Crown Boiler MWC116ENL, MWC, MWC116ELL, MWC116ELT, MWC116ENT User Manual

D E S I G N E D T O L E A D

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

Models:

: Improper installation, adjustment, alteration,

MWC116ENT

MWC116ELT

MWC116ENL

MWC116ELL

service or maintenance can cause property damage, injury,

or loss of life. For assistance or additional information, con-

sult a qualied installer, service agency or the gas supplier.

This boiler requires a special venting system. Read these

instructions carefully before installing.

Table of Contents

I. Product Description 2

II. Specifi cations 4

III. Before Installing 5

IV. Locating The Boiler 5

V. Mounting The Boiler 7

VI. Air For Ventilation 10

VII. Venting 12

A. Vent System Design 12

B. Removing An Existing Boiler From Common Chimney 19

C. Assembly of Crown 60/100 Concentric Venting 20

D. Assembly of Crown 80/125 Concentric Venting 24

E. Condensate Trap and Drain Line 33

VIII. Gas Piping 34

IX. System Piping 36

X. Domestic Water Piping 43

XI. Wiring 46

XII. Start-up and Checkout 51

XIII. Operation 58

XIV. Service and Maintenance 62

XV. Troubleshooting 66

XVI. Parts 69

Appendix A Special Requirements For Side-Wall 84

Vented Appliances In The Commonwealth

of Massachusetts

1

I Product Description

The MWC Series are gas fi red condensing boilers designed for use in forced hot water heating systems

requiring supply water temperatures of 176F or less and return water temperatures greater than 86F. The

primary heat exchanger is a copper water tube design. Additional heat is extracted from the fl ue gas in a

stainless steel secondary heat exchanger located down stream of the inducer. These boilers include a built in

circulator, expansion tank, and automatic air vent. In addition, “combi” models include a plate exchanger for

domestic hot water (DHW) generation. All MWC Series boilers are designed for installation on a wall and may

be vented vertically or horizontally with combustion air supplied from outdoors.

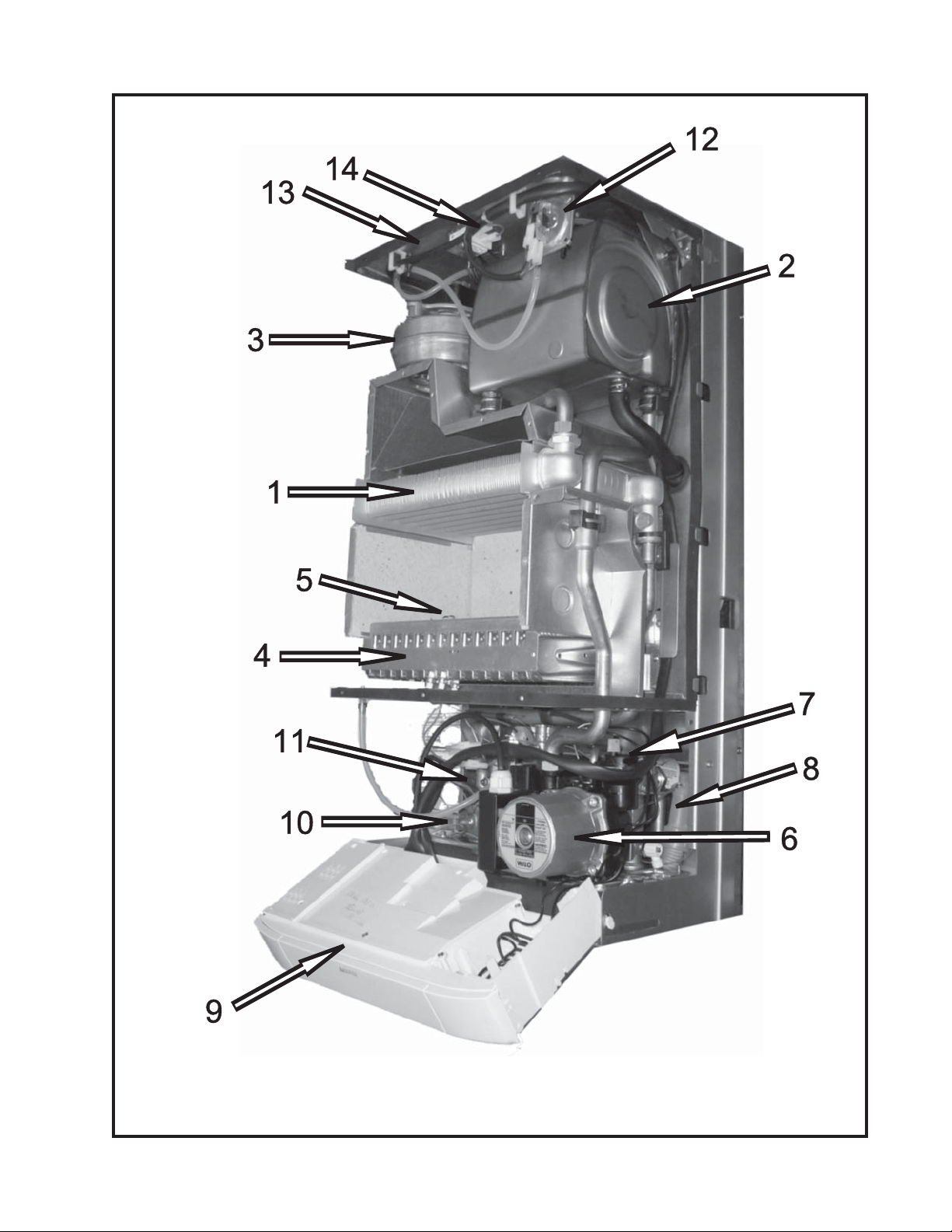

Key Component

1 Primary Heat Exchanger

2 Secondary Heat Exchanger

3 Inducer

4 Burner

5 Electrodes and Flame Rod

6 Circulator

7 Automatic Air Vent

8 Condensate Trap

9 Control Box

10 Differential Boiler Water Pressure Switch

11 Ignition module/Gas Valve

12 Air Pressure Switch

13 Flue Gas Temperature Limit

14 Supply Temperature Limit

* Expansion Tank

* Plate Heat Exchanger (Combi Only)

* 3-Way Diverting Valve (Combi Only)

* Supply Temperature Sensor

* DHW Temperature Sensor (Combi Only)

* DHW Flow Switch (Combi Only)

* Not visible

2

Figure 1.1: MWC Boiler Principle Components

3

II Specifi cations

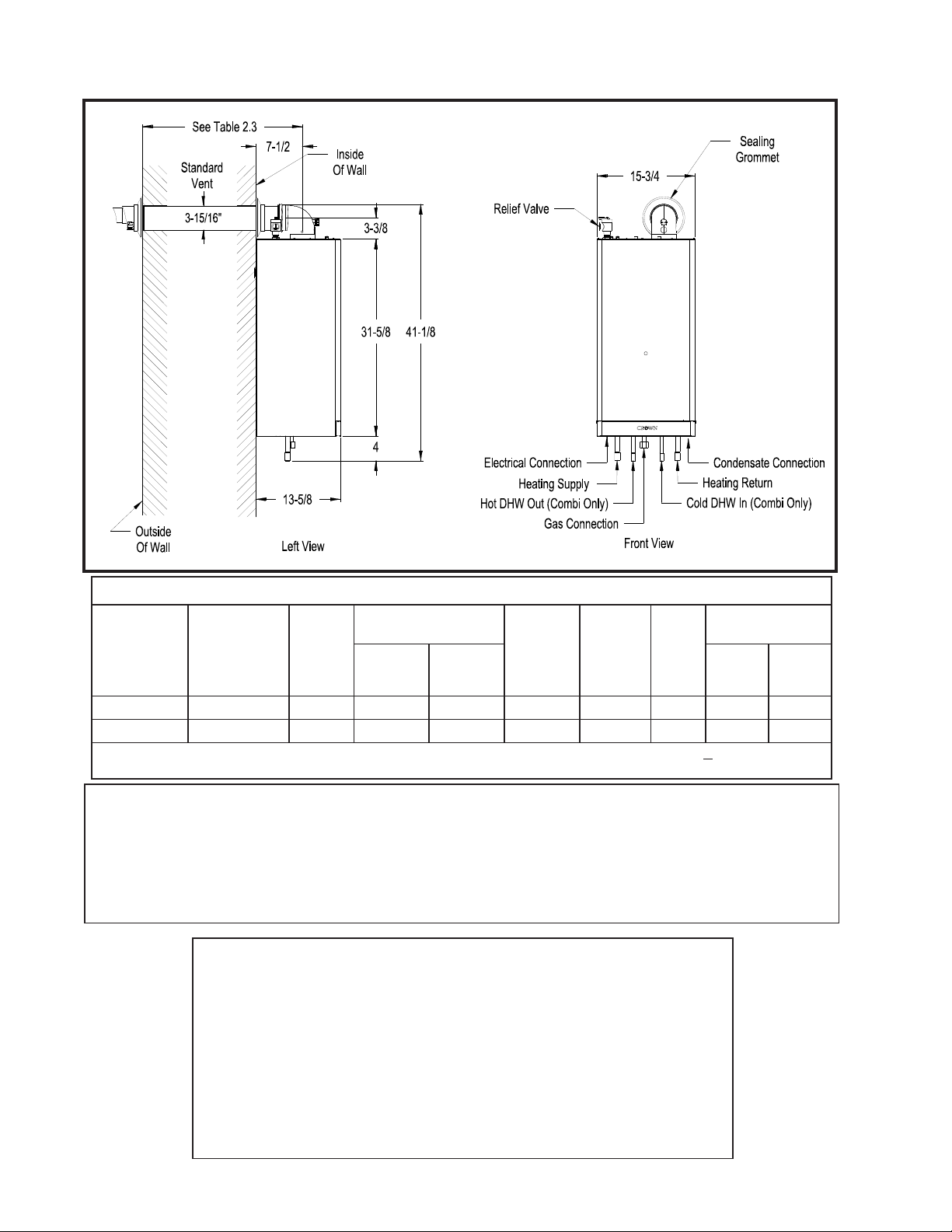

Figure 2.1: General Confi guration

Table 2.2: Ratings

MINIMUM INPUT (BTU/

MAX.

MODEL* APPLICATION

MWC116E*T Combi 116,000 75,000 49,500 102,000 89,000 85.0 2.67 2.25

MWC116E*L Heat Only 116,000 75,000 N/A 102,000 89,000 85.0 N/A N/A

* Insert suffi x “N” for natural gas and “L” for propane. Ratings are the same for both fuels (Example: MWC116ENT denotes Natural

Gas, Combi).

INPUT

(BTU/hr)

HEATING DHW 77F Rise 90F Rise

hr)

D.O.E.

HEATING

CAPY.

(BTU/hr)

IBR NET

RATING

(BTU/hr)

AFUE

DHW Output (GPM)

(%)

Table 2.3: Maximum Vent Lengths

Using 60/100mm Concentric Vent System Supplied with the Boiler ................................................................25 in.

Using Optional 60/100mm Concentric Vent Components ...............................................................................8ft -10in

Using Optional 80/125mm Concentric Vent Components ................................................................................27 ft

See Vent Section for additional venting options and requirements

Table 2.4: Other Specifi cations

Maximum Supply Temperature .............................................176 F

Minimum Continuos Return Temperature .............................86F

Maximum Allowable Working Pressure ................................30 psi

Minimum System Pressure (at boiler ...................................4.4 psi

Maximum Achievable Flow Through Boiler .........................5.5 GPM

Minimum Temperature Rise Across Boiler at High Fire ........37 F

Maximum Gas Inlet pressure ...............................................10.5” Nat / 13.0” LP

Minimum Gas Inlet Pressure ................................................5.3” Nat / 10.5” LP

Electrical Ratings ..................................................................120VAC/60Hz/1.8A

Thermostat Voltage ..............................................................120VAC

4

III Before Installing

Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in 1)

strict accordance with this manual and the authority having jurisdiction.

In the absence of an authority having jurisdiction, installation must be in accordance with this manual •

and the National Fuel Gas Code, ANSI Z223.1.

Natural Gas and Propane Installation Code.

Where required by the authority having jurisdiction, this installation must conform to the • Standard for

Controls and Safety Devices for Automatically Fired Boilers (ANSI/ASME CSD-1).

Read Section VII to verify that the maximum combustion air and exhaust pipe lengths will not be 2)

exceeded in the planned installation. Also verify that the vent terminal can be located in accordance with

Section VII.

Make sure that the boiler is correctly sized:3)

For heating systems employing convection radiation (baseboard or radiators), use an industry a)

accepted sizing method such as the I=B=R Heat Loss Calculation Guide (Pub. #H21 or #H22)

published by the Hydronics Institute in Berkeley Heights, NJ.

In sizing the boiler take into consideration the following boiler water fl ow/temperature limitations:b)

Maximum regulated supply temperature is 176F•

Maximum fl ow through the boiler is approximately 5.5GPM. •

Minimum boiler temperature rise is approximately 37F at high fi re. •

For new radiant heating systems, refer to the radiant tubing manufacturer’s boiler sizing guidelines. c)

For combi boilers make sure that the domestic hot water fl ow rate shown in Table 2.2, will be d)

adequate to meet the peak demand for domestic hot water.

/NFPA 54 and/or CAN/CSA B 149.1

Make sure that the boiler received is confi gured for the correct gas (natural or LP).5)

Make sure that the boiler is confi gured for use at the altitude at which it is to be installed. 6)

NOTICE

This product must be installed by a licensed plumber or gas fi tter when installed within the

Commonwealth of Massachusetts. See Appendix A for additional important information about

installing this product within the Commonwealth of Massachusetts.

IV Locating the Boiler

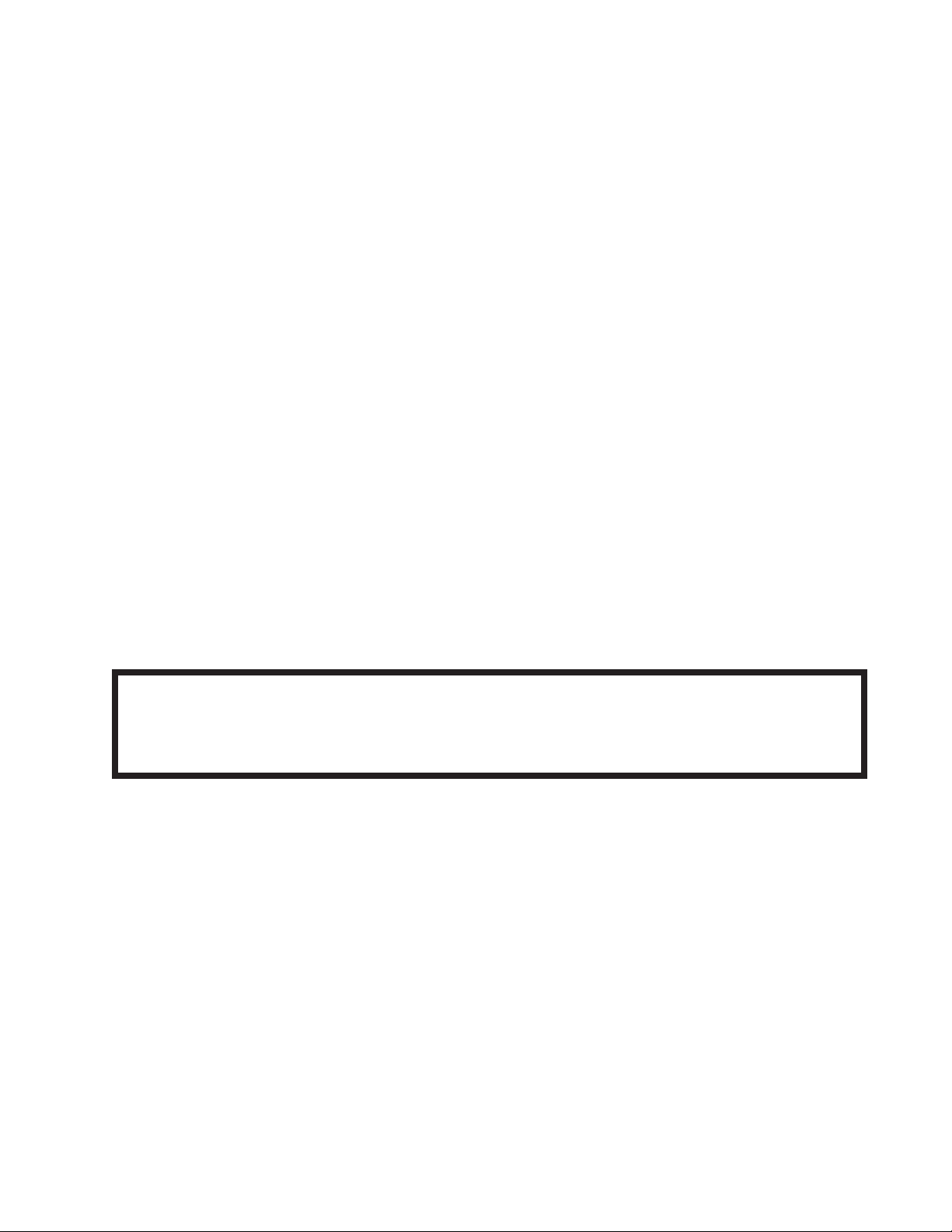

Observe the minimum clearances shown in Figure 4.1. These clearances apply to both combustible and 1)

non-combustible materials.

Note the recommended service clearances in Figure 4.1. These service clearances are recommended, 2)

but may reduced to the combustible clearances provided:

Access to the front of the boiler is provided through a door•

Access is provided to the condensate trap located underneath the boiler.•

The relief valve must be installed in the factory specifi ed location.3)

The boiler should be located so as to minimize the length of the vent system.4)

The boiler must not be installed on carpeting.5)

The combustion air piping must terminate where outdoor air is available for combustion and away from 6)

areas that will contaminate combustion air. Avoid areas near chemical products containing chlorine,

chloride based salts, chloro/fl uorocarbons, paint removers, cleaning solvents and detergents.

5

Clearance From

Hot Water Pipes To

Combustibles = 1”

Figure 4.1: Clearances To Combustible Or Non-combustible Material

6

V Mounting The Boiler

CAUTION

This boiler weighs approximately 110 pounds:

Two people are required to safely lift this boiler onto the wall mounting hook.•

Make sure that wall mounting hook is anchored to a structure capable of supporting the •

weight of the boiler and attached piping when fi lled with water.

Jurisdictions in areas subject to earthquakes may have special requirements for supporting

this boiler. These local requirements take precedence over the requirements shown below.

Mounting Steps:

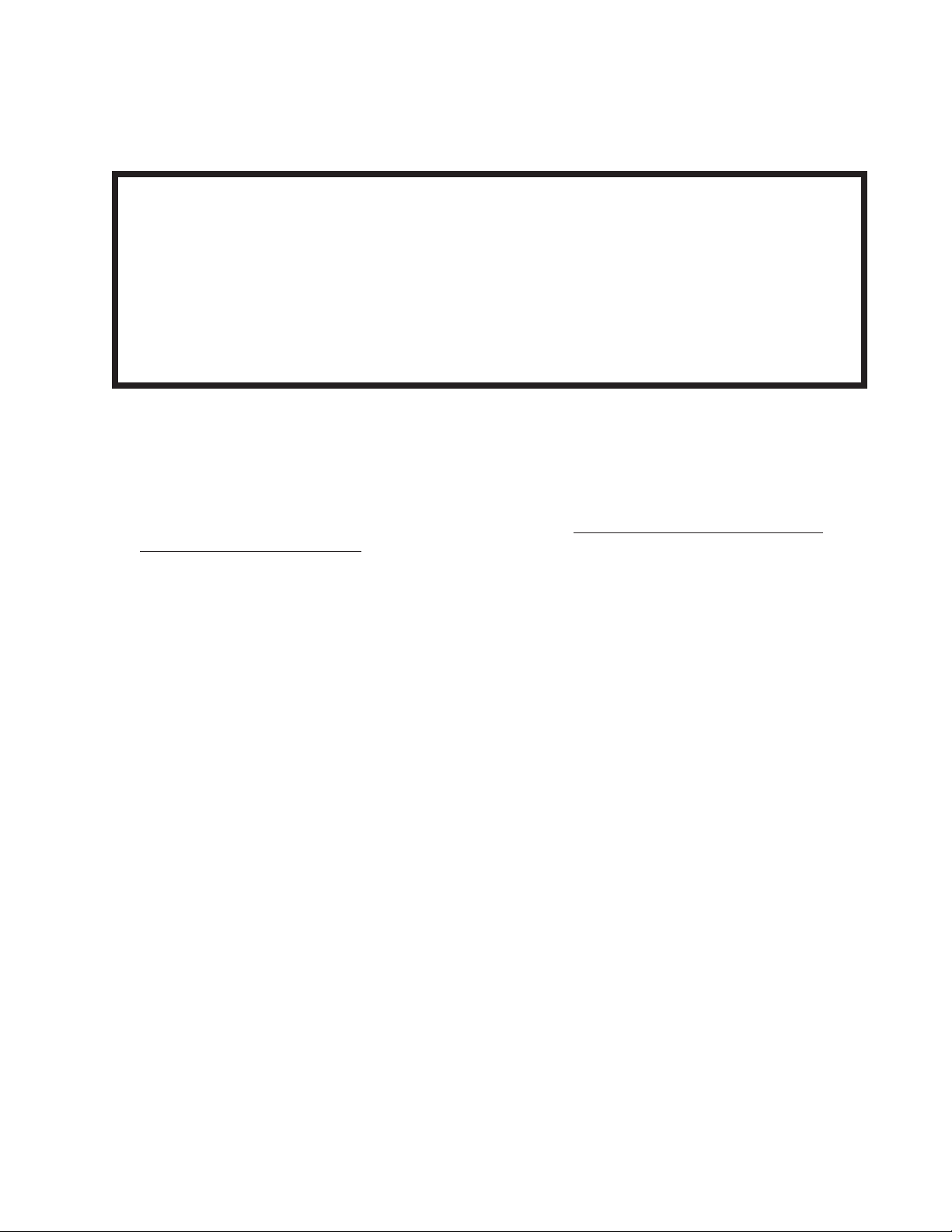

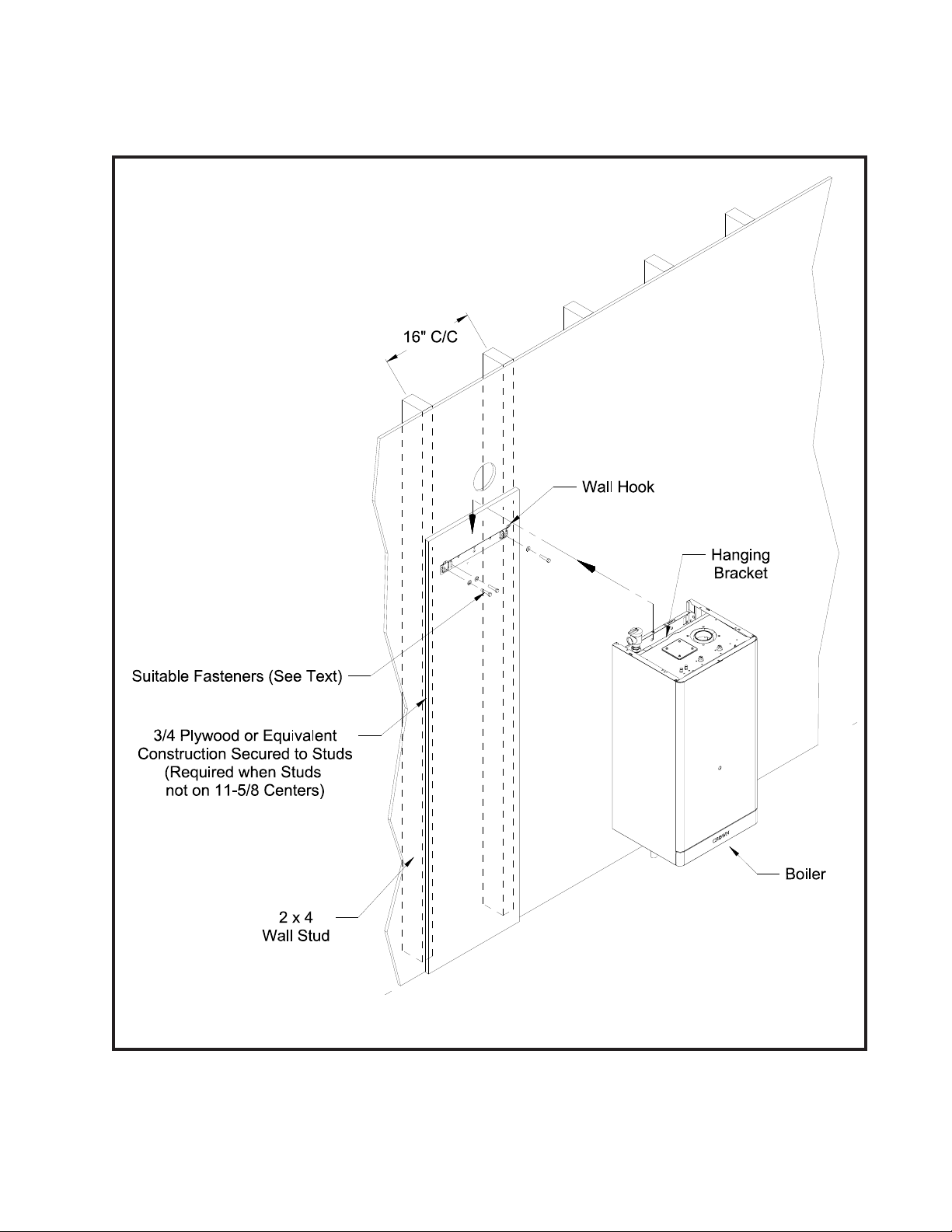

If the boiler is installed on a framed wall, minimum acceptable framing are 2 x 4 studs. The boiler 1)

mounting holes are on 11-5/8” centers. Usually the wall studs will be on 16” centers. In such cases, both

boiler bracket mounting holes must be anchored to ¾” Plywood, horizontal 2 x 4s anchored to the studs,

or some other framing system capable of supporting the boiler. Attachment of either bracket hole to

wallboard alone is unacceptable.

When mounting this boiler directly onto studs covered with 1/2” wall board, 5/16 x 2” lag screws are 2)

recommended. When the boiler is attached to other types of construction, such as masonry, use fasteners

capable of supporting the weight of the boiler and attached piping in accordance with good construction

practice and applicable local codes.

Make sure that the surface to which the boiler is mounted is plumb.3)

Before mounting the boiler, make sure that wall selected does not have any framing or other construction 4)

that will interfere with the vent pipe penetration.

Tape the paper template to the wall in the chosen location. Be sure to level the template.5)

Pre-drill two holes in the center of the “oval” slots on the mounting bracket sized for the hardware being 6)

used.

Mount the bracket to the wall. Be sure to level the bracket by adjusting the screw in the vertical slot.7)

Pre-drill the remaining hole in the mounting bracket and secure the fi nal screw.8)

Cut the opening in the wall for the vent system. The recommended hole diameter for the standard 9)

60/100mm venting is 4-3/8”.

Hang the boiler on the wall bracket as shown in Figure 5.2.10)

Verify that the front and sides of the boiler are plumb.11)

See Section VII (“Venting) for instructions on attaching the vent system to the boiler. 12)

A hot water boiler installed above radiation level or as the Authority having jurisdiction,

13)

must be provided with a low water cutoff device either as a part of the boiler or at the time of installation.

7

Figure 5.1 Wall Mounting Hole Locations

8

Figure 5.2 Boiler Mounting

9

VI Air for Ventilation

WARNING

Outdoor combustion air must be piped to the air intake. Never pipe combustion air from areas containing

contaminates such as areas where swimming pool chemicals are stored. Contaminated combustion

air will damage the boiler and may cause property damage, personal injury or loss of life.

Air for combustion and ventilation, of the National Flue Gas Code, ANSI Z223.1/NFPA 54 CAN/CSA B 149.1

Natural Gas and Propane Installation Code, or applicable provisions of the local building codes.

Air for combustion must always be obtained directly from outdoors, however suffi cient air for ventilation must

still be provided in the boiler room. Air for ventilation is required to keep various boiler components from

overheating and is always obtained from indoors. To ensure an adequate ventilation air supply, perform the

following steps:

Step 1: Determine whether the boiler is to be installed in a confi ned space - A confi ned space is defi ned by

the

as having a volume less than 50 cubic feet per 1000 BTU/hr input of all appliances

installed in that space. To determine whether the boiler room is a confi ned space:

Total the input of all appliances in the boiler room in thousands of BTU/hr. Round the result to the next A.

highest 1000 BTU/hr.

,ANSI Z223.1.

/NFPA 54 and/or CAN/CSA B 149.1National Fuel Gas Code

Natural Gas and Propane Installation Code.

Find the volume of the room in cubic feet. The volume of the room in cubic feet is:B.

Length (ft) x width (ft) x ceiling height (ft)

In calculating the volume of the boiler room, consider the volume of adjoining spaces only if no doors

are installed between them. If doors are installed between the boiler room and an adjoining space, do

not consider the volume of the adjoining space, even if the door is normally left open.

Divide the volume of the boiler room by the input in thousands of BTU/hr. If the result is less than 50, the C.

boiler room is a confi ned space.

Example:

A MWC116 and a water heater are to be installed in a room measuring 6ft – 3 in x 7ft with an 8 ft ceiling. The

water heater has an input of 30000 BTU/hr:

Total input in thousands of BTU/hr = (116000 BTU/hr + 30000 BTU/hr) / 1000 = 146 MBTU/hr

Volume of room = 6.25 ft x 7 ft x 8 ft = 350 ft

350/146 = 2.40. Since 2.33 is less than 50, the boiler room is a confi ned space.

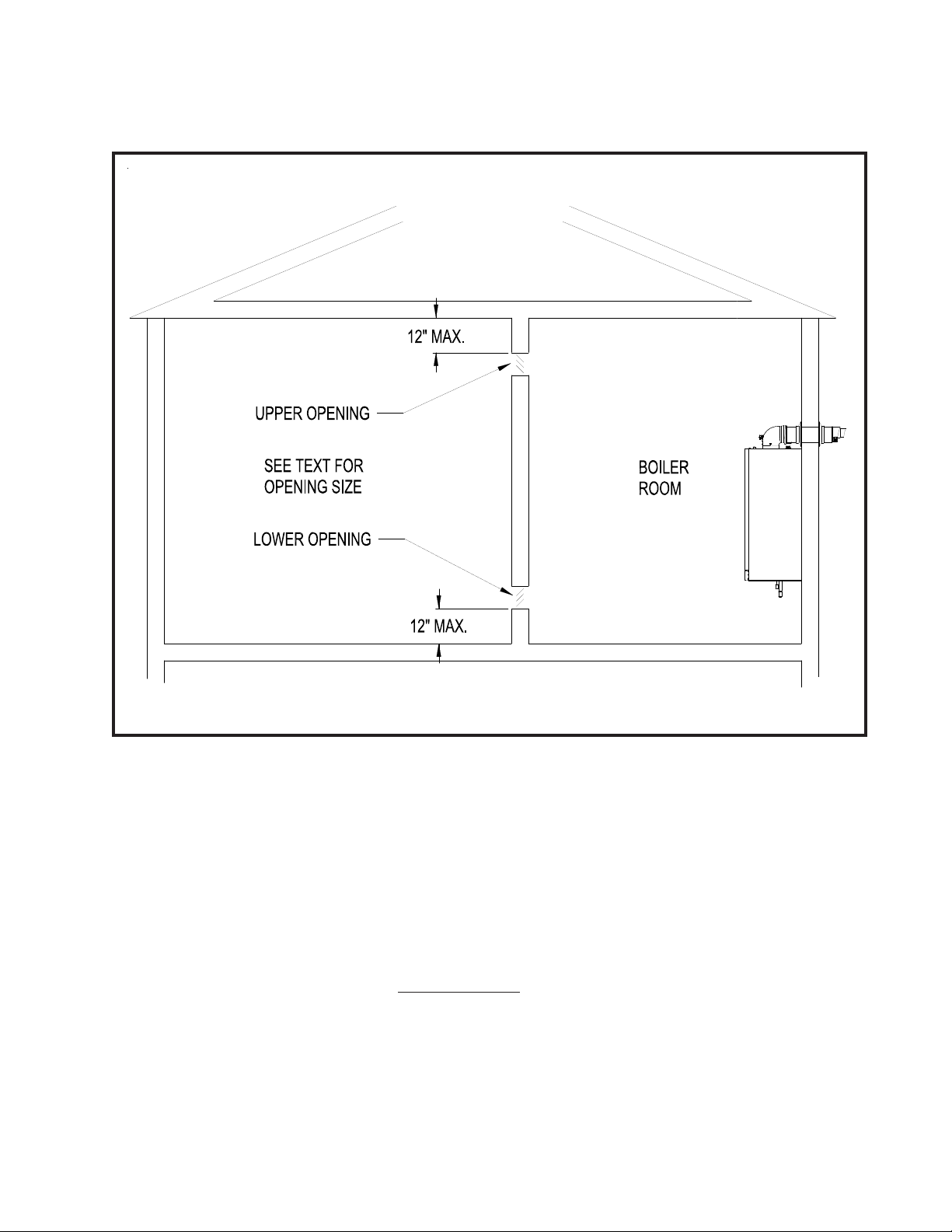

Step 2a: If the boiler is to be placed in a confi ned space, provide two openings into the boiler room, one near

the fl oor and one near the ceiling. The top edge of the upper opening must be within 12” of the ceiling and the

bottom edge of the lower opening must be within 12” of the fl oor (Fig 6.1). The minimum opening dimension is

3 inches.

3

If the MWC boiler is the only gas-burning appliance in the boiler room, these openings must each •

have a minimum free area of 54 square inches.

If other gas-burning appliances are in the boiler room, size the openings in accordance with the •

appliance manufacturer’s instructions or the National Fuel Gas Code

/NFPA 54 and/or CAN/CSA B 149.1.

54 square inches even if opening requirements for other appliances are less.

Minimum opening free area is

ANSI Z223.1.

10

Figure 6.1: Boiler Installed In A Confi ned Space, Ventilation Air From Inside

Step 2a (contd.)

If the total volume of both the boiler room and the room to which the openings connect is less than •

50 cubic feet per 1000 BTU/hr of total appliance input, install a pair of identical openings into a third

room. Connect additional rooms with openings until the total volume of all rooms is at least 50 cubic

feet per 1000 BTU/hr of input.

The “free area” of an opening takes into account the blocking effect of mesh, grills, and louvers. •

Where screens are used, they must be no fi ner than ¼” (4 x 4) mesh.

Step 2b: If the boiler is to be placed in an unconfi ned space the natural infi ltration into the boiler room will

provide adequate air for ventilation without additional openings into boiler room.

11

VII Venting

WARNING

Failure to vent this boiler in accordance with these instructions could cause fl ue gas to enter

the building resulting in severe property damage, personal injury, or death:

Do not attempt to vent this boiler with galvanized, PVC, or any other vent components not •

listed in Table 7.3.

Do not obtain combustion air from within the building. •

Do not install a barometric damper or drafthood on this boiler.•

CAUTION

Moisture and ice may form on the surfaces around the vent termination. To prevent

deterioration, surfaces should be in good repair (sealed, painted, etc.).

A. Vent System Design

There are two basic ways to vent this boiler:

Horizontal (“Side Wall”) Concentric Venting• - Vent system exits the building through an outside

wall. Concentric venting consists of a “pipe within a pipe”. Flue gas exits the building through the inner

pipe and combustion air is drawn into the boiler through the space between the inner and outer pipe.

Vertical Concentric Venting - • Vent system exits the building through the roof. Concentric venting

consists of a “pipe within a pipe”. Flue gas exits the building through the inner pipe and combustion

air is drawn into the boiler through the space between the inner and outer pipe.

Both of these systems are considered “direct vent” because in both, combustion is drawn directly from the

outdoors into the boiler. A description of all of these venting options are shown in Tables 7.1 and 7.6. For

clarity, these vent options are numbered from 1 to 6. One of the vent option columns in Tables 7.1 or 7.6 must

match the planned vent and air intake system exactly. In addition, observe the following guidelines:

Approved vent systems1) - Use only one Concentric vent system components supplied by Crown. The

standard boiler is supplied with a concentric vent system having a maximum usable length of 25” (Figure

2.1). For longer runs, additional straight lengths and elbows are available from Crown. In some cases,

larger diameter concentric pipe must be used. Each Crown concentric vent component consists of an

inner pipe of polypropylene and the outer pipe of steel. Integral gaskets on each concentric fi tting provide

a gas tight seal. A list of all Crown concentric vent components is shown in Table 7.3.

In this manual, concentric pipe sizes are called out in terms of the inner and outer pipe nominal

diameters in millimeters. For example, “60/100mm” pipe consists of a 60mm exhaust pipe inside a

100mm diameter outer pipe.

Maximum Vent and Air Intake Lengths2) - The maximum length of the vent air intake piping depends upon

the vent option selected. See Table 7.1 or 7.6 for the maximum vent length. In horizontal vent systems,

the lengths shown in Table 7.1 are in addition to the Elbow Adaptor on top of the boiler. If more elbows

are desired, the maximum allowable vent length must be reduced by the amount shown in Table 7.5 for

each additional elbow used. Termination fi ttings are never counted, although the length of the concentric

terminal section is counted.

12

2 (contd.)

Example: A 60/100mm concentric vent system is planned for a horizontally vented MWC116 which

has the following components:

60/100mm Elbow Adaptor (supplied with the boiler)•

1 ft Straight Pipe•

90 elbow•

Uncut Terminal Section (supplied with the boiler)•

The Vent Option #2 column in Table 7.1 describes a horizontal direct vent system using 60/100mm

concentric vent pipe. From this column, we see that a MWC116 may have a vent length of up to 8ft10in. The 60/100 Elbow Adaptor supplied with the boiler is not considered. The length of the terminal

section (not including the plastic terminal itself) is approximately 22 1/2” (1.9ft) installed. From Table

7.5, we see that the equivalent length of the 60/100mm elbow is 4.5ft. The total equivalent length of

the planned venting system is therefore:

1ft (Straight ) + 4.5ft (90 Elbow) + 1.9ft (Uncut Terminal Section) = 7.4ft.

Since Table 7.1 shows a maximum allowable vent length of 8ft-10in, the planned vent system length

is acceptable. Note that the 82mm inlet air orifi ce supplied with the boiler is not used.

Minimum Vent and Air Intake Lengths 3) - Observe the minimum vent lengths shown in Tables 7.1 and 7.6.

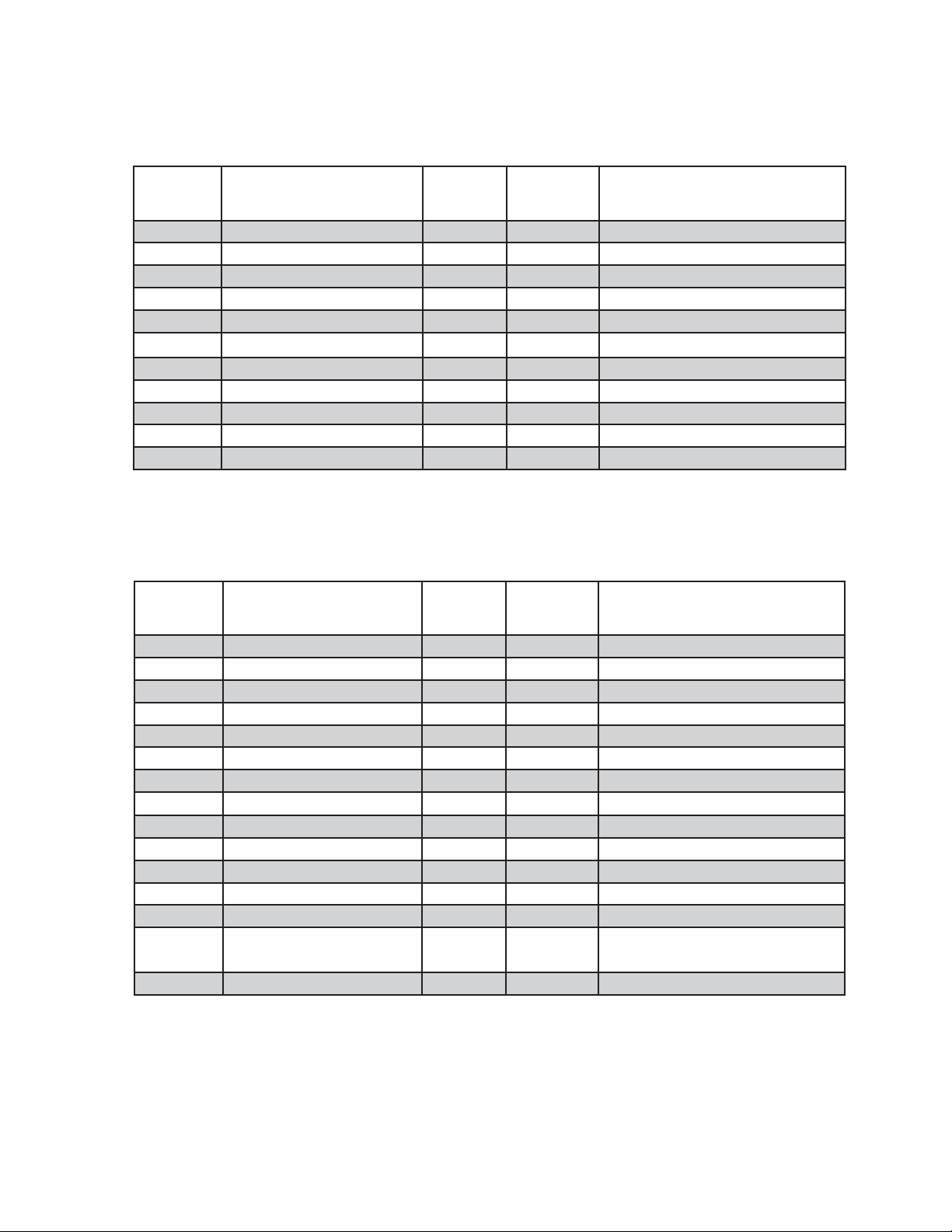

Permitted Terminals for Horizontal Venting:4)

Vent Option 1, 2• - The 60/100mm concentric vent terminal is supplied with the boiler as part of the

standard vent system.

Vent Option 3• - Use the optional 80/125mm Concentric Vent Terminal (Crown PN 230531)

Horizontal Vent Terminal Location5) - Observe the following limitations on the vent terminal location (also

see Figure 7.4).

Vent terminal must be at least 1 foot from any door, window, or gravity inlet into the building.•

The bottom of the terminal must be at least 12” above the normal snow line. In no case should it be •

less than 12” above grade level.

The bottom of the vent terminal must be at least 7 feet above a public walkway. •

Do not install the vent terminal directly over windows or doors.•

The bottom of the vent terminal must be at least 3 feet above any forced air inlet located within 10 •

feet.

In the USA, maintain a clearance of at least 4ft horizontally from the vent terminal to gas meters, •

electric meters, regulators and relief equipment. In Canada, maintain a 6ft clearance between the

vent terminal and these devices.

Do not locate the vent terminal under decks or similar structures.•

Top of vent terminal must be at least 5 feet below eves, soffi ts, or overhangs. Maximum depth of •

overhang is 3 ft.

Vent terminal must be at least 6 feet from an inside corner.•

Vent Terminal must be at least 2ft from adjacent buildings.•

Under certain conditions, water in the fl ue gas may condense, and possibly freeze, on objects around •

the vent terminal including on the structure itself. If these objects are subject to damage by fl ue gas

condensate, they should be moved or protected.

If possible, install the vent and air intake terminals on a wall away from the prevailing wind. Reliable •

operation of this boiler cannot be guaranteed if these terminals are subjected to winds in excess of 40

mph.

Air intake terminal must not terminate in areas that might contain combustion air contaminates, such •

as near swimming pools. See Section IV for

more information on possible contaminates.

13

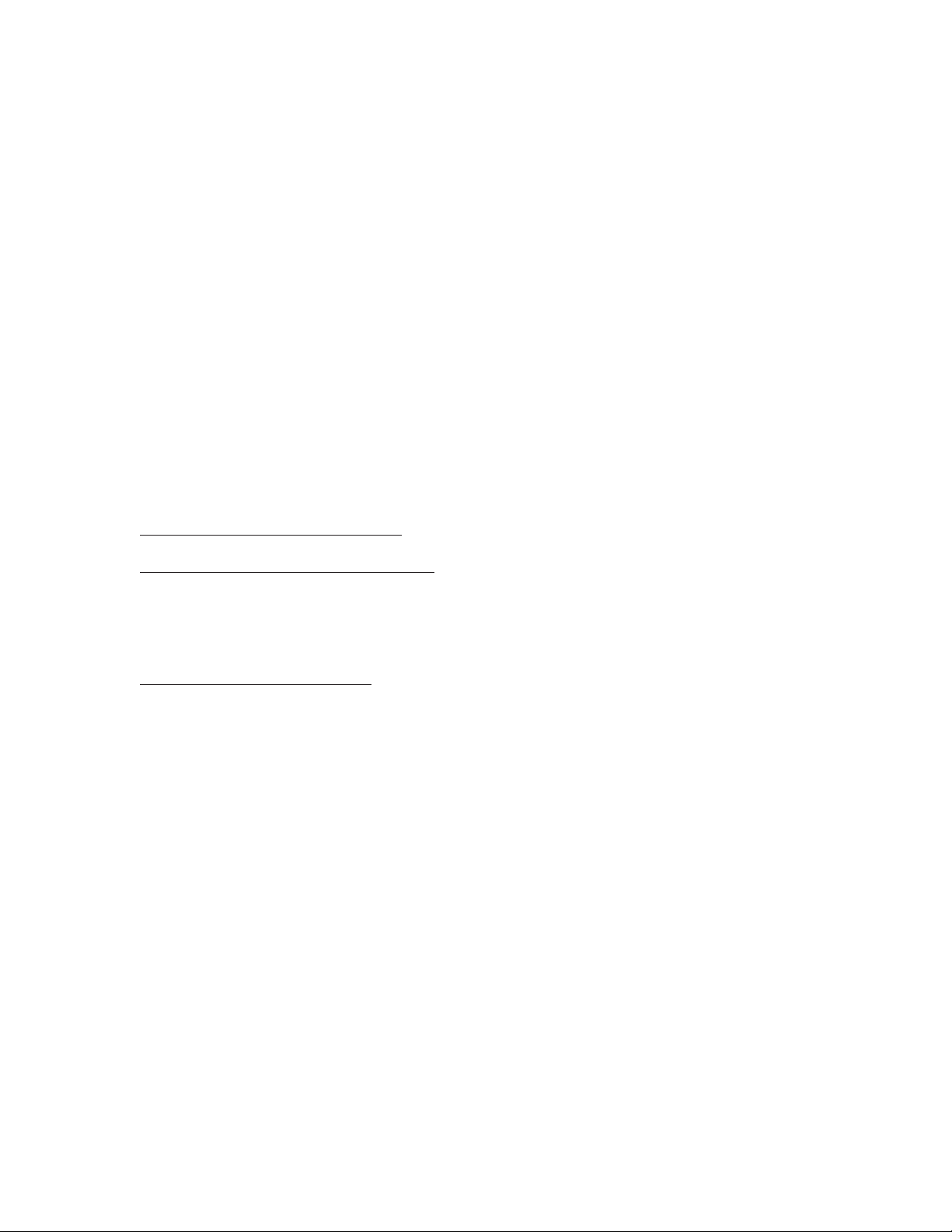

Table 7.1: Summary Of Horizontal Venting Options

VENT OPTION # 1 2 3 4

CLASSIFICATION USED IN THIS

MANUAL

ILLUSTRATED IN FIGURE 7.2 7.2 7.2

HORIZONTAL

CONCENTRIC

HORIZONTAL

CONCENTRIC

HORIZONTAL

CONCENTRIC

RESERVED

FOR FUTURE

USE

VENT PIPE PENETRATION

THROUGH STRUCTURE

VENT PIPE SIZE

INLET AIR ORIFICE SIZE

MAX. VENT LENGTH

MIN. VENT LENGTH

VENT TERMINAL

VENT MATERIAL

WALL WALL WALL

60/100 mm

CONCENTRIC

82mm

25in

6in

CROWN

#230520

(INCLUDED

WITH BOILER)

CROWN

60/100mm

VENT

COMPO-

NENTS

SHOWN IN

TABLE 7.3a

60/100 mm

CONCENTRIC

Not Used 82mm

8ft - 10in 27ft - 10in

26in 6in

CROWN

#230520

(INCLUDED

WITH BOILER)

CROWN

60/100mm

VENT

COMPO-

NENTS

SHOWN IN

TABLE 7.3a

80/125 mm

CONCENTRIC

CROWN

#230531

CROWN

80/125mm VENT

COMPONENTS

SHOWN IN

TABLE 7.3b

Figure 7.2: Horizontal Concentric Venting (Vent Options 1-3)

14

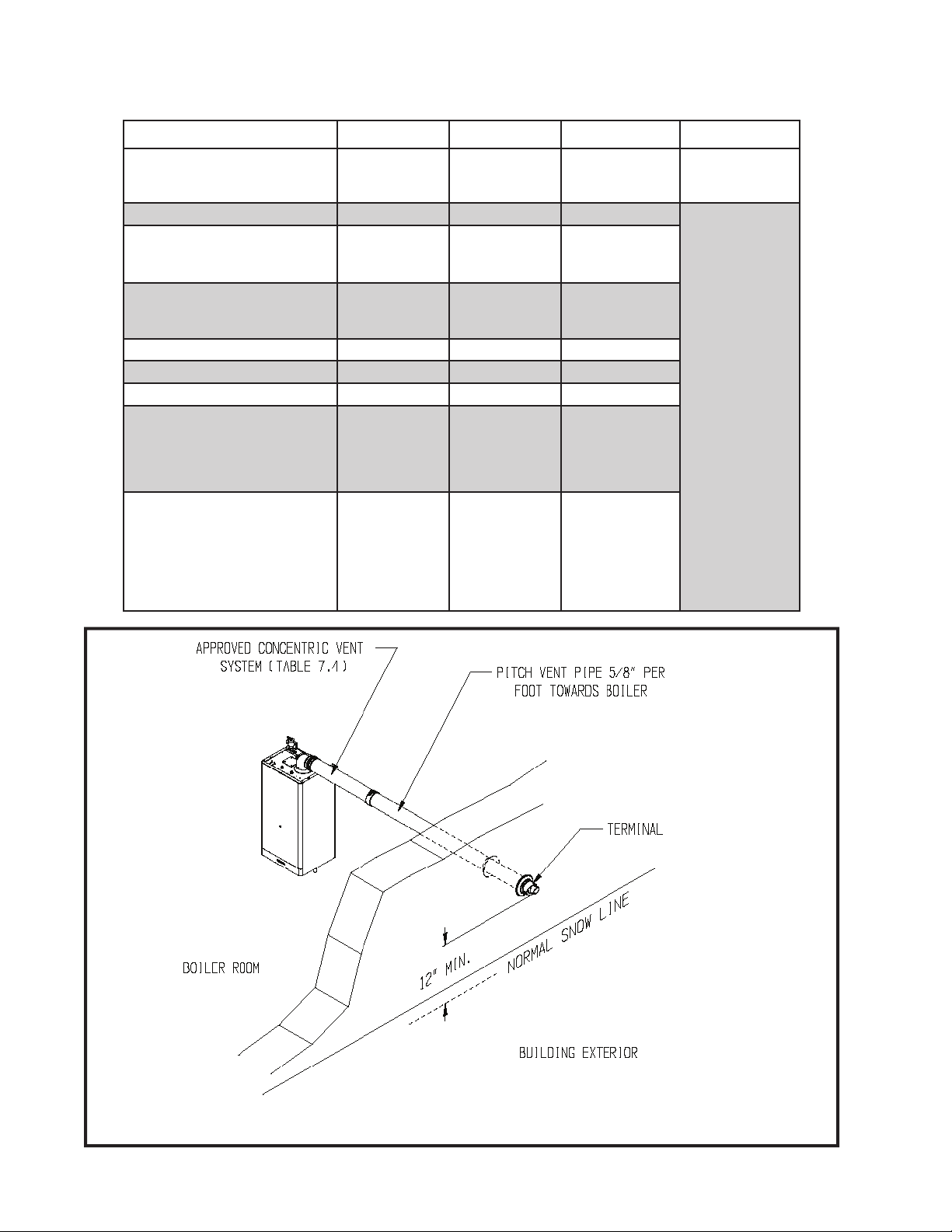

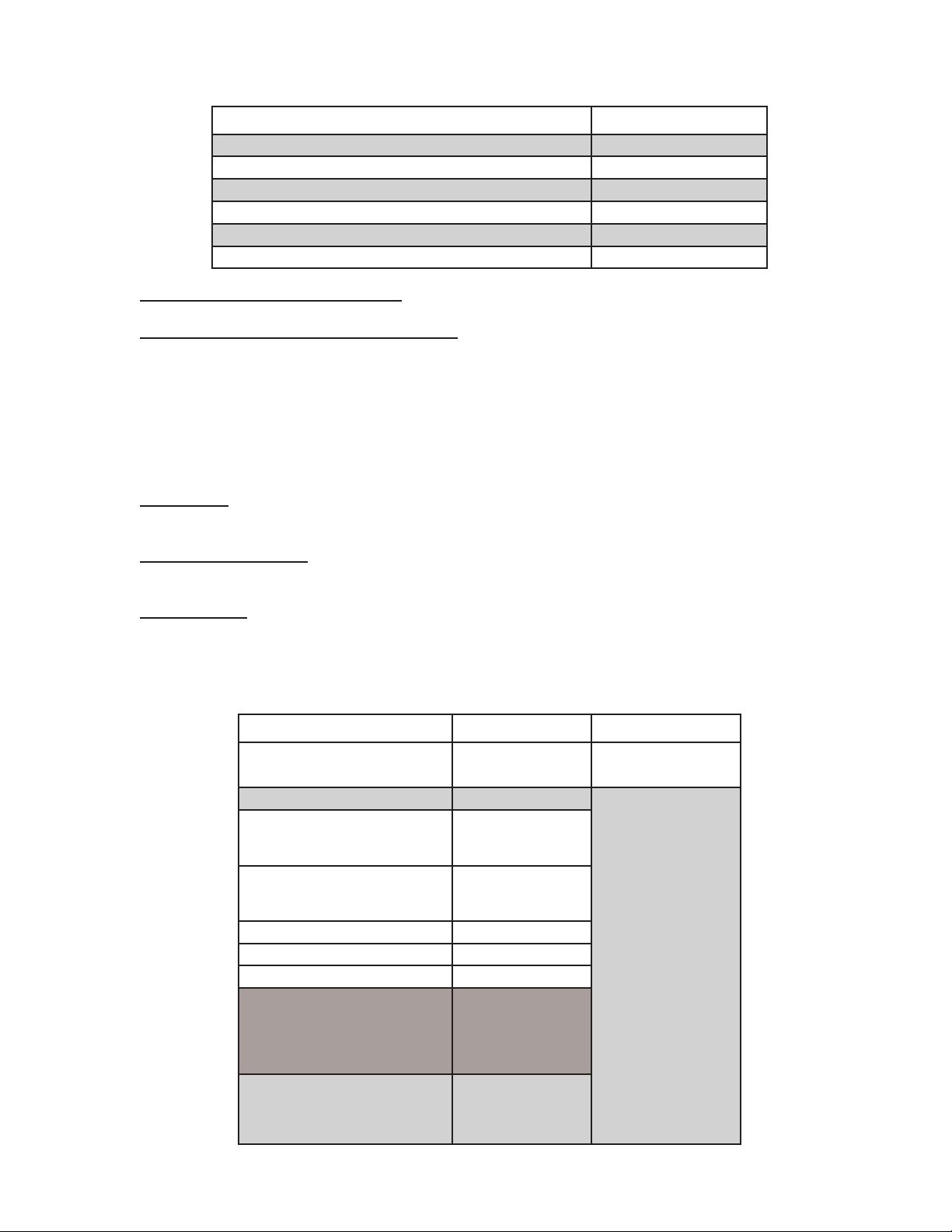

Table 7.3a: Crown Concentric 60/100 Vent Components (Vent Options 1,2)

USED ON

CROWN PN DESCRIPTION SIZE

340509 60/100mm ELBOW ADAPTOR 60/100mm 1,2 INCLUDED WITH STANDARD BOILER

340503 60/100mm STRAIGHT ADAPTOR 60/100mm 2 OPTIONAL

230520 TERMINAL SECTION 60/100mm 1,2 INCLUDED WITH STANDARD BOILER

230522 WALL GROMMET 60/100mm 1,2 INCLUDED WITH STANDARD BOILER

230505 39” STRAIGHT 60/100mm 2 OPTIONAL - MAY NOT BE CUT

230504 78” STRAIGHT 60/100mm 2 OPTIONAL - MAY NOT BE CUT

230506 19 1/2” STRAIGHT 60/100mm 1,2 OPTIONAL - CAN BE CUT

230507 90 DEGREE ELBOW 60/100mm 2 OPTIONAL

230508 45 DEGREE ELBOW 60/100mm 2 OPTIONAL

230515 39” STRAIGHT 80/125mm 1 OPTIONAL - CAN BE CUT

340130 82mm AIR INLET ORIFICE 82mm ID 1 INCLUDED WITH STANDARD BOILER

VENT

OPTION #

COMMENTS

Table 7.3b: Crown Concentric 80/125 Vent Components (Vent Options 3,5)

USED ON

CROWN PN DESCRIPTION SIZE

340523 80/125 STRAIGHT ADAPTOR 80/125mm 3,5

230527 90 DEGREE EL (STANDARD) 80/125mm 3,5

230528 90 DEGREE EL (SWEEP) 80/125mm 3,5

230526 45 DEGREE EL 80/125mm 3,5

230517 19 1/2” STRAIGHT 80/125mm 3,5 CAN BE CUT

230515 39” STRAIGHT 80/125mm 3,5 CAN BE CUT

230518 39” STRAIGHT 80/125mm 3,5 MAY NOT BE CUT

230519 78” STRAIGHT 80/125mm 3,5 MAY NOT BE CUT

230525 TELESCOPING STRAIGHT 80/125mm 3,5 ADJUSTABLE FROM 12-1/2” TO 16-1/2

230531 HORIZONTAL TERMINAL 80/125mm 3

230532 VERTICAL TERMINAL 80/125mm 5 (NOTE #1)

230533 FLAT ROOF FLASHING 80/125mm 5

230535 SLOPED ROOF FLASHING 80/125mm 5 (NOTE #2)

230530

230536 SUPPORT BAND 80/125mm 3,5

Table 7.3b Notes:

1) Vertical terminal can be used with either of the roof fl ashings listed beneath it.

2) Sloped roof fl ashing suitable for roof angles between 25 and 45 degrees.

3) Used at base of vertical run inside unused masonry chimney.

SUPPORT ELBOW WITH

CHIMNEY CHASE BRACKET

80/125mm 5 (NOTE #3)

VENT

OPTION #

COMMENTS

15

Figure 7.4a: Location Of Vent Terminal Relative To Windows, Doors, Grade

Figure 7.4b: Location Of Vent Terminal Relative To Meters And Forced Air Inlets

Figure 7.4c: Positioning Vent Terminal Under Overhangs

16

VENT FITTING EQUIVALENT LENGTH (ft)

60/100mm 90° CONCENTRIC ELBOW 4.5

60/100mm 45° CONCENTRIC ELBOW 4.0

80/125mm 90° CONCENTRIC ELBOW 8.5

80/125mm 90° SWEEP CONCENTRIC ELBOW 5.5

80/125mm 45° CONCENTRIC ELBOW 3.0

80/125mm 90° CONCENTRIC SUPPORT ELBOW 8.5

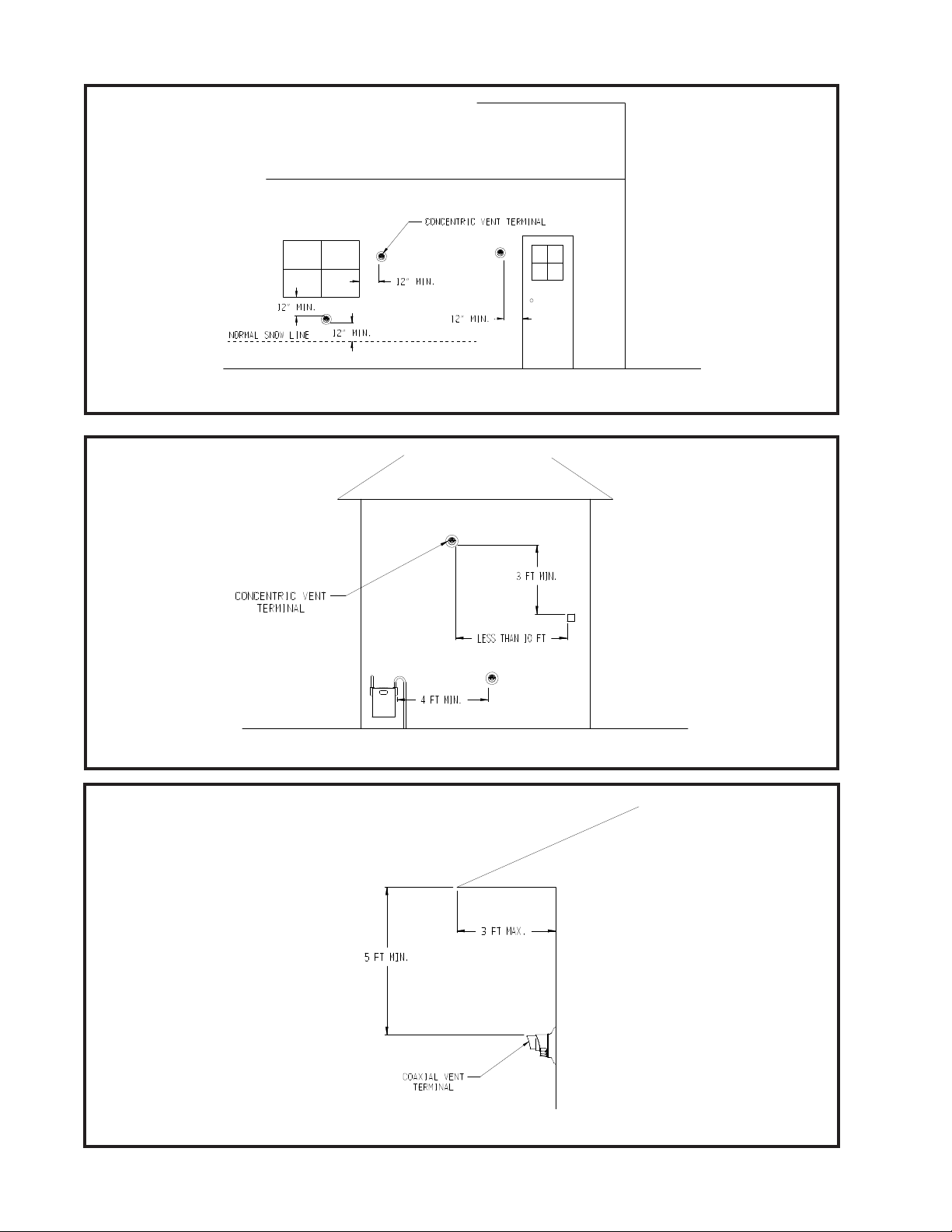

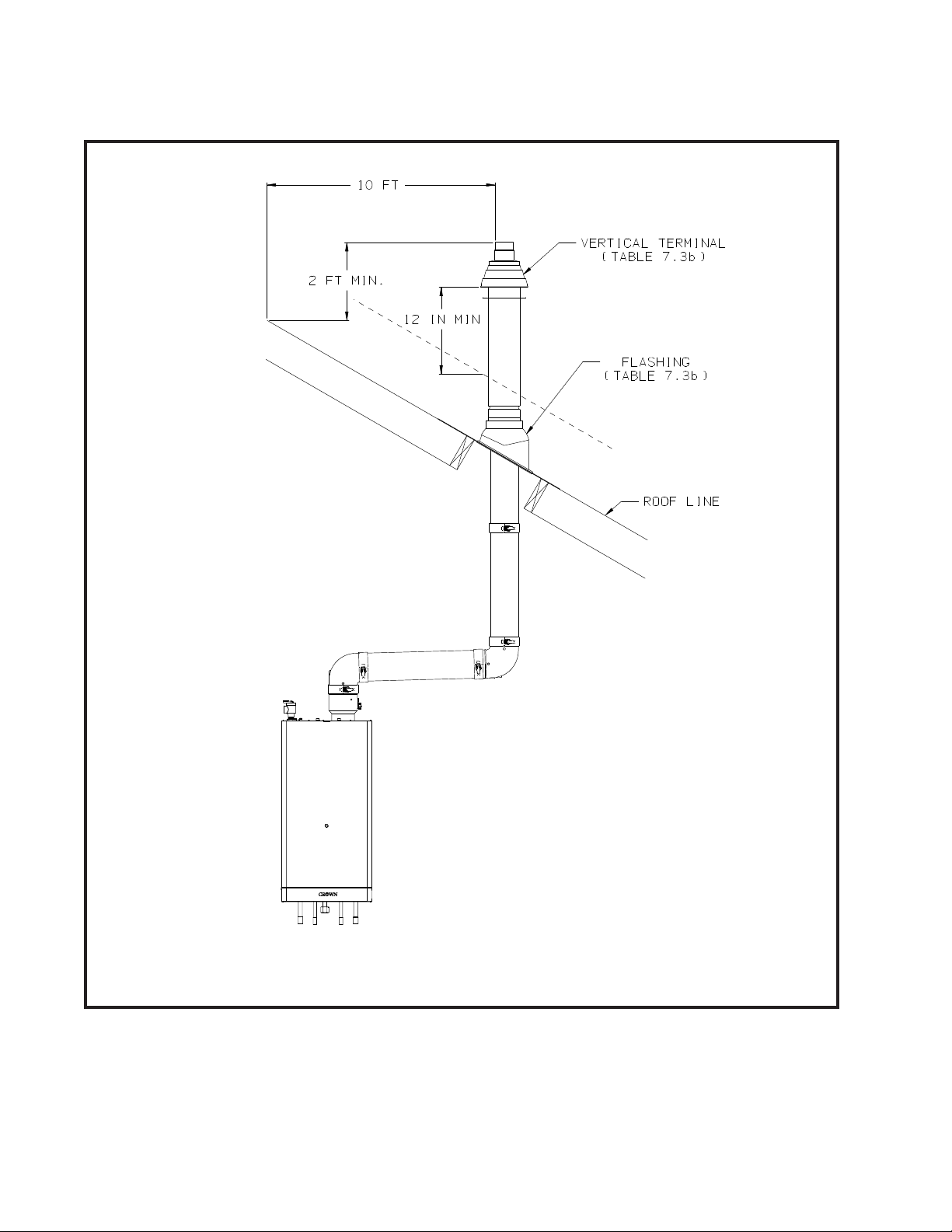

Permitted Terminals for Vertical Venting6) - Use Crown PN 230532 with the appropriate ashing (Table 7.3b)

Vertical Vent Terminal Locations (Vent Option 5)7) - Observe the following limitations on the location of all

vertical vent terminals (see Figure 7.7):

The top of the vent pipe must be at least 2 feet above any object located within 10 feet.•

The bottom of the air inlet terminal must be at least 12” above the normal snow accumulation that can be •

expected on the roof. The terminal used in Vent Option #5 has a xed distance above the storm collar of

19”. If a greater distance is needed to provide the clearance above the snow line, build a chase on the

roof and mount the vertical terminal on top of the chase.

Wall thimbles8) – Concentric vent has a “zero” clearance to combustibles and therefore does not require the

use of wall thimbles.

Pitch of Horizontal Piping9) - Pitch all horizontal piping so that any condensate which forms in the piping will run

towards the boiler. Pitch Crown horizontal concentric venting 5/8” per foot

Supporting Pipe10) - Vertical and horizontal sections of pipe must be properly supported. Support Crown

concentric venting near the female end of each straight section of pipe. Exception: Vertical runs of concentric

pipe in an unused chimney (Figure 7.36) need only be supported at the terminal and at the base of the run.

VENT OPTION # 5 6

CLASSIFICATION USED IN THIS

MANUAL

ILLUSTRATED IN FIGURE 7.7

VENT PIPE PENETRATION

THROUGH STRUCTURE

VENT PIPE SIZE

INLET AIR ORIFICE SIZE

MAX. VENT LENGTH

MIN. VENT LENGTH

VENT TERMINAL

VERTICAL

CONCENTRIC

ROOF

80/125mm

CONCENTRIC

82mm

27ft - 10in

6in

CROWN #230532

CONCENTRIC

TERMINAL (TABLE

7.3b)

RESERVED FOR

FUTURE USE

CROWN 80/125 mm

VENT MATERIAL

VENT COMPONENTS

SHOWN IN TABLE

7.3b

17

Figure 7.7: Vertical Concentric Vent System (Vent Option 5)

18

B. Removing an Existing Boiler From a Common Chimney

Read this only if the MWC boiler is replacing an existing boiler that is being removed from a common

chimney. This section does not apply to the installation of a MWC boiler.

In some cases, when an existing boiler is removed from a common chimney, the common venting system

may be too large for the remaining appliances. At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining connected to the common venting system placed

in operation, while the other appliances remaining connected to the common venting system are not in

operation.

(a) Seal any unused openings in the common venting system.

(b) Visually inspect the venting system for proper size and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and other defi ciencies which could cause an unsafe

condition.

(c) Insofar as practical, close all building doors and windows and all doors between the space in which

all the appliances remaining connected to the common venting system are located and other

spaces of the building. Turn on clothes dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a summer exhaust fan. Close fi replace dampers.

(d) Place in operation the appliance being inspected. Follow the lighting instructions. Adjust

thermostat so the appliance will operate continuously.

(e) Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use

the fl ame of a match or candle, or smoke from a cigarette, cigar, or pipe.

(f) After it has been determined that each appliance remaining connected to the common venting

system properly vents when tested as outlined above, return doors, windows, exhaust fans,

fi replace dampers and any other gas-burning appliances to their previous condition of use.

(g) Any improper operation of the common venting system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI Z223.1.

Natural Gas and Propane Installation Code.

common venting system, the common venting system should be re sized to approach the minimum

size as determined using the appropriate tables in Part 11 of the National Fuel Gas Code, ANSI

Z223.1.

/NFPA 54 and/or CAN/CSA B 149.1

When re-sizing any portion of the

/NFPA 54 and/or CAN/CSA B 149.1

WARNING

Never common vent a MWC boiler with other appliances.

19

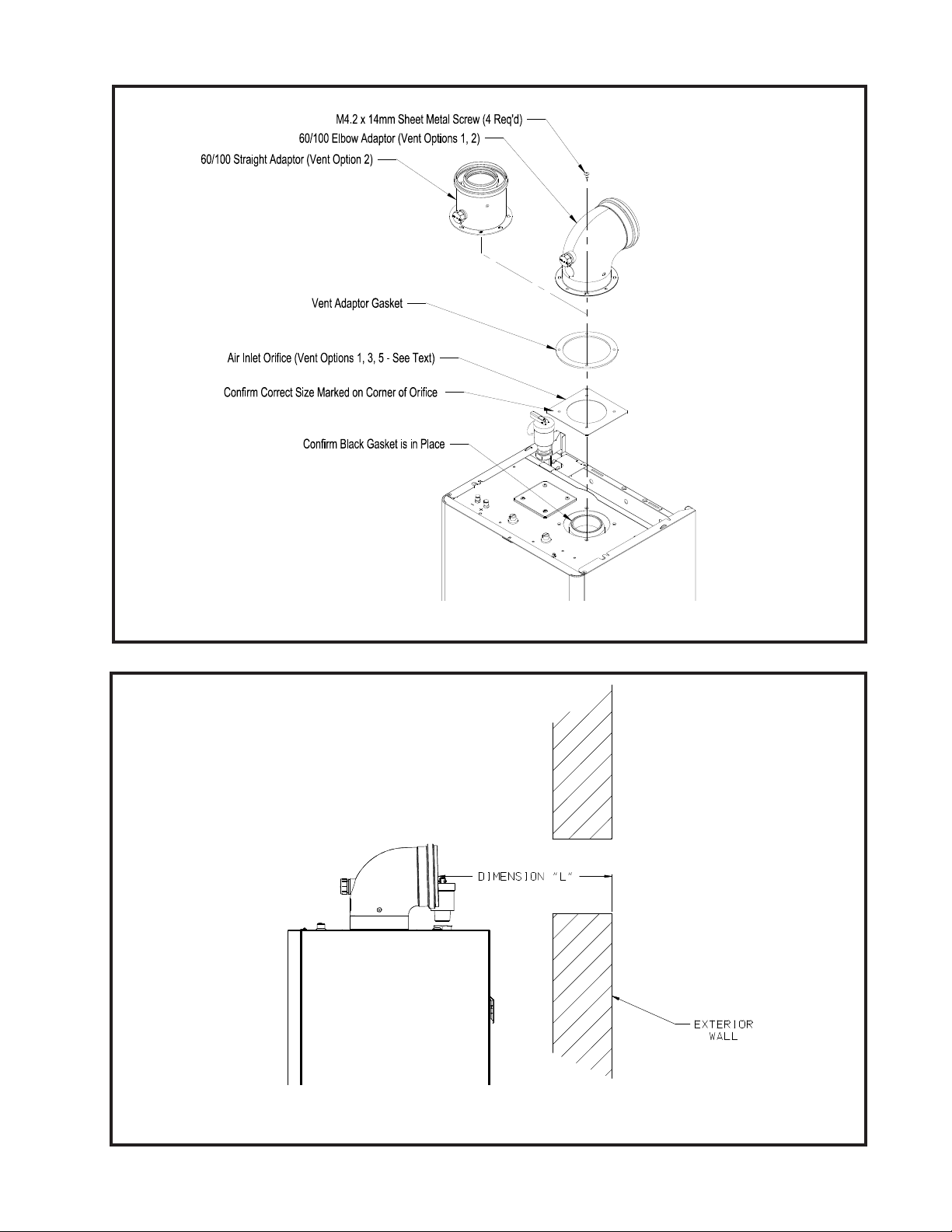

C. Assembly of Crown 60/100mm Concentric Venting

Figure 7.20. For V

(IMPORTANT - Skip to Section D for 80/125mm Concentric V ent Assembly)

WARNING

Failure to follow the instructions could result in fl ue gas leakage into the combustion air or indoor

air, resulting in unsafe or unreliable operation.

• Do not lubricate concentric gaskets with anything other than water.

• Do not attempt to cut any piping except as permitted in this section. When cutting these

sections, make sure all cuts are square and allow for proper insertion.

• Do not attempt to try to mix this concentric pipe with other venting systems.

Concentric vent components supplied with the boiler are packed in a separate carton and include the following:1)

60/100mm elbow adaptor (Crown PNa) 340509).

60/100mm terminal section (straight section with a terminal and overall length of 27 3/4” (Crown PN 230520).b)

Two (2) Rubber wall grommets (Crown PN c) 230522).

Vent gasket and screws for attachment of vent system to boiler. d)

The 82mm air inlet orifi ce required for Vent Option 1 is packed in the boiler carton.

The 60/100 straight adaptor is optional equipment. It is supplied with the same screws and gasket as the 60/100

elbow adaptor.

Start by attaching the elbow adaptor (or straight adaptor, if used instead) to the top of the boiler using the gasket 2)

and four 4.2mm sheet metal screws provided in the vent kit as shown in

82mm air inlet orifi ce as shown.

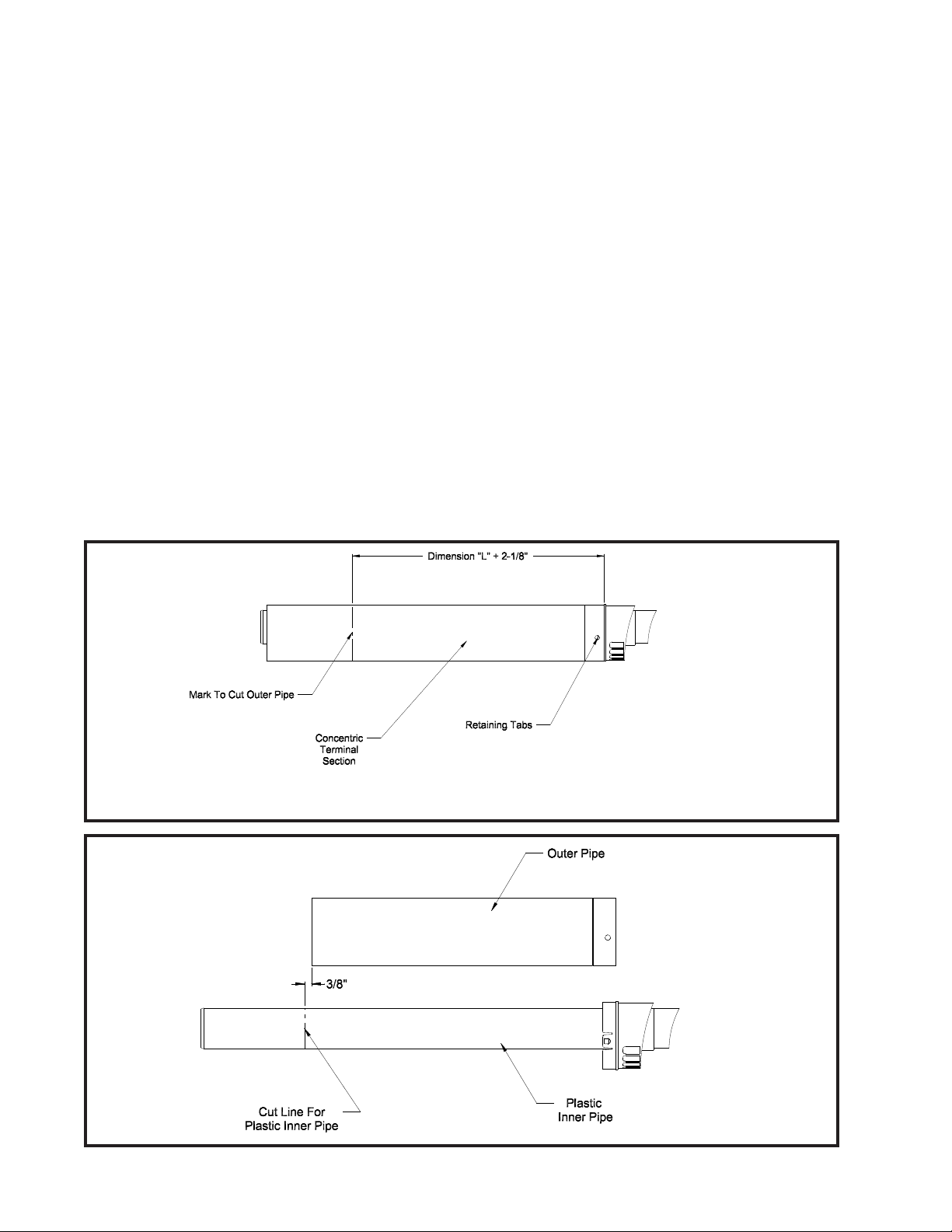

If no additional sections of concentric pipe are required, attach the terminal section to the elbow. In most cases, it 3)

will need to be cut before doing so. Use the following procedure to cut the pipe:

Measure distance “L” from the outside surface of the exterior wall to the end of the elbow as shown in Figure a)

7.21.

Add 2-1/8” to distance “L”. Carefully mark this length on the pipe as shown in Figure 7.22.b)

Press in the two tabs holding the plastic terminal in the terminal section (Figure 7.22). Carefully pull out the c)

terminal and the inner pipe.

Cut the d) outer pipe only at the point marked in Step (b) using aviation shears, a hacksaw, or an abrasive

wheel cutter. Be careful to cut the pipe square. De burr the cut end with a fi le or emery cloth.

Cut the plastic inner pipe so that it will protrude 3/8” beyond the outer pipe when reinstalled in the terminal e)

section (Figure 7.23). Use a fi ne tooth hacksaw or a PVC saw to cut the plastic pipe and be careful to cut the

pipe square. De burr the cut edge of the plastic pipe with a fi le, razor blade, or fi ne sandpaper.

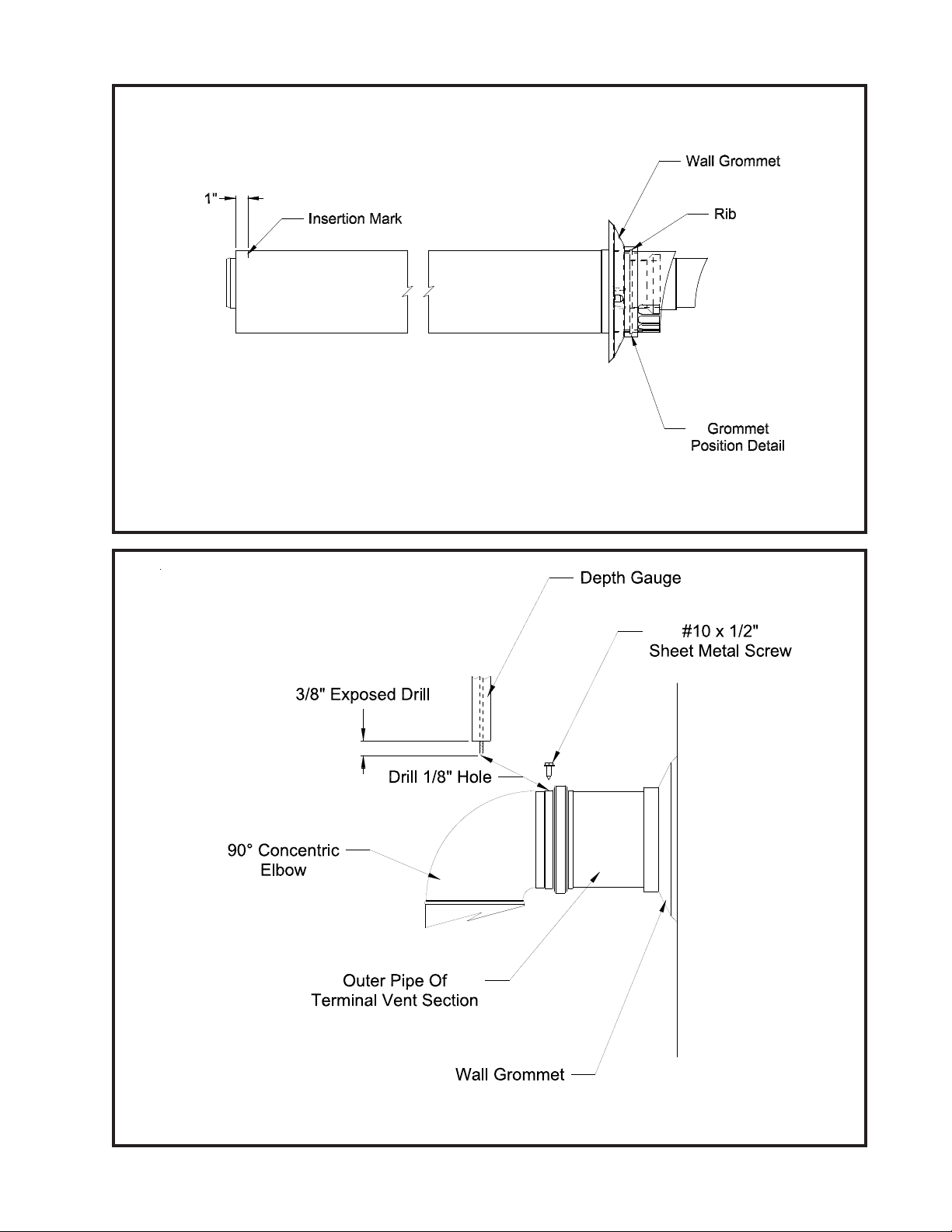

Reinstall the inner pipe in the terminal section. Slip the outside wall grommet over the terminal section and f)

position so that it covers the joint between the outer pipe and the terminal (Figure 7.24).

Make a mark on the terminal section 1” from the cut end of the outer pipe as shown in Figure 7.24.g)

Pass the terminal section through the wall from the outside. Push the remaining wall grommet over the h)

terminal section on the inside of the wall. Push the terminal section into the elbow until the mark made in Step

(g) is no longer visible. If necessary , the brown gasket in the inner pipe may be lubricated with a few drops of

water.

The terminal section must be attached to the elbow with a single #10 x 1/2” sheet metal screw ( not supplied) i)

at the top of the elbow. Drill a 1/8” hole in the location shown in Figure 7.25. Use a short drill bit or a drill

stop to ensure that the drill bit does not penetrate the pipe by more than 3/8”. Install a #10 x 1/2” screw

in this hole. Do not use a screw longer than 1/2” long.

If not already done, make sure that both wall grommets are fi rmly against the interior and exterior wall j)

surfaces. Seal any cracks or other openings near the terminal through which exhaust could enter the building.

Figure 7.20. For Vent Option 1, install the

20

FIGURE 7.20: INSTALLATION OF 60/100 ADAPTORS ON BOILER

FIGURE 7.21: DIMENSION “L”

21

If additional pieces of pipe are used, install them starting at the boiler elbow. Support each section of straight pipe 4)

at its female end.

Use locking bands provided to join adjacent sections of non-cuttable pipe as well as fi ttings. The male end of the 5)

terminal section and other cuttable sections must be held to the female end of the adjoining pipe with at least

three #10 x 1/2” sheet metal screws. Drill a 1/8 hole through both outer pipes to start this screw. Use a drill stop

or other means to ensure that the drill bit does not penetrate more than 3/8” into the outer pipe. Do not

use a sheet metal screw longer than 1/2”.

The only straight pipe that can be cut is the terminal section and the 19-1/2” section (Crown PN 230506). To cut 6)

this pipe:

Cut pipe from the male end. After marking the desired length of the outer pipe, remove the plastic inner pipe a)

by pulling it out from the female end.

Cut the b) outer pipe only at the point marked in Step (b) using aviation shears, a hacksaw, or an abrasive

wheel cutter. Be careful to cut the pipe square. De burr the cut end with a fi le or emery cloth.

Cut the plastic inner pipe so that it will protrude 3/8” beyond the outer pipe when reinstalled in the outer pipe. c)

Use a fi ne tooth hacksaw or a PVC saw to cut the plastic pipe and be careful to cut the pipe square. De burr

the cut edge of the plastic pipe with a fi le, razor blade, or fi ne sandpaper.

Reinstall the inner pipe.d)

Install the terminal as outlined in Step (4) above. Dimension “L” described in Step 3 is the distance from the 7)

exterior surface of the wall to the end of the last piece of pipe inside the building.

Figure 7.22: Cutting Outer Pipe

Figure 7.23: Cutting Inner Pipe

22

Figure 7.24: Preparing 60/100mm Terminal Section For Installation In The Wall

Figure 7.25: Attaching 60/100mm Terminal Section

23

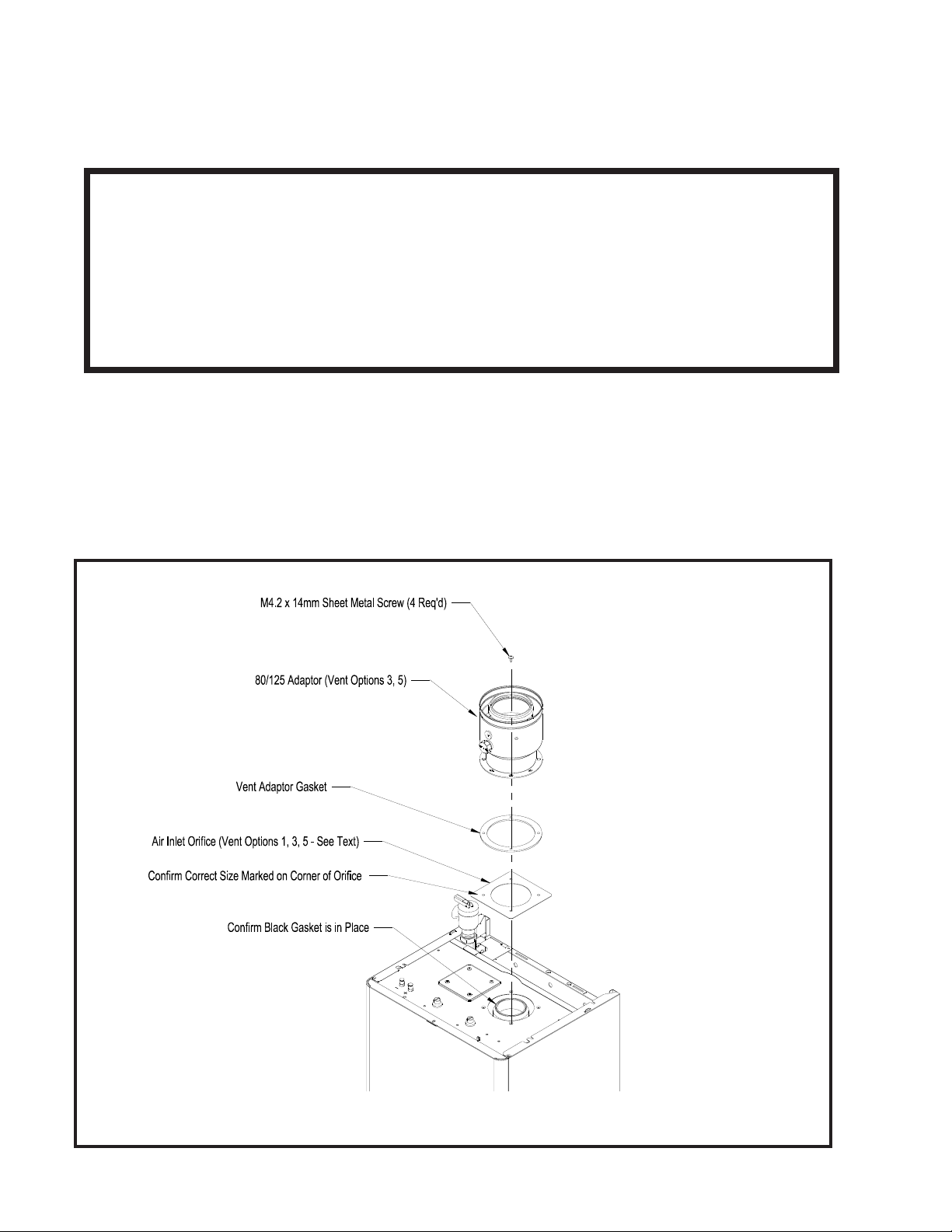

D. Assembly of Crown 80/125mm Concentric Venting

(IMPORTANT - See Section C for 60/100mm Concentric V ent Assembly)

WARNING

Failure to follow the instructions could result in fl ue gas leakage into the combustion air or indoor

air, resulting in unsafe or unreliable operation.

• Do not lubricate concentric gaskets with anything other than water.

• Do not attempt to cut any piping except as permitted in this section. When cutting these

sections, make sure all cuts are square and allow for proper insertion.

• Do not attempt to try to mix this concentric pipe with other venting systems.

The 60/100mm terminal section and concentric reducing elbow supplied with the boiler are not used in 1)

80/125mm vent systems. The components listed in Table 7.3b are required for 80/125mm installations and

are not supplied with the boiler. Before starting assembly of an 80/125mm vent system, make sure that

the planned installation is in accordance with the “Vent System Design” section of this manual and that

all required 80/125mm vent components are on hand. These components are available through Crown

distributors.

Figure 7.30: Installation Of 80/125 Adaptor On Boiler

24

Installation of the MWC1 16 with 80/125mm venting requires the use of the 80/125mm appliance adaptor 2)

(Crown PN 340523). This adaptor is installed on top of the boiler as shown in Figure 7.30. For vent options 3

and 5, sandwich the 82mm air inlet orifi ce between the boiler and the adaptor as shown.

Cutting Straight Pipe3) - The following straight pipe sections may be cut:

Part # Description

230517 19 1/2” Straight

230515 39” Straight

These sections have a plain male end (without beads - see Figure 7.31a). They are always cut from the

male end. Sections not shown on the above list may not be cut. These sections have beads on the male end

(Figure 7.31b).

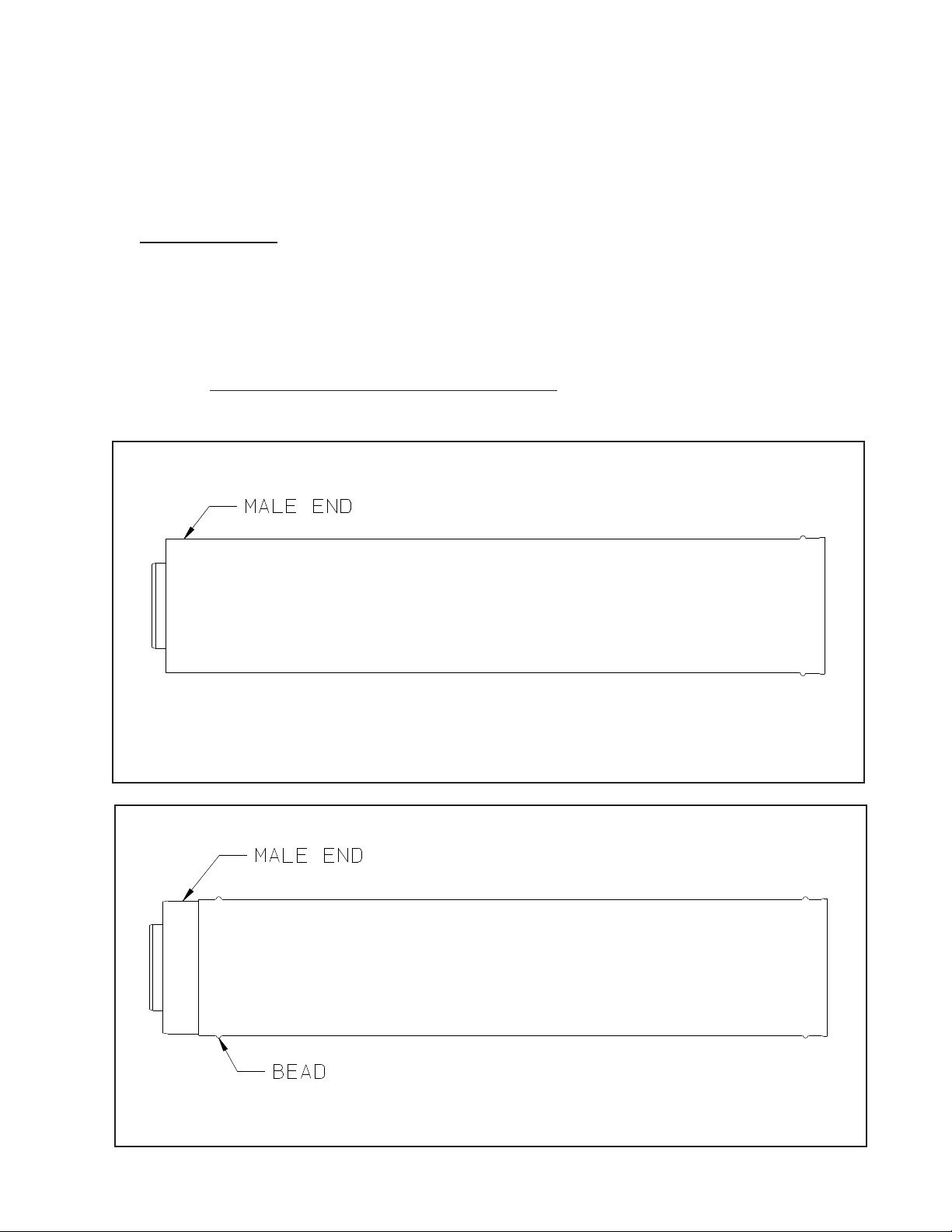

Figure 7.31a: Cuttable Straight Section

Figure 7.31b: Non Cuttable Straight Section

25

Loading...

Loading...