Page 1

P/N: MO-426 (Printed Instruction Manual)

Note: This page is not to be included as part of printed hard copy.

Overall Specifications:

Material: white plain paper

Printed text: black

Binder: staple upper left corner

Individual page specifications:

Cover page: printed single-side up

The balance of instruction manual pages to be printed utilizing both front and back side of paper.

Page 2

OIL-FIRED CENTRAL FURNACE

Installation, Operation, And Service Manual

With Users Information Section

Models:

CHB68-112 CHC68-96 CLBF68-112

CLBR68-112

• Do NOT store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

• Improper installation, adjustment, alteration, service, or maintenance can

cause a fire or explosion resulting in property damage, personal injury, or

loss of life. For assistance or additional information consult a qualified

installer or service agency.

These instructions should be:

• read prior to installing the furnace.

• retained for reference by qualified service personnel.

• reviewed before performing any service or maintenance.

c WARNING:

Crown Boiler Company

3633 “I” Street

Philadelphia, Pennsylvania 19134

Made in USA

MO-426

ECN 5079-MA

Page 3

Contents

SECTION PAGE

Notice to the Installer .................................................................................................. 4

INSTALLATION GUIDELINES ...................................................................................... 5

Codes ................................................................................................................. 5

Installation Location ............................................................................................ 5

Closet and Alcove Installation ............................................................................. 6

Standard Clearances .......................................................................................... 6

Air for Combustion and Ventilation ..................................................................... 7

Chimney Inspection ............................................................................................ 10

Flue / Chimney / Vent Connector ........................................................................ 10

Power (Side-Wall) Venting – Important Note Regarding ..................................... 11

Draft Regulator .................................................................................................... 11

Duct Work and Air Conditioning .......................................................................... 12

Air Filter Mounting ............................................................................................... 12

Electrical Connections ........................................................................................ 14

Room Thermostat ............................................................................................... 14

Combustion Chamber ......................................................................................... 15

Oil Burner and Oil Nozzle Installation .................................................................. 15

Fuel System Installation ....................................................................................... 18

Horizontal / Counterflow Furnace Setup ............................................................. 19

INITIAL OPERATION OF THE FURNACE .................................................................... 21

Initial Burner Operation ....................................................................................... 21

Supply/Return Airflow and Air Temperature ........................................................ 23

Furnace Limit and Blower Controls ..................................................................... 25

Room Thermostat ............................................................................................... 26

Instructions to Our Customer / End User ............................................................. 26

SERVICE ....................................................................................................................... 27

Troubleshooting .................................................................................................. 27

Flame Sensor (“Cad Cell”) Checkout Procedure ................................................ 31

Replacement Parts ............................................................................................. 32

MAINTENANCE ............................................................................................................. 33

Air Filter(s) ........................................................................................................... 33

Oil Burner ............................................................................................................ 33

Blower and Motor ................................................................................................ 33

Heat Exchanger .................................................................................................. 33

Flue and Chimney ............................................................................................... 35

USERS INFORMATION ................................................................................................. 36

Operating Instructions ........................................................................................ 36

Oil Supply ........................................................................................................... 37

Extended Shutdown ........................................................................................... 38

Combustion Air and Ventilation Supply ................................................................ 38

Inspection Areas ................................................................................................. 38

2

Page 4

APPENDIX A: SOURCES FOR REFERENCED STANDARDS ................................... 40

APPENDIX B: ELECTRICAL DIAGRAMS ..................................................................... 41

APPENDIX C: SPECIFICATION SHEETS .................................................................... 43

APPENDIX D: REPLACEMENT PARTS ....................................................................... 46

3

Page 5

Notice to the Installer

Installation of this oil-fired furnace must be performed by a qualified installer in accordance

with all local codes and authorities having jurisdiction. In the absence of local governing codes,

installation shall conform to these instructions and to the regulations of the National Fire

Protection Association’s

2001, and the National Electrical Code, ANSI/NFPA 70-2002, or the latest editions thereof.

A qualified installer, also referred to in this instruction manual as a “qualified heating

contractor”, is an individual, or agency, properly licensed and experienced to install and

service oil-burning equipment in accordance with all local codes and ordinances.

Material and Workmanship

This furnace was built with the highest quality materials and attention to workmanship.

However, omissions and defects occasionally occur. Before installing the furnace,

inspect the furnace thoroughly. If missing parts, defective material, or poor workmanship

are evident, report the model and serial numbers imprinted on the furnace rating label

to the seller for adjustment.

Packaging

A complete furnace is contained within two (2) packages. The factory completed all

feasible assembly. However certain components including oil burner and draft regulator

and, if supplied, door handle, air filter(s), and air filter rack(s), must be assembled to the

furnace, or the venting system, in the field. Refer to the assembly instructions.

Shipping Damage

If this furnace was damaged during transit, please immediately request the

transportation company inspect the furnace and issue a concealed damage report.

The party receiving the furnace should file the claim for shipping damage. Report any

shipping damage immediately.

It is absolutely essential that a damage report be obtained. If a concealed damage

report is not obtained, we cannot provide assistance in recovering your claim against

the transportation company.

Warranties

c WARNING: The manufacturer of this equipment assumes no liability for any

damages resulting from unauthorized modifications made to the furnace, or any

components thereof, or improper installation of the furnace in the field.

Furthermore, any such field modifications VOID THE WARRANTY and place

responsibility for safe and reliable operation of the furnace on those who

performed the modification(s).

Complete and return any enclosed warranty cards. These must be on file to verify

installation dates for replacement of any warrantied part(s).

Standard for the Installation of Oil-Burning Equipment, NFPA 31-

4

Page 6

Codes

All local codes and regulations take precedence over the instructions in this manual and

shall be followed accordingly. In the absence of local codes, this installation must

conform to these instructions and to the regulations of the National Fire Protection

Association (NFPA) publications, the Standard for the Installation of Oil-Burning

Equipment, NFPA 31-2001, and the National Electrical Code, ANSI/NFPA 70-2002, or

the latest editions thereof. To obtain copies of these publications for a fee, contact the

NFPA at the address given in Appendix A of this manual.

Installation Location

c WARNING:

• These furnaces are designed for indoor installation ONLY.

• These furnaces are NOT to be used as construction heaters.

• DO NOT hang the horizontal / counterflow furnace from a structure, or

surface, by any integral part or fastener of the furnace. The furnace was

not designed to support itself in this manner.

In as much as practical, the furnace should be positioned near a chimney or vent and

should be centralized with respect to the air distribution system.

For a utility room installation, the entrance door must be wide enough to permit the

largest part of the furnace to pass through the doorway or allow sufficient clearance to

permit the replacement of another appliance, e.g. a water heater, in the room.

If the furnace is installed in a residential garage, it must be installed so the burner is

located higher than 18 inches above the floor, unless the required combustion air is

taken from the exterior of the garage. Also, the furnace must be located or protected to

avoid physical damage from impacts by vehicles.

Highboy and lowboy furnace models must rest on sturdy, stable, and level surfaces.

The horizontal / counterflow model may be mounted on a level surface, as described

above, or it may be suspended from an overhead structure or surface. If this model is

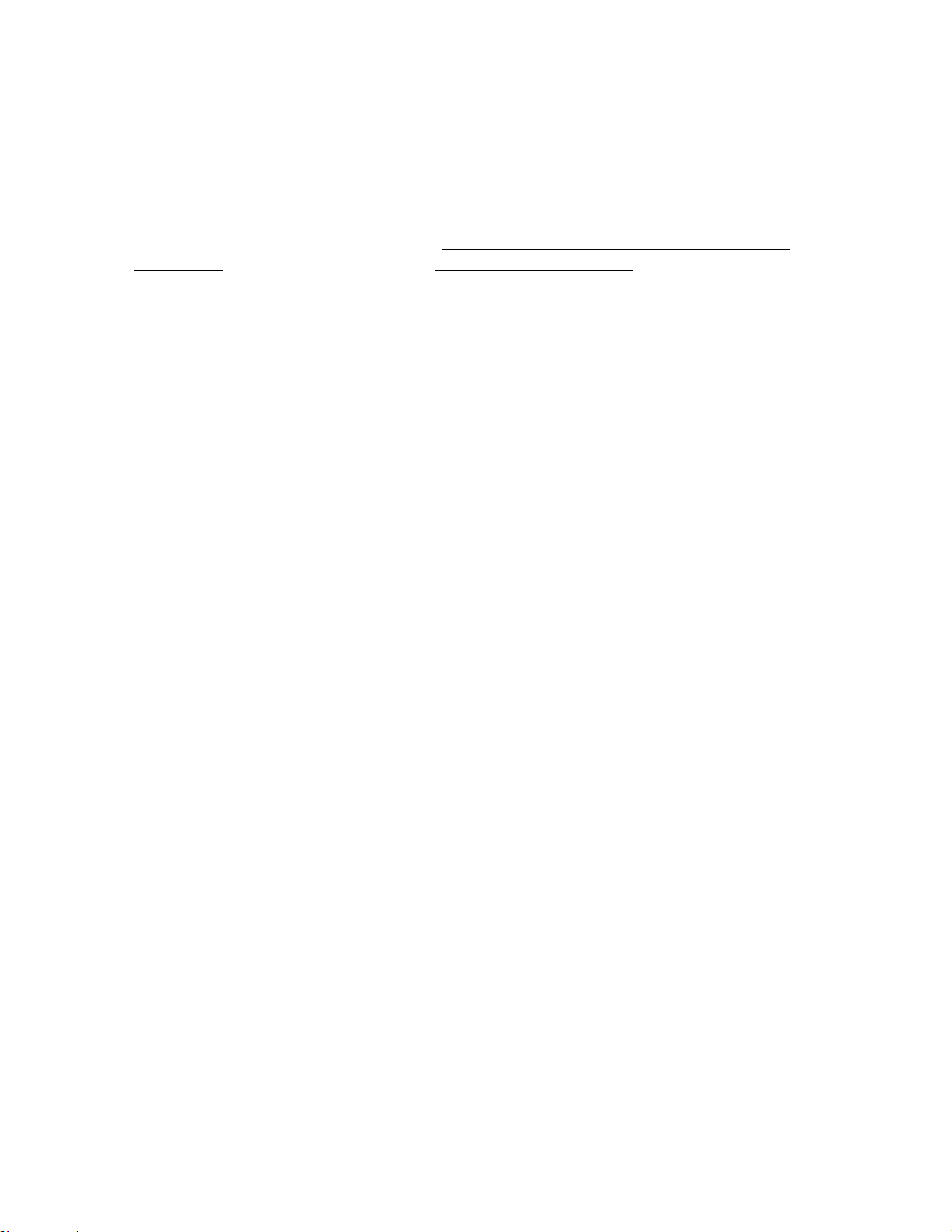

suspended from hanger rods, support the furnace from the bottom casing surface

at three (3) places, across both ends of the casing and across the casing, near the

middle of the furnace. Generally, a simple support frame for the furnace can be

fabricated from structural steel angle, threaded steel rod, and fastener hardware, refer

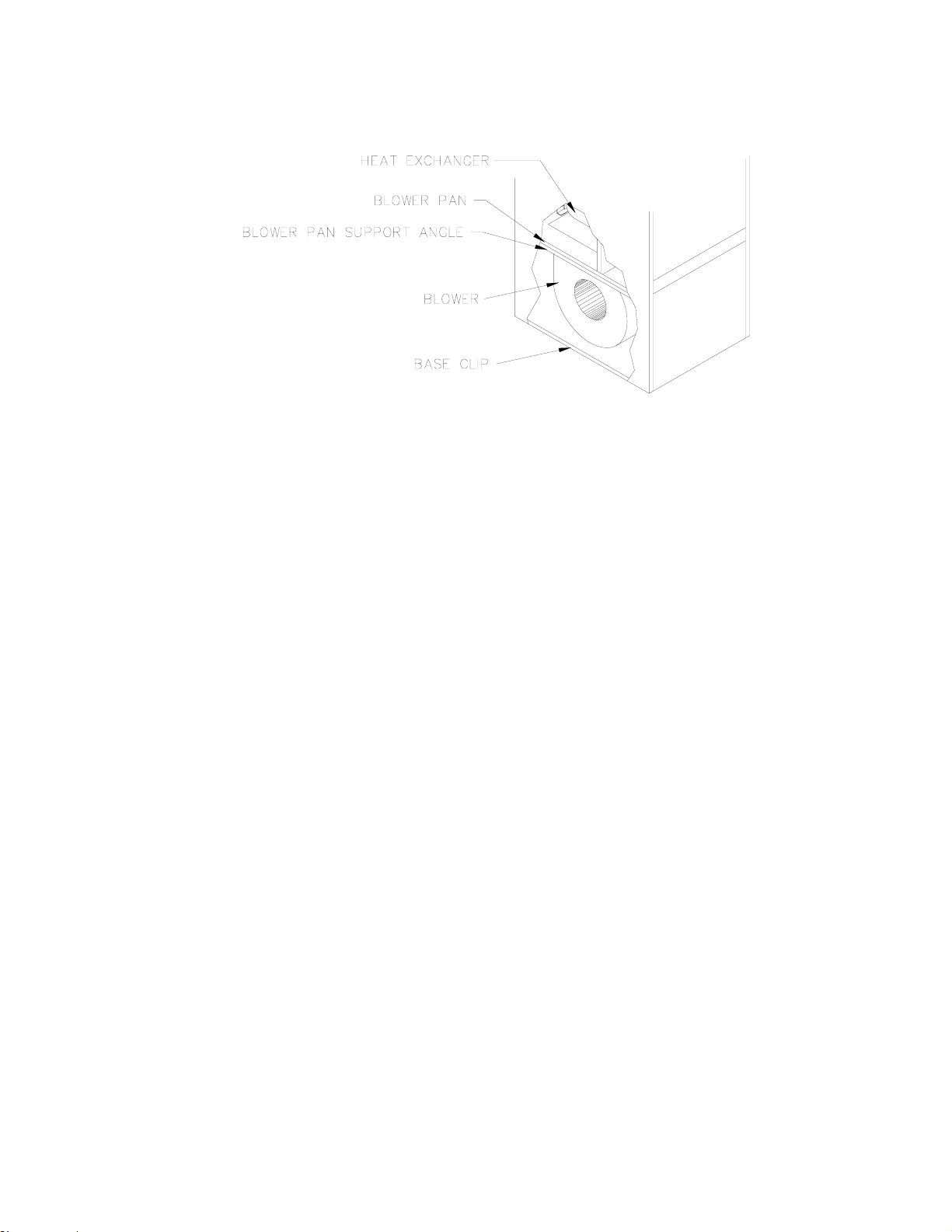

to Figure 1. Adjust the height of the support angles to level the unit in position.

INSTALLATION GUIDELINES

5

Page 7

Figure 1: Recommended Support Frame for Horizontal / Counterflow Furnaces

Closet and Alcove Installation

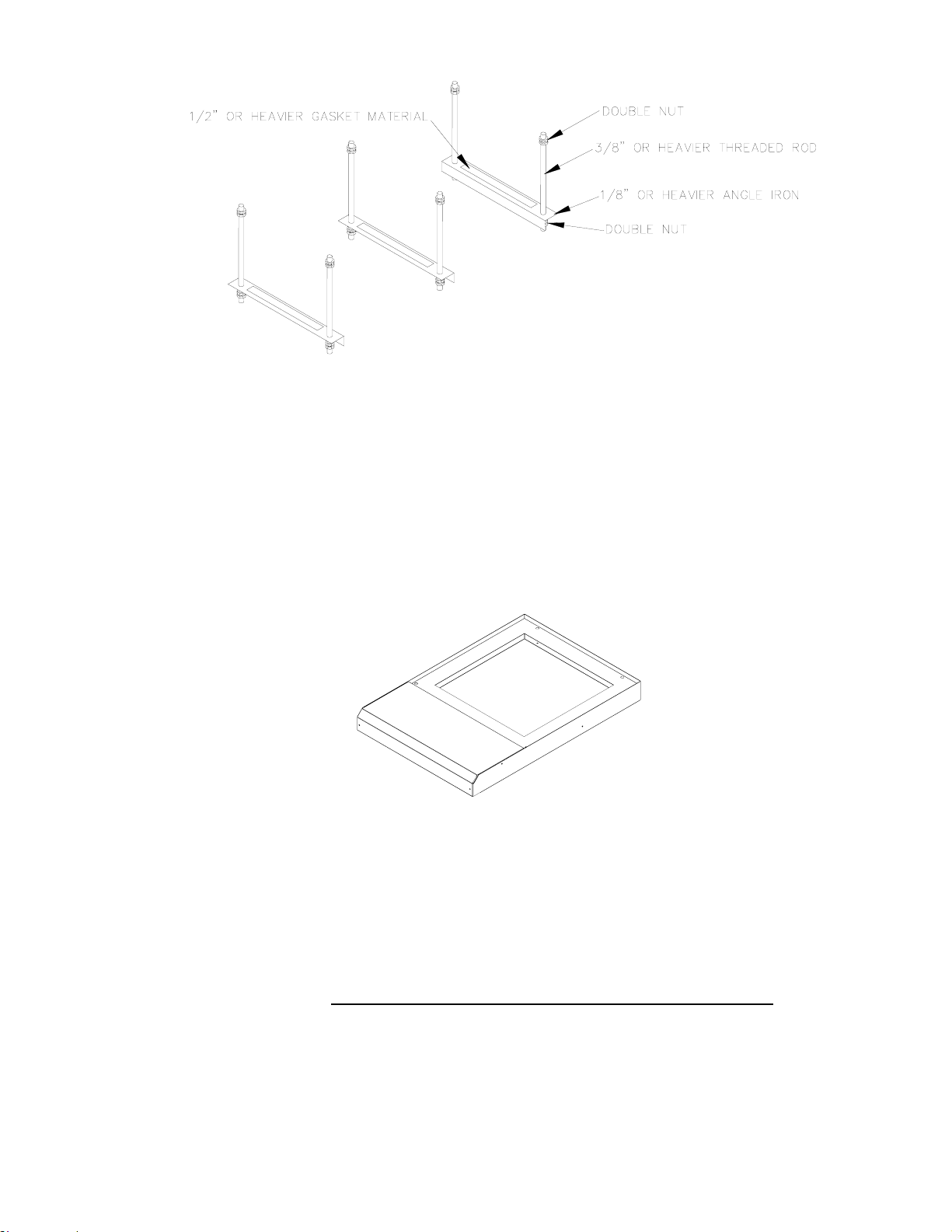

All furnace models may be installed in a closet or alcove on combustible flooring with

specified (standard) clearances to combustible construction. The horizontal /

counterflow furnace model requires an optional combustible surface-mounting

base (model # CSFB-HC68) for vertical installation (i.e., counterflow

configuration) directly on combustible materials, refer to Figure 2.

Figure 2: Counterflow Furnace Combustible Surface-Mounting Base

Standard Clearances

Standard clearances are mandatory minimum clearances from heated surfaces of the

furnace to combustible materials to assure protection from fire hazard during furnace

operation. (Refer to the Standard for the Installation of Oil-Burning Equipment, NFPA

31-2001, for definitions of combustible and non-combustible materials.)

6

Page 8

Accessibility clearances, which are typically greater, may exceed fire protection

clearances. Therefore, consider providing at least 24 inches of clearance from the front

(and the rear, for lowboy furnaces) of the furnace to obstructions and surfaces for

adequate service and maintenance access.

The minimum clearances from furnace casing surfaces to combustible materials are:

• 3 inches from casing sides and rear

• 8 inches from front casing of furnace to the closet door, with exception of:

o the lowboy rear flue model only requires 3 inches from front casing of the

furnace to the closet door

o the horizontal / counterflow furnace requires 22 inches from front casing of

the furnace to the closet door

• 9 inches from flue pipe/vent connector

• 3 inches from casing top

• 3 inches from any side of supply air plenum

• 3 inches above supply air ducts, within 6 feet of furnace

• For the horizontal / counterflow furnace only, when the optional combustible

surface-mounting base is used with the furnace in the counterflow configuration,

adequate clearances from the supply end surface of the furnace casing to

combustible surfaces are provided by the design of the mounting base.

Though these are approved clearances for these furnaces, space must be provided at

the front (18 inches minimum, 24 inches recommended) and at the rear of the furnace

for access, service, and replacement of the oil burner, air filter(s), circulating air blower,

and fan motor.

Air for Combustion and Ventilation

c CAUTION: Relief openings in the front or top of the furnace casing should not

be obstructed or blocked. These openings supply combustion and ventilation air

to the furnace.

Chloride, fluoride, iodide, and bromide bearing compounds when present, even in low

concentrations, in air supplied for combustion to the furnace, can result in accelerated

and severe corrosion of the heat exchanger and/or the venting system. This condition

can occur with less efficient furnaces, but is more likely to happen on furnaces with

efficiencies of 80% or greater.

7

Page 9

Often, household chemicals contain chloride-bearing compounds. There are many

compounds representative of this classification of chemicals. A few common examples

are listed below.

• Cleaning solvents

• Varnish and paint removers

• Bleaches

• Fabric softeners

• Water softener salt

• Tile adhesives

Avoid storing or using these chemicals within close proximity to the furnace. In addition,

avoid storing or using any chemicals, of an unknown and possibly flammable nature, in

close proximity to the furnace. If it is necessary to store or use chemicals in the same

space as the furnace, the area should be well-ventilated and all containers should be

sealed when not in use. If possible, keep chemicals in a separate, well ventilated, room

closed off from the furnace with a door.

The furnace shall be installed in a location within the building that permits a satisfactory

supply of air for combustion, ventilation, and proper operation of the venting system.

While all forms of building construction cannot be covered in detail in this manual, this

requirement may usually be met by application of one of the following methods in

ordinary building construction. However, applicable local installation codes always take

precedence and shall be followed.

The content of certain pertinent passages of NFPA 31-2001 on methods to obtain and

ensure adequate airflow to the furnace has been excerpted and, in some cases,

paraphrased below for reference purposes. Consult the Standard for the Installation of

Oil-Burning Equipment, NFPA 31-2001, for special cases and further details.

1. Utility Room (example of a confined space)

a. In buildings of conventional construction with normal air infiltration, two (2)

permanent openings connecting to a well-ventilated crawl space, attic, or

another large, well-ventilated internal area shall be provided. Each opening

shall have a minimum free area of one (1) square inch per 1000 BTUH of total

input rate (sum of the individual appliance input rates) of all appliances to be

installed in the utility room. One opening should be located near, or in, the

ceiling of the room and the other should be located near, or in, the floor.

b. In buildings of unusually tight construction (e.g. those having continuous

water vapor barriers; tightly-fitting, or weather-stripped, doors and windows;

and gasketed, caulked, or sealed outer wall joints and penetrations), wherein

infiltration and air exchange with the outdoors is very limited (0.35 air changes

per hour, or less), provision must be made to provide sufficient air for

combustion. The following method will usually be adequate to ensure

sufficient airflow into the space.

8

Page 10

Provide two (2) permanent openings, one (1) located within 12 inches of the

floor and one (1) within 12 inches of the ceiling, or roof, of the room. These

openings shall allow for direct exchange of air between the room and

outdoors. If required, ducting between the room and the outdoors shall be

provided.

• For horizontally -oriented ducts, each opening shall have a minimum free

area of one (1) square inch per 2000 BTUH of the total input rate (sum of

the individual appliance input rates) of all appliances to be installed in the

room.

• For vertically -oriented ducts, the minimum free area may be reduced to

one (1) square inch per 4000 BTUH of the total input rate (sum of the

individual appliance input rates) of all appliances to be installed in the

room.

• The minimum dimension of any air opening shall not be less than 3inches.

• When an opening in the outside wall must be provided, it should be

furnished with properly screened metal sleeves.

2. Full Basement (example of an unconfined space)

a. Where a furnace is installed in a full basement, in a building of conventional

construction with normal air infiltration, infiltration is normally adequate to

provide air for combustion and ventilation.

b. In buildings of unusually tight construction (such as those where weather

stripping and storm sash windows are used, and where basement windows

are also weather-stripped), one (1) permanent opening connecting to a wellventilated attic, or with the outdoors shall be provided, using a duct, if

necessary. This opening shall have a minimum free area of one (1) square

inch per 5000 BTUH of total input rate (sum of the individual appliance input

rates) of all appliances to be installed in the basement.

When an opening in the outside wall must be provided, it should be furnished

with properly screened metal sleeves.

If an exhaust fan, additional air consuming machines (e.g. an air compressor), or a

return air grill is present in the furnace room, there should be increased concern about

providing adequate airflow to the furnace. Additional efforts may be required to assure

an adequate supply of combustion and ventilation air is available to the furnace under

all conditions.

9

Page 11

Chimney Inspection

The chimney, vent, or any passageway for the stack gases to flow to the outdoor

atmosphere is a very important part of the heating system. No furnace, regardless of the

efficiency of the design, can perform satisfactorily when the chimney to which it is

connected is inadequate or in poor condition. Any of the following symptoms may

indicate a chimney has severe structural damage and is unsuitable for use.

• Chimney appears to be leaning to the side.

• Chimney appears to have structural damage, i.e. loose or missing blocks or

bricks, or excessive deterioration at mortar joints.

• Tile liner damaged or missing.

• Flue gas leakage along the length of the chimney between the chimney

connector and discharge termination.

• Excessive corrosion at the cleanout port or at the chimney connector entrance

into the chimney.

• Structural debris, i.e. mortar or tile liner flakes, in base of the flue way.

A qualified person shall inspect the chimney to confirm it is correctly sized for the

application, properly constructed, and in sound condition. Refer to the Standard for the

Installation of Oil-Burning Equipment, NFPA 31-2001, for details on proper chimney

sizing and construction. If needed, the chimney should be cleaned before installing the

furnace. Any accumulation of dirt or debris at the bottom of the flue should be removed.

Flue / Chimney / Vent Connector

c CAUTION:

• DO NOT install a manual damper in the chimney or vent connector.

• Motorized and thermally- activated type vent dampers are NOT

recommended for use on these furnaces.

It is desirable to install the shortest vent connector (also referred to as a flue or chimney

connector) possible with the fewest number of fittings, i.e. transitions and elbows.

Generally, 6-inch diameter, 24 Ga. or heavier, single wall, lock seam-type, galvanized

steel vent pipe and fittings are satisfactory materials for the fabrication of a vent

connector. However, always consult local codes and authorities for specific minimum

requirements.

For some installations, it may be prudent to turn the furnace flue elbow 90 degrees

clockwise, with respect to the front of the furnace, such that the elbow is open to the

right-hand side of the unit, rather than upward. Turning the flue elbow may better

facilitate connection of the vent connector piping to the flue elbow on the highboy and

front flue, lowboy furnaces. Due to the presence of the fan and limit control and the

wiring harness, the elbow may not be rotated 90 degrees counterclockwise. The

installer must carefully mark and cut a hole in the furnace housing to allow the vent

connector to pass through the housing.

10

Page 12

If desired, with the furnace flue elbow turned to the right, the standard furnace top front

panel (p/n 52-17346-1) may be replaced with the top front panel from the rear flue

lowboy model (p/n 52-17383-1). Refer to Appendix D: Replacement Parts for sketches

of these parts. Contact your Crown distributor to purchase this part.

All horizontal sections of the vent connector must slope upward not less than ¼ inch per

foot from the furnace to the vent termination. Long horizontal sections of the venting

system must be supported at least every five (5) feet with metal straps to prevent

sagging of the vent piping. Secure all joints in the vent connector with sheet metal

screws or equivalent fasteners. Vent piping must not be inserted beyond the inside wall

of the chimney flue.

Power (Side-Wall) Venting – Important Note Regarding

c CAUTION: Crown Boiler Company will NOT assume responsibility for damage

to, and deterioration of, exterior building materials, e.g. brick, siding, clapboards,

and etc., in close proximity to the vent terminal due to operation of a power

vented, oil furnace. This policy is applicable regardless of the cause of sooting.

Two (2) problems typically arise when power venting any oil-fired appliance.

1) Soot buildup may occur at an accelerated rate on critical components of the

furnace oil burner, e.g. the primary control flame sensor (“cad cell”), the burner

head, and oil nozzle.

2) Severe damage may occur to external surfaces of the structure in the event the

furnace continually produces a high level of smoke in the flue gases. Excess

smoke and soot can be produced for many reasons, some of which cannot be

successfully controlled by the installer and the appliance manufacturer.

NOTICE: Crown Boiler recommends the use of a chimney to vent residential oil

furnaces. If a power venter must be used, it is the responsibility of the installer

and power venter manufacturer to design, assemble, and demonstrate proper

operation of the power venting system with the furnace.

Draft Regulator

A barometric-type, draft regulator is supplied with the furnace. Installation or operating

conditions that produce excess amounts of draft can reduce the heating efficiency of the

furnace. The purpose of the regulator is to adjust and control the flow of flue gases from

the furnace by stabilizing the amount of chimney draft to which the furnace is subjected.

Generally, install the barometric draft regulator in the vent connector as close as

possible to the flue outlet collar of the furnace. However, always refer to the draft

regulator manufacturer’s installation instructions for application specific

recommendations.

11

Page 13

Duct Work and Air Conditioning

Design and installation of the duct system should follow the current guidelines of the Air

Conditioning Contractors of America (ACCA) or the American Society of Heating,

Refrigeration and Air Conditioning Engineers, Inc. (ASHRAE). Refer to the Residential

Duct Systems, Manual D, from the ACCA, and the ASHRAE Handbook Fundamentals

volume, from ASHRAE, for recommended practices in duct system design and

installation. To obtain copies of these publications for a fee, contact the ACCA and the

ASHRAE at the addresses given in Appendix A of this manual.

All furnaces are tested over a range of external static pressure that simulates the airflow

resistance of the ductwork, fittings, and diffusers connected to the furnace for a typical

(average) duct system. The furnace blower and blower motor have been selected to

work successfully against the following range of duct system resistance.

Recommended range of duct system resistance for all models: 0.2 to 0.5 in. W.G.

external static pressure.

Due to the need to maintain an adequate supply of combustion and ventilation air, the

furnace shall not be installed in small room without return air duct system. A duct the full

size of the furnace return air opening shall extend to a location outside the furnace

room.

If the furnace is used in connection with summer air conditioning (cooling), the furnace

should be installed in parallel with, or on the upstream side of, the evaporator coil to

avoid water vapor condensation in the furnace heat exchanger. If the cooling unit is

installed in a parallel flow arrangement, dampers (or other means used to control

airflow) should be provided to prevent chilled air from entering the furnace. If such a

damper is manually operated, it must be equipped with a means to prevent operation of

either unit, unless the damper is placed in either the full heat or full cool position.

NOTICE: Return air grilles and supply registers in the air distribution system

should never be obstructed.

Air Filter Mounting

c CAUTION: If cutting openings in the furnace casing is required, DO NOT cut

any supporting clips or angles. Cut as close to the scribed line as possible, but

DO NOT cut the base clip or blower pan support angle.

Lowboy furnaces are factory-equipped with permanent-type, air filters located above the

blower compartment, in the rear of the furnaces.

NOTICE: Horizontal / counterflow furnaces are not factory-equipped with an air

filter or filter rack. Furthermore, the furnace blower compartment does not contain

enough free space to permit an air filter to be mounted within the furnace casing.

However, the installer should supply, or fabricate, a filter rack and mount an air filter in

the return air plenum above, or upstream of, the furnace blower compartment.

12

Page 14

On the highboy furnace, it is necessary to cut the return air opening in the lower side, or

rear, of the casing depending upon the needs of the specific installation, refer to Figure

3.

Figure 3: Cutaway view of fan section of a typical highboy furnace.

The side casings have each been pre-punched with four (4), square, knockout openings

for use in locating the proper position for the return air filter rack. On the side of the

furnace, where the return air duct will attach, scribe a line connecting the outside edges

of the knockout openings to form a rectangle. Using a punch, or a large screwdriver,

and a hammer, remove the knockouts and cut the return air opening in the casing.

Sheet metal shears, or a power metal cutting tool, will be required to cut the casing.

Position the open end of the filter rack to the front of the furnace to permit access for

filter replacement. Align the filter rack with the rectangular hole and mark the locations

on the casing of the pre-punched mounting holes in the filter rack flange. Drill pilot holes

in the casing and permanently attach the filter rack to the furnace with screws, or poprivets (these fasteners are not included). Connect the return air plenum to the filter rack

and slide the air filter into position.

13

Page 15

Electrical Connections

NOTICE: All field wiring must conform to local, state, and national installation

codes.

A disconnecting switch equipped with overcurrent protection rated at 15 A. (e.g. a time

delay-type fuse or inverse time, circuit breaker) should be installed in the service line for

shutting down and protecting the furnace and electrical system.

Since the furnace is entirely pre-wired at the factory, it is only necessary to connect the

building electrical service lines to the two (2) pigtail wires extending from the fan center

junction box. The fan center is mounted inside the furnace burner compartment or

mounted on the front exterior of the furnace, in the case of the horizontal / counterflow

model. The service lines to the furnace should be no smaller than 14 Ga., insulated

copper wire with a temperature rating of 60ºC, or greater.

Connect an equipment ground wire to the furnace at the fan center junction box. If

wiring is run through metal electrical conduit, it may not be necessary to run a separate

equipment ground wire. Consult local codes and authorities for specific minimum

requirements.

A two (2) wire connection to the room thermostat from the oil primary control is also

necessary. This is typically a low voltage (24 VAC) circuit. Consult the National

Electrical Code, ANSI/NFPA 70-2002, for guidelines for proper wiring methods and

materials for this circuit.

Refer to the electrical diagrams contained in Appendix B of this manual for an electrical

schematic, a connection diagram, and operating instructions.

Room Thermostat

A room thermostat is not furnished with this furnace. However, a thermostat is required

to properly operate the furnace control system in a typical residential heating

application.

14

Page 16

The room thermostat should be located on an interior wall in the natural circulating path

of the room air.

The thermostat should not be installed in a location where it is directly exposed to,

• cold air infiltration, i.e. drafts from outside openings such as windows and doors,

• air currents produced by supply air registers, and

• heat from a nearby source, such as a fireplace, electrical appliances, lamps,

solar radiation, a wall enclosing warm air ducts, a chimney, or a flue gas vent.

These phenomena will adversely influence the operation of the thermostat, preventing it

from properly controlling the room temperature. Conversely, avoid installing the room

thermostat in a location where the natural circulation of air is blocked, such as behind

doors, in shelves, or in corners.

Generally, a room thermostat should be set at the lowest temperature that is

comfortable to the building occupants. This will result in the lowest cost to heat the

building.

Combustion Chamber

The furnace combustion chamber is a hollow, circular cylinder sealed at the bottom end

and open at the top end. The chamber is made of a lightweight, insulating, “soft”,

refractory material. The refractory material is composed of organically bound, aluminasilica fibers that provide a high temperature region for combustion of the oil to occur.

This type of material exhibits quiet operation and improved combustion efficiency due to

faster heat-up times compared to hard, dense, ceramic refractory materials.

Oil Burner and Oil Nozzle Installation

c CAUTION: This oil furnace is designed to use No. 2 distillate fuel (home

heating) oil only.

This furnace is designed to utilize any one (1) of the following four (4), specially

modified, oil burners interchangeably:

• R.W. Beckett Corp. model AF burner, specification #’s CI3701 & CI3702,

• R.W. Beckett Corp. model NX burner, specification # CI4002

• Carlin Combustion Technology, Inc. model EZ-1HP, specification #

8528200BCLBR1, and

• Riello Canada Inc. model 40-F3, specification # C8511477.

NOTICE: NO other burners may be used in this application.

The heat output from the furnace is fixed, based on the size of nozzle installed in the oil

burner. Four (4) heat input rates are permissible: 85,000, 105,000, 120,000, and

140,000 BTUH.

• For the Riello 40-F3 burner option only, the maximum heat input rate is

133,000 BTUH.

15

Page 17

Nozzle selection (i.e. heating capacity of the furnace) shall be based on a rate of heat

loss (heating load) calculation for the building. These calculations should be made

according to the manuals provided by the Air Conditioning Contractors of America

(ACCA) or the American Society of Heating, Refrigeration and Air Conditioning

Engineers, Inc. (ASHRAE).

Refer to the Residential Load Calculation, Manual J, from the ACCA, and the ASHRAE

Handbook Fundamentals volume, from ASHRAE, for the recommended procedure to

compute the design heating load of a residence. To obtain copies of these publications

for a fee, contact the ACCA and the ASHRAE at the addresses given in Appendix A of

this manual.

The oil burner is shipped in a separate carton from the furnace. In the field, it is

necessary to mount the oil burner, secure it to the furnace, and connect the wiring

harness to complete the installation. Refer to the following steps.

1) Remove the oil burner from the shipping carton and remove any shipping

materials adhering to the burner.

2) If it is necessary to adjust the heating capacity of the furnace, by changing the oil

burner nozzle, refer to these instructions. Also, consult the oil burner

manufacturer’s operating instructions (included with the burner) for detailed

instructions on this procedure.

a) The oil nozzle is factory installed in the oil burner. To change the oil

nozzle, remove the nozzle through the front end of the burner air tube. (If

the oil burner is already installed, the oil burner can be removed from the

heat exchanger mounting plate to gain access to the nozzle. Alternatively,

the nozzle and electrode assembly may be removed from the rear of the

burner assembly without removing the oil burner from the furnace.)

b) Install an appropriate replacement nozzle of the correct size, spray angle,

and spray type. Refer to the Specification Sheets, in Appendix C of this

manual, for nozzle recommendations.

3) The furnace may have been handled roughly while in transit. Under some

conditions, the combustion chamber can shift out of position. Check for proper

alignment of the burner air tube with the circular opening in the combustion

chamber and trial fit the burner to check the insertion depth of the oil burner into

the combustion chamber.

The end of the burner air tube should be inserted no farther than 1/4 inch back

from the inside surface of the combustion chamber, refer to Figure 4. Do not

allow the burner tube/end cone to physically touch or protrude into the chamber.

High temperatures in the combustion chamber can result in damage to the tube,

the end cone, or both. A distance greater than 1/4 inch back from the inside

chamber wall may cause flame impingement on the combustion chamber wall

and subsequent sooting or carbon char buildup.

16

Page 18

Figure 4: Side view of correct burner insertion into combustion chamber

4) Push the burner flange gasket (included with the burner) on to the burner

mounting plate threaded studs. Seat the gasket against the mounting plate.

5) Using fasteners supplied in the parts bag with each furnace, three (3) 5/16 in.

brass hex nuts and three (3) steel flat washers, install and secure the burner to

the mounting studs on the burner mounting plate, refer to Figure 5. (For

counterflow / horizontal units, refer to the next section “Horizontal / Counterflow

Furnace Setup”)

Figure 5: Installing and Securing the Oil Burner to the Furnace Mounting Plate

NOTICE: For the Riello 40-F3 burner only, an insulating annulet (included with

the burner) must be installed over the end of the burner air tube. The annulet fills

17

Page 19

the gap between the outer surface of the air tube and the inner wall surface of

the combustion chamber opening to provide a seal, keeping hot combustion

gases within the chamber.

6) Insert and secure the cable or conduit from the wiring harness in the burner

junction box. Snap together the two (2) mating, multipin quick connections, on

the wiring harness from the furnace fan center and the wiring harness of the oil

burner, inside the burner junction box.

• For the Riello 40-F3 burner only, wiring connections are made inside

the burner sound cover (an orange sheet metal shroud covering the

front of the burner). Secure the cable or conduit to the burner

enclosure back plate.

The oil burner provided with this furnace requires initial inspection, set-up, and proper

adjustment. Refer to this manual and the oil burner manufacturer’s operating

instructions for detailed information on the following items.

• Initial firing of burner

• Adjusting the burner combustion air

• Adjusting the fuel pump pressure

• Setting the draft control

NOTICE: This oil furnace must be installed and adjusted by only qualified oil

heating contractor using calibrated combustion test instruments to ensure safe

and reliable operation of the furnace.

Fuel System Installation

In situations where the oil storage tank is installed at the same level with, or above, the

burner, a single oil supply line run from the oil tank to the burner will be usually be

adequate. No return line will be required. If the oil tank is installed below the burner and

the lift exceeds approximately 8-ft. (6-1/2 ft. for the Riello 40-F3 burner), an oil supply

line and an oil return line are recommended.

Refer to the

Standard for the Installation of Oil-Burning Equipment, NFPA 31-2001, and

the oil burner operating instructions for detailed information on oil storage tank & oil

supply/return line installation.

NOTICE: We recommend installing a high efficiency oil filter, in the oil supply line,

capable of filtering 10 to 20 micron diameter (or preferably smaller) particles from

the fuel.

If available, the use of ultra-low or low sulfur (less than 0.0015% S and 0.0015 -

0.05% S, by weight, respectively), no. 2 fuel oil is highly recommended. Low sulfur

fuel oil can help to significantly reduce instances of blockage and corrosion of the oil

burner fuel delivery system (especially the nozzle), the furnace heat exchanger, and the

flue gas venting system. Air pollutants emitted by the furnace and the typical

malodorous smell of oil combustion will be reduced.

18

Page 20

Horizontal / Counterflow Furnace Setup

The horizontal / counterflow furnace is shipped from the factory upright for vertical

installation (counterflow configuration). If the furnace is to be installed lying down on the

right-hand or left-hand side (horizontal configuration), the positions of the oil burner and

the fan and limit control thermostat may have to be changed. The horizontal furnace

may be turned end for end, or rotated, making the top into the bottom, as shown in

Figure 6. Refer to the following instructions for installing the oil burner and thermostat.

Figure 6: A horizontal furnace rotated 180° (or flipped end for end) to reverse

airflow direction

1) When the furnace is installed in the horizontal configuration, the oil burner

must be mounted in an upright position. It will be necessary to cutoff one (1) of

the threaded burner-mounting studs before attempting to install the burner. Trial

fit the burner to the burner mounting plate to determine which stud to remove. (A

rotary tool with a cutting (abrasive) disk or a hacksaw should work well to remove

the stud.) A machine screw (furnished with the parts package) will substitute for

the removed stud and provide a third point to secure the burner flange to the

burner mounting plate. Thread the screw through the burner-mounting flange and

into the open hole within the burner mounting plate.

2) Install the flange gasket and the burner on the mounting plate threaded studs.

Using fasteners supplied in the parts bag with each furnace [use two (2) or three

(3) 5/16 in. brass hex nuts and flat washers, as required], secure the burner to

the mounting studs on the burner mounting plate.

3) Secure the electrical conduit of the wiring harness to the oil burner junction box

(or for the Riello burner, the burner enclosure back plate) with the hardware

provided.

19

Page 21

4) When the furnace is installed in the horizontal configuration, the high limit

and fan control must also be located in the upper position on the casing when the

furnace is placed in the final installed position, refer to Figure 7. If the control

must be relocated, remove the cover of the control to gain access to the

mounting screws. Remove the mounting screws and the control. Insert the

control into the alternate mounting hole in the casing and mark the screw

locations. Drill pilot holes for the new screws. Install the control in the new

mounting location and secure it with the mounting screws. Replace the cover of

the control. A metal, snap-in cap is furnished with the furnace to close the

unused hole, for the control, in the casing.

Figure 7: Correct locations for the horizontal furnace high limit and fan control.

20

Page 22

Initial Burner Operation

c WARNING: To avoid possible explosion, DO NOT attempt to light the burner if:

• Oil has accumulated in the base of the combustion chamber.

• The furnace is full of fuel vapors.

• The combustion chamber is very hot.

c CAUTION: The oil burner must be installed and adjusted using recently (within

the last year) calibrated combustion instruments by a qualified heating contractor

prior to placing the furnace in operation. Refer to this manual and the oil burner

instruction manual for details.

c CAUTION:

• To minimize initial fuel oil and combustion odors, ventilate the building

well while operating the furnace for the first time.

• Do not run the oil pump dry (without oil) for more than two (2) minutes.

Damage to the oil pump may result.

To initially operate the furnace:

1) Turn the electrical disconnecting switch to the “OFF” position.

2) Set the room thermostat above room temperature.

3) Be sure the oil tank is full of clean # 2 fuel oil.

4) Open all shutoff valves in the oil line.

5) Turn on the electrical disconnecting switch and prime the burner oil pump

according to the pump manufacturer’s instructions.

6) When ignition is established, make a temporary air adjustment for a clean,

smoke-free flame. At this point, the final burner adjustment should be made

using test instruments to measure oil pump pressure, smoke number, carbon

dioxide (CO

• Refer to item (4) under the Troubleshooting section of this manual for a list

of required test instruments.

In order to achieve the best combustion efficiency, the following procedure is

recommended.

INITIAL OPERATION OF THE FURNACE

), carbon monoxide (CO), draft, and flue gas temperature.

2

21

Page 23

7) Measure the oil pump pressure. If required, adjust it to deliver the

appropriate pressure for the burner. The oil pump should be set to produce,

• 130 PSIG, for the R.W. Beckett model AF burner,

• 150 PSIG, for the R.W. Beckett model NX burner,

• 140 PSIG, for the Carlin Combustion model EZ-1HP, and

• 150 PSIG, for the Riello model 40-F3.

NOTICE: On the Riello model 40-F3 burner only, the oil pump port threads

conform to British Standard Parallel Pipe (BSPP) thread design. Pressure

gages or pipefittings with American National Standard Taper Pipe (NPT)

threads will NOT mate with the BSPP design. Special gages compatible with

BSPP thread, or adapter fittings, are required.

8) Carbon Dioxide (CO2) and Carbon Monoxide (CO) – In order to assure that

proper and safe combustion is taking place, carbon dioxide and carbon

monoxide measurements must be taken. A CO2 reading within the limits of

Table 1 with no measurable CO is desirable. The maximum acceptable CO

reading is about 50 PPM. If the CO reading is too high, open the burner air

shutter, or air band, slightly to permit more combustion air to the flame.

Recheck the CO level and adjust as required.

NOTICE: On the Riello 40-F3 burner only, it will be necessary to remove

the oil burner sound cover to make adjustments to the oil pump pressure and

airflow. The presence of the burner sound cover over the burner acts to

restrict airflow to the burner. Thus, combustion quality will be adversely

affected when the cover is installed after airflow adjustments are made. If

adjustments to burner airflow are made w/o the burner cover, it is necessary

to confirm these adjustments produce satisfactory smoke, carbon dioxide,

and carbon monoxide readings w/ the burner cover installed. Repeated

adjustments and tests may be required.

9) Draft – Draft measurements should be taken through the overfire port and in

the vent connector, not more than 12 inches away from the furnace outlet. A

5/16 in. hex washer head bolt plugs the overfire port in the burner mounting

plate. Remove the bolt and insert a suitable draft measurement gage. After

the chimney (or stack gas passageway) has warmed up to operating

temperature, approximately 15 to 20 minutes of burner operation, adjust the

barometric damper to obtain the correct overfire draft reading. The overfire

draft should read 0.02 in. W.G. The draft measured at the flue (stack draft)

should read no more than 0.05 in. W.G.

NOTICE: The overfire draft is the more important measurement and

should be used to adjust the setting of the barometric draft control.

22

Page 24

10) Flue Gas Temperature – The flue gas temperature will vary depending on

heat input rate, air temperature rise across the heat exchanger, and air

flowrate through the furnace. To prevent excessive water vapor condensation

from the flue gases, the gross flue gas temperature should not fall below

330ºF. In addition, if the gross flue gas temperature exceeds 650ºF, the

heating efficiency of the furnace will be reduced.

To reduce high flue temperatures, after properly adjusting the burner, check

for blocked supply/return airflow. Remove any blockages, increase fan

speed, or consider reducing the furnace heat input rate. Also, verify there is

no air leakage into the combustion chamber from around the burner mounting

flange or heat exchanger mounting plate. If flue gas temperatures are too low,

consider increasing the heat input rate or reducing the amount of

supply/return airflow.

11) Cycle the furnace several times to verify the burner lights off and shutsdown

smoothly without excessive noise or smoke production.

Table 1: Oil Burner Application and Specifications for the Crown Furnaces

Furnace Model:

Burner Model: R.W. Beckett, AF R.W. Beckett, NX Carlin Combustion,

Standard Nozzle: Delavan, 0.75 GPH

/ 80 deg. angle /

hollow cone

Oil Pump Pressure (PSIG): 130 150 140 150

Burner Head Type: F3 Standard Standard F3

Head / Turbulator Setting: Z = 1.125 in. 3 A = 0.65 2

Air Band Setting: Fully-closed - 0.6 Air Shutter / Damper Setting: 5 - Fully-closed 3

Overfire Draft (in. W.G.):

Smoke Spot, Max. (Bacharach Scale):

Carbon Dioxide, CO2, Maximum (%):

Carbon Dioxide, CO2, Minimum (%):

Carbon Monoxide, CO (PPM)

Oil Solenoid Valve Equipped: No Yes No Yes

Prepurge Time (sec):

Postpurge Time (sec):

Ignition Type:

Delavan, 0.60 GPH

/ 60 deg. angle /

semi solid (W)

All

EZ-1HP

Delavan, 0.65 GPH

/ 60 deg. angle /

hollow cone

0.02

# 1

13

12*

0

None

None

Interrupted

Riello, 40-F3

Delavan, 0.70 GPH

/ 60 deg. angle /

hollow cone

* When operating these furnaces at the lowest input rate (84,000 BTUH), the carbon dioxide (CO

value may not be able to be adjusted above 12%.

a problem.

This is normal and does not necessarily indicate

Supply/Return Airflow and Air Temperature

The supply/return airflow shall be set to obtain an air temperature rise, across the

furnace, in the range of 70 to 100ºF. Since the flow resistance of each duct system is

slightly different, the airflow (fan speed) may have to be changed in the field to achieve

a satisfactory temperature rise.

)

2

23

Page 25

One way to measure the temperature rise across the furnace is to insert temperature

measuring devices (e.g. thermometers) into the return air duct and into the supply air

duct about 12 inches from the furnace. After the furnace has been firing continually for

over 20 minutes, read the temperature difference between the two (2) thermometers.

The temperature difference should not exceed 100ºF, nor be less than 70ºF. A

temperature rise of 85ºF is considered to be optimum for comfort. For better energy

efficiency, a temperature rise closer to 70ºF is recommended.

The blower (fan) speed fan is adjusted by changing the fan motor winding energized by

the control system. The furnace is set on the lowest fan speed, “L”, at the factory, refer

to Table 2. To adjust the fan speed, follow this procedure.

a. Turn off all electrical power to the furnace at the disconnecting switch.

b. Remove the blower compartment access door.

c. Move the orange wire from the low speed terminal block, marked “L”, to the next

higher fan speed (medium low), marked “ML” on the terminal block, refer to

Figure 8. Other available higher fan speeds are medium high, marked “MH” and

high, marked “H”.

NOTICE: The red wire is normally positioned on the high fan speed, for

cooling applications. However, the red wire may be moved to another

terminal block position, as required.

d. Replace the blower compartment access door.

e. Restore electrical power to the furnace at the disconnecting switch.

With the furnace operating, measure the air temperature rise across the furnace again.

If the value does not fall in the range of 70 to100ºF, repeat the above procedure.

Figure 8: Blower Motor Terminal Blocks and Wiring

24

Page 26

Furnace Limit and Blower Controls

All furnaces are equipped with a combined thermostatic high temperature limit and

blower (fan) control. The high temperature limit is set such that it does not permit a

supply (discharge) air temperature above 200ºF.

The thermostatic fan control should be set so the greatest fuel utilization efficiency of

the furnace is obtained. Generally, a blower “ON” setting of 130ºF should give the best

result. After the burner shuts down, the circulating air blower will continue to operate

until the air temperature inside the furnace falls below the lower setting on the fan

control.

This delay on blower shutdown extracts residual heat from the furnace heat exchanger

that would ordinarily be lost to the outdoor atmosphere. If a longer, or shorter, cooldown

period is desired, the fan control differential setting may be reset to lengthen, or shorten,

the cycle as desired. Refer to Table 2 for the standard fan and high limit control settings.

Table 2: Standard Furnace Fan / Limit Control and Speed Settings

High Limit Thermostat Setting (deg. F.): 230 (highboy / lowboy models)

190 (horizontal / counterflow model)

Fan “On” Setting (deg. F.): 130

Fan “Off” Setting (deg. F.): 100

Standard Fan Speed for 105 MBTUH Input Rate: Low, Orange Wire to “L” Terminal

In addition to the combined fan and limit control, the horizontal / counterflow furnace is

equipped with an auxiliary high limit temperature control located in the blower

compartment, refer to the electrical diagram in Appendix B. The purpose of this control

is to prevent overheating of the blower motor and air filter(s), if airflow is severely

reduced.

If the duct system becomes partially, or totally, blocked or the furnace air filter(s)

become excessively dirty causing the blower to fail to circulate enough air, the

thermostatic high temperature limit (or, if equipped, the auxiliary high temperature limit)

may activate to prevent very high discharge air temperatures from occurring.

Should airflow be restricted, the furnace might cycle on and off too frequently or become

inoperative. To correct this condition, verify that all supply and return dampers and

registers in the air distribution system are open. If this fails to resolve the problem, turn

off the electrical power to the furnace. Remove the blower compartment access door to

examine the air filter(s) and blower for blockages or a loose blower wheel. (On the

highboy and horizontal / counterflow furnaces, air filters should be mounted external to

the furnace casing.) If possible, correct the condition by cleaning or replacing the air

filter(s), freeing the blower wheel of any foreign materials, or securing the blower wheel

to the fan motor shaft. Always replace the blower compartment access door when

service is finished. Restore electrical power to the furnace.

25

Page 27

Room Thermostat

Most room thermostats are equipped with user adjustable, or selectable, levels of heat

anticipation. This feature helps to reduce the amount of room air temperature overshoot

that occurs after a heating cycle.

To adjust the heat anticipator, measure the electrical current output of the oil burner

primary safety control to the room thermostat. (If measurement is not possible, the value

of current output may be marked on the cover of the control). Set the thermostat heat

anticipator to match the electrical current output of the oil primary safety control.

Instructions to Our Customer / End User

! WARNING: If the burner does not operate properly after depressing the oil

primary reset button three (3) times, turn off the electrical power to the furnace

and close the manual oil shutoff valve. Immediately contact a qualified heating

contractor for service.

Before leaving a new installation, the installer should show the customer or end user

where the furnace instruction manual is kept. He should also discuss the following

points:

1) Describe the general operation of the furnace and, if properly equipped, the

cooling system.

2) Show the location of the furnace air filter(s) and those in the duct system, if

equipped. Demonstrate how to remove, clean, and replace the air filter(s).

3) Demonstrate how to set and adjust the room air temperature using the room

thermostat.

4) Demonstrate how to operate (turn on and off), the heating system and, if properly

equipped, the cooling system and the circulating air blower.

5) Show the location of the oil primary safety control in the furnace. Describe when

and demonstrate how to depress the oil primary reset button.

26

Page 28

Troubleshooting

c WARNING: When testing electrical equipment, always follow standard

electrical safety procedures.

Before beginning these troubleshooting procedures, always review these basic points.

1) Check for 120 VAC power to the furnace. If there is no voltage, check the

disconnecting switch for circuit breaker trip or blown fuses.

2) Make sure the room thermostat is set on the heating mode and is “calling for

heat”.

3) Check for sufficient oil supply and that all oil shutoff valves are open.

4) To successfully service this oil furnace, the following recently (within the last

year) calibrated instruments must be available.

5) Be familiar with the correct operation of these instruments as well as how to

adjust the oil burner settings (refer to burner manufacturer’s literature).

A. Symptom: Furnace does not operate.

Items to check:

SERVICE

• Smoke spot test kit with Bacharach-type oil burner smoke scale

• Carbon dioxide (CO2) and carbon monoxide (CO) test kit or analyzer

• Flue gas temperature measuring instrument

• Draft gauge, capable of measuring 0.01 to 0.25 in. W.G. draft

(Draft is the pressure differential between the static pressure measured in

the vent pipe, or just above the combustion chamber, and the indoor

atmospheric pressure. Under normal operating conditions, it will have a

negative value, i.e. the pressure in the combustion chamber and the vent

system are less than room air pressure.)

• Multimeter (analog or digital type)

• Oil pressure gauge, capable of measuring at least 0 to 200 PSIG

• Burner electrode and nozzle setting gauge

c WARNING: Repeated operation of the oil primary safety control

reset button can cause a build-up of unburned oil in the combustion

chamber. An accumulation of oil in the combustion chamber is a

hazardous situation and may cause a fire or explosion.

1) Make sure the disconnecting switch is “ON” and the circuit breaker has

not tripped, or fuses have not blown.

2) Confirm there is 120 VAC at the fan center junction box.

27

Page 29

3) Confirm the room thermostat is wired correctly, set on the “HEAT”

mode, and “calling for heat”.

4) For all primary controls, lockout can be confirmed by measuring

voltage from the oil primary safety control to the burner motor. If none,

depress the oil primary reset button. [On the Honeywell oil primary

control, lockout has occurred if the indicator light (an LED) is rapidly

flashing; depress the oil primary reset button.]

If the burner does not operate properly after depressing the reset

button three (3) times, turn off the electrical power to the furnace

and close the manual oil shutoff valve. Immediately contact a

qualified heating contractor for service.

B. Symptom: Burner short cycles or “locks out” on oil primary safety control.

Items to check:

1) Fuel oil tank nearly empty or oil flow restriction. Refill oil tank, replace

oil filter, open all shutoff valve(s), and purge oil line(s) of air.

2) If the oil primary control has not “locked out” (e.g., on the Honeywell

primary control, the indicator light is not flashing), measure the

electrical current to the room thermostat. Set the heat anticipator on

the room thermostat to the current value measured. Also, check the

wiring between the thermostat and primary control to be sure it is

correct and no loose connections exist.

3) Inspect the burner flame sensor, “cad cell”, to be sure the lens is clean

and the cell is correctly aimed at the flame.

4) Inspect the burner oil nozzle for blockages and signs of deterioration.

Replace the nozzle, if required. Also, measure and reset the electrode

gap and alignment. If badly worn or deformed, replace the electrodes.

(Refer to the burner manufacturer’s instructions.)

5) Confirm there is a strong spark across electrodes. Generally, viewing a

spark jump across the electrodes is sufficient indication the ignition

transformer is operating correctly. Testing an electronic ignition

transformer with a transformer tester is generally not

recommended.

6) Inspect the heat exchanger through the cleanout ports for signs of

excessive soot, scale buildup, or blockage. If a heavy deposits are

present, clean the heat exchanger.

28

Page 30

C. Symptom: Burner short cycles on high limit thermostat, but does not “lock

out” on oil primary safety control.

Items to check:

1) Open dampers or registers in the air distribution system. Clear any

duct system restrictions.

2) Inspect and clean all air filters in the air distribution system.

3) Inspect blower for interference with rotation or locked rotor condition.

Also, confirm the blower wheel is secured to the fan motor shaft.

4) The fan motor or run capacitor may be damaged. Test and replace the

motor or capacitor, as required.

5) Increase fan speed.

D. Symptom: Unable to achieve clean combustion by making burner air

adjustments.

Items to check:

1) Measure the burner air tube insertion depth and alignment. The end of

the tube should not protrude inside the combustion chamber. The end

of the tube should be approximately ¼ inch away from the inner wall

surface of the combustion chamber.

2) Inspect the oil nozzle for excessive wear, blockage, or deterioration.

Measure and, if necessary, reset the nozzle depth or turbulator

location with respect to end of the burner head. Replace the nozzle, if

necessary (refer to the oil burner manufacturer’s instructions).

3) Measure the oil pump pressure. If required, adjust the pressure to

burner nameplate value. (This is the typical minimum pressure

required to obtain the full input rate from the furnace).

4) Verify the burner is configured as specified in Table 1 and adjusted

according to the Initial Burner Operation section of this manual and

the burner manufacturer’s instructions.

5) Measure the overfire draft. If required, adjust the barometric damper to

increase the stack draft to obtain an overfire draft of 0.02 in. W.G. with

the burner operating. (This is the typical minimum draft required to

obtain the specified flue gas combustion analysis values given in Table

1.) If the specified overfire draft cannot be obtained with a stack draft of

0.02 in. W.G., the heat exchanger may be partially blocked and could

require cleaning.

29

Page 31

6) Measure the draft at the point where the vent connector attaches to the

heat exchanger flue pipe. With the burner operating, the stack draft

should not exceed 0.05 in. W.G. If the stack draft has been adjusted

above this value to give the proper overfire draft, the heat exchanger

will require cleaning.

If there is little or no stack draft, the chimney flue way may require

cleaning, the chimney is too restrictive, or a downdraft condition exists.

E. Symptom: Furnace blower will not start.

Items to check:

1) Confirm there is 120 VAC at the blower motor terminal block.

2) If there is not 120 VAC at the blower terminal block, measure the

voltage at the fan center relay. If the fan can be activated by itself from

the room thermostat subbase, confirm it will operate. If so, the fan

center relay contacts may be burnt, or damaged, or the fan limit control

may be defective. Test these components and replace the defective

component, as required.

3) If there is 120 VAC at the blower terminal block, either the run

capacitor or blower motor may be damaged. Test and replace the

capacitor or motor, as required.

F. Symptom: Blower cycles on and off after the burner has shutdown.

Item to check:

1) Increase the fan limit control differential. Typically, the fan “off” setting

should be 30 degrees F. below the fan “on” setting. Adjust the setting

as required.

NOTICE: If the fan and high limit control is faulty, it should be

replaced. However, it must only be replaced by the same make

and model as the original. All the original temperature settings

should be duplicated on the replacement model as well. REMOVE

THE LOW VOLTAGE JUMPER IN THE CONTROL, IF EQUIPPED.

Refer to the electrical diagram for proper electrical connections.

30

Page 32

Flame Sensor (“Cad Cell”) Checkout Procedure

On the Honeywell oil primary control, to check the electrical resistance of the flame

sensor (referred to as a cadmium sulfide photocell, or “cad cell”), depress the reset

button on the oil primary safety control while the burner is firing. The oil primary control

will report the measured resistance range of the cad cell by flashing the LED (light

emitting diode) one (1) to four (4) times. Refer to the oil burner manufacturer’s

instructions for further details.

For all primary controls, an alternate procedure to check the flame sensor operation is

as follows:

1) Remove the flame sensor lead wires from the terminals (labeled “CAD

CELL” on the underside of the Honeywell control) of the oil primary safety

control module. Start the burner. Shortly after combustion is established,

place a temporary jumper wire across the cad cell terminals, or leads, of

the control. Connect an ohmmeter across the flame sensor lead wires.

The measured resistance should be less than,

• 1600 Ohms for the Honeywell cad cell,

• 1500 Ohms for the Carlin cad cell, and

• 1200 Ohms for the Riello cad cell.

NOTICE: On the Riello 40-F3 burner only, it may be difficult or

impossible to measure the actual operating resistance of the cad cell with

the burner operating. With the electrical power off, carefully remove the

printed circuit board from the Riello oil primary control and subject the cad

cell to direct sunlight. The measured resistance of the cad cell should

reduce to 50 Ohms, or less. Cover the cad cell and measure the dark cell

resistance, refer to step 3 below.

2) Stop the burner and remove the jumper wire.

3) With the burner off, measure the resistance of the flame sensor with the

ohmmeter. The resistance of the sensor without “seeing” a light source

(so-called “dark” cell resistance) should be greater than,

• 20,000 Ohms for the Honeywell cad cell,

• 50,000 Ohms for the Carlin cad cell, and

• 40,000 Ohms for the Riello cad cell.

4) If the sensor resistances are outside the acceptable ranges given above,

confirm the lens of the cell is clean and the cell is located correctly in the

burner housing. If the cell is clean and correctly located, replace the flame

sensor.

NOTICE: All resistances are approximate values only and will vary

depending upon the intensity of the light source (flame or sunlight) and the

condition or age of the cad cell.

31

Page 33

Replacement Parts

Appendix D of this manual contains a list of replacement parts available for these

furnaces.

On the Riello 40-F3 burner only, the cad cell is an integral part of the oil

primary control. If replacement of the cad cell is required, the entire

primary control must be replaced.

32

Page 34

MAINTENANCE

Air Filter(s)

c CAUTION: To avoid injury from moving parts, hot surfaces, or electrical

shock, shut off the power to the furnace and allow the furnace to cool BEFORE

removing any furnace access doors to service air filters.

Highboy and lowboy furnace models are factory-supplied with a permanent-type, air

filter. At least twice a year, remove the air filter(s) for cleaning. Clean a filter by soaking

it in water with a mild detergent and then rinsing it with clean water. Allow the filter to air

dry before reinstalling it in the furnace filter rack.

If the furnace, or duct system, is equipped with disposable-type (paper element), air

filters, inspect them every month for an excessive accumulation of dust and dirt.

Replace disposable air filters at least twice a year. Make certain the replacement filter is

the same size as the one being replaced. The filter size is marked on the outer edge of

the air filter. Install the filter with the arrow marked on the filter pointing toward the

furnace.

Oil Burner

NOTICE: A qualified heating contractor MUST service the oil burner in this

furnace at least once a year.

Generally, service to the burner will involve a thorough inspection and cleaning of the

burner, replacement of the oil nozzle and oil filter, and readjustment of the burner to

achieve proper ignition and clean combustion.

Blower and Motor

NOTICE: The fan motor has sealed bearings that do NOT require lubrication.

The blower and fan motor will not normally require any service. This furnace is

equipped with a directly-driven blower. Therefore, it will not require any retensioning or

replacement of a drive belt.

Heat Exchanger

c CAUTION: DO NOT attempt to clean the heat exchanger unless electrical power

and fuel flow to the furnace are turned off and the furnace is at room temperature.

c CAUTION: The combustion chamber refractory material is fragile and can be

easily damaged. If the inner radiator of the heat exchanger is cleaned, avoid

scraping or hitting the walls of the combustion chamber.

CAUTION: Do not brush or scrape the surface of the combustion chamber. It can be

easily damaged.

33

Page 35

NOTICE: A qualified heating contractor MUST inspect the heat exchanger in this

furnace at least once a year. If heavy deposits are found, immediate cleaning is

required.

All heat exchanger surfaces should be as clean as possible for the most efficient

operation of the furnace. The heat exchanger may require cleaning after every heating

season, as combustion of fuel oil tends to produce soot, particulate matter, and scale,

due to corrosion. These materials coat the inner walls of the heat exchanger. This

coating reduces the heat transfer effectiveness of the heat exchanger and can hinder

the flow of flue gases from the furnace.

NOTICE: Accumulation of heavy soot deposits over one heating season may

indicate the oil burner is out of adjustment.

The heat exchanger may be inspected and cleaned through two (2) access, or cleanout,

ports located in the burner compartment, on highboy and lowboy models, or protruding

through the front casing panel, on the horizontal/counterflow model. Each cleanout port

consists of a 2-inch O.D. tube closed by a pressed-in cap, refer to Figure 9.

Figure 9: Location and Design of the Highboy Heat Exchanger Cleanout Ports

Using a screwdriver, or a large pair of adjustable jaw pliers, remove each cleanout port

cap. With the aid of a portable light source, peer into the heat exchanger. As much as

possible, loosen all material and deposits clinging to the heat exchanger walls using

wire brushes, or any suitable tool. Collect and remove this material by hand or with the

assistance of a vacuum cleaner and a nozzle-type attachment.

34

Page 36

The heat exchanger may also be cleaned through the flue pipe connection. With the

furnace turned off and at room temperature, carefully remove the vent connector and

the heat exchanger flue pipe, if equipped, to inspect and clean the heat exchanger.

The inner radiator of the heat exchanger may be cleaned from the inside of the

combustion chamber. This involves removal of the burner and the burner mounting

plate from the heat exchanger.

Using a portable light source with a mirror inserted through and into the heat exchanger,

check for an accumulation of soot, scale, and particulate matter on the walls and in the

base of the drum, or on the floor of the combustion chamber. If a significant

accumulation is present, it should be removed. Use a flexible wire brush to loosen the

deposits on the heat exchanger walls. Remove any loose foreign material using a

vacuum cleaner.

Replace all gaskets, if removed, with new (unused) gaskets. Reassemble the burner

mounting plate, burner flange, and new gaskets in the reverse order they were

removed. A rubber mallet, or equivalent tool, may be useful for reinstalling the caps in

the cleanout tubes.

Flue and Chimney

At least once a year, thoroughly inspect the heat exchanger flue pipe, the vent

connector, the chimney, or vent, and the barometric damper for signs of sagging, loose

connections, excessive corrosion, and deterioration. Clean, repair, or replace any

components for continued safe and proper operation of the furnace.

35

Page 37

USERS INFORMATION

c WARNING:

• The area around the furnace should be kept free and clear of flammable vapors,

liquids, and material, especially papers and rags.

• NEVER burn garbage or refuse in the furnace. NEVER try to ignite oil by tossing

burning papers or other material into the furnace.

• This oil furnace is designed to burn No. 2 distillate fuel (home heating) oil ONLY.

NEVER USE GASOLINE OR A MIXTURE OF OIL AND GASOLINE.

• DO NOT attempt to make repairs to the furnace yourself!

Operating Instructions

For your safety, read this information before operating this furnace.

c WARNING: Failure to follow these instructions may result in fire or explosion

causing property damage, personal injury, or loss of life.

WHAT TO DO IN THE EVENT OF AN OIL LEAK:

• Do not try to operate this or any other nearby appliance.

• If present, close the manual oil shutoff valve on the fuel oil supply line.

• Immediately call a qualified heating contractor for service.

• If you cannot reach a qualified heating contractor, call the fuel oil supplier of the

fire department.

DO NOT use this furnace if any component was underwater. Immediately call a

qualified heating contractor to inspect the furnace and replace any part of the furnace

control system that was underwater.

This furnace does not have a pilot light. It is equipped with an electronic ignition system

that automatically lights the burner. DO NOT attempt to light the burner by hand.

TO OPERATE THIS FURNACE:

1) Adjust the room thermostat to the lowest setpoint and set the operating mode, if

equipped, to “OFF”.

2) Turn off all electric power to the furnace at the disconnecting switch.

3) Turn the manual oil shutoff valve to the open or “ON” position.

36

Page 38

4) This furnace is equipped with an electronic ignition system that automatically

5) Turn on the electric power to the furnace at the disconnecting switch.

6) Adjust the room thermostat to the desired setpoint and set the operating mode, if

7) If the furnace will not operate, call a qualified heating contractor for service.

TO INTERRUPT (STOP) OPERATION OF THIS FURNACE:

1) Adjust the room thermostat to the lowest setpoint and set the operating mode, if

2) If service will be performed, turn off all electric power to the furnace at the

3) Turn the manual oil shutoff valve to the closed or “OFF” position.

Oil Supply

• If available, the use of ultra-low or low sulfur (less than 0.0015% S and 0.0015 -