Page 1

BWC Series

D ESIGNED TO L EAD

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

Direct Vent Condensing Boilers

INSTALLATION SUPPLEMENT FOR BOILERS

VENTED WITH CPVC/PVC PIPE

These instructions must be afxed on or adjacent to the boiler.

Models:

• BWC070

• BWC090

• BWC120

• BWC151

• BWC150

• BWC225

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury,

or loss of life. For assistance or additional information, con-

sult a qualied installer, service agency or the gas supplier.

This boiler requires a special venting system. Read these

instructions carefully before installing.

Page 2

1

Page 3

Table of Contents

A. Vent System Design 2

B. Assembly of CPVC/PVC Concentric Venting 14

C. Condensate Trap and Drain 20

D. Removing An Existing Boiler From Common Chimney 22

E. Special Requirements For Side-Wall Vented Appliances

In The Commonwealth of Massachusetts 23

1

Page 4

3

WARNING

Failure to vent this boiler in accordance with these instructions could cause ue gas to enter the building

resulting in severe property damage, personal injury, or death:

Use of the BWC boiler with CPVC/PVC venting requires a special vent kit available from Crown •

Boiler Company. Do not attempt to vent the boiler using either CPVC/PVC without the use of the

appropriate vent kit called for in this manual.

Do not apply thermal insulation to vent pipe or ttings.•

Do not interchange vent systems or materials unless otherwise specied.•

Do not obtain combustion air from within the building. •

Do not install a barometric damper, vent damper, or drafthood on this boiler.•

Unless otherwise noted, the• use of CPVC is required where the vent pipe passes through enclosed

spaces and through wall penetrations.

Do not use cellular core PVC (ASTM F891).•

Pitch the vent piping as called for in these instructions to prevent condensate from pooling in the •

venting.

Starting at the boiler, the rst 30” of straight pipe, and the rst 90 degree elbow, in the vent system •

must be CPVC. PVC may only be used in the vent system downstream of this CPVC piping.

CAUTION

Moisture and ice may form on the surfaces around the vent termination. To prevent deterioration,

surfaces should be in good repair (sealed, painted, etc.).

A. Vent System Design

There are several different ways to vent BWC series boilers. This installation supplement covers installation of

those vent systems that employ CPVC and PVC plastic pipe. Refer to the BWC installation manual when installing a

vent system using stainless steel or concentric PPs venting.

When CPVC/PVC pipe is used, there are two basic ways to vent a BWC boiler, each having several variations:

• Horizontal (“Side Wall”) Twin Pipe Venting (Table 1.1) - Vent system exits the building through an outside

wall. Combustion air and ue gas are routed between the boiler and the terminal using separate pipes.

• Vertical Twin Pipe Venting (Table 1.12) - Vent system exits the building through a roof. Combustion air and

ue gas are routed between the boiler and the terminal using separate pipes.

All of these systems are considered “direct vent” because in all of them air for combustion is drawn directly from

the outdoors into the boiler. A description of all of these venting options are shown in Tables 1.1 and 1.12. One of

the vent option columns in Tables 1.1 or 1.12 must match the planned vent and air intake system exactly. In addition,

observe the following guidelines:

CPVC/PVC Adaptor Kits1. - The use of CPVC/PVC venting on BWC boilers requires the use of a special kit. Each

kit consists of the following principle components:

Adaptor/s for the Vent and Intake Connections•

30” Section of Straight CPVC Pipe•

CPVC Elbow•

(2) PVC Termination Tees•

(2) Rodent Screens•

(1 ea.) Can PVC/CPVC Primer and Cement•

Part Numbers for each kit are shown in Table 1.5

NOTE: Models BWC070, 090, 120 and 151 may be ordered from the factory with the above components

packaged in the boiler. When this is done the vent adaptor may be shipped installed on the boiler.

2

Page 5

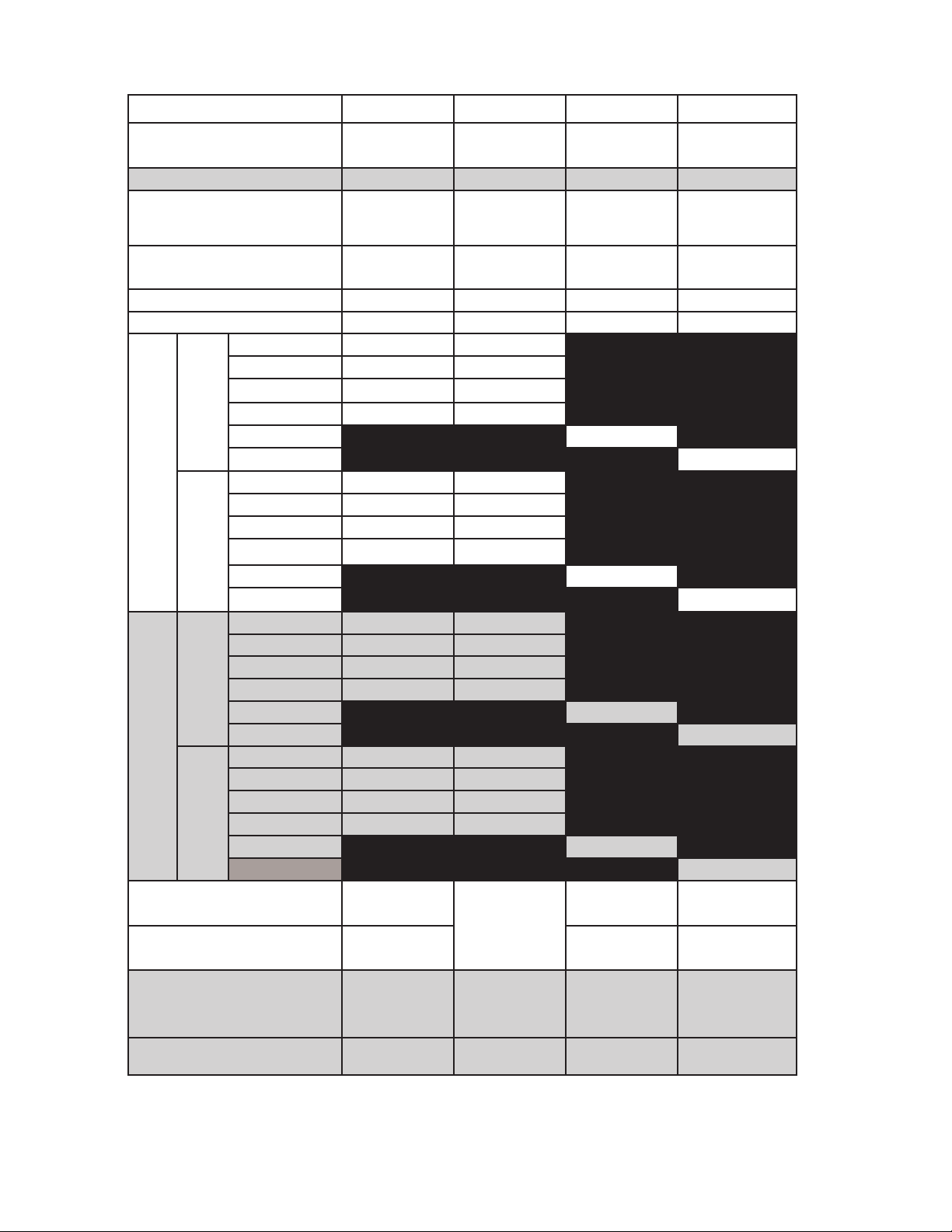

TABLE 1.1: SUMMARY OF HORIZONTAL VENTING OPTIONS

VENT OPTION # 1 2 3 4

CLASSIFICATION USED IN THIS

MANUAL

ILLUSTRATED IN FIGURE 1.2 1.3 1.4 1.4

VENT PIPE PENETRATION

THROUGH STRUCTURE

AIR INTAKE PIPE PENETRATION

THROUGH STRUCTURE

VENT PIPE SIZE

AIR INTAKE PIPE SIZE

BWC070 100ft 100ft

BWC090 100ft 100ft

BWC120 100ft 100ft

VENT

BWC151 100ft 100ft

BWC150

BWC225

BWC070 100ft 100ft

BWC090 100ft 100ft

MAXIMUM LENGTH

MINIMUM LENGTH

BWC120 100ft 100ft

BWC151 100ft 100ft

INLET

BWC150

BWC225

BWC070 2ft 2ft

BWC090 2ft 2ft

BWC120 2ft 2ft

VENT

BWC151 2ft 2ft

BWC150

BWC225

BWC070 2ft 2ft

BWC090 2ft 2ft

BWC120 2ft 2ft

INLET

BWC151 2ft 2ft

BWC150 2ft

BWC225 2ft

HORIZONTAL

TWIN PIPE

WALL WALL WALL WALL

WALL WALL WALL WALL

3” 3”

3” 3”

HORIZONTAL

TWIN PIPE

HORIZONTAL

TWIN PIPE

3” 4”

4” 4”

55ft

60ft

2ft

HORIZONTAL

TWIN PIPE

55ft

60ft

2ft

VENT TERMINAL TEE (Note #1)

AIR INTAKE TERMINAL TEE (Note #1) TEE (Note #1) TEE (Note #1)

VENT MATERIAL

AIR INTAKE MATERIAL PVC PVC PVC PVC

Note #1: TEEs may be offset on snorkels as shown in Figure 1.10

Note #2: First 30” and Elbow connected to boiler must be CPVC. Downstream vent pipe can be PVC, except as noted in text.

CPVC + PVC

(Note #2)

CROWN

PN 230873

CONCENTRIC

TERMINAL

CPVC + PVC

(Note #2)

TEE (Note #1) TEE (Note #1)

CPVC + PVC

(Note #2)

CPVC + PVC

(Note #2)

3

Page 6

5

Approved vent components and materials - The adaptor kits listed in Table 1.5 are required to connect the venting 2.

to the boiler. Starting at the boiler, the rst 30 inches of the vent system, and the rst elbow, must be CPVC. In

addition, use only pipe that meets the following standards:

CPVC - ASTM F441•

PVC - ASTM D2665•

The primer and cement used must be designed for use with the venting materials being joined (PVC, CPVC or

CPVC to PVC).

CAUTION

The CPVC and PVC vent materials supplied with this boiler do not comply with B149.1.S1-07 and are not

approved for use in Canadian jurisdictions that require that vent systems be listed to ULC S636-2008. In

these jurisdictions, vent this boiler using one of the AL29-4c stainless steel vent systems shown in the BWC

installation manual or a listed ULC S636 Class II - 90°C venting system.

Maximum Vent and Air Intake Lengths3. - The maximum length of the vent air intake piping depends upon the

vent option selected and the boiler size. See Table 1.1 or 1.12 for the maximum vent lengths. In horizontal

vent systems, the lengths shown in Table 1.1 are in addition to the rst 90 elbow. For vertical vent systems, the

maximum vertical vent lengths shown in Table 1.12 are in addition to two 90 elbows. If more elbows are desired, the

maximum allowable vent length must be reduced by the amount shown in Table 1.7 for each additional elbow used.

Termination ttings are never counted.

The elbows supplied in the CPVC/PVC vent kit are “standard radius” elbows. It is recommeded that all eld

supplied elbows must be “1/4 Bend” (Sanitary 90 El) or “Long Sweep 1/4 Bend” type elbows (Figure 1.8). In this

manual “sanitary” and “long sweep” elbows are treated as having the same equivalent length.

Example:

A 3” twin pipe horizontal CPVC/PVC vent system is planned for a horizontally vented BWC120 which has the

following components in the vent system:

1 ft CPVC Straight Pipe•

90 CPVC Elbow (Supplied in Crown vent kit)•

1-1/2 ft CPVC Straight Pipe•

Coupling•

10 ft PVC Straight Pipe•

90 PVC Elbow (Sanitary Elbow Design)•

15 ft PVC Straight Pipe•

PVC Tee Terminal•

The Vent Option #1 column in Table 1.1 describes a horizontal direct vent system using 3” CPVC and PVC pipe.

Fromthiscolumn,weseethataBWC120mayhaveaventlengthofupto100ft.TherstCPVC90degreeelbowis

not considered. From Table 1.7, we see that the equivalent length of the 90 PVC elbow is 4ft and that the equivalent

length of the coupling is 0ft. The total equivalent length of the planned venting system is therefore:

1ft(StraightCPVC)+0ft(rstCPVC90Elbow)+1.5ft(StraightCPVC)+0ft(Coupling)+10ft (Straight PVC) +

4ft (PVC 90 Elbow) + 15ft (Straight PVC) + 0ft (Tee Terminal) = 31.5ft.

Since Table 1.1 shows a maximum allowable vent length of 100ft, the planned vent system length is acceptable.

Minimum Vent and Air Intake Lengths 4. - Observe the minimum vent lengths shown in Table 1.1.

Permitted Terminals for Horizontal Venting (Vent Option #1-3)5. - Use one of the following terminals:

PVC Teesa. - PVC Tees are used for both the inlet and vent. They are the same size as the connected vent

or intake system and are installed with the run vertical as shown in Figures 1.2 and 1.4. Rodent screens are

installed in the side connection of the Tee where it is connected to the vent or intake pipe. Terminal Tees and

rodent screens are provided with the CPVC/PVC vent kit.

PVC Tees on Snorkelsb. - If desired, the PVC Tees terminations may be installed on snorkels as shown in Figure

1.10. When this is done, all exterior piping except for the termination Tees themselves must be counted when

calculating the equivalent length. The maximum vertical run of the snorkel is 5ft. Observe all restrictions on the

location of the Tee terminal described in Paragraph 6.

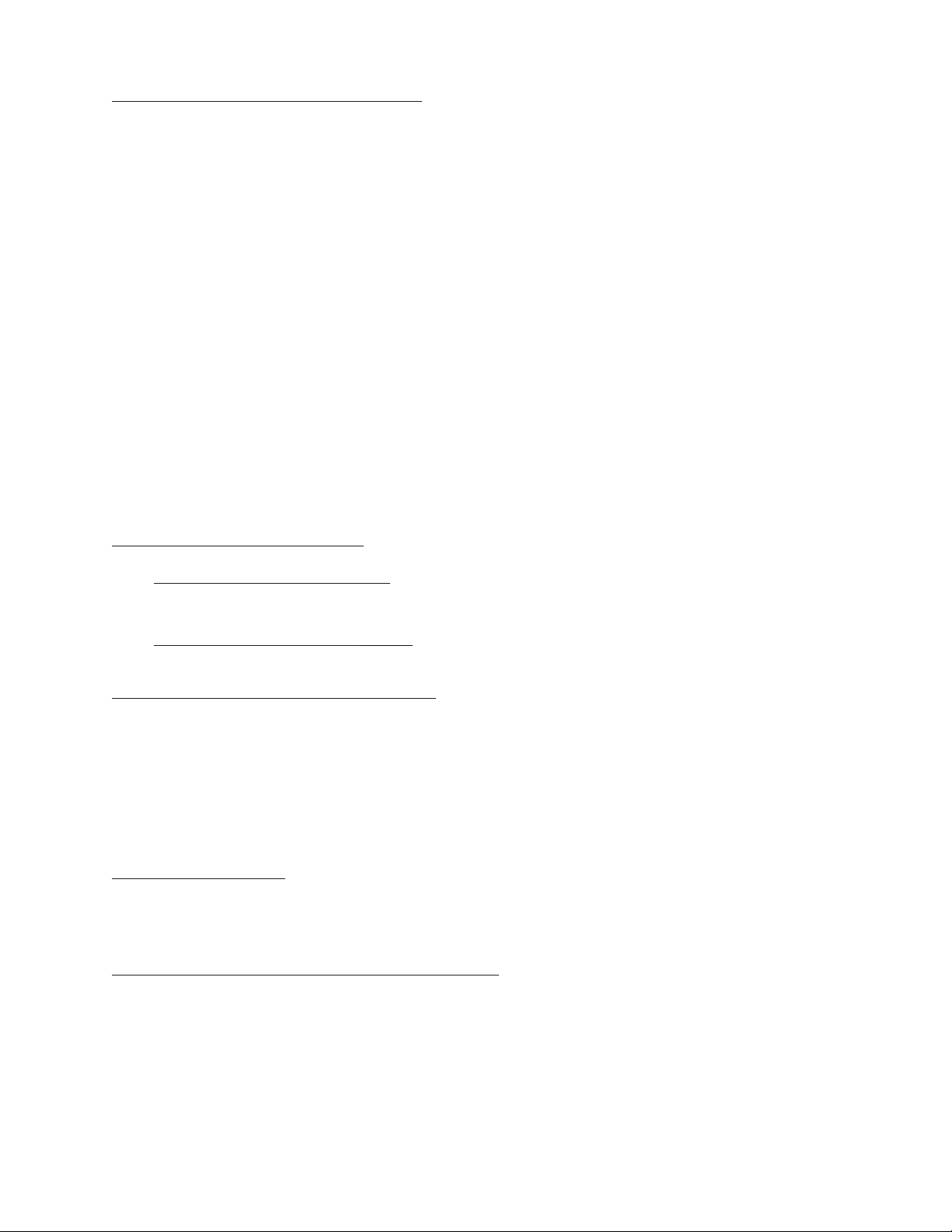

Crown Concentric Terminc. al (PN 230873 ) - This optional terminal may be used in place of the Tees on the

BWC070, 090, 120, and 151 (Figure 1.3). It may not be used on the BWC150 or 225.

4

Page 7

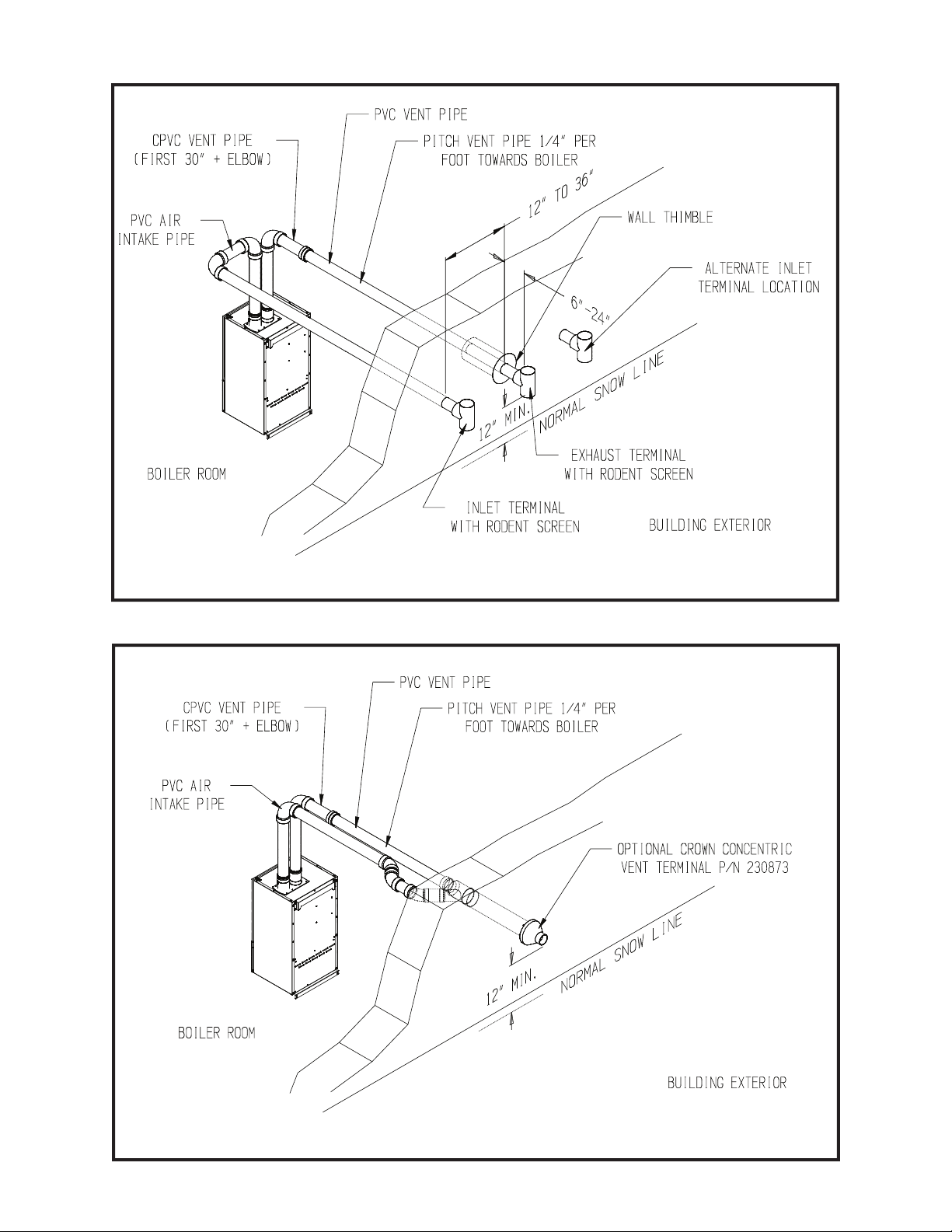

FIGURE 1.2: HORIZONTAL CPVC/PVC VENTING, BWC070/090/120/151 (Vent Option #1)

FIGURE 1.3: HORIZONTAL CPVC/PVC VENTING, BWC070/090/120/151 (Vent Option #2)

5

Page 8

7

Horizontal Vent and Air Intake Terminal Location6. - Observe the following limitations on the vent terminal location

(also see Figure 1.9). When locating a concentric terminal, observe the limitations outlined below for “vent

terminals”.

Vent terminal must be at least 1 foot from any door, window, or gravity inlet into the building.•

For Tee terminals, maintain the correct clearance and orientation between the vent and air intake terminal. •

The vent and air intake terminals must be at the same height and their center lines must be between 12 and 36

inches apart. Both terminals must be located on the same wall.

The bottom of all terminals must be at least 12” above the normal snow line. In no case should they be less •

than 12” above grade level.

The bottom of the vent terminal must be at least 7 feet above a public walkway. •

Do not install the vent terminal directly over windows or doors.•

The bottom of the vent terminal must be at least 3 feet above any forced air inlet located within 10 feet.•

USA Only: A clearance of at least 4 feet horizontally must be maintained between the vent terminal and gas •

meters, electric meters, regulators, and relief equipment. Do not install vent terminal over this equipment. In

Canada, refer to B149.1 Installation Code for clearance to meters, regulators and relief equipment.

Do not locate the vent terminal under decks or similar structures.•

Top of vent terminal must be at least 5 feet below eves, softs, or overhangs. Maximum depth of overhang is 3 •

ft.

Vent terminal must be at least 6 feet from an inside corner.•

Under certain conditions, water in the ue gas may condense, and possibly freeze, on objects around the vent •

terminal including on the structure itself. If these objects are subject to damage by ue gas condensate, they

should be moved or protected.

If possible, install the vent and air intake terminals on a wall away from the prevailing wind. Reliable operation •

of this boiler cannot be guaranteed if these terminals are subjected to winds in excess of 40 mph.

Air intake terminal must not terminate in areas that might contain combustion air contaminates, such as near •

swimming pools. See the installation manual for more information on possible contaminates.

Permitted Terminals for Vertical Venting7. - Use either of the following terminals:

Coupling On Vent, 180 Bend On Inleta. - A coupling is installed in the end of the vent pipe. Install a rodent

screen between this coupling and the last piece of vent piping. Use a 180 bend or two 90 elbows to make the

inlet termination (Figures 1.14, 1.16). Rodent screens are provided with the CPVC/PVC vent kit. The elbow/s

and coupling must be procured locally.

Crown Concentric Terminal (PN b. 230873) - This optional terminal may be used in place of the coupling and

180 bend on the BWC070, 090, 120, and 151 (Figure 1.15). It may not be used on the BWC150 or BWC225.

Vertical Vent Terminal Locations (Vent Options 5,6)8. - Observe the following limitations on the location of all

vertical vent terminals (see Figures 1.14 - 1.16):

The top of the vent pipe must be at least 2 feet above any object located within 10 feet.•

For Coupling/Elbow terminations, the vertical distance between top of the vent and air inlet terminal openings •

must be at least 12”.

The bottom of the air inlet terminal must be at least 12” above the normal snow accumulation that can be •

expected on the roof.

For Coupling/Elbow terminations, the air intake terminal must be located on the roof and must be no further •

than 24” horizontally from the exhaust pipe.

Clearances to Combustibles9. - Maintain the following clearances from the vent system to combustible construction:

Vent - 1” (also observe clearances through both combustible and non-combustible walls - see 10 below)•

Air Intake - 0”•

Concentric Portion of • Crown 230873 Terminal - 0”

Running PVC Vent Pipe Inside Enclosures and Through Walls10. - PVC vent pipe must be installed in a manner that

permits adequate air circulation around the outside of the pipe:

Do not enclose PVC venting - Use CPVC in enclosed spaces, even if PVC is installed upstream. •

PVC venting may not be used to penetrate combustible or non-combustible walls unless all of the following •

conditions are met:

The wall pentration is at least 66 inches from the boiler as measured along the vent.a.

The wall is 12” thick or lessb.

An airspace of at least that shown in Figure 1.13 is maintained around the OD of the vent.c.

If any of these conditions cannot be met, use CPVC for the wall pentetration.

6

Page 9

FIGURE 1.4: HORIZONTAL CPVC/PVC VENTING, BWC150/225 (Vent Option #3, 4)

TABLE 1.5: CROWN CPVC/PVC VENTING COMPONENTS

USED ON

CROWN PN DESCRIPTION

230595 CPVC/PVC VENT KIT, BWC070/090/120/151 1,2,5,6

230596 CPVC/PVC VENT KIT, BWC150 3,7

230597 CPVC/PVC VENT KIT, BWC225 4,8

230873 PVC CONCENTRIC TERMINAL 2,6 Use with BWC070/090/120/151 Only

Note: BWC070/090/120/151 may be ordered with components in 230595 vent kit packaged inside the boiler

carton.

Pitch of Horizontal Piping4. - Pitch all horizontal piping 1/4” per foot so that any condensate which forms in the

piping will run towards the boiler.

Supporting Pipe5. - Vertical and horizontal sections of pipe must be properly supported. Maximum support spacing is

four feet.

Allowing for Thermal Expansion6. - Design the vent system to allow 3/8” of thermal expansion for every 10ft of

CPVC/PVC pipe. The boiler will always act as an anchor to one end of the vent system. If at all possible, select and

install hangers and wall thimbles so that the vent system can expand towards the terminal. When a straight run of

pipe exceeds 20ft and must be restrained at both ends, an offset or expansion loop must be provided (Figures 1.11a,

1.11b). When a straight horizontal run of pipe exceeds 20ft and is restrained at one end with an elbow at the other,

avoid putting a hanger or guide less than “Y” inches from the elbow in the adjoining straight section (Figure 1.11c).

Thermal expansion ttings are not permitted.

VENT

OPTION #

COMMENTS

7

Page 10

9

TABLE 1.6: CROWN CPVC/PVC VENT KIT CONTENTS

QTY PER VENT KIT

CROWN PN DESCRIPTION SIZE

230840 CPVC/PVC VENT/INTAKE ADAPTOR 3” 1 0 0

230843 CPVC VENT ADAPTOR 3” 0 1 0

230844 CPVC VENT ADAPTOR 4” 0 0 1

230854 INTAKE ADAPTOR 4” 0 1 1

230841 VENT/INTAKE ADAPTOR GASKET N/A 1 0 0

230855 FLUE GAS SAMPLE CAP N/A 1 1 1

230823 30” STRAIGHT CPVC SECTION 3” 1 1 0

230824 30” STRAIGHT CPVC SECTION 4” 0 0 1

230813 90 DEG CPVC ELBOW 3” 1 1 0

230814 90 DEG CPVC ELBOW 4” 0 0 1

230803 PVC TEE 3” 2 1 0

230804 PVC TEE 4” 0 1 2

230833 RODENT SCREEN 3” 2 1 0

230834 RODENT SCREEN 4” 0 1 2

230865 IPS MULTI-PURPOSE 790 CEMENT 4 oz 1 1 1

230860 IPS P-70 PRIMER 4 oz 1 1 1

240550 TAPPED CONDENSATE TRAP PLUG N/A 0 1 1

240560 66” OF 1/2” CLEAR PVC TUBING N/A 0 1 1

240555 90° HOSE BARB N/A 0 2 2

240557 1/2” HOSE CLAMP N/A 0 2 2

PN 230595

(BWC070/090/120/151)

PN 230596

(BWC150)

PN 230597

(BWC225)

TABLE 1.7: VENT/ AIR INTAKE FITTING EQUIVALENT LENGTH

VENT FITTING EQUIVALENT LENGTH (ft)

3” 90 ELBOW (“SANITARY BEND”) 4.0

4” 90 ELBOW (“SANITARY BEND”) 5.5

3” 90 ELBOW (“SHORT BEND” ) 10.0

4” 90 ELBOW (“SHORT BEND”) 13.5

3” 45 ELBOW 2.0

4” 45 ELBOW 3.0

3” COUPLING 0.0

4” COUPLING 0.0

FIGURE 1.8: ELBOWS

8

Page 11

FIGURE 1.9a: LOCATION OF VENT TERMINAL RELATIVE TO WINDOWS, DOORS, GRADE

FIGURE 1.9b: LOCATION OF VENT TERMINAL RELATIVE TO METERS AND FORCED AIR INLETS

FIGURE 1.9c: POSITIONING VENT TERMINAL UNDER OVERHANGS

9

Page 12

11

FIGURE 1.10: SNORKEL TERMINAL CONFIGURATION

FIGURE 1.11.bFIGURE 1.11.a

FIGURE 1.11.c

FIGURE 1.11: EXPANSION LOOPS

10

Page 13

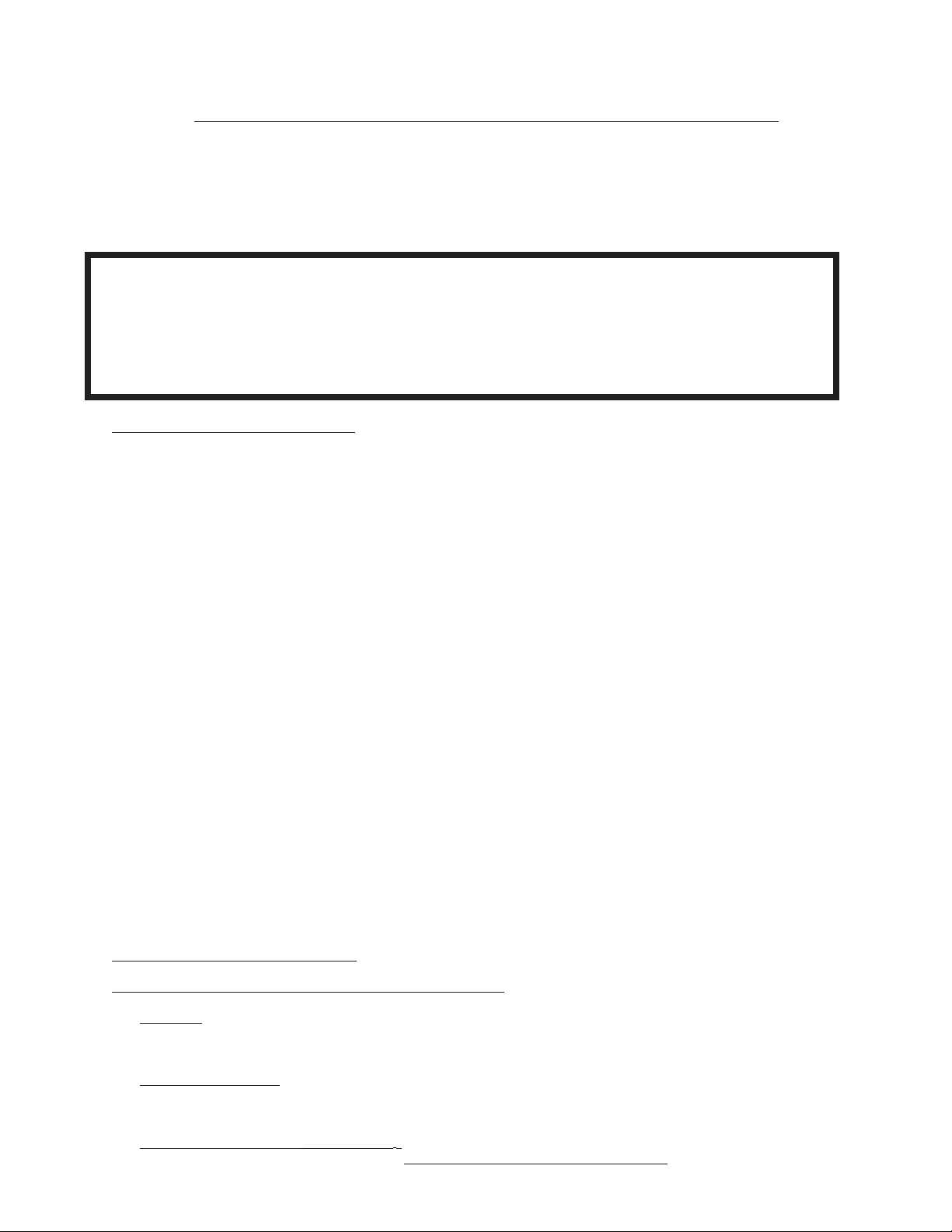

TABLE 1.12: SUMMARY OF VERTICAL VENTING OPTIONS

VENT OPTION # 5 6 7 8

CLASSIFICATION USED IN THIS

MANUAL

ILLUSTRATED IN FIGURE 1.14 1.15 1.16 1.16

VENT PIPE PENETRATION

THROUGH STRUCTURE

AIR INTAKE PIPE PENETRATION

THROUGH STRUCTURE

VENT PIPE SIZE

AIR INTAKE PIPE SIZE

BWC070 98ft 98ft

BWC090 98ft 98ft

BWC120 98ft 98ft

VENT

BWC151 98ft 98ft

BWC150

BWC225

BWC070 98ft 98ft

BWC090 98ft 98ft

MAXIMUM LENGTH

MINIMUM LENGTH

BWC120 98ft 98ft

INLET

BWC151 98ft 98ft

BWC150

BWC225

BWC070 2ft 2ft

BWC090 2ft 2ft

BWC120 2ft 2ft

VENT

BWC151 2ft 2ft

BWC150

BWC225

BWC070 2ft 2ft

BWC090 2ft 2ft

BWC120 2ft 2ft

INLET

BWC151 2ft 2ft

BWC150 2ft

BWC225 2ft

VERTICAL

TWIN PIPE

ROOF ROOF ROOF ROOF

ROOF ROOF ROOF ROOF

3” 3”

3” 3”

VERTICAL

TWIN PIPE

VERTICAL

TWIN PIPE

3” 4”

4” 4”

51ft

54.5ft

2ft

VERTICAL

TWIN PIPE

49.5ft

54.5ft

2ft

VENT TERMINAL COUPLING

AIR INTAKE TERMINAL 180 ELBOW 180 ELBOW 180 ELBOW

VENT MATERIAL

AIR INTAKE MATERIAL PVC PVC PVC PVC

Note #1: First 30” and Elbow connected to boiler must be CPVC. Downstream vent pipe can be PVC, except as noted in text.

CPVC + PVC

(Note #1)

CROWN

PN 230873

CONCENTRIC

TERMINAL

CPVC + PVC

(Note #1)

COUPLING COUPLING

CPVC + PVC

(Note #1)

CPVC + PVC

(Note #1)

11

Page 14

13

FIGURE 1.13: WALL PENETRATION CLEARANCES FOR PVC VENT PIPE

FIGURE 1.14: VERTICAL CPVC/PVC VENTING, BWC070/090/120/151 (VENT OPTION 5)

12

Page 15

FIGURE 1.15: VERTICAL CPVC/PVC VENTING, BWC070/090/120/151 (VENT OPTION 6)

FIGURE 1.16: VERTICAL CPVC/PVC VENTING, BWC150/225 (VENT OPTIONS 7 & 8)

13

Page 16

15

B. Assembly of CPVC/PVC Vent Systems

WARNING

Failure to follow the instructions could result in ue gas leakage into the combustion air or indoor air, resulting in

unsafe or unreliable operation.

All CPVC vent components (supplied with the boiler) must be used for near boiler vent piping before •

transitioning to Schedule 40 PVC (ASTM 2665) components for the remainder of the system.

The use of cellular core PVC (ASTM F891) is prohibited.•

The use of CPVC is required where venting passes through chase ways and through walls with clearances less •

than shown in Figure 1.13.

Never leave the boiler in operation without the silicone gas sample cap in place• (Figure 1.17, 1.18)

Install the vent adaptor and intake adaptor on the boiler. 1.

BWC070, 090, 120, 151 - If the CPVC/PVC vent/intake adaptor is not factory installed, install the vent/intake

adaptor as shown in Figure 1.17.

If the boiler has been supplied with a different vent adaptor, remove the six #10 sheet metal screws which a.

attach it to the boiler. Remove the old adaptor from the boiler (this may be easier if a twisting motion is

applied to the collar while removing it).

Attach the self adhesive gasket supplied with the stainless steel vent/intake adaptor to the bottom of the b.

adaptor.

Lubricate the brown gasket in the female end of the plastic vent stub (inside the boiler) with a few drops of c.

water.

Push the vent/intake adaptor onto the boiler with a slight twisting motion. Make sure that this vent adaptor d.

is inserted at least 1” into the boiler stub.

Secure the collar ange to the top of the boiler with the (6) #10 x 1/2” sheet metal screws supplied with the e.

vent kit or those removed in Step (a).

Verify that the silicone gas sample cap is in place (Figure 1.17).f.

BWC150, 225 - Install the vent and air inlet adaptors as shown in Figure 1.18.

Remove the hose clamp shipped on the BWC150 or 225 vent collar.a.

Bend the three hose clamp tabs on this collar outward slightly.b.

Clean the exterior of the male end of the CPVC adaptor with an alcohol pad.c.

Apply a ¼” wide bead of high temperature silicone approximately ½ inch from the male end of the adaptor. d.

Also apply a ¼” bead of silicone along the rst 2 ½” of the longitudinal weld.

Insert the male end of the adaptor into the boiler vent collar until it bottoms out.e.

Apply an additional bead of silicone over the outside of the joint and smooth out.f.

Replace and tighten the clamp on the vent collar.g.

Verify that the silicone gas sample cap is in place (Figure 1.18).h.

Attach the 1/2” ID Clear tubing provided to the condensate drain connection (Upper 1/2” tube) as shown in i.

Figure 1.18. Secure with one of the hose clamps provided.

Route the tubing down the right side panel and into the 1-3/8” knockout located in the lower portion of this j.

panel. Be sure to remove all burrs from the knockout to prevent the hose from being punctured.

Remove the plug and black gasket ring from the bottom of the condensate trap located under the boiler k.

(Figure 1.24)

Replace the original gray trap plug with the white tapped plug. Screw the 90 degree hose barb provided into l.

this white plug (Figure 1.24).

Attach the other end of the 1/2” ID tubing to the 90 degree hose barb and secure with the remaining hose m.

clamp (Figure 1.24).

Slip the air inlet adaptor into the intake collar on the top of the boiler as shown in Figure 1.18. Secure with n.

at least one #10 sheet metal screw.

14

Page 17

FIGURE 1.17: INSTALLATION OF VENT/INTAKE ADAPTOR (BWC070/090/120/151)

FIGURE 1.18: INSTALLATION OF VENT AND INTAKE ADAPTORS (BWC150/225)

15

Page 18

17

FIGURE 1.19: INSTALLATION OF STANDARD HORIZONTAL TERMINALS

Assemble the vent system, starting at the boiler: 2.

The CPVC elbow and the 30” straight section of CPVC provided with the kit must be used before a.

transitioning to PVC. If necessary, the 30” straight section of CPVC may be cut at any location and the

CPVC elbow inserted between the two resulting segments.

When cutting CPVC or PVC pipe, use a miter saw or a saw designed to cut PVC pipe. Use a miter box or b.

other method to cut pipe squarely. De-burr both the inside and outside of the cut end.

Dry t all vent components before assembly. c.

Lubricate the gasket in the vent adaptor with water. Insert the rst straight section of CPVC into the vent d.

adaptor and tighten the hose clamp.

Clean all CPVC and PVC components with the appropriate primer before cementing. Cement the vent e.

system together, starting at the boiler and following the instructions provided on the cans of cement

and primer. Use the cement provided with the kit to assemble all CPVC components and to make all

connections between CPVC and PVC components. If additional cement/primer is needed, use cement/

primer that are designed for use with the plastics being joined (CPVC and/or PVC).

Depending on the layout of the vent system, the rst piece of PVC vent will be connected to either the f.

CPVC elbow or the end of a section of CPVC pipe. In the latter case, use a PVC coupling to connect the

rst piece of PVC to the last section of CPVC.

Assemble the rest of the vent system, being sure to pitch horizontal sections back towards the boiler 1/4”/ft. g.

Support the vent at intervals not exceeding 4ft.

Maintain the clearances from the vent pipe outlined in Part A of this manual. If exiting the exterior wall h.

using PVC pipe, use half of an appropriately sized wall thimble (or a sheet metal plate) on the exterior of

the building, to provide a weather tight seal while maintaining the proper clearance in the wall penetration.

Seal the joint between the pipe and the wall plate using RTV applied on the exterior side of the wall. This

sealant must not restrain the expansion of the vent pipe.

Installation of Air intake System3. - Start assembly of the air intake system at the boiler. Assembly of the air intake

system is done in the same manner as the vent system except as follows:

The rst piece of air intake pipe on the BWC150 and BWC 225 is installed over the intake adaptor installed a.

in Step (1i). This piece of pipe is secured to the adaptor using at least one sheet metal screw (drill a

clearance hole in the PVC intake pipe). Seal the joint between the intake pipe and the adaptor with RTV.

All intake piping may be PVC.b.

There is a 0” minimum clearance between the air intake piping and all types of construction.c.

To the extent possible, pitch horizontal air intake piping towards the outside . d.

16

Page 19

FIGURE 1.20: INSTALLATION OF STANDARD VERTICAL TERMINALS

Installation of Standard Terminals:4.

Horizontal (Tee Terminals):

When using Tee terminals, the inside edge of the run of the Tee must be between 6 and 24” from the wall. a.

The run of the Tee must be vertical. (Figure 1.19). b.

If desired, the Tees can be attached to the end of the vent and/or intake pipes with eld supplied stainless c.

steel screws so that they can be later removed for cleaning and inspection. If this is done, drill a clearance

hole in the Tee and a tap hole in the end of the vent/intake pipes to accept these screws.

If Tee terminals are installed on snorkels, assemble the snorkels as shown in Figure 1.10. Brace the vertical d.

run of piping on the building exterior as required.

Vertical (Coupling on Exhaust, 180 Elbow on Intake):

See Figure 1.20a. for the proper orientation of twin pipe vertical terminals.

The coupling is used to secure the rodent screen to the end of the vent pipe. b.

A 180 bend (or two 90 elbows) are installed on the top of the air intake pipe. If two 90 elbows are used, c.

the rodent screen provided can be installed between them (Figure 1.20). If a 180 bend is used, install the

rodent screen in the open side of the bend, using a ring made of PVC pipe. (Figure 1.20). If desired, the

termination ttings can be attached to the end of the vent and/or intake pipes with eld supplied stainless

steel screws so that they can be later removed for cleaning and inspection. If this is done, drill a clearance

hole in these ttings and a tap hole in the end of the vent/intake pipes to accept these screws.

Use roof ashings and storm collars to prevent moisture from entering the building. Seal the roof ashing d.

to the roof using generally accepted practice for the type of roof on the installation. Apply RTV to seal the

storm collars to the vent and intake pipes.

WARNING

Method of securing and sealing terminals to the outside wall must not restrain the expansion of vent pipe.

17

Page 20

19

Installation of Optional Crown # 5. 230873 concentric vent terminal - This terminal may be used for either

horizontal or vertical venting. Do not attempt to use this terminal on a BWC150 or BWC225. All CPVC

supplied with the vent kit must be used prior to connection of the vent system to this terminal. If the vent system

is too short to permit this, do not use this terminal:

Horizontal Installations-

Cement the 4” diameter section of PVC pipe supplied with this kit to the Wye tting using a primer and a.

cement listed for use with PVC.

Cut a 4-5/8” dia round hole in the exterior wall at the location of the terminal (see Section A of this manual b.

for permitted terminal locations).

If desired, the terminal can be shortened. If this is done, cut the 4” (outer) pipe so that it protrudes between c.

1-1/4 and 2-1/4” from the exterior surface of the wall. Cut the pipe squarely and de-burr both the OD and

ID of the cut edge.

If the terminal is shortened, “dry-t” the inner pipe in the Wye tting. Cut the inner pipe so that it protrudes d.

between 5-1/8 and 5-1/4” from the outside edge of the outer pipe.

Cement the inner pipe to the Wye, being careful, to keep the opposite end centered inside the outer pipe.e.

Slip the partially assembled terminal through the wall from the inside and orient so that the side outlet on f.

the Wye is on or above the horizontal plane.

Seal the gap between the OD of the “outer pipe” and the exterior side of the wall with RTV sealant.g.

Cement the rain cap onto the inner pipe. If desired, the rain cap can be attached to the inner pipe with a eld h.

supplied stainless steel screw so that it can be later removed for cleaning and inspection. If this is done,

drill a clearance hole in the rain cap and a tap hole in the inner pipe to accept this screw. A 1/2” mesh eld

supplied rodent screen may also installed between the rain cap and the inner pipe (Figure 1.21)

Vertical Installations -

Cement the 4” diameter section of PVC pipe supplied with this kit to the Wye tting using a primer and a.

cement listed for use with PVC.

Cut a hole in the roof large enough to clear the concentric terminal at the location of the terminal (see b.

Section A of this manual for permitted terminal locations).

Use a roof ashing and storm collar to prevent moisture from entering the building. Seal the roof ashing to c.

the roof using generally accepted practice for the type of roof on the installation.

Slip the partially assembled terminal through the roof from the inside.d.

Install the storm collar after verifying that the bottom of the rain cap will be at least 12” above the normal e.

snow line. Apply RTV to seal the storm collars to the terminal.

Cement the inner pipe to the Wye, being careful, to keep the opposite end centered inside the outer pipe. f.

Cement the rain cap onto the inner pipe. If desired, the rain cap can be attached to the inner pipe with a eld

supplied stainless steel screw so that it can be later removed for cleaning and inspection. If this is done,

drill a clearance hole in the rain cap and a tap hole in the inner pipe to accept this screw. A 1/2” mesh eld

supplied rodent screen may also installed between the rain cap and the inner pipe (Figure 1.22)

WARNING

Do not attempt to use this terminal on a BWC150 or BWC225•

All CPVC supplied with the vent kit must be used prior to connection of the vent system to this terminal. If •

the vent system is too short to permit this, do not use this terminal

Do not operate boiler without the rain cap in place. •

Method of securing and sealing terminals to the outside wall must not restrain the expansion of vent pipe. •

18

Page 21

FIGURE 1.21: INSTALLATION OF OPTIONAL CONCENTRIC TERMINAL THROUGH SIDEWALL

FIGURE 1.22: INSTALLATION OF OPTIONAL CONCENTRIC TERMINAL THROUGH ROOF

19

Page 22

21

C. Condensate Trap and Drain Line

All condensate which forms in the boiler or vent system collects in the sump under the heat exchanger and leaves

the boiler through the condensate trap. This trap allows condensate to drain from the sump while retaining ue gases

in the boiler. On some BWC series boilers, this trap is supplied loose and must be installed as shown in Figure 1.23. A

length of drain hose is supplied with the boiler and is connected to the trap as shown in Figures 1.23 and 1.24. Note the

following when disposing of the condensate:

If the condensate drain line must be extended, construct the extension from PVC or CP1. VC pipe. Insert the hose

provided with the boiler into the end of the extension as shown in Figure 1.23 or 1.24, as appropriate.

Condensate is slightly acidic. Do not use metallic pipe or ttings in the condensate drain line. Do not route the drain 2.

line through areas that could be damaged by leaking condensate.

Some jurisdictions may require that the condensate be neutralized before being disposed of. Dispose of condensate 3.

in accordance with local codes.

Do not route, or terminate, the condensate drain line in areas subjected to freezing temperatures. 4.

If the point of condensate disposal is above the trap, it will be necessary to use a condensate pump to move the 5.

condensate to the drain. In such cases, select a condensate pump that is approved for use with condensing furnaces.

If overow from this pump would result in property damage, select a pump with an overow switch and use this

switch to shut down the boiler. Alternatively, if heat is a necessity, use the overow switch to trigger an alarm.

Do not attempt to move the trap from the location shown in 6. Figure 1.23 or 1.24. Do not attempt to substitute another

trap for the one provided with the boiler.

The vent shown in Figures 1.23 and 1.24 must be left open for the trap to work properly.7.

WARNING

Failure to install the condensate trap and condensate drain in accordance with the above instructions could cause

ue gas to enter the building, resulting in personal injury or death.

CAUTION

Boiler condensate is corrosive. Route condensate drain line in a manner such that any condensate leakage •

will not cause property damage.

Some jurisdictions may require that condensate be neutralized prior to disposal.•

20

Page 23

FIGURE 1.23: CONDENSATE PIPING ARRANGEMENT (BWC070/090/120/151)

FIGURE 1.24: CONDENSATE PIPING ARRANGEMENT FOR BWC150, 225

21

Page 24

23

D. Removing an Existing Boiler From a Common Chimney

Read this only if the BWC boiler is replacing an existing boiler that is being removed from a common chimney. This

section does not apply to the installation of a BWC boiler.

In some cases, when an existing boiler is removed from a common chimney, the common venting system may be too

large for the remaining appliances. At the time of removal of an existing boiler, the following steps shall be followed

with each appliance remaining connected to the common venting system placed in operation, while the other appliances

remaining connected to the common venting system are not in operation.

Seal any unused openings in the common venting system.(a)

Visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or (b)

restriction, leakage, corrosion and other deciencies which could cause an unsafe condition.

Insofar as practical, close all building doors and windows and all doors between the space in which all the (c)

appliances remaining connected to the common venting system are located and other spaces of the building. Turn on

clothes dryers and any appliance not connected to the common venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan.

Close replace dampers.

Place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so the appliance (d)

will operate continuously.

Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the ame of a match (e)

or candle, or smoke from a cigarette, cigar, or pipe.

After it has been determined that each appliance remaining connected to the common venting system properly vents (f)

when tested as outlined above, return doors, windows, exhaust fans, replace dampers and any other gas-burning

appliances to their previous condition of use.

Any improper operation of the common venting system should be corrected so the installation conforms with the (g)

National Fuel Gas Code, ANSI Z223.1. When re-sizing any portion of the common venting system, the common

venting system should be re sized to approach the minimum size as determined using the appropriate tables in Part

11 of the National Fuel Gas Code, ANSI Z223.1.

WARNING

NEVER COMMON VENT A BWC BOILER WITH OTHER APPLIANCES.

22

Page 25

E: Special Requirements For Side-Wall Vented Appliances

In The Commonwealth of Massachusetts

IMPORTANT

The Commonwealth of Massachusetts requires compliance with regulation 248 CMR 4.00 and 5.00 for

installation of side-wall vented gas appliances as follows:

1. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment, where

the bottom of the vent terminal and the air intake is installed below four feet above grade the following

requirements must be satised:

a. If there is not already one present, on each oor level where there are bedroom(s), a carbon

monoxide detector and alarm shall be placed in the living area outside the bedroom(s). The carbon

monoxide detector shall comply with NFPA 720 (2005 Edition).

b. A carbon monoxide detector shall be located in the room that houses the appliance or equipment

and shall:

i. Be powered by the same electrical circuit as the appliance or equipment such that only one

service switch services both the appliance and the carbon monoxide detector;

ii. Have battery back-up power;

iii. Meet ANSI/UL 2034 Standards and comply with NFPA 720 (2005 Edition); and

iv. Have been approved and listed by a Nationally Recognized Testing Laboratory as recognized

under 527 CMR.

c. A product-approved vent terminal must be used, and if applicable, a product-approved air intake

must be used. Installation shall be in strict compliance with the manufacturer’s instructions. A copy

of the installation instructions shall remain with the appliance or equipment at the completion of the

installation.

d. A metal or plastic identication plate shall be mounted at the exterior of the building, four feet

directly above the location of the vent terminal. The plate shall be of sufcient size to be easily read

from a distance of eight feet away, and read “Gas Vent Directly Below”.

2. For direct-vent appliances, mechanical-vent heating appliances or domestic hot water equipment, where

the bottom of the vent terminal and the air intake is installed above four feet above grade the following

requirements must be satised:

a. If there is not already one present, on each oor level where there are bedroom(s), a carbon

monoxide detector and alarm shall be placed in the living area outside the bedroom(s). The carbon

monoxide detector shall comply with NFPA 720 (2005 Edition).

b. A carbon monoxide detector shall :

i. Be located in the room that houses the appliance or equipment

ii. Be either hard-wired or battery powered or both; and

iii. Comply with NFPA 720 (2005 Edition)

c. A product-approved vent terminal must be used, and if applicable, a product-approved air intake

must be used. Installation shall be in strict compliance with the manufacturer’s instructions. A copy

of the installation instructions shall remain with the appliance or equipment at the completion of the

installation.

23

Page 26

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

PN: 980034 Rev. 2

10/10

Loading...

Loading...