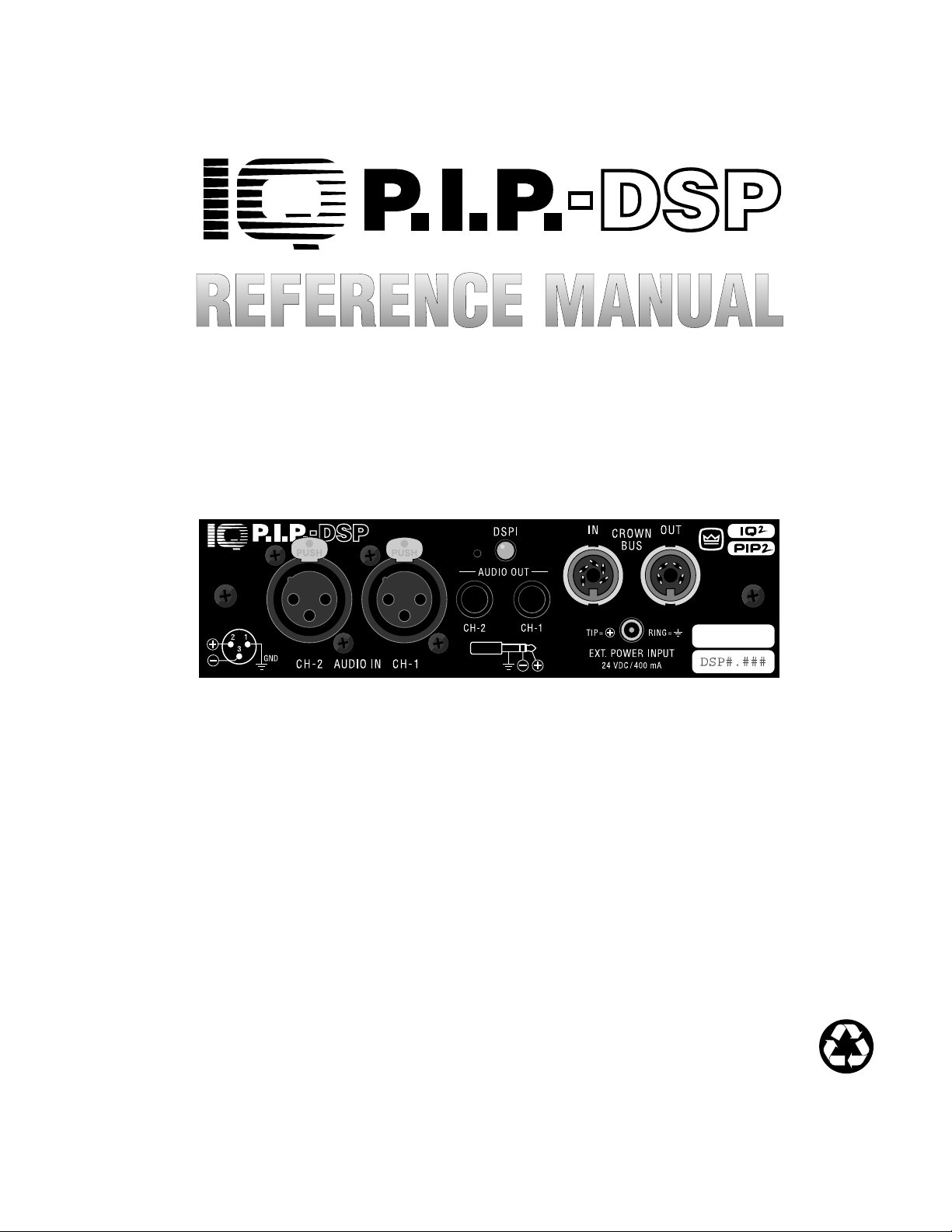

Page 1

An IQ System® Programmable Input Processor with DSP

for Crown® P.I.P.®-compatible Power Amplifiers

©1999 by Crown International, Inc., P.O. Box 1000, Elkhart, Indiana 46515-1000 U.S.A. Telephone: 219294-8000. The

™

6

,

SmartAmp

Macro-Tech

IQ–P.I.P.–DSP

™

and

Macro Reference

®

,

Com-Tech

is produced by Crown International, Inc. Trademark Notice:

®

and

™

are trademarks and

®

P.I.P.

are registered trademarks of Crown International, Inc. Other

Amcron

®

,

Crown

®

,

IQ System

®

MPX-6

,

IOC

®

,

™

,

SMX-

ODEP

trademarks are the property of their respective owners.

®

,

Printed on

recycled paper.

103291-2

9/99

Page 2

3

YEAR

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

THREE YEAR

FULL WARRANTY

3

YEAR

WORLDWIDE

The Crown Audio Division of Crown International, Inc., 1718 West

Mishawaka Road, Elkhart, Indiana 46517-4095 U.S.A. warrants to you,

the ORIGINAL PURCHASER and ANY SUBSEQUENT OWNER of each

NEW Crown

purchase by the original purchaser (the “warranty period”) that the new

Crown product is free of defects in materials and workmanship, and we

further warrant the new Crown product regardless of the reason for failure,

except as excluded in this Crown Warranty.

1

Note: If your unit bears the name “Amcron,” please substitute it for the

name “Crown” in this warranty.

ITEMS EXCLUDED FROM THIS CROWN WARRANTY

This Crown Warranty is in effect only for failure of a new Crown product

which occurred within the Warranty Period. It does not cover any product

which has been damaged because of any intentional misuse, accident,

negligence, or loss which is covered under any of your insurance

contracts. This Crown Warranty also does not extend to the new Crown

product if the serial number has been defaced, altered, or removed.

We will remedy any defect, regardless of the reason for failure (except as

excluded), by repair, replacement, or refund. We may not elect refund

unless you agree, or unless we are unable to provide replacement, and

repair is not practical or cannot be timely made. If a refund is elected, then

you must make the defective or malfunctioning product available to us free

and clear of all liens or other encumbrances. The refund will be equal to

the actual purchase price, not including interest, insurance, closing costs,

and other finance charges less a reasonable depreciation on the product

from the date of original purchase. Warranty work can only be performed

at our authorized service centers. We will remedy the defect and ship the

product from the service center within a reasonable time after receipt of the

defective product at our authorized service center.

You must notify us of your need for warranty service not later than ninety

(90) days after expiration of the warranty period. All components must be

shipped in a factory pack. Corrective action will be taken within a

reasonable time of the date of receipt of the defective product by our

authorized service center. If the repairs made by our authorized service

center are not satisfactory, notify our authorized service center

immediately.

DISCLAIMER OF CONSEQUENTIAL AND INCIDENTAL DAMAGES

YOU ARE NOT ENTITLED TO RECOVER FROM US ANY INCIDENTAL

DAMAGES RESULTING FROM ANY DEFECT IN THE NEW CROWN

PRODUCT. THIS INCLUDES ANY DAMAGE TO ANOTHER PRODUCT

OR PRODUCTS RESULTING FROM SUCH A DEFECT.

No person has the authority to enlarge, amend, or modify this Crown

Warranty. This Crown Warranty is not extended by the length of time which

you are deprived of the use of the new Crown product. Repairs and

replacement parts provided under the terms of this Crown Warranty shall

carry only the unexpired portion of this Crown Warranty.

We reserve the right to change the design of any product from time to time

without notice and with no obligation to make corresponding changes in

products previously manufactured.

No action to enforce this Crown Warranty shall be commenced later than

ninety (90) days after expiration of the warranty period.

THIS STATEMENT OF WARRANTY SUPERSEDES ANY OTHERS

CONTAINED IN THIS MANUAL FOR CROWN PRODUCTS.

Telephone: 219-294-8200. Facsimile: 219-294-8301

Page 2

SUMMARY OF WARRANTY

1

product, for a period of three (3) years from the date of

WHAT THE WARRANTOR WILL DO

HOW TO OBTAIN WARRANTY SERVICE

WARRANTY ALTERATIONS

DESIGN CHANGES

LEGAL REMEDIES OF PURCHASER

9/90

NORTH AMERICA

The Crown Audio Division of Crown International, Inc., 1718 West Mishawaka

Road, Elkhart, Indiana 46517-4095 U.S.A. warrants to you, the ORIGINAL

PURCHASER and ANY SUBSEQUENT OWNER of each NEW Crown product, for a period of three (3) years from the date of purchase by the original

purchaser (the “warranty period”) that the new Crown product is free of defects

in materials and workmanship. We further warrant the new Crown product

regardless of the reason for failure, except as excluded in this Warranty.

ITEMS EXCLUDED FROM THIS CROWN WARRANTY

This Crown Warranty is in effect only for failure of a new Crown product which

occurred within the Warranty Period. It does not cover any product which has

been damaged because of any intentional misuse, accident, negligence, or loss

which is covered under any of your insurance contracts. This Crown Warranty

also does not extend to the new Crown product if the serial number has been

defaced, altered, or removed.

We will remedy any defect, regardless of the reason for failure (except as

excluded), by repair, replacement, or refund. We may not elect refund unless

you agree, or unless we are unable to provide replacement, and repair is not

practical or cannot be timely made. If a refund is elected, then you must make

the defective or malfunctioning product available to us free and clear of all liens

or other encumbrances. The refund will be equal to the actual purchase price,

not including interest, insurance, closing costs, and other finance charges less

a reasonable depreciation on the product from the date of original purchase.

Warranty work can only be performed at our authorized service centers or at the

factory. We will remedy the defect and ship the product from the service center

or our factory within a reasonable time after receipt of the defective product at

our authorized service center or our factory. All expenses in remedying the

defect, including surface shipping costs in the United States, will be borne by us.

(You must bear the expense of shipping the product between any foreign

country and the port of entry in the United States and all taxes, duties, and other

customs fees for such foreign shipments.)

You must notify us of your need for warranty service not later than ninety (90)

days after expiration of the warranty period. All components must be shipped in

a factory pack, which, if needed, may be obtained from us free of charge.

Corrective action will be taken within a reasonable time of the date of receipt of

the defective product by us or our authorized service center. If the repairs made

by us or our authorized service center are not satisfactory, notify us or our

authorized service center immediately.

DISCLAIMER OF CONSEQUENTIAL AND INCIDENTAL DAMAGES

YOU ARE NOT ENTITLED TO RECOVER FROM US ANY INCIDENTAL

DAMAGES RESULTING FROM ANY DEFECT IN THE NEW CROWN

PRODUCT. THIS INCLUDES ANY DAMAGE TO ANOTHER PRODUCT OR

PRODUCTS RESULTING FROM SUCH A DEFECT. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATIONS OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

No person has the authority to enlarge, amend, or modify this Crown Warranty.

This Crown Warranty is not extended by the length of time which you are

deprived of the use of the new Crown product. Repairs and replacement parts

provided under the terms of this Crown Warranty shall carry only the unexpired

portion of this Crown Warranty.

We reserve the right to change the design of any product from time to time

without notice and with no obligation to make corresponding changes in

products previously manufactured.

THIS CROWN WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, YOU

MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

No action to enforce this Crown Warranty shall be commenced later than ninety

(90) days after expiration of the warranty period.

THIS STATEMENT OF WARRANTY SUPERSEDES ANY OTHERS

CONTAINED IN THIS MANUAL FOR CROWN PRODUCTS.

Telephone: 219-294-8200. Facsimile: 219-294-8301

SUMMARY OF WARRANTY

WHAT THE WARRANTOR WILL DO

HOW TO OBTAIN WARRANTY SERVICE

WARRANTY ALTERATIONS

DESIGN CHANGES

LEGAL REMEDIES OF PURCHASER

9/90

Reference Manual

Page 3

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

Important Safety Instructions

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with a damp cloth.

7) Do not block any of the ventilation openings. Install

in accordance with the manufacturer’s instructions.

8) Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that

produce heat.

9) Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two

blades with one wider than the other. A groundingtype plug has two blades and a third grounding

prong. The wide blade or the third prong is pr ovided

for your safety. When the provided plug does not fit

into your outlet, consult an electrician for replacement of the obsolete outlet.

10) Protect the power cord from being walked on or

pinched, particularly at plugs, convenience receptacles, and the point where they exit from the apparatus.

11) Only use attachments/accessories specified by the

manufacturer.

12) Use only with a car t, stand, bracket, or table specified by the manufacturer, or sold with the apparatus.

When a cart is used, use caution when moving the

cart/apparatus combination to avoid injury from tipover.

13) Unplug this apparatus during lightning storms or

when unused for long periods of time.

14) Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or

plug is damaged, liquid has been spilled or objects

have fallen into the apparatus, the apparatus has

been exposed to rain or moisture, does not operate

normally, or has been dropped.

Reference Manual

Page 3

Page 4

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

The information furnished in this manual does not include all of the details of design, production, or variations of

the equipment. Nor does it cover every possible situation which may arise during installation, operation or

maintenance. If you need special assistance beyond the scope of this manual, please contact our Technical

Support Group.

Crown Audio Division Technical Support Group

Plant 2 SW, 1718 W. Mishawaka Rd., Elkhart, Indiana 46517 U.S.A.

Phone: 800-342-6939 (North America, Puerto Rico and Virgin Islands) or 219-294-8200

Fax: 219-294-8301 Fax Back (North America only): 800-294-4094 or 219-293-9200

Fax Back (International): 219-294-8100 Internet: http://www.crownaudio.com

WARNING

TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE!

FCC COMPLIANCE NOTICE

This equipment has been tested and found

to comply with the limits for a Class A digital

Device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference when the equipment is

operated in a commercial environment. This

equipment generates, uses and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruction

manual, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case the

user will be required to correct the

interference at his own expense.

“The user is cautioned that any changes or

modifications not expressly approved by

Crown International could void the user’s

authority to operate the equipment. ”

Page 4

Reference Manual

Page 5

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

Quick Install Procedure

This procedure is provided for those who are already familiar with Crown’s

and who would like to install the

experienced installers or those wishing a full explanation of the installation procedure

are encouraged to go to Section 4 where the full installation procedure is described.

Prepare the IQ–P.I.P.–DSP:

1. Set the IQ address switch SW1 (Figures 4.1 and 4.2) on the

IQ address. (Tip: Record the IQ address on the small blank label that is provided on

lower right corner of the

2. Set jumpers JP4 and JP5. Set both jumper JP4 and JP5 to the “OUT” position if either a

PIP2

-compatible or

Both JP4 and JP5 should be set to the “IN” position for all other amplifiers.

Prepare the amplifier:

3. Turn down the level controls of the amplifier and turn off the amplifier.

4. Unplug the power cord of the amplifier from the AC mains.

5. Remove the existing

6. Set the amplifier input sensitivity switch to 0.775 V. (See the

Manual

of the amplifier.)

Install the IQ–P.I.P.–DSP into the amplifier:

7. Carefully ground yourself to the chassis of the amplifier before installing the

DSP

. It is a good idea to maintain ground contact between yourself and the amplifier

while inserting the module into the

8. Install the

IQ–P.I.P.–DSP

Standard P.I.P. Amplifiers:

and firmly push the unit in until it is seated against the mounting bracket (Figure 4.4).

PIP2 Compatible Amplifiers:

cables. Plug the

the

P.I.P.

opening in the back of the amplifier (Figures 4.5 and 4.6).

9. Tighten the two

P.I.P.

Install the wiring:

10. Connect the

information is needed).

11. Connect the audio signal wiring to the

and the phone jack daisy chain wiring—if desired (see Section 4.7 if more information is

needed).

IQ–P.I.P.–DSP

Note: FCC and EC EMI regulations require that the EMI suppression core

provided with this P.I.P. be installed on the daisy chain cables, if used.

12. Connect the amplifier back to the AC receptacle.

an external power supply in some amplifiers. See Section 4.8 for more information.

Adjust the levels and scale factors:

13. Turn the level controls of the amplifier to their full setting. Use the software-controlled

input attenuators on the

14.

Standard P.I.P. Amplifiers:

with appropriate

PIP2 Compatible Amplifiers:

P.I.P.

Macro-Tech 5000VZ

P.I.P.

into the amplifier:

IQ–P.I.P.–DSP

mounting screws until it is secured to the amplifier back panel.

IQ–P.I.P.–DSP

IQ System

IQ–P.I.P.–DSP

panel.)

or cover panel from the amplifier back panel (two screws).

P.I.P.

card rails in the next step.

Align the edges of the

Connect the

into the

to the

PIP2

IQ System

IQ–P.I.P.–DSP

in the shortest time possible. Less

amplifier will be used (Figures 2.1 and 4.7).

IQ–P.I.P.–DSP

PIP2

input adapter to the amplifier input

input adapter and insert the assembly into

via the Crown Bus (see Section 4.6 if more

. This includes the XLR input wiring

Note: The IQ–P.I.P.–DSP may require

to adjust the input levels down.

Manually configure the scaling factors of the

software.

The scaling factors will be automatically set.

IQ–P.I.P.–DSP

Reference

in the

P.I.P.

IQ System

to an unused

or

Owner’s

IQ–P.I.P.–

card rails

IQ–P.I.P.–DSP

Reference Manual

Page 5

Page 6

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

CONTENTS

Quick Install Procedure .......................................... 5

1 Welcome..................................................................7

1.1 Unpacking ...................................................... 7

2 Facilities .................................................................. 8

3 Installation.............................................................10

3.1 Prepare the

3.2 Prepare the Amplifier ....................................11

3.3 Install the

3.4 Install the Wiring ...........................................11

3.5 Adjust the Levels & Scale Factors................. 12

3.6 A Closer Look at Crown Bus Wiring .............. 12

3.7 A Closer Look at Audio Signal Wiring............ 14

3.8 When External Power is Needed................... 14

4 Operation ..............................................................15

4.1 Power/Standby Indicators ............................. 15

4.2 IOC Event Monitor.........................................15

4.3 Input Signal Level Monitor............................. 14

4.4 Output Signal Level Monitor ..........................14

ODEP

4.5

4.6 Power Control ...............................................14

4.7 Signal Mute................................................... 14

4.8 Polarity Inverter ............................................. 16

4.9 Input Signal Attenuator .................................16

4.10 Input Protection Limiter .................................16

4.11 Auto ........................................................... 16

4.12 Input Signal Compressor/Limiter ...................16

4.13 Smooth/Output Signal Limiter .......................16

4.14 Auto Standby ................................................ 17

ODEP

4.15

4.16 Excessive

IQ–P.I.P.–DSP

IQ–P.I.P.–DSP

Level Monitor...................................... 14

Limite r ................................................17

IOC

Warning ................................17

.............................10

into the Amplifier ..... 11

4.17 Excessive

4.18 Fault Warning................................................18

4.19 Signal Delay..................................................18

4.20 Programmable Filters.................................... 18

4.21 Memory Backup ........................................... 20

4.22 Amp Mode.................................................... 20

4.23 Amplifier Information ....................................... 2

4.24 IQ2 Protocol Support .................................... 20

4.25 Crown Bus “Drop Out” Relays.......................20

4.26 Data Signal Presence Indicator.....................20

4.27 Reset 20

4.28 User Default Settings ....................................20

5 Technical Information ........................................... 21

5.1 Audio Signals................................................21

5.1.1 Hardware Processing..........................21

5.1.2 Signal Flow Processing ....................... 21

5.2 Control/Monitor Functions .............................22

5.2.1 Audio Signals...................................... 22

5.2.2 Status Signals .....................................22

5.2.3 DSPI Control ....................................... 22

IQ System

5.3

5.4 Microprocessor and Reset Switch.................22

6 Specifications ....................................................... 23

7 IQ Address Tables.................................................24

8 Service...................................................................26

8.1 Worldwide Service ........................................ 26

8.2 North American Service ................................26

8.2.1 Service at a N. American Ser. Center .. 26

8.2.2 Factory Service ................................... 26

ODEP

Warning............................. 18

Communications.......................... 22

ILLUSTRATIONS

1.1

IQ–P.I.P.–DSP .............................................................................................................................................................

3.1 IQ Address Switch (SW1) Location ..........................................................................................................................10

3.2 IQ Address Switch (SW1) Values .............................................................................................................................10

3.3 Installation into a Standard P.I.P. Amplifier ................................................................................................................ 11

3.4 PIP2 Input Adapter Connection................................................................................................................................11

3.5 Installation into a PIP2 Amplifier ...............................................................................................................................11

3.6 Amplifier Scale Factor Values and Output Signal Pad Settings.................................................................................12

3.7 IQ–P.I.P.–DSP Output toIQ Component with DIN ......................................................................................................13

3.8 IQ–P.I.P.–DSP Output to IQ Component w/ Screw Terminal Plug ..............................................................................13

3.9 IQ Component with Screw Terminal Plug to the IQ–P.I.P.–DSP Input.........................................................................13

3.10 Crown Bus Wiring “Loops” from Output to Input.......................................................................................................13

3.11 Audio Input Wiring ...................................................................................................................................................14

3.12 Audio Output Wiring.................................................................................................................................................14

5.1 IQ–P.I.P.–DSP Hardware Circuit Block Diagram........................................................................................................21

5.2 IQ–P.I.P.–DSP Audio Signal Flow Block Diagram ......................................................................................................22

7.1 IQ Address Switch (SW1) Settings from 0 to 125......................................................................................................24

7.2 IQ Address Switch (SW1) Settings from 126 to 250..................................................................................................25

Page 6

Reference Manual

7

Page 7

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

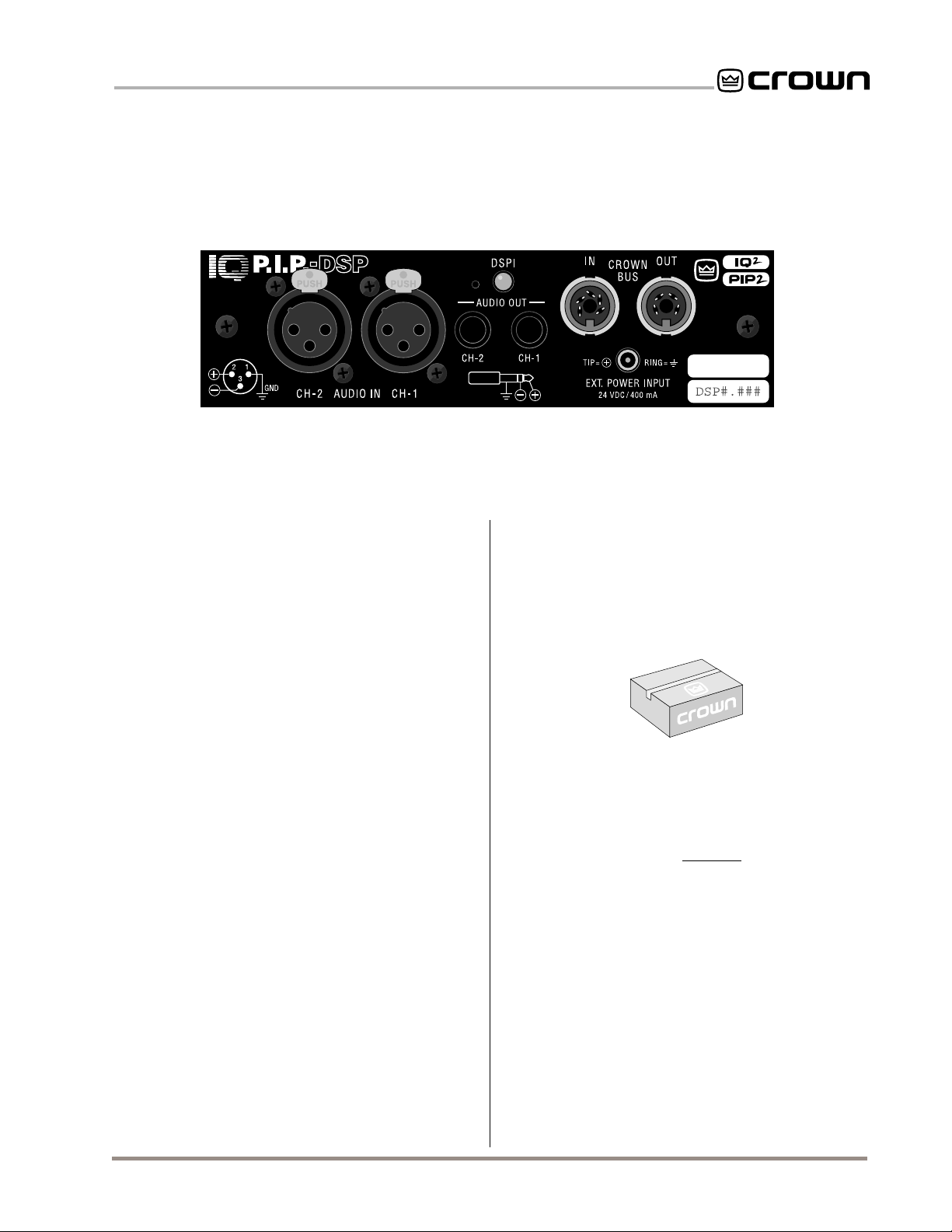

Fig. 1.1 IQ–P.I.P.–DSP

1 Welcome

The

IQ–P.I.P.–DSP

nects an IQ-compatible amplifier to the Crown Bus of

an

IQ System

monitored. Its DSP (digital signal processing) capabilities enable it to offer a variety of programmable functions, such as filters and crossovers, signal delay , input

compressor and output limiter and a variety of other

useful features similar to those included with our other

SmartAmp

™

amplifier (an external AC power adapter may be required with certain amplifiers).

is a powerful IQ component that con-

so the amplifier can be controlled and

IQ P.I.P.s

. The module is powered by the

This manual will help you successfully install your unit.

We strongly recommend you read all the instructions,

warnings and cautions contained within. Also for your

protection, please send in the warranty registration car d

today and save the bill of sale since it is your official

proof of purchase.

The

IQ–P.I.P.–DSP

®

P.I.P.

(programmable input processor) and

patible amplifiers. Because it is also an

is a

PIP2

input module for Crown

IQ2

-series com-

PIP2

-com-

ponent, it supports Crown’s UCODE protocol and

requires an

IQ System

®

with an

IQ2

-compatible IQ interface. UCODE (universal code) enables users and

third parties to develop custom software objects to control and monitor

IQ–P.I.P.–DSP

To ensure fast and accurate processing, the

DSP

features two separate onboard processors. A

Motorola 6811 microprocessor inside the

sees communication with the

SmartAmp

IQ2

-compatible components like the

.

IQ System

features (similar to an

IQ–P.I.P.-

P.I.P.

over-

and most

IQ–P.I.P.–SMT)

. A

Motorola 56002 microprocessor handles all digital signal processing.

Each

IQ–P.I.P.–DSP

is easy to install and includes an IQ

address switch, allowing the unit to have a unique address on the Crown Bus. Its error-tolerant design enables it to automatically reset itself if noise “spikes” or

other disturbances are encountered.

Reference Manual

1.1 Unpacking

The unit is shipped in a protective antistatic bag.

CAUTION: STATIC ELECTRICITY MAY DAMAGE

THE UNIT. Use caution when handling the unit.

Carefully ground yourself BEFORE touching the unit.

For added safety, touch the outer metal collar of either

Crown Bus connector. Avoid unnecessarily touching

the components, edge connector or solder pads on

the circuit boards.

Please unpack and inspect the unit for any damage

that may have occurred during transit. If damage is

found, notify the transportation company immediately.

Only you, the consignee, may initiate a claim with the

carrier for shipping damage. Crown will be happy to

cooperate fully as needed. Save the shipping carton

as evidence of damage for the shipper’s inspection.

Even if the unit arrived in perfect condition, as most do,

save all packing materials. NEVER SHIP THE UNIT

WITHOUT THE FACTORY PACK.

Page 7

Page 8

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

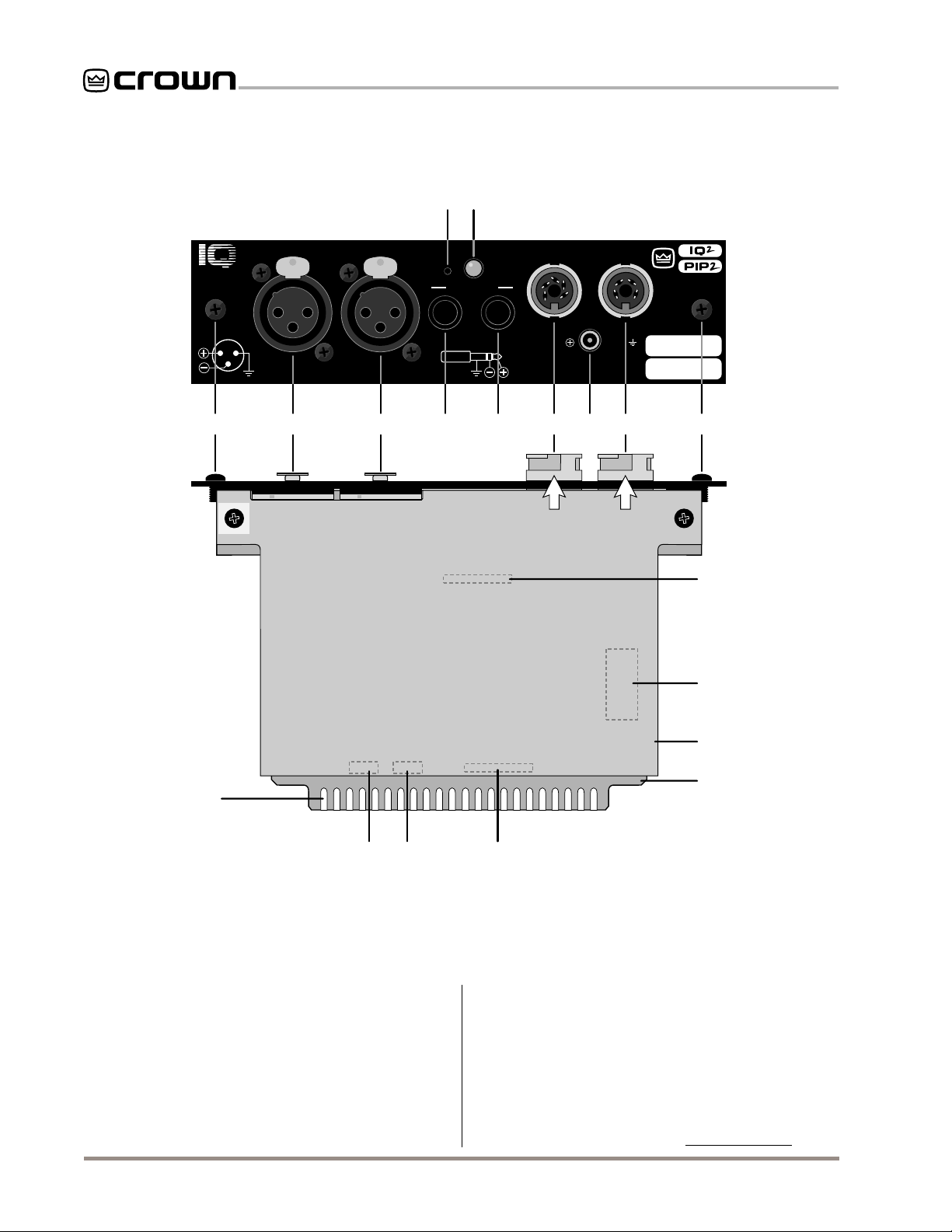

-

DSP

DCE

Front View

Bottom View

21

3

P. I.P.

GND

DSPI

PUSH

CH-2 CH-1AUDIO IN

PUSH

AUDIO OUT

CH-2 CH-1

B B C F HA A

IN OUT

CROWN

BUS

TIP=

EXT. POWER INPUT

RING=

24 VDC / 400 mA

G

DSP#.###

AVOID STATIC DAMAGE!

GROUND YOURSELF TO THE OUTER

METAL COLLAR OF ONE OF THE

CROWN BUS CONNECTORS.

RN1

SW1

K

N

JP4 JP5

CH1 CH2

I

J J

Fig. 2.1 The IQ–P.I.P.–DSP Facilities

2 Facilities

A. Mounting Screws

The

IQ–P.I.P.–DSP

amplifier with two phillips-head screws and star-tooth

lock washers. The lock washers are required for proper

ground connection.

B. Balanced Audio Inputs

A 3-pin female XLR connector is provided for balanced

audio input to each channel of the amplifier. Pin 1 is

ground (gnd); pin 2 is not inverted (+); and pin 3 is

Page 8

is secured to the back panel of the

RN2

M

L

K

inverted (–).

configured in either Bridge or Parallel-Mono mode.

C. Balanced Audio Outputs

A balanced phone jack is provided at the output of

each channel for “daisy chain” connection to other

components. Either balanced (tip, ring, sleeve) or unbalanced (tip, sleeve) wiring may be used. The audio

signal feeding these outputs is post-processed.

Do not use the Ch.2 input if the amplifier is

Reference Manual

Page 9

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

D. Reset Switch

A multifunction reset switch is provided to restore the

IQ–P.I.P.–DSP

a straightened paper clip through the small hole in the

P.I.P.

panel. Press the reset switch for less than 2 seconds and all settings, except the amplifier model scale

factors, will be reset with “user default” parameters and

the Data LED will flash once. (If no “user default” settings have been stored, the unit will be reset to the “factory default” settings described next.) Press the reset

switch for more than 2 seconds and the same settings

will be reset with “factory default” parameters and the

Data LED will flash twice. After the unit has been reset

to the factory default settings, it will behave like a standard

P.I.P.-FX

tem

or it is toggled to the “user default” settings.

WARNING: Pressing the reset switch can cause the

IQ–P.I.P.–DSP

that the level controls of the amplifier be turned down

before pressing the reset switch.

to a prior state. It can be depressed with

until it is reprogrammed by an

to emit a brief pulse. We recommend

IQ Sys-

E. Data Signal Presence Indicator (DSPI)

The Data Signal Presence Indicator (DSPI) is a Data

LED which flashes whenever a valid IQ command has

been received. The indicator can also be forced to stay

on to aid rapid troubleshooting of the Crown Bus wiring.

F. Crown Bus Input Connector

A lockable 5-pin female DIN connector is provided for

input connection to the Crown Bus. A mating

Switchcraft 502-series connector can be ordered from

Crown (part C 7776-5). Pin 1 is negative (–), pin 2 is

positive (+), and pin 3 is ground (gnd). Pins 4 and 5

are not used.

H. Crown Bus Output Connector

A lockable 4-pin female DIN connector is used for output

connection to the Crown Bus. A mating Switchcraft 502

series connector can be ordered from Crown (part

C 7777-3). Pin 1 is negative (–) and pin 2 is positive (+).

Pins 3 and 4 are not used.

I.

P.I.P.

Edge Connector

The gold-plated edge connector of the top IQ circuit

board inserts into the

of the amplifier. Use care when installing a

ule to be certain that the edge connector is properly

inserted into the amplifier’s

P.I.P.

connector inside the back

P.I.P.

connector.

P.I.P.

mod-

J. Amplifier Output Pad Jumpers (JP4, JP5)

These jumpers enable the circuitry that pads the output signal feeding the

erly scaled. They should normally be set to the “IN”

position as marked on the digital circuit board. Use the

“OUT” position whenever the unit is installed into a

PIP2

-compatible or

K.

PIP2

SIP Sockets (RN1, RN2)

These eight-pin SIP (single in-line package) sockets

are provided for full

PIP2

modules (required for PIP2-compatible amplifiers)

should come with the SIP networks already installed.

The SIP networks are not required and should be absent on standard

IQ–P.I.P.–DSP

Macro-Tech 5000VZ

PIP2

compatibility.

IQ-P.I.P.-DSP

modules.

so it can be prop-

amplifier.

IQ-P.I.P.-DSP-

L. IQ Circuit Board (Top)

The top circuit board contains the IQ communication

and data acquisition circuitry , including the IQ address

switch (SW1), amplifier output pad jumpers (JP4, JP5),

PIP2

SIP sockets (RN1, RN2) and the

nector.

P.I.P.

edge con-

G. External Power Input

A mini jack is provided to receive power from an external 24 VDC, 400 mA source. External power is not

needed when the

Tech 5000VZ

PIP2

-compatible amplifier. However, other

models may require additional power for the

DSP

. An external 120 VAC power adapter (C 7926-6)

is available from Crown. See Section 3.8.

CAUTION: Use only an individual, isolated power sup-

ply for each

common power supply with more than one unit or the

IQ–P.I.P.–DSP

Reference Manual

IQ–P.I.P.–DSP

or

10,000

, a Com-Tech, a Reference or a

IQ–P.I.P.–DSP

modules may be damaged.

is installed in a

. Do not attempt to share a

Macro-

Macro-Tech

IQ–P.I.P.–

M. Audio Circuit Board (Bottom)

The bottom circuit board contains the audio analog and

digital signal processing circuitry.

N. IQ Address Switch (SW1)

An 8-section DIP (dual in-line package) switch is used

to set the IQ address of the unit (see Section 3.1). This

switch is located on the top circuit board. Each IQ component on a Crown Bus is given a unique IQ address

so it can be independently controlled and monitored.

Two or more IQ components of the same type should

NEVER have the same address on the same Crown

Bus loop.

Page 9

Page 10

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

-

DSP

3 Installation

Before beginning, please carefully note:

CAUTION: STATIC ELECTRICITY MAY DAMAGE

THE

IQ–P.I.P.–DSP

handling the unit. Carefully ground yourself BEFORE

touching the

IQ–P.I.P.–DSP

touch the outer metal collar of either Crown Bus

connector (see Figure 2.1). This should safely

discharge any static electricity through the ground

plane of the module. Avoid unnecessarily touching the

components, edge connector or solder pads on the

circuit boards.

NOTE — Amplifier Compatibility

The version of the

vary depending on whether you indicated the card will

be installed on a PIP2-compatible amplifier (such as

the Crown MA-5000VZ or CT-10 Series amplifiers). The

correct card to install in a PIP2-compatible amplifier is

the

IQ-P.I.P.-DSP-PIP2

should be ordered for non-PIP2-compatible amplifiers.

Should you later wish to change the amplifier you are

using for your

alter the card's configuration by simply removing or

installing two SIPS from the card’s circuit boards1. For

instructions on installing or removing these SIPS,

contact Crown Technical Support.

MODULE. Use caution when

module. For added safety,

IQ-P.I.P .-DSP

card you received will

. The standard

IQ-P.I.P.-DSP

installation, it is possible to

IQ-P.I.P.-DSP

is used to set the IQ address of the

DSP.

No two IQ components of the same type

IQ–P.I.P .–

which are connected to the same Crown Bus

can have the

ample, an

1 and 2, and this

same address. Suppose, for ex-

IQ System

has two Crown Bus loops,

IQ–P.I.P.–DSP

is to be installed

into loop 1 and given an address of 77. No other

IQ–P.I.P.–DSP

loop 1. However, an

can be given the same address in

IQ–P.I.P.–DSP

in loop 2 can

have the same address.

Different IQ components in the same Crown Bus

loop can have the same address. For example,

both an

SMX-6

mixer and an

IQ–P.I.P.–DSP

can

use address 77 in the same loop.

A valid IQ address is any number from 1 to 250.

Do not use a number higher than 250 since they

are reserved for special use. An address of “0”

(zero) should never be used except to put the

IQ–P.I.P.–DSP

is invisible to the

into a stand-alone mode where it

1

VALUE

IQ System

8163264128

2

4

and acts as a

ON

SW1

12345678

TOP VIEW

3.1 Prepare the

IQ–P.I.P.–DSP

1. Set the IQ address switch SW1. By giving each

IQ component a unique address, it can be individually controlled and monitored. Whenever the

System

wants to send a command to just one IQ

component, it first sends its address and then the

CROWN

IN OUT

BUS

T

-1

H

C

=

G

IN

R

DSP#.###

T

=

U

P

TIP

IN

R

E

W

A

O

m

0

. P

0

T

X

/ 4

C

E

D

V

4

2

21

3

P. I. P.

D

N

G

PUSH

CH-2

AUDIO IN

PUSH

CH-1

DSPI

U

O

IO

D

U

A

-2

H

C

BOTTOM

Fig. 3.1 IQ Address Switch (SW1) Location

command down the Crown Bus.

The 8-segment DIP switch (SW1) shown above

1

IQ-P.I.P.-DSP-PIP2

Page 10

has SIPS installed;

IQ-P.I.P.-DSP

IQ

SW1

has SIPS removed.

Fig. 3.2 IQ Address Switch (SW1) Values

“dumb” balanced audio input.

Switch SW1 is located on the right side on the

underside of the top circuit board (Figure 3.1). It

has eight segments because it actually contains

eight tiny switches inside. There is an arrow

printed on the switch along its left side that

points to the “ON” position and the switches are

numbered along the bottom (Figure 3.2).

Each of the eight switches in SW1 has a value

which doubles as the switch number increases.

For example switch 1 has a value of 1; switch 2

has a value of 2; switch 3 has a value of 4; switch

4 has a value of 8 and so on.

The address is determined by adding the values

of all “ON” switches. In Figure 3.2 switches 1, 3,

4 and 7 are on. Simply add the values to find the

address: 1+4+8+64=77.

A convenient series of IQ address tables are included in Section 7. The tables show the switch

Reference Manual

Page 11

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

settings for all 250 addresses.

2. Set the jumpers JP4 and JP5. If the

DSP

is being installed into a

Macro-Tech 5000VZ

PIP2

amplifier, move both

IQ–P.I.P.–

-compatible or

jumper JP4 and JP5 on the IQ circuit board to

the “OUT” position (Figures 2.1 and 3.6). Set

both JP4 and JP5 to the “IN” position for all other

amplifiers.

3.2 Prepare the Amplifier

3. Turn down the level controls (full counter-

clockwise) and turn off the amplifier.

4. Disconnect the amplifier’s power cord.

5. Remove the existing

amplifier back panel (two screws). For

ers this may involve disconnecting the

PIP2

input adapter (Figure 3.4). If a

P.I.P .

or cover panel from the

PIP2

P.I.P .

PIP2

amplifi-

from a

input

adapter is already present, do not remove the ribbon cables from the adapter. Otherwise you will

have to reconnect them in Step 9.

6. Set the amplifier input sensitivity to 0.775 V.

(See the amplifier’s

3.3 Install the

Reference Manual

IQ–P.I.P.–DSP

.)

into the

Amplifier

7. Carefully ground yourself to the chassis of the

amplifier before installing the

a good idea to maintain ground contact between yourself and the amplifier while inserting

the module into the

P.I.P.

-compatible amplifiers) or the

tor (

PIP2

-compatible amplifiers).

8. Install the

IQ–P.I.P.–DSP

P.I.P.

Standard P.I.P. Amplifiers:

IQ–P.I.P.–DSP

in the

P.I.P.

push the unit in until it is seated against the

mounting bracket (see Figure 3.3).

PIP2 Amplifiers:

Connect the

to the two input cables of the amplifier (Figure

Fig. 3.3 Installation into a Standard P.I.P. Amplifier

IQ–P.I.P.–DSP

. It is

card rails (standard

PIP2

connec-

into the amplifier:

Align the edges of the

card rails and firmly

PIP2

input adapter

BACK PANEL

OF AMPLIFIER

P.I.P.

MODULE

3.4). Notice that the

be positioned with the

PIP2

input adapter should

P.I.P.

edge connector on

top facing away from the amplifier. The 20 pin

cable (A) is connected first then the 18 pin cable

FROM AMPLIFIER

Fig. 3.4 PIP2 Input Adapter Connection

PIP2 ADAPTER

B

A

18 PIN (B)

B

20 PIN (A)

A

(B) is connected. Both ribbon cables should extend below the

Next, insert the edge connector of the

DSP

into the

Fig. 3.5 Installation into a PIP2 Amplifier

and insert the assembly into the

PIP2

input adapter.

PIP2

input adapter (see Figure 3.5)

BACK PANEL

OF PIP2

AMPLIFIER

PIP2 ADAPTER

P.I.P.

O

M

P.I.P.

IQ–P.I.P.–

LE

U

D

opening in

the back of the amplifier.

9. Tighten the two

the

P.I.P.

is secured to the amplifier back panel.

P.I.P.

mounting screws until

3.4 Install the Wiring

10. Connect the

via the Crown Bus. See Section 3.6 for full in-

structions.

11. Connect the audio signal wiring to the

P.I.P.–DSP

and, if desired, the phone jack daisy chain wiring. See Section 3.7 for full instructions.

The supplied EMI suppression core must be

used on the daisy chain outputs for the IQ–P.I.P .–

DSP to comply with FCC and EC EMC regulations (see Section 3.7).

12. Connect the amplifier back to the AC recep-

tacle.

Note: The IQ–P.I.P.–DSP may require an

external power supply in some amplifiers. See

IQ–P.I.P.–DSP

to the

IQ System

IQ–

. This includes the XLR input wiring

Note:

Reference Manual

Page 11

Page 12

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

Section 3.8 for more information.

3.5 Adjust the Levels & Scale Factors

13. Turn the level controls of the amplifier to their

full or maximum setting. This is required by the

IQ–P.I.P.–DSP

trolled input attenuators on the

. If needed, use the software-con-

IQ–P.I.P.–DSP

to re-

duce the audio levels.

14. Configure the amplifier scale factors.

P.I.P .

-compatible amplifiers only—the scale factors for

PIP2

-compatible amplifiers are set automatically.) It is

(Standard

necessary to configure software scale factors in the

microprocessor of the

IQ–P.I.P .–DSP

in order for it to

properly interpret the output signal level of the amplifier model in which it is installed. This is easily done by

connecting a host computer to the

IQ–P.I.P .–DSP

via

an IQ interface and the Crown Bus and running the

appropriate software (see the IQ software

Manual

for details). In the appropriate input area of the

User’s

software, specify the amplifier model. The software

will then send the appropriate scale factors to the P .I.P.

Note that for some amplifiers, the scale factors will

also need to be specified by the user. When

prompted by the software, input the appropriate scale

factor. The scale factor values are listed in Figure 3.6

Amplifier

Model

Com-Tech 200 (8 ohm)

Com-Tech 400 (8 ohm)

Com-Tech 800 (8 ohm)

Com-Tech 1600 (8 ohm)

All Com-Tech (70-volt)

Macro-Tech 600

Macro-Tech 1200

Macro-Tech 2400

Macro-Tech 24x6

Macro-Tech 3600VZ

Macro-Tech 36x12

Macro-Tech 5000VZ

Macro-Tech 10000

Reference I

Reference II

PIP2-Compatible (Auto)

Fig. 3.6 Amplifier Scale Factor Values

and Output Signal Pad Settings

Scale Values (Decimal)

Channel 1

57

45

40

30

27

44

39

30

30

14

14

30

24

17

30

51

Channel 2

57

45

40

30

27

44

39

24

44

14

39

30

24

17

30

51

Output Signal Pads

(JP4, JP5)

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

IN

OUT

IN

IN

IN

OUT

along with the settings of jumpers JP4 and JP5.

Note: Since it is possible to configure one channel of a Com-Tech amplifier in the 8-Ohm output

mode and the other channel in the 70-Volt output

mode, it may be necessary to configure the

scale factors differently for each channel.

3.6 A Closer Look at Crown Bus Wiring

The

IQ–P.I.P.–DSP

must be connected to a Crown Bus

IQ2

loop having an

the

IQ System

-compatible IQ interface in order for

to control or monitor it. The Crown Bus is

a serial communication loop designed to transmit IQ

commands and data. As implemented in the

DSP

, it is a 20 milliamp current loop operating at a

IQ–P.I.P.–

BAUD rate of 38.4 K. The loop must be unbroken to

function properly.

If the system includes an

IQ–INT II

interface, it can accept eight different Crown Bus loops or zones. Dividing

the sound system into different zones, each with its own

Crown Bus loop, can have several advantages. The following list contrasts those advantages with those of a

single loop.

Multiloop Advantages

• A break in communication in one loop does not

affect other loops.

• Over 250 IQ components of the same type can

be used in a system.

• The same IQ address can be used more than

once (once per loop per model).

Single Loop Advantages (with IQ-INT II interfaces)

• The

IQ System

can send and retrieve data faster

in a single loop.

• “Real time” level display of a greater number of

units is possible.

The

IQ–P.I.P.–DSP

can be connected to the Crown Bus

with inexpensive twisted-pair wiring (shielded or

unshielded). If fiber optic wiring is required contact the

Crown Technical Support Group (see page 4).

Here are some guidelines for twisted-pair wiring:

• Use shielded twisted-pair wire at least 26 AWG

in size when interference is a problem. The wire

should be of good quality and should have low

capacitance—30 picofarads/foot or less is good.

(West Penn 452 or an equivalent wire works well.)

The shield serves two purposes: First, it helps

prevent the IQ data signal from transmitting to

nearby audio wiring. Second, it helps prevent

outside RF from interfering with the data signal.

However, in most cases interference is not a

problem and, since unshielded wire has lower

capacitance, it is a better choice.

• Minimize the total capacitance of each Crown

Bus loop. The total capacitance should be less

than 30 nanofarads. Allow for approximately 60

picofarads for each IQ component in a loop. This

accounts for a slight delay which occurs as data

signals pass through a component.

• Add an IQ Repeater for very long loops—greater

Page 12

Reference Manual

Page 13

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

than 1,000 feet (305 m)—or when required by

high-capacitance wire. Although we recommend

adding a repeater for loops longer than 1,000 feet,

it is often possible to go 2,000 feet (610 m) or

more. The most significant characteristic of the

wire is its capacitance. The lower the capacitance, the longer the loop can be. Unshielded

wire typically has less capacitance.

• Never use the ground wire in a mic snake line.

It may sometimes be convenient to run Crown Bus

data signals to and from stage monitor amplifiers

along unused wire pairs in a mic snake. If this is

done, do not use the ground wire which is normally connected to pin 1 on an XLR connector or

data noise will be added to the audio lines. Use

only the signal lines which normally connect to

pins 2 and 3 of the XLRs. The maximum possible

Crown Bus loop distance will be less because

typical mic cables have high capacitance.

Outside RF interference is seldom a problem for a

Crown Bus loop—especially if shielded twisted-pair

wire is used. However, there are extreme situations

when fiber optic wiring is recommended. For example,

locating a Crown Bus loop next to an AM radio

transmission line may require fiber optic cabling. An

extremely long Crown Bus loop distance may also

require fiber optic cabling.

There are two different types of connectors used for

Crown Bus wiring: DIN connectors and screw terminal

plugs. The

IQ–P.I.P.–DSP

uses a 5-pin DIN connector

for input and a 4-pin DIN connector for output. Figure

3.7 shows how they should be wired.

IQ–P.I.P.–DSP Output

IQ Component Input

should be connected to an IQ component with a screw

terminal plug.

IQ–P.I.P.–DSP Output

41

23

GND 1

Output (+) 2

Not used 3

Not used 4

O

ptional Shield

Figure 3.8 IQ–P.I.P.–DSP Output Connection to an

IQ Component with a Screw Terminal Plug Connector

IQ Mixer

OUT IN

+ – + –

Output (+)

Output (–)

Input (+)

Input (–)

Optional Shield

Figure 3.9 An IQ Component with Screw Terminal

Plug Connected to the IQ–P.I.P.–DSP Input

IQ Mixer

OUT IN

+ – + –

Output (+)

Output (–)

Input (+)

Input (–)

IQ–P.I.P.–DSP Input

5

4

1

2

3

1 Input (–)

2 Input (+)

3 GND

4 Not used

5 Not used

The IQ components in a Crown Bus loop are wired

sequentially. The loop begins and ends with the IQ

interface. The output of one IQ component “loops” to

the input of the next and so on as shown in Figure 3.10.

IQ Interface

41

23

GND 1

Output (+) 2

Not used 3

Not used 4

5

4

Optional Shield

1

2

3

1 Input (–)

2 Input (+)

3 GND

4 Not used

5 Not used

Figure 3.7 IQ–P.I.P.–DSP Output Connection

to Another IQ Component with DIN Connectors

The next two figures show how to connect the

P.I.P.–DSP

to other IQ components with different

IQ–

connectors. Figure 3.8 shows how the Crown Bus

output of the

IQ–P.I.P.–DSP

should be connected to an

IQ component with a screw terminal plug. Figure 3.9

shows how the Crown Bus input of the

Reference Manual

IQ–P.I.P.–DSP

IQ Component

IQ Component

CROWN BUS LOOP

IQ Component

Fig. 3.10 Crown Bus Wiring “Loops” from the

Output to the Input of Each IQ Component

Page 13

Page 14

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

3.7 A Closer Look at Audio Signal Wiring

Balanced 3-pin female XLR connectors are provided

for audio input connection. The audio cables should

be wired in one of the following manners:

Fig. 3.11 Audio Input Wiring

We strongly recommend that balanced wiring be used

if possible. Some important guidelines follow:

• Always use shielded wire. The higher the density

of the shield (the outer conductor), the better.

Spiral wrapped shield is not recommended.

• When using unbalanced lines, keep the cables

as short as possible. Avoid lengths greater than

10 feet (3 meters).

• Do not run audio input cables together with

high-level wiring such as loudspeaker wires or

AC cords. (This lessens the chance of hum or

noise being induced into the input cables.)

• Do not connect audio and data grounds together. For example, do not connect the audio

ground to the Crown Bus ground.

• Turn the entire sound system off before changing any connections. Turn the level controls

down before powering the system back up.

Crown is not liable for damage incurred when

any transducer or component is overdriven.

Balanced phone jacks are provided for “daisy chain”

audio output connection. The audio cables should be

wired in one of the following manners:

plifier (if provided). The phone jacks are wired in parallel with the output of the

plifier. Any audio signal fed into the phone jacks could

feed back into the output of the

erate a distorted input signal. The phone jacks can be

used to “daisy chain” the post-processed signal from

the

IQ–P.I.P.–DSP

DO NOT USE THE CHANNEL 2 INPUT if the amplifier

is used in either Bridge-Mono or Parallel-Mono mode.

For additional information on audio input connection

please refer to the amplifier’s

Manual

unwanted subsonic frequencies, radio frequency inter ference, ground loops, and feedback oscillation.

. It contains helpful information on preventing

to the inputs of other amplifiers.

P.I.P.

connector inside the am-

IQ–P.I.P.–DSP

Reference

or

and gen-

Owner‘s

3.8 When External Power is Needed

The

IQ–P.I.P.–DSP

mA at –24 VDC. Many Crown amplifiers can provide

this power via the

these

IQ–P.I.P.-DSP

nal power supply is needed. Amplifiers which can supply adequate power include all

Macro-Tech 5000VZ

and all

installations into 50-Hz versions of

ers (excluding the

ommends use of the S4 version of these amplifiers.

Please contact Crown Technical Suppor t for more information about power supply options for the 50-Hz

PIP2

Macro-Tech

Other Crown

able to supply the full 320 mA of +24 VDC power for

the

IQ–P.I.P .–DSP

the AC mains are that feed them and how hard the

amplifiers are driven. This includes the

600, 1200, 2400, 24x6, 3600VZ

gest that a 400 mA +24 VDC supply be added for

these amplifiers as a safety measure to be certain that

adequate power is available.

power of only 200 mA is needed for these amplifiers,

but a 400 mA supply is recommended to be certain

that the external supply, itself, has a safety margin.

mini jack is provided on the

DSP

for external power connection.

draws 320 mA at +24 VDC and 160

P.I.P.

edge connector inside. For

/amplifier combinations, no exter-

Com-Techs

, all

Studio Reference

-compatible amplifiers. For

Macro-Tech

Macro-Tech 5000VZ),

versions.

P.I.P.

-compatible amplifiers may not be

, depending on how well regulated

and

36x12

Note: Actually, external

P.I.P.

panel of the

, all

amplifiers

IQ–P.I.P.-DSP

amplifi-

Crown rec-

Macro-Tech

. We sug-

A

IQ–P.I.P.–

Fig. 3.12 Audio Output Wiring

In order to comply with FCC and EC EMC regulations,

it is necessary to add an EMI (electro-magnetic interference) core to the daisy chain cable(s). A core, large

enough to snap over both cables, is provided.

IMPORTANT: Do not feed a signal into the phone

jacks on the

Page 14

IQ–P.I.P.–DSP

or the back panel of the am-

IMPORT ANT: The

from an external power supply if the enable switch of

the amplifier is turned off. The amplifier is required to

provide –24 VDC.

CAUTION: If external power is needed, use an individual, isolated power supply for each

Do not attempt to share a common power supply with

multiple

modules may be damaged.

IQ–P.I.P.–DSP

IQ–P.I.P.–DSP

modules or the

cannot be operated

IQ–P.I.P.–DSP

IQ–P.I.P.–DSP

Reference Manual

.

Page 15

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

4 Operation

With an

can be monitored and controlled from a remote

location through the use of an

module features

enable the amplifier to function automatically. For

example, the

the high voltage supplies of the amplifier when no input

signal is present. This can lower electrical usage and

provide long-term cost savings. And it can

automatically limit the audio signal and detect and

report various problems.

In addition, the

signal processing capabilities, including signal delays

and a wide variety of filters. Combined, this adds up to

a powerful array of audio control functions which are

easily accessed via the

Most of the following features can be controlled or

configured using IQ software running on an

host computer. Commands are transmitted via an IQ

interface to the specified IQ component (an

compatible interface is required). Please contact your

Crown representative or Crown’s Technical Support

Group if you are unfamiliar with IQ software. Where

specified, some features are accessed via controls

located on the unit itself.

4.1 Power/Standby Indicators

(IQ for Windows software only.) The power/standby indicators allow you to monitor the power and standby

(mute) status of each channel via

ware.

4.2

The Input/Output Comparator

of the amplifier can be monitored by the

The

provide you

distortion of any kind equals or exceeds 0.05%, the

circuit will cause an indicator on the front of the

amplifier to flash. By monitoring these events, the

System

computer to alert a user that distortion is occurring.

4.3 Input Signal Level Monitor

The input signal level of each channel can be monitored by IQ software. This monitor feature has a range

from +20 dBu to –40 dBu in ½-dB steps.

IQ–P.I.P.–DSP

IQ–P.I.P.–DSP

IQ–P.I.P.–DSP

module, your Crown amplifier

SmartAmp

IQ System

™

capabilities which will

can automatically turn off

features distinctive digital

. This P.I.P.

IQ System.

IQ System

IQ for Windows

IOC

Event Monitor

(IOC®)

of each channel

IQ System

IOC

circuitry acts as a sensitive distortion meter to

proof of distortion-free performance

can flash an indicator on the screen of the host

IQ2

soft-

. If

IOC

IQ

4.4 Output Signal Level Monitor

The output signal level of each channel of the amplifier

can be monitored by the

feature has a range from 0 dB to –40 dB where 0 dB is

referenced to the rated output voltage of the amplifier

model. (This is assumed to be 70-V or the rated 8 ohm

output for

output voltage for all other amplifiers.)

The output signal of some amplifiers must be padded

before the

accomplished by setting jumpers JP4 and JP5 on the

IQ circuit board to the “IN” position. Only the

Tech 5000VZ

require these pads. Set jumpers JP4 and JP5 to the

“OUT” position for them (see Figure 3.6).

The output signals of all amplifiers must be scaled in

order to “calibrate” the 0 dB level. (See Section 4.4.)

This is accomplished with either an amplifier ID code

or a user scale factor. The factory default setting for

this is an amplifier ID code of “CT-70V” which assumes

that the output level is that of a

model) with both channels in the 70-V output mode.

4.5

The Output Device Emulation Protection

of each channel of the amplifier can be monitored by

the IQ software. This level represents the percent of

available thermodynamic capacity that is currently

being used. When the

amplifier cannot produce any more power and

limiting” will begin to limit the drive level to the output

devices, thereby protecting them from too much stress.

(See the amplifier’s

more information about

4.6 Power Control

.

Each channel’s high-voltage supply can be

independently turned on and off with the Power control.

The

Com-Tech

IQ–P.I.P.–DSP

ODEP

Level Monitor

IQ System

and

PIP2

Reference

is used to set this control.

IQ System

amplifiers or the rated 8 ohm

can scale them. This is

-compatible amplifiers do not

Com-Tech

. This monitor

amplifier (any

(ODEP®)

ODEP

level reaches 100%, the

or

Owner’s Manual

ODEP

and how it works.)

4.7 Signal Mute

The output signal of each channel can be

independently muted by the

typically provides 80 dB or more of attenuation.

IMPORTANT: The daisy chain outputs are also muted

by this function.

IQ System

. The function

Macro-

level

“ODEP

for

Reference Manual

Page 15

Page 16

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

4.8 Polarity Inverter

The polarity of the input signal of each channel can be

independently inverted by the

IQ System

.

4.9 Input Signal Attenuator

An attenuator is available at the input of each channel

to control the input signal level. These attenuators are

controlled and monitored by the

appear to move like “flying faders” on some IQ software

screens because they reflect all reductions in gain that

are dynamically applied by the input compressor/

limiter, input protection limiter and

functions. Each input attenuator has a range from 0 dB

to –80 dB in ½ dB steps. (Zero equals no attenuation.)

IQ System

ODEP

conservation

. They may

Note: The IQ–P.I.P.–DSP was designed for a nominal

input level of 0 dBu. If “hot” input signals are required,

use the input signal attenuators to “pad” the input

levels.

4.10 Input Protection Limiter

The input protection limiter is not designed to be

changed by the user. It is set at the factory for minimal

interaction while providing adequate input protection.

It protects the A/D converter from an excessive input

signal. Normally there is no risk of this problem if the

unit is installed as instructed in Section 3 of this manual.

The input protection limiter operates after the input

compressor (Section 4.12) and input attenuator

(Section 4.9) of each channel. If the compressor and/

or attenuator reduce the input gain enough to prevent

distortion, the input protection limiter will do nothing.

Note: Since the input attenuators can be dynamically

monitored by the IQ System, they may appear to move

as “flying faders” on some IQ software screens to

reflect dynamic gain reductions. Moving faders while

all other dynamic processing functions are turned off,

is an indication that the input protection limiters are

activating because the gain has not been optimized.

To prevent the input protection limiters from operating,

configure the amplifier with an input sensitivity of 0.775

V and operate the amplifier with the output level

controls at full volume as described in the installation

instructions in Section 3. In this configuration the

amplifier will clip before the threshold of the input

protection limiter is exceeded.

4.11 Auto

An Auto function (Auto System Actuate or “ASA”) is

available to provide consistency with other IQ

components in the

System

disable many of the functions in the

functions that are enabled/disabled by the Auto control

are: input signal compressor/limiter, output limiter, auto

standby and

The filter and signal delay settings are not affected by

the Auto function. In the case of the filters, this can be

very important. For example, a high-frequency driver

should not be fed a full-band signal when someone

turns off the Auto control. Please refer to the

Manual

the Auto function.

and it serves as a toggle to quickly enable or

for your IQ software for more information about

IQ System

ODEP

Limiter warning.

. It is controlled by the

IQ–P.I.P.–DSP

. The

User’s

IQ

4.12 Input Signal Compressor/Limiter

An input signal compressor/limiter is available for each

channel. Each one is controlled by the

has five parameters:

Input Compressor: Turns this function on/off.

Threshold: Sets the threshold, in dB, above which

the compressor acts. The level is measured at the

input to the

shown on an input meter. The compressor is

“feedforward,” meaning that the level detection

point is located before the gain control stage. The

range is from +16 dBu to –40 dBu.

Attack Time: Sets the attack time of the

compressor. The attack time is defined as the time

it takes the compressor to attenuate the input

signal by 10 dB. The range is from 1 millisecond to

2 seconds.

Release Time: Sets the release time of the

compressor. The release time is defined as the

time it takes the compressor to increase the input

gain by 10 dB. The range is 100 milliseconds to 30

seconds.

Ratio: Sets the compression ratio for the

compressor. The range is 1, 2, 4, 8, 16, 32, ¥ to 1.

P.I.P.

and corresponds to the level

IQ System

and

Note: 1:1 is the same as “off.”

4.13 Smooth/Output Signal Limiter

An output signal limiter is available for each channel.

They can be used either as “smooth” output levelers

(similar to other IQ

they can be used as fast output limiters to protect

drivers and other system components from large

transient signals. They follow the filter functions in the

DSP, making them frequency dependent. The output

voltage of the amplifier is limited (within ½ dB) based

on real-time sampling of the actual amplifier output. The

P.I.P.s

with

SmartAmp

features) or

Page 16

Reference Manual

Page 17

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

output limiters are controlled by the

five parameters:

Output Limiter: Turns this function on/off.

Threshold: Sets the threshold, in dB, above which

the limiter acts. The level is based on the scaled

output voltage monitors (see Section 4.4). The

range is from 0 dB to –40 dB.

Attack Time: Sets the attack time of the limiter. The

attack time is defined as the time it takes the limiter

to attenuate the input signal by 10 dB. The range is

from 10 milliseconds to 30 seconds.

Release Time: Sets the release time of the limiter.

The release time is defined as the time it takes the

limiter to increase the input gain by 10 dB. The

range is 100 milliseconds to 30 seconds.

Ratio: The compression ratio is fixed at ¥:1.

IQ System

and has

4.14 Auto Standby

The Auto Standby feature automatically turns off the

high-voltage supplies of the amplifier when no audio

signal is detected at the input for a predetermined

period of time. The channels are controlled

independently. Using it, many

themselves in just a few years due to reduced energy

costs. There are four parameters which control this

feature:

Auto Standby: Turns this function on/off.

Standby Level: Sets the level, in dB, below which

the high voltage supply of an amplifier channel will

be turned off. The range is from +16 dBu to –40

dBu.

Standby Time: Sets the time, in minutes, that the

input signal must remain below the Standby Level

before the channel’s high-voltage supply is turned

off. The range is from 0 to 255 minutes. A setting of

0 (zero) yields a turn-off delay of approximately 2

seconds to facilitate setup of the function.

Use Turn-On Delay: Enables or disables the IQ

address turn-on delay. This is a delay that prevents

all the amplifiers from turning on at the same instant

and tripping power breakers when an “all amps on”

command is issued by the

delay is calculated by: 10 msec x IQ address

value. It may be desirable to disable this turn-on

delay when using the Auto Standby feature so that

the first syllable of speech is not missed when a

voice page suddenly causes the Auto Standby

function to turn a high-voltage supply back on.

IQ Systems

IQ System

can pay for

. The turn-on

4.15

ODEP

Limiter

The effects of

output devices (as described in Section 4.5) are very

audible. To overcome this, an

to proportionally limit the input audio signal as the

thermodynamic energy reserve of the amplifier is

consumed. This helps to prevent the amplifier from

“

ODEP

limiting” the drive level of the output devices as

described earlier. In the majority of cases, limiting the

input signal produces a very smooth sound. And since

the input signal is only limited when and to the degree

necessary, it is very difficult to detect. There are four

parameters which control this feature:

ODEP

Conservation: Turns this function on/off.

ODEP

percent, above which the conservation limiting will

begin. The range is from 1 to 100%.

ODEP

Conservation Amount: Sets the amount,

in dB, that the input signal level will be attenuated

for each percentage point that the

exceeds the trigger level. The range is ½ to 6 dB in

½-dB steps.

ODEP

release time of the conservation limiter. The release

time is based on 10 dB of attenuation. For example,

a setting of 10 seconds will result in the

DSP

taking 10 seconds to release 10 dB of

attenuation. The range for this parameter is 200

milliseconds to 30 seconds.

4.16 Excessive

A “trigger” can be set that will cause a warning

message to appear on the host computer’s screen if

too many

time. Three parameters control this feature:

IOC

Error Detect: Turns this function on/off.

IOC

Error Time: Sets the time interval over which

IOC

events will be counted. The range is from 1 to

10 seconds.

IOC

Error Count: Sets the number of

that must occur during the preceding time interval

before a warning message is displayed.

“IOC event” is one complete on-off-on cycle.

range is from 1 to 100 events per unit time

4.17 Excessive

The user can set a “trigger” that will cause a warning

message to appear on the host computer’s screen if

the

ODEP

It is generally assumed that a sudden rise in the

“ODEP

Trigger Level: Sets the

Conservation Release Time: Sets the

limiting” the drive level of the

ODEP

limiter is available

ODEP

level, in

ODEP

level

IQ–P.I.P.–

IOC

Warning

IOC

events occur over a specified length of

IOC

events

Note: An

The

ODEP

Warning

level ever rises above a predetermined level.

ODEP

Reference Manual

Page 17

Page 18

IQ–P.I.P.–DSP Programmable Input Processor with DSP for IQ Systems

level would indicate a sudden decrease in the load

impedance—such as a shorted speaker cable or

shorted loudspeaker. There are two parameters which

control this feature:

ODEP

Short Detect: Turns this function on/off.

ODEP

Short Level: Sets the

which a short is presumed to have occurred in the

load resulting in a warning message being

displayed. The range is from 1 to 100%.

ODEP

level above

4.18 Fault Warning

Fault conditions can be monitored by the

and a warning message displayed on the host

computer’ s screen if they occur . If desired, the AUX port

can also be turned on during a “fault” condition. An

amplifier “fault” condition occurs when a channel fails.

The symptoms are a normal input signal, an

tion that is “locked” on, a high voltage supply (VCC)

that reports a normal condition and no signal at the

output of the amplifier.

monitor a “fault” signal from the amplifier while standard

P.I.P.

-compatible amplifiers deduce a “fault” condition from the aforementioned symptoms. There are

two parameters which control this feature:

Fault: Turns this function on/off.

Input Drive Level: Sets the threshold below which

a fault condition is presumed to exist in a standard

P.I.P.

amplifier. This parameter is necessary

because it may be normal for an

persist if the audio input signal level is high.

Monitoring the input level can help determine

whether a fault condition really exists or whether

the amplifier output is distorted simply because of

an excessive input level. The range is from +16

dBu to –40 dBu.

PIP2

-compatible amplifiers

IQ System

IOC

IOC

error to

condi-

4.19 Signal Delay

A signal delay is available for each channel. Each one

is controlled by the

Delay: Sets the amount of signal delay. The range is

1.25 milliseconds to 0.175 seconds in 22.7

microsecond steps. (The minimum delay of 1.25

milliseconds is inherent in the DSP system design.)

Note: The signal delays are not disabled by the ASA

control.

IQ System

and has one parameter:

filter cells). There are seven different filter types from

which to choose—all controlled by the

Low-pass crossover filter (1st–4th order)

High-pass crossover filter (1st–4th order)

Parametric equalization filter (2nd order only)

Low-pass equalization filter (2nd order only)

High-pass equalization filter (2nd order only)

Low-pass shelving equalization (1st order only)

High-pass shelving equalization (1st order only)

All filters have IIR based topologies to insure a proper

magnitude/phase relationship for use in professional

audio applications such as equalizer or crossover

(dividing) networks. Each channel has a total of eight

“biquad” filter cells.

Note: “Biquad” refers to the double

IQ System:

quadratic equations which mathematically describe

each filter implemented in the digital signal processor.

The 1st and 2nd-order filters each require one biquad

filter cell. The 3rd and 4th-order filters each require two

biquad filter cells. This means that a channel can have

no more than four filters if they are all 3rd or 4th-order

filters. Remember that only eight filter cells are

available—this limits the total number of filters that a

channel can have. An error message will be reported

by the IQ software if this capacity is exceeded.

A description and list of the parameters of each filter

type are presented next:

Low-Pass Crossover Filter

Description: This filter rolls off high frequencies

at a rate determined by the shape parameter.

The filter is commonly used to feed the low

frequency portion of an audio signal to woofers

or subwoofers. It can be combined with a highpass crossover filter to create a band-pass

crossover filter for driving mid-range drivers.

Passband gain: Fixed at unity.

Frequency: Sets the –3 dB corner frequency of

the filter. The range is 20 Hz to 20 kHz.

Shape: Sets the response shape of the filter.

Available response shapes are: 1st-order

Butterworth, 2nd-order Butterworth, 3rd-order

Butterworth, 4th-order Butterworth, 2nd-order

Bessel, 3rd-order Bessel, 4th-order Bessel and

4th-order Linkwitz-Riley.

4.20 Programmable Filters