Page 1

WARNING: Improper installation,

adjustment, alteration, service or

maintenance can cause property

damage, injury , or loss of life.

For assistance or additional

information, consult a qualified

installer , service agency or the

oil supplier. Read these instructions carefully before installing.

D

ESIGNED TO

L

EAD

TWZ Series

Oil-Fired Hot Water Boilers

INST ALLA TION INSTRUCTIONS

These instructions must be affixed on or adjacent to the boiler

Models:

• TWZ065

• TWZ075

• TWZ100

• TWZ090

• TWZ125

• TWZ150

• TWZ120

• TWZ175

• TWZ200

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

7HO)D[ZZZFURZQERLOHUFRP

1

Page 2

Table of Contents

I. Product Description ............................................................. 1

II. Specifications ....................................................................... 1

III. Before Installing...................................................................2

IV. Locating the Boiler............................................................... 3

V. Air for Combustion & Ventilation........................................ 5

VI. V enting .................................................................................. 9

VII. System Piping Connections ............................................... 11

VIII. T ankless Heater Piping ................................15

IX. Fuel Line Piping...........................................16

X. Wiring .......................................................... 19

XI. Start-up and Checkout..................................21

XII. Service & Maintenance................................24

XIII. Parts .............................................................27

I Product Description

The TWZ series boiler is a cast iron oil-fired water boiler designed for use in closed forced circulation heating systems.

This boiler must be vented by natural draft into a lined masonry or metal chimney, or Type L vent. An adequate supply of air

for combustion, ventilation and dilution of flue gases must be available in the boiler room. An optional tankless heater is

available to generate domestic hot water.

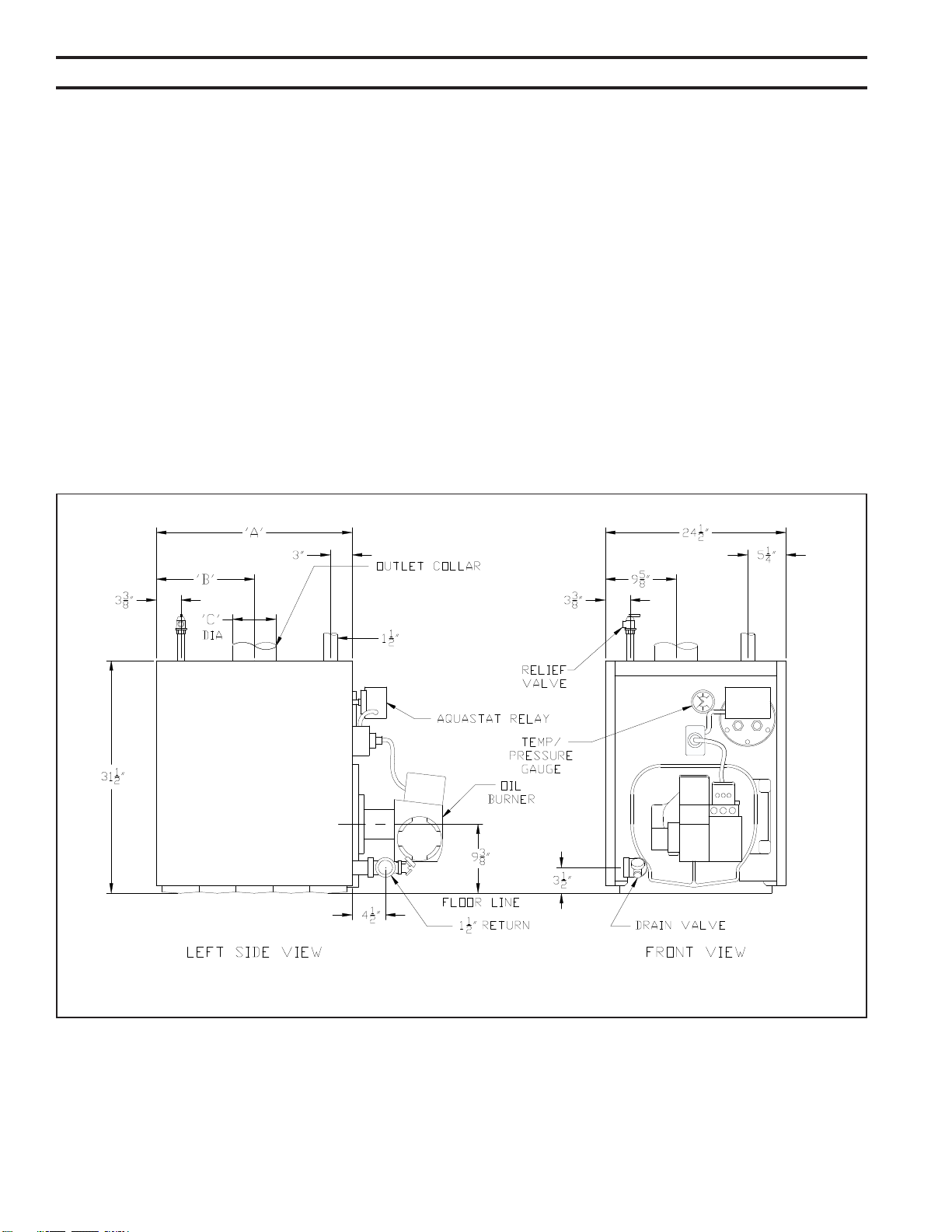

II Specifications

SUPPLY PIPE

LOCATION

FIGURE 1: GENERAL CONFIGURATION *

*Notes: 1. Tankless Coil Opening Not Present On Less-Coil Boilers.

2. Circulator Supplied Loose - May Be Installed On Supply Or Return.

1

2

Page 3

TABLE 1a: GENERAL SPECIFICATIONS

g

(

)

g (

)

A

)

A

(

(

)

(

)

Burner

Number of

Boiler Model

TWZ065 3 0.65 80000 70000 86.1 16.0 16 1/2 8 5/16 6

TWZ075 3 0.75 91000 79000 85.8 16.0 16 1/2 8 5/16 6

TWZ100 3 1.00 120000 104000 84.3 16.0 1 6 1/2 8 5/16 6

TWZ090 4 0.90 111000 97000 86.0 20.0 21 1/2 10 13/16 7

TWZ125 4 1.25 152000 132000 84.9 20.0 2 1 1/2 10 13/16 7

TWZ150 4 1.50 179000 156000 83.8 20.0 2 1 1/2 10 13/16 7

TWZ120 5 1.20 147000 128000 86.0 24.0 2 6 1/2 13 5/16 8

TWZ175 5 1.75 210000 183000 83.5 24.0 2 6 1/2 13 5/16 8

TWZ200 5 2.00 238000 207000 83.3 24.0 2 6 1/2 13 5/16 8

Sections

Input

Gal/hr

DOE Heating

Capacity

Btu/hr

I=B=R Net

Ratin

Btu/hr

FUE (%

pprox. Water

Content

Gal)

Dimensions (inches)

"A" "B" "C"

TABLE 1b: OPTIONAL TANKLESS HEATER RATINGS

Boiler Model

TWZ065

TWZ075

TWZ100

TWZ090

TWZ125

TWZ150

TWZ120

TWZ175

TWZ200

Tankless Heater Ratin

Gal/min

2.75

3.00

3.25

3.25

3.75

4.00

3.50

4.25

4.75

Notes:

1. Net Ratings are based on piping and pick-up allowances of 1.15.

2. Burner Capacity Rating, GPH is based on #2 oil with a Gross

Heating Value equal to 140000 BTU/Gal.

3. Maximum Working Pressure, Water - 50 PSI.

4. Tankless Heater Ratings based on I=W=H test standard.

III Before Installing

1) Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in strict

accordance with this manual and the requirements of the authority having jurisdiction.

• In the absence of an authority having jurisdiction, installation must be in accordance with this manual and the latest

edition of Installation of Oil Burning Equipment (ANSI/NFPA31).

• Where required by the authority having jurisdiction, this installation must conform to the latest edition of Standard for

Controls and Safety Devices for Automatically Fired Boilers (ANSI/ASME CSD-1).

2) Make sure that a properly sized chimney is available which is in good condition. Consult the authority having

jurisdiction, Part VI of this manual, and ANSI/NFPA31 for additional information on venting requirements.

Power (“Side Wall”) Venting - Important Note

Two problems arise when any oil-fired appliance is power vented:

1. There is sometimes an accelerated rate of soot buildup on the oil burner cad-cell, spinner etc.

2. There is a potential for severe damage to the side of the structure in the event that the boiler operates at a high smoke

level. This can happen for many reasons, some of which are out of the control of both the installer and appliance

manufacturer.

Crown Boiler Company recommends the use of a chimney to vent the TWZ series boilers. If a power venter must be used,

it is the responsibility of the installer and power vent manufacturer to “engineer” the power vent system. CROWN

BOILER COMPANY WILL ASSUME NO RESPONSIBILITY FOR DAMAGE TO SIDING, ETC. FROM A POWER

VENTED OIL-FIRED BOILER. THIS APPLIES REGARDLESS OF THE CAUSE OF THE SOOTING.

2

3

Page 4

3) Make sure that the boiler is correctly sized:

• For heating systems employing convection radiation (baseboard or radiators) use an industry accepted sizing

method such as the I=B=R Heat Loss Calculation Guide (Pub. #H21 or #H22) published by the Hydronics

Institute in Berkeley Heights, NJ.

• For new radiant heating systems refer to the radiant tubing manufacturer’s boiler sizing guidelines.

• For systems including a Crown Mega-Stor indirect water heater, size the boiler to have either the DOE

Heating Capacity required for the Mega-Stor or the net rating required for the heating system, whichever

results in the larger boiler.

• For systems that incorporate other indirect water heaters, refer to the indirect water heater manufacturer’s

instructions for boiler output requirements.

4) In some cases, boilers installed at altitudes above 2000ft may require a different burner configuration from that at sea

level. Consult the local Crown representative for more information.

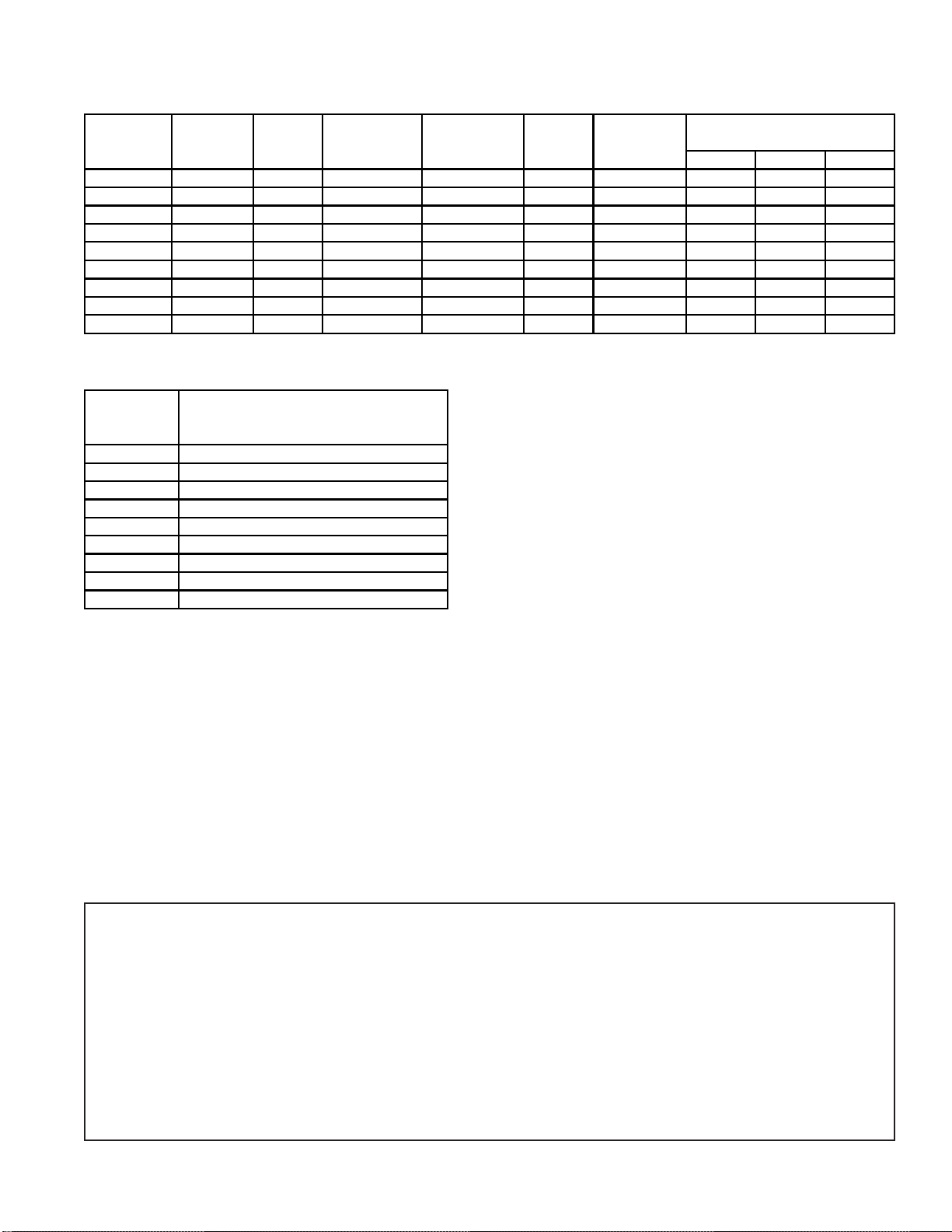

IV Locating the Boiler

1) Clearances:

• Observe the minimum clearances shown below. Except as noted, these clearances apply to all combustible

construction, as well as noncombustible walls, ceilings and doors. Also see Figure 2.

Front – 24”

Left Side – 6”

Right Side – 6”

Rear – 6”

Top – 6”

Single Wall Chimney Connector (to combustible construction) - 18”

• A 24” service clearance from the jacket is recommended from the top of the boiler. This clearance may be

reduced to that shown above; however, servicing the boiler will become increasingly difficult as this clearance

is reduced.

2) If listed Type L vent is used, follow vent pipe manufacturer recommendations for minimum clearances.

3) Do not install this boiler directly on a combustible surface. Where it is desired to install the TWZ over a non-carpeted

combustible surface, install the boiler on the base shown in Figure 3.

4) Do not install this boiler in a location where gasoline or other flammable vapors or liquids will be stored or used. Do

not install this boiler in an area where large amounts of airborne dust will be present, such as a workshop.

3

4

Page 5

18*

6

FRONT VIEW SIDE VIEW

* CLEARANCE FROM SINGLE WALL C ONNECT OR TO COMBUSTIBLE CONSTRUC TION

FIGURE 2: CLEARANCES

6

24

6

Sh ee t Me ta l (2 4 GA o r Thicker)

0.47"

4“ MI N.

Openings Aligned To Permit Free Air Circulation

Hollow Masonry Blocks

FIGURE 3: INSTALLATION OVER A COMBUSTIBLE FLOOR

4

5

Combustible Surface

Page 6

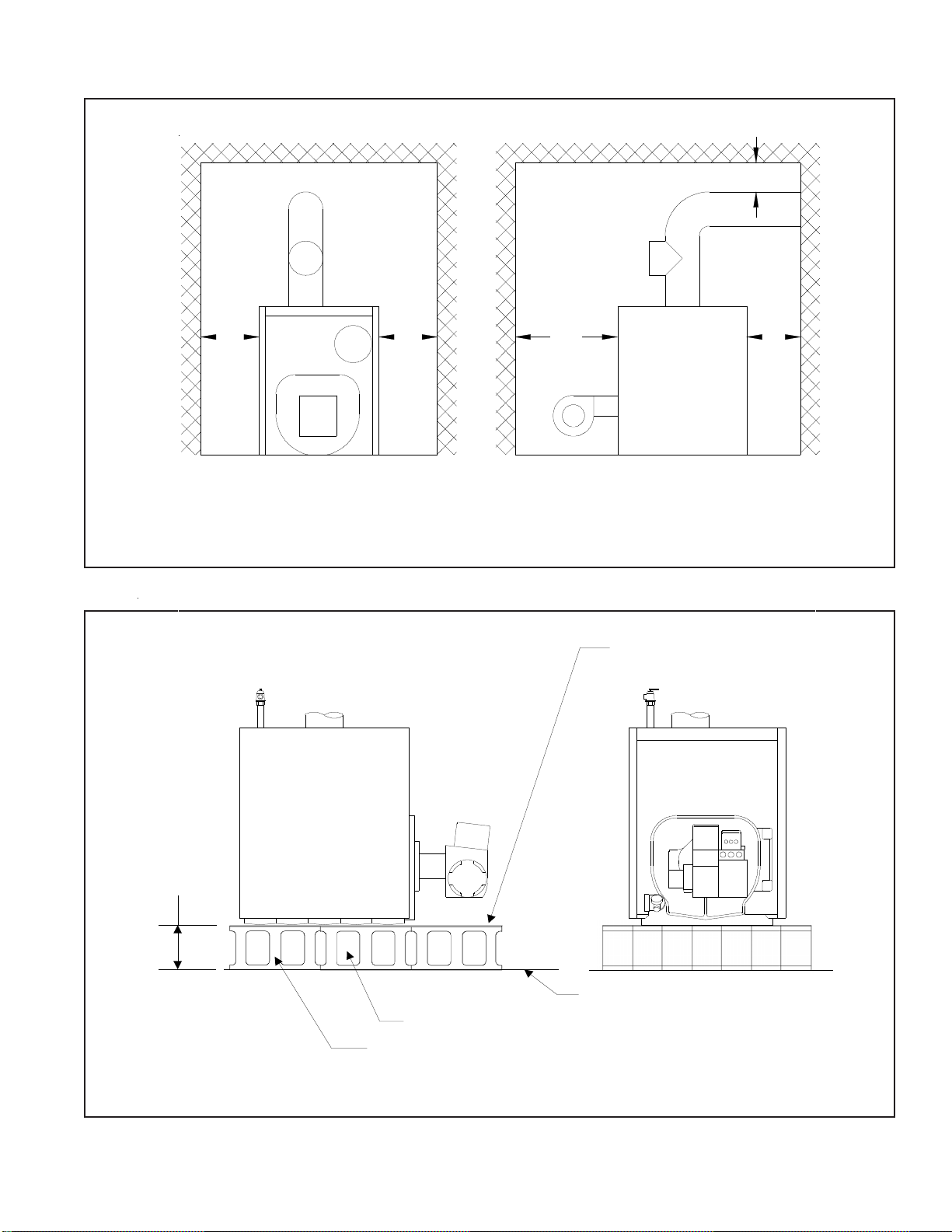

V Air for Combustion and Ventilation

Sufficient fresh air must be supplied for combustion and ventilation. Provisions for combustion and ventilation air for oil

burning equipment must be made in accordance with Section 1.5, Air for Combustion and Ventilation, in the latest edition

of Installation of Oil Burning Equipment (ANSI/NFPA 31).

To ensure an adequate supply of air for combustion, ventilation and flue gas dilution, start by determining whether the

boiler is to be installed in a building of unusually tight construction. A building of unusually tight construction is defined as

having all of the following features:

• Walls and ceilings exposed to outside atmosphere have a continuous water vapor retarder with a rating of 1 perm

or less with openings gasketed and sealed

• Weather stripping has been added on openable windows and doors

• Caulking and sealants are applied to areas such as joints around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas lines, and

at other openings.

For Buildings of Other than Unusually Tight Construction

1) Determine whether the boiler is to be installed in a confined space - A confined space is defined as having a volume

less than 50 cubic feet per 1000 BTU/hr input of all appliances installed in that space. To determine whether the boiler

room is a confined space:

a. Total the input of all appliances in the boiler room in thousands of BTU/hr. Round the result to the next highest

1000 BTU/hr.

b. Find the volume of the room in cubic feet. The volume of the room in cubic feet is:

Length (ft) x width (ft) x ceiling height (ft)

In calculating the volume of the boiler room, consider the volume of adjoining spaces only if no doors are

installed between them. If doors are installed between the boiler room and an adjoining space, do not consider the

volume of the adjoining space, even if the door is normally left open.

c. Divide the volume of the boiler room by the input in thousands of BTU/hr. If the result is less than 50, the boiler

room is a confined space.

Example:

A TWZ090 and a water heater are to be installed in a room measuring 6 ft - 3 in x 7 ft with an 8 ft ceiling. The

water heater has an input of 30000 BTU/hr:

Input of TWZ090 = 0.90 Gal/hr x 140000 BTU/Gal = 126000 BTU/hr

Total input in thousands of BTU/hr = (126000 BTU/hr + 30000 BTU/hr)/1000 = 156

Volume of room = 6.25 ft x 7 ft x 8 ft = 350 ft

350/156 = 2.24. Since 2.24 is less than 50, the boiler room is a confined space.

3

2) Unconfined Space - Natural infiltration into the boiler room will normally provide adequate air for combustion and

ventilation without additional louvers or openings into boiler room.

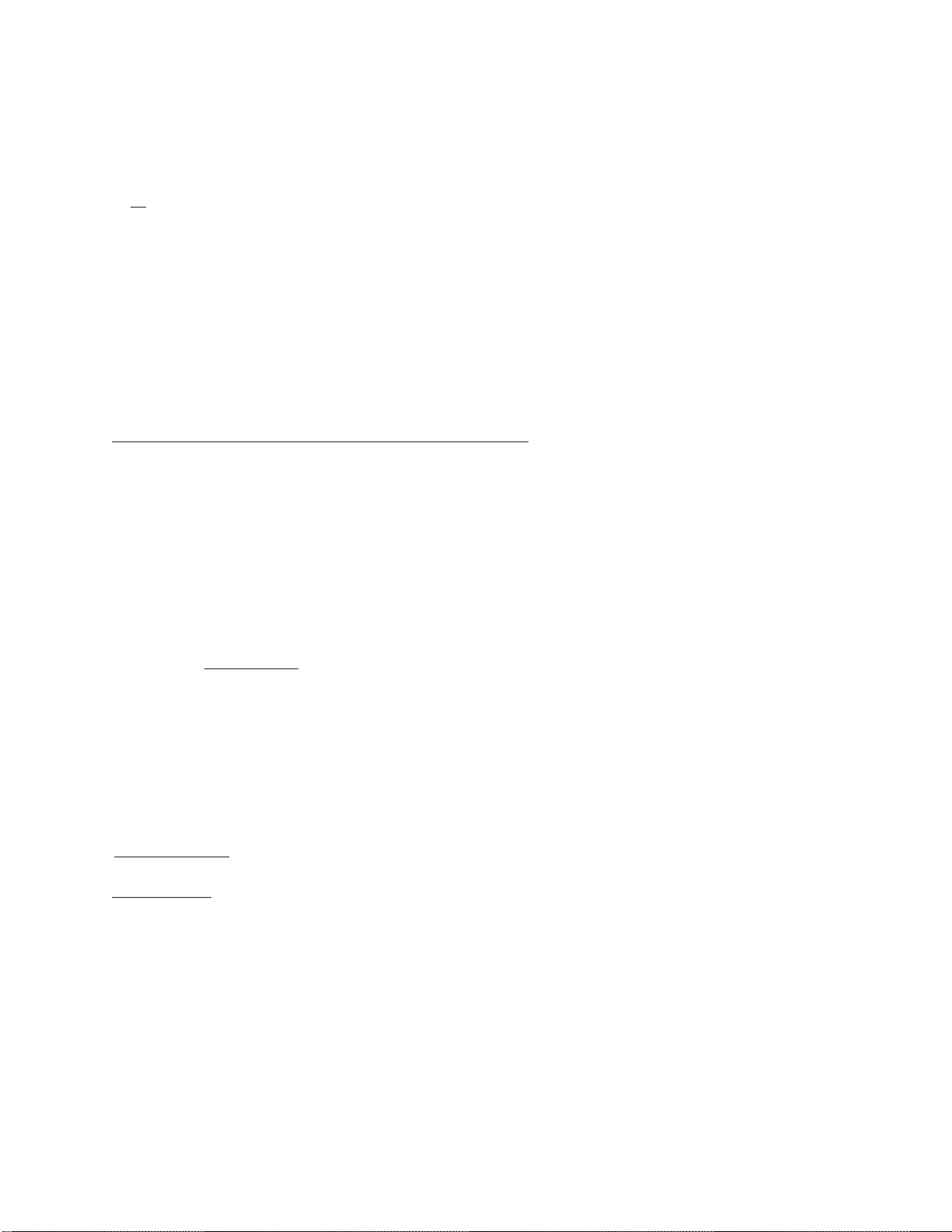

3) Confined Space - Provide two openings into the boiler room, one near the floor and one near the ceiling. The top edge

of the upper opening must be within 12” of the ceiling and the bottom edge of the lower opening must be within 12” of the

floor (Figure 4).

• Each opening must have a free area of 1 square inch per 1000 BTU/hr input of all fuel burning appliances in the

boiler room. The minimum opening dimension is 3 inches. Minimum opening free area is 100 square inches per

opening.

• If the total volume of both the boiler room and the room to which the openings connect is less than 50 cubic feet per

1000 BTU/hr of total appliance input, install a pair of identical openings into a third room. Connect additional

rooms with openings until the total volume of all rooms is at least 50 cubic feet per 1000 BTU/hr of input.

• The “free area” of an opening takes into account the blocking effect of mesh, grills, and louvers. Where screens are

5

6

Page 7

FIGURE 4: BOILER INSTALLED IN CONFINED SPACE,

ALL AIR FROM INSIDE

used, they must be no finer than ¼” (4 x 4) mesh.

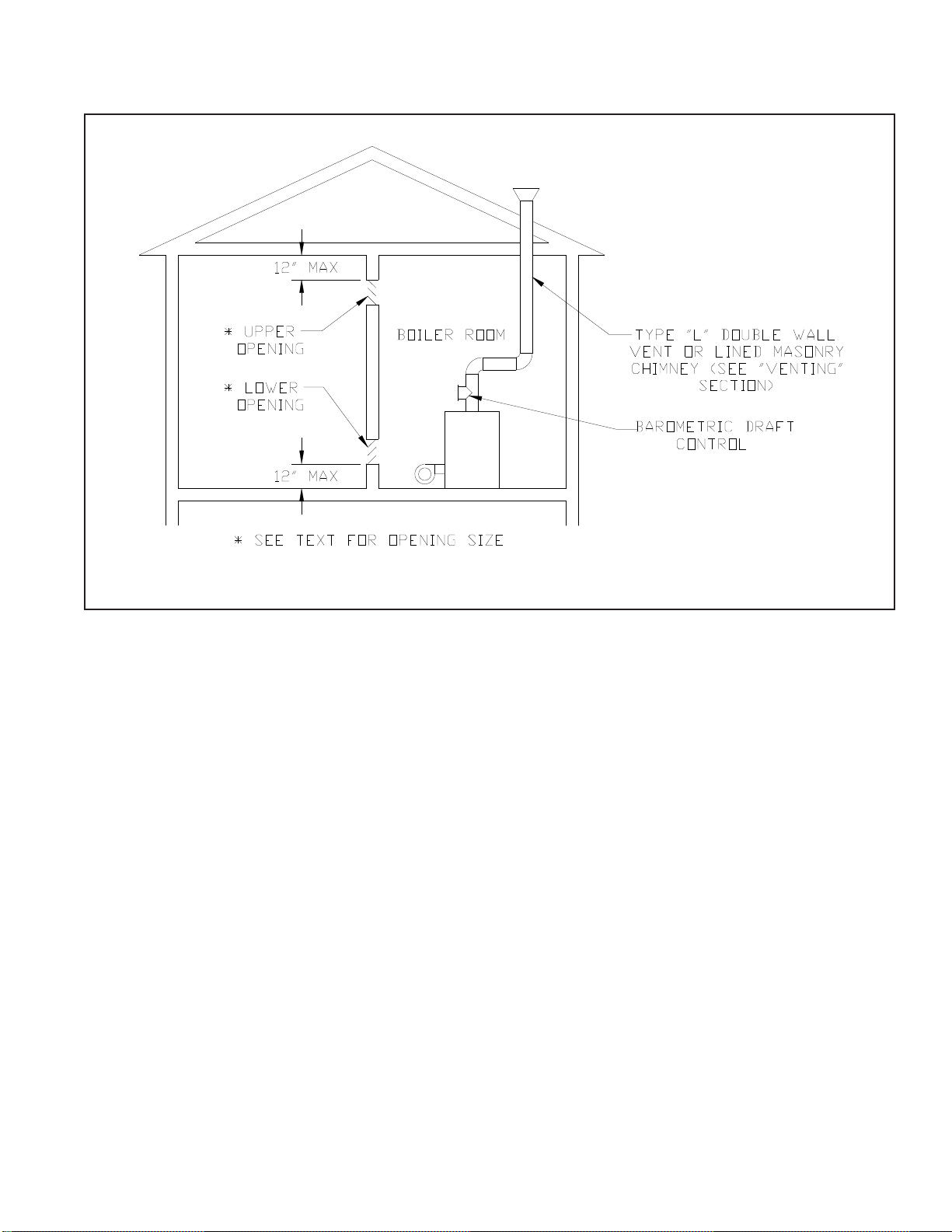

For Buildings of Unusually Tight Construction:

1) Openings must be installed between the boiler room and the outdoors or a ventilated space, such as an attic or crawl

space, which communicates directly with the outdoors.

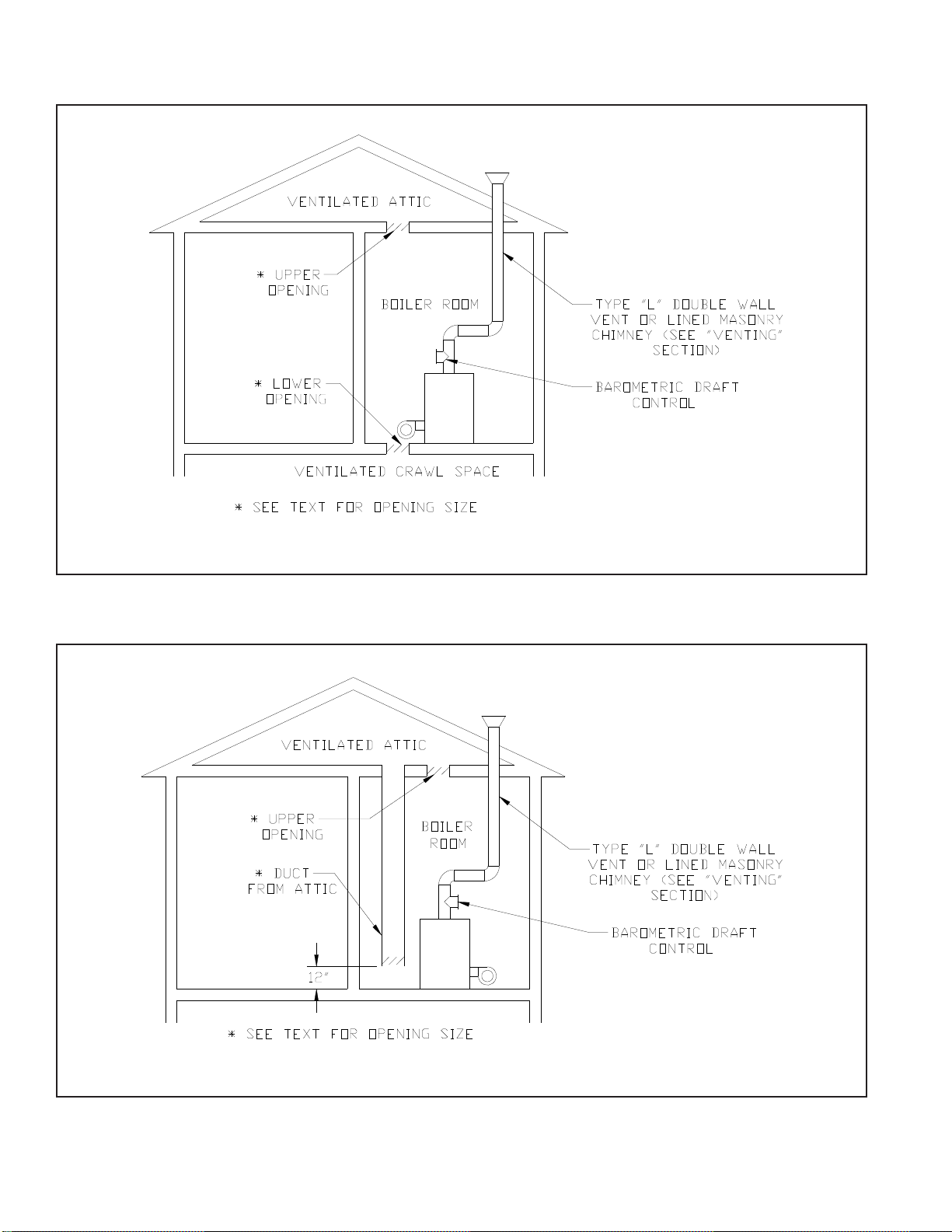

2) Two openings are required. The top edge of the upper opening must be within 12 inches of the ceiling. The bottom

edge of the lower opening must be within 12 inches of the floor.

3) Size openings and ducts as follows:

• Vertical ducts or openings directly outdoors (Figure 5, Figure 6, and Figure 7) - Each opening must have a free

cross sectional area of 1 square inch per 4000 BTU/hr of the total input of all fuel fired appliances in the boiler

room but not less than 100 square inches. Minimum opening size is 3 inches.

• Openings to outdoors via horizontal ducts (Figure 8) - Each opening must have a free cross sectional area of 1

square inch per 2000 BTU/hr of the total input of all fuel fired appliances in the boiler room but not less than

100 square inches. Minimum opening size is 3 inches.

• The “free area” of an opening takes into account the blocking effect of mesh, grills, and louvers. Where screens

are used, they must be no finer than ¼” (4 x 4) mesh.

6

7

Page 8

FIGURE 5: ALL AIR FROM OUTDOORS,

VENTILATED CRAWL SPACE AND ATTIC

FIGURE 6: ALL AIR FROM OUTDOORS,

VIA VENTILATED ATTIC

7

8

Page 9

FIGURE 7: ALL AIR FROM OUTDOORS, USING

OPENINGS INTO BOILER ROOM

FIGURE 8: ALL AIR FROM OUTDOORS, USING

HORIZONTAL DUCTS INTO BOILER ROOM

8

9

Page 10

VI Venting

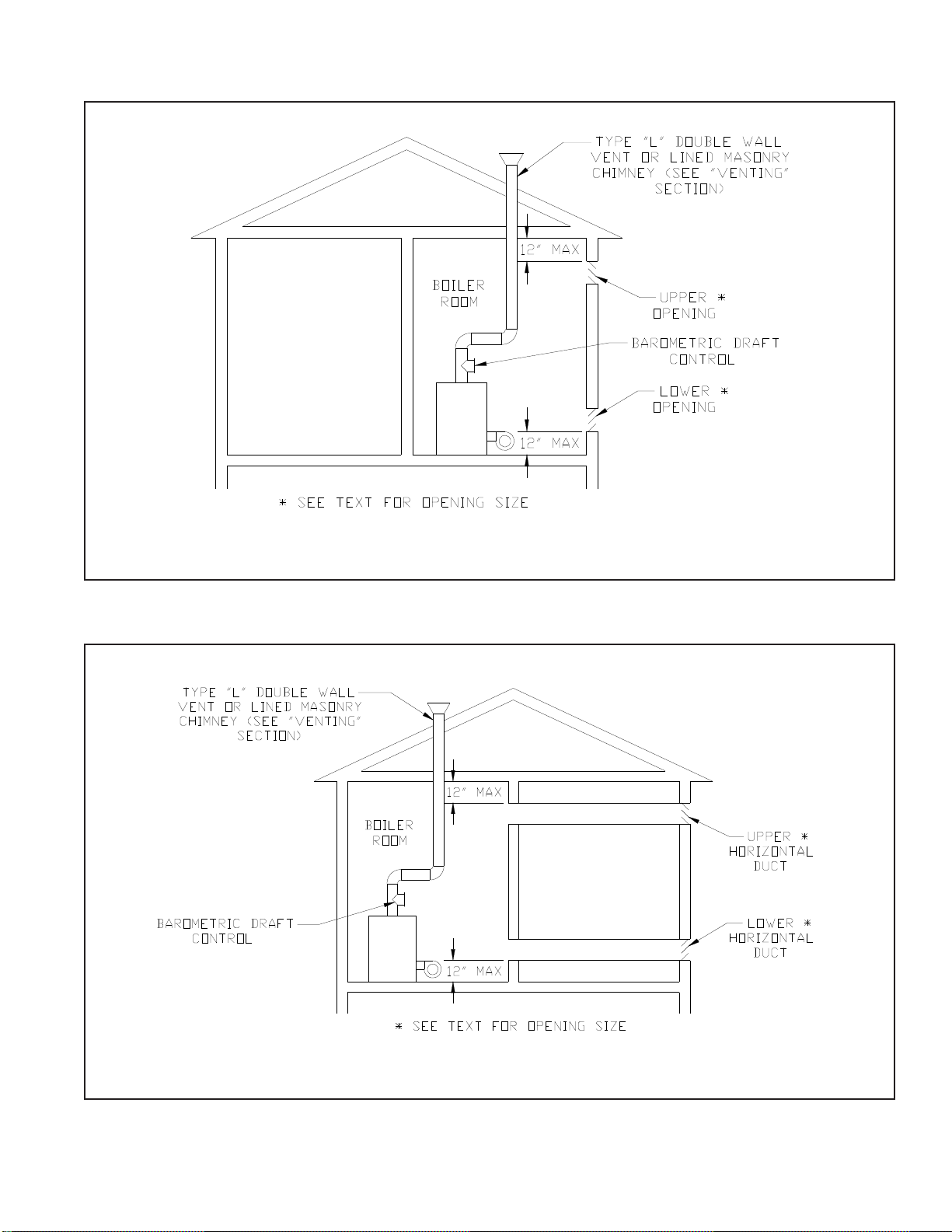

Vent installation must be in accordance with local building codes, or the local authority having jurisdiction.

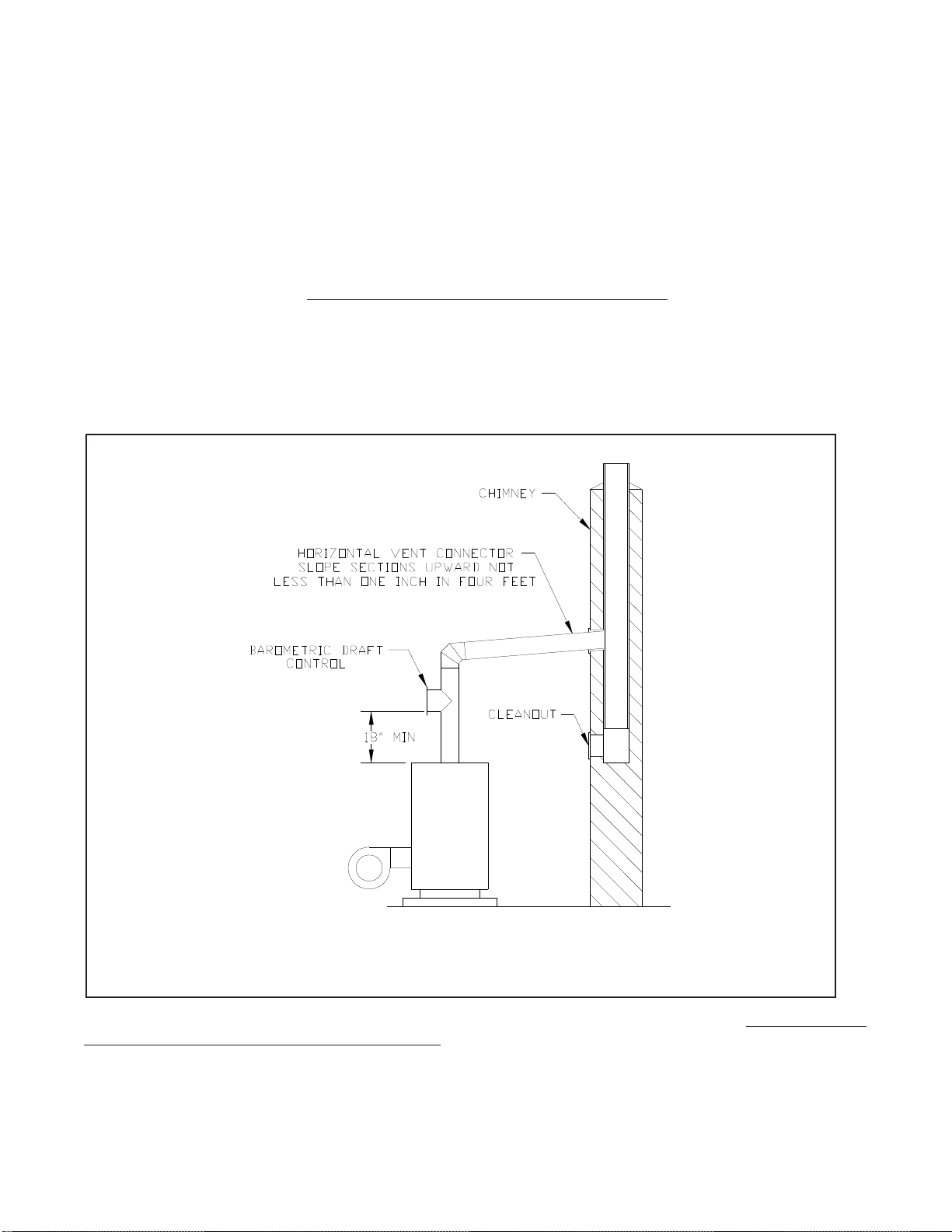

Typical vent installation is illustrated by Figure 9. The components of vent installation are the vent connector (breeching),

barometric draft regulator, and chimney.

1 ) Acceptable Chimneys - The following chimneys may be used to vent a TWZ series boiler:

• Listed Type L vent - Install in accordance with the manufacturer’s instructions, the terms of its listing, and

applicable codes.

• Masonry Chimney - The masonry chimney must be constructed in accordance with the latest edition of Standard

for Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances (NFPA 211) and lined with a clay liner or

other listed lining system.

2) Acceptable Vent Connectors - The following may be used for vent connectors:

• Listed Type L vent.

• Single Wall Galvanized Pipe - Use 0.018” (26 gauge) or heavier.

Do not vent a TWZ series boiler into an unlined chimney.

FIGURE 9: TYPICAL VENT SYSTEM

INSTALLATION AND COMPONENTS

3 ) Chimney and Vent Connector Sizing - See Table 2 for minimum vent connector and chimney sizing. The vent connector

size must not be smaller than boiler flue collar diameter. Where two or more appliances vent into a common vent, the

cross-sectional area of the common vent should at least equal the area of largest vent plus 50% of the area in the additional

vents.

4) Do not vent this appliance into any portion of a mechanical vent system operating under positive pressure.

5) Do not connect the boiler into a chimney flue serving an open fireplace or other solid fuel appliance.

9

10

Page 11

6) Prior to boiler installation, inspect chimney for obstructions or other defects and correct as required. Clean chimney

(

)

as necessary.

7) Vent pipe should slope upward from boiler not less than one inch in four feet. No portion of vent pipe should run

downward or have sags. Vent pipe must be securely supported.

8) The vertical section of vent pipe coming off the boiler should be as tall as possible, while still maintaining the proper

clearance from the horizontal vent connector to combustibles and the proper pitch called for in (7) above.

9) Vent pipe should be installed above the bottom of the chimney to prevent blockage.

10) Vent pipe must be inserted flush with inside face of the chimney liner and the space between vent pipe and chimney

sealed tight. A thimble permanently cemented in place can be used to facilitate removal of chimney connector for cleaning.

11) Install the barometric draft regulator in accordance with the regulator manufacturer’s instructions.

12) Secure all joints in the vent connector system with sheet metal screws. This includes the joint between the vent

connector and the boiler collar, as well as the barometric draft regulator. Use at least three screws at each joint.

TABLE 2: MINIMUM RECOMMENDED BREECHING AND

CHIMNEY SIZE

Boiler

Model

Min Breeching

Dia.

inches

Min. Recommended Chimney Size and Height

Round I.D. (in) Rectangular I.D. (in) Height (ft)

TWZ065 6 6 8 x 8 15

TWZ075 6 6 8 x 8 15

TWZ100 6 6 8 x 8 15

TWZ090 7 7 8 x 8 15

TWZ125 7 7 8 x 8 15

TWZ150 7 7 8 x 8 15

TWZ120 8 8 8 x 8 15

TWZ175 8 8 8 x 8 15

TWZ200 8 8 8 x 8 15

Power (“Side Wall”) Venting - Important Note

Two problems arise when any oil-fired appliance is power vented:

1. There is sometimes an accelerated rate of soot buildup on the oil burner cad-cell, spinner etc.

2. There is a potential for severe damage to the side of the structure in the event that the boiler operates at a high smoke

level. This can happen for many reasons, some of which are out of the control of both the installer and appliance

manufacturer.

Crown Boiler Company recommends the use of a chimney to vent the TWZ series boilers. If a power venter must be used,

it is the responsibility of the installer and power vent manufacturer to “engineer” the power vent system. CROWN

BOILER COMPANY WILL ASSUME NO RESPONSIBILITY FOR DAMAGE TO SIDING, ETC. FROM A POWER

VENTED OIL-FIRED BOILER. THIS APPLIES REGARDLESS OF THE CAUSE OF THE SOOTING.

10

11

Page 12

VII System Piping

CAUTION

• INSTALL BOILER SO THAT ALL ELECTRICAL COMPONENTS ARE PROTECTED FROM WATER (DRIPPING,

SPRAYING, RAIN, ETC.) DURING APPLIANCE OPERATION AND SERVICE (CIRCULATOR REPLACEMENT,

ETC.).

• OPERATION OF THIS BOILER WITH CONTINUOUS RETURN TEMPERATURES BELOW 120°F CAN CAUSE

SEVERE HEAT EXCHANGER CORROSION DAMAGE.

• OPERATION OF THIS BOILER IN A SYSTEM HAVING SIGNIFICANT AMOUNTS OF DISSOLVED OXYGEN CAN

CAUSE SEVERE HEAT EXCHANGER CORROSION DAMAGE.

• DO NOT USE TOXIC ADDITIVES, SUCH AS AUTOMOTIVE ANTIFREEZE, IN A HYDRONIC SYSTEM.

Standard Piping

Figure 10 shows typical boiler system connections on a single zone system. Additional information on hydronic system

design may be found in Installation of Residential Hydronic Systems (Pub. #200) published by the Hydronics Institute in

Berkeley Heights, NJ. The components in this system and their purposes are as follows:

1) Relief valve (Required) - Mount the relief valve on the top left side of the boiler as shown in Figure 10 using the 3/4”

nipple provided. The relief valve shipped with the boiler is set to open at 30 psi. This valve may be replaced with one

having a pressure up to the “Maximum Allowable Working Pressure” shown on the rating plate. If the valve is replaced,

the replacement must have a relief capacity in excess of the DOE heating capacity for the boiler.

Pipe the discharge of the relief valve to a location where water or steam will not create a hazard or cause property

damage if the valve opens. The end of the discharge pipe must terminate in an unthreaded pipe. If the relief valve

discharge is not piped to a drain, it must terminate at least 6 inches above the floor. Do not run relief valve discharge

piping through an area that is prone to freezing. The termination of the relief valve discharge piping must be in an area

where it is not likely to become plugged by debris.

FIGURE 10: STANDARD BOILER PIPING

11

12

Page 13

2) Circulator (Required) - Figure 10 shows the ideal location of the circulator which is in the supply piping immediately

DANGER

• PIPE RELIEF VALVE TO A SAFE LOCATION

• DO NOT INSTALL A VALVE IN THE RELIEF VALVE DISCHARGE LINE

• DO NOT MOVE RELIEF VALVE FROM FACTORY SPECIFIED

LOCATION

• DO NOT PLUG RELIEF VALVE DISCHARGE

IMPORTANT

THE 1 1/2” PLUGGED TAPPING ON THE BOTTOM REAR SECTION IS

PRESENT FOR MANUFACTURING PURPOSES ONLY. DO NOT ATTEMPT

TO USE THIS TAPPING AS A RETURN CONNECTION.

downstream of the expansion tank. A less ideal, but acceptable, location for most residential circulators is in the return

(if this is done, be sure that adequate clearance exists to open the door.

3) Expansion Tank (Required) - If this boiler is replacing an existing boiler with no other changes in the system, the old

expansion tank can generally be reused. If the expansion tank must be replaced, consult the expansion tank

manufacturer’s literature for proper sizing.

Fill Valve (Required) - Either a manual or automatic fill valve may be used. The ideal location for the fill is at the

4)

expansion tank.

5)

Automatic Air Vent (Required) - At least one automatic air vent is required. Manual vents will usually be required in

other parts of the system to remove air during initial fill.

6) Low Water Cut-Off (Required in some situations) - A low water cut-off is required when the boiler is installed above

radiation. In addition, some codes such as ASME CSD-1 require low water cut-offs. Codes may also require that this

low water cut-off have a manual reset function. The low water cut-off may be a float type or probe type, but must be

designed for use in a hot-water system. The low water cut-off should be piped into the boiler supply just above the

boiler with no intervening valves between it and the boiler.

Use a low water cut-off that breaks the 120 VAC supply to the boiler. Do not attempt to wire a 24-volt low water cutoff into the boiler factory wiring.

7) Manual Reset High Limit (Required by some codes) - This control is required by ASME CSD-1 and some other codes.

Install the high limit in the boiler supply piping just beyond the boiler with no intervening valves. Set the manual reset

high limit as far above the operating limit setting as possible, but not over 240°F. Wire the control to break the 120

VAC electrical supply to the boiler.

8) Flow Control Valve (Required under some conditions) - The flow control valve prevents flow through the system unless

the circulator is operating. A flow control valve may be necessary on converted gravity systems to prevent gravity

circulation. Flow control valves are also used to prevent “ghost flows” in circulator zone systems through zones that are

not calling for heat.

9) Isolation Valves (Optional) - Isolation valves are useful if the boiler must be drained, as they will eliminate having to

drain and refill the entire system.

10) Drain Valve - The drain valve is shipped in the boiler parts bag. Install it in the tee on the boiler return as shown in

Figure 1.

12

13

Page 14

FIGURE 11: INDIRECT WATER HEATER

BOILER SIDE PIPING

FIGURE 12: BOILER BYPASS PIPING

Piping for Special Situations

Certain types of heating systems have additional requirements. Some of the more common variations follow:

1) Indirect Water Heaters - Figure 11 shows typical indirect water heater piping. Boiler piping is the same as for any twozone system. Figure 11 shows circulator zoning, which is usually preferred for indirect water heaters. Size the

circulator and indirect water heater piping to obtain the boiler water flow through the indirect water heater called for by

the indirect water heater manufacturer.

2) Large Water Volume Systems - The piping shown in Figure 12 will minimize the amount of time that the boiler operates

with return temperatures below 120°F on these systems. A bypass is installed as shown to divert some supply water

directly into the return water. The bypass pipe should be the same size as the supply. The two throttling valves shown

are adjusted so that the return temperature rises above 120°F during the first few minutes of operation. A three-way

valve can be substituted for the two throttling valves shown.

13

14

Page 15

Low Temperature Systems - Some systems, such as radiant tubing systems, require the system water temperature to be

3)

limited to a value below the temperature of the water leaving the TWZ. These systems also typically have return

temperatures well below the 120°F minimum.

Figure 13 illustrates the use of a heat exchanger to connect the TWZ boiler to this type of system. The heat exchanger

will permit the transfer of heat from the boiler water to the low temperature system while holding the system supply and

boiler return temperatures within their limits. For this system to work properly, the heat exchanger must be properly

sized and the correct flow rates are required on either side of the heat exchanger. Consult the heat exchanger

manufacturer for sizing information. The water in the boiler is completely isolated from the water in the system. This

means that separate fill and expansion tanks are required for the heating system loop.

There are several other ways to connect low temperature systems to the non-condensing boilers like the TWZ such as

four way mixing valves and variable speed injection pumping systems.

4)

Systems containing oxygen - Many hydronic systems contain enough dissolved oxygen to cause severe corrosion

damage to a cast iron boiler such as the TWZ. Some examples include:

• Radiant systems that employ tubing without an oxygen barrier.

• Systems with routine additions of fresh water.

• Systems which are open to the atmosphere.

If the boiler is to be used in such a system, it must be separated from the oxygenated water being heated with a heat

exchanger as shown in Figure 13.

Consult the heat exchanger manufacturer for proper heat exchanger sizing as well as flow and temperature requirements.

All components on the oxygenated side of the heat exchanger, such as the pump and expansion tank, must be designed

for use in oxygenated water.

5) Air Handlers - Where the boiler is connected to air handlers through which refrigerated air passes, use flow control

valves in the boiler piping or other automatic means to prevent gravity circulation during the cooling cycle.

FIGURE 13: ISOLATION OF BOILER FROM SYSTEM

WITH A HEAT EXCHANGER

14

15

Page 16

WARNING

A mixing valve does not eliminate the risk of scalding.

• Set the mixing valve and boiler low limit adjustments as low as possible.

• Feel water before showering or bathing.

• If anti-scald or anti-chill protection is required, use devices specifically designed for such service. Install

and maintain these devices in accordance with the manufacturer’s instructions. Do not use the mixing valve

as a substitute for pressure balancing valves or other devices required by plumbing codes to protect against

scalding.

VIII T ANKLESS HEA TER PIPING

If the TWZ is installed with an optional tankless heater, pipe the heater as shown in Figure 14. The components in this

system and their functions are as follows:

1) Mixing Valve (Required) - During the heating season, the water exiting the tankless heater may be 180 degrees or

more. The mixing valve blends hot water leaving the tankless heater with cold water so as to maintain the hot water

supplied to the fixtures at a fixed temperature. This saves energy, increases the amount of usable hot water available to

the homeowner, and reduces the risk of scalding.

Install a mixing valve with a setting range of approximately 110 to 130F. Follow the manufacturer’s instructions for

installing this valve. Usually a “heat trap” will be required between the coil and the “hot” connection on the mixing valve.

2) Flow Restrictor (Recommended) - If water is drawn from the tankless coil at a rate in excess of the rating in Table 1b,

the temperature of the hot water may be too low to be of use. The use of a flow restrictor will prevent this problem by

limiting the rate at which water can pass through the tankless heater. If a restrictor is used, select one having a rating in

GPM approximately equal to the rating shown in Table 1b. If possible, locate this restrictor at least 3 feet from the

tankless heater inlet so that it is not subjected to excessive temperatures when no water is flowing through the coil.

3) Pressure Relief Valve (Required) - Limits the pressure in the tankless heater and piping. Use an ASME constructed

valve designed for domestic water service, such as the Watts #3L. Note that this is a pressure relief valve, not a T&P

valve. Select a valve with a pressure setting less than or equal to the working pressure marked on the tankless coil. Pipe

the discharge to a safe location using piping the same size as the discharge connection on the valve.

4) Hose Bib Valves (Recommended) - These valves permit the coil to be periodically “backflushed” to remove sediment.

5) Globe or Ball Valve (Recommended) - Used to adjust the flow through the entire tankless heater system if needed.

6) Unions (Required) - Tankless heaters may require periodic gasket replacement or other maintenance which requires

removal of the heater from the boiler. Install unions anywhere in the tankless heater piping that will facilitate removal of

the heater.

15

16

Page 17

FIGURE 14: TANKLESS HEATER PIPING

IX Fuel Line Piping

Fuel line piping design, materials and construction must be in accordance with local building codes, requirements of the

local authority having jurisdiction, and, the latest edition of Installation of Oil-Burning Equipment (ANSI/NFPA 31). Refer

also to the instruction manuals provided with the burner and oil pump.

Depending on the location of the fuel oil storage tank in relation to an oil burner, there are four types of oil piping systems

generally being used:

a) ONE-PIPE GRAVITY SYSTEM - used when a fuel oil storage tank is positioned above an oil burner fuel pump. See

Figure 15. A vertical distance from top of the tank to center line of the pump (Dimension ‘H’) over 8 feet will result

in a pump inlet pressure in excess of the 3-psi limit in NFPA-31.

FIGURE 15: ONE-PIPE GRAVITY SYSTEM

16

17

Page 18

ONE-PIPE LIFT SYSTEM (not recommended) - Used when a fuel oil storage tank is located below an oil burner

b)

fuel pump. See Figure 16. The vertical distance from bottom of the tank to center line of the pump (Dimension ‘H’)

must not exceed that shown in the pump manufacturer’s instructions. Although all oil piping systems must be airtight,

one-pipe lift systems are particularly susceptible to nuisance lockout problems if the suction line is not completely

airtight. A two-pipe lift system is therefore recommended over a one-pipe lift system.

c)

TWO-PIPE GRAVITY SYSTEM (not recommended) - Used when a fuel oil storage tank is located above an oil

burner fuel pump. See Figure 17. A vertical distance from top of the tank to center line of the pump (Dimension ‘H’)

over 8 feet will result in a pump inlet pressure in excess of the 3-psi limit in NFPA-31. This type of system should

be converted to a one-pipe gravity system, as doing so will result in lower inlet line flow and longer filter life.

d) TWO-PIPE LIFT SYSTEM - used when a fuel oil storage tank is located below an oil burner fuel pump suction port.

See Figure 18. The vertical distance from bottom of the tank to center line of the pump (Dimension ‘H’) must not

exceed that shown in the pump manufacturer’s instructions. Distance ‘H’ allowed is reduced by the number of

fittings, filters and valves installed in the line.

Once the type of system has been selected, observe the following:

1) Fuel line piping must be airtight. Do not use compression type fittings for tubing connections in fuel line piping. Use

only listed flare type fittings. Cast iron threaded fittings shall not be used for wrought iron or steel piping connections.

2) Piping shall be substantially supported and protected against physical damage and corrosion where required.

3 ) Refer to supplied oil pump instruction manual for proper connections. On one-pipe systems, ensure that the fuel pump

return port plug is tightened securely.

4 ) Some fuel pumps, such as the Suntec A and B series, are supplied with a loose bypass plug which must be installed on

two-pipe systems. If such a plug is supplied, install it as shown in the pump manufacturer’s instructions. Do not install

this bypass plug on one-pipe systems as pump seal damage will result.

5) Do not use check valves, especially on gravity feed systems.

6) Do not use Teflon tape for threaded connections. Use a listed non-hardening thread sealant instead.

7) Attach required piping between burner fuel pump and fuel oil storage tank. Install one fuel shut-off valve near the storage

tank and second fuel shut-off valve near the oil burner fuel pump. Use heavy wall copper tubing in a continuous run. On

two-pipe systems, the return line should terminate 3” - 4” above suction line depth within the storage tank. Refer to the

pump manufacturer’s instructions for tube sizing information.

8) All systems require an oil filter. On TWZ065 and TWZ075 boilers, the use of a Garber cartridge type filter is

recommended.

9) Use only #2 Fuel Oil with physical and chemical characteristics meeting the requirements of ASTM D-396.

FIGURE 16: ONE-PIPE LIFT SYSTEM

17

18

Page 19

FIGURE 17: TWO-PIPE GRAVITY FEED SYSTEM

FIGURE 18: TWO-PIPE LIFT SYSTEM

18

19

Page 20

X Wiring

WARNING

All wiring and grounding must be done in accordance with the authority having jurisdiction or, in the absence of such

authority, with the National Electric Code (ANSI/NFPA70).

Single Zone Wiring

1) 120 Volt Wiring - The boiler should be provided with its own 15A branch circuit with fused disconnect. All 120 volt

connections are made inside the L8148 or L8124 aquastat relay as follows (also see Fig. 19):

• Hot (“black”) - T erminal “L1”

• Neutral (“white”) - T erminal “L2”

• Ground (“green” or bare) - Ground screw on case of L8148 or L8124

2) Thermostat Wiring - Follow thermostat manufacturer instructions. To insure proper thermostat operation, avoid

installation in areas of poor air circulation, hot spots (near any heat source or in direct sunlight), cold spots (outside

walls, walls adjacent to unheated areas, locations subject to drafts). Provide Class II circuit between thermostat and

boiler. Connect thermostat wire leads to terminals “T” and “T” inside L8148 or L8124 aquastat relay.

Wiring V ariations

1) Multiple Circulator Zones – Figure 20 shows wiring for two or more circulator zones using Honeywell R845As. One

R845A is required for each circulator zone. Circulator terminals “C1” and “C2” on the L8148 are not used. A DPST

Honeywell RA832A may be substituted in place of the R845A using the “X” and “X” terminals in place of the “5” and

“6” terminals on a R845A.

A call for heat from any thermostat will energize the DPST relay in that zone’s R845A. When this relay is energized,

electrical continuity is created between terminals 3 and 4, energizing the circulator for that zone. At the same time,

electrical continuity is created between terminals 5 and 6 on the R845A, creating a current path from terminal “T” to

“T” on the L8148 or L8124. Assuming that the supply water temperature is below the high limit setting, the normal

ignition sequence will be initiated.

2) Multiple Zones using Zone Valves – Figure 21 shows wiring for multiple zones using Honeywell V8043F zone valves.

This wiring diagram may be used for other 24-volt zone valves as long as they are equipped with end switches. Do not

attempt to use the transformer on the L8148 or L8124 to power the zone valves; use a separate transformer. Up to five

V8043Fs may be powered by one 48VA transformer, such as the Honeywell AT87A.

A call for heat from a given thermostat will result in the application of 24 volts across the TH and TR terminals on the

corresponding zone valve, energizing the zone valve motor. The zone valve opens and the end switch contacts are then

made. The end switches are connected in parallel with each other and to the “T” and “T” thermostat connections so that

any zone valve that opens will also start the circulator and fire the boiler (assuming the high limit is not open). Zone

valve terminal TH/TR has no internal connection on the zone valve; it is merely a “binding post” used to connect two or

more wires.

19

20

Page 21

HO NEYWELL

A

L814 8 OR L8 12 4

AQUAS TAT RELAY

NOT E:

1 ) BURNER WIRING SHOWN IS FOR BECKETT

MANUAL FOR O THER BURNERS

2) AQUASTAT PICTURED IS L8148. TERMINAL 3

AND JUMPER FROM L1 TO 3 ARE NOT PRESENT

ON L8124. L8124 HAS TWO TERMINALS,

MARKED ZC AND ZR, WHICH ARE NOT USED.

FIGURE 19: WIRING DIAGRAM, SINGLE HEATING ZONE ONLY

L1

INT ERRUPT ED

INTERM ITTENT

BURNER M OTOR

LIM IT

VALVE

L2

FG BURNERS. CO N SULT BURNER I N STRUCTIO N

CAD

CELL

FIGURE 20: WIRING DIAGRAM, CIRCULATOR ZONE WIRING USING HONEYWELL R845A’s

(FACTORY BOILER WIRING NOT SHOWN - SEE FIGURE 19)

20

21

Page 22

FIGURE 21: WIRING DIAGRAM, ZONE WIRING USING HONEYWELL V8043F ZONE VALVES

WARNING

• NEVER ATTEMPT TO FILL A HOT EMPTY BOILER.

• MAKE SURE THAT THE AREA AROUND THE BOILER IS CLEAR AND FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE, AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

• SAFE RELIABLE OPERATION OF THIS BOILER REQUIRES THAT THE BURNER BE CHECKED AND

ADJUSTED BY A QUALIFIED OIL SERVICEMAN USING COMBUSTION TEST INSTRUMENTS.

• FAILURE TO PERFORM ALL OF THE CHECKS OUTLINED IN THE FOLLOWING PROCEDURE

COULD RESULT IN UNRELIABLE OPERATION, DAMAGE TO THE BOILER NOT COVERED UNDER

WARRANTY, PROPERTY DAMAGE, OR UNSAFE OPERATION.

(FACTORY BOILER WIRING NOT SHOWN - SEE FIGURE 19)

XI Start-up and Checkout

Use the following procedure for initial start-up of the boiler:

1) Ensure that the boiler and entire heating system are filled with water.

2) Check all new piping for leaks and purge heating system piping sections that are air bound.

3) Verify that the vent system is complete and free of obstructions prior to start-up of the boiler.

4) Inspect all wiring for loose or uninsulated connections, proper size fuses installed, etc.

5) Verify that oil tank is filled with #2 fuel oil meeting ASTM D396 specifications, oil piping has been tested and is air

tight, and shutoff valve(s) are closed.

21

22

Page 23

6) Check initial settings of oil burner air band and air shutter, head setting etc., and readjust if needed. See Table 3 for setup

CAUTION

ATTEMPTS TO USE BURNERS OR BURNER CONFIGURATIONS OTHER THAN THOSE SHOWN

IN TABLE 3 COULD RESULT IN RELIABILITY PROBLEMS, PROPERTY DAMAGE OR UNSAFE

OPERATION.

and combustion data pertaining to a particular boiler/ burner combination.

7) Attach plastic hose to oil pump vent fitting and provide a container to catch oil during oil pump bleeding procedure.

8) Install 0-200 PSI pressure gauge into oil pump gauge port.

9) Open all oil line shutoff valves.

10) Open flame observation port cover on burner swing door to see flame.

11) Adjust system thermostat to highest setting.

12) Set boiler controls (high limit, low limit, etc.) to suit individual requirements of the installation.

13) Turn the line service switch to “ON” position.

14) Crack open vent fitting on the oil pump and allow burner to run until a solid oil stream, free of air bubbles, flows for 15

seconds into container. As the vent fitting is closed, the burner should fire and flame should be visible through observation

port immediately (or after prepurge timing has expired, if a burner is so equipped). Refer to burner instructions for more

details.

15) Immediately upon firing the boiler, check the smoke level. If the smoke level is in excess of a #1, open the air

adjustment to bring the smoke level below a #1.

16) Make sure that the oil pressure matches that shown in Table 3 for the burner supplied. Adjust pressure if required.

17) Check the vacuum at the inlet of the fuel pump. Make sure that the vacuum does not exceed the fuel pump

manufacturer’s limit (consult the pump manufacturer’s instructions).

18) Close the flame observation cover.

19) After chimney has warmed-up to operating temperature, adjust barometric draft regulator for a draft of -0.02 inch w. c.

over the fire.

20) Check the CO2 and confirm that it is between the minimum and maximum limits shown in Table 3. Adjust if necessary.

21) Verify that the smoke level still does not exceed #1 and that the draft over fire is -0.02 inch w.c.

22) Turn off the burner and remove pressure gauge. Install and tighten gauge port plug, then restart the burner.

23) Check for clean cutoff of the burner. Air in the oil line between fuel pump and nozzle will compress, while burner is

running, and expand, when burner shuts off, causing oil line pressure to drop and nozzle drip after burner stops. Cycle

burner on and off 5 to 10 times to purge air completely.

24 ) Check thermostat operation by raising or lowering its set point as required, cycling burner on and off.

25 ) Verify primary control operation and safety features according to procedure outlined in the instructions furnished with

control.

26) Check high limit control operation. Jump thermostat terminals and allow burner to run until boiler water temperature

exceeds high limit setting. The burner should shut down, and circulator continue running. Allow the temperature to drop

below the control setting. The burner must restart. Boiler installation is not complete unless these checks are made and are

satisfactory. Remove thermostat jumper and reconnect thermostat upon check completion.

27) After the boiler has operated for approximately 30 minutes, check the boiler and heating system for leaks. Repair any

leaks found at once.

After the above checks have been completed, leave thermostat(s) at desired setting. Leave all instructions provided with the

boiler with owner or in boiler room, displayed near boiler.

22

23

Page 24

TABLE 3a: BECKETT BURNER CONFIGURATION AND SETUP DATA

A

BOILER MODEL

BURNER MODEL

AIR TUBE COMBO.

HEAD TYPE

STATIC PLATE

LOW FIRING RATE

BAFFLE

INSERTION LENGTH

PITCH ANGLE

STANDARD

NOZZLE

LTERNATE

NOZZLE

PUMP PRESS (psi)

HEAD SETTING

TWZ065 TWZ075 TWZ100 TWZ090 TWZ125 TWZ150

KSZ065 KSZ075 KSZ100 KSZ090 KSZ125 KSZ150

AFG AFG AFG AFG AFG AFG AFG AFG AFG

70MMAQ 70MMAQ 70MMAQ 70MMAQ 70MDAQ 70MDAQ 70MLAQ 70MLAQ 70MLAQ

L1 L1 L1 L1 V1 V1 V1 V1 V1

3 3/8 3 3/8 3 3/8 3 3/8 2 3/4 2 3/4 NONE NONE NONE

BECKETT

#3708

BECKETT

#3708

2 1/4 2 1/4 2 1/4 2 1/4 2 1/4 2 1/4 2 1/4 2 1/4 2 1/4

222222222

HAGO HAGO HAGO DEL. HAGO HAGO HAGO HAGO HAGO

0.55/60B 0.65/60B 0.85/60B 0.75/60B 1.00/60B 1.25/60B

DEL. DEL. DEL. HAGO DEL. DEL. DEL. DEL. DEL.

0.55/60W 0.65/60W 0.85/60W 0.75/60B 1.00/60B 1.25/60B

140 140 140 140 140 140 175 175 175

NA NA NA NA 0 0

STARTING:

SHUTTER SETTING

BAND SETTING

DRAFT OVER FIRE

(in w.c.)

MAX. SMOKE

(bacharach scale)

1105 71010

12200.56

-0.02 -0.02 -0.02 -0.02-0.02 -0.02 -0.02

#1 #1 #1 #1 #1 #1 #1 #1

FLUE CO2 (%)

MIN.

MAX

PREPURGE

11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0

12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5 12.5

15 SECONDS None

IGNITION MODE INTERUPTED

TWZ120 TWZ175 TWZ200

KSZ120 KSZ175 KSZ200

NONE NONENONE NONE NONE NONE NONE

0.90/60B 1.35/45B 1.50/45B

0.90/60B 1.35/45B 1.50/45B

034

868

164

-0.02 -0.02

#1

TABLE 3b: CARLIN BURNER CONFIGURATION AND SETUP DATA

TWZ065 TWZ075 TWZ100 TWZ090 TWZ125 TWZ150 TWZ120 TWZ175 TWZ200

BURNER MODEL EZ-1HPEZ-1HPEZ-1HPEZ-1HPEZ-1HPEZ-1HPEZ-1HPEZ-2HP

STANDARD DEL. HAGO HAGO DEL. DEL. HAGO HAGO DEL.

NOZZ LE 0.55/70B 0.60/60ES 0.85/60B 0.75/60A 1.00/60A 1.25/60B 1.00/60B 1.50/60A

PUMP PRE SS (psi) 150 150 150 150 150 15 0 150 150

HEA D BAR 0.50 0.60-0. 6 5 0.85-1.00 0.75 0.85-1. 0 0 1.10-1.25 0.85-1.00 1.5 0

STARTING

BAND SETTING 0.55 0.60 0.75 0.75 1.00-1.10 1.25-1.35 0.90 1.75

DRAF T OVER FIRE

(in w.c.)

MAX. SMOKE

(bac ha rach scale)

FLUE CO2 (%)

MIN. 11.0 11. 0 11.0 11. 0 11.0 11.0 11. 0 11.0

MA X 12. 5 1 2.5 12.5 1 2.5 12. 5 12.5 12.5 12.5

PREPURGE NONE

IGNITION MODE INTERRUPTED

#1 #1 #1 #1 #1 #1 #1 #1

23

24

-0.02 -0.02 -0.02 -0.02-0.02 -0.02 -0.02 -0.02

Page 25

TABLE 3c: RIELLO BURNER CONFIGURATION AND SETUP DATA

BURNER MODEL

STANDARD

NOZZLE

PUMP PRESS (psi)

TURBULATOR

AIR

SHUTTER SETTING

DRAFT OVER FIRE

(in w.c.)

MAX. SMOKE

(bacharach scale)

FLUE CO2 (%)

MIN.

MAX

TWZ065 TWZ075 TWZ100 TW Z090 TW Z125 TWZ150

40F5 40F5 40F5 40F10 40F10 40F10

DEL DEL DEL. DEL HAGO DEL

0.60/60A 0.85/60W 1.00/60A 1.25/60B

150 150 150 150 150 150

02 41

2.60 2.85 4 3

-0.02 -0.02 -0.02-0.02 -0.02 -0.02

#1 #1 #1 #1 #1 #1

11.0 11.0 11.0 11.0 11.0 11.0

12.5 12.5 12.5 12.5 12.5 12.5

TWZ120 TWZ175 TWZ200

1.35/45B 1.65/45B

1.5 2

33.8

XII Service and Maintenance

The following procedure should be performed on an annual basis:

1) Turn off electrical power and oil supply to the boiler.

2) Clean the boiler as follows:

a) Remove vent connector and piping.

b) Remove barometric draft regulator.

c) Remove top jacket panel to gain access to boiler flue collector.

d) Unscrew four wing nuts and remove canopy retaining carriage bolts, lift off the canopy and ceramic fiber sealing

strips.

e) Unplug the burner, disconnect the oil lines (if the pump is hard piped), and remove the two 5/16” bolts securing the

burner door. Open the burner swing door.

f) Thoroughly brush boiler flueways from the top and diagonally between casting pin rows. Be careful when brushing

the rear passage not to damage the rear target wall insulation.

g) Vacuum soot and debris from combustion chamber.

h) Check condition of rear target wall insulation, combustion chamber liner, and burner door insulation; replace if

required.

i) Check burner head for signs of deterioration. Clean the head of any deposits.

j) Close burner door, reinstall 5/16” bolts, reconnect fuel oil and electrical lines.

k) Installation of boiler canopy, jacket top panel barometric draft regulator and breeching piping is done in reverse

order of removal. Make sure canopy is sealed tight to the casting; replace ceramic fiber sealing strips as needed. All

vent piping joints must be flue gas leak free and secured with sheet metal screws.

24

25

Page 26

CAUTION

WATER LEAKS CAN CAUSE SEVERE CORROSION DAMAGE TO THE BOILER OR OTHER SYSTEM

COMPONENTS. REPAIR ANY LEAKS FOUND IMMEDIATELY.

IMPORTANT

• CLEAN THE BOILER EVEN IF THERE ARE NO SIGNIFICANT SOOT DEPOSITS. FAILURE TO

REMOVE ALL SULFUR AND ASH DEPOSITS ANNUALLY CAN CAUSE SEVERE CORROSION

DAMAGE.

• WHEN CLEANING THE REAR FLUE PASSAGE, BE CAREFUL NOT TO PUSH THE BRUSH TOO FAR

BEYOND THE BOTTOM OF THE PINS. DOING SO MAY DAMAGE THE TARGET WALL.

3) Inspect the vent system:

a) Make sure that the vent system is free of obstructions and soot.

b) Make sure that all vent system supports are intact.

c) Inspect joints for signs of condensate or flue gas leakage.

d) Inspect venting components for corrosion or other deterioration. Replace any defective vent system components.

4) Service the oil burner:

a) Replace oil nozzle with identical make and model (see Table 3).

b) Inspect the electrodes. Replace if they are deteriorated. Make sure that the electrode position is set according to the

burner manufacturer’s instructions.

c) Remove and clean fuel pump strainer.

d) Remove any accumulations of dust, hair, etc. from the air shutter, blower wheel, and other air handling parts of the

burner.

5) Replace the fuel oil line filter element and gaskets.

6) Inspect all oil piping and fittings for kinks and leaks. Repair any found.

7) Inspect the hydronic piping, tankless coil gasket, and boiler plugs for water leaks. Repair any leaks found immediately.

8) Verify operation of relief valve by manually lifting lever; replace relief valve immediately if valve fails to relieve

pressure.

9) Open fuel line shut-off valve(s) and restore electrical power to the boiler.

10) Fire the boiler and check it out using the procedure outlined in “Start-up and Checkout” . This must include checking

the burner adjustments using instruments. Check for proper operation of all controls.

252726

26

Page 27

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Parts list designates parts that contain refractory ceramic fibers (RCF).

RFC has been classified as a possible human carcinogen. When exposed to

temperatures about 1805°F, such as during direct flame contact, RFC changes

into crystalline silica, a known carcinogen. When disturbed as a result of

servicing or repair, these substances become airborne and, if inhaled, may be

hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

:

Page 28

KEY #

1 COMPLETE HEAT EXCHANGER ASSY. 1 ea. 270013 270013 270013 270014 270014 270014 270015 270015 270015

* FRONT SECTION 275050 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* REAR SECTION 275060 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* INTERMEDIATE SECTION 275055 1 ea. 1 ea. 1 ea. 2 ea. 2 ea. 2 ea. 3 ea. 3 ea. 3 ea.

* LOWER PUSHNIPPLE 275070 2 ea. 2 ea. 2 ea. 3 ea. 3 ea. 3 ea. 4 ea. 4 ea. 4 ea.

* UPPER PUSHNIPPLE 275075 2 ea. 2 ea. 2 ea. 3 ea. 3 ea. 3 ea. 4 ea. 4 ea. 4 ea.

2 BURNER SWING DOOR HINGE 275030 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

3 FRONT SECTION HINGE 275035 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

SWING DOOR INSULATION†

4

5 5/16-18 X 1-1/2 HX HEAD CAP SCREW 900415 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

6 5/16 FLAT WASHER 900102 10 ea. 10 ea. 10 ea. 10 ea. 10 ea. 10 ea. 10 ea. 10 ea. 10 ea.

7 5/16-18 X 1 HX HEAD CAP SCREW 900410 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea.

8 FLAME INSPECTION COVER 270022 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

9 5/16-18 X 3/4 HEX HEAD CAP SCREW 900400 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

TARGET WALL (REPLACEMENT KIT)†

10

REFRACTORY BLANKET†

11

12 SWING DOOR 270020 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

1/2" x 1" SEALING STRIP†

20

21 FLUE COLLECTOR 1 ea. 270123 270123 270123 270124 270124 270124 270125 270125 270125

22 1/4-20 x 3" CARRIAGE BOLT 900126 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

23 1/4-20 x 3-1/2" CARRIAGE BOLT 900127 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

24 1/4" USS FLAT WASHER 90-215 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea.

25 1/4-20 WING NUT 900125 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea. 4 ea.

30 TANKLESS HEATER GASKET 270001 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

31 TANKLESS HEATER (OPTIONAL) 270002 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

32 HEATER OPENING COVER PLATE 270003 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

33 3/8-16 X 7/8 HX HEAD CAP SCREW 900450 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea.

34 3/8 USS FLAT WASHER 90-036 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea. 6 ea.

† SEE PAGE 26 FOR WARNING REGARDING THE HANDLING OF PARTS THAT CONTAIN REFRACTORY CERAMIC FIBERS.

DESCRIPTION

QTY. OR

CROWN P.N.

270021 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

270025 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

1 ea. 275003 275003 275003 275004 275004 275004 275005 275005 275005

900145 4.0 ft 4.0 ft 4.0 ft 4.8 ft 4.8 ft 4.8 ft 5.7 ft 5.7 ft 5.7 ft

65

75 100 90 125 150 120

QUANTITY PER BOILER OR CROWN P.N.

175 200

27

28

Page 29

28

29

Page 30

KEY #

40 LEFT SIDE JACKET PANEL 1 ea. 270233 270233 270233 270234 270234 270234 270235 270235 270235

41 RIGHT SIDE JACKET PANEL 1 ea. 270223 270223 270223 270224 270224 270224 270225 270225 270225

* REAR JACKET PANEL 270220 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

43 TOP JACKET PANEL 1 ea. 270243 270243 270243 270244 270244 270244 270245 270245 270245

44 FRONT PANEL 270210 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

45 UPPER FRONT PANEL 270215 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

46 #10 X 1/2" SHEET METAL SCREW 90-212 15 ea. 15 ea. 15 ea. 15 ea. 15 ea. 15 ea. 15 ea. 15 ea. 15 ea.

47 5/16-18 X 1/2 PAN HEAD SCREW 900420 8 ea. 8 ea. 8 ea. 8 ea. 8 ea. 8 ea. 8 ea. 8 ea. 8 ea.

48 1/2" LONG WELL 35-1006 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

49 AQUASTAT (L7248C1048) 3503020 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

49 AQUASTAT (L7224A1008) 3503305 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

51 JUNCTION BOX 96-001 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

52 8-32 X 1/2 SCREW 90-052 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

* 8-32 HEX NUT 90-053 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea. 2 ea.

54 TWIST RECEPTICAL 96-010 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

55 TWIST RECEPTICAL COVER 96-019 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

56 TRIDICATOR GAUGE 95-069 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

60 BECKETT BURNER ASSY. (NOTE #1) 1 ea. 130511 130512 130513 130514 130515 130516 130517 130518 130519

60 CARLIN BURNER ASSY. (NOTE #1) 1 ea. 130521 130522 130523 130524 130525 130526 130527

60 RIELLO BURNER ASSY. (NOTE #1) 1 ea. 130532 130533 130535 130536 130538 130539

* BURNER CORD ASSY. (BCKT./CARLIN) 960275 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* BURNER CORD ASSY. (RIELLO) 960276 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

61 5/16-18 X 1-1/4 STUD 90-012 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea.

62 5/16-18 HEX NUT 90-010 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea. 3 ea.

DESCRIPTION

QTY. OR CROWN

P.N.

65 75 100 90 125 150 120 175 200

QUANTITY PER BOILER OR CROWN P.N.

70 3/4" RELIEF VALVE (30 psi) 95-040 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* CIRCULATOR (TACO 007) 95-012 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* 1-1/2" TACO FLANGE SET 950150 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* 3/4" BOILER DRAIN 95-041 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea. 1 ea.

* NOT PICTURED

NOTE #1: PART NUMBERS PROVIDED ARE FOR FULLY CONFIGURED BURNERS AND INCLUDE NOZZLES, BURNER CORD

ASSEMBLIES, AND (WHERE APPLICABLE) LOW FIRING RATE BAFFLES.

29

30

Page 31

30

31

Page 32

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

7HO)D[ZZZFURZQERLOHUFRP

32

PN980270 Rev 6 09/10

Loading...

Loading...