C

Specifications

RD 5200 Series

S Class

Narrow-Aisle

Reach Truck

RD 5200

Series

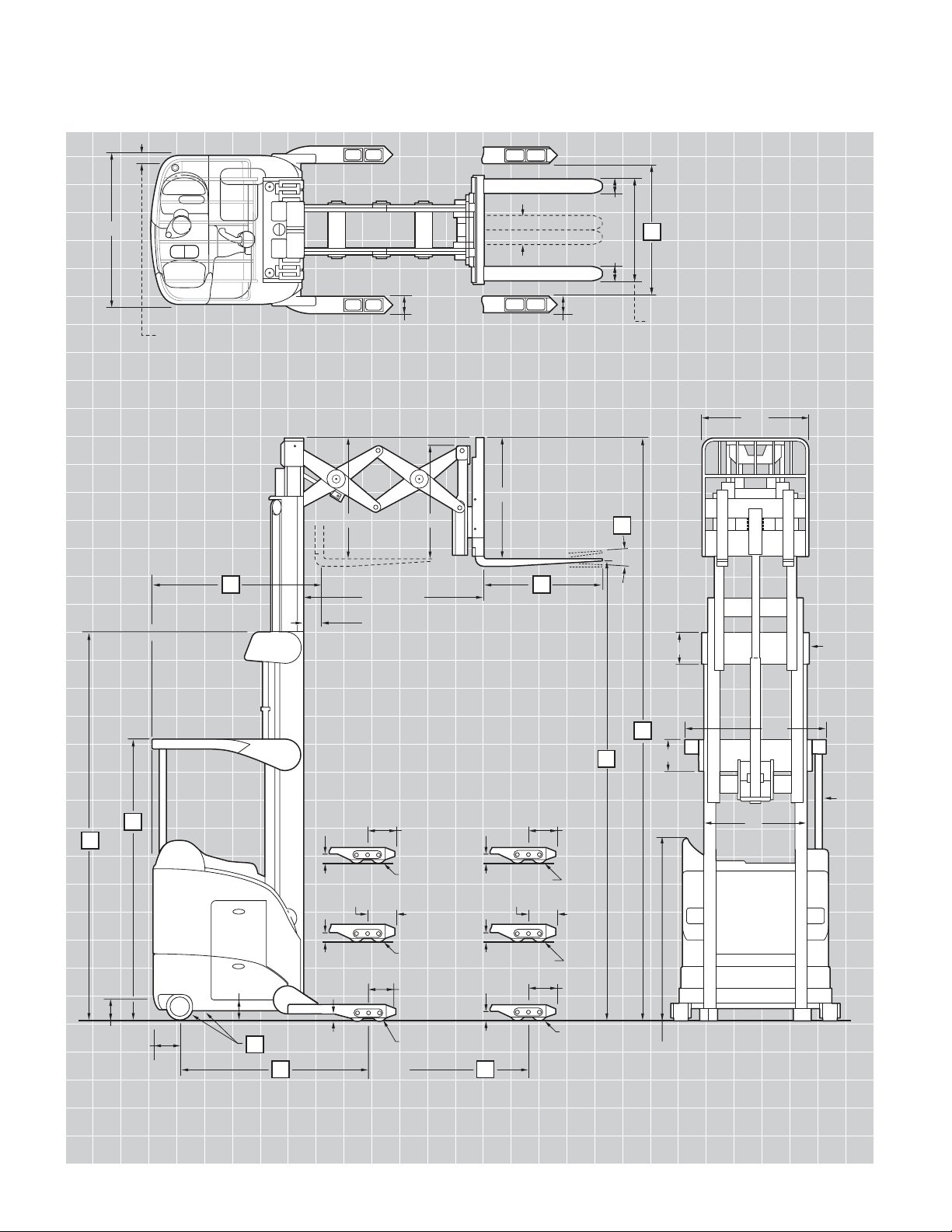

48"

20

8" w/side shift

4"

4"

12" w/o side shift

20

36"

27" w/side shift

30" w/o side shift

4.25"

18

9

13

14

15

53.3" max.

17

10

37

38

12.4"

9.9"

2.0"

7.2"

2 ø 5 x 2.9"

2 ø 6 x 2.9"

8.1"

2.0"

34.5"

* Top tie bar width – 33" for 240" or 270" lift. 35" for 300" and above.

36"

12.5" w/side shift

10.5" w/o side shift

38

2 ø 6 x 4.1"

2.0"

2 ø 5 x 4.1"

7.2"

2.0"

5275S - 62.5"

5285S - 57.5" to 62.5" adjustable

7.13"

2 ø 4 x 2.9"

6.1"

1.0"

2 ø 4 x 4.1"

6.1"

1.0"

8.1"

** 1.0" on lift heights above 321"

**

**

5.5"

*** Standard third post location, refer to dimension in top view.

32.5"

46.5"

*

31"

8.75"

8"

2.1" Standard third post

***

C

RD 5200 Series

S Class

Narrow-Aisle

Reach Truck

RD 5200 Series

S Class

Specifications

1 Manufacturer Crown Equipment Corporation

2 Model RD 5275S RD 5285S

3 Load Capacity* Max lb 3000 3000

4 Load Center Fork Face to Load CG in 24 24

5 Power 36 Volts 36 Volts

6 Operator Type Reach Sit/Stand Sit/Stand

7 Tire Type Load/Caster/Drive Poly/Poly/Poly

8 Wheels (x = driven) Load/Power Unit 4/2 (1x)

Mast Type Hi-Visibility TT

9 Lift Height in See Mast Chart

10 Guard Height in See Mast Chart

13 Forks Standard L x W x T in 36 x 4 x 1.5

Optional Lengths in 30, 39, 42, 45, 48

14 Carriage Tilt F°/B° degree 3 / 4

15 Headlength** Comp’t “C” in 60.06

Comp’t “D” in 61.81

Comp’t “E” in 64.43 / 69.18†

17 Overall Collapsed Height in See Mast Chart

18 Overall Extended Height in See Mast Chart

20 Inside Straddle Width In 1" increments in 34 - 50

24 Speed Travel

Power Unit First (E/L)

mph 7.5 / 7.5 8.3 / 7.5

Forks First (E/L) mph 6.2 / 6.2 6.7 / 6.2

24a Speed Travel -

Power Unit First (E/L)

mph 8.3 / 7.5 Std.

Max Performance System †† Forks First (E/L) mph 6.7 / 6.2 Std.

25 Speed Lift*** Empty fpm 131 143

1000 lb fpm 116 125

2000 lb fpm 103 111

3000 lb fpm 93 99

25a High Speed Lift**** Empty/Loaded fpm 143 / 99 Std.

26 Speed Lower Empty/Loaded fpm 85 / 90 110 / 90

26a Speed Lower - Empty/Loaded fpm 110 / 90 Std.

Max Performance System ††

37 Tires Size - Drive/Caster in 13 x 5.5 / 8.5 x 2.7 x (2)

38 Wheelbase (Standard Wheel) Comp’t “C” in 61.32

Comp’t “D” in 63.07

Comp’t “E” in 65.70 / 70.45†

39 Suspension Drive Articulated

Caster Articulated, Swivel

42 Brakes Drive Elec Release / Mech Applied

Caster Electronically Applied

Parking Elec Release / Mech Applied

Battery Removal Drive Side

45 Type Lead Acid

46 Min Weight/Max Amp Comp’t “C” lb/amp 2000 / 930 2000 / 930

Comp’t “D” lb/amp 2280 / 1085 2280 / 1085

Comp’t “E” ≤ 400" lb/amp 2600 / 1240 2600 / 1240

Comp’t “E” 401-442" lb/amp 2800 / 1240 2800 / 1240

Max Battery Size Comp’t “C” in 16.25x38.69x31 16.25x38.69x31

Comp’t “D” in 18.00x38.69x31 18.00x38.69x31

Comp’t “E” in 20.75x38.69x31 20.75x38.69x31

General Information

Dimensions

Performance

Chassis

Battery

* Contact factory. Capacity may be subject to derating at height.

** Add 2" with optional sideshift.

*** 5285S “C” Battery compartment has lift speeds of 5275S

**** Optional maximum lift speeds available on units with the “D” or “E” Battery Compartment.

† 442" Lift Height

†† Maximum Performance System optional on 5275S.

TT

9 Lift Height 341" 366" 400" 421" 442"

Free Lift* 113 124 136 142 154

10 Guard Height 95 95 95 95 95

17 Overall Collapsed Height 149 160 172 178 190

18 Overall Extended Height* 377 402 436 457 478

Minimum Straddle OD 49 50 53 53 53

Truck Weight w/o Battery Battery Compartment

“C” lb na na na na na

RD 5275S

“D” lb 8136 na na na na

RD 5285S

“E” lb 8191 8407 8641 9109 9473

TT

9 Lift Height 198" 210" 240" 270" 300" 321"

Free Lift* 53 59 71 83 95 104

10 Guard Height 89 95 95 95 95 95

17 Overall Collapsed Height 89 95 107 119 131 140

18 Overall Extended Height* 234 246 276 306 336 357

Minimum Straddle OD 42 42 42 42 42 42

Truck Weight w/o Battery Battery Compartment

“C” lb 6329 6439 6752 7041 7548 7725

RD 5275S

“D” lb 6379 6489 6802 7091 7598 7775

RD 5285S

“E” lb 6434 6544 6857 7146 7653 7830

Weight

Mast

*With load backrest.

Above 321", 6" high load wheel standard.

RD 5200 Series

S Class

Specifications

Weight

Mast

Capacity

Model RD 5275S - 3000 lb at 24"

load center, 36 volt

Model RD 5285S - 3000 lb at 24"

load center, 36 volt

Batteries

Battery removal from left side of

truck. Standard battery compartment rollers for extraction with

mechanized equipment.

Standard Equipment

1. Crown’s Access 1 2 3

®

Comprehensive

System Control

2. InfoPoint®- quick reference

guide and maps support

diagnostics

3. 36 volt electrical system

4. Enhanced Display Panel

•16 character alphanumeric

message center, 6 button

direct access

• Access 1 2 3 diagnostics

with real time troubleshooting diagnostics

• Four hour meters

• Fuel gauge with lift interrupt

• PIN security

5. Rack Height Select

6. Motor brush wear and

overtemp indicator

7. 5285S model includes

capacity monitor, high

performance travel (8.3 mph/e

power unit first), high performance quiet lift pump (143

fpm/e) - not available on “C”

battery compartment, and tilt

position assist

8. Standard performance lift

pumps (131 fpm/e), on

5275S “C”, “D” and “E” battery

compartment and 5285S “C”

Battery Compartment

9. Operator compartment

• Variable side stance

• Flexible five-point

positioning

• Adjustable suspended seat,

perch, backrest, and MultiTask Control armrest

• Adjustable steer tiller

• Back support with integral

hip support

•

Arm/elbow support padding

• Padded compartment

interior walls

• Operator console with work

surface and storage

•

Lower storage compartment

• Entry bar

• Suspended floor

• 383 square inch floor area

• 178 square inch upper

footrest area

• Non-skid rubber floor mat

11. Load wheel sizes and

compounds

12. Removable outrigger tips

13. Mesh screen mast guard

14. Overhead guard mesh

15. Crown-manufactured

sideshifter, 2" each way

16. Polished and tapered forks

17. Fork lengths

18. Keyless on/off switch

19. Drive-in rack mast

20. Mounting hardware

and power supply for

RF terminals

21. Chain slack kit

22. Drive-in rack cylinder

package

23. Work Assist™ Accessories:

• Accessory tube

• Accessory RF

mounting plate

• Accessory RF

mounting bracket

• Accessory clamp

• Accessory clip pad

• Accessory hook

• Accessory clip pad

and hook

• Accessory pocket

24. InfoLink

®

Ready System

Operator Compartment

Soft, rounded surfaces make

compartment interior more

comfortable. Streamlined

exterior smooths entry/exit for

the operator.

A lower floor height, (9.9")

first greets the operator. A

383 square inch floorboard

and patented suspended floor

provide comfortable footing.

All S Class reach trucks include

an upper footrest area, (178

square inch) with smart foot

interlocks and brake control.

Using these large, exclusive

footrests can improve operator

comfort. From the standing

position, the ability to lift either leg

to a footrest can reduce fatigue

which increases productivity.

A brake pedal design allows

variable side-stance positions for

the operator. The operator can

change positions to increase

comfort and productivity.

An entry bar with sensors to

automatically slow truck travel,

encourages safe foot positioning

inside the truck.

The S Class model offers a

superior level of flexibility for the

operator with an adjustable suspended seat, perch, backrest,

armrest, control handle and steer

tiller. The combination of these

features lets the operator move

from a standing, leaning or seat-

•

Console light

• Urethane covered MultiTask Control and steer tiller

10. Hydrostatic power steering

11. High visibility power unit

12. High visibility mast

13. 36" high load backrest

14. Tilting fork carriage

15. Tandem articulating

load wheels

16. Silent mast staging system

17. High-speed lift cutout 12"

from maximum lift

18. Crown-manufactured AC

drive and DC lift motors

19. Articulated drive axle with

190º steer arc

20. Key switch

21. Horn

22.

Emergency power disconnect

23. 350 amp battery connector

24. Large diameter battery rollers

25. Color-coded wiring

26. Third post

Optional Equipment

1. Mast lift heights to 442"

2. Performance Options for

5275S:

• Maximum Performance

System

- Enhanced Display

- Rack Height Select

- Capacity Monitor

- Productivity Package

High performance travel

(8.3 mph/e - power unit

first) and high speed lower

(110/90 fpm)

• Tilt Position Assist

• High performance quiet lift

pump (143 fpm/e) - available

with “D” or “E” battery box

3. Forward steering

4. Lift limit with or without

override (requires height

encoder)

5. Battery retainer with interlock

6. 36" and 42" high load

backrests

7. Work lights

8. Fan

9. Corrosion/freezer conditioning

(freezer conditioning includes

a 5/8" thick power unit skirt

with extended coverage of

the drive and caster tires)

10. ThermoAssist™ freezer

comfort options (freezer

conditioning required)

• ThermoAssist™

(“C” or “D” battery

compartment)

• ThermoAssist+™

(“E” battery compartment)

ed driver position. The stress of

standing can be relieved by sitting

and the stresses of sitting can be

relieved by standing. By changing

postures and using different sets

of muscles, significant ergonomic,

physiological and orthopedic

benefits may result.

The Multi-Task Control naturally

bridges Crown’s current and past

designs. Intuitive operation is

increased, reducing the learning

curve. Blending of hydraulic

control functions and traction can

improve productivity. Control

handle activation forces are

reduced. Soft grip steer tiller with

hydrostatic steering reduces

operator fatigue.

Operator visibility is improved with:

• Low-profile power unit

• High visibility mast

• Angled mast cross bracing

• Angled overhead guard

cross bars

• Variable side stance

Superior Thermal Management is

the result of several unique design

features: reduced heat generating

components, positioning of heat

generating components away

from the compartment, padding

to insulate the compartment from

heat and improved air paths

through the truck.

Clipboard surface and console

storage pockets are standard.

A large storage area is located

below the operator backrest.

Crown’s Access 1 2 3

®

Comprehensive

System Control

Crown’s Integrated Control

System provides unmatched

truck control for all primary

truck systems:

• Traction control

• Hydraulic raise/lower

• Hydraulic accessory

• Hydrostatic steering control

• Braking

• Operator interface

• Diagnostics

Crown’s patented traction system

technology provides high available

torque utilizing Crown-manufactured motors. The closed loop

traction control system maintains

top speed throughout the battery

charge.

The AC powered traction motor

offers closed loop performance to

maintain top speed as the battery

discharges. The AC drive motor

offers increased acceleration and

improved plug reversal.

RD 5200 Series

S Class

Technical Information

On ramps or when interfacing

with push-back racking, the

“truck hold” feature electronically

brakes the truck when the handle

is in neutral. Operator does not

have to release the brake pedal,

improving comfort and control in

these applications. Selected

travel speed remains constant

regardless of surfaces, load

weight or grades. Less throttling

of control handle means better

truck control and less fatigue to

the operator.

Crown’s Access 1 2 3

®

advanced diagnostic system

consists of three modules. This

technology provides quick

access to critical information on

any fault condition telling your

technician; “what it is, where it is,

and what it does”.

Access 1 Module

This is the display panel,

(Enhanced) and the first point of

troubleshooting. No tools are

required. Access 1 has three

levels of interface:

• Operator feedback

• Full functionality of the truck

while monitoring analog and

digital inputs and outputs.

• Components can be “driven”

with full currents and voltage

eliminating inconclusive

continuity guesswork.

InfoPoint developed as part of

the Access 1 2 3, allows your

technician to troubleshoot

without complicated schematics,

wiring diagrams or cumbersome

service manuals for over 95%

of your repairs. Simplicity is

complete with InfoPoint Quick

Reference Guide, colored component maps and “information

nuggets” located on the truck.

Access 2 Module

This is the power supply for the

hydraulic system including lift, all

accessory functions and load

sense hydrostatic steering.

Access 3 Module

Full-time management control

of traction, braking and other

system inputs and outputs.

Access 3 simplifies the system

by reducing componentry

including directional and pump

contactors, relays and other

hard-wired components.

Information On Time consists of

clearly labeling each component

and providing an area map

showing the component

location. A Quick Reference

Troubleshooting Guide is

supplied with each truck

showing display operation,

code definitions and an overall

component ID of the entire truck.

Performance Profiling

Performance Profiling can be

accessed at the display to

customize truck performance for

specific applications or operator

requirements.

Crown’s Integrated Control System provides a responsive, energy

efficient and reliable machine.

Access 1 2 3 diagnostics has

been extensively developed

to address the real world of

troubleshooting and repair.

Travel

Increased travel speeds improve

transport productivity especially

when long distances are involved.

Acceleration is increased to get

the operator to the task quickly.

An AC traction system provides

improved plug response

and even better acceleration

which may be valuable in short

shuttle applications.

Steering

Load-sense hydrostatic steering

is a low-idle stand-by system

which reduces energy consumption. Smooth, quiet steering

control with minimal operator

effort required at the steer tiller.

Drive tire rotates 190° for maximum maneuverability. Crown’s

hydrostatic steering system is

simplified with significantly

fewer parts, thus reducing

maintenance requirements.

Braking

A disc brake on the motor

armature shaft combined with

motor regenerative braking

provides sure braking with fewer

parts and maintenance requirements. An electronically-applied

brake on the caster wheel works

with the motor brake to provide

good brake performance for the

S Class truck.

Suspension

The offset, articulated drive

unit design provides positive

floor contact.

Load Handling

The Maximum Performance

System (MPS) incorporates the

Productivity Package, the

Capacity Monitor and the Rack

Height Select feature.

The Capacity Monitor shows the

approximate weight on the forks

and the fork height. It will alert the

operator when the truck capacity is

exceeded for the fork height. It will

also show how high or to which lift

zone you can raise the load.

The Rack Height Select feature

allows the truck to be programmed to stop at preselected

heights.

As the name implies, MPS offers

the maximum productivity in those

high-throughput applications.

Another useful option is the

Tilt Position Assist. This allows

the fork tilt to stop at a preprogrammed position. If set to a

fork level condition, this will

allow maximum fork clearance

when entering pallets and

improve productivity.

Lift and lower speeds were

increased for productive pallet

put away and retrieval. Blending

of hydraulic and traction functions,

(travel, lift and reach), is attainable.

Lift, reach and sideshift are

proportional for load handling

accuracy.

Mast

High visibility mast design with

angled cross bracing and angled

overhead guard braces improve

visibility for high or low stacking.

Crown’s patented staging

cushions coupled with lowering

dampers and speed reductions

at maximum lift improve overall

load handling control.

Rolled steel outer channel masts

and inner “I” beams roll on

canted, steel, anti-friction roller

bearings for minimal current draw

and long life. Telescoping mast

sections nest to reduce truck

length. Heavier mast cross

bracing design increases stiffness.

Above 270" lift, vertical mast

reinforcement maintains

maximum capacity.

Reach Mechanism

Inner arm has a one piece plate

with continuous welding. Torque

plate is also used to give the

mechanism stiffness to resist

twisting for long-lasting durability. Outer arms are designed

with large heel to provide more

material for stresses to be

distributed evenly. Robotically

welded for maximum strength.

Carriage

A hook-type carriage conforming

to ITA specifications is used.

Load backrest is standard.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with audible

travel alarms and flashing

lights include:

• Multiple alarms and/or lights

can cause confusion.

• Workers ignore the alarms

and/or lights after day-in and

day-out exposure.

• Operator may transfer the

responsibility for “looking out”

to the pedestrians.

• Annoys operators and

pedestrians.

Other Options Available

Contact your local Crown dealer.

Dimensions and performance

data given may vary due to

manufacturing tolerances. Performance is based on an average

size vehicle and is affected by

weight, condition of truck, how it

is equipped and the conditions

of the operating area. Crown

products and specifications are

subject to change without notice.

RD 5200 Series

S Class

Technical Information

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Crown logo, the color beige, the

Momentum symbol, Access 1 2 3, InfoPoint, InfoLink,

ThermoAssist, ThermoAssist+ and Work Assist

are trademarks of Crown Equipment Corporation.

Copyright 2001-2007 Crown Equipment Corporation

SF12898 Rev. 11/07

Printed in U.S.A.

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

You can count on Crown to build lift trucks

designed for safe operation, but that’s

only part of the safety equation. Crown

encourages safe operating practices through

ongoing operator training, safety-focused

supervision, maintenance and a safe working

environment. Go to crown.com and view our

safety section to learn more.

C

Loading...

Loading...