Page 1

D E S I G N E D T O L E A D

Series 24

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

Forced Draft Steam or Water Boilers

INSTALLATION INSTRUCTIONS

These instructions must be affixed on or adjacent to the boiler.

Models:

• 24-03

• 24-04

• 24-05

• 24-06

• 24-07

• 24-08

• 24-09

• 24-10

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage, injury,

or loss of life. For assistance or additional information, consult a qualified installer, service agency or the gas supplier.

This boiler requires a special venting system. Read these

instructions carefully before installing.

• 24-11

• 24-12

1

Page 2

2

Page 3

IMPORTANT INFORMATION - READ CAREFULLY

,gnibmulPlacoLdnaetatS,lanoitaNhtiwecnadroccanidellatsniebtsumsreliobllA

esehT.seitilitugnivresehtfosnoitalugerehtdnasedoClacirtcelEdnagnitaeH

gnivahseitirohtuA.launamnoitcurtsnisihtmorfreffidyamsnoitalugeRdnasedoC

.edamerasnoitallatsnierofebdetlusnocebdluohsnoitcidsiruj

:sdradnatSgniwollofehtotedamebdluohsecnerefer,sesacllanI

.A

.B

.C

.D

.E

liOfonoitallatsnI“,13APFN/ISNAdradnatSlanoitaNnaciremAfonoitidEtnerruC

.secitcarpnoitallatsnidednemmocerrof,”tnempiuqEgninruB

.1.322ZISNA/45APFN,edoCsaGleuFlanoitaNfonoitidEtnerruC

,syenmihC“,112APFN/ISNAdradnatSlanoitaNnaciremAfonoitidEtnerruC

.stnemeriuqergnitneVroF,”secnailppAgninruBleuFdiloSdna,stneV,secalperiF

,1-DSCEMSAsreenignElacinahceMfoyteicoSnaciremAfonoitidEtnerruC

dnaylbmessarof,"srelioBderiFyllacitamotuArofseciveDytefaSdnaslortnoC"

.secivedytefasdnaslortnocfosnoitarepo

lacirtcelElanoitaNehthtiwecnadroccaniedamebllahssreliobnogniriwllA

.snoitalugeRlacoLro/dnaedoC

DANGER

Indicates an imminently haz ardous situation

which, if not avoided, will result in death,

serious injury or substantial property

damage.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in moderate

or minor injury or property damage.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death,

serious injury or substantial property

damage.

NOTICE

Indicates special instructions on installation,

operation, or maintenance which are

important but not related to personal injury

hazards.

3

Page 4

WARNING

Imp roper ins tallation, adju stment, alteration, service or main tenan ce can cause p roperty

da mage, personal injury or loss of life. Failu re to follow a ll in structions in th e proper orde r

ca n cause personal in jury or death. R ead and u n d erstand all instructions, including all

those con tained in compon e nt manufa cturers manuals which are pro vide d w ith the

ap p liance before installing, starting-up, o perating, maintaining or servicing this appliance.

Keep this man u al an d literature in legib le con d itio n a nd poste d near ap p liance for referenc e

by o w ner and serv ice technician.

Th is boiler requires regular main tenan c e and servic e to operate safe ly. Follo w the

instructions contain e d in this manual. Ins tallation, mainte nance, and servic e must be

pe rformed only by an experienced, skilled and knowledgeable installer o r servic e agency.

All h e ating systems should be designed by competent co n tra ctors and only persons

kn o w ledgeable in the layout and insta llation of hydro n ic hea ting systems should a ttempt

installation of any b oiler. It is th e respo n sibility of the installing contractor to see that all

co n trols a re correctly in stalled and are opera ting prop e rly w hen the installation is

co mplete d . Installatio n is not comp lete unless a pressure relief va lve is installed into the

sp ecified ta p ping located at the rear of applian c e - See Section III of this manual for details.

Th is boiler is suita b le for insta llation on combustible floorin g . Do not install b o iler o n

ca rpetin g . Do not operate on flo o rs where h eat affecte d material is b elow.

Do not tamper w ith or alter the boiler or controls. Retain your co n tractor or a competen t

se rviceman to as sure that the unit is properly adjusted and main tained.

Clean boiler at le ast onc e a year - preferably at the start of the heating season to remove

so o t and sc ale. The inside of c ombustion chamb er should also be cleaned and inspected

at th e same time.

Have B u rner and C o ntrols c hecked at le ast once a y ear or as ma y be necess itate d .

Do not operate unit w ith jumpered or absent controls o r safety devices.

Do not operate unit if any control, sw itch, componen t, or device has bee n subject to w a ter.

Return w ate r cannot be low e r th an 135°F for prolonged p e riods of time. Op eratio n under

these co n d itio n s w ill result in susta ined c ondensing w ithin the combustion ch a mber and

po tentia lly reduce boile r longevity.

In addition, th e return water can n o t be introduced into the boiler if it is mo re than 40°F le ss

than the id le boiler tempe rature. Continued operation under these conditions may res u lt in

prema ture boiler failure thro u gh thermal shock .

Exa mple

: A b oiler that has been idle fo r some time since th e la st heat demand cycle ma y

ha ve it's boiler water temperatu re reduced to 150°F. The retu rn te mperatu re from the nex t

zone activa tion cannot be less th a n 110°F.

If the abo v e conditions exist, an R TC system must b e installe d to protect th e boiler from

su stained con d ensin g o peration and th e rmal sh o ck.

DANGER

DO NOT store o r use gaso line or o ther flammable vapors or liq u ids in th e vicinity o f this or a n y

other appliance.

4

Page 5

GNINRAW

,animulaniatnocleufehtdnanoitsubmocfostcudorp,noitcurtsnocfoslairetamecnailppA

rocixotrehtoro/dnasedyhedla,sedixonegortin,edixonomnobrac,slatemyvaeh,acilis

ehtotnwonkerahcihwdnayrujnisuoiresrohtaedesuacnachcihwsecnatsbuslufmrah

esusyawlA.mrahevitcudorperrehtodnastcefedhtrib,recnacesuacotainrofilaCfoetats

ehtybraengnikrowrognicivresnehwtnempiuqednasrotaripser,gnihtolcytefasreporp

.ecnailppa

ynawercsnutonoD.serusserphgihrednumaetsroretawtohyrevsniatnocreliobsihT

ylevitisoptuohtiwreliobsihtfostnenopmocynatcennocsidottpmettaronsgnittifepip

dnagnihtolcevitcetorpraewsyawlA.erusserponsahdnaloocsiretawehtgnirussa

oD.seirujnidlacstneverpotreliobsihtgnicivresropugnitrats,gnillatsninehwtnempiuqe

erusserpdnaerutarepmetehtenimretedotseguagerutarepmetdnaerusserpehtnoylerton

sireliobehtnehwtohyrevemocebhcihwstnenopmocsniatnocreliobsihT.reliobehtfo

.loocerayehtsselnustnenopmocynahcuottonoD.gnitarepo

doognimetsystnevdevorppanaotdetcennocdnadetnevylreporpebtsumecnailppasihT

.metsystnevdevorppanafoecnesbaehthtiwreliobetarepotonoD.noitidnoc

snoisivorperaerehtosdellatsniebtsumdnanoitarepoefasrofriahserfsdeenreliobsihT

.rianoitalitnevdnanoitsubmocetauqedarof

ehterofebdenaelcdnadetcepsniebtsumsmetsysekatniriadnagnitnevehtforoiretniehT

gnitaehehttuohguorhtyllacidoirepdetcepsniebdluohsdnanosaesgnitaehehtfotrats

erasmetsysekatniriadnagnitnevdetcurtsbonudnanaelC.snoitcurtsboynarofnosaes

dnaylefastnevotefilfossolroyrujniesuacdluoctahtsemufsuoixonwollaotyrassecen

.ycneiciffes'reliobehtgniniatniamdrawotetubirtnoclliw

-ertondnanwodtuhsotreliobehtesuacyamhcihwslortnochtiwdeilppussireliobsihT

metsysgnitaeheht,ytilibissopasisepipnezorfoteudegamadfI.ecivrestuohtiwtrats

dluohssmraladnasdraugefasetairporpparo;rehtaewdlocnidednettanutfelebtondluohs

.evitareponisireliobehtfiegamadtneverpotmetsysgnitaehehtnodellatsnieb

esutonoD.ylnosagPLro/dnalarutan,lioleuf2.oNnrubotdengisedsireliobsihT

repaproegabragnrubreveN.enilosaggniniatnoclioynaro,sgniniardesacknarc,enilosag

elbammalfllA.)laoc,doow.e.i(leufdilosynanrubotreliobtrevnoctonoD.reliobsihtni

peeK.semitllatareliobehtforaelctpekebdluohs,.cte,sparcsdoow,repap,sgar,sirbed

.sdrazaheriffoeerfdnanaelcaerareliobeht

.ecnanetniamdnanoitcepsnilaunnaeriuqersecivedffotucretawwolepyttaolfdnaeborP

.snoitcurtsnigninaelcdnanoitcepsnirofCmetI,15egaPnosnoitcurtsniotrefeR

NOTICE

All Series 24 cast iron boilers are designed, built, marked and tested in accordance with the

ASME Boiler and Pressure Vessel Code

, Section IV

, Heating Boilers

. An ASME Data Label is

factory applied to each Series 24 jacket, which indicates the boiler Maximum Allowable Working

Pressure (MAWP). Each cast iron section is permanently marked with the MAWP listed on the

boiler's ASME Data Label. Those values for the Series 24 are as follows:

MAWP, Steam - 1

5 psi

M

AWP, Water (USA) - 80 psi

M

AWP, Water (Canada) - 45 psi

I

t is common and acceptable practice to install these boilers in lower pressure systems, below

the boiler MAWP. Therefore, Crown offers safety relief valves set at or below the MAWP of the

boiler. See page 9 for standard safety relief valve set pressures.

5

Page 6

TABLE OF CONTENTS

SECTION I - GENERAL INFORMATION

Dimensional Information ............................................................................................................................................... 8

Ratings/Data .................................................................................................................................................................. 9

Locating the Unit . ........................................................................................................................................................ 10

Air Supply/Venting ....................................................................................................................................................... 11

SECTION II - CAST IRON BLOCK ASSEMBLY

Assembly of Sections, Manual Draw-up ..................................................................................................................... 13

Assembly of Sections, Hydraulic Draw-up ................................................................................................................. 16

Hydrostatic Test ........................................................................................................................................................... 18

SECTION III - INSTALLATION INSTRUCTIONS

Knockdown

Canopy ......................................................................................................................................................................... 19

Flue Cover Plates ......................................................................................................................................................... 22

Rear Observation Port Cover ........................................................................................................................................ 23

Inspect All Boiler Seals ................................................................................................................................................ 23

Jacket Assembly .......................................................................................................................................................... 23

Burner Mounting Plate / Burner Adapter Plate ........................................................................................................... 25

Steam Trim .................................................................................................................................................................. 26

Water Trim . .................................................................................................................................................................. 30

Burner Installation ....................................................................................................................................................... 32

Common Installation Requirements

Boiler Piping - Heating Applications .......................................................................................................................... 32

Boiler Piping - Domestic Hot Water (DHW) Applications .......................................................................................... 33

Tankless Heater Piping ................................................................................................................................................ 41

Electric Wiring ..............................................................................................................................................................43

Return Temperature Control (RTC) and Components .................................................................................................. 43

SECTION IV - OPERATING INSTRUCTIONS

Filling System ............................................................................................................................................................... 47

Adjusting Controls ....................................................................................................................................................... 47

Adjusting Burner ......................................................................................................................................................... 48

Return Temperature Control; Initial Set-Up and Operation .........................................................................................48

Diverting Valve Actuator .............................................................................................................................................. 50

Boiler Operating Aquastat ............................................................................................................................................ 50

Boiler High Limit Aquastat .......................................................................................................................................... 50

Boiler Modulating Control ........................................................................................................................................... 50

Test Controls ................................................................................................................................................................ 50

Initial Cleaning, Steam Boilers .................................................................................................................................... 51

Initial Cleaning, Water Boilers ....................................................................................................................................52

Frequent Water Addition ..............................................................................................................................................53

Oxygen Corrosion ........................................................................................................................................................53

SECTION V - SERVICE INSTRUCTIONS

Cleaning Boiler Heating Surfaces ............................................................................................................................... 54

Maintenance of Low Water Cutoff Devices ................................................................................................................55

Checking Burner & Controls ........................................................................................................................................ 56

Lubrication ...................................................................................................................................................................56

General Maintenance Considerations ........................................................................................................................... 56

Attention to Boiler While Not in Operation ................................................................................................................. 56

6

Page 7

TABLE OF CONTENTS - Continued

SECTION VI - BURNER SPECIFICATIONS

Beckett Burners (Table VI) ........................................................................................................................................... 57

SECTION VII - REPAIR PARTS & CARTON CONTENTS

Regional Office Directory ............................................................................................................................................58

Jacket Assembly .......................................................................................................................................................... 60

Bare Boiler Assembly ................................................................................................................................................... 62

Steam/Water Trim ......................................................................................................................................................... 65

RTC Related Components ............................................................................................................................................ 66

SECTION VIII - APPENDIX

A. Application Drawings - Mechanical and Electrical

A1. 3-way RTC in Primary/Secondary – Heating Only/No DHW; with/without Outdoor reset

A2. 3-way RTC in Primary/Secondary – Heating/DHW with/without priority using Tankless coils and Outdoor reset.

A3. 3-way RTC in Primary/Secondary – Heating/DHW with/without priority using Indirect Water Heater and

Outdoor reset.

A4. 3-way RTC in Primary/Secondary –Indirect Water Heater as load on primary loop without Outdoor reset.

A5. 3-way Multiple Boiler RTC in Primary/Secondary – Indirect Water Heater (or other heat exchanger) as Load on

Primary Loop using Sequencer and Outdoor Reset.

A6. Tankless Application Only with boiler circulation loop. No building heating load.

A7. Indirect Water Heater Only with boiler circulation loop. No building heating load.

B. Boiler Circulator and Diverting Valve Selection Charts

B1. S24, 20 and 40 ∆Τ − Taco

B2. S24, 20 and 40 ∆Τ − Grundfos

B3. S24, 20 and 40 ∆Τ − Bell and Gossett

B4. S24, 20 and 40 ∆Τ - Armstrong

C. Valve and Actuator Mounting Instructions

7

Page 8

Section I - General Information

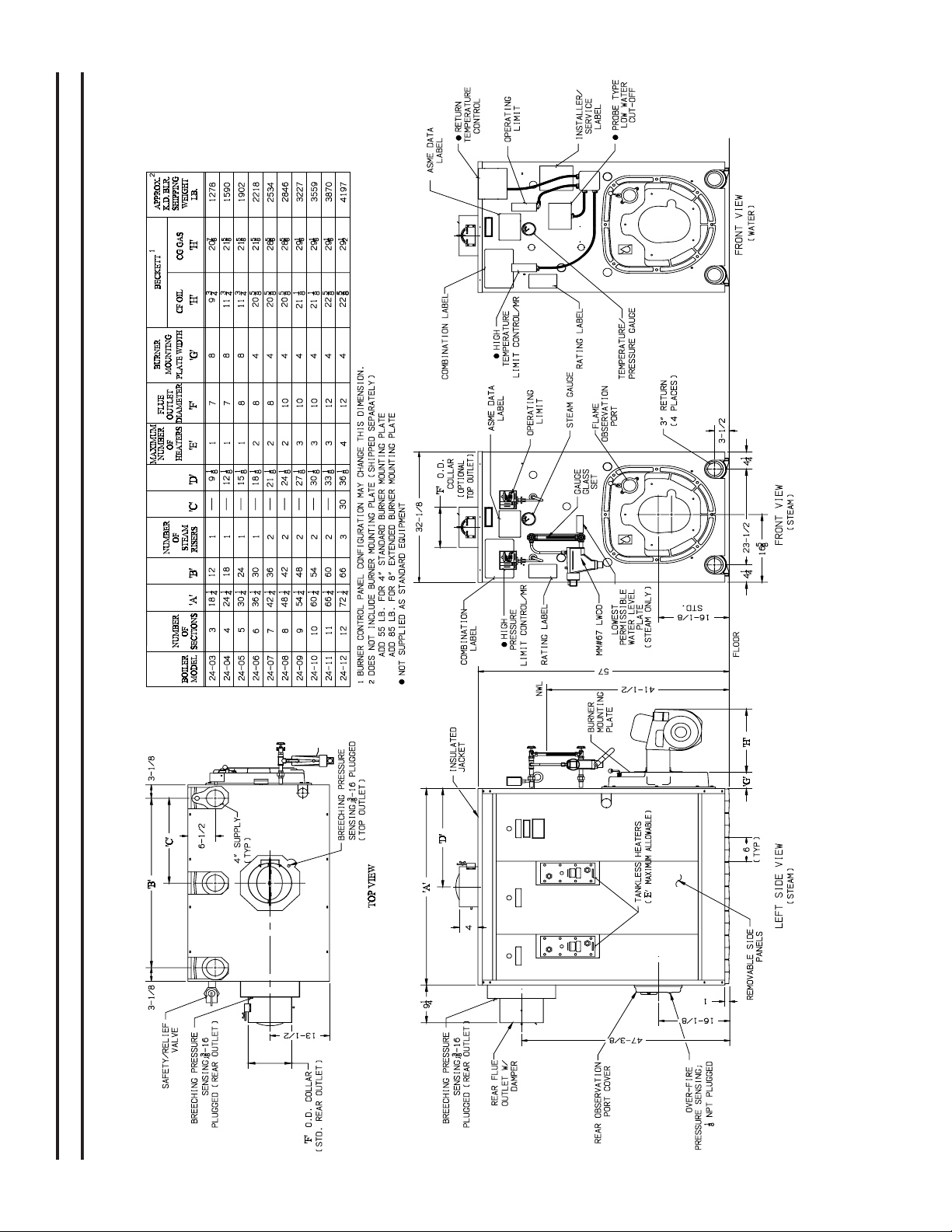

FIGURE 1: Dimensional Information

8

Page 9

TABLE I

)1( )2( )3( )4(

relioB

ledoM

-esroH

rewoP

ssorG

tuptuO

)HBM(

gnitaRR=B=IteN

renruB

tupnI

gnitaeH

ecafruS

).tF.qS(

teN

xoberiF

emuloV

).tF.uC(

erusserP

ni

xoberiF

).C.W"(

retaW

tnetnoC

).laG(

thgieWrelioB

retaW/w

).sbL(

tneV

.aiD

).nI(

.tF.qS

maetS

HBM

maetS

HBM

retaW

liO

)HPG(

saG

)HBM(

maetS retaW maetS retaW

m

aetS retaW

30-42

2.01 243 1

701 752 792 50.3 834 2.43 0.73 2.3 33. 5.44 0.66 9341 8

161 7

40-42

1.41 174 1

741 353 014 01.4 495 6.84 3.45 8.4 83. 0.35 0.57 1181 5991 7

50-42

9.81 436 3891 674 155 05.5 297 0.36 5.17 4.6 1

3. 5.16 0.48 4812 2732 8

60-42

8.32 797 2942 895 396 09.6 099 5.77 8.88 9.7 8

3. 0.07 0.39 7552 9472 8

70-42

0.82 739 9292 307 518 01.8 4711 9.19 0.601 5.9 6

3. 5.87 0.201 0392 6213 8

80-42

5.23 7801 6933 518 549 04.9 8531 3

.601 3.321 0.11 53. 0.78 0.111 3033 3053 01

90-42

3.93 6131 6414 599 8411 04.11 1461 7.021 5

.041 6.21 53. 5.59 0.021 6763 0883 01

01-42

0.54 5051 8874 9411 9031 00.31 7681 1

.531 8.751 2.41 04. 0.401 0.921 8404 7524 01

11-42

5.05 0961 9245 3031 0741 06.41 3902 5

.941 0.571 7.51 54. 5.211 0.831 1244 4364 21

21-42

3.55 2581 3895 6341 0161 00.61 0232 0

.461 3.291 3.71 94. 0.121 0.741 4974 1105 21

BOILER RATINGS/DATA

(1) Trim Suffix: S = Steam Boiler, W = Water Boiler

Fuel Suffix: N = Natural Gas, P = LP Gas, O = Oil

(2) I=B=R net ratings shown are based on piping and pick-up allowances which vary from 1.333 to 1.289 for steam and

1.15 for water

intermittent system operation, extensive piping systems, etc. The I=B=R burner capacity in GPH is based on oil having a

heat value of 140,000 BTU per gallon.

(3)

(refer to Figure 1), add 0.7 cu. ft. to volume listed above.

(4)

fl

Firebox volume does not include added volume of 8” extended burner mounting plate (BMP). If 8” BMP is specified

Boiler ratings are based on 12.5% CO2 (oil) and 9.7% CO2 (natural gas), + .10” (inches) water column pressure at boiler

ue outlet. Ratings shown above apply at altitudes up to 1000 feet on oil and 2000 feet on gas.

. Consult manufacturer for installations having unusual piping and pick-up requirements, such as

For altitudes above those indicated, the ratings should be reduced at the rate of 4% for each 1000 feet above sea level.

Maximum Allowable W

Standard Safety (Relief) Valve Set Pressure: Steam Boiler - 15 PSI, Water Boiler - 30 PSI

orking Pressure: Steam Boiler - 15 PSI, Water Boiler - 50 PSI

9

Page 10

SECTION I - GENERAL INFORMATION (CONTINUED)

Flue

Outlet

Size

Top

Flue

Outlet

Rear Flue Outlet

Combustible

Surfaces

Non-Combustible

Surfaces

7" D ia.

18"

37" 22"

8" D ia. 38" 23"

10" Dia. 40" 25"

12" Dia. 43" 28"

NOTICE

Reco mme n ded clearan c e for serv ice may be

reduced to minimum cle arance to

co mbustib le material. How ever, in creas ed

se rvice and main tenanc e difficulty w ill

result.

WARNING

Boiler is suitab le for installatio n o n

co mbustib le flo or. D o n o t install boiler

on c arpetin g.

Floor construction s h ould have

ad equate load bearin g charac teristics

to bear the weight of the boiler filled

with water (see Table 1). A boiler

foundatio n similar to the one shown in

Figure 2 is recommen d ed if the b o iler

room floor is w eak or uneven or if a

water co n d itio n e xis ts.

A

evobA

B

tnorF

C

raeR

D

sediS

E

rotcennoCtneV

6 42 6 6 81

sseccaotecnaraelcecivresdednemmoceRrofIIIelbaTeeS*

reliobforaer

lanoitaNnaciremAhtiwylpmocsecnaraelcdetsiL:1ETON

.tnempiuqegninrubliofonoitallatsnI,13APFN/ISNAdradnatS

htiwsmoornidellatsniebnacsreliob42seireS:2ETON

detsiL.evobadetsilsalairetamelbitsubmocmorfsecnaraelc

tesolcroevoclarofdecuderebtonnacsecnaraelc

.snoitallatsni

,lairetamelbitsubmocotsecnaraelcdecuderroF:3ETON

evobaehtnidebircsedsadedivorpebtsumnoitcetorp

.dradnats13APFN/ISNA

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be filed immediately against the carrier by the

consignee. No claims for variances from, or shortage in orders, will be allowed by the manufacturer

unless presented within sixty (60) days after the

receipt of goods.

3. Make sure that appropriate items on the Master Parts

List (pg 59) are all on hand.

B. LOCATE THE UNIT

1. RECOMMENDED SERVICE CLEARANCE

- Locate the unit in the boiler room so as to

provide ease of venting and adequate clearance

for maintenance, serviceability, and installation of

piping. Refer to Figure 1 for boiler dimensional

data.

FRONT — Provide 43” service clearance for

removal, maintenance, and servicing of burner and

controls.

REAR — Provide a minimum clearance from the

boiler jacket for access to flame observation port,

rear flue damper and vent piping, relief valve, and

boiler return piping. See Table III.

LEFT SIDE — Provide a minimum clearance from

the boiler jacket of 26” for cleaning of flueways and

installation and removal of tankless heater(s).

RIGHT SIDE — Provide a minimum clearance from

the boiler jacket of 12”.

T

OP — Provide a minimum clearance from the

boiler jacket of 24”

2. FOR MINIMUM CLEARANCES to combustible

materials, See Table II.

3. PROVIDE ADEQUATE FOUNDATION for the

unit. Refer to Figure 2.

Table II: Minimum Clearances To Combustible

Materials (Inches)

Boilers with Top Flue Outlet

Boilers with Rear Flue Outlet

Table III: Recommended Rear Service Clearance

10

Page 11

Figure 2: Boiler Foundation

WARNING

Fa ilure to supply adequate air to the boile r

will re sult in u nsafe b o iler o p eratio n .

C. PROVIDE AIR SUPPLY AND VENTILATION to

accommodate proper combustion.

For commercial and industrial equipment, permanent

facilities for supplying an ample amount of outside air

shall be provided in accordance with the following.

For boiler rooms adjacent to outside walls, and where

combustion air is provided by natural ventilation from

the outside, there shall be a permanent air supply inlet

having a total free area of not less than 1 sq. inch per

4,000 Btu per hr. (35 sq. inch per gallon per hour)

(5.5 cm2 per kw.) of total input rating of the burner or

burners and in no case less than 35 sq. inch (0.425m2).

For boiler rooms not adjacent to outside walls, the

combustion air shall be supplied in a manner acceptable

to the authority having jurisdiction.

1. In the absence of local requirements, the confined

space shall be provided with two permanent

openings, one in or near the top of the room and one

near the bottom. The openings shall communicate

by means of ducts, with the outdoors or to such

spaces (crawl or attic) that communicate with the

outdoors.

a. Where communicating by means of vertical

ducts, each opening shall have a free area of not

less than 1 sq. inch per 4,000 Btuh (35 sq. inch

per gph) (5.5 cm2 per kw) of total input rating of

all appliances in the enclosure.

b. If horizontal ducts are used, each opening shall

have a free area of not less than 1 sq. inch

per 2,000 Btuh (70 sq. inch per gph.) (11 cm

per kw) of total input of all appliances in the

enclosure.

2

D. CHIMNEY OR VENT

The Series 24 boiler is designed for forced draft firing

and may be used with a conventional natural draft

stack (15’ minimum height) or a stub vent, sometimes

called a diesel stack (see Figure 3a). See Table I for

the proper vent outlet size. For low silhouette vent

terminations, see Figure 3b. Draft controls are not

normally required, although they may be used on

installations where a natural draft stack is used or on

multiple boiler installations with a common stack. The

boiler is provided with a breeching damper, which

should be adjusted to maintain a positive pressure of

0.1” W.C. in the vent connector box during burner high

fire operation (see breeching pressure sensing port in

Figure 1).

Figure 3a: Typical Arrangement for Stub Vent

11

Page 12

GNINRAW

fongisedehtnotrepxegnitnevatlusnoC.ylnosnoitadnemmocererasnoitcurtsnIgnitneV

lanoitaNehTdnaediuGgnitneVEARHSAehT.noitacilpparuoyrofmetsystnevcificepsa

.smetsysgnitnevllanideredisnocebdluohs45APFN,edoCsaGleuF

kaelnacsesageulF.noitacilppaehtrofelbatiusebtonyamlairetamtnevlanoitnevnoC

yrujnilanosreperevesnitlusernacdnaslairetamesehtnostniojehtmorfedixonomnobrac

.htaedro

lliwswobleroseetfotnuomaevissecxenarosnurlatnozirohgnolgnivahsnoitallatsnI

foegakaelsageulf,noitasnednocnitlusernacdnasesagnoitsubmocfowolfehttcirtser

.htaedroyrujnilanosreperevesnignitluser,edixonomnobrac

If the venting system is designed for positive or forced

draft venting, the boiler, vent connector and stack will

operate under positive pressure. Gas tight vent systems

designed for pressure systems must be used to prevent

flue by-product leakage. The vent height is usually

limited to prevent negative draft, typically three (3)

feet above the roof line (see Figure 3a). The damper

shall be adjusted to maintain a positive pressure of 0.1”

W.C. in the vent connector box during burner high fire

operation (see breeching pressure sensing port in Figure

1).

If the venting system is designed for negative pressure

(natural draft), the boiler still operates with positive

pressure in the chamber and up to the fixed damper on

the flue collar. However, if the venting system is larger

than what is required, the stack will provide a surplus

draft (or negative pressure) that may require the use of

a barometric damper to maintain the positive 0.1” W.C.

pressure at the flue outlet. Multiple forced draft boiler

stacks should always be designed as negative to ensure

the products of combustion do not exit a boiler that is

not firing.

FIGURE 3b: VENTS — FAULTS & SUGGESTIONS

TYPICAL VENTS THAT ARE USED ON FORCED DRAFT BOILERS, ON LOW SILHOUETTE BUILDINGS

A

RAIN CAP

RIGHT

D

WRONG

VENT SIZING - Area must be the same as or greater than the boiler breeching (Smoke Outlet). A barometric damper may be required on

installations with a high draft condition.

1. If improper vent is suspected, remove pipe at breeching and operate boiler. This will determine if excessive down draft,

blocked or restricted flue, etc. is causing the problem.

2. If using type shown in A above, be sure cap is raised sufficiently above main pipe to allow flue gases to vent unimpeded.

3. A popular type cap is shown in B.

4. The tee is frequently used as shown in C.

5. D and E should not be used due to possible fl

B

“A” CAP

RIGHT

E

WRONG

FAULTY BOILER BURNER OPERATION

uctuations in back pressure.

C

TEE TYPE

RIGHT

90°

ELBOW

UP or DOWN

12

Page 13

CAUTION

Boiler sections must be draw n -up on

pe rfectly level surface or improper

as sembly may res ult.

CAU TION

When assembling sec tions without

hy draulic draw-u p equip ment, nev er

as semble mo re than one sectio n at a time.

SECTION II - CAST IRON BLOCK ASSEMBLY

A. FIELD ASSEMBLED SECTIONS — If the boiler

was ordered to be field assembled, follow the assembly

procedure outlined on the following pages.

1. ASSEMBLY OF SECTIONS (MANUAL DRAWUP)

These sections are designed to be drawn together,

one section at a time, using the 9¾” long draw-up

rods (provided) and ordinary hand tools.

Tools required:

(1) ¾” Drive Ratchet

(1) 1-1/16” Socket

(1) 1-1/16” Combination or Open End Wrench

(1) Container of grease, oil or other appropriate

lubricant.

ENSURE THAT THE ADHESIVE DOES

NOT COME IN CONTACT WITH THE

NIPPLES OR NIPPLE PORTS.

e. Clean nipples and nipple ports thoroughly with

a de-greasing solvent. Use the Loctite #592

supplied to lubricate the nipples and nipple

ports. Apply the lubricant to the nipples and

nipple ports, then use a brush to disperse it

evenly around the nipples and the nipple ports.

Use approximately 25 ml of Loctite #592 per

flueway [(1) 7” and (2) 3” nipples and their (6)

corresponding nipple ports].

f. Drive nipples squarely into section using

block of wood and hammer, or preferably,

an aluminum head hammer. (Crown offers a

Polyethylene Block for setting the nipples, part

number 330010). Place block over entire nipple

edge and hit the wood with the hammer.

a. Place the rear section in its approximate final

position, as outlined in Section I, and support it

with a suitable prop and wedges. See Figure 5.

b. On size 24-03 only— Open target wall carton,

apply Silastic to back of target wall and secure

target wall to rear section.

c. Clean the groove in the ground joint along the

edge of the section with the wire brush.

d. Open the Boiler Assembly Carton(s) and remove

the bottle of adhesive. Using the dauber supplied

in the bottle, apply the adhesive to the groove.

Be sure to use enough adhesive to sufficiently

coat the entire groove surface. If so desired,

a multi-purpose spray adhesive (supplied by

others) may be used instead. HOWEVER,

GREAT CARE MUST BE TAKEN TO

Figure 5: Positioning of Back Section

13

Page 14

WARNING

Nipples mus t be drive n in eve nly a nd to

the pro per depth to a ssure tight joints.

Most n ipple leaks are caused b y tilted

or cocked nipples.

DO NOT use steel/iron head hammer to

drive nip p les w ithout usin g a w ood

block. Nip p le damage may result.

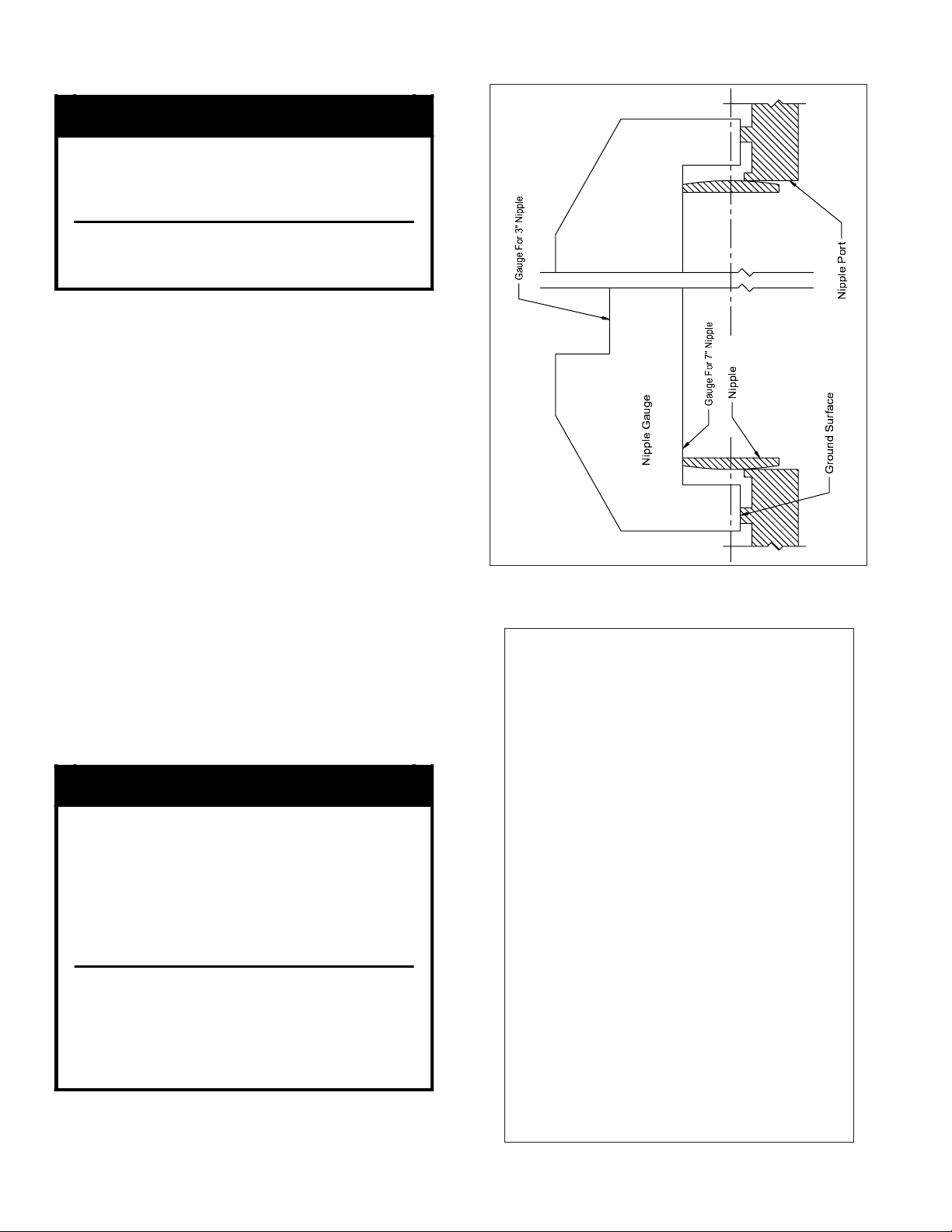

g. A special nipple setting gauge is provided for

WARNING

Sec tions mu s t be draw n -up tig h t

immediate ly a fter properly ap p lying

se ala n t for best re sults. Although

se ctions may be join e d w ithin tw o (2)

ho u rs of applyin g sealant, humidity and

temp erature a ffect c ure time. If a "thick

sk in" has b e en formed o n the sea lant

be ad, remove an d re-apply sealant.

Sea lant mus t be properly applied to

ALL grooves. Failure to pro perly seal

the boile r join ts will resu lt in

co mbustio n g as le aks th rough the jo int.

DO NOT operate boile r with

co mbustio n g as le aks.

the nipples. Gauge nipple in both directions to

insure that it is driven to the proper depth into

the nipple opening (nipple port). Cut-out in

gauge must rest on nipple, with legs of gauge

touching finished face of section, when nipple is

properly driven. See Figure 6.

h. Remove a 96” length of fiberglass rope from the

assembly carton. Starting with the area around

the upper 7” nipple port, firmly press the rope

into the groove, so that the adhesive holds it in

place. (If more than 25 minutes have passed

since the adhesive was applied, it may be

necessary to reapply.) Continue to affix the

rope to the groove in this fashion around the

perimeter of the section. Make sure that the rope

does not droop or hang outside of the groove.

When the end of the groove is reached, cut off

the excess rope. Push the length of excess rope

into the groove at the top corner of the section

face (opposite of the 7” nipple port.) Cut off and

discard any remaining rope after groove is filled.

See Figure 7.

Figure 6: Nipple Gauge

Figure 7: Affixing the Fiberglass Rope

14

Page 15

NOTICE

Th e sections must b e assemb led according

to th e arrangeme n t shown to ensure p roper

op e ratio n , proper as sembly of canopy,

jacke t and alignment of p iping and tankless

he aters w ith ja cket k n ockouts. Start w ith

the back section and w o rk tow a rds the

fro n t.

CAUTION

To avoid damage to the draw-u p rod

thre ads w h ile dra w ing up sections , apply

oil or other lubrican t to tie rod threa ds

while assemb ling sectio ns to prevent

stripping of threads on ro d and to make

as sembling easier.

BOILER SECTION IDENTIFICATION CODE

F = FRONT SECTION WITH 4” SUPPLY TAPPING C = CENTER SECTION

B = BACK SECTION WITH 4” SUPPLY TAPPING CX = CENTER SECTION WITH 4” TOP SUPPLY TAPPING

NOTES: FOR BOILERS LESS TANKLESS HEATER, REPLACE THE “CT” SECTIONS WITH “C” SECTIONS.

Figure 8: Series 24 Section Arrangement

i. From the “Section Arrangement” chart, select

the next section according to the “Identification

Code” at the top of the chart. See Figure 8. Use

a wire brush to clean the groove in the face of

the next section. Then, using a cartridge of RTV

6500 or RTV 736 sealant in a caulking gun, fill

the groove in this section with silastic sealant.

Touch-up any missed spots before draw-up.

T

ouch-up after draw-up has no value.

j. Clean and lubricate nipple ports on next section

to be assembled and place on nipples previously

installed in rear section. To facilitate assembly,

it is advisable to enter the upper nipple first in

its port. Then enter the lower nipples in their

respective ports. If necessary, place a lifting bar

15

(crowbar) under the center of the section and lift

the nipple port onto the upper nipple.

k. Drive section in place with a heavy block of

wood, striking blows as squarely as possible over

nipple port.

l. The lar

m. DRAW UP SECTION SLOWLY AND

ge draw-up rod lugs with dual holes

are cast in the four (4) corners of each casting.

Starting with the upper holes, install four

(4) 5/8” x 9¾” long draw-up rods along with

washers and nuts (see Figure 9).

EVENLY using an alternating pattern starting

with the upper right lug and proceeding to the

lower left , lower right and finishing with upper

left lug.

Page 16

WARNING

Do not over torq u e draw up nuts after grind

su rfaces me et.

Figure 9: Draw-Up Rods (Alternating Pattern -

GNINRAW

LLAotdeilppaylreporpebtsumtnalaeS

reliobehtlaesylreporpoteruliaF.sevoorg

skaelsagnoitsubmocnitluserlliwstnioj

reliobetarepoTONOD.tniojothguorht

tnalaesehT.skaelsagnoitsubmochtiw

sinoitceshcaeerofebdeilppaebdluohs

.ylbmessaehtnodecalp

Manual Draw-up)

When you start, grind surfaces between

adjoining sections should be approximately

3/8” apart. Use three (3) or four (4) passes at

tightening the four (4) draw-up rods a little at

a time so that sections are pulled up evenly.

During the last pass, pay close attention to the

silastic sealant as it squeezes when the sections

come in close contact. The silastic sealant will

continue to squeeze out wafer thin until the

sections are connected metal to metal. While

tightening the nuts, close attention should be

given to the connection area to determine that

the silastic has stopped squeezing out from

between the sections. This will give assurance

that the sections are assembled metal to metal. If

the silastic has stopped squeezing out from the

connection and the sections still do not appear

to be drawn metal to metal, measure any gaps

between the sections with a feeler gauge. A

maximum gap of .025” is acceptable. Gaps

should be measured at the outer edge of the

connection. DO NOT PUNCTURE THE

GASKET CREATED BY THE FIBERGLASS

ROPE AND SILASTIC

SEALANT WITH THE FEELER GAUGE.

KEEP NIPPLES ALIGNED WITH NIPPLE

PORTS. If necessary, tap edge of nipples lightly

with a blunt tool or rod to keep nipples from

cocking while sections are being drawn-up. DO

NOT DRAW UP SECTION WHEN NIPPLES

ARE COCKED. If the torque required becomes

excessive, periodically place a heavy block of

wood over

as possible with several blows to relieve tension

on the draw-up rods.

n. CONTINUE ASSEMBLING SECTIONS IN

THEIR RESPECTIVE ORDER alternating

the draw-up rods from the upper to lower set

of holes in draw-up lugs. Be certain that all

sections are drawn up IRON-TO-IRON at all

three (3) nipple ports.

BE SURE TO APPLY THE SEALANT to

the groove in the ground joints between

adjacent sections as the boiler operates with a

positive pressure in the firebox and products of

combustion will escape between sections unless

the sections are properly sealed. The sealant

should be applied before each section is placed

on the assembly.

o. If a joint springs apart it must be redrawn tight

within four (4) hours of the time of application of

Silastic to that joint.

2. ASSEMBL

UP)

The entire boiler assembly may be drawn up at one

time using hydraulic draw-up equipment providing

the operation is completed within four (4) hours after

application of the sealant.

a. Repeat steps 1a through 1k under “Field

Assembled Sections (Manual Draw-Up).”

b. Continue driving sections in place (in their

respective order) until all sections are in the

assembly. Ground surfaces between adjoining

sections should be spaced 1/4” to 3/8” apart.

Spacing of more than 3/8” will limit number of

sections that can be drawn up in one unit and

could indicate cocked nipples.

On long boiler assemblies, it may be necessary to

draw-up a partial block if the entire boiler is not

ready to be drawn-up tight within four (4) hours

of the first application of Silastic. If the block

assembly time extends overnight, the partial block

completed must be drawn-up tight before leaving

the boiler overnight. If a joint springs out, it must

be redrawn tight within four (4) hours of first

application of Silastic to the joint.

16

c. Insert the three (3) ¾” draw-up rods (and

couplings, if appropriate) through the tapped holes

in the rear section extending them through the

each nipple port and strike as squarely

Y OF SECTIONS (HYDRAULIC DRAW-

Page 17

CAU TION

Do not apply pres sure directly on thread e d

tappings on front and rea r sectio ns w ith

draw-up ch a nnels during assembly

procedures.

Rods should be approximately centered in

op e nings s o that rods a n d couplings (when

us ed) do not drag o n p ipe thread in end

se ction tappin g s.

WARNING

READ THE STATEMENTS BELOW BEFORE

ATTEMPTING TO USE HYDRAULIC EQUIPMENT.

*

*

*

*

Re

lease p ressu re in ram pumps b e fore

attemptin g to re move clamp s .

Do not sta nd in line w ith draw -up ro d s at

either en d w hen hydraulic p ressure is

be ing ap p lied. As a safe ty measure,

en d s of draw-up rods should be covered

while sections are bein g drawn in case

rods should snap while under te n sio n .

Do not operate ram ag a inst dra w -up

co u pling.

Do not operate pump after ram has

reached s tro ke limit.

tapped holes in the front section. Be sure to

screw draw-up rods into couplings far enough to

prevent stripping threads.

d. Place a 3” x 12” lg. steel channel on each end of

the upper draw-up rod and a 3” x 8½” lg. steel

channel on each end of the lower draw-up rods.

Refer to Figures 10 and 11 for proper placement

of channel block during assembly procedures.

Install nuts and washers on one end of the drawup rods and the hydraulic rams, washers and

draw-up rod clamps on the other. See Figure 13.

g. After all sections have been drawn up, but before

removing the hydraulic rams and draw-up rods,

the 9¾” long tie rods must be installed.

The large draw-up rod lugs with dual holes

are cast in the four (4) corners of each casting.

Starting with the upper holes in the back section,

install four (4) 5/8” x 9¾” long tie rods along

with washers and nuts. Continue installing the

tie rods alternating from the upper to lower set

of holes in draw-up lugs until front section is

secured. Be certain that all sections are drawn

up IRON TO IRON at all three nipple ports.

h. Excess length of draw-up rods must not extend

beyond front and rear section. To ensure proper

fit of jacket, adjust accordingly. Tighten all tie

rod nuts until finger tight. Then tighten them

an additional ½ turn with a wrench to prevent

section damage to thermal expansion.

e. Draw-Up Sections

Use hydraulic rams to draw up sections by

applying pressure alternately on the draw-up

rods. When rams reach stroke limit, release

pressure in ram pumps and then move clamps to

new position.

f. Continue to draw-up until all sections make

contact at the ground joints.

Figure 10: Front and Rear Section Channel

Block Positions (Hydraulic Draw-up)

Figure 11: Center Section Channel Block Position

(Partial Block Draw-Up)

17

Page 18

Figure 12: Hydraulic Draw-Up of Sections

CAU TION

DO NOT install gauge until after hydro s tatic

testing the boiler. Gauge failure may result.

WARNING

Fa ilure to pro p erly hydrotes t all b o ilers at

the correct pres sure may re sult in section

as sembly failure in o p eratio n .

B. HYDROSTATIC TEST — After the boiler sections

have been assembled, it is essential that the boiler be

hydrostatically tested before the canopy, flue cover

plates, jacket, or piping is installed.

1. Tankless Heater Installation

If boiler is ordered with tankless heaters, install

heaters with the gaskets provided. Table IV

on Page 37 gives the maximum number of heaters

permissible per assembly and the heater ratings.

2. Plug all boiler tappings and fill boiler completely

with cold water.

3. All completed boilers must satisfactorily pass the

prescribed hydrostatic test.

a. STEAM BOILERS:

be subjected to a hydrostatic test of 45 psig to 55

psig.

b. HOT WATER BOILERS: The assembled boiler

must be subjected to a hydrostatic test of not less

than 1½ times the maximum allowable working

pressure (MAWP).

The assembled boiler must

4. EXAMINE BOILER CAREFULLY, INSIDE AND

OUTSIDE, to insure against leaks from cocked

nipples or through concealed breakage caused in

shipping and handling. This precaution is for your

protection and will simplify handling of necessary

replacements and adjustment claims.

5. After making certain that there are no leaks, drain

boiler and remove plugs for boiler trim and other

connections.

Figure 13: Boiler Section Assembly

18

Page 19

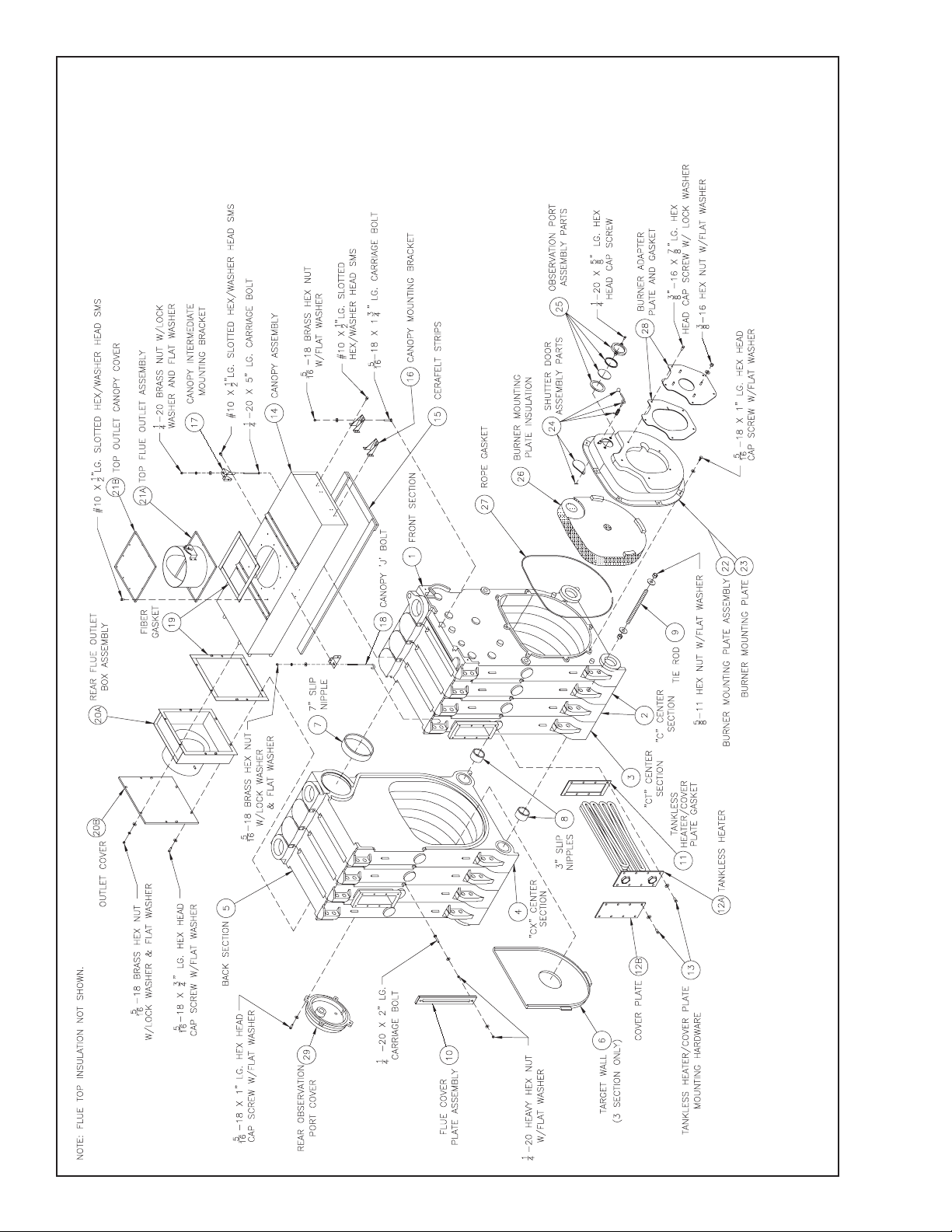

SECTION III - INSTALLATION INSTRUCTIONS

A. INSTALL CANOPY/FLUE OUTLET ASSEMBLY,

Refer to Figures 14, 15 and 16.

1. Open canopy carton.

2. Attach the two (2) canopy brackets to the front end

cap of canopy with four (4) #10 x 1/2” sheet metal

screws each.

3. Across the top of the front section and along the top

ledges running back each side of the sections, place

continuous 2” wide strips of cerafelt and overlap

joints at front corners. Cerafelt strip should extend

1/4” beyond rear surface of back section. Cut off

excess.

4. Place the canopy on the sections.

5.

Position rear flange (end with studs) of canopy flush

with rear surface of back section.

6. Loosely attach the canopy brackets to the lugs on

the front section of the block assembly with 5/16”

carriage bolts, flat washers and locknuts.

7. Check to see if rear flange of canopy is still flush

with raised flange on back section.

8. Open either the rear flue outlet carton (standard) or

top flue outlet carton (optional).

9. Attach the 1/8” x 1” wide self-adhesive fiber gasket

to the surface of either the rear flue outlet damper

assembly or rear flue outlet cover that mounts

against the canopy and back section. Gasket must

be centered over all attachment holes. Do not

overlap corners, cut butt joints.

10. Attach either the rear flue outlet damper assembly

or rear outlet canopy cover to the canopy with the

5/16” flat washers, lock-washers and brass

nuts and tighten securely. Attach the rear flue

outlet damper assembly or cover to the back section

with the four (4) 5/16” flat washers and cap screws

and tighten securely.

11. Tighten front canopy carriage bolt until canopy is

secure.

12. On the longer canopy sizes, Intermediate Mounting

Brackets are provided, two (2) are required on sizes

24-07 thru 24-09 and four (4) are required on sizes

24-10 thru 24-12A. Refer to Figures 17 and 18.

a. Intermediate brackets are shipped flat. Bend

side flanges down approximately 90° as shown.

Adjust bends until holes in bracket match hole

pattern on canopy.

b. Secure brackets to both sides of canopy with

three (3) #10 x ½” sheet metal screws per

bracket.

c. Secure canopy left side bracket(s) with

appropriate canopy ‘J’ bolt(s). Insert threaded

end through holes in brackets and hook ‘J’ bolt

on center section draw-up rod (hooks should

Damper Assembly (Rear Cover Removed)

Figure 14: Canopy with Rear Flue Outlet

Damper Assembly

Figure 15: Canopy with Top Flue Outlet

19

Page 20

Figure 16: Bare Boiler Assembly

20

Page 21

Warning:

Important Product Safety Information

Refractory Ceramic Fiber Product

This product contains refractory ceramic fibers (RCF). RCF has been classified

as a possible human carcinogen. After this product is fired, RCF may, when

exposed to extremely high temperature (>1800F), change into a known human

carcinogen. When disturbed as a result of servicing or repair, RCF becomes

airborne and, if inhaled, may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace previously fired RCF (combustion chamber insulation,

target walls, canopy gasket, flue cover gasket, etc.) or attempt any service or

repair work involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH) approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing ma-

chine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an air tight plastic bag.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location with clean fresh air. Seek immediate medical attention if breathing difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek immediate medical attention.

21

Page 22

Figure 17: Left Side Canopy Intermediate Bracket Figure 18: Right Side Canopy Intermediate Bracket

face outward). Secure canopy with 5/16” flat

washers, lock washers and brass nuts. See

Figure 17.

d. Secure canopy right side bracket(s) with ¼ - 20

x 5” lg. carriage bolts. Insert head of carriage

bolt between canopy body and casting. Slide

carriage bolt into slot provided between castings.

Lower carriage bolt until threaded end will pass

through hole in bracket. Secure canopy with ¼”

flat washers, lock washers and brass nuts. See

Figure 18.

13. Attach the 1/8” x 1” wide self-adhesive fiber gasket

to the surfaces of either the top flue outlet damper

assembly or top outlet canopy cover that mounts

against the canopy. Gasket must be centered over

all attachment holes. Do not overlap corners, cut

butt joints.

14. Secure either the top flue outlet damper assembly or

top outlet canopy cover with #10 x 1/2” sheet metal

screws.

against boiler and secure with washers and nuts.

Tighten until insulation on cover plate provides a

tight seal to casting. If after tightening, a gap is still

evident where the sections join, apply silastic along

top and bottom edge of insulation board.

5. Repeat steps 3 through 6 for mounting remaining

flue cover plates.

B. INSTALL FLUE COVER PLATES over cleanout

openings on left side of boiler as shown in Figure 19.

See Important Product Safety Information on Page

21 of this manual, regarding refractory ceramic

fiber product warning.

1. Locate the cover plates, carriage bolts, nuts and

washers in the boiler assembly carton(s).

2. Remove insulation from two (2) 3/8” diameter holes

in flue cover plates using a 3/8” drill bit. Rotate bit

through insulation by hand.

3. Attach the carriage bolts to the top and bottom of the

flue openings with washers and hex nuts to provide

a fixed stud.

4. Install flue cover plates over studs with insulation

Figure 19: Flue Cover Plate Attachment

22

Page 23

C. MOUNT REAR OBSERVATION PORT COVER

NOTICE

To install

multiple s ide panels, sta rt a t th e

rear o f boile r and work forw ard . To re move

pa n els , revers e order of assembly.

PANEL 1 PANEL 2 PANEL 3 PANEL 4 PANEL 5 PANEL 3 PANEL 2 PANEL 1

24-03 L10 L5 - - - 24-03 - - R15 (SINGLE)

24-04 L10 L11 - - - 24-04 - - R21 (SINGLE)

24-05 L10 L17 - - - 24-05 - - R27 (SINGLE)

24-06 L10 L18 L5 - - 24-06 - - R33 (SINGLE)

24-07 L10 L18 L11 - - 24-07 - R15 R24

24-08 L10 L18 L17 - - 24-08 - R21 R24

24-09 L10 L18 L18 L5 - 24-09 - R27 R24

24-10 L10 L18 L18 L11 - 24-10 - R27 R30

24-11 L10 L18 L18 L17 - 24-11 - R33 R30

24-12 L10 L18 L18 L18 L5 24-12 R21 R24 R24

JACKET LEFT SIDE PANEL USAGE CHART RIGHT SIDE PANEL USAGE CHART

BOILER

MODEL

BOILER

MODEL

SINGLE / MULTIPLE RIGHT SIDE PANELS*MULTIPLE LEFT SIDE PANELS*

*NOTE: TO INSTALL MULTIPLE SIDE PANELS, START AT THE REAR AND WORK FORWARD. TO REMOVE PANELS, REVERSE ORDER OF ASSEMBLY.

REAR OF BOILER

FRONT OF BOILER

FRONT OF BOILER

REAR OF BOILER

Refer to Figure 16.

1. With the silastic sealant, secure the 3/16” diameter

rope gasket into the groove around the perimeter of

the rear observation port cover.

2. Mount the rear observation port cover onto the rear

section (with the word “Top” in the upright position)

using the four (4) 5/16” - 18 x 1” lg. cap screws and

flat washers provided.

D. INSPECT ALL BOILER SEALS

1. A visual inspection should be made of all sealed

joints and repairs made as necessary. Darken

the boiler room and place a light source in the

combustion space and canopy to observe any gaps

or open seals. Poor seals must be repaired and

rechecked before continuing.

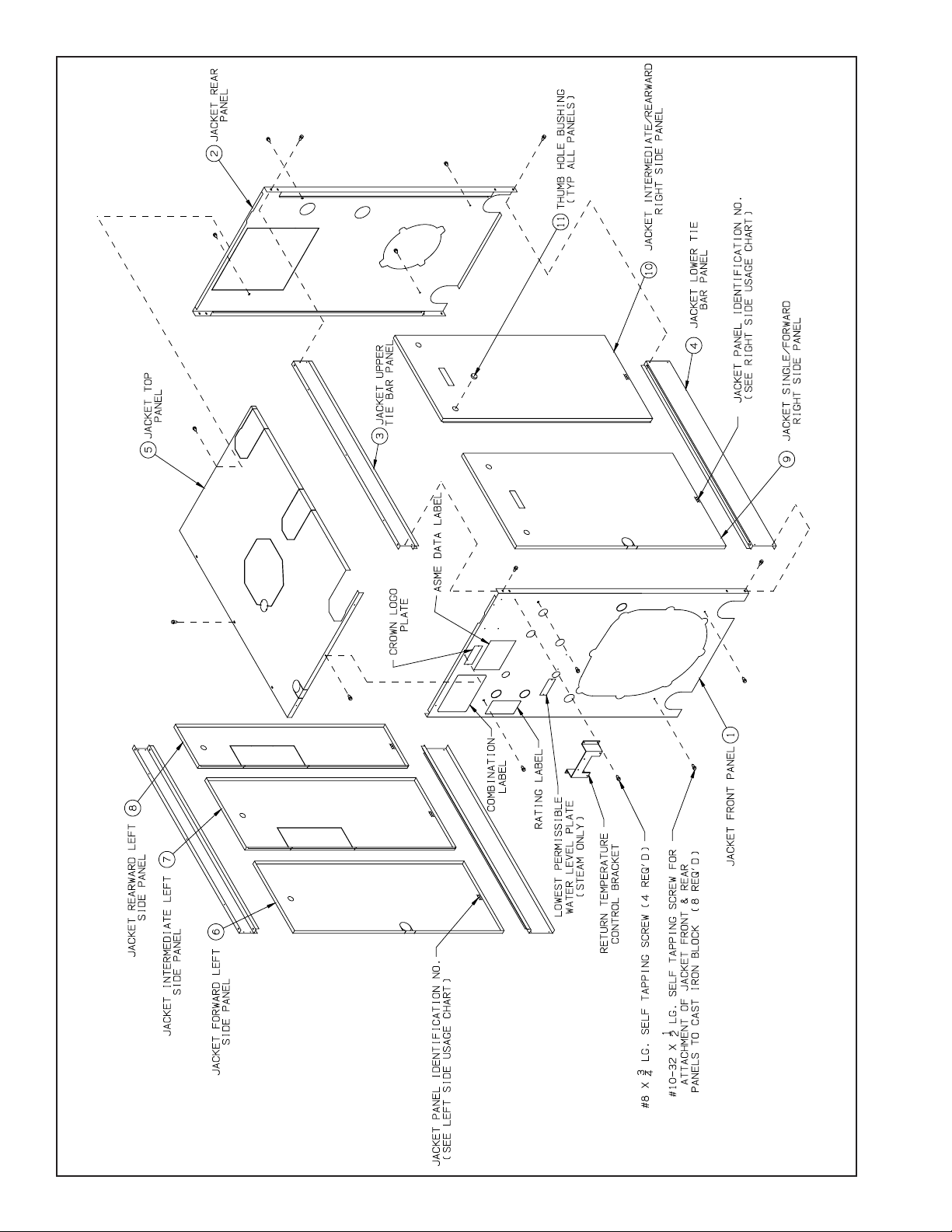

E. JACKET ASSEMBLY - See Figure 22 for Jacket

Assembly Details.

1. Open jacket carton and jacket hardware package.

Unless otherwise stated, all jacket components are

fastened with #8 x ½” hex head sheet metal screws.

Do not drive sheet metal screws tight until jacket

assembly is complete.

2. On boilers with rear flue outlet damper assembly,

remove square knockout from jacket rear panel. To

remove knockout, use a single hacksaw blade with

handle or aviation snips to cut metal tabs between

slotted holes.

3. Attach jacket front panel to front section and jacket

rear panel to back section using the eight (8) #10

x ½” self tapping screws. Tighten these screws

securely.

4. Attach jacket lower tie bar panel (approximately

5-5/8” high) to the bottom of the jacket front and

rear panels using four (4) sheet metal screws.

Repeat for opposite side.

5. Attach jacket upper tie bar panel (approximately

4-1/8” high) to the top of the jacket front and rear

panels using four (4) sheet metal screws. Repeat for

opposite side.

6. Jacket Top Panel Attachment

a. On boilers with top flue outlet damper assembly,

remove octagon shaped knockout. To remove

knockout, use a single hacksaw blade with handle

or aviation snips to cut metal tabs between

slotted holes.

b. Remove knockout(s) for necessary supply piping

in a similar manner

.

c. Attach jacket top panel to the front panel, rear

panel and upper tie bar panels with sheet metal

screws.

7. Install Jacket side Panels

a. Snap black thumb hole bushings into all side

panel holes.

b. Use the left side panel and right side panel usage

charts to determine correct positions of side

panels. The three (3) digit panel identification

numbers shown in the charts are also stamped

along the bottom edge of each panel. Refer to

Figures 20 and 21.

c. Rearward and Intermediate panels have reverse

bend flanges on one side of panel. These panels

must be installed prior to forward panels.

d. If boiler is equipped with tankless heaters they

should be installed at this time if they were not

installed for hydrostatic test outlined on Page 18.

e. Install right side panels into position by inserting

top of panel into ‘U’ shaped channel, pushing

bottom of panel in toward boiler, and sliding

panel down into ‘J’ shaped channel. Repeat

procedure until all right side panels are in place.

f. Remove the knockouts necessary for tankless

heater operation on left side panels.

g. Install left side panels, using the same procedure

used to install the right side panels.

Figure 20: Left Side Panel Usage Chart

23

Figure 21: Right Side Panel Usage Chart

Page 24

24

Figure 22: Series 24 Jacket Assembly (Boiler Models 24-03 thru 24-12)

Page 25

8. Combination Label and Crown Logo Plate were

CAUTION

Fa ilure to properly fill all gap s b etween the

insulatio n a nd burner blast tube may re sult

in damage to the burn er

attached to jacket front panel at time of manufacture.

If loose or peeling, apply pressure to reset adhesive.

9. On steam boilers, attach lowest permissible water

level plate (from steam trim carton) to the front

panel using sheet metal screws.

10. Tighten all sheet metal screws to complete jacket

assembly.

11. RTC Bracket (if used)- install bracket in top right

corner of front panel with four (4) #8 x 3/4” self

tapping screws.

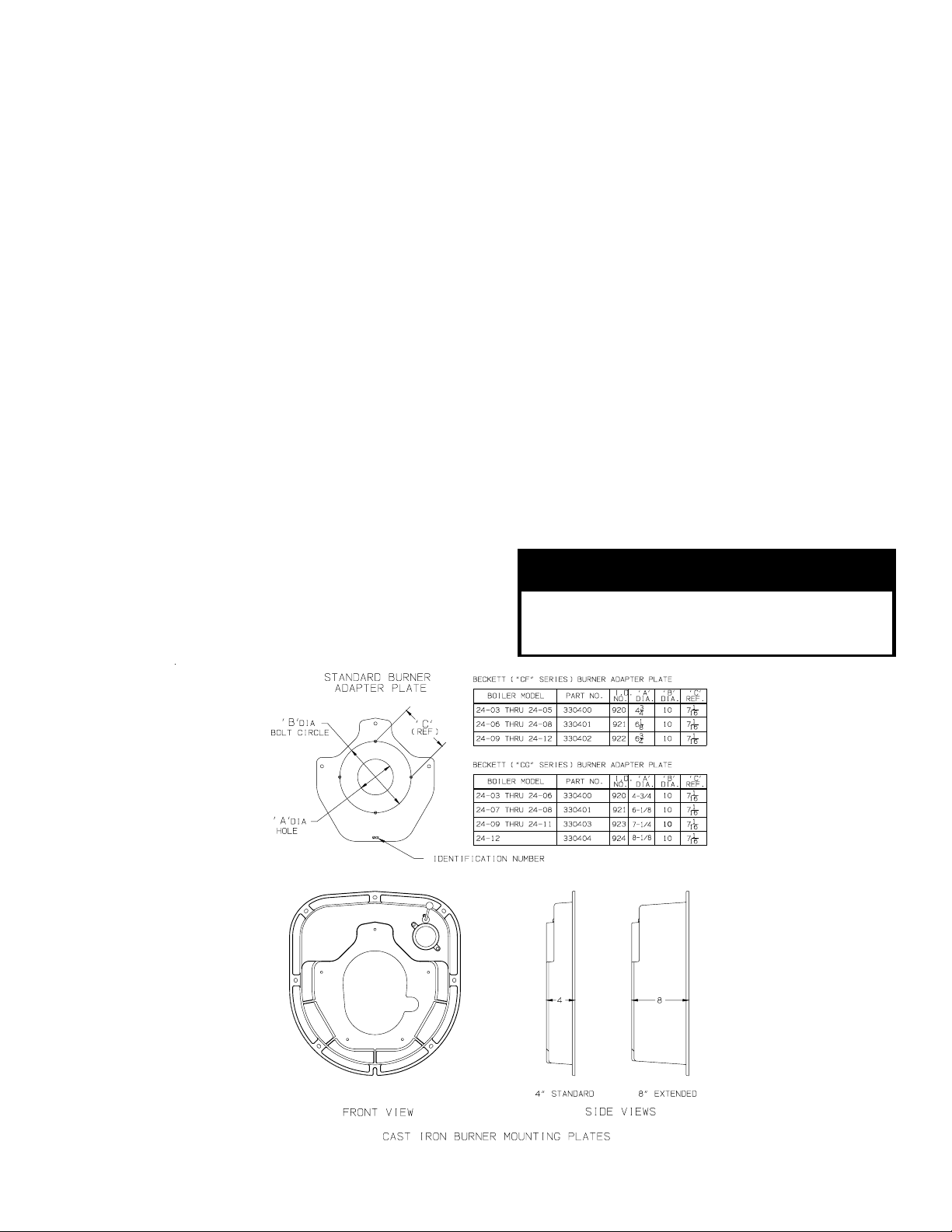

F. BURNER MOUNTING PLATE - Refer to Figures 16

and 23.

1. Using silastic sealant, secure the 3/16” diameter

rope gasket to the groove along the mounting plate

opening in the front section.

2. Install 5/16” x 1” lg. cap screw in lower tapping on

front section to carry weight of burner mounting

plate.

3. Engage bottom slot on burner mounting plate with

matching bolt in bottom tapping of front section.

Align mounting holes and fasten the mounting plate

to the boiler sections with seven (7) remaining 5/16”

cap screws and washers. Fully tighten all bolts.

Apply four (4) small dabs of silastic on rear surface

of adapter plate to temporarily hold gasket in

place. Hold adapter plate in position against burner

mounting plate, align holes and secure with five (5)

3/8” lock washers and 3/8” x 7/8” lg. cap screws.

3. Follow burner manufacturer’s instructions using

gasket material and hardware provided with burner.

4. USE A HOLE SAW OR KNIFE TO CUT BURNER

MOUNTING PLATE INSULATION TO MATCH

HOLE SIZE ON BURNER ADAPTER PLATE.

After cutting, remove any and all loose pieces of

insulation which may become lodged or interfere

with the head of a burner air tube after insertion.

Confirm that hole in insulation fits snugly around

burner blast tube. If hole is oversized, use fiberglass

rope gasket provided with burner to fill in any space

between insulation and blast tube. If rope gasket

is not provided with the burner, use 3/8” fiberglass

rope (provided by others).

5. For boilers without tankless heaters, proceed

to Step H (Install Steam Trim) or I (Install Water

Trim).

6. For boilers with tankless heaters, install the

tankless heater manifolds according to Figure 37.

G. MOUNT BURNER ADAPTER PLATE TO

BURNER MOUNTING PLATE.

Refer to Figures 16 and 23.

1. In all cases the burner adapter plate carton for the

specified burner will be provided by Crown.

2. Open Adaptor Plate carton and remove contents.

Figure 23: Burner Mounting Plate/Burner Adapter Plate Options

25

Page 26

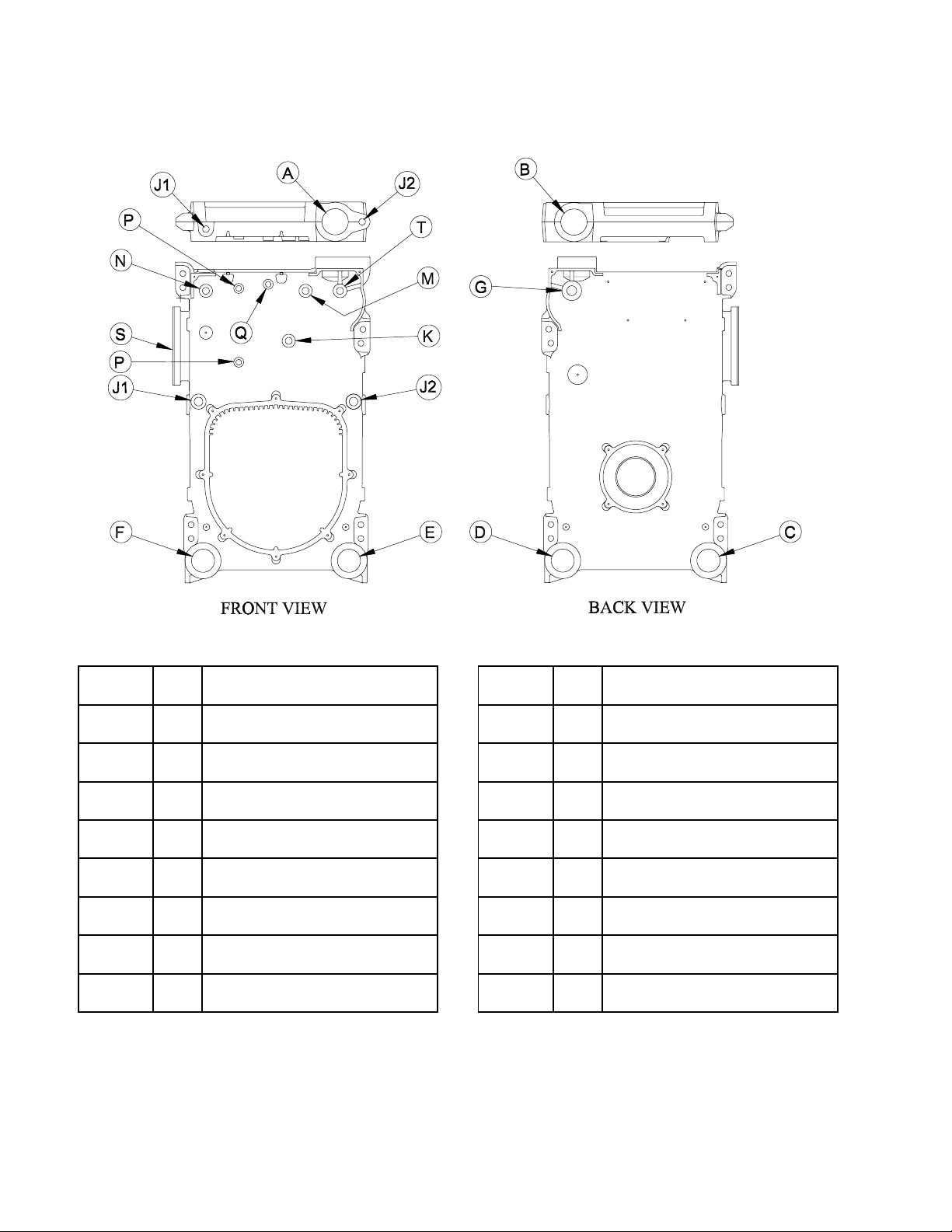

Size Size

(in) (in)

B 4

Plug (24-03 thru 24-06)

Supply (24-07 thru 24-12)

K

Steam Boiler

A 4 Supply

Tapping

Location

Steam Boiler

Tapping

Location

C

3 Blow-Off Valve

D 3 Return

E 3 Plug

J1 1

F 3 Plug

G 1-1/2 Safety Valve/Surface Skim Tap

Plug

J2 1 Float L.W.C.O.

3/4 Plug

M 3/4 Operating Pressure Limit Control

N 3/4

Hi Pressure

Limit Control/Manual Reset

P 1/2 Gauge Glass/#67 L.W.C.O.

Q 1/2 Steam Gauge (Bush to 1/4")

S 3/4 Tankless Heater Control

T 3/4 Firing Rate Pressure Control

Figure 25a Purpose of Tappings - Steam Boilers

26

Page 27

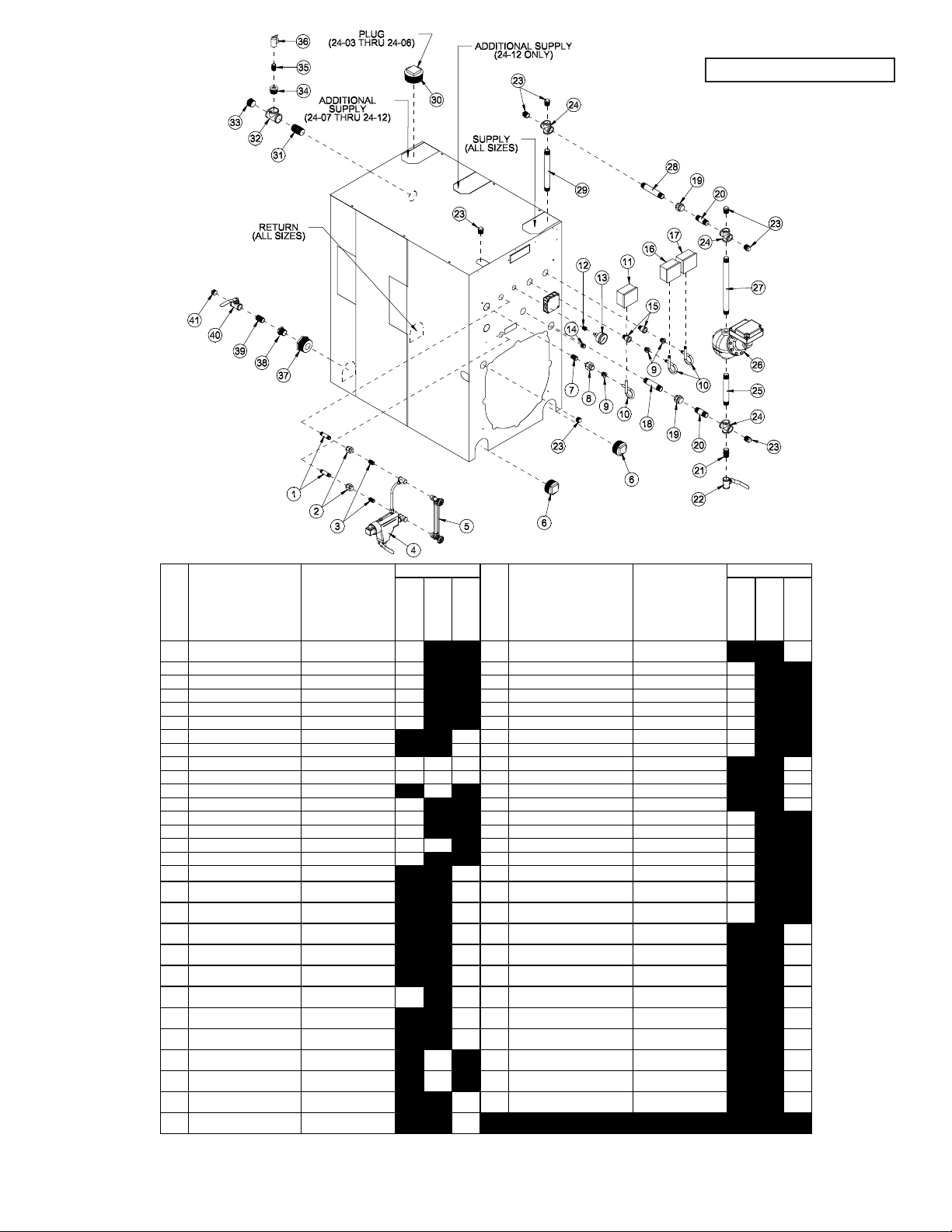

1 1/2" X 3" BR NIPPLE ALL 2 29 1" X 12" NIPPLE

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1

2 1/2" BR UNION ALL 2 30 4" BK PLUG ALL 1

3 1/2" BR CLOSE NIPPLE ALL 2 31 1-1/2" X 4 NIPPLE ALL 1

4 LWCO, #67 ALL 2 32 1-1/2" TEE ALL 1

5 GAUGE GLASS SET ALL 2 33 1-1/2" SQ. HD. PLUG ALL 1

6 3" SQ. HD. PLUG ALL 2 34 1-1/2" x 3/4" BLK BUSHING 24-03 1

7 3/4" X 2" NIPPLE ALL 1 34 1-1/2" x 1" BLK BUSHING 24-04 1

8 3/4" UNION ALL 1 34 1-1/2" x 1-1/4" BLK BUSHING 24-05 THRU 24-08 1

9 3/4" X 1/4" HEX BUSHING ALL 1 1 1 35 3/4" CLOSE NIPPLE 24-03 1

10 1/4" 90° BR PIGTAIL ALL 1 1 1 35 1" CLOSE NIPPLE 24-04 1

11 L404C1147

CSD-1 EQUIPPED BOILERS

1 35 1-1/4" CLOSE NIPPLE 24-05 THRU 24-08 1

12 1/2" X 1/4" BR BUSHING ALL 1 35 1-1/2" CLOSE NIPPLE 24-09 THRU 24-12 1

13 PRESSURE GAUGE ALL 1 36 SAFETY VALVE 13-211 24-03 1

14 3/4" RECESSED HD PLUG ALL 1 36 SAFETY VALVE 13-202 24-04 1

15 3/4" BLK EXTENSION ALL 1 1 36 SAFETY VALVE 13-213 24-05 THRU 24-08 1

16 L404F1367 ALL 1 36 SAFETY VALVE 13-214 24-09 THRU 24-12 1

17 FIRING RATE PRES CTRL

MODULATING BOILERS

1 37 3" X 1-1/4" BLK BUSHING ALL 1

18 1" X 5-1/2" NIPPLE

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1 38 1-1/4" X 3/4" BUSHING 24-03 THRU 24-04 1

19 1" UNION

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

2 38 1-1/4" X 1" BUSHING 24-05 THRU 24-08 1

20 1" X 3-1/2" NIPPLE

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

2 39 3/4" CLOSE NIPPLE 24-03 THRU 24-04

1

21 1" CLOSE NIPPLE

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1 39 1" CLOSE NIPPLE 24-05 THRU 24-08

1

22 1" BALL VALVE

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1 39 1-1/4" CLOSE NIPPLE 24-09 THRU 24-12

1

23 1" RECESSED HD PLUG

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

4 3 40 3/4" BALL VALVE 24-03 THRU 24-04

1

24 1" CROSS

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

3 40 1" BALL VALVE 24-05 THRU 24-08

1

25 1" NIPPLE*

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1 40 1-1/4" BALL VALVE 24-09 THRU 24-12

1

26 #150-MD LWCO

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1 41 3/4" SQ. HD. PLUG 24-03 THRU 24-04

1

26 #64 LWCO

CSD-1 EQUIPPED BOILERS

GRAVITY RETURN

1 41 1" SQ. HD. PLUG 24-05 THRU 24-08

1

27 1" NIPPLE**

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1 41 1-1/4" SQ. HD. PLUG 24-09 THRU 24-12

1

28 1" NIPPLE***

CSD-1 EQUIPPED BOILERS

PUMPED RETURN

1

*SIZE NIPPLE TO SET WATER LEVEL OF LWCO.

**SIZE NIPPLE TO MAKE UP LENGTH BETWEEN 24 & 26.

QUANTITY

KEY DESCRIPTION BOILER MODELS DESCRIPTION BOILER MODELS

QUANTITY

KEY

OPTIONAL

NOT

SUPPLIED

STANDARD

***SIZE NIPPLE TO MAKE UP LENGTH BETWEEN 19 & 24.

STANDARD

OPTIONAL

NOT

SUPPLIED

Figure 25b: Steam Trim

27

Page 28

WARNING

Safety valve discharg e pip ing must be

piped to w ithin s ix (6) inches o f floo r or to

floor drain to eliminate potential of severe

bu rns. D o n ot pipe in any area w h ere

fre ez ing could occur. Do not install a n y

sh u t-off valves, plu g s or caps in discharge

piping.

H. STEAM BOILERS — INSTALL STEAM TRIM

ECITON

yrucremniatnocstimiLerusserP404LemoS

oD.ebutdelaesani ton ehtnitimilecalp

.efillufesustifodneehttahsart

sniatnoctahttimilagnicalpersitimilsihtfI

od,ebutdelaesaniyrucrem ton ruoyecalp

.hsartehtnitimildlo

tnemeganametsawlacolruoytcatnoC

gnidragersnoitcurtsnirofytirohtua

sihtfolasopsidreporpehtdnagnilcycer

niyrucremgniniatnoctimildlonaforo,timil

.ebutdelaesa

ta.cnIllewyenoHllac,snoitseuqevahuoyfI

.2051-864-008-1

Items for steam trim are located in the steam trim carton

(except for the separately ordered low water cutoff and

tankless heater control). Figures 25a and 25b show the

proper tappings for each item.

1. Install the gauge glass set.

2.

Install the low water cut-off. Follow manufacturer’s

instructions furnished with control.

3. Install the pressure limit control as shown in Figure

25b.

4. Level the pressure limit control by carefully bending

the syphon until the control’s leveling indicator hangs

freely with its pointer directly over the index mark

inside the back of the case.

5. Install the steam gauge using the ½” NPT x ¼” FPT

hex bushing.

6. Install the safety valve as shown in Figures 25a

and 40a. Safety valve must be installed in vertical

position.

7. For boilers with tankless heaters, install the operating

control in an unused tapping through one of the

heater plates.

8. Plug extra boiler tappings.

9. Install required bottom blowoff/drain valve and

connecting piping (supplied by others) per minimum

piping requirements for steam boilers. See Figure

25b.

28

Page 29

This Page

Is Intentionally

Left Blank.

29

Page 30

Tapping

Location

Size

Water Boiler

Tapping

Location

Size

Water Boiler

(in) (in)

A 4 Supply J2 1 Plug

B 4 Plug K 3/4 Probe L.W.C.O.

C 3 Return M 3/4

Operating Temperature

Limit Control

D 3

Plug (24-03 thru 24-11)

Return (24-12)

N 3/4

Hi Temperature

Limit Control/Manual Reset

E 3 Blow-Off / Drain Valve P 1/2 Plug

F 3 Plug Q 1/2

Temperature/Pressure Gauge

(Bush to 1/4")

G 1-1/2 Relief Valve S 3/4 Tankless Heater Control

J1 1 Plug T 3/4 Firing Rate Temperature Control

Figure 26a: Purpose of Tappings - Water Boilers

30

Page 31

1 3" SQ. HD. PLUG 24-03 THRU 24-12 2 16 1-1/2" x 3/4" BLK BUSHING 24-03 THRU 24-07 1

1 3" SQ. HD. PLUG 24-12 WITH 20° DROP 1 16 1-1/2" x 1" BLK BUSHING 24-08 THRU 24-10 1

2 1" RECESSED HD PLUG ALL 4 16 1-1/2" x 1-1/4" BLK BUSHING 24-11 THRU 24-12 1

3 3" X 3/4" BLK BUSHING ALL 1 17 3/4" X 3" NIPPLE 24-03 THRU 24-07 1

4 3/4" CLOSE NIPPLE ALL 1 17 1" X 4" NIPPLE 24-08 THRU 24-10 1

5 3/4" BALL VALVE ALL 1 17 1-1/4" X 4" NIPPLE 24-11 THRU 24-12 1

6 3/4" SQ. HD. PLUG ALL 1 18 3/4" 90° ELBOW 24-03 THRU 24-07 1

7 1/2" RECESSED HD PLUG ALL 2 18 1" 90° ELBOW 24-08 THRU 24-10 1

8 3/4" LONG WELL ALL 1 1 1 18 1-1/4" 90° ELBOW 24-11 THRU 24-12 1

9 L4006E1109

CSD-1 EQUIPPED BOILERS

1 19 3/4" CLOSE NIPPLE 24-03 THRU 24-07 1

10 #550 PROBE LWCO

CSD-1 EQUIPPED BOILERS

1 19 1" CLOSE NIPPLE 24-08 THRU 24-10 1

11 L4006A2015 ALL 1 19 1-1/4" CLOSE NIPPLE 24-11 THRU 24-12 1

12 FIRING RATE TEMP CTRL

MODULATING BOILERS

1 20 RELIEF VALVE 10-408-05 24-03 THRU 24-04 1

13 TRIDICATOR GAUGE ALL 1 20 RELIEF VALVE 10-614-05 24-05 THRU 24-07 1

14 1/2" X 1/4" BLK BUSHING ALL 1 20 RELIEF VALVE 10-615-05 24-08 THRU 24-10 1

15 4" BK PLUG ALL 1 20 RELIEF VALVE 10-616-05 24-11 THRU 24-12 1

NOT

SHOWN

3/4" RECESSED HD. PLUG ALL 4

QUANTITY

KEY DESCRIPTION BOILER MODELS DESCRIPTION BOILER MODELS

QUANTITY

KEY

OPTIONAL

NOT

SUPPLIED

STANDARD

STANDARD

OPTIONAL

NOT

SUPPLIED

Figure 26b: Water Trim

31

Page 32

WARNING

Failure to properly pipe boiler may result in

improper, unsafe system operation and void

manufacturer's warranty.

DO NOT improperly pipe boiler.

WARNING

All steam and hot water pipes must have

clearances of at least 1/2" from all

combustible construction.

I. WATER BOILERS - INSTALL WATER TRIM

WARNING

Relief valve discharge pip ing mus t be piped

within six (6) inches of floor o r to floor

drain to eliminate p otential of severe burn s.

Do not pip e in an y area where fre ez ing

co u ld occ u r. D o n o t install any shut-off

va lve s, plugs or caps in discharge p iping.

Items for water trim are located in the water trim carton

(except for the separately ordered low water cutoff and

tankless heater control). Figures 26a and 26b show the

proper tappings for each item.

1. Install the temperature pressure gauge.

2. Install the low water cutoff (supplied by others).

Follow manufacturer’s instructions furnished with

control.

3. Install the immersion well and mount the aquastat

(limit control) onto the well.

4. Install the pressure relief valve as shown in Figure

40b. Relief valve must be installed in vertical

position.

5. Plug extra boiler tappings.

6. Install required bottom blowoff/drain valve

(supplied by others) per minimum piping

requirements for water boilers, see Figures 31, 32

and 33.

J. BURNER INSTALLATION

Refer to burner manufacturer’s installation manual

for proper installation, fuel piping, wiring, burner

adjustment, burner start-up and service instructions.

Consult Section VI of this manual for burner

specifications and burner settings.

K. BOILER PIPING - HEATING APPLICATIONS

CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM (see Figures 31, 32 and/or 33 for

water boilers and Figures 34 and 35 for steam boilers).

32

Page 33

WARNING

Return wate r cannot be low er than 135 °F for prolo nged periods of time. Operation under these

co n ditio ns w ill result in sustained condensing within the c o mbustio n chambe r and potentially

reduce boiler longevity.

In addition, th e return water canno t be introduced into the boiler if it is more than 40°F less tha n

the idle b o iler temperature . Continued o p eratio n under these cond ition s may result in

prema ture boiler failure thro u g h thermal shock.

Exa mple

: A b o iler that has been idle for some time since the last heat demand cycle may have

it's boiler w a ter tempera ture reduce d to 150°F. The return temp erature fro m th e next zone

ac tivation cannot be less th an 110°F.

If the abo v e conditions exist, an RTC system must be installed to pro tect the b o iler fro m

su stained cond e nsin g o p eratio n and therma l shoc k.

WARNING

A hot w ater boiler insta lled above radiation

level mu st be provided w ith a low w ater

cu toff dev ice a s p art of the in stallation.

1. HOT WATER HEATING - This boiler must be

installed in strict accordance to the instructions

found in this installation manual. Deviations

from these installation instructions may void

manufacturer’s warranty. See warning below

to determine the use of the RTC. A Return

Temperature Control (RTC) may be provided to

protect the boiler from thermal shock and sustained

condensing operation. In addition, a properly

selected boiler circulator and diverting valve, along

with the return sensor, must be installed when using

the RTC. A number of typical Crown applications

have been added to the appendix (Appendix A).

Select the appropriate application before proceeding.

a. Parallel Piping Systems – An existing parallel

piping system may be used, provided the return

water is not below 135°F for prolonged periods

of time, and the return water temperature is

not more than 40°F less than the idle boiler

temperature (see warning below). A flow

analysis should be performed to determine the

flow through the boiler when the minimum (and

smallest) and maximum number of zones are

activated. A sufficient flow through the boiler

should be maintained to assure a maximum of

40°F difference between the boiler supply and

return.

If the conditions above cannot be met, then

parallel piping systems must be converted to a

primary/secondary arrangement, de-coupling

the system pump from the boiler loop. The

system pump cannot influence the flow through

the boiler(s) in a primary/secondary piping

arrangement. The concept must be for the boiler

loop to inject heat into a primary loop, provided

the return water into the boiler is at least 135°F.

A by-pass containing two closely spaced tees

must be installed to de-couple the boiler loop

from the primary loop (see Figure 30). Care

must be taken to avoid dead heading the

system pump. Conversions should be reviewed

and approved by a Consulting Engineer or

other qualified professional to avoid system

deficiencies.

Primary/Secondary Piping – Boiler(s) must

b.

be installed into a heating system that is

(are) designed as a primary/secondary piping

arrangement when the flow through the boiler

cannot be maintained to provide a 20°F - 40°F

difference between the boiler supply and

return. When using an RTC, the boiler loop

contains a boiler, boiler circulator and diverting

valve, along with the return temperature control

(RTC) and return sensor. The diverting valve

consists of a 3-way valve, positioned through

the use of an electronic actuator. The boiler loop

injects heat into the primary loop, provided the

temperature of the boiler return water is greater

than 135°F. If the temperature is below 135°F,

the diverting valve closes, recirculating the

boiler water until it has heated above the 135°F

minimum limit. The supply and return of the

boiler loop is connected to the primary loop

through the use of two closely spaced “Tees”, at

a maximum branch centerline distance of 4 times

the primary loop diameter (4 x D Max.) The

RTC provides a signal to the actuator based on

the absolute water temperature and the rate of

change in water temperature.

c. Multiple Boilers – Multiple boilers are installed

the same as single boiler installations. Each

boiler loop will contain it’s own boiler circulator,

diverting valve, RTC and return sensor (see

Appendix A). Commonly available sequencers

can be used in conjunction with the Return

Temperature Control by energizing the control’s

heat demand circuit. The outdoor reset feature

of the sequencer must be used in multiple

boiler installations. The outdoor reset feature

33

Page 34

WARNING

If the boiler circ ulator y ou have selected is

greater than 1/3 H P, an isolation re lay must

be a dded w h en usin g the RTC.

If a 3-pha se boiler circulato r has been

se lec ted than a pro p erly siz ed motor starter

must b e installe d w hen using th e R T C .

Figure 27:

Typical Crown Boiler - Primary - Secondary Loop

System (Return Temps always Greater than 135°F.)

Figure 28: