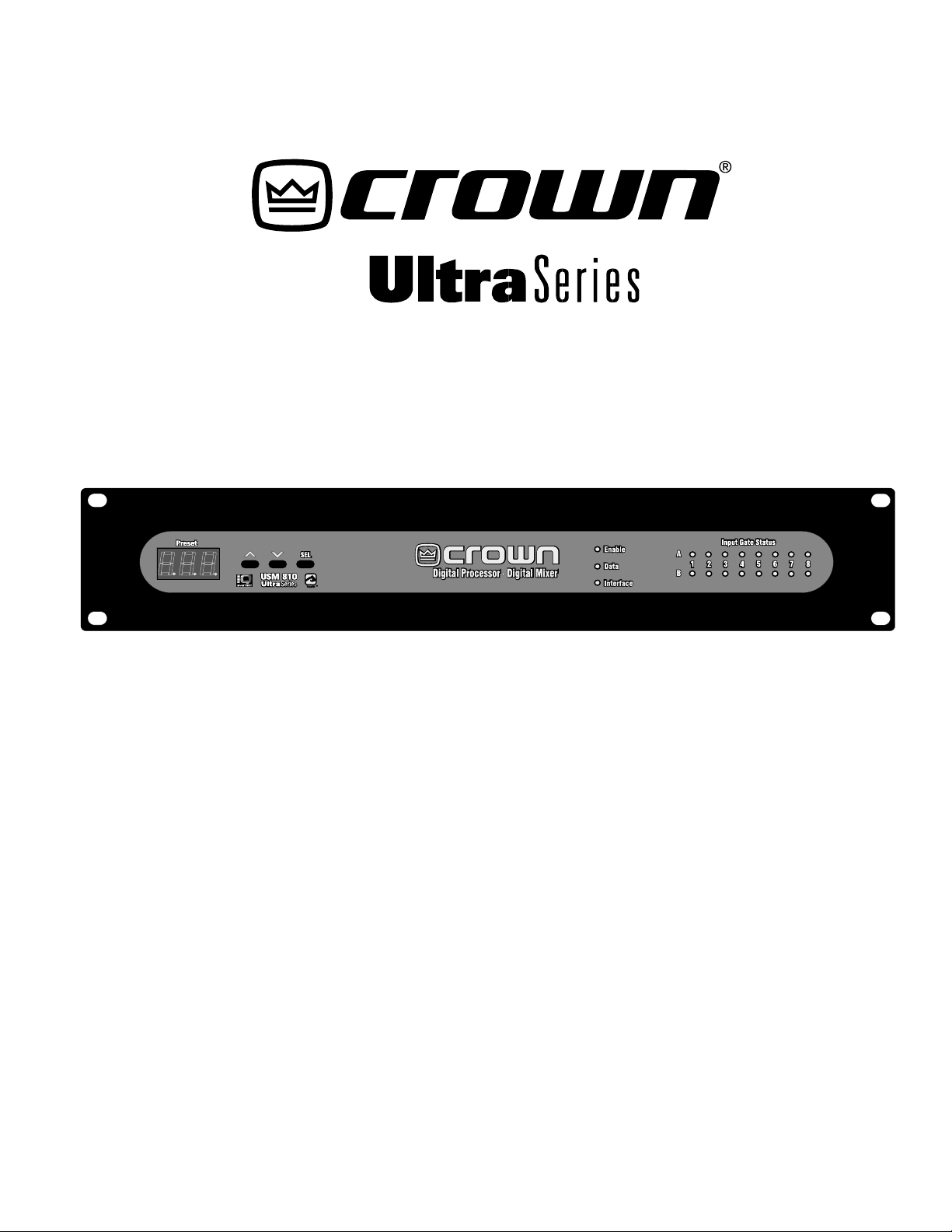

Page 1

Digital Processor / Digital Mixer

SERVICE MANUAL

Models:

IQ-USM 810

Some models may be exported under the name Amcron.

®

©2000 by Crown International, Inc., P.O. Box 1000, Elkhart, Indiana 46515-1000 U.S.A.

Telephone: 219-294-8000. Trademark Notice: Distributed Intelligence™ and IQ for Windows™

are trademarks and Crown®, IQ®, and IQ System

International, Inc. Other trademarks are the property of their respective owners.

®

are registered trademarks of Crown

130447-1

04-00

Rev. A

Page 2

IQ-USM 810 Service Manual

The information furnished in this manual does not include all of the details of design, production, or variations

of the equipment. Nor does it cover every possible situation which may arise during installation, operation or

maintenance. If you need special assistance beyond the scope of this manual, please contact the Crown

Technical Support Group.

Mail: P.O. Box 1000 Elkhart IN 46515-1000

Shipping: Plant 2 SW 1718 W. Mishawaka Road Elkhart IN 46517

Phone: (800) 342-6939 / (219) 294-8200

FAX: (219) 294-8301

130447-1 Rev. A

CAUTION

TO PREVENT ELECTRIC SHOCK DO

NOT REMOVE TOP OR BOTTOM

COVERS. NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE

PERSONNEL. DISCONNECT

POWER CORD BEFORE REMOVING

REAR INPUT MODULE TO ACCESS

GAIN SWITCH.

WARNING

AVIS

À PRÉVENIR LE CHOC

ÉLECTRIQUE N’ENLEVEZ

PAS LES COUVERTURES.

RIEN DES PARTIES

UTILES À L’INTÉRIEUR.

DÉBRANCHER LA BORNE

AVANT D’OUVRIR LA

MODULE EN ARRIÈRE.

TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE!

The lightning bolt

triangle is used to

alert the user to the

risk of electric shock.

II

The exclamation point

triangle is used to alert the

user to important operating

or maintenance instructions.

©2000 Crown International, Inc.

Page 3

130447-1 Rev. A

IQ-USM 810 Service Manual

Revision History

Revision Number

Rev. A

Date

04-2000 Initial Printing

Comments

©2000 Crown International, Inc.

III

Page 4

IQ-USM 810 Service Manual

130447-1 Rev. A

This page intentionally left blank

IV

©2000 Crown International, Inc.

Page 5

130447-1 Rev. A

1 Introduction ............................................................................ 1-1

2 Specifications ......................................................................... 2-1

3 Circuit Theory ........................................................................ 3-1

IQ-USM 810 Service Manual

Table of Contents

1.1 Introduction ................................................................................1-1

1.2 The IQ-USM 810 ........................................................................1-1

1.3 Warranty.....................................................................................1-1

3.1 Overview .................................................................................... 3-1

3.2 Power Supply .............................................................................3-1

3.3 Input ...........................................................................................3-1

3.3.1 Input Analog Processing...................................................3-1

3.3.2 Clock Signals ....................................................................3-2

3.3.3 A/D Conversion .................................................................3-2

3.3.4 DC Voltages ......................................................................3-4

3.4 Output ........................................................................................ 3-4

3.4.1 Clock Buffers.....................................................................3-4

3.4.2 DAC Conversion................................................................3-4

3.4.3 Output Analog Processing................................................ 3-4

3.5 SHARC Processing ....................................................................3-5

3.5.1 +3.3V Power Supply..........................................................3-5

3.5.2 Clocks ...............................................................................3-5

3.5.3 Reset .................................................................................3-5

3.5.4 System Control Interface................................................... 3-5

3.5.5 PLDs.................................................................................. 3-6

3.5.6 Bus Arbitration...................................................................3-6

3.5.7 Bus Utilization....................................................................3-6

3.5.8 DSP Processing ................................................................3-6

3.5.9 Audio Routing....................................................................3-8

3.6 System Controller.......................................................................3-8

3.6.1 Control Processing............................................................ 3-9

3.6.2 RS232.............................................................................. 3-10

3.6.3 Crown Bus Loop..............................................................3-10

3.6.4 Real Time Clock ..............................................................3-10

3.6.5 Front Panel ......................................................................3-10

3.6.6 Control Port .....................................................................3-10

3.7 Front Display ............................................................................3-10

4 Maintenance........................................................................... 4-1

4.1 General Information....................................................................4-1

4.2 Definitions...................................................................................4-1

4.3 Required Test Equipment ..........................................................4-1

4.4 Message String Syntax ..............................................................4-2

©2000 Crown International, Inc.

V

Page 6

IQ-USM 810 Service Manual

4.5 Standard Initial Conditions........................................................4-2

4.6 Test Procedures.........................................................................4-2

4.7 Typical Measurements............................................................... 4-7

4.8 Test/Debug Objects...................................................................4-7

4.9 Display Test Patterns ................................................................. 4-8

4.10 Error Codes..............................................................................4-9

4.11 Troubleshooting FAQs ............................................................. 4-9

5 Parts Information................................................................... 5-1

5.1 General Information ..................................................................5-1

5.2 Ordering and Receiving Parts ..................................................5-1

5.2.1 Terms ..................................................................................... 5-1

5.2.2 Shipment ................................................................................ 5-1

6 Exploded View Parts ............................................................. 6 -1

130447-1 Rev. A

Table of Contents

7 Module and Schematic Information..................................... 7 -1

8 Module Parts.......................................................................... 8-1

PWA 126451-3 ................................................................................. 8-3

PWA 126690-3 ............................................................................... 8-13

PWA 126693-4 ............................................................................... 8-47

PWA 126744-3 ............................................................................... 8-59

PWA 128045-1 ............................................................................... 8-65

PWA 128047-3 ............................................................................... 8-75

PWA 128047-4 ............................................................................... 8-87

PWA 128049-1 ............................................................................... 8-99

PWA 128051-3 ............................................................................. 8-117

9 Schematics ............................................................................ 9-1

VI

©2000 Crown International, Inc.

Page 7

130447-1 Rev . A

1 Introduction

1.1 Introduction

This manual contains complete service information

on the Crown® IQ-USM 810 Digital Processor/Digital

Mixer. It is designed to be used in conjunction with

the Reference Manual; however, some important information is duplicated in this Service Manual in case

the Reference Manual is not readily available.

NOTE: THE INFORMATION IN THIS MANUAL IS

INTENDED FOR USE BY AN EXPERIENCED TECHNICIAN ONLY!

1.2 The IQ-USM 810

The Crown IQ-USM 810 is an 8x10 mixer/processor

that provides unique dual input processing paths. As

an IQ® component, it can be controlled by an IQ Sys-

tem®, and with its distributed intelligence™ capability ,

continue to operate even when an IQ System is not

connected. The IQ-USM 810 can also act as a system interface to other IQ components.

The IQ-USM 810 features high-quality 24-bit A/D and

D/A converters along with 240MIPS of full 32-bit floating point DSP for optimum dynamic range.

The dual input processing paths include a full complement of signal processing features, including advanced algorithms for gating, auto-leveling, filtering,

compression and automixing.

A full 8x8 Matrix Mixer allows any combination of routing and mixing from any input to any output. The Matrix Mixer outputs are routed to the two Main Audio

IQ-USM 810 Service Manual

Outputs and eight AUX Audio Outputs. The Main and

AUX Audio Output sections further process the signal with individually adjustable signal delay and filters along with an Ambient-Leveler and a high performance Output Limiter for system protection.

A Multi-Function Control Port implements analog and

digital I/O for control and monitor by simple potentiometer and switch wall controllers and indicator panels.

All of the IQ-USM 810 parameters are backed up via

reliable FLASH memory. System configurations may

be stored for recall from any of thirty-two system presets from the front panel control or via IQ for Windows

software.

1.3 Warranty

Each Reference Manual contains basic policies as

related to the customer . In addition, it should be stated

that this service documentation is meant to be used

only by properly trained personnel. Because most

Crown products carry a 3-Year Full Warranty (including round trip shipping within the United States), all

warranty service should be referred to the Crown Factory or Authorized Warranty Service Center. See the

applicable Reference Manual for warranty details. To

find the location of the nearest Authorized Warranty

Service Center or to obtain instructions for receiving

Crown Factory Service, please contact the Crown

Technical Suppor t Group (within North America), or

your Crown/Amcron Importer (outside North America).

If you are an Authorized Warranty Service Center and

have questions regarding the warranty of a product,

please contact the Crown Factory Service Manager

or the Crown Technical Suppor t Group.

©2000 Crown International, Inc.

Crown Customer Service

Technical Support Group

Factory Service

Parts Department

Mailing Address: P.O. Box 1000, Elkhart IN 46515

Shipping Address: Plant 2 S. W.

1718 W. Mishawaka Rd., Elkhart IN 46517

Phone: (219) 294-8200

Toll Free: (800) 342-6939

Fax: (219) 294-8301

http://www.crownaudio.com

Introduction 1-1

Page 8

IQ-USM 810 Service Manual

130447-1 Rev . A

Figure 1.1 IQ-USM 810 Front and Rear Views

1-2 Introduction

©2000 Crown International, Inc.

Page 9

130447-1 Rev. A

2 Specifications

General

Front Panel Controls: Front-panel switches select IQ

Address, Baud Rate, factory default preset (P00), and

any of 32 user-defined presets (P01–P32).

Rear-Panel Controls: A 3-position selector switch

(mic/line/phantom) and a calibrated gain control for

each input.

Connectors: Crown Bus: RJ-45 for input/output, RJ-45

for daisy output, RS232: DB9F computer interface for

both component and interface modes. Multi-function

Port: DB37M for analog inputs, digital inputs, digital

outputs, +5VDC, +10VDC and Ground. Audio Inputs

and Outputs: 3-pin male removable barrier block connectors, Euro-style cable connector supplied. AC

Power: IEC320 connector for AC power cord.

Display: A blue front-panel Enable indicator lights to

show that the unit is plugged in and AC power is being

supplied. An amber front-panel Data Signal Presence

Indicator (DATA) flashes whenever commands addressed to the IQ-USM 810 are received. A green

front-panel Interface indicator lights when the IQ-USM

810 is being used as system interface. A three-digit

digital display indicates the IQ-USM 810’s initialization

sequence by displaying each processor’s name as it

comes online, indicates the presently selected preset,

indicates the IQ address and baud rate while those

parameters are being adjusted, indicates when a parameter has been stored in flash memory, and when

any parameter is varied from its value within the currently selected preset. Ladder Display: A front panel,

sixteen-segment LED display matrix can be set to

three different operating modes: Level Meter, Input

Gate Status, and Infinity Pattern.

Power Requirements: 100VAC to 240VAC, 35VA

nominal.

Protection: if communication is lost, the unit will continue to function with the last commands received.

RS232 Data Communication

Baud Rate: Selectable to 19.2 K, 38.4 K, 57.6 K, or

115.2 K BAUD.

Data Format: Serial, binary, asynchronous; 1 start bit;

1 stop bit; 8 data bits; no parity.

Crown Bus Data Communication

Data Rate: 38.4 K BAUD.

Data Format: Serial, binary, asynchronous; 1 start bit;

IQ-USM 810 Service Manual

1 stop bit; 8 data bits; no parity.

Crown Bus Interface Type: Optically isolated 20 mA

current loop.

Operation: Half-duplex.

Transmission Distance: Variable from 200 to 3000

feet (61 to 914 meters), depending upon wire capacitance. Typically 1000 feet (305 meters) using shielded

twisted-pair wire, #26 AWG or larger. Can be extended

with an IQ Repeater.

Audio

Phantom V oltage: +24VDC at 10 mA.

Input Gain Range: +20 dB to –12 dB.

Digital Sampling: 24 bit, 48 kHz.

Input Impedance: 20 k ohms balanced, 10 k ohms

unbalanced.

Dynamic Range: Greater than 100 dB (A-weighted,

20 Hz–20 KHz).

Frequency Response: ± 0.5 dB, 20 Hz–20 kHz.

Common Mode Rejection: 50 dB (typical).

Crosstalk: Greater than 80 dB at 10 kHz.

T otal Harmonic Distortion: Less than 0.05% THD + N

(1 kHz, 0 dBu).

Output Impedance: 100 ohms balanced, 50 ohms

unbalanced.

Max Input Level: +32 dBu (line) or +7 dBu (mic).

Max Output Level: +20 dBu.

Control Port

Power Supply: +5VDC and +10VDC outputs are provided. The total output current is limited to 1A.

Outputs

Logic Low: less than 0.1V.

Logic High: 10V (via internal pull-up).

Output Current is limited to 10mA max per pin.

Inputs

Input Impedance: greater than 50 k ohms.

Logic Low: less than 0.5V.

Logic High: greater than 5V.

Analog Range: 0 to 10V (for inputs 9-16 only).

Max Input Voltage: 25V.

Mechanical

Weight: 13 pounds, 4 ounces (6.1 kg).

Dimensions: 19-inch (483-cm) standard rack mount

width (EIA RS-310-B), 16-inch (40.6-cm) depth behind

mounting surface, and 3.5-inches (8.9-cm) height.

©2000 Crown International, Inc.

Specifications 2-1

Page 10

IQ-USM 810 Service Manual

130447-1 Rev. A

This page intentionally left blank

2-2 Specifications

©2000 Crown International, Inc.

Page 11

130447-1 Rev. A

3 Circuit Theory

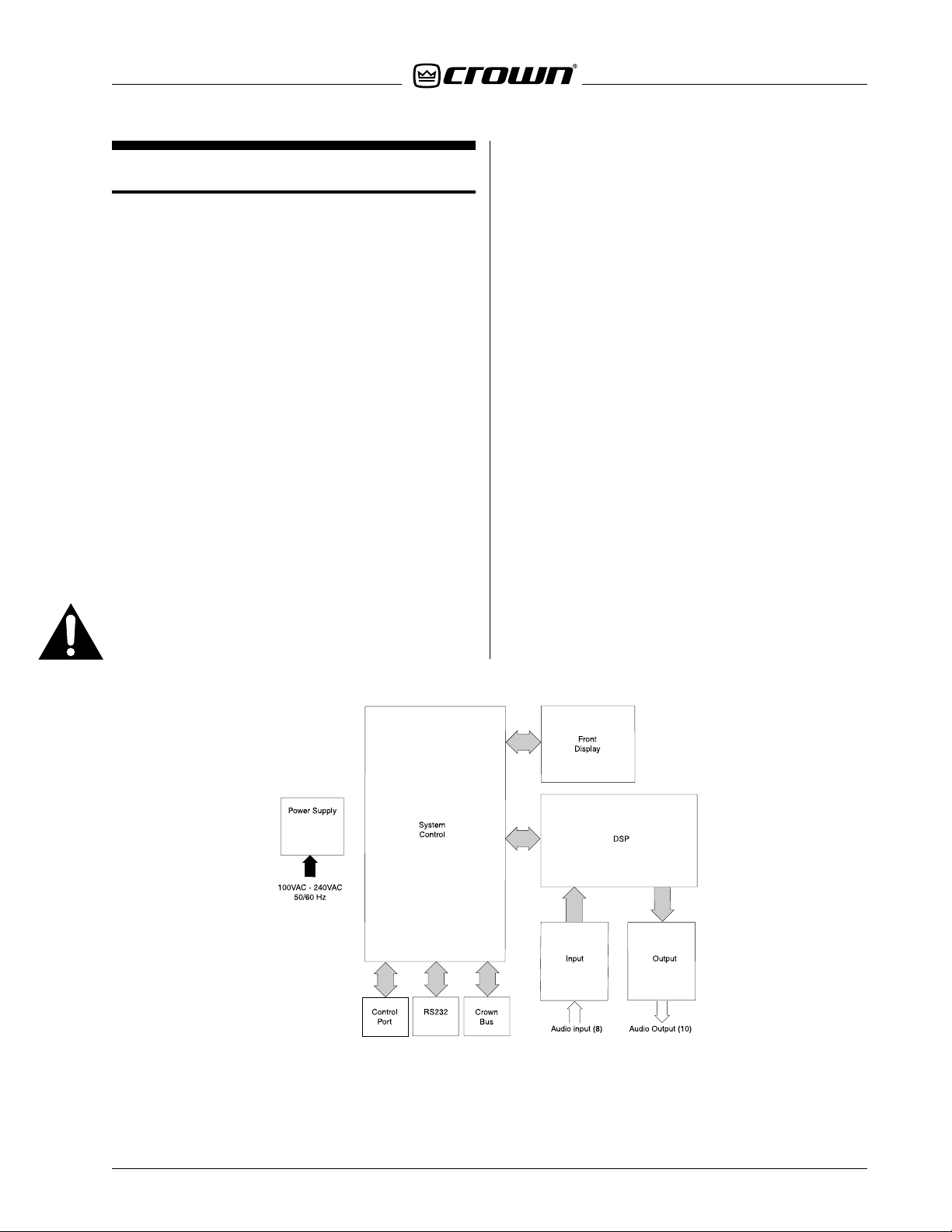

3.1 Overview

This section explains operation of the IQ-USM 810 circuitry . Please refer to the IQ-USM 810 Reference Manual

and IQ for Windows help files for information about the

IQ-USM 810 features and operation.

The IQ-USM 810 consists of a universal power supply

and 5 PWAs (see Figure 3.1). Each PW A has a particular function and initial troubleshooting should focus on

attempting to determine which PWA is causing the malfunction. The PWAs are not unit-dependent, so a known

good working PWA or unit can be used to pinpoint which

PWA is faulty.

3.2 Power Supply

The universal power supply used by the IQ-USM 810

resides underneath the System Controller at the back

of the unit. It receives AC input from the IEC filter located on the back panel and supplies +15V, –15V , and

+5VDC to the System Controller . There is a fuse located

on the supply and should be checked if the power supply is suspected. Replace fuse with the same rated

type only.

IQ-USM 810 Service Manual

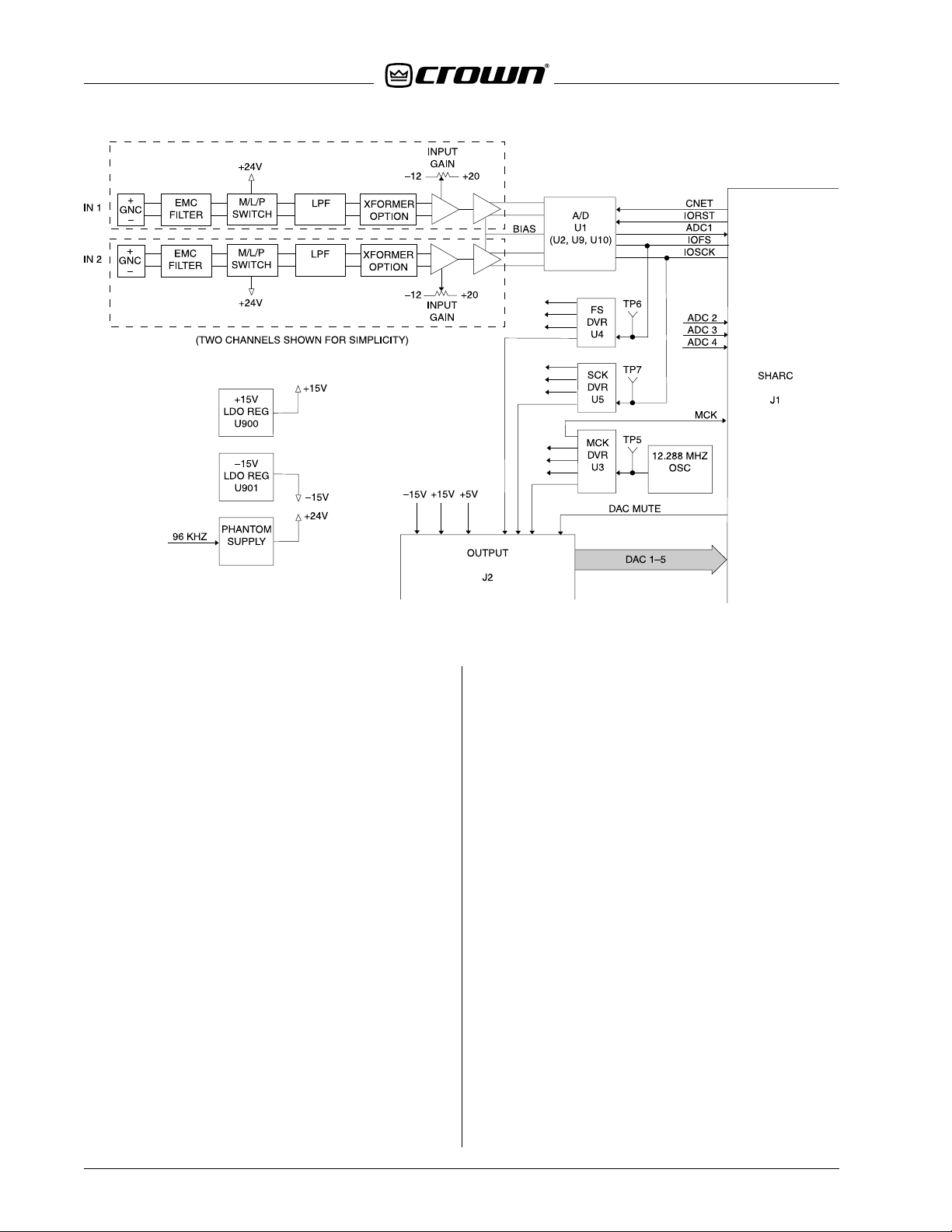

3.3 Input

The input Printed Wire Assembly (PWA) is located at

the back of the unit on the bottom. It offers eight balanced input audio channels via 3 pin connectors. Figure 3.2 shows the block diagram of the input PWA. The

PWA is composed of the following sections: Input Analog Processing, Clock Signals, A/D Conversion, and DC

Voltages.

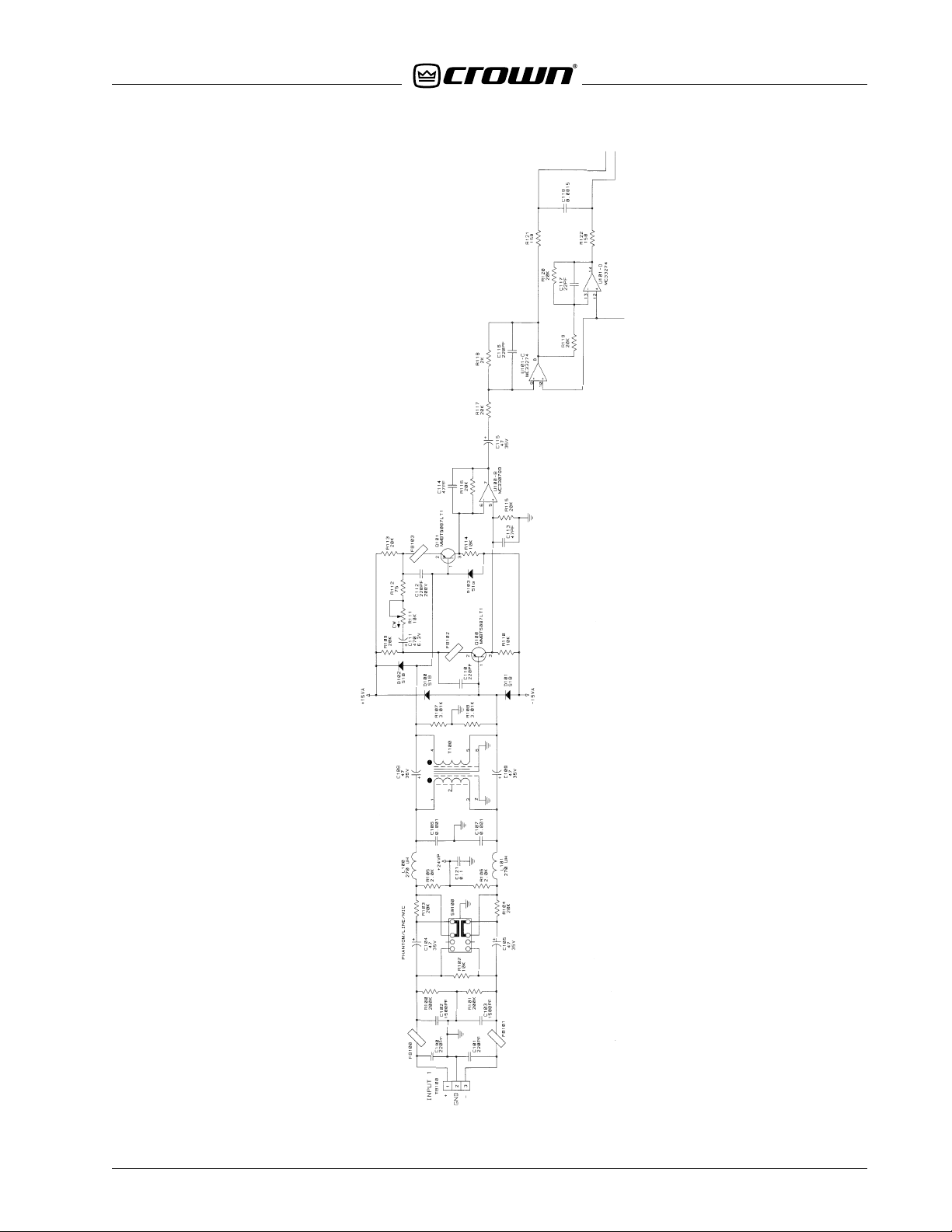

3.3.1 Input Analog Processing

Each input channel has analog processing that provides filtering, line/mic switching, phantom power, optional input transformer isolation, and variable gain control. The balanced output of each analog channel is fed

to a shared A/D converter.

All eight analog input channels are identical (Figure 3.3).

The balanced analog input is RF filtered by FB100,

FB101, C102, and C103. Capacitors C100 and C101

provide filtering to ensure that no noise from the unit

goes out. R100-102 provide a 10 k ohm balanced input

impedance in the line mode. Switch SW100 provides

switching between Phantom, Line, and Mic modes.

• Phantom: SW100 shorts R103/C104 and R104/

C105 to allow the phantom DC voltage (+24VDC)

to be available on the input connector. In addition, no gain reduction is provided on the input

path. R105 & R106 allows current limiting of the

phantom voltage.

©2000 Crown International, Inc.

Figure 3.1 Overall Block Diagram

Circuit Theory 3-1

Page 12

IQ-USM 810 Service Manual

130447-1 Rev. A

Figure 3.2 Input PWA Block Diagram

• Line: In Line mode, both the coupling capacitors

(C104 & C105) and the series resistors (R103 &

R104) are in the signal path. The capacitors block

the phantom voltage from the input while the series resistors work as a voltage divider with R105

& R106 to provide a 17.7x (25 db) reduction in

gain.

• Mic: The coupling capacitors are provided to block

the phantom power, but the series resistors are

shorted, allowing full gain through the input channel.

L100/C106 (L101/C107) provide an additional low-pass

filter. C108 & C109 provide coupling to the variable

gain preamp, except when the optional input isolation

transformer (T100) is in place. Q100 and Q101 form a

differential amplifier whose gain is adjusted by R111.

U100B provides a filtered differential to single-ended

conversion. U101C provides a gain reduction and biases the input signal to +2.2VDC. The output bias voltage of the A/D converter's pin 15 is fed to the op amp to

bias the signal to the A/D's bias point. Lack of voltage

at pin15 is an indication that the A/D converter is either

in reset or is not being clocked.

3.3.2 Clock Signals

The master oscillator for the audio signals is Y1, which

generates a 12.288 MHz signal (256Fs). This clock is

buffered by U3 and provides separate outputs to each

of the A/D converters, the Output PWA for the DAC's,

and to the SHARC PWA for distribution to the optional

CobraNet™ (CNET) PWA.

U1 normally acts as the generator of the Serial Clock

and the Frame Clock. Serial Clock provides the timing

of the serial audio data, 3.032 MHz (64Fs), and Frame

Clock is the actual sampling clock frequency, 48 kHz

(Fs). U1 monitors the CNET line from the SHARC PWA

immediately out of reset. If the pin is low, it acts as a

master source and begins providing Serial Clock and

Frame Clock to U4 & U5 for buffering and distribution. If

U1 senses a high on the CNET pin out of reset, it oper ates in slave mode like the other A/D converters and

waits for Serial and Frame Clocks from the CNET PWA.

3.3.3 A/D Conversion

Each A/D converter processes 2 input channels. Full

scale input signals are 2.82Vp-p and are sampled at a

48-kHz rate with 24-bit resolution. The converters are

reset by the DSP's by the IO_RST line with a low being

reset. The converters provide an I2S 32-bit time-division

multiplexed data audio stream. The most significant 24

bits are linear PCM (two's complement) audio data followed by 8 bits of converter peak hold data that is un-

3-2 Circuit Theory

©2000 Crown International, Inc.

Page 13

130447-1 Rev. A

IQ-USM 810 Service Manual

©2000 Crown International, Inc.

Figure 3.3 Input Analog Processing Circuitry (one channel)

Circuit Theory 3-3

Page 14

IQ-USM 810 Service Manual

130447-1 Rev. A

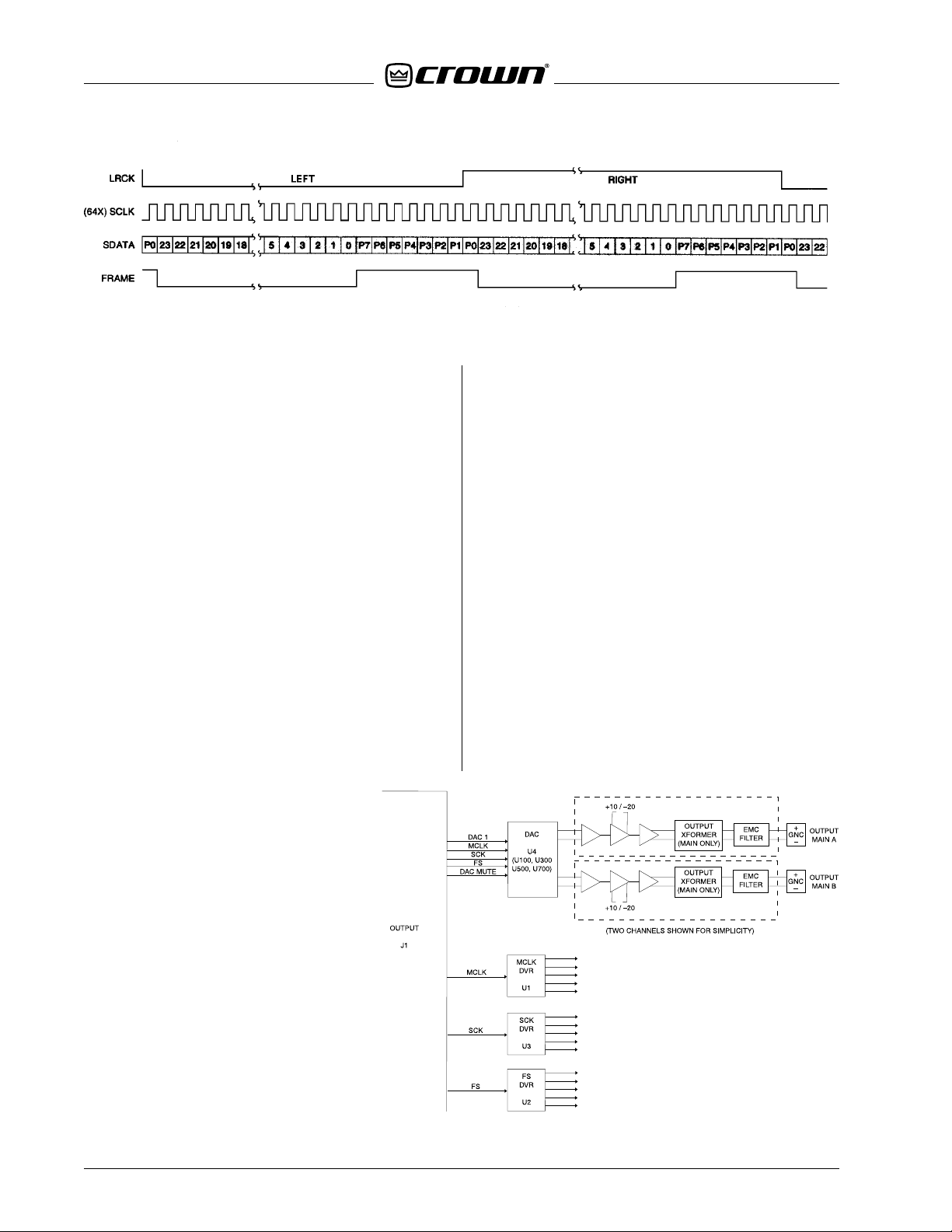

Figure 3.4 Audio Data and Clock Signals

used. This data is routed to the SHARC PWA for processing (ADC1-4). Figure 3.4 shows the audio data and

its relationship to the clock signals.

3.3.4 DC Voltages

The Input PWA receives +/–15V and +5V fr om the System Controller . +15V from P900 is filtered and then r egulated by a low dropout regulator, U900. R900 & R901

set the output voltage of the regulator at +14.5V. The

–15V is processed similarly by U901. The +5V is filtered

separately for the digital portion of the PWA than the

analog side.

The phantom power voltage is generated by U902. +15V

from P900 drives L904 while Q900 acts as a switch to

charge L904. R905 acts as a current sense and limits

the output current of the phantom power by reducing

the voltage at currents over 50 mA. R904 & R908 set

the output voltage at about +26V. U902 is driven from a

96-kHz clock provided by U10. This ensures that the

switching supply is synced to the sampling frequency

of the converters (2Fs). During reset, U902 will run at a

slightly lower frequency due to the lack of an input clock.

3.4 Output

The Output PWA sits on top of the Input

PWA and provides 10 audio outputs; Main

A/B and AUX 1-8. The Output PWA receives all of its signals from the Input PWA

via a 26-pin ribbon cable. Functionality

can be divided into Clock Buffers, DAC

Conversion, and Output Analog Processing. A block diagram of the Output PWA

is shown in Figure 3.5.

Each DAC takes a 2 channel I2S 32-bit time-division

multiplexed data audio stream from the SHARC PWA

and converts it at a 24-bit, 48-kHz rate (Figure 3.4). Like

the A/D converter, the audio output of the DAC is biased positive by 2.2V and a full signal is 2.82Vp-p.

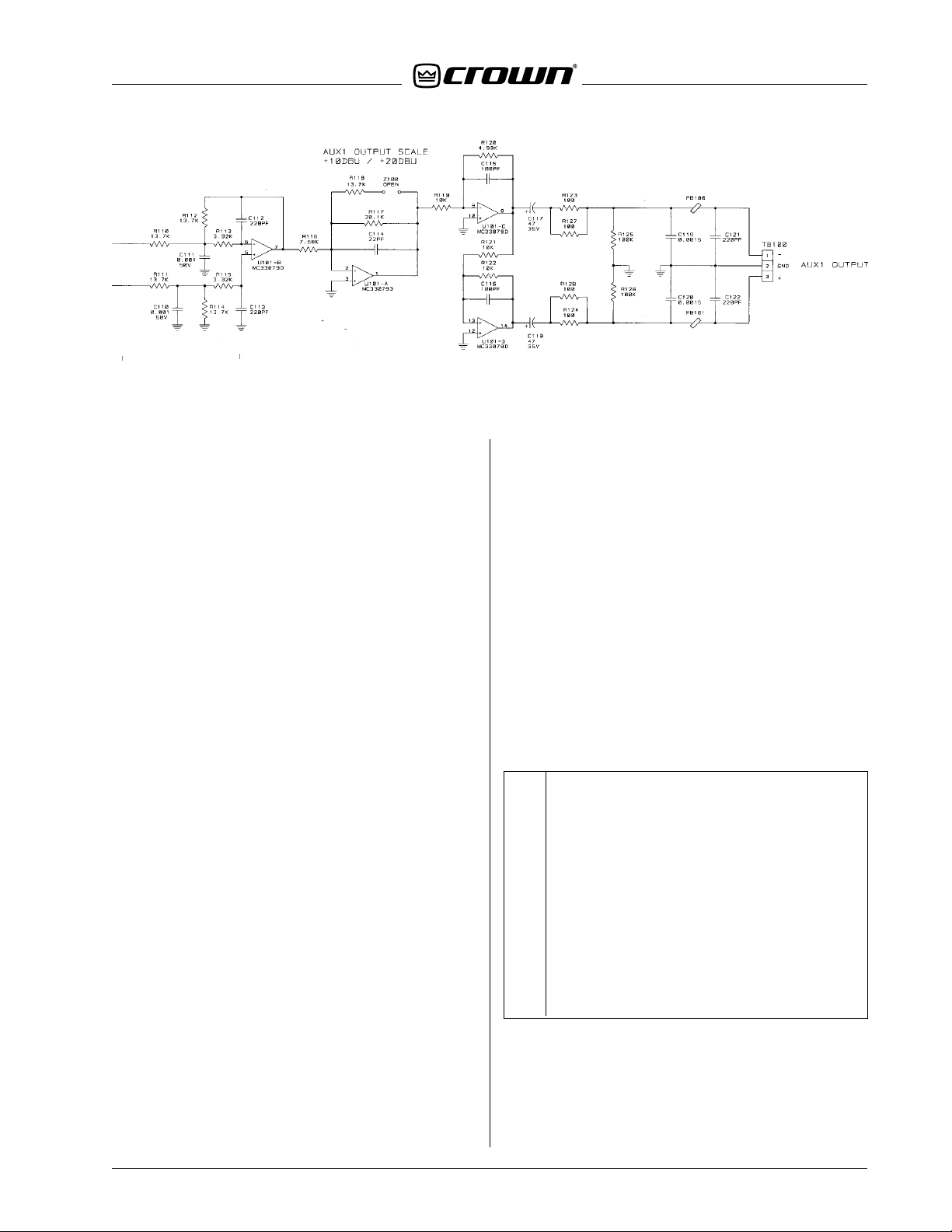

3.4.3 Output Analog Processing

All ten analog output channels are identical (Figure 3.6).

The balanced output of the DAC drives a unity gain

amplifier that also filters the audio signal. The singleended output is fed to U101A which provides gain of

either 1.2 (+10 dbu) or 3.9 (+20 dbu). Z100 is normally

open, which provides a +20 dbu output for a full scale

signal from the DAC. U101C provides a gain reduction

of 2, then U101D inverts the signal and provides the

other balanced output. An output impedance of 50 ohms

is provided by the series resistors while the output ferrite bead provides RF filtering to ensure isolation. Optional isolation transformers are available on the Main

outputs by removing the series resistors and placing

the transformers.

3.4.1 Clock Buffers

Three clock buffers, U1-3, accept the Master (12.288 MHz), Serial (3.032 MHz), and

Frame (48 kHz) clocks from the Input PWA

and provide separate outputs to each of

the five DAC's.

3.4.2 DAC Conversion

3-4 Circuit Theory

Figure 3.5 Output PWA Block Diagram

©2000 Crown International, Inc.

Page 15

130447-1 Rev. A

IQ-USM 810 Service Manual

Figure 3.6 Output Analog Processing Circuitry (one channel)

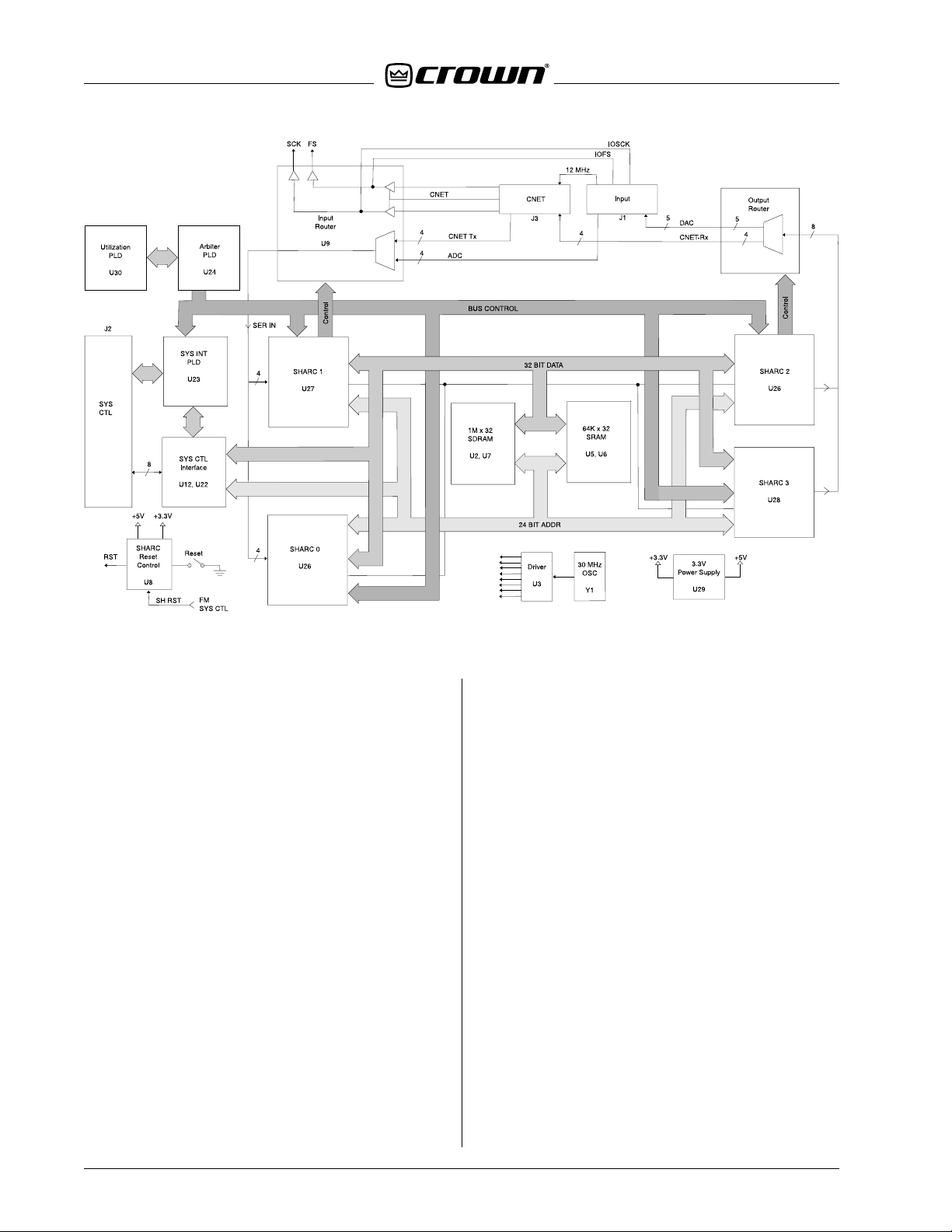

3.5 SHARC Processing

The SHARC PWA sits in the center of the chassis and is

the DSP engine that provides all of the signal processing for the unit. At the core of this processing is four

Analog Devices ADSP-21065L SHARC 32-bit floating

point DSP's running at an internal rate of 60 MHz. Full

speed SDRAM interface is provided. Figure 3.8 shows

the block diagram of the SHARC PWA. Features include

a +3.3V Power Supply, Clocks, Reset, System Controller Interface, PLD's, Bus Arbitration, Bus Utilization, DSP

Processing, and Audio Routing.

3.5.1 +3.3V Power Supply

The entire SHARC PWA utilizes +3.3V by taking the +5V

from P1 and converts it to +3.3V using a 300-kHz switching supply IC, U29. Q2 & Q3 work with U29 to control

the charging of L1. R200 current senses the supply for

overload protection. C27 & C113 provide output filtering of the supply.

3.5.2 Clocks

Oscillator Y1 provides a 30-MHz clock to buffer U3 for

distribution to all SHARC's, SRAM, and other circuitry.

3.5.3 Reset

U8 monitors both the +5V and +3.3V power supplies

and places the SHARC's into reset if either supply

droops. In addition, the System Controller uses U8 to

reset the SHARC's using pulldown via D1. Switch S1

allows manual reset of the SHARC's for troubleshooting. Q1 monitors the reset line to the SHARC's and lights

LED E5 when the SHARC's are not in reset. The active

low \RST line resets all four SHARC's and the PLD's

(U9, U11, U23, U24, and U30).

3.5.4 System Controller Interface

Communications between the System Controller and

SHARC processors occurs through a series of latches

(U12-22) that provide address and data. PLD U23 re-

ceives commands from the System Controller (SH_A02, \HCS, HR/W) to load data and addresses into these

latches. Once the data is in the latches, U23 communicates with Arbiter PLD U24 (\SYSBR, \SYSBG, \RD, \WR)

to request access to the SHARC bus.

There are no non-volatile memory resources on the

SHARC PWA, so the System Controller stores the

SHARC firmware and downloads it during boot. The

System Controller boots each SHARC in succession by

loading code into SRAM and into each SHARC via the

Interface. Once all four SHARC have been booted, they

are allowed to begin audio processing.

If the System Controller encounters any problems during the boot process, it will display an error code on the

front panel display . These er ror codes are shown in the

table in Figure 3.7:

E1 UART f ailed system controller po wer-on self test

E2 RAM failed system controller power-on self test

E3 Application code in flash failed CRC test

E4 Flash verify error

E5 Unrecoverab le firmw are error

E10 SHARC 0 interface hardware error (timeout, etc.)

E11 SHARC 1 interface hardware error (timeout, etc.)

E12 SHARC 2 interface hardware error (timeout, etc.)

E13 SHARC 3 interface hardware error (timeout, etc.)

E22 SHARC 0 software watchdog timeout

E23 SHARC 1 software watchdog timeout

E24 SHARC 2 software watchdog timeout

E25 SHARC 3 software watchdog timeout

Figure 3.7 System Controller Error Codes

Note: Errors 1-9 are for power-up self test and other

miscellaneous errors. Errors 10-25 are err ors related to

the SHARC subsystem.

©2000 Crown International, Inc.

Circuit Theory 3-5

Page 16

IQ-USM 810 Service Manual

130447-1 Rev. A

Figure 3.8 SHARC PWA Block Diagram

The System Controller will display the error code, then

begin the boot process again. By watching the boot

process on the front display , the error code can be r ead

at the end of the boot process before the next boot begins.

3.5.5 PLDs

There are five Programmable Logic Devices (PLD) on

the SHARC PWA (U9, U11, U23, U24, and U30). These

IC's are programmed on the PWA and can be reprogrammed. They have common control and clock lines

(ETCK, ETMS) and are daisy-chained by having each

output (TDO) tied to the next PLD's input (TDI). P3 allows connection to the external PLD programmer.

3.5.6 Bus Arbitration

The 32-bit data and 24-bit address busses of the SHARC

PWA are shared between the System Controller and

the four SHARC processors. Shared SRAM memory

(U5-6) is also available to all processors. The Arbiter

PLD, U24, polices which has access to the bus through

the use of control signals such as bus requests (\HBR,

\SYSBR, \BR0-3), bus grants (\HBG, \SYSBG, \BG0-3),

and SHARC chip selects (\CS0-3). It regulates which

and when each processor has control of the bus to ensure there is no contention.

3.5.7 Bus Utilization

The Arbiter PLD also works with the Bus Utilization PLD,

U30, to monitor each SHARC processor and determine

how much of the available SHARC bus bandwidth each

is using. The Arbiter tells the Utilization PLD on an individual bus cycle basis when each SHARC is on the bus

(UTILIN0-5) and this information is fed to the individual

SHARC's pulse width modulation inputs (UTILOUT0-3)

for calculation of bus access time. This information is

then reported to the System Controller when requested.

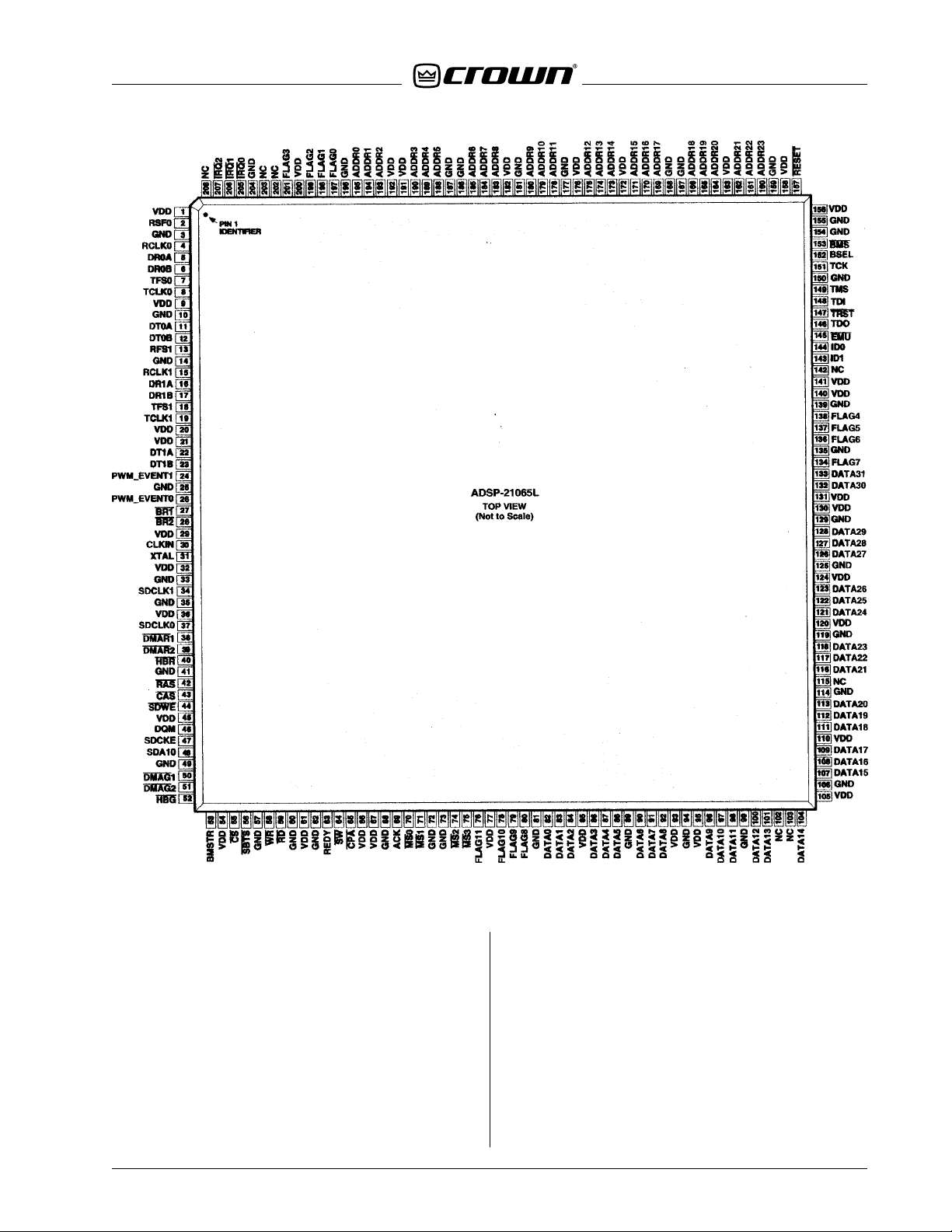

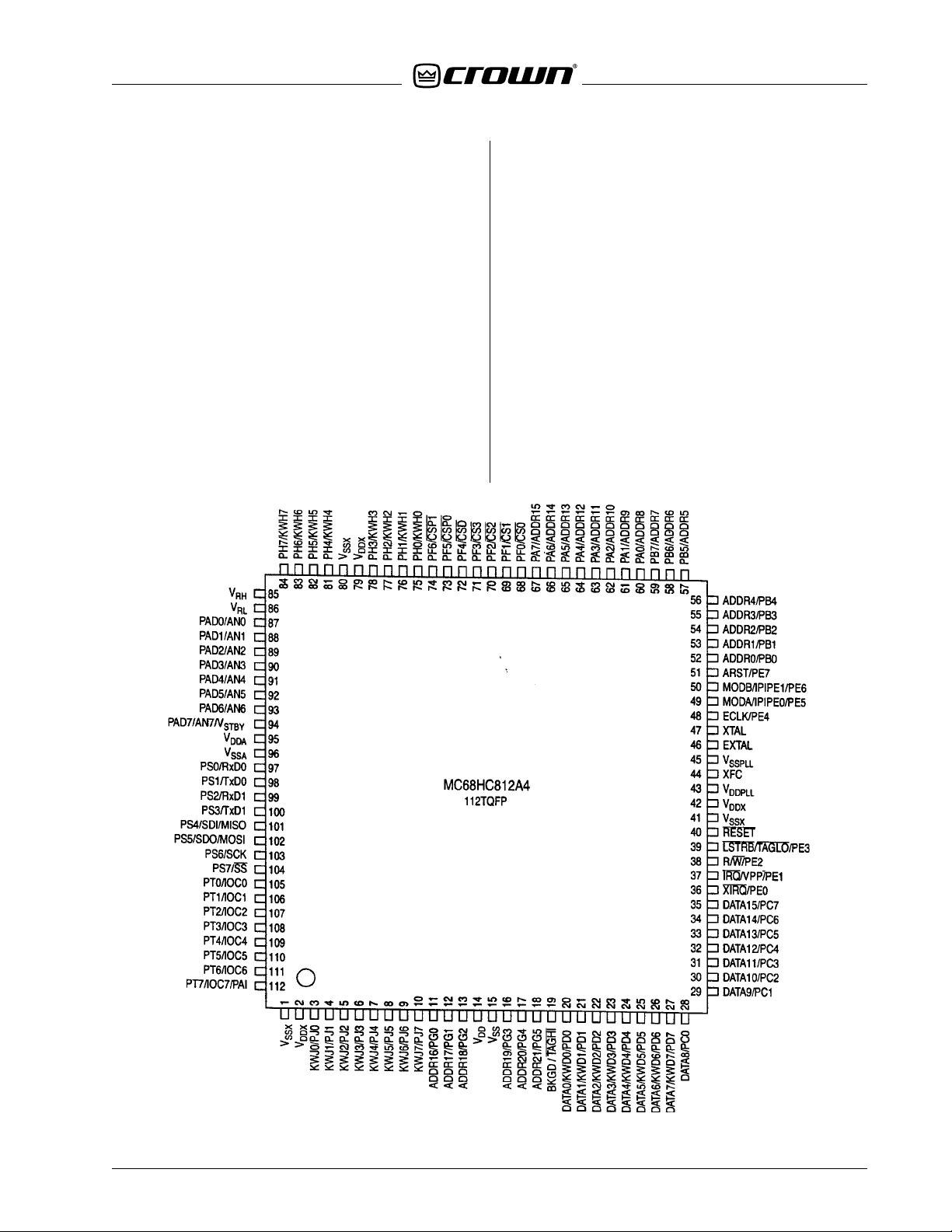

3.5.8 DSP Processing

As stated, the four SHARC processors (U25-28) are the

core of the DSP engine. These processors are 208-pin

Plastic Quad Flat Packs (PQFP) and the pinout is shown

in Figure 3.9.

Each SHARC has a specific task in the audio processing chain. SHARC 0 (U25) processes the input audio

for channels 1-4, while SHARC 1 (U27) is tasked with

the input audio processing for channels 5-8. T wo channel serial audio data from the Input Router, U9, is sent

to the appropriate SHARC's serial port along with audio

clock signals Serial Clock (SCK) and Frame Clock (FS).

The input audio is stored by the SHARC until 16 samples

are accumulated, then this audio “brick” is processed.

3-6 Circuit Theory

©2000 Crown International, Inc.

Page 17

130447-1 Rev. A

IQ-USM 810 Service Manual

Figure 3.9 SHARC Pinout

The time allotted for the SHARC to process this audio

data is 330us (16 samples x 48-kHz). At that point the

next audio brick has been collected and is ready for

processing. The processed output audio brick is then

deposited into SRAM (U5, U6). The audio bricks are

then taken by the Output SHARC's for mixing and output processing. SHARC 2 (U26) processes Main A and

Outputs 1-4 while SHARC 3 (U28) is responsible for

Main B and Outputs 5-8. If additional delay is required,

the bricks are allowed to remain in SDRAM before pr ocessing. The minimum delay through the audio processing is as follows:

©2000 Crown International, Inc.

• A/D Conversion 667us

• 5x "brick" delay 1667us

• DAC Conversion 520us

• Total Delay 2854us

This delay is constant and not dependent upon the

particular processing being done.

SDRAM provides a high speed synchronous memory

resource. Only the four SHARC processors have access to SDRAM and they are responsible for the access and maintenance of it. Each SHARC monitors the

Circuit Theory 3-7

Page 18

IQ-USM 810 Service Manual

130447-1 Rev. A

bus and accesses SDRAM when it is available. The

SHARC blocks access to the bus through the use of

the \SDLOCK pin during SDRAM transfers. SDRAM is

utilized only for audio delay processing and has no firmware. If audio is available at the input SHARC's, but is

not being seen by the output SHARC's, a good place to

begin troubleshooting would be with SDRAM.

The System Controller periodically accesses the

SHARC's to query about meter data. As discussed, the

System Controller utilizes the Interface to ask and receive this data.

3.5.9 Audio Routing

Serial audio from the Input PWA is sent to the SHARC

PWA for processing. ADC1-4 is fed to PLD U9 for r outing to the input SHARC's, U25 & U27. Serial digital audio from the optional CobraNet PWA is also available

as CNET_TX1-4. The Input Router sends the appropriate serial audio data to the input SHARC's as directed

by the System Controller via SHARC 1. A serial control

link (IN_MOSI, IN_SPICK) tells the Input Router which

of the serial digital inputs are to be sent to each SHARC's

serial ports.

The Input Router is also responsible for buffering the

audio clocks. By sensing the CNET input from the CNET

PWA, the Input Router can tell if the CNET PW A is con-

nected. If CNET is available, the CNET PWA is responsible to provide the Serial and Frame Clocks. The PLD

accepts the CNET audio clocks and routes them to the

SHARC's and Input PWA. If the CNET PWA is not connected, the audio clocks from the Input PWA are accepted and routed to the SHARC's.

The Output Router , U11, is r esponsible for sending the

serial audio outputs of the output SHARC's to the appropriate place. Five output lines, DAC1-5, allow 10

audio channels to be sent to the Output PWA for DAC

conversion. In addition, four output lines, CNET_RX1-4,

allow 8 audio channels to be directed to the optional

CNET PWA for inclusion onto the CNET system. The

Output Router is programmed by SHARC 2 via

OUT_MOSI & OUT_SPICK.

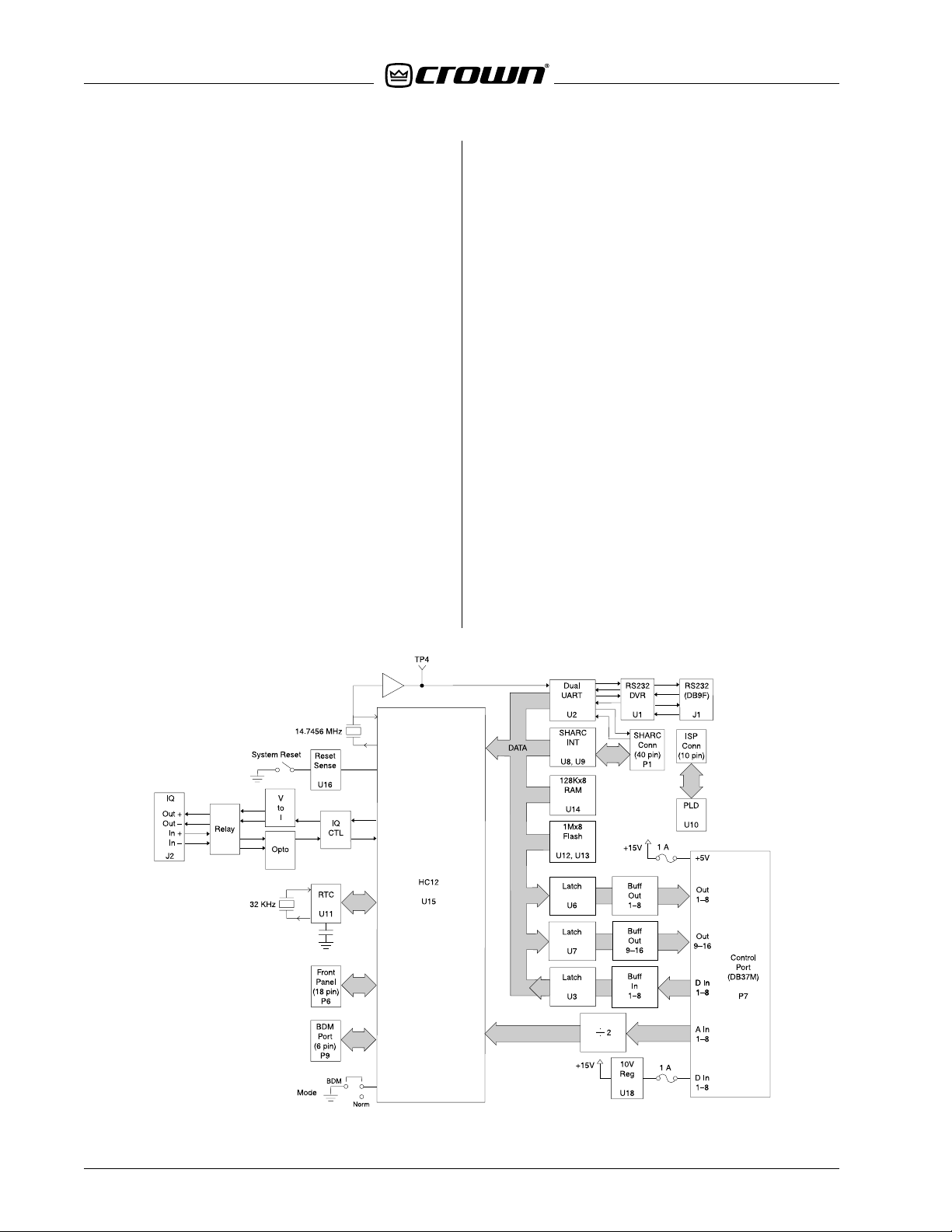

3.6 System Controller

The System Controller PWA sits on the one side of the

chassis and is supported over the power supply. It is

responsible for the coordination and communication with

the outside world, non-volatile memory storage of all

code, and various other functions. The System

Controller's tasks includes Control Processing, RS232,

Crown Bus loop, Real-Time Clock, Front Panel, and

Control Port. Figure 3.10 shows a block diagram for the

System Controller PWA.

3-8 Circuit Theory

Figure 3.10 System Controller Block Diagram

©2000 Crown International, Inc.

Page 19

130447-1 Rev. A

IQ-USM 810 Service Manual

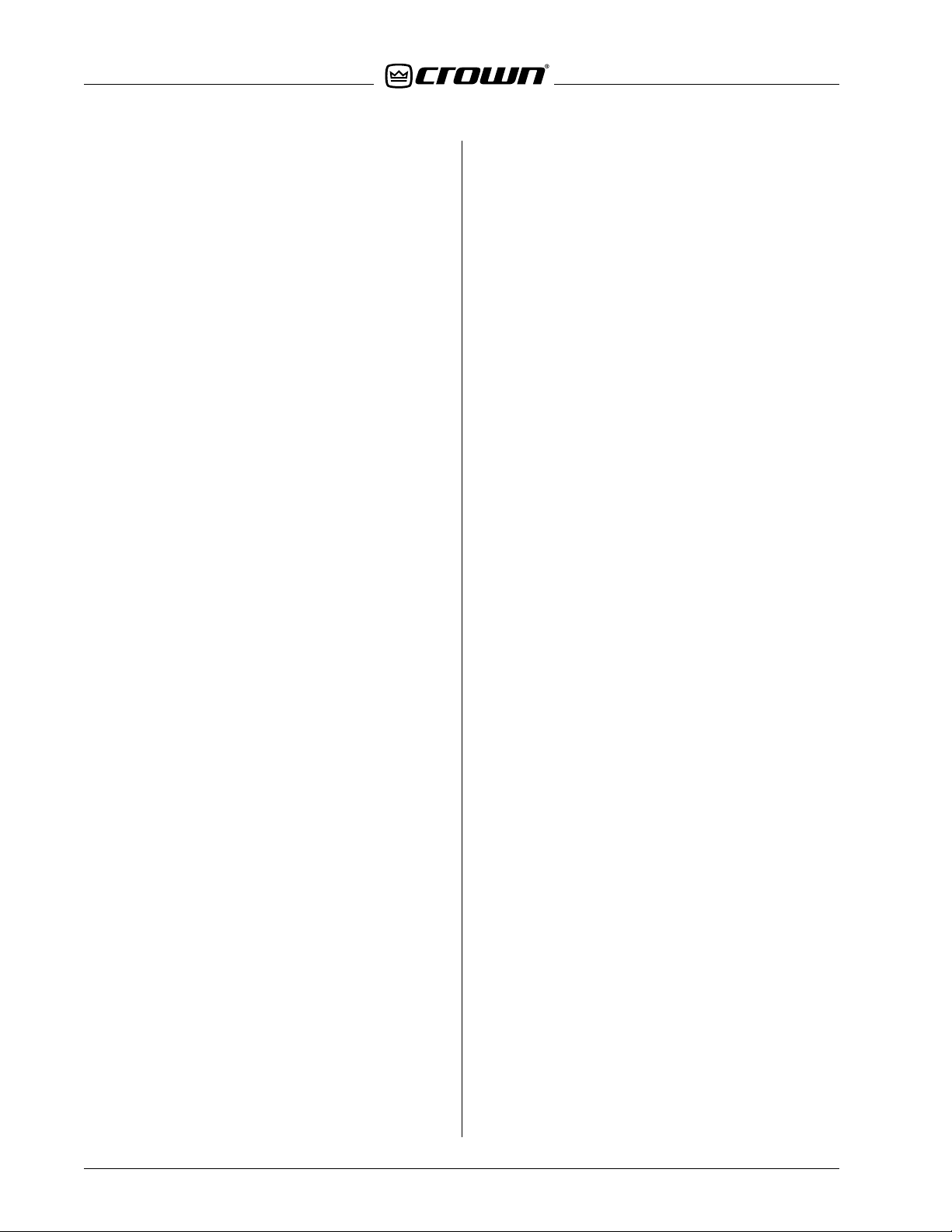

3.6.1 Control Processing

The brain of the System Controller PWA is the Motor ola

68HC12 microcontroller, U15. The 112pin QFP pinout

is shown in Figure 3.11.

The HC12 has a Background Debug Mode (BDM) connection that allows access to the internal workings of

the microcontroller . By connecting a pod to P9 and placing the HC12 in BDM mode, the HC12 can be accessed.

This function is not used in normal operation or troubleshooting, and the BDM jumper should be left in the

NORM position.

The HC12 provides all of the processing for the contro l

of the IQ-USM 810. U16 provides sensing of the +5V

power supply and brings the HC12 out of reset once

the supply is stable. Switch S1 allows resetting of the

controller externally . Q17 monitors the reset line and LED

E1 is lit whenever the processor is not in reset.

Crystal Y2 provides the 14.7456-MHz clock for the

HC12. The clock is buffered by U5D and is provided to

dual UART U2 for baud rate creation.

When the HC12 comes out of reset, it looks to the flash

memory (U13) and begins its boot process. Due to the

slow response of flash memory, normal code processing is carried out in SRAM. The HC12 copies its firmware out of flash memory into SRAM (U14) and once

complete, jumps to SRAM and begins code processing. The HC12 initializes the dual UART and looks for a

break on the RS232 input. If a break is detected, it activates its loader routine and waits for 'S' records from

the RS232 port to be downloaded to flash memory. This

process allows external programming of firmware revisions.

If no break is detected, the HC12 begins loading the

SHARC firmware from flash memory into SHARC

memory via the System Controller Interface. U8 and U9

provide buffering to the SHARC PW A via P1.

©2000 Crown International, Inc.

Figure 3.11 68HC12 microcontroller Pinout

Circuit Theory 3-9

Page 20

IQ-USM 810 Service Manual

130447-1 Rev. A

The HC12 firmware uses a real time operating system

(RTOS) to make efficient use of the HC12's processing

capability. Various tasks are given priorities, and the

RTOS supervises what task has control of the processor at any particular time.

3.6.2 RS232

As mentioned, the RS232 port is used to load firmware

into flash memory. UART U2 provides the serial port

interface to the HC12. The baud rate is programmed

by the HC12 as directed by the front panel (19.2 k to

115 kbps) and the clock is generated from the 14-MHz

clock. The 8-bit parallel interface to the UART is controlled by the U_RD (read), U_CS (chip select), and

FLSH_WE (write) lines. Internal registers control various functions such as baud rate, fifo usage, etc. The

serial I/O of the UART is buffered by RS232 Tx/Rx driver

U1. This buffer takes the +5V and creates the +/–12V

needed for RS232 levels. These signals are available

on the DB9F connector, J1, which is available on the

back panel of the chassis.

The other half of dual UART U2 is used as a serial inter face to the optional CNET PWA. It connects to the CNET

PWA via SHARC connector P1.

3.6.3 Crown Bus Loop

The HC12 has two serial ports and one of them is used

for the interface to the Crown Bus loop hardware. This

is a fixed 38.4-kbps baud rate and uses a dual RJ45

connector J2 to the back panel. In normal operation,

data detected at the input of the Crown Bus loop hardware is sent back out via U19A & B, U20B, and U21A.

When the HC12 wants to communicate, MSTR0 is pulled

high and the TX0 goes out to the Crown Bus loop. R142

provides 20 mA of current to the OUT+ line during nor mal operation. Communication occurs by interrupting

the OUT– path via D4 and U21A.

The input of the Crown Bus loop is buffered by

optoisolator U17 which senses the 20-mA current and

sends the signals to the HC12 (RX0) and directs it back

out the Crown Bus loop via U19A.

Relay K1 provides paths to the I/O circuitry while the

IQ-USM 810 is powered. When the unit is turned off, the

relay allows the Crown Bus loop to pass through the

unit to prevent Crown Bus loop communication from

being interrupted.

3.6.4 Real Time Clock

U11 is a Real Time Clock (RTC) IC that provides timing

to the HC12 for scheduling of real time events. U11 has

an internal oscillator provided by 32-kHz crystal Y1. The

HC12 communicates with the RTC via a serial interface

composed of RTCLK (serial clk), RTC (data), and

RTC_CS (chip select) and periodically queries the RTC

to get or set the time.

Capacitor C25 is a 1F supercap that allows the RTC to

continue to keep time after the unit is powered down.

The RTC senses the loss of power and automatically

switches to the capacitor to provide power . The capacitor can keep the RTC running for up to 45 days without

external power. While the unit is power ed, the RTC trickle

charges the capacitor.

3.6.5 Front Panel

The HC12 interfaces the Front Display PWA via P6. The

three front panel switches are sensed by the HC12 and

display of the front panel LED's are controlled via a serial interface; SCK, MOSI, MISO, and LED_CS. Two display IC's on the Front Display PWA interface both the

discrete LED's and the triple 7-segment display.

3.6.6 Control Port

The control port interface allows external signals or

events to control objects within the box. Additionally,

outputs allow signaling of object status to the outside.

The DB37M connector P7 provides back panel access.

+5V, +10V, and GND is also provided via the connector. Regulator U18 takes the +15V and provides +10V

out. The external power is protected by resettable fuses

limited to 1 A.

The HC12 interfaces the output buffers through latches

U6 and U7. These 16 outputs drive NPN transistors that

provide 10V @ 10 mA to the outside. Ferrite beads and

transient voltage suppressors (TVS) protect the output

circuits.

The digital inputs are buffered by NPN transistors that

allow current drive of the inputs. V oltages up to +25VDC

can be used to drive these inputs. The transistor buffers drive a latch that the HC12 polls to collect the input

status. U4 is used by the HC12 to address the particular I/O latch it wishes to query .

The analog inputs allow a 0 to +10VDC input to be digitized by the HC12's eight 8-bit A/D converters. A voltage divider ensures that the HC12's inputs will not be

overdriven.

3.7 Front Display

The Front Display PWA has the three front panel

switches, triple 7-segment display, Input Status LED's,

Enable, Data, and Interface LED's. The three switches

are sensed and processed directly by the HC12 on the

System Controller PWA. The two IC's, U1 & U2, contr ol

all of the front panel LED's by switching the LED's at a

20%, 1-kHz rate. The serial control from the HC12 tells

the IC's which LED's to light.

3-10 Circuit Theory

©2000 Crown International, Inc.

Page 21

130447-1 Rev . A

4 Maintenance

4.1 General Information

This chapter provides test procedures to be used to

verify operation of this IQ component. Minimum specifications for proof of performance are given with each

procedure. Procedures are in suggested format and

the exact test need not be performed; however, the test

conditions and results must be verified for proof of per formance. These tests, though meant for verification

and alignment, may also be very helpful in troubleshooting. For best results, the tests should be performed in

order.

4.2 Definitions

• IQ Ucode Protocol: The Protocol used by IQ2 products for communication on the Crown IQ Bus.

• DA: IQ Ucode Device Address. A part of the Ucode

string that identifies it as pertaining to a particular

device. The DA for the IQ-USM 810 is set by the

front panel controls. At first power up the IQ-USM

810 defaults to address $01.

• DT: IQ Ucode Device Type Identifier. A part of an

Ucode string that identifies it as pertaining to a

particular type of Ucode component. The DT for

the IQ-USM 810 is $19.

• AK: IQ Message Acknowledgment. This byte is

present in all Ucode device to host messages. It

indicates if the last host to device message was

correctly formatted.

IQ-USM 810 Service Manual

• CT: IQ Message data byte count. A part of the IQ

string that indicates the number of bytes in its

message portion. Note: This byte is automatically

inserted when using IQ Util in enhanced mode.

• CS: Ucode Message Checksum. The last byte of

a Ucode string containing the check sum of the

entire message. Note: This byte is automatically

inserted when using IQ Util in enhanced mode.

4.3 Required Test Equipment

Audio sine-wave generator (Output amplitude accuracy

better than ±0.5 dB)

Oscilloscope

Audio THD+N analyzer

True RMS AC voltmeter

DC voltmeter

Audio multiplexer (balanced) or other means of switch-

ing the audio generator to the eight mixer inputs.

Audio multiplexer (balanced) or other means of switch-

ing the ten mixer outputs to the Audio analyzer and RMS

voltmeter.

PC running applicable IQ Ucode compatible software

Crown IQ Interface IQ-INT II or equivalent

Crown IQ standard 2000' test cables

Method of generating TTL Control Port inputs.

Method of generating analog Control Port inputs.

Method of measuring the Control Port outputs.

Method of measuring the phantom power outputs.

©2000 Crown International, Inc.

WARNING

Circuitry is ESD sensitive. When servicing

the IQ component, the technician must have

approved ESD protection. Proper grounding straps and test equipment are required.

Failure to use proper protection will result

in component failure.

Maintenance 4-1

Page 22

IQ-USM 810 Service Manual

130447-1 Rev . A

4.4 IQ Message String Syntax

4.4.1 Host to Device Messages

The following syntax is used for host to device messages:

Send: XX XX XX XX XX; Description

XX: A byte of the message explicitly given in hexadeci-

mal.

XX: A byte of the message as defined by the two-letter

codes in Section 4.2.

Description: A short phrase to indicate the function of

the message string. The description is added for refer ence only . It is not sent as part of the Ucode message.

4.4.2 Device to Host Messages

The following syntax is used for device to host messages.

Return String: XX XX XX XX XX

XX: A byte of the message explicitly given in hexadeci-

mal.

XX: A byte of the message as defined by the two-letter

codes in Section 4.2.

XX: A byte of the returned message that requires range

testing in accordance to the associated test.

4.5 Standard Initial Conditions

The following tests assume this setup unless stated otherwise.

Unit under test built and programmed as documented,

less top cover and labels.

Preset 32 loaded

Inputs set to line mode.

Input potentiometers set to 0 dB.

Unit under test powered by 120VAC

Unit under test connected to test computer via the

RS232 connector with constant IQ communication at

115.2 K baud.

Output Impedance of Audio Sine-wave Source: 50 W

balanced.

Audio Output Load: ≥10 kW balanced.

4.6 Test Procedures

4.6.1 LOAD PRESET 32

Note: Preset 32 is the factory default test preset. This preset

sets the audio paths straight through (no gain, filters, or processing) to their respective AUX outputs . Main outputs A and

B are driven from inputs 1 and 2 respectively.

Procedure:

Send the select preset 32 command:

Send: DA DT CT B2 7F 09 20 CS; Select preset 32

Send the load preset command:

Send: DA DT CT B4 7F 09 01 CS; Load preset

Note: The load preset command m ust be sent within appro ximately 2 seconds of the select preset command.

Note: Preset 32 may also be selected using the front panel

controls.

1) Use the “∧” and “∨” buttons to select preset 32. (Display shows P32.)

2) Press “SEL” button.

4.6.2 OUTPUT NOISE

Spec: LINE mode: ≤ –75 dBu and ≥ –80 dBu, 22 Hz to

22 kHz bandwidth.

Note: The test and printed specifications do not match. The

printed specifications are for an "A" weighted 20-Hz to 22-kHz

bandwidth. Production tests do not use "A" weighted filtering.

Initial Conditions: Inputs terminated at ≤ 50 W bal-

anced. Bandwidth = 22 Hz to 22 kHz.

Procedure: Verify each main and AUX output meets

spec.

4.6.3 FREQUENCY RESPONSE

Spec: +0.1, –0.6 dB from 20 Hz to 20 kHz.

Initial Conditions: Normalized to a reference of a

1 kHz, 0 dBu signal.

Procedure:

Verify each main and AUX output meets spec with one

of the following methods:

A 10+ point, logarithmically spaced, sweep.

Testing at these frequencies: 20 Hz, 100 Hz, 500 Hz

1 kHz, 5 Hz, 10 kHz, and 20 kHz.

4.6.4 HARMONIC DISTORTION

Spec: < 0.030 % and > 0.001 % THD+N, with a 22 Hz

to 22 kHz bandwidth.

Initial Conditions: Input signal: 1 kHz, 0 dBu.

Procedure: Verify each main and AUX output meets

spec.

4.6.5 COMMON MODE REJECTION

Spec: >40 dB at 60 Hz in line mode, 22 Hz to 22 kHz

bandwidth.

Procedure:

Input a 60 Hz +18 dBu balanced signal.

Monitor the associated AUX output with a 22 Hz to

22 kHz bandwidth and set the reference.

Change the input to common mode (same frequency

and amplitude)

Verify the associated AUX output is attenuated at least

40 dB below reference with a 22 Hz to 22 kHz bandwidth.

4-2 Maintenance

©2000 Crown International, Inc.

Page 23

130447-1 Rev . A

IQ-USM 810 Service Manual

4.6.6 HEAD ROOM / INPUT CLIP LEVEL

Spec: < 1 % THD+N, with a +19.9 dBu input signal.

Initial Conditions: Input signal: 1 KHz, +19.9 dBu.

Procedure: Verify each main and AUX output meets

spec.

4.6.7 INPUT POTENTIOMETER

Spec: ± 2 dB at the –12, and +20 dB settings.

Initial Conditions: Input signal: 1 kHz, 0 dBu in to all

inputs.

Procedure: Verify each input potentiomenter by

perfoming the following:

Set all potentiometers full counter clockwise.

Verify each AUX output is –13 ±2 dBu.

Set potentiometer full clockwise.

Verify each AUX output is +20.5 ±2 dBu.

Return potentiometer to the zero setting.

4.6.8 PHANTOM SUPPLY

Spec: 25.75 ±1VDC unloaded, between each signal pins

(+, –) and chassis ground.

Initial Conditions: Remove all input signals and

impedences. Set all inputs to phantom mode.

Procedure: For each input, Verify the DC voltage on

the “+” and “–” pins referenced to chassis ground pin

on all audio inputs.

4.6.9 CONTROL PORT OUTPUT VOLTAGE PINS

Spec: Pins at rated voltage ±10%.

Procedure:

.

Verify voltage between pins 9 and 10 of the contr ol port

is 5 ±0.25VDC.

Verify voltage between pins 29 and 28 of the control

port is 10 ±0.5VDC.

4.6.10 CONTROL PORT LOGIC INPUTS

Spec: TTL level inputs are detected on the control port

inputs.

Procedure:

Inject a TTL high on the odd numbered control port logic

inputs (IN1, IN3, IN5, and IN7) and leave the even numbered inputs open.

Use the following commands to read the control port

inputs and verify the odd numbered inputs return $01

and the even inputs return $00:

Send: DA DT CT 80 50 0A CS; Get Control Port Digital

Input 1

Return String: DA DT AK CT 80 50 0C IN1 CS

Send: DA DT CT C0 50 0A CS; Get Control Port Digital

Input 2

Return String: DA DT AK CT C0 50 0C IN2 CS

Send: DA DT CT 80 51 0A CS; Get Control Port Digital

Input 3

Return String: DA DT AK CT 80 51 0C IN3 CS

Send: DA DT CT C0 51 0A CS; Get Control Port Digital

Input 4

Return String: DA DT AK CT C0 51 0C IN4 CS

Send: DA DT CT 80 52 0A CS; Get Control Port Digital

Input 5

Return String: DA DT AK CT 80 52 0C IN5 CS

Send: DA DT CT C0 52 0A CS; Get Control Port Digital

Input 6

Return String: DA DT AK CT C0 52 0C IN6 CS

Send: DA DT CT 80 53 0A CS; Get Control Port Digital

Input 7

Return String: DA DT AK CT 80 53 0C IN7 CS

Send: DA DT CT C0 53 0A CS; Get Control Port Digital

Input 8

Return String: DA DT AK CT C0 53 0C IN8 CS

Inject a TTL high on the even numbered control port

logic inputs (IN2, IN4, IN6, and IN8) and leave the odd

numbered inputs open.

Use the above commands to read the control port inputs and verify the even numbered inputs return $01

and the odd inputs return $00.

4.6.11 CONTROL PORT LOGIC OUTPUTS

Spec: Control Port Logical Outputs individually switch

between On and Off.

Procedure:

Use the following commands to set the odd control port

logical outputs and the even outputs off:

Send: DA DT CT 80 58 09 01 CS; Set Control Port Digital Output 1 On.

Send: DA DT CT C0 58 09 00 CS; Set Control Port Digital Output 2 Off.

Send: DA DT CT 80 59 09 01 CS; Set Control Port Digital Output 3 On.

Send: DA DT CT C0 59 09 00 CS; Set Control Port Digital Output 4 Off.

Send: DA DT CT 80 5A 09 01 CS; Set Control Port Digital Output 5 On.

Send: DA DT CT C0 5A 09 00 CS; Set Control Port Digital Output 6 Off.

Send: DA DT CT 80 5B 09 01 CS; Set Control Port Digital Output 7 On.

Send: DA DT CT C0 5B 09 00 CS; Set Control Port Digi-

©2000 Crown International, Inc.

Maintenance 4-3

Page 24

IQ-USM 810 Service Manual

130447-1 Rev . A

tal Output 8 Off.

Send: DA DT CT 80 5C 09 01 CS; Set Control Port Digi-

tal Output 9 On.

Send: DA DT CT C0 5C 09 00 CS; Set Control Port Digi-

tal Output 10 Off.

Send: DA DT CT 80 5D 09 01 CS; Set Control Port Digi-

tal Output 11 On.

Send: DA DT CT C0 5D 09 00 CS; Set Control Port Digi-

tal Output 12 Off.

Send: DA DT CT 80 5E 09 01 CS; Set Control Port Digi-

tal Output 13 On

Send: DA DT CT C0 5E 09 00 CS; Set Control Port Digi-

tal Output 14 Off.

Send: DA DT CT 80 5F 09 01 CS; Set Control Port Digi-

tal Output 15 On.

Send: DA DT CT C0 5F 09 00 CS; Set Control Port Digi-

tal Output 16 Off.

Verify the odd control port outputs are on (> 3 volts)

and the even control port outputs are off (<1 volts).

Use the following commands to set the even control

port logical outputs on and the odd outputs off:

Send: DA DT CT 80 58 09 00 CS; Set Control Port Digi-

tal Output 1 Off.

Send: DA DT CT C0 58 09 01 CS; Set Control Port Digi-

tal Output 2 On.

Send: DA DT CT 80 59 09 00 CS; Set Control Port Digi-

tal Output 3 Off.

Send: DA DT CT C0 59 09 01 CS; Set Control Port Digi-

tal Output 4 On.

Send: DA DT CT 80 5A 09 00 CS; Set Control Port Digi-

tal Output 5 Off.

Send: DA DT CT C0 5A 09 01 CS; Set Control Port Digi-

tal Output 6 On.

Send: DA DT CT 80 5B 09 00 CS; Set Control Port Digi-

tal Output 7 Off.

Send: DA DT CT C0 5B 09 01 CS; Set Control Port Digi-

tal Output 8 On.

Send: DA DT CT 80 5C 09 00 CS; Set Control Port Digi-

tal Output 9 Off.

Send: DA DT CT C0 5C 09 01 CS; Set Control Port Digi-

tal Output 10 On.

Send: DA DT CT 80 5D 09 00 CS; Set Control Port Digi-

tal Output 11 Off.

Send: DA DT CT C0 5D 09 01 CS; Set Control Port Digi-

tal Output 12 On.

Send: DA DT CT 80 5E 09 00 CS; Set Control Port Digi-

tal Output 13 Off

Send: DA DT CT C0 5E 09 01 CS; Set Control Port Digi-

tal Output 14 On.

Send: DA DT CT 80 5F 09 00 CS; Set Control Port Digital

Output 15 Off.

Send: DA DT CT C0 5F 09 01 CS; Set Control Port Digital Output 16 On.

Verify the even control port outputs are on (> 3 volts)

and the odd control port outputs are off (<1 volts).

Use the following commands to set the even control

port logical outputs off:

Send: DA DT CT C0 58 09 00 CS; Set Control Port Digital Output 2 Off.

Send: DA DT CT C0 59 09 00 CS; Set Control Port Digital Output 4 Off.

Send: DA DT CT C0 5A 09 00 CS; Set Control Port Digital Output 6 Off.

Send: DA DT CT C0 5B 09 00 CS; Set Control Port Digital Output 8 Off.

Send: DA DT CT C0 5C 09 00 CS; Set Control Port Digital Output 10 Off.

Send: DA DT CT C0 5D 09 00 CS; Set Control Port Digital Output 12 Off.

Send: DA DT CT C0 5E 09 00 CS; Set Control Port Digital Output 14 Off.

Send: DA DT CT C0 5F 09 00 CS; Set Control Port Digital Output 16 Off.

4.6.12 CONTROL PORT ANALOG INPUTS

Spec: Each input measures 0, 5, and 10 VDC within

10%.

Procedure:

Inject 10 VDC into the odd Control Port Analog Inputs.

Inject 5 VDC into the even Control Port Analog Inputs.

Use the following commands to verify the odd analog

inputs are between $FF and $E6:

DA DT CT 81 54 0A CS; Get Control Port Analog Input 9

Return String: DA DT AK CT 81 54 0C IN9 CS

Send: DA DT CT 81 55 0A CS; Get Control Port Analog

Input 11

Return String: DA DT AK CT 81 55 0C IN11 CS

Send: DA DT CT 81 56 0A CS; Get Control Port Analog

Input 13

Return String: DA DT AK CT 81 56 0C IN13 CS

Send: DA DT CT 81 57 0A CS; Get Control Port Analog

Input 15

Return String: DA DT AK CT 81 57 0C IN15 CS

5.13.4. Use the following commands to verify the even

analog inputs are between $98 and $66:

Send: DA DT CT C1 54 0A CS; Get Control Port Analog

Input 10

Return String: DA DT AK CT C1 54 0C IN10 CS

4-4 Maintenance

©2000 Crown International, Inc.

Page 25

130447-1 Rev . A

IQ-USM 810 Service Manual

Send: DA DT CT C1 55 0A CS; Get Control Port Analog

Input 12

Return String: DA DT AK CT C1 55 0C IN12 CS

Send: DA DT CT C1 56 0A CS; Get Control Port Analog

Input 14

Return String: DA DT AK CT C1 56 0C IN14 CS

Send: DA DT CT C1 57 0A CS; Get Control Port Analog

Input 16

Return String: DA DT AK CT C1 57 0C IN16 CS

Open drive to all Control Port Analog Inputs.

Use the following commands to verify all the analog

inputs are between $19 and $00:

Send: DA DT CT 81 54 0A CS; Get Control Port Analog

Input 9

Return String: DA DT AK CT 81 54 0C IN9 CS

Send: DA DT CT C1 54 0A CS; Get Control Port Analog

Input 10

Return String: DA DT AK CT C1 54 0C IN10 CS

Send: DA DT CT 81 55 0A CS; Get Control Port Analog

Input 11

Return String: DA DT AK CT 81 55 0C IN11 CS

Send: DA DT CT C1 55 0A CS; Get Control Port Analog

Input 12

Return String: DA DT AK CT C1 55 0C IN12 CS

Send: DA DT CT 81 56 0A CS; Get Control Port Analog

Input 13

Return String: DA DT AK CT 81 56 0C IN13 CS

Send: DA DT CT C1 56 0A CS; Get Control Port Analog

Input 14

Return String: DA DT AK CT C1 56 0C IN14 CS

Send: DA DT CT 81 57 0A CS; Get Control Port Analog

Input 15

Return String: DA DT AK CT 81 57 0C IN15 CS

Send: DA DT CT C1 57 0A CS; Get Control Port Analog

Input 16

Return String: DA DT AK CT C1 57 0C IN16 CS

4.6.13 DISPLAY TEST

Spec: All LEDs and LED segments individually light.

Procedure:

Start the display test mode:

Send: DA DT CT 80 06 09 03 CS; Select test display

mode.

Verify display lights all LEDs according to the test pat-

tern. (See Section 4.9 for test pattern)

Stop the display test mode:

Send: DA DT CT 80 06 09 02 CS; Select test display

mode.

4.6.14 PUSHBUTTON TEST

Spec: Pushbuttons operational.

Procedure:

Use one of the following two methods to test the three

front panel pushbuttons:

Method 1 (Manual Verification)

Hold in the “SEL” button and verify the IQ-USM 810

display cycles between the three display modes (preset, address, and baud rate).

Use the “SEL” button to select the preset mode

Press the “∧” button and verify the preset display in-

creases its number.

Press the “∨” button and verify the preset display de-

creases its number.

Method 2 (Auto Verification)

Use the following IQ command to continually poll the

switch status object:

Send: DA DT CT C1 05 0A CS; Return button status

Return String: DA DT AK CT C1 05 0C BTN CS

Press the “SEL” button and very the object returns $01.

Press the “∧” button and verify the object returns $02.

Press the “∨” button and verify the object returns $04.

4.6.15 REAL TIME CLOCK

Spec: The RTC can be set, can be read, keeps time,

and power backup is operational.

Note: The real time clock Ucode object uses a four-byte time

code. The code is the number of seconds from 12:00AM on

January 1, 1970. The data bytes are returned least significant

first.

Example: For 3:34:14 PM on J ul y 21,1999:

1999-1970 = 29 years =

29 years / 4 = 8 leap year days=

July 1 = (31+28+31+30+31+30)=

181 days =

21st = 21 days =

PM = 12 hours =

3:34:14 =

Time from 12:00 AM Jan. 1,1970=

932,744,054 converted to hex = $37988B76

$37988B76 broken into bytes, LSB first = $76 $8B $98 $37.

Note: The real time clock is powered from a 1 mF capacitor

(C25) when the unit is unpowered. This capacitor must be

charged above 2.2 volts f or the real time clock to operate without unit power. Normal charging time is 14 minutes. To fast

charge the capacitor short TP7 and TP8 for at least 4.2 minutes. Remove jumper prior to a power cycle to prevent discharging the capacitor.

914,544,000 seconds

691,200 seconds

15,638,400 seconds

1,814,400 seconds

43,200 seconds

12,854 seconds

932,744,054 seconds

©2000 Crown International, Inc.

Maintenance 4-5

Page 26

IQ-USM 810 Service Manual

Procedure:

Set the clock to the current time with the clock write

command.

Send: DA DT CT 80 03 09 CK4 CK3 CK2 CK1 CS; Set

real time clock

Where CK1, CK2, CK3, and CK4 are the four bytes of

the time code.

5.16.2. Allow the IQ-USM810 to operate for > 100 seconds.

Note: other tests may be performed during this time.

Remove TP7-TP8 jumper if in use.

Perform a power cycle on the IQ-USM810.

Note; this ma y be the same po wer cycle used for the IQ Bus

Dropout Relay Operation test.

Read the clock and compare its time with the current

time.

Send: DA DT CT 80 03 0A CS

Return String: DA DT AK CT 80 03 0C CK4 CK3 CK2

CK1 CS

Where CK1, CK2, CK3, and CK4 are the four bytes of

the time code.

The two times must be within one second.

4.6.16 IQ BUS MASTER CONTROL

Spec: Har dware can for ce the IQ Bus high. (Open the

loop)

For this test, perform IQ communication via the Crown

bus.

Procedure:

Send the Master IQ Bus command:

Send: DA DT CT C0 05 09 01 CS; Master IQ bus (Open

loop)

Verify no echo r esponses on subsequent IQ commands:

Suggested test string: 01 02 03 04 FE FF

Send the normal IQ Bus command…

Send: DA DT CT C0 05 09 00 CS; Unmaster IQ bus

(Close loop)

Verify echo responses on subsequent IQ commands:

Suggested test string: 01 02 03 04 FE FF

Return string: 01 02 03 04

4.6.17 IQ BUS DROPOUT RELAY OPERATION

Spec: IQ Bus remains connected when power is removed.

For this test, perform IQ communication via the Crown

bus.

Procedure:

Power down IQ-USM 810.

130447-1 Rev . A

Verify IQ messages pass thr ough the unit under test:

Suggested test string: 01 02 03 04 FE FF

Return string: 01 02 03 04

Reapply power to IQ-USM 810.

4.6.18 IQ BUS HUB / DAISY CONNECTIONS

Spec: Both types on IQ Bus connections are functional.

Note: This product has tw o types of IQ bus connections. The

Daisy type connects the input in one port of the dual RJ-45

and the output in the other. The Hub type connects both input

and output to one RJ-45 port.

For this test, perform IQ communication via the Crown

bus.

Procedure:

For each type of bus connection (Daisy , Hub), perform

at least one of the above tests that require a test on the

IQ response.

4.6.19 SHIPPING STATE RESTORATION

Spec: The IQ-USM 810 is returned to the factory defaults.

Note: This section may be skipped when testing a service unit

if it is known that the customer wishes to retain the mixers

settings and presets.

Note: The following steps must be performed as par t of the

final power down sequences to ensure the IQ-USM 810 has

been returned to factory defaults and presets. If the IQ-USM

810 is re-powered before packing, the following procedure

should be repeated.

Procedure:

Send the select preset 0 command:

Send: DA DT CT B2 7F 09 00 CS; Select preset 0

Send the load preset command:

Send: DA DT CT B4 7F 09 01 CS; Load preset

Note: The load preset command m ust be sent within appro ximately 2 seconds of the select preset command.

Send the select preset 32 command:

Send: DA DT CT B2 7F 09 20 CS; Select preset 32

Send the load preset command:

Send: DA DT CT B4 7F 09 01 CS; Load preset

Note: The load preset command m ust be sent within appro ximately 2 seconds of the select preset command.

Note: Preset 0 and 32 may also be selected using the front

panel controls.

1) Use the “∧” and “∨” keys to select preset 0. (Display

shows P00.)

2) Press “SEL” switch.

3) Use the “∧” and “∨” keys to select preset 32. (Display shows P32.)

4) Press “SEL” switch.

4-6 Maintenance

©2000 Crown International, Inc.

Page 27

130447-1 Rev . A

IQ-USM 810 Service Manual

4.6.20 CHASSIS GROUND

Spec: Ground conductor of the power inlet is connected

to chassis ground.

Note: This test to be completed after the complete product

assembly.

Procedure:

Verify power inlet less than 1 W between connector

ground and chassis.

Recommended chassis test points:

RS232 Connector shell or screw locks, Multi-Function

Control Port shell of screw locks or Crown bus connector shield.

4.4.21 HI-POT

Spec: Power Supply withstands Hi-Pot spikes.

Procedure: Verify unit allows no breakdown leakage

current with a 1-second, 1.2-kV Hi-Pot from AC mains

(Hot and Neutral) to earth ground.

4.7 Typical Measurements

Output Noise 20 Hz to 20 KHz bandwidth, line mode:

–77 dBu

Frequency Response 20 Hz to 20 KHz, referenced to

1 KHz, line mode: –0.27 dB.

Harmonic Distortion THD+N, at 1 KHz, 20 Hz to 20

KHz bandwidth, line mode, 0 dBu input: 0.013 %.

Common Mode Rejection at 60 Hz, line mode: –66.5

dB.

Head Room / Input Clip Level highest input level before 1 % TDH+N, Line mode: –.131 % TDH+N @ +20

dBu.

Input Potentiometer at 1 KHz, 0 dBu input:

Potentiometer

at –12 setting: –12.85 dB

at +20 setting: +20.43 dB

Phantom Supply between each signal pin (“+ and “–”)

and ground of each input: 25.77 VDC

Control P ort Output Voltage Pins

5 volt supply (between pins 9 and 10): 4.92 VDC

10 volt supply (between pins 29 and 28): 10.26 VDC

4.8 Test/Debug Objects

Object Number

Dec Hex/ASN1 Description / Command string format

704 $2C0

$C0 $05

768 $300

$80 $06

705 $2C1

$C1 $05

Bus Master: Allows manual control of the bus master function. (Normally an internal function of the Ucode protocol). With this object set, no IQ bus, communication passes through

the IQ-USM 810 Crown bus port.

Send: DA DT CT C0 05 09 01 CS; to master the IQ Bus, open the loop

Response: None

Send: DA DT CT C0 05 00 CS; to unmaster the IQ Bus, close the loop

Response: DA DT AK CT 00 CS; standard ACK

Display T est Mode: Cycles each section of the display thr ough a known sequence allowing

the operator to verify that all segments and indicators are functional. See Section 4.7 for

known sequence.

Send: DA DT CT 80 06 09 01 CS; To force the preset LED on

Response: DA DT AK CT 00 CS; standard ACK

Send: DA DT CT 80 06 09 00 CS; To set the preset LED in normal mode

Response: DA DT AK CT 00 CS; standard ACK

Pushbutton Test: Reads a single byte that is bit mapped to indicate a pushbutton depression (bit 0 = “SEL” depressed, bit 1 =”∧” depressed, bit 2 = “∨” depressed):

Send: DA DT CT C1 05 0A CS, To get data

Response: DA DT AK CT C1 05 0C BTN CS

©2000 Crown International, Inc.

Maintenance 4-7

Page 28

IQ-USM 810 Service Manual

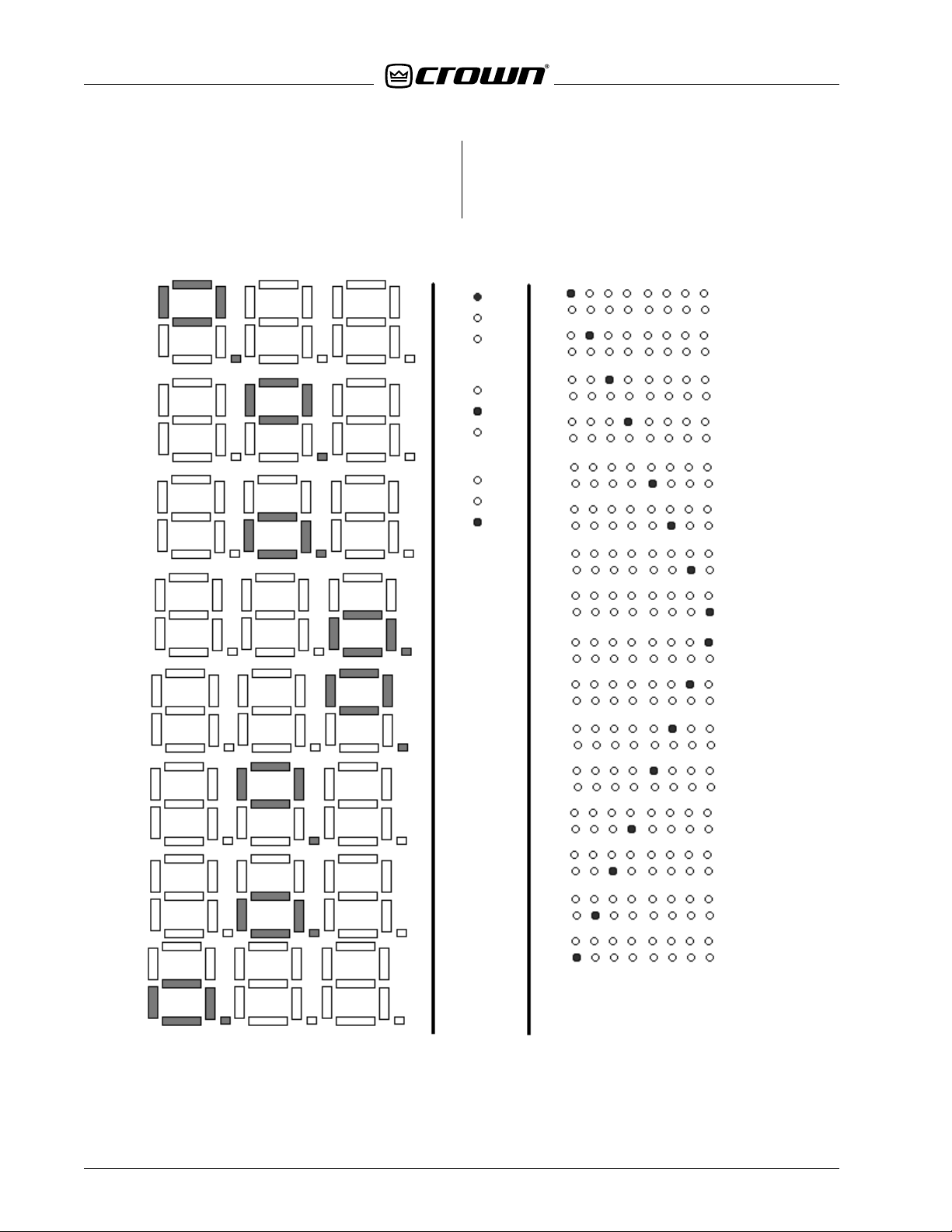

4.9 Display Test Patterns

Figure 4.1 shows display test patterns for the IQ-USM

810. For each display section, the sequence starts at

the top and cycles to the bottom, and then repeats.

LED Display Enable/Data/Interface Input Gate Status

130447-1 Rev . A

4-8 Maintenance

Figure 4.1 Display Test Patterns

©2000 Crown International, Inc.

Page 29

130447-1 Rev . A

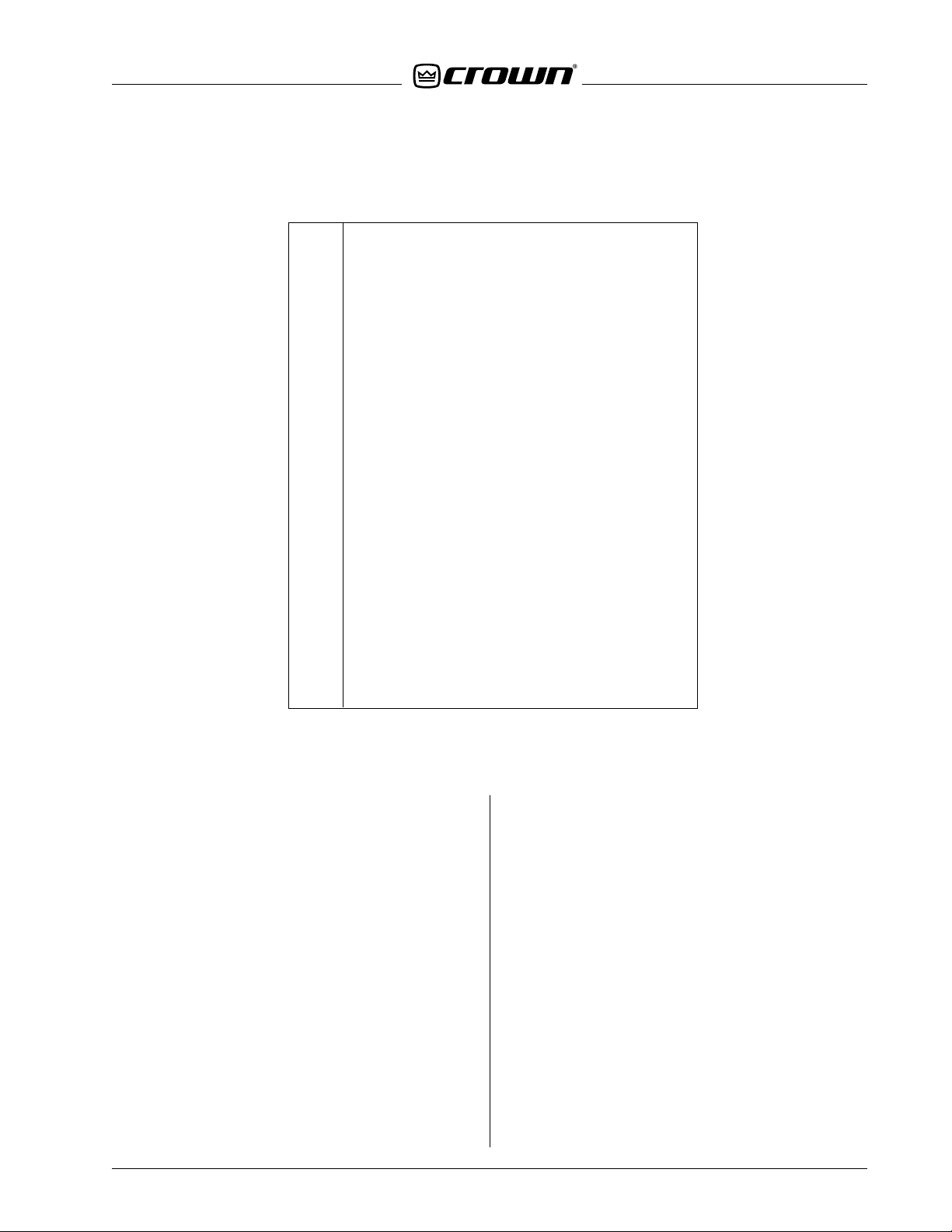

4.10 Error Codes

Figure 4.2 shows error codes for the IQ-USM 810.

E01 UART failed system contr oller power-on self test

E02 RAM failed system controller power-on self test

E03 Application code in flash failed crc test

E04 Flash verify error

E05 Unrecoverable firmware error

E10 Sharc 0 interface hardware err or (timeout, etc.)

E11 Sharc 1 interface hardware err or (timeout, etc.)

E12 Sharc 2 interface hardware err or (timeout, etc.)

E13 Sharc 3 interface hardware err or (timeout, etc.)

E14 Sharc 0 failed SRAM test

E15 Sharc 1 failed SRAM test

E16 Sharc 2 failed SRAM test

E17 Sharc 3 failed SRAM test

E18 Sharc 0 failed SDRAM test

E19 Sharc 1 failed SDRAM test

E20 Sharc 2 failed SDRAM test

E21 Sharc 3 failed SDRAM test

E22 Sharc 0 software watchdog timeout

E23 Sharc 1 software watchdog timeout

E24 Sharc 2 software watchdog timeout

E25 Sharc 3 software watchdog timeout

IQ-USM 810 Service Manual

Figure 4.2 IQ-USM 810 Error Codes

4.11 Troubleshooting FAQs

The following FAQs ar e provided to answer a few questions that may arise in the course of servicing the IQUSM 810.

Q. What does the display indicate during power up?

A. When the IQ-USM 810 initially powers up, it

displays the following:

dSP…810…SH0…SH1…SH2…SH3…Pxx.

This is the boot sequence for the internal processors.

Initially, the System Controller processor boots, then it

sequentially boots the four DSP processors (SH0-3).

After the System Controller processor successfully boots

all four DSP processors, audio processing is allowed to

begin.

Q. When I power up the IQ-USM 810, it continues to boot.

What's up?

A. If the System Controller processor encounters an error

©2000 Crown International, Inc.

during the boot process, it terminates the process at

that point, displays an error code on the front panel,

then reboots. See Section 4.10 for a list of error codes.

Q. What is the most common error?

A. Hopefully, no error is common. When “E22” is displayed as the error code, it is most likely due to a loss of

digital audio clocking from the Input board. The short

26-pin ribbon cable carries digital audio and clocking

from the Input board to the SHARC board. Check for

creation of Master Clock (12.288 MHz), Serial Clock

(3.032 MHz), and Frame Clock (48 kHz) by the Input

board.

Q. How do I reboot the IQ-USM 810?

A. There are a couple of dif ferent ways to reboot the IQUSM 810. The most straightforward way is to remove

the AC power cord from the IEC320 connector on the

rear panel, then replace the cord. The loss of AC power

Maintenance 4-9

Page 30

IQ-USM 810 Service Manual

130447-1 Rev . A

will cause the IQ-USM 810 to automatically reboot. If

the top cover is off the unit, switch S1 on the System

Controller board (the long board with the rear panel

DB9F and DB37M connectors) will reboot the unit. The

LED located next to the switch is lit when the unit is not

in reset.

Q. I notice there is a switch on the SHARC board. What is it

for?

A. The switch on the SHARC board resets the SHARC

processors independently of the System Controller . The

problem with using this switch to reset the SHARC processors is they need the System Controller to reboot

them. In practice, the SHARC board reset switch is not

used. The LED by the switch lights when the SHARC's

are not in reset. Reset is controlled by the System Controller. If a reboot of the SHARC's is required, use the

System Controller reset switch to reset the entire IQUSM 810 and reboot the SHARC's.

Q. I plug in the IQ-USM 810 and nothing happens. What's

the matter?

A. First, ensure that AC power is indeed being applied

to the unit. Next, take the cover off the unit and see if

any of the LED's on the System Controller or SHARC

boards are lit. If so, check the cable between the System Controller board and Front Display board. If no

LED's are lit, check the cable between the power supply (located under the System Controller board) and

the System Controller . If that seems OK, check the power

supply by removing the System Controller. A fuse is located on the power supply board. Replace ONLY with

the same type fuse.

Q. What is preset “P00?”

A. Preset P00 is a factory default preset that allows the

IQ-USM 810 to be placed into a known, safe state. In

P00, all faders are at minimum and all filters, gates,

delays, etc. are off. It is a good place to start when starting to configure a unit or if you need to get back to a

known starting point.

Q. What is the purpose of the “Infinity Pattern” on the front

panel?

A. The Infinity pattern is also referred to as a “test” pattern. It’s serves no real purpose other than to provide

an attractive display when front panel level or gate status indication is not desired.

Q. How should I set the baud rate on the IQ-USM 810?

A. The baud rate for the RS232 interface is adjustable

and is accessed by the front panel (see the Reference

Manual for information on settng the baud rate). In practice, you should try to run at as a fast a rate as you can

without problems. Some computers have difficulties

keeping up at 115 k baud. If you notice the IQ-USM

810 dropping off-line occasionally, tr y a slower baud

rate. The IQ for Windows software automatically adjusts

to the selected baud rate of the IQ-USM 810 during

initialization, so no setup of the software is required.

Q. Why don't I have a control to set the baud rate of the IQ

loop?

A. The IQ loop's baud rate is fixed at 38.4 k baud and

is not adjustable.

Q. What voltage should I use to wire analog control pots to

the IQ-USM 810's Control Port?

A. The IQ-USM 810 needs a 0 to +10V voltage to utilize

the full range of the Control Port's analog inputs. +10VDC

is provided on the Control Port connector for this purpose. If you want the remote pot to control only a portion of the fader range, use the IQ for Windows software

to tailor the range desired. In general, the Control Port

pots should be wired between GND and +10VDC.

4-10 Maintenance

©2000 Crown International, Inc.

Page 31

130447-1 Rev . A

5 Parts

5.1 General Information

This chapter includes both a mechanical and electrical

parts list for this product. All serviceable parts and assemblies will have a Crown Part Number (CPN) listed

in this chapter. The parts listed are current as of the

date printed. Crown reserves the right to modify and

improve its products for the benefit of its customers.

PART PRICES AND AVAILABILITY ARE SUBJECT

TO CHANGE WITHOUT NOTICE.

5.2 Ordering and Receiving Parts

When ordering parts, be sure to give the product model,

and include a description and part number from the

parts listing. Price quotes are available on request.

IQ-USM 810 Service Manual

5.2.1 Terms

Normal terms are prepaid. Net-30 Days applies to only

those having pre-established accounts with Crown. The

Crown Parts Department does accept Visa or Master

Card. If prepaying, the order must be packed and

weighed before a total bill can be established, after

which an amount due will be issued and shipment made

upon receipt of payment. New parts returned for credit

are subject to a restocking fee, and authorization from

the Crown Parts Department must be obtained before

returning parts for credit.

5.2.2 Shipment

Shipment will normally be made via UPS, or best other