Page 1

D E S I G N E D T O L E A D

BWC Series

BWC150/225 CONCENTRIC VENTING

INSTALLATION INSTRUCTIONS

These instructions must be affi xed on or adjacent to the boiler.

Models:

• BWC150

• BWC225

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury ,

or loss of life. For assistance or additional information, consult a qualifi ed installer, service agency or the gas supplier.

This boiler requires a special venting system. Read these

instructions carefully before installing.

Page 2

Page 3

Table of Contents

A. Concentric Vent System Design 2

B. Concentric Vent Adapter Kit Installation 9

C. Assembly of Crown Concentric Venting and Condensate Drain 11

1

Page 4

WARNING

F AILURE T O VENT THIS BOILER IN ACCORDANCE WITH THESE INSTRUCTIONS COULD CAUSE

FLUE GAS TO ENTER THE BUILDING RESULTING IN SEVERE PROPERTY DAMAGE, PERSONAL

INJURY, OR DEATH:

* Do not attempt to vent this boiler with galvanized, PVC, or any other vent components not listed in Table 1.6.

* Do not attempt to mix components from different approved vent systems.

* Do not obtain combustion air from within the building.

* Do not install a barometric damper or drafthood on this boiler.

CAUTION

Moisture and ice may form on the surfaces around the vent termination. To prevent deterioration, surfaces

should be in good repair (sealed, painted, etc.).

Concentric Venting For BWC150 and BWC225

A. Concentric Vent System Design

In addition to the vent options listed in the installation manual there are two other ways to vent this boiler:

• Horizontal (“Side Wall”) Concentric Venting - Vent system exits the building through an outside wall.

Concentric venting consists of a “pipe within a pipe”. Flue gas exits the building through the inner pipe and

combustion air is drawn into the boiler through the space between the inner and outer pipe.

• Vertical Concentric Venting - Vent system exits the building through the roof. Concentric venting consists of a

“pipe within a pipe”. Flue gas exits the building through the inner pipe and combustion air is drawn into the boiler

through the space between the inner and outer pipe.

These systems are considered “direct vent” because air for combustion is drawn directly from the outdoors into

the boiler. A description of these venting options are shown in Tables 1.1 and 1.5. For clarity, the vent options

are numbered 3 and 4 for the horizontal options and 8 and 9 for the vertical options. One of the vent option columns

in Tables 1.1 or 1.5 must match the planned vent and air intake system exactly. In addition, observe the following

guidelines:

1) Approved concentric vent systems - The concentric vent system is optional for the BWC150 and BWC225 boilers.

Each Crown concentric vent component consists of an inner pipe of polypropylene and the outer pipe of steel.

Integral gaskets on each concentric fi tting provide a gas tight seal. Concentric pipe sizes are called out in terms

of the inner and outer pipe nominal diameters in millimeters. For example, “80/125mm” pipe consists of a 80mm

exhaust pipe inside a 125mm diameter outer pipe. A list of all Crown concentric vent components is shown in Table

1.6. Use only one of the approved concentric vent systems shown in Table 1.6.

A concentric vent adapter kit is required to use these boilers with concentric pipe. Part numbers for these kits are:

BWC150 P/N 230550

BWC225 P/N 230555

2) Maximum Vent and Air Intake Lengths - The maximum length of the vent air intake piping depends upon the vent

option selected and the boiler size. See Table 1.1 or 1.5 for the maximum vent length. In horizontal vent systems,

the lengths shown in Table 1.1 are in addition to the vent components which come with the Air Intake Box Kit and

one standard radius elbow. For vertical vent systems, the maximum vertical vent lengths shown in Table 1.5 are in

addition to the vent components which come with the Air Intake Box Kit and two standard radius elbows. If more

elbows are desired, the maximum allowable vent length must be reduced by the amount shown in Table 1.4 for each

additional elbow used. Termination fi ttings are never counted, although the length of the concentric terminal section

is counted.

2

Page 5

Example:

A 80/125mm concentric vent system is planned for a horizontally vented BWC150 which has the following

components:

Standard Radius 90° Elbow

5ft Straight Pipe

Standard Radius 90° Elbow

1-1/2ft Straight Pipe

45° Elbow

Uncut Terminal Section

The Vent Option #3 column in Table 1.1 describes a horizontal direct vent system using 80/125mm concentric vent

pipe. From this column, we see that a BWC150 may have a vent length of up to 55ft The fi rst 90° standard radius

elbow is not considered. The length of the terminal section (not including the terminal itself) is approximately 22.1”

(1.84ft) installed. From Table 1.4, we see that the equivalent length of the 80/125mm 90° elbow is 8.5ft and that

the equivalent length of the 45 degree elbow is 3.0ft. The total equivalent length of the planned venting system is

therefore:

5ft (Straight ) + 8.5ft (90 Elbow) + 1.5ft (Straight ) + 3.0ft (45 Elbow) + 1.84ft (Uncut Terminal Section) = 19.84ft.

Since Table 1.1 shows a maximum allowable vent length of 55ft, the planned vent system length is acceptable.

3) Minimum Vent and Air Intake Lengths - Observe the minimum vent lengths shown in Tables 1.1 and 1.5.

4) Permitted Terminals for Horizontal Venting:

• Vent Option 3 - 80/125mm Concentric Vent Terminal (Crown PN 230531)

• Vent Option 4 - 100/150mm Concentric Vent Terminal (Crown PN 230569)

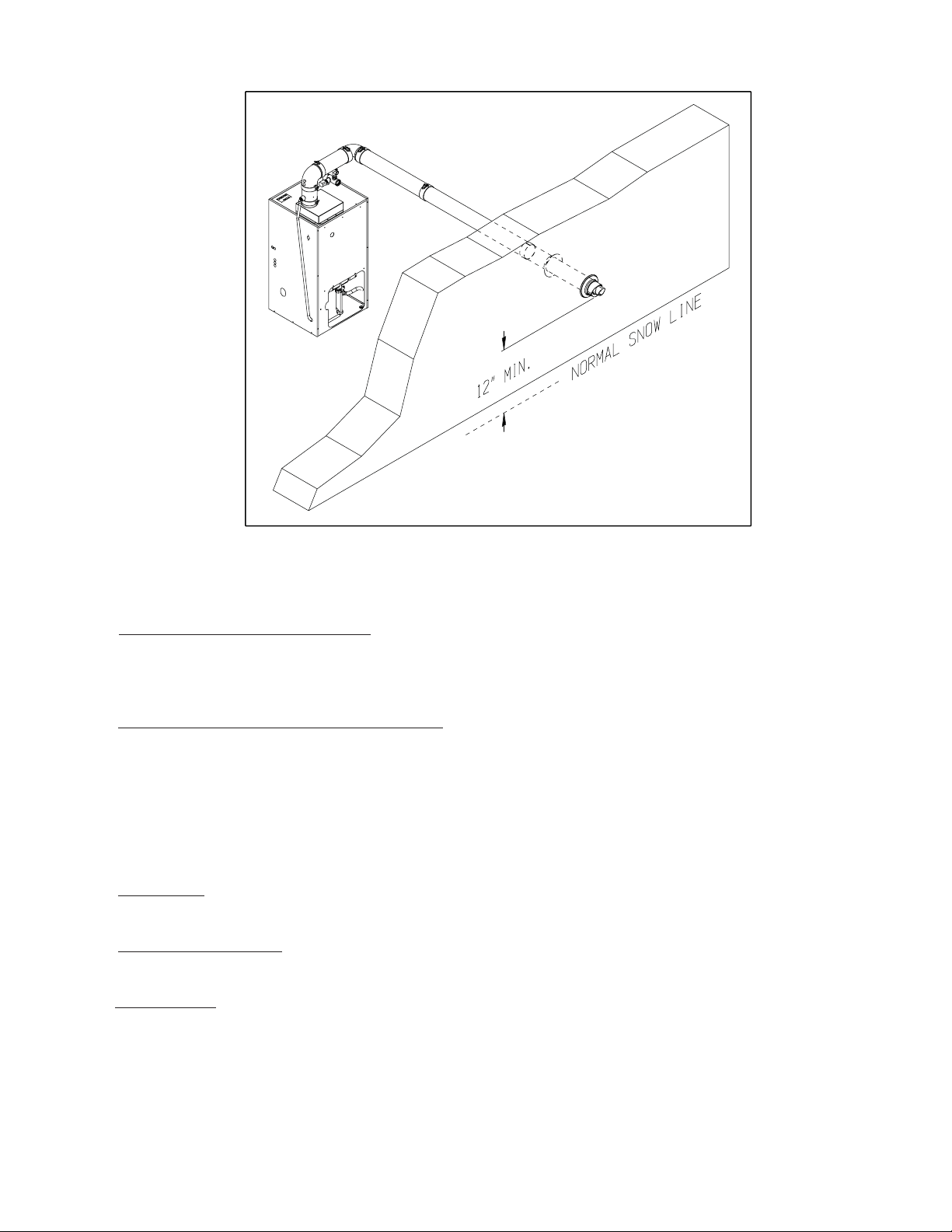

5) Horizontal Vent and Air Intake Terminal Location - Observe the following limitations on the vent terminal location

(also see Figure 1.3). When locating a concentric terminal, observe the limitations outlined below for “vent

terminals”.

• Vent terminal must be at least 1 foot from any door, window, or gravity inlet into the building.

• The bottom of terminal must be at least 12” above the normal snow line. In no case should it be less than 12” above

grade level.

• The bottom of the vent terminal must be at least 7 feet above a public walkway.

• Do not install the vent terminal directly over windows or doors.

• The bottom of the vent terminal must be at least 3 feet above any forced air inlet located within 10 feet.

• A clearance of at least 4 feet horizontally must be maintained between the vent terminal and gas meters, electric

meters, regulators, and relief equipment. Do not install vent terminal over this equipment.

• Do not locate the vent terminal under decks or similar structures.

• Top of vent terminal must be at least 5 feet below eves, soffi ts, or overhangs. Maximum depth of overhang is 3 ft.

• Vent terminal must be at least 6 feet from an inside corner.

• Under certain conditions, water in the fl ue gas may condense, and possibly freeze, on objects around the vent

terminal including on the structure itself. If these objects are subject to damage by fl ue gas condensate, they should

be moved or protected.

• If possible, install the vent and air intake terminals on a wall away from the prevailing wind. Reliable operation of

this boiler cannot be guaranteed if these terminals are subjected to winds in excess of 40 mph.

• Terminal must not terminate in areas that might contain combustion air contaminates, such as near swimming

pools. See Section IV in the installation manual for more information on possible contaminates.

3

Page 6

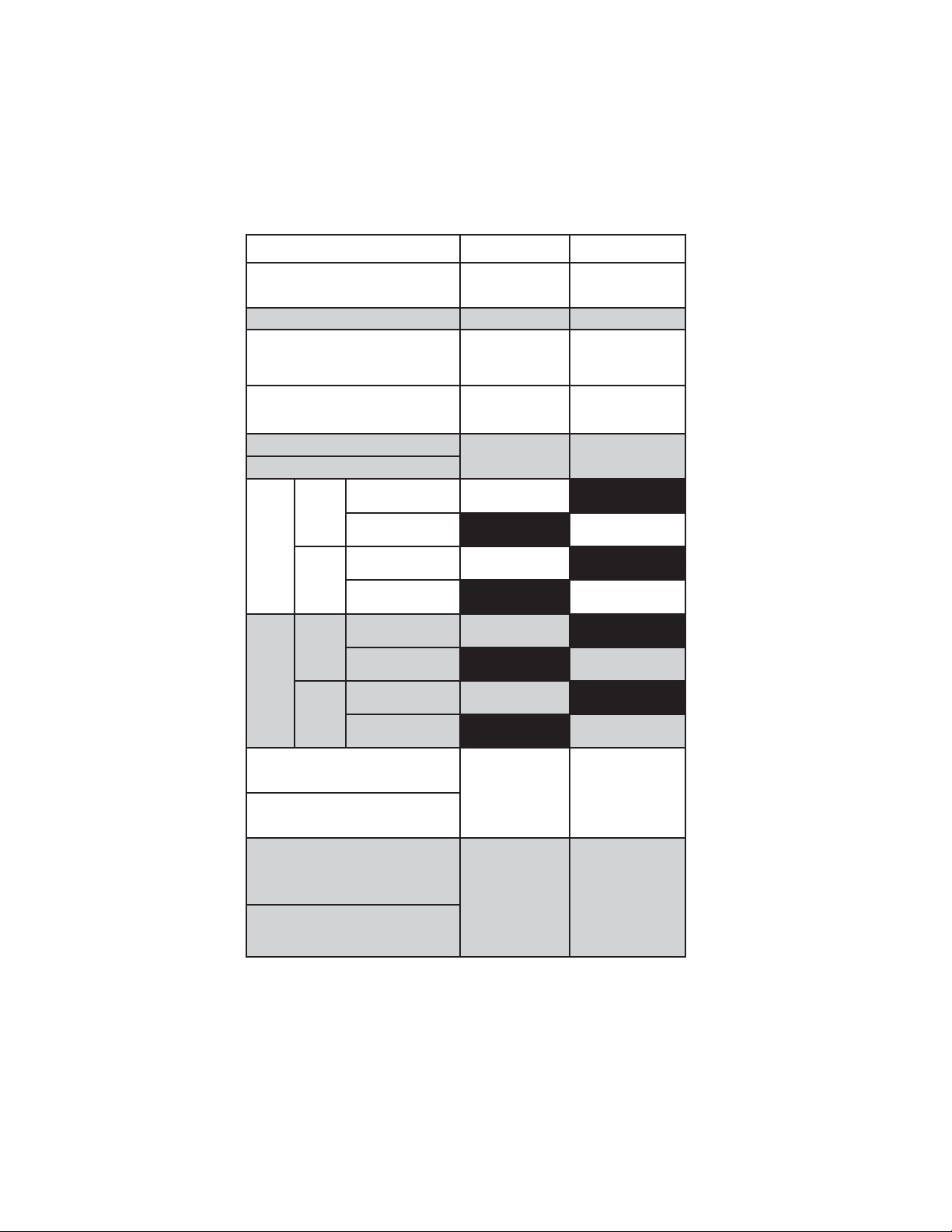

TABLE 1.1: SUMMARY OF HORIZONTAL VENTING OPTIONS

VENT OPTION # 3 4

CLASSIFICATION USED IN THIS

MANUAL

ILLUSTRATED IN FIGURE 1.2 1.2

VENT PIPE PENETRATION

THROUGH STRUCTURE

AIR INTAKE PIPE PENETRATION

THROUGH STRUCTURE

VENT PIPE SIZE

AIR INTAKE PIPE SIZE

BWC150 55

VENT

BWC225 55

BWC150 55

INLET

MAXIMUM LENGTH

MINIMUM LENGTH

BWC225 55

BWC150 2

VENT

BWC225 2

BWC150 2

INLET

BWC225 2

HORIZONTAL

CONCENTRIC

WALL WALL

WALL WALL

80/125 mm

CONCENTRIC

CONCENTRIC

HORIZONTAL

CONCENTRIC

100/150 mm

VENT TERMINAL

AIR INTAKE TERMINAL

VENT MATERIAL

AIR INTAKE MATERIAL

Crown 230531

CONCENTRIC

TERMINAL

CROWN

80/125mm

COMPONENTS

SHOWN IN

TABLE 1.6a

4

VENT

Crown 230569

CONCENTRIC

TERMINAL

CROWN

100/150mm

VENT

COMPONENTS

SHOWN IN

TABLE 1.6b

Page 7

FIGURE 1.2: HORIZONTAL CONCENTRIC VENTING

(VENT OPTION 3,4)

6) Permitted Terminals for Vertical Venting -

• Vent Option 8 - Use Crown PN 230532 with the appropriate fl ashing (Table 1.6a)

• Vent Option 9 - Use Crown PN 230570 with the appropriate fl ashing (Table 1.6b)

7) Vertical Vent Terminal Locations (Vent Options 8,9) - Observe the following limitations on the location of all vertical vent

terminals (see Figure 1.7):

• The top of the vent pipe must be at least 2 feet above any object located within 10 feet.

• The bottom of the air inlet terminal must be at least 12” above the normal snow accumulation that can be expected

on the roof. The terminal used in Vent Options 8 & 9 has a fi xed distance above the storm collar of 19”. If a greater

distance is needed to provide the clearance above the snow line, build a chase on the roof and mount the vertical

terminal on top of the chase.

8) Wall thimbles – Concentric vent has a “zero” clearance to combustibles and therefore does not require the use of wall

thimbles.

9) Pitch of Horizontal Piping - Pitch all horizontal piping 5/8” per foot so that any condensate which forms in the piping will

run towards the boiler:

10) Supporting Pipe - Support Crown concentric venting near the female end of each straight section of pipe.

Exception: Vertical runs of concentric pipe in an unused chimney (Figure 1.14) need only be supported at the

terminal and at the base of the run.

5

Page 8

FIGURE 1.3a: LOCATION OF VENT TERMINAL RELATIVE TO WINDOWS, DOORS, GRADE

FIGURE 1.3b: LOCATION OF VENT TERMINAL RELATIVE TO METERS AND FORCED AIR INLETS

FIGURE 1.3c: POSITIONING VENT TERMINAL UNDER OVERHANGS

6

Page 9

TABLE 1.4: VENT/ AIR INTAKE FITTING EQUIVALENT LENGTH

VENT FITTING EQUIVALENT LENGTH (ft)

80/125mm 90° CONCENTRIC ELBOW 8.5

80/125mm 90° SWEEP CONCENTRIC ELBOW 5.5

80/125mm 45° CONCENTRIC ELBOW 3.0

80/125mm 90° CONCENTRIC SUPPORT ELBOW 8.5

100/150mm 90° SWEEP CONCENTRIC ELBOW 8.0

100/150mm 45° CONCENTRIC ELBOW 3.0

100/150mm 90° CONCENTRIC SUPPORT ELBOW 10.0

TABLE 1.5: SUMMARY OF VERTICAL VENTING OPTIONS

VENT OPTION # 8 9

CLASSIFICATION USED IN THIS

MANUAL

ILLUSTRATED IN FIGURE 1.7 1.7

VENT PIPE PENETRATION

THROUGH STRUCTURE

AIR INTAKE PIPE STRUCTURE

THROUGH STRUCTURE

VENT PIPE SIZE

AIR INTAKE PIPE SIZE

BWC150 47

VENT

BWC225 45

BWC150 47

INLET

MAXIMUM LENGTH

MINIMUM LENGTH

BWC225 45

BWC150 2

VENT

BWC225 2

BWC150 2

INLET

BWC225 2

VERTICAL

CONCENTRIC

ROOF ROOF

ROOF ROOF

80/125 mm CONCENTRIC 100/150 mm CONCENTRIC

VERTICAL

CONCENTRIC

VENT TERMINAL

AIR INTAKE TERMINAL

VENT MATERIAL

AIR INTAKE MATERIAL

CROWN #230532

CONCENTRIC TERMINAL

(TABLE 1.6a)

CROWN 80/125 mm VENT

COMPONENTS SHOWN IN

TABLE 1.6a

7

CROWN #230570

CONCENTRIC TERMINAL

(TABLE 1.6b)

CROWN 100/150 mm VENT

COMPONENTS SHOWN IN

TABLE 1.6b

Page 10

TABLE 1.6a: CROWN CONCENTRIC 80/125 VENT COMPONENTS

(VENT OPTIONS 3,8)

USED ON

CROWN PN DESCRIPTION SIZE

230527 90 DEGREE EL (STANDARD) 80/125mm 3,8

230528 90 DEGREE EL (SWEEP) 80/125mm 3,8

230526 45 DEGREE EL 80/125mm 3,8

230517 19 1/2” STRAIGHT 80/125mm 3,8 CAN BE CUT

230515 39” STRAIGHT 80/125mm 3,8 CAN BE CUT

230518 39” STRAIGHT 80/125mm 3,8 MAY NOT BE CUT

230519 78” STRAIGHT 80/125mm 3,8 MAY NOT BE CUT

230525 TELESCOPING STRAIGHT 80/125mm 3,8 ADJUSTABLE FROM 12-1/2” TO 16-1/2

230531 HORIZONTAL TERMINAL 80/125mm 3

230532 VERTICAL TERMINAL 80/125mm 8 (NOTE #1)

230533 FLAT ROOF FLASHING 80/125mm 8

230535 SLOPED ROOF FLASHING 80/125mm 8 (NOTE #2)

230530

230536 SUPPORT BAND 80/125mm 3,8

SUPPORT ELBOW WITH

CHIMNEY CHASE BRACKET

80/125mm 8 (NOTE #3)

VENT

OPTION #

COMMENTS

Table 1.6a Notes:

1) Vertical terminal can be used with either of the roof fl ashings listed beneath it.

2) Sloped roof fl ashing suitable for roof angles between 25 and 45 degrees.

3) Used at base of vertical run inside unused masonry chimney.

TABLE 1.6b: CROWN CONCENTRIC100/150 VENT COMPONENTS

(VENT OPTIONS 8,9)

USED ON

CROWN PN DESCRIPTION SIZE

230567 90 DEGREE EL (SWEEP) 100/150mm 4,9

230565 45 DEGREE EL 100/150mm 4,9

230560 19 1/2” STRAIGHT 100/150mm 4,9 CAN BE CUT

230562 39” STRAIGHT 100/150mm 4,9 CAN BE CUT

230561 39” STRAIGHT 100/150mm 4,9 MAY NOT BE CUT

230563 78” STRAIGHT 100/150mm 4,9 MAY NOT BE CUT

230564 TELESCOPING STRAIGHT 100/150mm 4,9 ADJUSTABLE FROM 12-1/2” TO 17-1/2

230569 HORIZONTAL TERMINAL 100/150mm 4

230570 VERTICAL TERMINAL 100/150mm 9 (NOTE #1)

230571 FLAT ROOF FLASHING 100/150mm 9

230572 SLOPED ROOF FLASHING 100/150mm 9 (NOTE #2)

230568

230573 SUPPORT BAND 100/150mm 4,9

SUPPORT ELBOW WITH

CHIMNEY CHASE BRACKET

100/150mm 9 (NOTE #3)

VENT

OPTION #

COMMENTS

Table 1.6b Notes:

1) Vertical terminal can be used with either of the roof fl ashings listed beneath it.

2) Sloped roof fl ashing suitable for roof angles between 25 and 45 degrees.

3) Used at base of vertical run inside unused masonry chimney.

8

Page 11

FIGURE 1.7: VERTICAL CONCENTRIC VENT SYSTEM (VENT OPTION 6)

B. Concentric Vent Adapter Kit Installation

1) The Concentric Vent Adapter Kits include:

P/N 230550

(BWC150)

240470 240480 Rubber Gasket

240471 240481 Air Intake Box

90-054 90-054 #10 x 3/4” Sheet Metal Screws

240472 240482 Stainless Vent Adapter

230539 230575 Concentric Condensate Collector

240552 240552 Condensate Collector Adapter

240550 240550 Tapped Condensate Trap Plug

240560 240560 66”of 1/2” Clear PVC Tubing

240555 240555 90° Hose Barb (2)

240557 240557 1/2” Hose Clamps (2)

Where the use of “silicone” is called for in the following instructions, use GE RTV106 for the vent adapters and

any general-purpose silicone sealant such as GE RTV102 for the air inlet piping connection.

a) Start assembly of the air intake box by fi rst removing the hose clamp shipped on the BWC vent collar.

Bend the three hose clamp tabs on this collar inward slightly.

b) Place the gasket over the vent collar and air intake collar as shown in Figure 1.8. The gasket should fi t

snugly against the vent collar and air intake collar with no gaps.

c) Bend the three hose clamp tabs on the vent collar outward slightly.

d) Clean the exterior of the male end and interior of the female end of the stainless vent adapter and the

inside of the vent collar on the boiler. Remove dirt, grease, and moisture from the surfaces to be sealed. Dry

surfaces or allow to dry thoroughly.

P/N 230555

(BWC225)

Description

9

Page 12

e) On the male end of the stainless vent adapter, apply a ¼” wide bead of silicone approximately 1/2” from

the end of the pipe.

f) Insert the male end of the stainless vent adapter into the boiler vent collar until it bottoms out.

g) Apply an additional bead of silicone over the outside of the joint and smooth out.

h) Replace and tighten the clamp on the vent collar.

i) Remove one (BWC150) or two (BWC225) of the #10 sheel metal screws on the top of the rear jacket panel

and place the air intake box over the vent and onto the boiler.

j) Use the exposed holes to line up the air intake box and gasket.

k) Insert the concentric condensate collector into the stainless vent adapter and the air intake box until the bead

on the collector bottoms out on the air intake box collar. Turn the fi tting so that the threaded stub faces to the

right.

l) Square up the air intake box and the foam rubber gasket to the boiler jacket and loosely attach the box to the

rear jacket panel with one of the previously removed #10 sheet metal screws.

m) Drill a single 1/8” hole through one of the mounting holes on the opposite side of the air intake box and

attach the box to the jacket with one of the #10 sheet metal screws. This will insure the rest of the mounting

holes line up.

n) Drill 1/8” holes in through the remaining mounting holes and attach the air intake box and gasket to the boiler

jacket with the remaining #10 sheet metal screws.

o) Apply pipe thread sealant tape (not supplied) to the 90° barbed hose fi ttings. Attach one to the condensate

collector adapter and the other to the bottom of the tapped condensate trap plug. (Figures 1.8, 1.15)

p) Attach the condensate collector adapter to the threaded portion of pipe sticking out the side of the concentric

condensate collector so that the hose barb is facing down. Slide one end of the 1/2” clear plastic tubing over

the hose barb and attach the hose clamp.

q) Run the tubing down the right side panel and into the 1-3/8” knockout located on the lower right of the right

side panel. Be sure to remove all burrs from the knockout to prevent the hose from being punctured.

r) Remove the plug and black gasket ring from the bottom of the condensate trap located under the boiler.

s) Reinstall the gasket ring onto the tapped condensate trap plug. Insert the tapped plug (which has the barbed

hose fi tting attached to it) in the base of the trap in place of the original plug. Slide the other end of the clear

plastic tubing over the hose barb and attach the hose clamp. (Figure 1.15)

t) Allow the silicone to cure per the silicone manufacturer’s instructions before operating the boiler.

FIGURE 1.8: CONCENTRIC VENT

ADAPTER ASSEMBLY

10

Page 13

C. Assembly of Crown Concentric Venting

WARNING

Failure to follow the instructions could result in fl ue gas leakage into the combustion air or indoor air,

resulting in unsafe or unreliable operation.

• Do not lubricate concentric gaskets with anything other than water.

• Do not attempt to cut any piping except as permitted in this section. When cutting these sections, make sure

all cuts are square and allow for proper insertion.

• Do not attempt to try to mix this concentric pipe with other venting systems.

1) The components listed in Table 1.6 are required for 80/125mm and 100/150mm installations and are not supplied

with the BWC150/225 boilers. Before starting assembly of the vent system, make sure that the planned installation

is in accordance with the “Vent System Design” section of this manual and that all required vent components are on

hand. These components are available through Crown distributors.

2) Cutting Straight Pipe - The following straight pipe sections may be cut:

80/125 Part # 100/150 Part # Description

230517 230560 19 1/2” Straight

230515 230562 39” Straight

These sections have a plain male end (without beads - see Figure 1.9a). They are always cut from the male end.

Sections not shown on the above list may not be cut. These sections have beads on the male end (Figure 1.9b).

To cut the straight sections listed above refer to Figure 1.10 and the following instructions:

FIGURE 1.9a: CUTTABLE STRAIGHT SECTION

FIGURE 1.9b: NON CUTTABLE STRAIGHT SECTION

11

Page 14

a) Determine the required length of the outer pipe. When doing this allow an additional 1” of length for insertion

into the female end of the adjoining pipe. Mark the cut line on the outer pipe.

b) Remove the plastic inner pipe by pulling it out from the female end.

c) Cut the OUTER PIPE ONLY at the point marked in Step (a) using aviation shears, a hacksaw, or an abrasive

wheel cutter. Be careful to cut the pipe square. De burr the cut end with a fi le or emery cloth.

d) Make an insertion mark 1” from the male end of the outer pipe.

e) Cut the plastic inner pipe so that it will protrude 3/8” beyond the male end of the outer pipe when reinstalled

in the outer pipe. Use a fi ne tooth hacksaw or a PVC saw to cut the plastic pipe and be careful to cut the pipe

square. De burr the cut edge of the plastic pipe with a fi le, razor blade, or fi ne sandpaper.

f) Reinstall the inner pipe.

3) Joining Pipe -

FIGURE 1.10: CUTTING STRAIGHT PIPE

12

Page 15

a) Start assembly of the vent system at the boiler. Lubricate the brown gasket in the boiler vent collar with a few drops

of water.

b) Push the male end of the fi rst fi tting into the boiler collar until it bottoms out. The male end of cuttable sections

should go 1” into the collar until the insertion mark (made in Step 2d above) is covered. On other fi ttings, the bead

on the male pipe will bottom out on the collar (Figure 1.11b).

c) The male end of cuttable fi ttings must be held to the collar with three #10 x 1/2” sheet metal screws. Drill a 1/8 hole

through both outer pipes to start this screw. Use a drill stop or other means to ensure that the drill bit does not

penetrate more than 3/8” into the outer pipe. Do not use a sheet metal screw longer than 1/2” (Figure 1.11a).

d) Use locking bands (provided with all fi ttings) to secure non-cuttable pipe, as well as fi ttings, to the boiler collar

(Figure 1.11b).

e) Use the same method to join all remaining vent components except for the terminal.

4) Horizontal Terminal Installation

FIGURE 1.11a: JOINING CUTTABLE PIPE

FIGURE 1.11b: JOINING NON CUTTABLE PIPE

13

Page 16

a) Cut a 5-1/2” diameter hole through the exterior wall at the planned location of the horizontal terminal.

b) Measure distance “L” from the outside surface of the exterior wall to the end of the last fi tting as shown in

Figure 1.12a.

c) Add 1-1/4” to distance “L”. Carefully mark this length on the pipe as shown in Figure 1.12b.

d) Remove the aluminum inner pipe from the terminal, by gently pulling on it from the male end. Set aside.

e) Cut the outer pipe only at the point marked in Step (c) using aviation shears, a hacksaw, or an abrasive

wheel cutter. Be careful to cut the pipe square. De-burr the cut end with a fi le or emory cloth.

f) Reinstall the aluminum inner pipe in the terminal, making sure that the female end of this pipe is

completely bottomed out over the aluminum male connection visible behind the air intake grill. Place a

mark on the aluminum inner pipe 3/8” beyond the end of the outer pipe (Figure 1.12c). Use a fi ne tooth

hacksaw or hand shears to cut the aluminum pipe and be careful to cut the pipe square (if necessary, the

aluminum pipe can be removed from the terminal again for cutting). De-burr the cut edge of the aluminum

pipe with a fi le or fi ne sandpaper.

g) Make a mark on the terminal section 1” from the cut end of the outer pipe as shown in Figure 1.12c.

h) Slip the terminal section through the wall from the outside. Pass the terminal through the inner wall plate

and push into the last section of vent pipe until the mark made in Step (h) is not longer visible (Figure

1.12d). Secure the terminal to the last piece of pipe with three #10 x 1/2” sheet metal screws. Drill a 1/8

hole through both outer pipes to start these screws. Use a drill stop or other means to ensure that the

drill bit does not penetrate more than 3/8” into the outer pipe. Do not use a sheet metal screw longer

than 1/2”.

i) Slip the outer wall plate over the terminal and secure to the wall (Figure 1.12d). Apply a 1/8” bead of

weather resistant RTV over the joint between the outside wall plate and the terminal. Secure the other wall

plate to the inside wall.

FIGURE 1.12a: DIMENSION “L”, HORIZONTAL TERMINAL

FIGURE 1.12b: CUTTING OUTER PIPE OF HORIZONTAL TERMINAL

14

Page 17

FIGURE 1.12c: CUTTING INNER PIPE OF HORIZONTAL TERMINAL

FIGURE 1.12d: COMPLETING HORIZONTAL TERMINAL INSTALLATION

15

Page 18

6) Vertical Terminal Installation - In addition to the vertical terminal, either a Flat Roof Flashing (80/125 PN

230533, 100/150 PN 230571) or Sloped Roof Flashing (80/125 PN 230535, 100/150 PN 230572) is required for

this installation.

a) Determine the center line of the terminal location on the roof. If the roof is fl at, cut a 5-1/2” diameter hole for

the 80/125 terminal and a 6-1/2” diameter hole for the 100/150 terminal. If the roof is sloped, cut a hole large

enough for the terminal to pass through the roof while remaining plumb. Caution: If the boiler is installed

directly under the hole, cover it while cutting the hole to prevent saw dust and other debris from falling

into the boiler.

b) Install the roof fl ashing using standard practice for the roofi ng system on the structure.

c) If not already done, assemble the venting system inside the building. The last section of pipe needs to be on the

same center line as the terminal and within 19-1/4” (80/125) or 28” (100/150) of the top edge of the roof fl ashing

(Figure 1.13a).

d) Measure distance “H” from the top edge of the storm collar to the end of the last fi tting as shown in Figure 1.13a.

e) Add 1” to distance “H”. Carefully mark this length on the pipe as shown in Figure 1.13b.

f) Cut the outer pipe only at the point marked in Step (e) using aviation shears, a hacksaw, or an abrasive wheel

cutter. Be careful to cut the pipe square. De-burr the cut end with a fi le or emery cloth.

g) Place a mark on the aluminum inner pipe 3/8” beyond the end of the outer pipe (Figure 1.13b). Use a fi ne tooth

hacksaw to cut the aluminum pipe and be careful to cut the pipe square. De-burr the cut edge of the aluminum

pipe with a fi le or emery cloth.

h) Make a mark on the terminal section 1” from the cut end of the outer pipe as shown in Figure 1.13b.

i) Slip the terminal section through the roof from the outside. Push into the last section of vent pipe until the mark

made in Step (h) is not longer visible. Secure the terminal to the last piece of pipe with three #10 x 1/2” sheet

metal screws. Drill a 1/8” hole through both outer pipes to start these screws. Use a drill stop or other means

to ensure that the drill bit does not penetrate more than 3/8” into the outer pipe. Do not use a sheet metal

screw longer than 1/2”.

j) Secure the terminal section to the inside of the roof structure using the mounting bracket provided with the

terminal (Figure 1.13c).

7) Chimney Chase Installation - A vertical vent system can be installed in an unused masonry chimney. This

installation is similar to other vertical installations with the following exceptions (Also see Figure 1.14):

a) The chimney chase elbow kit (80/125 PN230530, 100/150 PN 230568) is used at the base of the chimney. This

kit consists of a support elbow and a mounting bracket. Slip the elbow over the M10 x 35 screw in the support

bracket. Determine the desired vertical location of the support elbow in the chimney and mark the location of

the pin on the back of the support bracket on the back wall of the chimney. Drill a 7/16”dia x 2-1/2” deep hole

at this location to support the back of the bracket. The front of the elbow mounting bracket is supported by the

bottom of the opening into the chimney or by an installer supplied bracket.

b) Construct a weather-tight fl at roof to cover the top of the old chimney. Install the vertical terminal through this

roof using the fl at roof fl ashing.

FIGURE 1.13a: DIMENSION “H”

16

Page 19

FIGURE 1.13b: CUTTING VERTICAL TERMINAL

FIGURE 1.13c: COMPLETING VERTICAL TERMINAL INSTALLATION

17

Page 20

WARNING

• Do not attempt to construct a vertical vent system inside a chimney that is used to vent a fi replace or other

appliances.

• Do not attempt to construct a vertical vent system inside a chimney fl ue adjacent to another fl ue used by a fi replace

or other appliances.

FIGURE 1.14: CHIMNEY CHASE INSTALLATION

18

Page 21

8) Condensate Drain Line - In systems where a concentric vent is used, all condensate which forms in the boiler or

vent system collects in both the condensate vent adapter and the sump under the heat exchanger and leaves the

boiler through the condensate trap. This trap allows condensate to drain from the boiler and vent while retaining

fl ue gases. A length of corrugated drain hose is supplied with the boiler and is connected to the trap as shown

in Figure 1.15. This hose may be routed through the back of the boiler or to the left side through the knockout

provided. Route this hose to a drain or other suitable point for disposal. Note the following when disposing of the

condensate:

a) If the condensate drain line must be extended, construct the extension from PVC or CPVC pipe. Insert the

hose provided with the boiler into the end of the extension as shown in Figure 1.15.

b) Condensate is slightly acidic. Do not use metallic pipe or fi ttings in the condensate drain line. Do not route

the drain line through areas that could be damaged by leaking condensate.

c) Some jurisdictions may require that the condensate be neutralized before being disposed of. Dispose of

condensate in accordance with local codes.

d) Do not route, or terminate, the condensate drain line in areas subjected to freezing temperatures.

e) If the point of condensate disposal is above the trap, it will be necessary to use a condensate pump to

move the condensate to the drain. In such cases, select a condensate pump that is approved for use

with condensing furnaces. If overfl ow from this pump would result in property damage, select a pump

with an overfl ow switch and use this switch to shut down the boiler. Alternatively, if heat is a necessity,

use the overfl ow switch to trigger an alarm.

f) Do not attempt to move the trap from the location shown in Figure 1.15. Do not attempt to substitute

another trap for the one provided with the boiler.

g) The vent shown in Figure 1.15 must be left open for the trap to work properly.

FIGURE 1.15: CONDENSATE DRAIN LINE ASSEMBLY

19

Page 22

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

PN: 980241 Rev. 0

BWC - 12/07

Loading...

Loading...