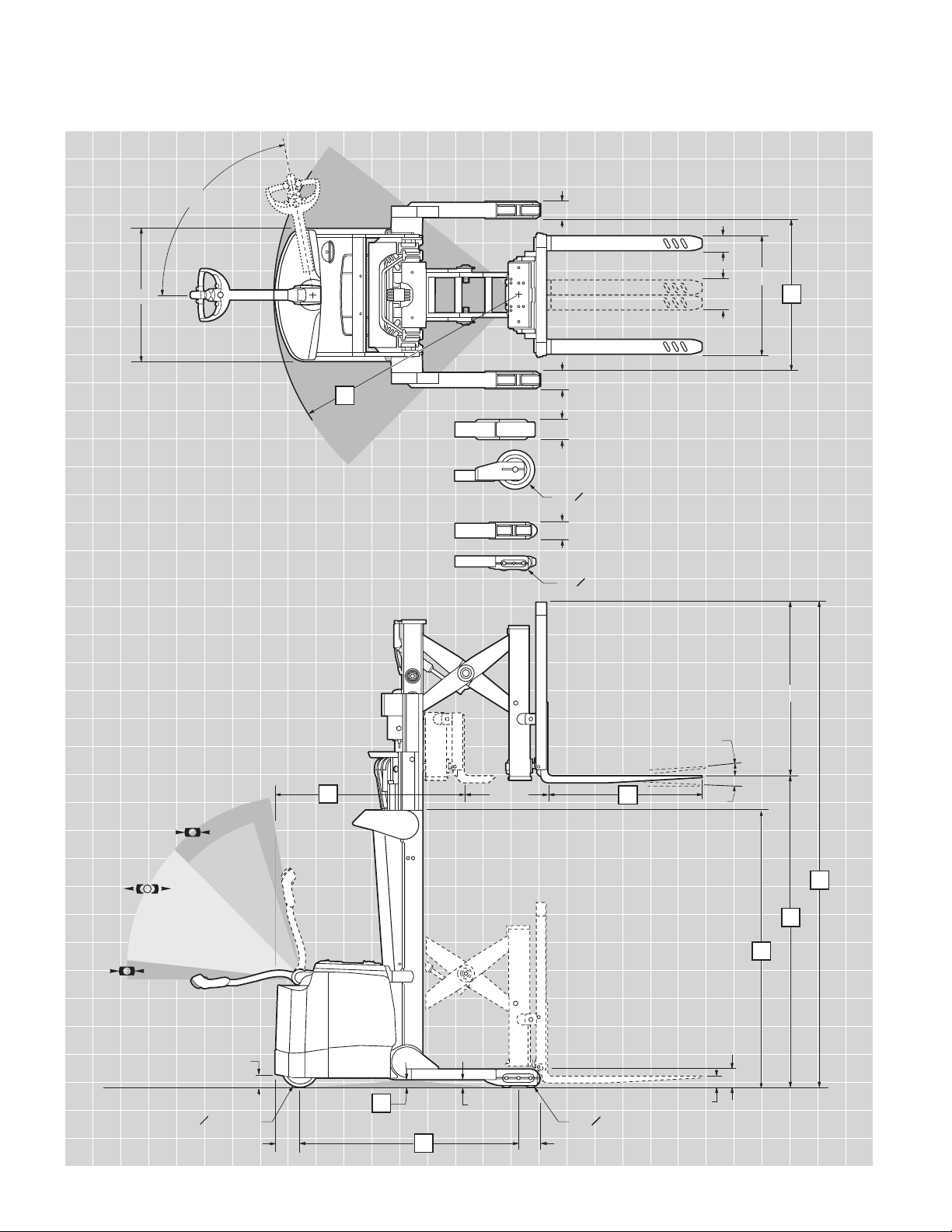

BRAKE

o 10" x 3"

80°

3°

3°

36"

4.13"

4"

8"

32"

16

4.13"

5.5"

4.13"

6.76" 5.73"

12

9

47"

17

23.2"

14

21

(1) o 10.5" x 4"

(2) o 4" x 2.88"

2"

(2) o 5" x 2.88"

3"

5"

13

11

3.5"

BRAKE

OVERRIDE

BRAKE

DRIVE

15

C

SHR 5500 Series

Heavy-Duty Walkie

Reach Stacker

Page 3

SHR 5500 Series

1 Manufacturer Crown Equipment Corporation

2 Model SHR 5520-25 SHR 5520-30 SHR 5540-35

3 Load Capacity lb See Chart See Chart See Chart

4 Load Center in 24 24 24

5 Power Electric 24 Volts 24 Volts 24 Volts

6 Operator Type Walkie Reach Stacker Reach Stacker Reach Stacker

General Information

7 Tire Type Load/Drive Poly/Vulkolan Poly/Vulkolan Poly/Vulkolan

8 Wheels (x=driven) Load/Drive 4/1x 4/1x 4/1x

9 Lifting Height in See Chart See Chart See Chart

13 Head Length* in 44 44 50.5

14 Wheelbase in 52.7 52.7 59.2

15 Turning Radius in 59.4 59.4 65.9

16 Inside Straddle in 34 - 50 inches in 2" increments

Dimensions

17 Forks Standard LxWxT in 36 x 4 x 1.5 36 x 4 x 1.5 36 x 4 x 1.75

Optional Lengths in 30, 39, 42, 45, 48, 54, 60

18 Travel Speeds Empty/Loaded mph 3.7 / 3.4

19 Lift Speeds Empty/Loaded fpm 48.4 / 29.5

20 Lowering Speeds Empty/Loaded fpm 50 / 50

21 Grade Clearance %998

22 Battery Min Weight/Max Amp 510 / 300 510 / 300 975 / 660

Performance

Max Battery Size WxLxH 6.62 x 34.37 x 24.8 6.62 x 34.37 x 24.8 13.12 x 31.10 x 24.8

Specifications

* Add 2.1" for Side Shift

Mast Type TL – Limited Free Lift TT – Triple Telescopic

9 Lifting Height in 127.5 150.5 156 192

3 Load Capacity SHR 5520-25 lb 2500 2500 2500 na

SHR 5520-30 lb 3000 3000 3000 na

SHR 5540-35 lb 3500 3500 3500 2500

10 Free Lift with LBR in 6 6 28 42

11 Collapsed Height in 83.5 95.5 75 89

12 Extended Height with LBR in 175 198 204 240

Mast and Weight

23 Min ID Straddle Width in 34 34 34 42

24 Truck Weight SHR 5520-25 lb 3585 3690 4130 na

w/o Battery**

** Add 105 lb for Side Shift

SHR 5520-30 lb 4100 4205 4650 na

SHR 5540-35 lb 4055 4160 4600 4735

Page 4

SHR 5500 Series

B

Right Angle Aisles

Pallet

Length

Pallet

Width

A

Equal Intersecting Aisles

Aisle Planning Guide

Capacity

Model SHR 5520-25: 2500 lb

at 24" load center

Model SHR 5520-30: 3000 lb

at 24" load center

Model SHR 5540-35: 3500 lb

at 24" load center

Maximum Battery Size

SHR 5520-25: 6.62" wide

x 34.37" long x 24.8" high –

up to 300 amp hours, 24 volts

SHR 5520-30: 6.62" wide

x 34.37" long x 24.8" high –

up to 300 amp hours, 24 volts

SHR 5540-35: 13.12" wide

x 31.10" long x 24.8" high –

up to 660 amp hours, 24 volts

Standard Equipment

1. 24-volt electrical system

2. Crown’s Access 1 2 3

®

Comprehensive

System Control

3. Access 1 2 3 display

• Eight-character scrolling

display, 5 button access

• Three selectable

performance levels

• BDI with lift interrrupt

• Five hour meters

• Event codes

• Access 1 2 3

diagnostics with real

time troubleshooting

• PIN code capability

4.

AC traction and steer motors

5. Performance enhancing

features

• X10®Handle

• Brake override

• Electronic power steering

• Ramp hold and

speed control

• Power boost

• High-visibility mast

and carriage

• Low profile power unit

• Tool storage tray

6. Wire mesh guard - mast

7. Volkollan drive tire –

10" dia. x 3" wide

8. Polyurethane load wheels –

5" dia. x 2.88" wide

9. InfoPoint®System

10. Steel power unit covers

11. 47" tall load backrest

12. Emergency power

disconnect

13. Key switch

14. Horn

15. SB175 gray

battery connector

16. Reversing button

17. Electric park brake

18. Fork tip indicators

19. Battery compartment

rollers

SHR 5520

Pallet 30 36 40 42 48

Width

36 in 62 78 62 81 62 85 62 89 62 97

40 in 64 78 64 82 64 87 64 90 64 97

42 in 65 78 65 81 65 88 65 90 66 97

48 in 68 80 68 83 68 87 68 91 69 99

SHR 5540

Pallet 30 36 40 42 48

Width

36 in 65 83 65 86 66 92 66 95 66 102

40 in 68 84 68 87 68 92 68 95 68 102

42 in 68 84 68 86 68 93 68 95 69 103

48 in 72 85 72 87 72 93 72 96 72 104

A = Equal Intersecting Aisles

B = Right Angle Aisles

Add 2.5" if side shift option is used.

Add 6" to 12" to all aisle dimensions for maximum maneuverability.

ABABAB AB AB

ABABAB AB AB

SHR 5500 Series

Optional Equipment

1. 30 amp on-board charger

(6.62" battery box)

2. Keyless on-off switch

3. Work Assist™ Accessories:

• Clip pad

• Hook

• Clip pad and hook

• Pocket

• Fan

4. Sideshift with internal hosing

5. Optional fork lengths (30",

39", 42", 45", 48", 54", 60")

6. Freezer conditioning

(Continuous -30° C / -22° F)

7. Plexiglass safety shield

8. 10" dia. x 4" wide drive tire

• Soft poly

• Siped soft poly

9. Polyurethane load wheels

• 4" dia. x 2.88" wide

• 10.5" dia. x 4" wide

10. InfoLink® ready

11. SBE 160 battery connector

Pallet Length

Pallet Length

Technical Information

Operator Controls

Crown’s robust X10 handle

places all control buttons in the

optimum position for ease of

operation with either hand and

to minimize hand and wrist

movements. An ergonomic

forward/reverse thumb wheel

allows for precise maneuvering.

The control hand grips are

urethane covered for insulation

from cold and vibration with

integrated horn buttons for easy

activation. The handle contains a

safety button which reverses the

direction of the truck should the

button touch the operator.

The physical efforts to hold the

handle at a comfortable height

was minimized to reduce fatigue.

A rabbit/turtle switch incorporates two levels of programmable

travel performance so operators

can select the setting that

matches their experience level

or application requirements.

Exclusive brake override feature

allows slow speed travel with

the handle near vertical. This

feature improves maneuverability

in tight areas.

Page 5

SHR 5500 Series

Technical Information

Performance

The SHR 5500 Series incorporates the latest generation AC

drive system enhanced with

Access 1 2 3 technology.

Crown’s Access 1 2 3 technology

continuously monitors truck

systems and adjusts system

parameters to deliver optimum

performance and control. The

Access Display provides a

convenient interface for operators

keeping them informed of any

changes impacting truck performance and allowing them to

choose from three performance

profiles when enabled.

Programmable performance

settings enable authorized

personnel to tune the lift truck

to different operator skill levels,

or to meet specific application

requirements. In addition,

up to 25 PIN codes can be

assigned to individual operators

and matched to one of the

pre-programmed performance

profiles if desired.

Electronic power steering allows

the operator to maneuver heavy

loads in tight spaces throughout

the day while minimizing fatigue.

Smooth travel and lift performance combine with excellent

controls provided by the X10

handle to increase productivity.

The SHR 5500 Series features

ramp hold and speed control

to improve operation on small

inclines or ramps. The ramp hold

feature uses the motor to prevent

truck movement when the brake

is released and no travel command is present. The ramp speed

control feature insures that actual

travel speed matches requested

travel speed. If the truck encounters an obstacle, a power boost

feature delivers up to 15 percent

more power than normally available for a full three seconds to

overcome the obstruction.

Electrical System

A heavy-duty 24-volt fused

electrical system utilizes

microprocessor controls for

maximum energy efficiency,

reduced maintenance and infinite

speed control capability.

Access control modules for

travel, lift and steer are sealed

from dirt, dust and moisture

for trouble-free operation. All

contactors have been eliminated

except for the main line contactor.

A 175 amp battery connector with

disconnect handle is standard.

Hydraulic System

Heavy-duty hydraulic motor

(4.8 kw) is transistor controlled

and matched with a gear type

pump selected for optimum lift

performance and low noise.

Single-speed lift with programmable acceleration - deceleration

and programmable two-speed

lowering enables customization

to match operator preference or

application requirements.

Cylinder rods are hard-plated

chrome with polyurethane seals.

Relief valve tuned to capacity

protects all components in the

hydraulic system. Reservoir

incorporates an in-tank 10

micron return filter for removing

debris from oil.

Drive Unit / Brake

Heavy-duty gearbox with

helical spur input gear for quiet

operation.

Regenerative motor braking

is activated under a downhill

condition, during plugging or

when the directional control is

returned to neutral. An electromagnetic brake, spring applied

and electrically released, is

mounted on top of the drive

motor. The electro-magnetic

brake serves as the parking

brake and applies when the

control handle position moves

from the operating zone to brake

zone during truck operation.

Power Steering

Electronic power steering is provided by a heavy-duty AC motor

that pivots the drive unit when

steer tiller movement is detected.

Mast

High visibility two and three-stage

mast design with angled cross

bracing and lift cylinders located

behind nested I-beams provides

maximum visibility for load

positioning and placement.

Crown’s staging cushions

coupled with lowering dampers

ensure smooth operation.

Rolled steel outer mast channels

and inner I-beams roll on canted,

steel, anti-friction roller bearings

for minimal current draw and long

life. Mast and chain rollers are

sealed and lubricated for life.

Telescoping mast sections nest

to reduce truck length. Heavier

mast cross bracing design

increases stiffness.

Reach Mechanism

An exclusive reach mechanism

design provides unmatched

visibility at all rack levels.

Serviceability / Durability

The Access display simplifies

service for technicians by

providing advanced diagnostics

without the need for separate

handsets. The display allows the

technician to view event service

codes and truck hours when

event occurred, perform system

calibrations or functional tests of

components, and make necessary adjustments. Crown’s

InfoPoint System compliments

Access 1 2 3 diagnostics by

providing a Quick Reference

Guide, on-truck component

maps and information nuggets to

further simplify troubleshooting.

All wiring is color coded.

Removable steel power unit

doors are hinged for ease of

opening providing excellent

accessibility to the distribution

panel and all other components.

Steel covers provide added

protection to critical internal

components.

Removable steel battery covers

and hinged cover allow easy

access to the battery. Battery

removal can be accomplished

from either side. Battery compartment rollers are standard.

The X10 handle incorporates a

vacuum die cast process using

high-grade aluminum and benefits

from structural webbing for maximum strength and durability.

Other Options

1. Amber strobe light

2. Travel alarm: reverse, forward

or both

Safety considerations and

dangers associated with audible

travel alarms and strobe lights

include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifications are subject to change

without notice.

Page 6

C

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

You can count on Crown to build lift trucks

designed for safe operation, but that’s

only part of the safety equation. Crown

encourages safe operating practices through

ongoing operator training, safety-focused

supervision, maintenance and a safe working

environment. Go to crown.com and view our

safety section to learn more.

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Crown logo, the color beige, the Momentum

symbol, Access 1 2 3, InfoPoint, InfoLink and X10 Handle

are trademarks of Crown Equipment Corporation.

Copyright 2008 Crown Equipment Corporation

SF14906 1/08

Printed in U.S.A.

Loading...

Loading...