Page 1

Freeport ODV Series

D ESIGNED TO L EAD

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

Oil-Fired Direct Vent Hot Water Boilers

These instructions must be afxed on or adjacent to the boiler.

Models

ODV-75•

ODV-100•

ODV-125•

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury,

or loss of life. For assistance or additional information

consult a qualied installer or service agency. This boiler

requires a special venting system. Read these instructions

carefully before installing.

Page 2

Page 3

TABLE OF CONTENTS

Product Description 1

Specications 2

BeforeInstalling 3

LocatingTheBoiler 3

VentSystemInstallation 4

SystemPiping 13

FuelPiping 17

Wiring 18

Start-UpAndCheckout 19

ServiceNotes 20

Maintenance 22

Parts 24

Page 4

WARNING

FAILURE TO VENT THIS BOILER IN ACCORDANCE WITH THESE INSTRUCTIONS

COULD CAUSE FLUE GAS TO ENTER THE BUILDING RESULTING IN SEVERE

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH:

Do not attempt to vent this boiler with galvanized, PVC, or any other vent components •

not described in this manual

Do not obtain combustion air from within the building. •

Do not install a barometric damper or vacuum relief valve in the vent system of this •

boiler.

CAUTION

Moisture and ice may form on the surfaces around the vent termination. To prevent

deterioration, surfaces should be in good repair (sealed, painted, etc.).

DANGER

THE VENT SYSTEM SUPPLIED WITH THE ODV IS NOT DESIGNED FOR VENTING

OF FLUE PRODUCTS FROM NATURAL GAS OR PROPANE. DO NOT ATTEMPT TO

CONVERT THE ODV TO EITHER GAS.

I Product Description

The ODV series boiler is a cast iron oil red boiler designed for use in forced hot water heating

systems. The ODV boiler must be vented using the factory supplied venting system with combustion air taken from outdoors. The ODV uses the same three pass “scotch marine” heat exchanger as

the CT series boiler. The ODV series boiler is ideal for use in installations where a chimney is not

available.

The ODV boiler is not designed for use in gravity or “open” heating systems.

CAUTION

As with any oil appliance, certain adverse conditions can cause this boiler to operate at high

smoke levels. Since the ODV is vented through a wall, this can result in severe soot damage

to the side of the structure around the terminal. To minimize the risk of this:

• Follow these installation instructions exactly

• Oil burner must be set up by a qualied serviceman using combustion test instruments

• Use only the vent components supplied in the ODV vent kit

• Combustion air must be supplied from outdoors

• Follow the maintenance procedure in this manual

• Use only #2 fuel oil meeting ASTM D-396

1

Page 5

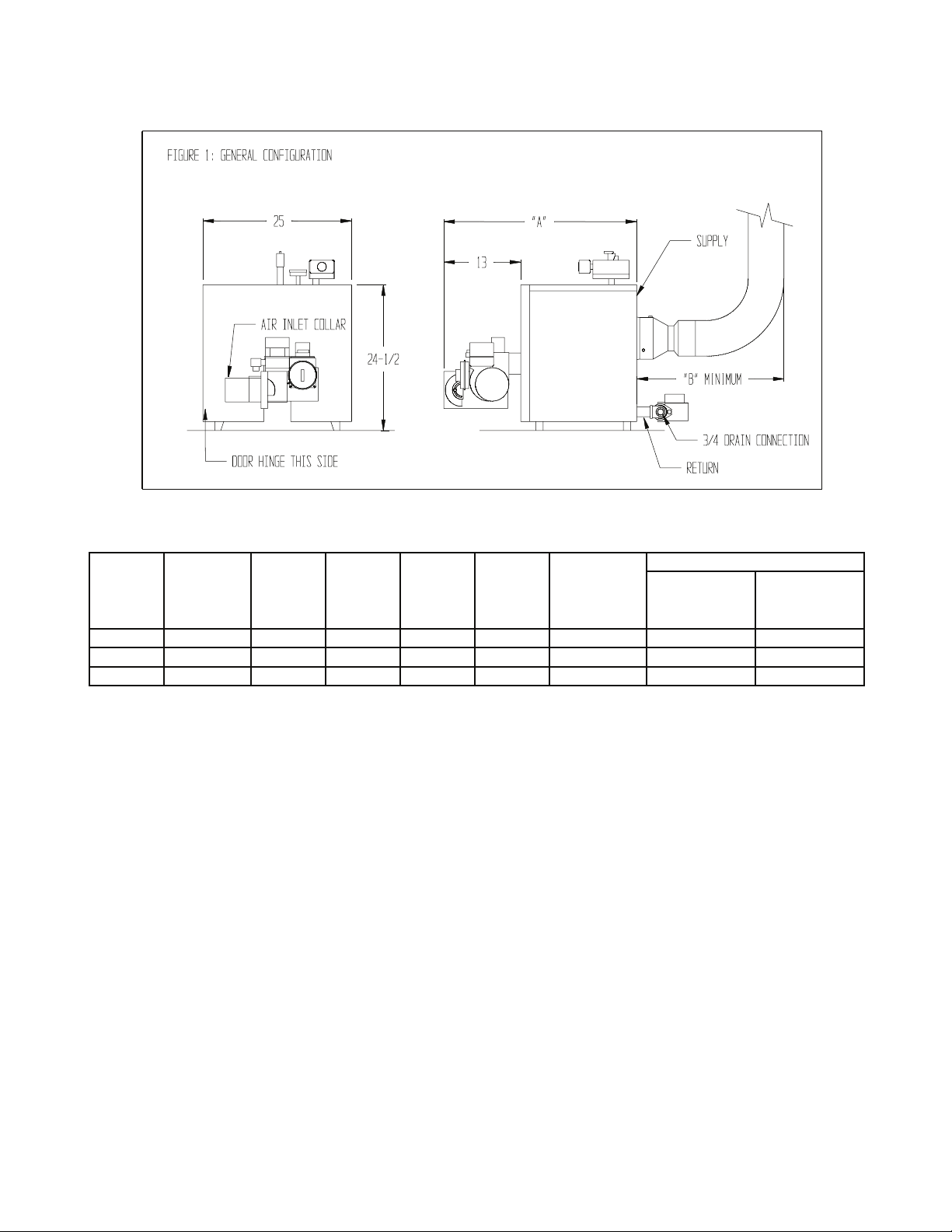

IISpecications

D.O.E.

HEATING IBR NET FIG. 1

NO. INPUT CAPY. RATING DIMENSION

MODEL SECTIONS Gal/hr) (BTU/hr) (BTU/hr) AFUE (%) "A" (IN.)

ODV-75 3 0.75 91,000 79,000 85.0 32-1/4 24 14

ODV-100 3 1.00 119,000 103,000 83.1 32-1/4 24 14

ODV-125 4 1.25 150,000 130,000 83.5 37-1/4 24 14

FIG. 1 DIMENSION "B" (IN.)

STANDARD

CONNECTION

USING

OPTIONAL

TEE

TABLE 1: SPECIFICATIONS

Ratings based on #2 fuel oil having a higher heating value of 140,000 BTU/Gal

Net ratings based on a piping and pickup loss allowance of 1.15

Exhaust pipe: 4” I.D. insulated exible vent pipe.

Maximum exhaust pipe length – 15 ft.

Inlet pipe: 4” I.D. Corrugated Aluminum

Maximum Inlet pipe length – 20 ft

Maximum Wall Thickness in which Terminal is Installed – 12”

2

Page 6

IIIBeforeInstalling

1) Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in

strict accordance with this manual and the authority having jurisdiction.

• In the absence of an authority having jurisdiction, installation must be in accordance with this manual

and Installation of Oil-Burning Equipment (ANSI/NFPA 31).

• Where required by the authority having jurisdiction, this installation must conform to the

Standard for Controls and Safety Devices for Automatically Fired Boilers (ANSI/ASME CSD-1)

2) Read Section VI to verify that the maximum combustion air and exhaust pipe lengths will not be

exceeded in the planned installation. Also verify that the vent terminal can be located in accordance with

Section VI. Note: The maximum wall thickness through which the terminal can be installed is 12”.

3) Make sure that the boiler is correctly sized:

• For heating systems employing convection radiation (baseboard or radiators) use an industry

accepted sizing method such as the I=B=R Heat Loss Calculation Guide (Pub. #H21 or #H22)

published by the Hydronics Institute in Berkely Heights NJ.

• For new radiant heating systems refer to the radiant tubing manufacturer’s boiler sizing guidelines.

• For systems including a Crown Mega-Stor indirect water heater, size the boiler to have either the DOE

Heating Capacity required for the Mega-Stor or the net rating required for the heating system,

whichever results in the larger boiler.

• For systems that incorporate other indirect water heaters, refer to the indirect water heater manufac-

turer’s instructions for boiler output requirements.

4) Do not install this boiler at altitudes above 2000ft.

5) Inspect shipment. This boiler is shipped in three pieces:

a) Wire-bound crate with boiler

b) Vent terminal carton – Includes terminal, vent adapters, inlet piping and hardware

c) Vent pipe carton - Includes exible vent pipe.

IVLocatingtheBoiler

1) Observe the clearances below. Top, side and rear clearances are from jacket. Front clearance is from

burner door.

To Combustible Construction To Non-Combustible Construction

Front 24 15

Left* 6 2-1/2

Right 6 1

Rear Determined by clearance to Flexible Vent Pipe (below)

Top 24 24

Terminal 0 0

Flexible Vent Pipe 3 0

* 14 inch clearance required to open door.

2) Boiler must be installed on a non-combustible surface.

3) Boiler must be located so that the 15-foot vent pipe supplied with the boiler will reach the

terminal location. Approximately 1.3 feet of pipe length is used up in making a 90-degree bend

(Fig 11). See Section V for more information on venting requirements.

3

planned

Page 7

VVentSystemInstallation

WARNING

• Read the installation instructions carefully and completely before proceeding

with the installation of vent system.

• For continued safe operation, the appliance vent system must be inspected and

maintained annually by a qualied agency.

Failure to properly maintain the appliance vent system combination can lead to

Death, Personal Injury and or Property Damage.

• Plan the vent system layout before installation to avoid the possibility of

accidental contact with concealed wiring or plumbing inside walls.

The ODV boiler is shipped with a complete venting system consisting of the following components:

• FDVS-4 direct vent terminal

• Backing plate

• 15-ft length of insulated 4” FOVP exible oil vent pipe

• 4” x 7” appliance adapter

• (2) Cover rings

• (2) Cover sleeves

• Bagged hardware

• (4) Inner pipe clamps

• 20 ft length 4” exible aluminum air intake pipe

• (2) Hose clamps

• “Red” high temperature RTV silicone sealant

CAUTION

• Do not use vent system components other than those supplied with the boiler

• Use only the red RTV sealant provided with this boiler anywhere that this manual

calls for the use of “sealant”

• Combustion air must be brought from outside as shown in this manual

• Do not install a “vacuum relief” damper

• Do not attempt to splice vent piping

• Do not put holes in venting

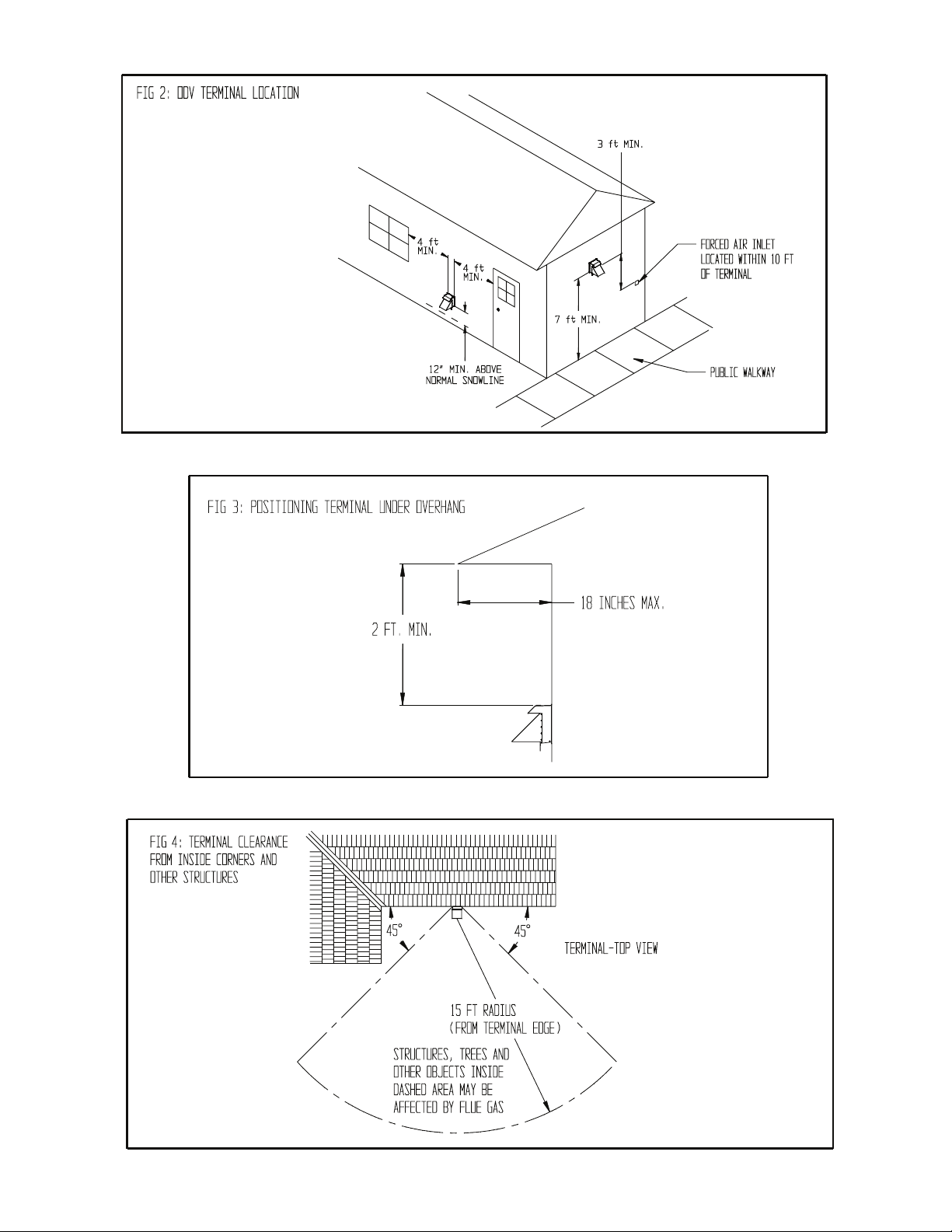

1) LOCATING THE TERMINAL – Observe the following requirements in locating the terminal:

a) Maximum wall thickness through which terminal can be installed is 12”.

b) Wall can be combustible or noncombustible.

c) Bottom of terminal must be at least 12 inches above the normal snowline. If normal snowfall is

negligible, terminal must be at least 12 inches above grade (Fig 2).

d) Bottom of Terminal must be at least 7 feet above a public walkway (Fig 2).

e) Locate edge of terminal at least 4 ft horizontally from doors, windows, or gravity air inlets. Do

not put terminal under windows which can be opened (Fig 2).

f) Terminal must be close enough to boiler to be connected to it using the vent components

supplied.

4

Page 8

5

Page 9

g) Do not locate terminal under decks.

h) It is preferable to install the terminal on the wall that is away from the prevailing wind.

i) Do not put terminal under a soft or other overhang deeper than 18 inches. Top edge of terminal

must be at least 2 ft below soft or overhang (Fig 3).

j) Position terminal to avoid accidental contact with people or pets.

k) Over time, the area around the terminal may become stained. Locate the terminal on a wall

where this is not objectionable.

l) No part of an inside corner should extend into the shaded area shown in Figure 4.

m) Terminal must be positioned so that no other buildings are within the shaded area shown in

Figure 4. Other permanent objects in this area may become stained or otherwise effected by ue

gas.

n) The terminal is a potential source of odors. Although the above restrictions will generally prevent

inltration of these odors into the building, care should be taken in positioning the terminal near

outdoor areas where people congregate, such as patios. This is particularly true when the boiler is

used with an indirect water heater that will cause the boiler to run during warm months.

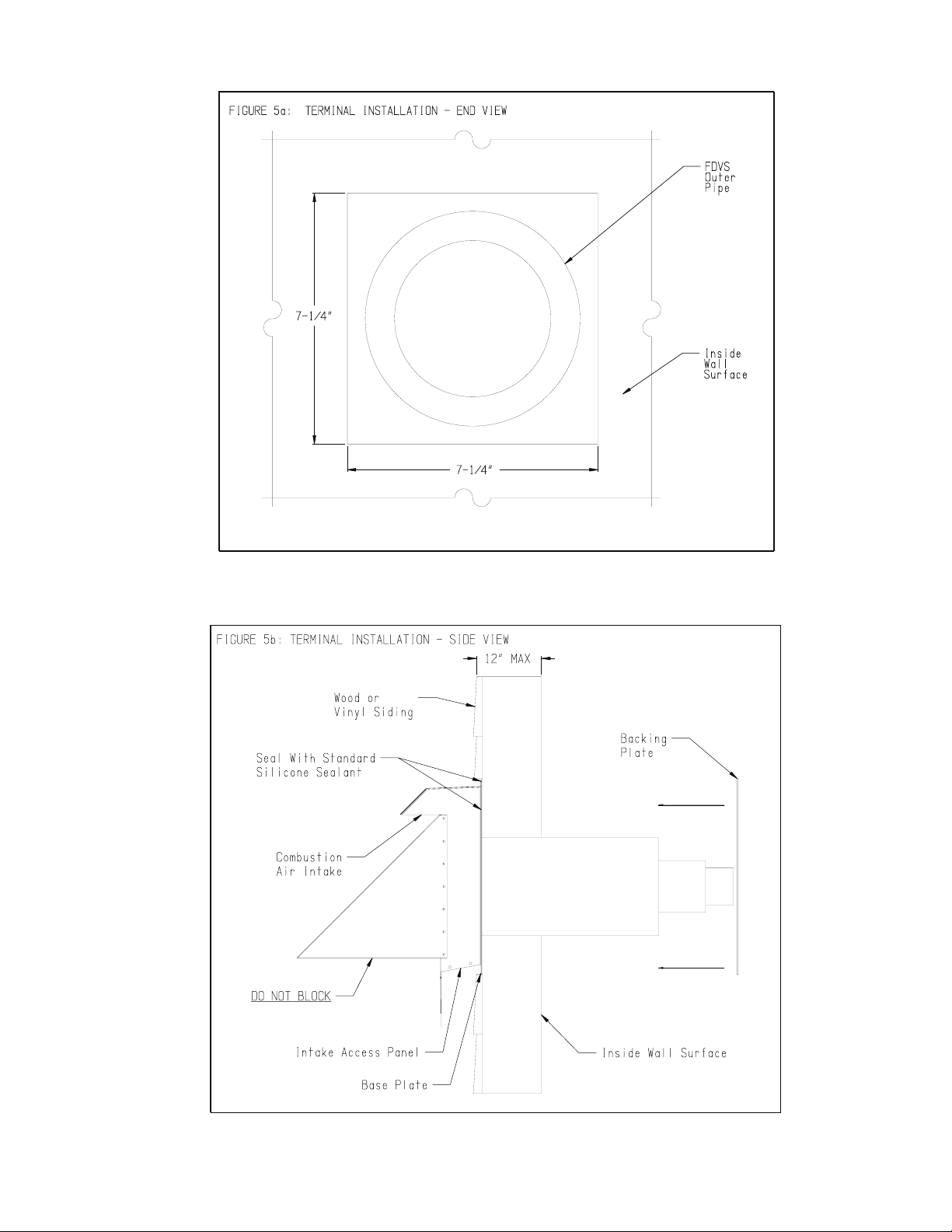

2) INSTALLING THE FDVS-4 VENT TERMINAL

a) Remove vent system components from box and inspect for damage. If the carton has been

crushed or mutilated, check components very carefully for damage. DO NOT install if any

damage is apparent.

b) Remove the combustion air tee assembly from the vent terminal. Set the tee aside for later

use.

c) After determining the location of the vent terminal (Figures 2,3 & 4), cut a 7-1/4” square hole in

the wall. (Figure 5a) Note: Maximum wall thickness: 12”

d) Seal the back side of the base plate around the outer pipe of the vent terminal with a bead

of standard silicone sealant (not supplied). (Figure 5b) Mount the vent terminal through

the wall, keeping the outer pipe centered in the hole. (Figure 5a) Fasten the vent terminal to

the outside wall with appropriate fasteners. Seal the edges of the vent terminal base

plate to the wall with standard silicone sealant.

CAUTION

Failure to apply this bead of silicone properly can cause ue gas to recirculate into

the air inlet resulting in sooting of the boiler, vent system, and side of the strucure.

e) Mount the backing plate over the outer pipe. Fasten the backing plate to the inside wall with

appropriate fasteners. (Figure 5b)

DO NOT BLOCK the intake or exhaust openings, or the intake access panel on the vent terminal body.

Wood or vinyl siding should be cut so that the unit mounts directly on the wallboard to provide a stable

support. If the siding is greater than 1/2” thick use a spacer plate or board behind the vent terminal

mounting plate. (Figure 5b)

f) If the inside terminal section is not supported by the wall through which it passes, install

additional supports or bracing to rigidize the terminal. Bracing in contact with the co-axial

section of the terminal may be combustible.

6

Page 10

7

Page 11

3) INSTALLATION OF THE VENT TERMINAL COMBUSTION AIR TEE (Figure 5c)

a) Assemble the combustion air tee assembly body to the vent terminal outer pipe, and rotate to the

desired position. Attach the tee assembly body to the vent terminal outer pipe with at least 3 sheet

metal screws evenly spaced apart (not included).

b) Perform step 3c only after installing the exible oil vent pipe to the inner pipe on the terminal as

outlined in step 6. (Figure 6)

c) Apply standard silicone sealant (not supplied) to the cover pan around the inner pipe, around the joint

between the collar and the tee assembly, and seal or tape the joint from the FDVS terminal to the tee

assembly.

8

Page 12

NOTE: The tee may be rotated into any position so that the collar is in a convenient orientation.

4) APPLIANCE ADAPTER INSTALLATION

a) Apply a bead of red silicone sealant (supplied) to the boiler vent collar approx. 1” from end of

collar. (Figure 7a)

b) Remove all oil and grease from the inside of the appliance adapter, and apply a bead of red

silicone sealant to inside of adapter ½” from end (Figure 7a).

c) With a twisting motion, assemble the appliance adapter onto the vent collar.

d) Using a block of wood on the end of the adapter, push the adapter onto the vent collar, using care

to avoid damaging the vent collar or the adapter (Figure 7b).

e) Keep the sampling port in the 12 o’clock position and align the prepunched slots in the appliance

adapter to the threaded holes on the vent collar.

f) Secure the appliance adapter to the boiler vent collar with (3) 1/4-20 x 1/2” stainless steel cap

screws inserted into the three tapped holes in the appliance collar and tighten. (Figure 6b).

g) Apply red silicone sealant to the end of the adapter and anchoring screws. (Figure 7b).

h) After testing and burner adjustments have been made, apply red silicone sealant to the supplied

3/8” sampling port plug screw and install the screw in the sampling port (Figure 7b).

i) Maintain clearances to combustibles. If the appliance adapter is within 18” of combustible

material, wrap minimum 1-1/2” ceramic insulation (installer-supplied) around the exposed

portion of the appliance adapter.

5) OPTIONAL REDUCING TEE ADAPTER INSTALLATION

a) An optional reducing tee adapter is available for use in place of the standard appliance

adapter (Figure 8a). This reduces the clearance needed from the back of the boiler.

b) Apply a bead of red silicone sealant (supplied) to appliance collar approx. 1” from end of the

boiler vent collar. (Figure 8a)

c) Remove all oil and grease from the inside of the reducing tee adapter, and apply a bead of red

silicone sealant to inside of adapter ½” from end (Figure 8b).

9

Page 13

d) With a twisting motion, assemble the reducing tee adapter onto the boiler vent collar.

e) Push the adapter onto the vent collar, using care to avoid damaging the appliance collar or the

adapter (Figure 8b).

f) Keep the sampling port in the 12 o’clock position and align the prepunched slots in the

reducing tee adapter to the threaded holes on the vent collar.

g) Secure the reducing tee adapter to the vent collar with (3) 1/4-20 x 1/2” stainless steel cap screws

inserted into the three tapped holes in the vent collar and tighten. (Figure 8b).

h) Apply red silicone sealant to the end of the adapter and anchoring screws. (Figure 8b).

i) After testing and burner adjustments have been made, apply red silicone sealant to the

supplied 3/8” sampling port plug screw and install the screw in the sampling port (Figure 8b).

j) Maintain clearances to combustibles. If the reducing tee adapter is within 18” of combustible

material, wrap minimum 1-1/2” ceramic insulation (installer-supplied) around the exposed

portion of the reducing tee adapter.

10

Page 14

6) VENT PIPE INSTALLATION

CAUTION

• Do not enclose vent pipe in walls or ceilings

• If necessary, the vent pipe may be cut to length with a hacksaw or cut off saw.

Use safety glasses and other appropriate safety gear when cutting.

• Make sure that the vent pipe route is nalized and pipe is accurately

marked before cutting. Pipe cannot be spliced if accidently cut too short.

a) Pull outer vent pipe back 1”-2” from inner vent pipe end and remove insulation (Figure 9a).

b) Slide Cover Sleeve onto end of vent pipe a few inches back from end of outer vent pipe

(Figure 9a).

c) Slide Cover Ring over stop bead on termination inner pipe or appliance adapter (Figure 9a).

d) Assemble inner pipe clamp halves using the supplied ¼” bolts and square nuts, and position

inner pipe clamp ¼” from end of inner pipe (Figure 9a).

e) Remove all oil and grease from end of termination inner pipe or appliance adapter, and apply a

bead of red silicone sealant to between the stop bead and retainer bead (Figure 9b).

f) Apply a thick bead of red silicone sealant to inside of inner vent pipe ½” from the end of pipe,

working the sealant into the corrugations (Figure 9b).

11

Page 15

g) Push the inner vent pipe onto the termination inner pipe or appliance adapter all the way up to

the stop bead.

h) Tighten the inner pipe clamp bolts until both clamp halves are within 1/8” of each other at each

end (Figure 9c).

i) Slide the cover sleeve and cover ring together to engage the ring in the groove of the sleeve, and

tighten the cover sleeve clamp (Figure 9d).

j) To maintain 3” clearance to combustibles, wrap minimum 1-1/2” thick ceramic insulation

(installer-supplied) around the exposed portion of the termination inner pipe (Figure 9d), and

secure with foil tape (installer supplied).

k) Allow sealant to cure for at least one hour before ring boiler.

l) Use the same procedure to install vent pipe on Reducing Tee (Figure 9e).

8) AIR INTAKE PIPE INSTALLATION

a) Attach exible air intake pipe to the terminal and the collar on the burner and secure it with the

hose clamps provided.

12

Page 16

VISystemPiping

CAUTION

• Operation of this boiler with continuous return temperatures below 120f can

cause severe heat exchanger corrosion damage

• Operation of this boiler in an system having signicant amounts of dissolved

oxygen can cause severe heat exchanger corrosion damage

• Do not use toxic additives, such as automotive antifreeze, in a hydronic system

StandardPiping

Figure 17 shows typical boiler system connections on a single zone system. Additional information

on hydronic system design may be found in Installation of Residential Hydronic Systems (Pub. #200)

published by the Hydronics Institute in Berkely Heights NJ. The components in this system and their

purposes are as follows:

1) Relief valve (Required) – The relief valve is factory mounted and must not be moved. The relief

valve shipped with the boiler is set to open at 30 psi. This valve may be replaced with one

having a setting of up to the MAWP shown on the boiler rating plate. If the valve is replaced, the

replacement must have a relief capacity in excess of the DOE heating capacity for the boiler.

Pipe the discharge of the relief valve to a location where water or steam will not create a hazard or cause

property damage if the valve opens. The end of the discharge pipe must terminate in an unthreaded pipe.

If the relief valve discharge is not piped to a drain it must terminate at least 6 inches above the oor. Do

not run relief valve discharge piping through an area that is prone to freezing. The termination of the

relief valve discharge piping must be in an area where it is not likely to become plugged by debris.

DANGER

• PIPE RELIEF VALVE DISCHARGE TO A SAFE LOCATION

• DO NOT INSTALL A VALVE IN THE RELIEF VALVE DISCHARGE LINE

• RELIEF VALVE MUST BE INSTALLED IN BOILER AT LOCATION

SHOWN IN FIGURE 17.

• DO NOT PLUG RELIEF VALVE DISCHARGE

2) Circulator (Required) – Although the circulator is shipped on the boiler return, it can be installed on

the boiler supply. If the circulator is moved to the supply it should be positioned just downstream of

the expansion tank as shown in Figure 17.

3) Expansion Tank (Required) – If this boiler is replacing an existing boiler with no other changes in

the system, the old expansion tank can generally be reused. If the expansion tank must be replaced,

consult the expansion tank manufacturer’s literature for proper sizing.

13

Page 17

4) Fill Valve (Required) – Either a manual or automatic ll valve may be used. The ideal location

for the ll is at the expansion tank.

5) Automatic Air Vent (Required) – At least one automatic air vent is required. Manual vents will

usually be required in other parts of the system to remove air during initial ll.

6) Low Water Cut-Off (Required in some situations) – A low water cut-off is required when the

boiler is installed above radiation. In addition, some codes such as ASME CSD-1 require

low water cut-offs. Codes may also require that this low water cut-off have a manual reset

function. The low water cut-off may be a oat type or probe type but must be designed for use

in a hot-water system. The low water cut-off should be piped into the boiler supply just above the

boiler with no intervening valve between it and the boiler.

Use a low water cut-off that breaks the line voltage electrical supply to the boiler.

7) Manual Reset High Limit (Required by some codes) – This control is required by ASME CSD-1

and some other codes. Install the high limit in the boiler supply piping just beyond the boiler

with no intervening valves. Set manual reset high limit as far above the operating limit setting

as possible, but not over 240F. Wire the control to break the line voltage electrical supply to the

boiler.

8) Flow control valve (Required under some conditions) – The ow control valve prevents ow

through the system unless the circulator is operating. A ow control valve may be necessary

on converted gravity systems to prevent gravity circulation. Flow control valves are also used to

prevent “ghost ows” in circulator zone systems through zones that are not calling for heat.

9) Isolation Valves (Optional) – Isolation valves are useful if the boiler must be drained, as they will

eliminate having to drain and rell the entire system.

14

Page 18

PipingforSpecialSituations

Certain types of heating systems have additional requirements. Some of the more common variations

follow:

1) Indirect Water Heaters – Figure 18 shows typical indirect water heater piping. Boiler piping is

the same as for any two-zone system. Figure 18 shows circulator zoning, which is usually

preferred for indirect water heaters. Size the circulator and indirect water heater piping to obtain

the boiler water ow through the indirect water heater called for by the indirect water heater

manufacturer.

2) Gravity and “Large Water Volume” Systems – The piping shown in Figure 19 will minimize the

amount of time that the boiler operates with return temperatures below 120F on these systems.

A bypass is installed as shown to divert some supply water directly into the return water. The

bypass pipe should be the same size as the supply. The two throttling valves shown are

adjusted so that the return temperature rises above 120F during the rst few minutes of opera-

tion. A three-way valve can be substituted for the two throttling valves shown. If the circulator is

mounted on the supply, the bypass must be on the discharge side of the circulator.

3) Low Temperature Systems – Some systems, such as radiant tubing systems, require the system

water temperature to be limited to a value below the temperature of the water leaving the ODV.

These systems also typically have return temperatures well below the 120F minimum.

Figure 20 illustrates the use of a heat exchanger to connect an ODV boiler to this type of system.

The heat exchanger will permit the transfer of heat from the boiler water to the low temperature

system while holding the system supply and boiler return temperatures within their limits.

For this system to work properly the heat exchanger must be properly sized and the correct ow

rates are required on either side of the heat exchanger. Consult the heat exchanger manufacturer

for sizing information. The water in the boiler is completely isolated from the water in the

system. This means that separate ll and expansion tanks are required for the heating system

loop.

There are several other ways to connect low temperature systems to the non-condensing boilers like

the ODV such as four way mixing valve and variable speed injection pumping systems.

15

Page 19

4) Systems containing oxygen – Many hydronic systems contain enough dissolved oxygen to cause

severe corrosion damage to a cast iron boiler such as the ODV. Some examples include:

• Radiant systems that employ tubing without an oxygen barrier.

• Systems with routine additions of fresh water

• Systems which are open to the atmosphere

If the boiler is to be used in such a system, it must be separated from the oxygenated water being

heated with a heat exchanger as shown in Figure 20. Consult the heat exchanger manufacturer

for proper heat exchanger sizing as well as ow and temperature requirements. All components

on the oxygenated side of the heat exchanger, such as the pump and expansion tank, must be

designed for use in oxygenated water.

16

Page 20

VIIFuelPiping

IMPORTANT

• Installation of oil storage tanks, ll pipes, and oil lines must conform to local code

requirements. In the absence of any codes, installation must be in conformance

with ANSI/NFPA-31.

• Use of this boiler with an unenclosed above ground outdoor oil tank is not

recommended.

Two basic piping systems are used to connect the boiler to the oil supply:

1) One-Pipe – Recommended where the fuel pump is below the lowest possible level of the oil in

the tank. Basic piping is shown in Figure 21a.

2) Two-Pipe – Recommended where the fuel pump is above the lowest possible level of the oil in

the tank. This system is self-priming. Basic piping is shown in Figure 21b.

Consult the instructions supplied with the pump for limitations on lift, horizontal run, and required line

sizes. Pumps supplied with the ODV boiler generally require the installation of a bypass plug when

converted for use in a two-pipe system. See the pump instructions for specic information. Also note the

following:

1) If the boiler is being installed as a replacement, the existing oil system may be two-pipe even

though the pump is below the lowest level in the oil tank. Such systems should be converted

to one-pipe systems as doing so will result in warmer oil temperatures, lower vacuums, and

longer lter life.

17

Page 21

2) Do not use compression ttings in oil piping.

3) Do not use Teon tape in oil piping

4) Do not manifold multiple oil appliances on a two-pipe system. Run dedicated lines for each

appliance back to the tank or use a transfer pump and day tank to get oil to a location where it

can be gravity fed to each appliance.

5) Do not use check valves in gravity feed systems.

6) Where a new oil tank is to be installed, and where codes permit, the best location for the tank is

in a warm space (such as basement) where a one-pipe gravity system can be used. Such a

location will eliminate problems caused by air-inltration and cold oil.

7) Use only #2 fuel oil with physical and chemical characteristics meeting the requirements in

ASTM D-396.

CAUTION

Fuel oil will attack silicone pressure switch tubing. If at all possible, route oil lines

under air inlet collar.

VIII WIRING

WARNING

All wiring and grounding must be done in accordance with the authority having jurisdiction or, in the absence of such requirements, with the National Electrical Code

(ANSI/NFPA 70).

Figure 22 is a connections diagram for the ODV boiler. The following connections must be made in

the eld:

L1 – Line voltage “hot”

L2 – Line voltage “neutral

C1 – Circulator “hot”

C2 – Circulator “neutral”

T, T – 24 volt thermostat connections.

Green Screw in L7248A – Ground connection

This boiler must be wired to a dedicated circuit having a 15-amp fuse or circuit breaker. The minimum

size wire that should be used in this circuit is 14 AWG.

If this boiler is to be used in a multiple zone installation, T, T are generally connected to either zone

valve end switches or a set of dry relay contacts which will start the boiler when any one zone calls for

heat. A separate transformer must be used to power zone valves. If this boiler is to be used in a circulator

zone system, terminals C1 and C2 cannot be used as they will be energized regardless of which zone is

calling for heat.

18

Page 22

IXStart-upandCheckout

WARNING

• If antifreeze is used in the system, it must be a nontoxic type such as propylene

glycol.

• Never attempt to ll a hot empty boiler

• Make sure that the area around the boiler is clear and free from combustible

materials, gasoline, and other ammable vapors and liquids.

CAUTION

• Safe reliable operation of this boiler requires that the burner be checked and

adjusted by a qualied oil serviceman using combustion test instruments

• Do not drill a hole in the vent system to take combustion gas samples. Take

combustion gas samples through the bolthole on the top of the 7 x 4 adapter.

Use the following procedure for initial start-up of the boiler:

1) Make sure that the boiler and system are lled with water.

2) Check all system and fuel piping for leaks. Repair any leaks found immediately.

3) Vent system must be complete and free of obstructions before attempting to re boiler. Do not

re boiler until all vent sealant has had at least one hour to cure.

4) Inspect all line voltage wiring for loose or un-insulated connections.

5) If the boiler is connected to a one-pipe system, purge the suction line in accordance with the

instructions supplied with the pump.

1919

Page 23

6) Start the boiler. Immediately take a smoke. If any smoke is present, open the air adjustment to

obtain a zero smoke.

NOTE

The ODV boiler is equipped with a ceramic combustion chamber. On initial start-up,

the binder on this chamber will burn out, possibly resulting in a yellow spot on smoke

paper. This binder should burn out in approximately 30 minutes of operation and

should not reappear. Successive smoke readings taken over this 30-minute “burn-out”

period should result in decreasing amounts of yellow on each smoke spot.

7) Allow boiler to warm up for about 15 minutes or until the binder has completely burned out of

the combustion chamber. Adjust the air to obtain a CO2 between 11.0% and 12.5% with a zero

smoke. If a zero smoke cannot be obtained in this range of CO2s, see “Service Notes” on

page 18.

8) Cycle the boiler several times to make sure that the light-offs are smooth and reliable.

9) Allow the boiler to re until the water temperature reaches the high limit setting. Conrm that

the high limit shuts down the burner.

10) Conrm that the thermostat/s cycle the burner and the appropriate circulator/s and/or zone

valves.

11) Recheck the piping for leaks. Repair any leaks found at once.

12) Inspect the vent system for ue gas leaks. Repair any leaks found before leaving the boiler in

operation.

X Service Notes

1) The pressure switch on the ODV is designed to protect the boiler against blockages in the vent

or intake piping. The electrical contacts on this switch are connected to “T-T” on the burner’s

primary control and are normally closed. This pressure switch is equipped with an orice on the

negative pressure side of so that the blockage must be present for several seconds before the

switch shuts down the burner.

In the event that a blockage appears in either side of the vent/ intake piping, the pressure switch

will open the burner after a delay of 10 –60seconds. The burner will go into post purge and

then shut down. After a delay of approximately 4 seconds it will go into pre-purge. If the block-

age is still present, the burner will cycle in and out of pre-purge at intervals of approximately 20

seconds until the blockage is removed or power to the burner is interrupted.

Each size ODV boiler has a different pressure switch setting:

Model Switch Contacts Open on Pressure Rise

ODV-75 0.23 +/- 0.025” w.c.

ODV-100 0.305 +/- 0.025” w.c.

ODV-125 0.45 +/- 0.025 “ w.c.

Route the 1/8 silicone tubing shipped wrapped over the intake collar along the left side of the

jacket to the hose barb on the 7 x 4 adapter. Use the cable clamps provided to attach this hose to

the left side jacket panel. Figure 23 shows the pressure switch tubing connections.

20

Page 24

2) If a zero smoke cannot be obtained at a CO2 between 11.0 and 12.5%, check the following:

ODV-75 ODV-100 ODV-125

CARLIN BURNER

EZ1-HPV EZ1-HPV EZ1-HPV

CARLIN PRIMARY CONTROL #

6020002 6020002 6020002

PRE/POST PURGE TIMING (s)

30/120 30/120 30/120

INSERTION LENGTH

2 1/4 2 1/4 2 1/4

PITCH ANGLE (degrees)

2 2 2

NOZZLE

DELAVAN DELAVAN DELAVAN

0.65/70W 0.85/60A 1.00/60A

PUMP PRESS (psi)

150 150 150

HEAD BAR

0.75 0.85 - 1.00 1.10 - 1.25

STARTING SHUTTER SETTING

0.75 1.00 1.25

MAX. SMOKE (Bacharach scale)

TRACE TRACE TRACE

CO2:

MIN.

11.0 11.0 11.0

MAX.

12.5 12.5 12.5

TABLE 2

ODV BURNER APPLICATIONS

a) Check nozzle and settings against those shown in Table 2 below. Nozzle must be identical

to that called for in Table 2 including manufacturer. Check the burner manufacturer’s manual

for dimensional settings not shown in this manual (e.g. electrode settings, nozzle to spinner

dimensions, etc).

b) Check oil lines for air inltration.

c) Inspect burner air handling components (burner head, spinner etc.) for visible damage or

distortion.

d) Check that oil characteristics are in conformance with ASTM D 396.

e) Check for oil leaks in the nozzle line and pump seal.

f) Nozzle may be defective or partially plugged – replace with an identical nozzle.

g) Check the vacuum at the inlet to the fuel pump to be certain that it is not in excess of the

pump manufacturer’s specications.

21

Page 25

XIMaintenance

Steps 1 – 10 below should be performed on an annual basis to assure reliable operation of the ODV

boiler. If the boiler is used to power an indirect water heater, such as a Mega-Stor, it is advisable to

check the CO2 and smoke level approximately half way between annual cleanings.

1) Shut off power to the boiler

2) Open the swing door and remove the bafes

3) Thoroughly clean the boiler. If necessary, also clean the vent system.

NOTE

Clean the boiler even if there is not a signicant amount of soot. Sulfur and ash

deposits left in the boiler can cause severe long-term corrosion damage.

4) Inspect the pressure switch tubing for cracks, blockages, and swelling. Run a pipe cleaner into

the hose barbs on both the inlet collar and the 7 x 4 adapter to make sure that they are open.

5) Inspect the chamber and door refractory for deterioration. It is normal for hairline cracks to

appear in both of these parts after a short time in service. These parts should be replaced if

sections of them are loose or missing.

6) Replace the nozzle with one identical in brand and pattern to that shown in Table 2.

7) Replace the oil lter.

8) Reassemble the boiler.

9) Adjust the burner to obtain a CO2 of between 11.0% and 12.5% as called for in Table 2 . It

should be possible to obtain a CO2 in this range with a zero smoke.

10) Inspect the vent system for signs of leakage. Seal any leaks found with Boss Hi-Temp red

silicone #326 or equivalent.

22

Page 26

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Parts list designates parts that contain refractory ceramic fibers (RCF).

RFC has been classified as a possible human carcinogen. When exposed to

temperatures about 1805°F, such as during direct flame contact, RFC changes

into crystalline silica, a known carcinogen. When disturbed as a result of

servicing or repair, these substances become airborne and, if inhaled, may be

hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

23

Page 27

1 Sight Glass Retaining Clip 110007

2 Sight Glass Retaining Ring 110008

3 Sight Glass Gasket 110009

4 Sight Glass 110010

5 Door Refractory Retaining Screw (1/4-14 x 7/8" w/ Washer) 110050

6 Door Refractory Retaining Clip 110055

7 Setscrew 10MT x 50mm 90-027

8 Setscrew 10MT x 16mm 90-022

9 Hinge Bracket for Burner Plate 110023

10 CT-3 Tie Rod 11-015

10 CT-4 Tie Rod 11-001

10 CT-5 Tie Rod 11-004

10 CT-6 Tie Rod 11-034

10 CT-7 Tie Rod 11-007

10 CT-8 Tie Rod 11-008

11 Washer 12MT 900021

12 Nut 12MT 90-026

13 Stud 10MT x 40mm 90-023

14 Washer 10MT 90-024

15 Nut 10MT 90-025

16 Front Burner Plate 110017

17 Door Refractory 12-055

18 Front Section 11-016

19 Intermediate Section 11-014

20 Rear Section 11-012

21 Flue Collector 11-0065

22 Fiberglass Rope 8mm dia. 11-005

23 Fiberglass Rope 8mm dia. 11-011

24 Fiberglass Rope 8mm dia. 11-011

25 Pipe Plug - 1-1/4"BSP thread 95-024

26 Push Nipple 11-013

27 Second Pass Flue Baffles (4 used) CT-3 only 11-025

28 Third Pass Flue Baffles (2 used) CT-3 through 7 11-024

SECTION XII: REPLACEMENT PARTS

PART NUMBER

PARTS LIST - BOILER (See Figure 24)

KEY # DESCRIPTION

24

Page 28

Figure 24: Boiler Parts

25

Page 29

ODV-75, ODV 100

ODV-125

1 RIGHT SIDE JACKET PANEL 1 ea. 110300 110400

2 LEFT SIDE JACKET PANEL 1 ea. 110310 110410

3 REAR JACKET PANEL 110210 1 ea. 1 ea.

4 FLUE COLLECTOR COVER 110215 1 ea. 1 ea.

5 TOP PANEL 1 ea. 110320 110420

7 REAR JACKET MOUNTING BRACKET 700110 2 ea. 2 ea.

8 M12 WASHER 90-033 2 ea. 2 ea.

9 M12 NUT 90-026 2 ea. 2 ea.

10 1/4-20 NUT 90-202 4 ea. 4 ea.

11 1/4-20 x 3/4 SCREW 90-213 4 ea. 4 ea.

12 #10 x 1/2 SHEET METAL SCREW 90-212 18 ea. 18 ea.

* INSULATION MATT 1 ea. 110153 110154

18 DOOR BRACKET 60-303 2 ea. 2 ea.

19 8-32 X 1/2 SCREW 90-052 4 ea. 4 ea.

20 8-32 HEX NUT 90-053 4 ea. 4 ea.

21 10-24 X 3/4 SCREW 90-218 5 ea. 5 ea.

23 FRONT JACKET MOUNTING BRACKET 110110 1 ea. 1 ea.

24 FRONT JACKET PANEL 110200 1 ea. 1 ea.

25 DOOR KNOB 90-210 2 ea. 2 ea.

26 8-32 x 1/4 SCREW 90-211 2 ea. 2 ea.

27 M10 x 16mm SCREW 90-022 2 ea. 2 ea.

*

COMBUSTION CHAMBE

R

†

1 ea. 12-060 12-062

KEY #

* NOT PICTURED

QUANTITY PER BOILER OR CROWN

P.N.

QTY. OR

CROWN P.N.

DESCRIPTION

† SEE PAGE 23 FOR WARNING REGARDING THE HANDLING OF PARTS THAT CONTAIN REFRACTORY CERAMIC FIBERS.

26

Page 30

KEY # ITEM # DESCRIPTION QTY

Consisting of: ODV-75 ODV-100 ODV-125

N/P

13-151 CARLIN BURNER ASSY. ODV- 75 1

*

N/P 13-152 CARLIN BURNER ASSY. ODV- 100 1

*

N/P 13-153 CARLIN BURNER ASSY. ODV- 125 1

*

N/P 13-150 CARLIN EZ-1 MODIFIED BURNER 1

***

N/P 13-167 DELAVAN 0.65/70W NOZZLE 1

*

N/P 13-114 DELAVAN 0.85.60A NOZZLE 1

*

N/P 13-136 DELAVAN 1.00/60A NOZZLE 1

*

N/P 12-120 AIR INLET COLLAR 1

***

N/P 90-222 10-32 x 1/8 I.D. HOSE BARB 1

***

N/P 90-219 10-32 S.S. HEX NUT (FOR HOSE BARB) 1

***

N/P 12-085 ODV PRESSURE SW ITCH BRACKET 1

***

N/P 12-070 ODV PRESSURE SW ITCH 1

*

N/P 12-075 ODV PRESSURE SW ITCH 1

*

N/P 12-080 ODV PRESSURE SW ITCH 1

*

N/P 96-1020 PRESSURE SWITCH HARNESS 1

***

N/P 14-008 .125 I.D. SILICONE TUBING (INLET SIDE) 1.2 ft

***

N/P 14-008 .125 I.D. SILICONE TUBING (EXHAUST SIDE) 5.84 ft

***

ODV SERIES

BUNRNER ASSEM BLY

N/P = Not Pictured

ODV-75 ODV-100 ODV-125

1 12-000A FDVS-47 Terminal Kit 1 * * *

2 12-030A X FDVS-47 Terminal 1 * * *

3 12-033A X Combustion Air Tee (w/ Cover Pan N/P) 1 * * *

4 12-020A X 4" Nominal Dia. Flexible Air Intake Pipe 20 ft * * *

5 12-036A X Cover Ring 2 * * *

6 12-037A X Inner Pipe Clamp 4 * * *

7 12-005A X Cover Sleeves 2 * * *

8 12-001A X Appliance Adapter 1 * * *

N/P 12-032A X Backing Plate 1 * * *

N/P 12-035 X 4" Nominal Dia. Hose Clamp 2 * * *

N/P 900850A X 3/8-16 x 1/2" SS Slotted Hex Screw 1 * * *

N/P X 1/4-20 x1" Hex Bolt 4 * * *

N/P X 1/4-20 Square Machine Nut 4 * * *

N/P X 1/4-20 x 1/2" SS Cap Screw 3 * * *

N/P X 1/4" x 2" Lag Screw 4 * * *

N/P X 1/4" Flat Washer 7 * * *

N/P X Cable Clamp 2 * * *

N/P 12-050 X Tube Hi-Temp Silicone 2 * * *

9 12-015A Individually Boxed FOVP-415 Flexible Insulated Oil Vent Pipe 15 ft * * *

10 120100 Individually Boxed RT-74 Reducing Tee 1 optional optional optional

12-010

Procure Locally

QTY

ODV SERIES

VENTING ASSEMBLY

KEY # ITEM # Consisting of: DESCRIPTION

27

Page 31

NOTES

28

Page 32

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

PN: 98-100

10/10 Rev.4

Loading...

Loading...