Page 1

Operation Manual

CTs 2-Channel Series

CTs 600

CTs 1200

CTs 2000

CTs 3000

Obtaining Other Language Versions:

local Crown Distributor. If you need assistance locating your local distributor, please contact Crown at 574-294-8000.

This manual does not include all of the details of design, production, or variations of the equipment. Nor does it cover every possible

situation which may arise during installation, operation or maintenance.

The information provided in this manual was deemed accurate as of the publication date. However, updates to this information may have

occurred. To obtain the latest version of this manual, please visit the Crown website at www.crownaudio.com.

Trademark Notice:

trademarks of Crown International. Other trademarks are the property of their respective owners.

©2003 by Crown Audio, Inc. P.O. Box 1000, Elkhart, Indiana 46515-1000 U.S.A. Telephone: 574-294-8000

Com-Tech, Crown, Amcron and Multi-Mode are registered trademarks of Crown International. PIP and PIP2 are

To obtain information in another language about the use of this product, please contact your

Some models may be exported under the name Amcron.

®

134433-4

7/03

Page 2

Important Safety

Instructions

CTs 2-Channel Power Amplifiers

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with a dry cloth.

7) Do not block any ventilation openings. Install

in accordance with the manufacturer’s instructions.

8) Do not install near any heat sources such as

radiators, heat registers, stoves, or other

apparatus that produce heat.

9) Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug

has two blades with one wider than the other.

A grounding-type plug has two blades and a

third grounding prong. The wide blade or the

third prong is provided for your safety. If the

provided plug does not fit into your outlet,

consult an electrician for replacement of the

obsolete outlet.

10) Protect the power cord from being walked on

or pinched, particularly at plugs, convenience

receptacles, and the point where they exit from

the apparatus.

11) Only use attachments/accessories specified

by the manufacturer.

12) Use only with a cart, stand, bracket, or table

specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution

when moving the cart/apparatus combination

to avoid injury from tip-over.

13) Unplug this apparatus during lightning storms

or when unused for long periods of time.

14) Refer all servicing to qualified service personnel. Servicing is required when the apparatus

has been damaged in any way, such as powersupply cord or plug is damaged, liquid has

been spilled or objects have fallen into the

apparatus, the apparatus has been exposed to

rain or moisture, does not operate normally,

or has been dropped.

15) To reduce the risk of fire or electric shock, do

not expose this apparatus to rain or moisture.

TO PREVENT ELECTRIC SHOCK DO NOT REMOVE

TOP OR BOTTOM COVERS. NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

À PRÉVENIR LE CHOC ÉLECTRIQUE N’ENLEVEZ

PAS LES COUVERCLES. IL N’Y A PAS DES PARTIES SERVICEABLE À L’INTÉRIEUR. TOUS REPARATIONS DOIT ETRE FAIRE PAR PERSONNEL

QUALIFIÉ SEULMENT.

IMPORTANT

CTs Series amplifiers require Class 2 output wiring.

MAGNETIC FIELD

CAUTION! Do not locate sensitive high-gain equipment such as preamplifiers or tape decks directly

above or below the unit. Because this amplifier has

a high power density, it has a strong magnetic field

which can induce hum into unshielded devices that

are located nearby. The field is strongest just above

and below the unit.

If an equipment rack is used, we recommend locating the amplifier(s) in the bottom of the rack and the

preamplifier or other sensitive equipment at the top.

WATCH FOR THESE SYMBOLS:

The lightning bolt triangle is used to alert the user

to the risk of electric shock.

The exclamation point triangle is used to alert the

user to important operating or maintenance instructions.

FCC COMPLIANCE NOTICE

This device complies with part 15 of the FCC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

CAUTION: Changes or modifications not expressly approved by the party responsible for

complicance could void the user’s authority to operate the euqipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

page 2

Operation Manual

Page 3

CTs 2-Channel Power Amplifiers

Crown International, Inc.

ISSUED BY: Crown International, Inc.

1718 W. Mishawaka Road

Elkhart, Indiana 46517 U.S.A.

European Representative's Name and Address:

Nick Owen

19 Clos Nant Coslech

Pontprennau

Cardiff

CF23 8ND United Kingdom

Equipment Type: Commercial Audio Power Amplifiers

Family Name: CTs

Model Names: CTs 3000, CTs 2000, CTs 1200, CTs 600

EMC Standards:

EN 55103-1:1995 Electromagnetic Compatibility - Product Family Standard for Audio, Video, Audio-Visual and Entertainment Lighting Control Apparatus for Professional Use, Part 1: Emissions

EN 55103-1:1995 Magnetic Field Emissions-Annex A @ 10 cm and 1 M

EN 61000-3-2:1995+A14:2000 Limits for Harmonic Current Emissions (equipment input current ≤16A per phase)

EN 61000-3-3:1995 Limitation of Voltage Fluctuations and Flicker in Low-Voltage Supply Systems Rated Current ≤16A

EN 55022:1992 + A1: 1995 & A2:1997 Limits and Methods of Measurement of Radio Disturbance Characteristics of ITE: Radiated, Class B Limits; Conducted, Class B

EN 55103-2:1996 Electromagnetic Compatibility - Product Family Standard for Audio, Video, Audio-Visual and Entertainment Lighting Control Apparatus for Professional Use, Part 2: Immunity

EN 61000-4-2:1995 Electrostatic Discharge Immunity (Environment E2-Criteria B, 4k V Contact, 8k V Air Discharge)

EN 61000-4-3:1996 Radiated, Radio-Frequency, Electromagnetic Immunity (Environment E2, criteria A)

EN 61000-4-4:1995 Electrical Fast Transient/Burst Immunity (Criteria B)

EN 61000-4-5:1995 Surge Immunity (Criteria B)

EN 61000-4-6:1996 Immunity to Conducted Disturbances Induced by Radio-Frequency Fields (Criteria A)

EN 61000-4-11:1994 Voltage Dips, Short Interruptions and Voltage Variation

Safety Standard:

EN 60065: 1998 Safety Requirements - Audio Video and Similar Electronic Apparatus

I certify that the product identified above conforms to the requirements of the EMC Council Directive 89/336/EEC as amended by 92/31/EEC, and the Low Voltage Directive 73/23/EES as amended by 93/68/EEC.

Signed

Larry Coburn

Title: Senior Vice President of Manufacturing

DECLARATION of CONFORMITY

Date of Issue: March 1, 2002

Sue Whitfield

574-294-8289

swhitfield@crownintl.com

Operation Manual

Due to line current harmonics, we recommend that you contact your supply authority before connection.

page 3

Page 4

Table of Contents

CTs 2-Channel Power Amplifiers

Important Safety Instructions .......................................................... 2

Declaration of Conformity .............................................................. 3

1 Welcome ...................................................... 5

1.1 Features ............................................................................. 5

2 How to Use This Manual .................................... 6

3 Setup ........................................................... 7

3.1 Unpack Your Amplifier ....................................................... 7

3.2 Install Your Amplifier ......................................................... 7

3.3 Ensure Proper Cooling ....................................................... 7

3.4 Choose Input Wire and Connectors .................................... 8

3.5 Choose Output Wire and Connectors ................................. 8

3.6 Wire Your System .............................................................. 9

3.6.1 Dual 8/4/2 Mode ....................................................... 9

3.6.2 Bridge-Mono 16/8/4 Mode........................................ 9

3.6.3 Dual 70V/100V Mode ................................................ 10

3.6.4 Bridge-Mono 140V/200V Mode ................................ 10

3.6.5 Dual Mode with “Y” Input .......................................... 11

3.7 Connect to AC Mains ......................................................... 12

3.8 Startup Procedure .............................................................. 12

4 Operation ...................................................... 12

4.1 Precautions ........................................................................12

4.2 Front Panel Controls and Indicators ...................................13

4.3 Back Panel Controls and Connectors ................................. 14

5 Advanced Features and Options ...........................15

5.1 Protection Systems ............................................................15

5.1.1 Thermal Level Control (TLC) .....................................15

5.1.2 Junction Temperature Simulation (JTS) .....................15

5.1.3 Fault ..........................................................................15

5.1.4 High-Pass Filters ......................................................15

5.1.5 Low-Pass Filters .......................................................15

5.1.6 AC Under/Over Voltage Protection ............................15

5.1.7 Circuit Breaker ..........................................................15

5.1.8 DC Output Servo .......................................................15

5.1.9 Inrush Limiting ..........................................................15

5.1.10 Variable-speed Fans ................................................15

5.2 Advanced Features .............................................................15

5.2.1 Switching Power Supply ...........................................15

5.2.2 Input Compressor .....................................................15

5.2.3 Sleep Circuit..............................................................15

5.2.4 Input Sensitivity Switches .........................................16

5.3 Options ..............................................................................16

5.3.1 Nominal Attenuation Settings ....................................17

6 Troubleshooting ...............................................18

7 Specifications .................................................20

8 Service .........................................................24

8.1 Worldwide Service .............................................................24

8.2 US and Canada Service.......................................................24

8.2.1 Service at a US or Canada Service Center .................24

8.2.2 Factory Service .........................................................24

8.2.3 Factory Service Shipping Instructions .......................24

8.2.4 Crown’s Profit Protection Plan ...................................24

9 Warranty........................................................25

Crown Factory Service Information Form .......................................27

page 4

Operation Manual

Page 5

CTs 2-Channel Power Amplifiers

20 Hz–20 kHz

*

CTs 600

2-ohm Dual (per ch.)

4-ohm Dual (per ch.)

8-ohm Dual (per ch.)

16-ohm Dual (per ch.)

70V Dual (per ch.)

4-ohm Bridge

8-ohm Bridge

16-ohm Bridge

140V Bridge

*20 Hz–20 kHz Power: refers to maximum

average power in watts from 20 Hz

to 20 kHz with 0.1% THD.

CTs 1200

2-ohm Dual (per ch.)

4-ohm Dual (per ch.)

8-ohm Dual (per ch.)

16-ohm Dual (per ch.)

70V Dual (per ch.)

4-ohm Bridge

8-ohm Bridge

16-ohm Bridge

140V Bridge

*20 Hz–20 kHz Power: refers to maximum

average power in watts from 20 Hz

to 20 kHz with 0.1% THD.

Power

150W

300W

300W

300W

300W

300W

600W

600W

600W

20 Hz–20 kHz

*

Power

250W

600W

600W

300W

600W

500W

1200W

1200W

1200W

1 Welcome

Building on the foundation of the Com-Tech®

Series, the Crown

bility and value for installed sound. The ComTech Series was the first to offer independent

selection of high- and low-impedance operation for a specific channel, and CTs Series

amplifiers continue that tradition, with power

levels and features carefully chosen to perfectly

integrate into fixed install design requirements.

Modern power amplifiers are sophisticated

pieces of engineering capable of producing

extremely high power levels. They must be

treated with respect and correctly installed if

they are to provide the many years of reliable

service for which they were designed.

In addition, CTs Series amplifiers include a

number of features which require some explanation before they can be used to their maximum advantage.

Please take the time to study this manual so

that you can obtain the best possible service

from your amplifier.

1.1 Features

• Switching Power Supply for reduced

weight.

• High power-density, with all two-channel

models in a 2U chassis.

®

CTs Series offers new flexi-

• Direct constant-voltage

(70V/100V/140V/200V) or low-impedance

(2/4/8 ohm) operation. No switch

required.

• Input sensitivity is independently selectable for each channel. Choose low-impedance (4/8 ohm), constant-voltage (70V/

100V/140V/200V), or 26 dB.

• TLC protection circuitry protects the

amplifier from long-term excessive heat by

subtly and dynamically reducing the gain

only when necessary.

• JTS circuitry (CTs 600/1200 only) quickly

protects BJT output transistors from

unsafe operating conditions without shutting the channel down. (Not applicable to

BCA amplifiers as they are inherently protected.)

• PIP2™ (Programmable Input Processor)

connector accepts accessory modules that

tailor the amplifier to suit specific applications.

• Removable terminal block input connectors, with “Y” Input Switch in the standard

PIP2-BBY module.

(Continued on next page)

20 Hz–20 kHz

*

CTs 2000

2-ohm Dual (per ch.)

4-ohm Dual (per ch.)

8-ohm Dual (per ch.)

16-ohm Dual (per ch.)

70V Dual (per ch.)

100V Dual (per ch.)

4-ohm Bridge

8-ohm Bridge

16-ohm Bridge

140V Bridge

200V Bridge

*20 Hz–20 kHz Power: refers to maximum

average power in watts from 20 Hz

to 20 kHz with 0.35% THD.

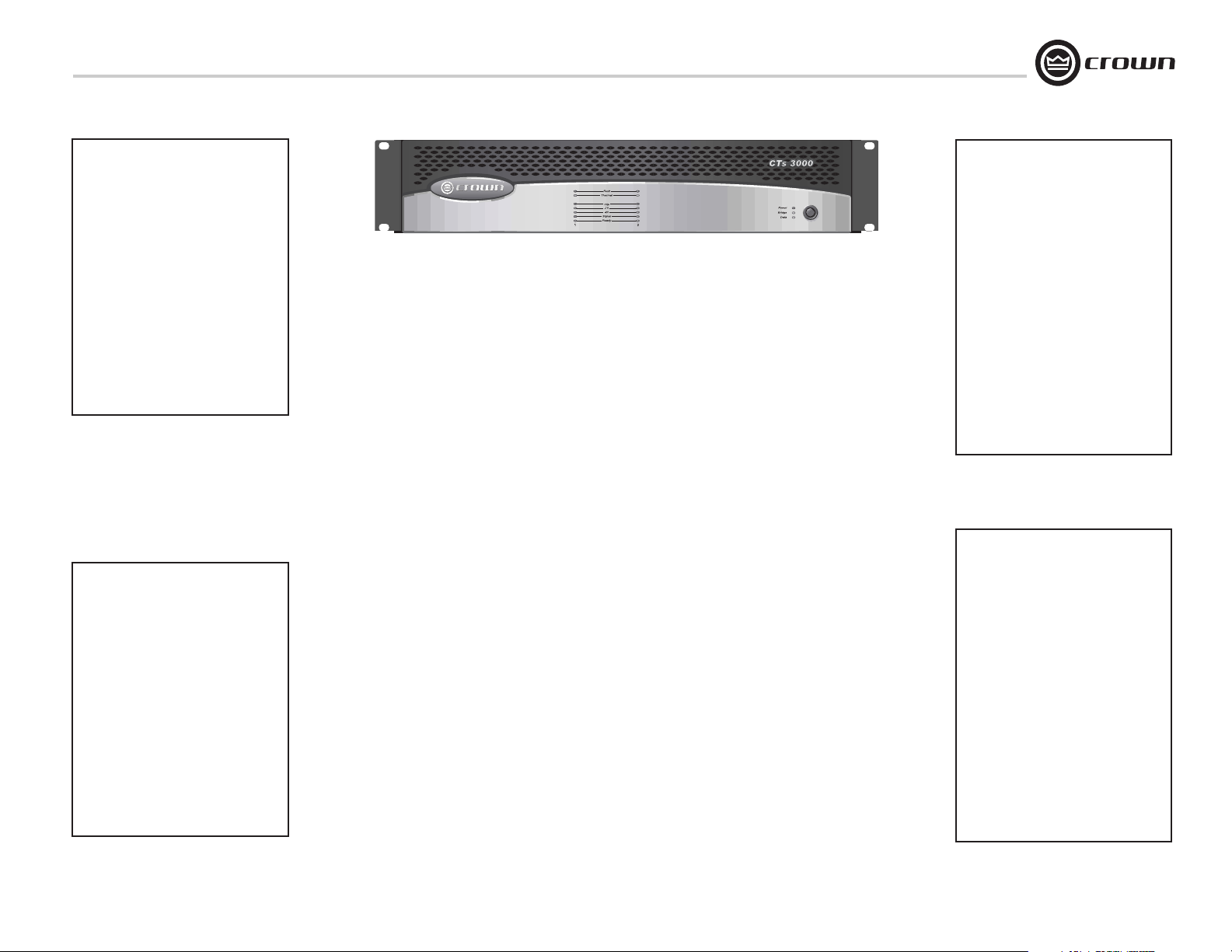

CTs 3000

2-ohm Dual (per ch.)

4-ohm Dual (per ch.)

8-ohm Dual (per ch.)

16-ohm Dual (per ch.)

70V Dual (per ch.)

100V Dual (per ch.)

4-ohm Bridge

8-ohm Bridge

16-ohm Bridge

100V Bridge

200V Bridge

*20 Hz–20 kHz Power: refers to maximum

average power in watts from 20 Hz

to 20 kHz with 0.35% THD.

Power

1000W

1000W

1000W

625W

1000W

1000W

2000W

2000W

2000W

2000W

2000W

20 Hz–20 kHz

*

Power

1500W

1500W

1250W

625W

1500W

1500W

3000W

3000W

2500W

3000W

3000W

Operation Manual

page 5

Page 6

1 Welcome

CTs 2-Channel Power Amplifiers

Features (continued from page 4)

• Switchable high-pass filter for each channel provides low-frequency roll off to eliminate step down transformer saturation

when used in distributed systems.

• Comprehensive array of indicators including Power, Data, and Bridge; along with

Ready, Signal, Clip, Thermal and Fault for

each channel, provide accurate diagnostics.

• Blue Power Indicator flashes if the amplifier shuts off due to an under/over-voltage

condition on the AC mains.

• Advanced protection circuitry guards

against: shorted outputs, DC, mismatched

loads, general overheating, under-/overvoltage, high-frequency overloads and

internal faults.

• Legendary Crown class I (BCA) and class

AB+B (Multi-Mode

offer the best in amplifier reliability. CTs

600/1200 use Class AB+B; CTs 2000/

3000 use Class I.

• Class I is the lowest distortion, lowest

noise, and highest performing topology

available among switch-mode amplifiers.

• Continuously-variable fans optimize cooling efficiency.

• Three Year, No-Fault, Fully-Transferable

Warranty completely protects your investment and guarantees its specifications.

• Crown’s Profit Protection Plan guarantees

replacement of covered amps should they

fail at any time during the original threeyear warranty period (available in U.S.

only).

®

) output topologies

2 How to Use This

Manual

This manual provides you with the necessary

information to safely and correctly setup and

operate your amplifier. It does not cover every

aspect of installation, setup or operation that

might occur under every condition. For additional information, please consult Crown’s

Amplifier Application Guide (available online at

www.crownaudio.com), Crown Tech Support,

your system installer or retailer.

We strongly recommend you read all instructions, warnings and cautions contained in this

manual. Also, for your protection, please send

in your warranty registration card today. And

save your bill of sale—it’s your official proof of

purchase.

page 6

Operation Manual

Page 7

CTs 2-Channel Power Amplifiers

3 Setup

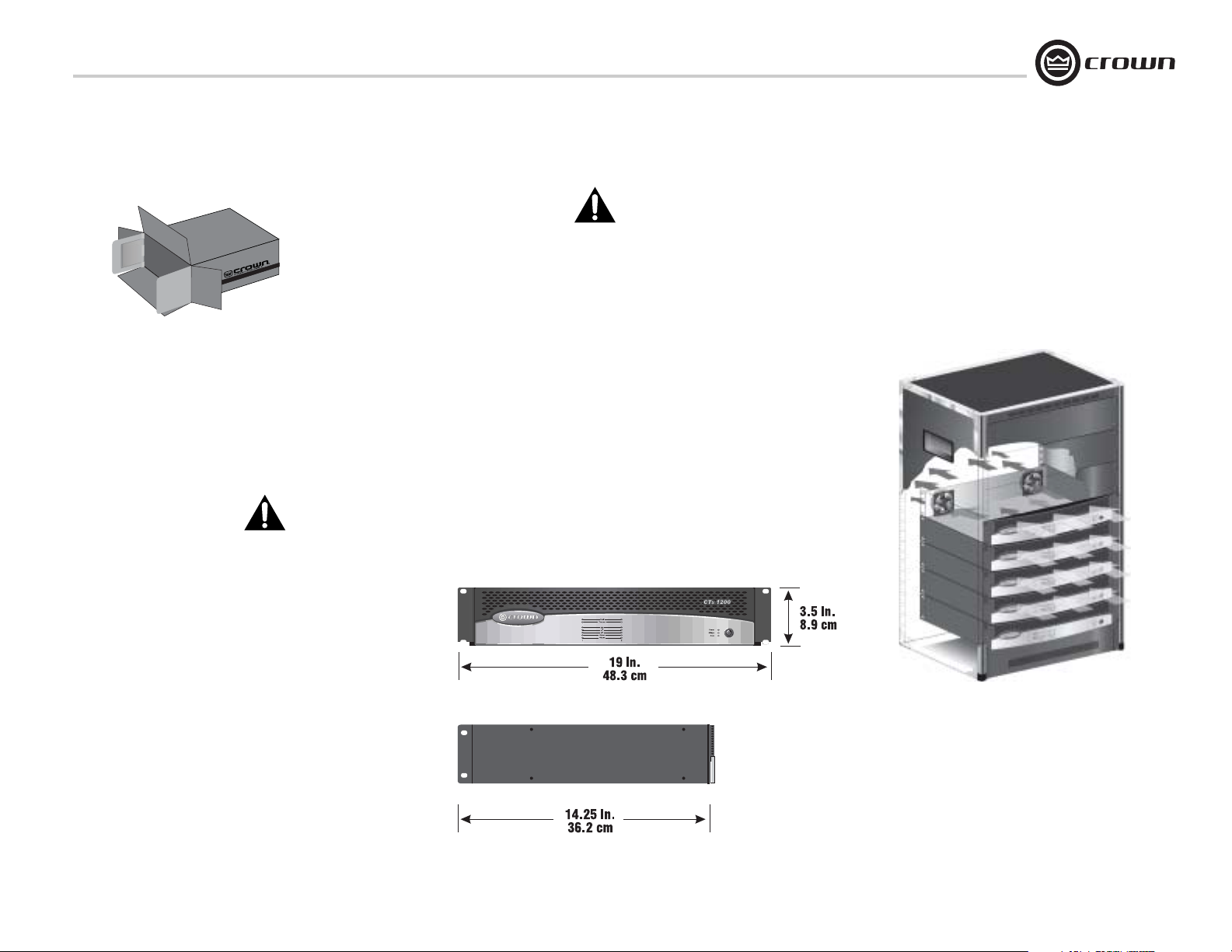

3.1 Unpack Your Amplifier

Please unpack and inspect your amplifier for

any damage that may have occurred during

transit. If damage is found, notify the transportation company immediately. Only you can initiate a claim for shipping damage. Crown will

be happy to help as needed. Save the shipping

carton as evidence of damage for the shipper’s

inspection.

We also recommend that you save all packing

materials so you will have them if you ever

need to transport the unit. Never ship the

unit without the factory pack.

YOU WILL NEED (not supplied):

• Input wiring cables

• Output wiring cables

Rack for mounting amplifier (or a stable surface

for stacking)

WARNING: Before you start to set up

your amplifier, make sure you read and

observe the Important Safety Instructions found at the beginning of this

manual.

3.2 Install Your Amplifier

CAUTION: Before you begin, make sure

your amplifier is disconnected from the

power source, with power switch in the

“off” position and all level controls

turned completely down (counterclockwise).

Use a standard 19-inch (48.3 cm) equipment

rack. See Figure 3.1 for amplifier dimensions.

You may also stack amps without using a cabinet.

NOTE: When transporting, amplifiers should be

supported at both front and back.

3.3 Ensure Proper Cooling

When using an equipment rack, mount units

directly on top of each other. Close any open

spaces in rack with blank panels. DO NOT

block front or rear air vents. The side walls of

the rack should be a minimum of two inches

(5.1 cm) away from the amplifier sides, and the

back of the rack should be a minimum of four

inches (10.2 cm) from the amplifier back panel.

Figure 3.2 illustrates standard amplifier airflow.

Operation Manual

Figure 3.2 Airflow

FRONT

Figure 3.1 CTS 2-Channel Series Dimensions

page 7

Page 8

3 Setup

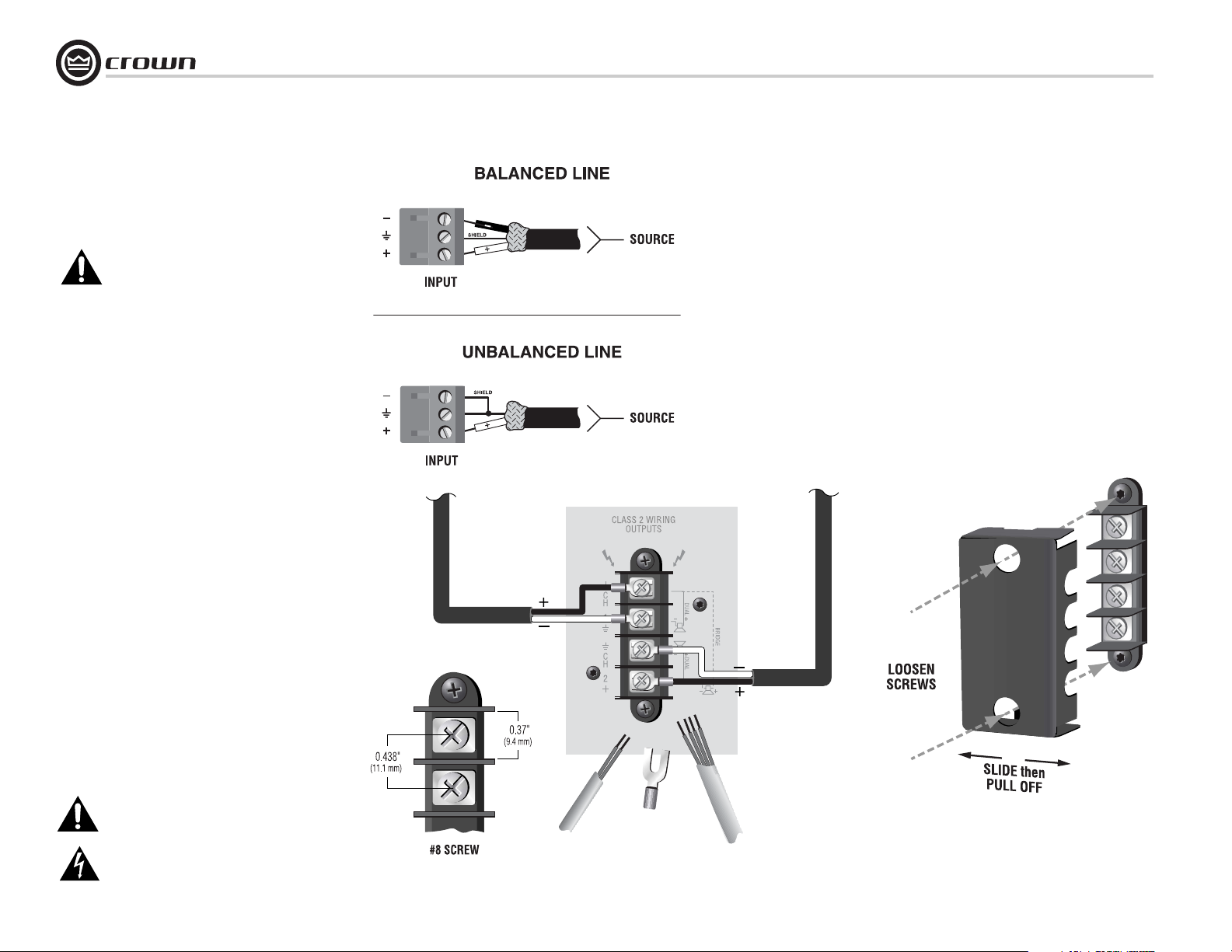

3.4 Choose Input Wire

and Connectors

Figure 3.3 shows connector pin assignments for

balanced wiring, and Figure 3.4 shows connector pin assignments for unbalanced wiring.

NOTE: Custom wiring should only be performed by qualified personnel.

3.5 Choose Output Wire and Connectors

A protective cover is installed over the barrierstrip output. Some models have a cover with two

holes. To remove this type of cover:

1. Loosen screws inside top and bottom holes of

cover (see Figure 3.6).

2. Slide cover to left or right, then pull it off away

from the amplifier.

Crown recommends using professionally constructed, high-quality, two- or four-conductor,

heavy gauge speaker wire and connectors. You

may use terminal forks up to 10 AWG or bare

wire for your output connectors (see Figure 3.5).

To prevent the possibility of short-circuits, wrap

or otherwise insulate exposed loudspeaker cable

connectors. For best results, Crown recommends Panduit part #PV10-10LF-L or equivalent

terminal fork. Screw spacing is shown in Figure

3.5.

Using the guidelines below, select the appropri-

ate size of wire based on the distance from

amplifier to speaker (low-impedance loads only).

Distance Wire Size

up to 25 ft. (7.6m) 16 AWG

26-40 ft. (7.9-12.2m) 14 AWG

41-60 ft. (12.5-18.3m) 12 AWG

> 60 ft (18.3m) 10 AWG

CTs 2-Channel Power Amplifiers

Figure 3.3

Balanced Input

Connector Wiring

Figure 3.4

Unbalanced Input

Connector Wiring

page 8

CAUTION: Never use shielded cable for

output wiring.

Replace output cover after output wiring

is complete.

Figure 3.6 How to Remove the Two-Holed

Barrier-Block Cover

Figure 3.5 Typical Output Connector Wiring

Operation Manual

Page 9

CTs 2-Channel Power Amplifiers

3 Setup

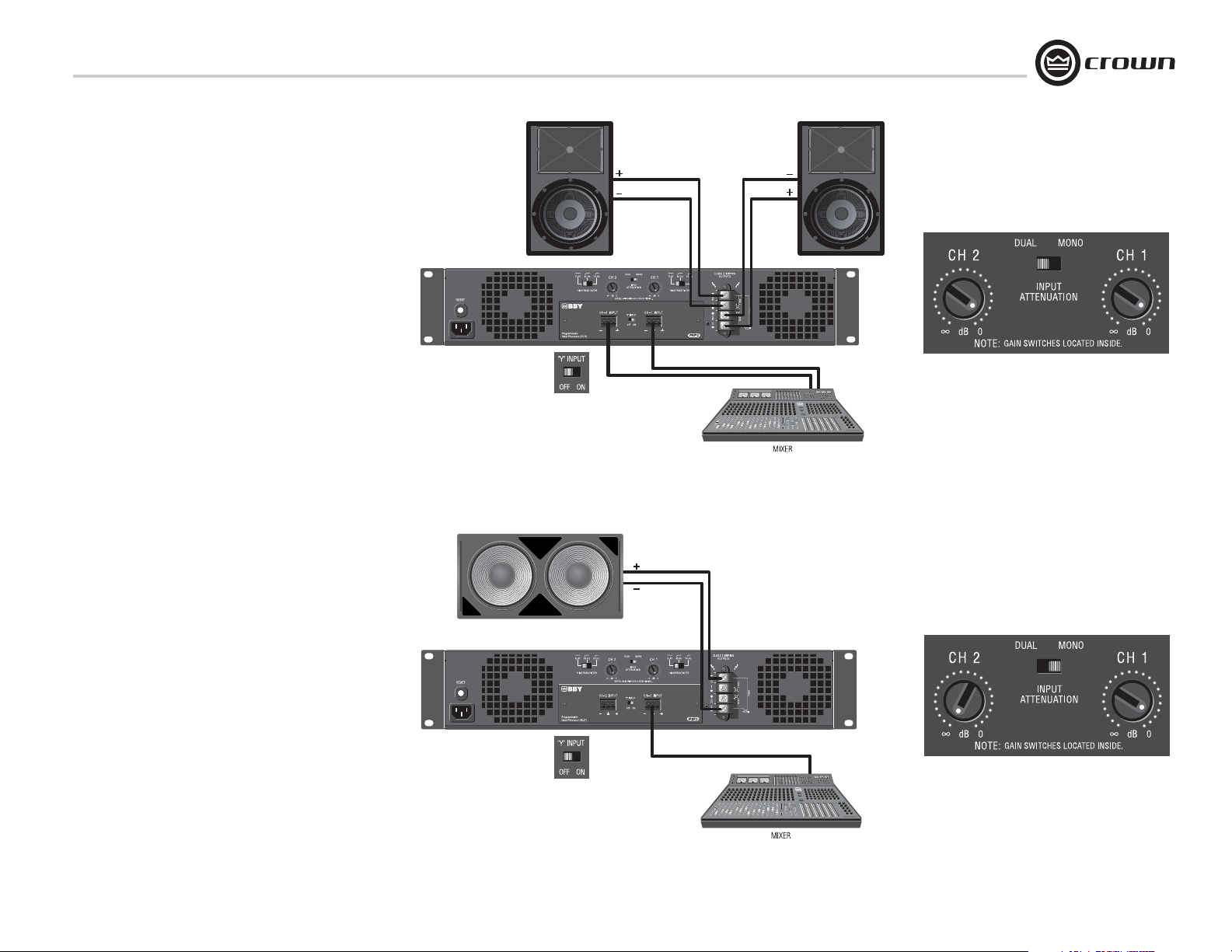

3.6 Wire Your System

3.6.1 Dual 8/4/2 Mode

Typical input and output wiring, along with Attenuator

and Mode Switch settings are shown in Figures 3.6 and

3.7. Make sure the Mode switch is set to the “Dual” position when operating in Dual mode.

INPUTS: Connect input wiring for each channel. The Y

switch on the rear PIP panel can be used to parallel the

channel inputs when only mono input signals are necessary. The amplifier’s channel outputs are still independent.

OUTPUTS: Maintain proper polarity (+/–) on

output connectors.

Connect the Channel 1 speaker’s positive (+) lead to

amplifier Channel 1 positive terminal; repeat for negative

(–). Repeat Channel-2 wiring as for Channel 1. Refer to

Section 3.5 for output connector pin assignments.

3.6.2 Bridge-Mono 16/8/4 Mode

Typical input and output wiring, along with Attenuator

and Mode Switch settings, are shown in Figures 3.8 and

3.9. Make sure the Mode switch is set to the “Mono”

position when operating in Bridge-Mono mode.

INPUTS: Connect input wiring to Channel 1 only.

OUTPUTS: Connect the speaker across the positive ter-

minals of each channel pair. Do not use the negative terminals of the channel pair when the pair is being

operated in Bridge-Mono mode. Refer to Section 3.5 for

output connector pin assignments.

NOTE: Crown provides a reference of wiring pin assignments for commonly used connector types in the Crown

Amplifier Application Guide available at

www.crownaudio.com.

NOTE: When operating in Bridge-Mono mode,

turn down (full CCW) the Input Attenuator for

Channel 2. The Channel-1 Input Atttenuator

works both channels.

See the next page for constant-voltage operation.

Figure 3.8 Attenuator and Mode-

Switch Settings for Dual Mode

Figure 3.7 System Wiring, Dual Mode.

Always route the input and output wires in

separate bundles.

Figure 3.10 Attenuator and Mode-

Switch Settings for Bridge-Mono Mode

Operation Manual

Figure 3.9 System Wiring, Bridge-Mono Mode

page 9

Page 10

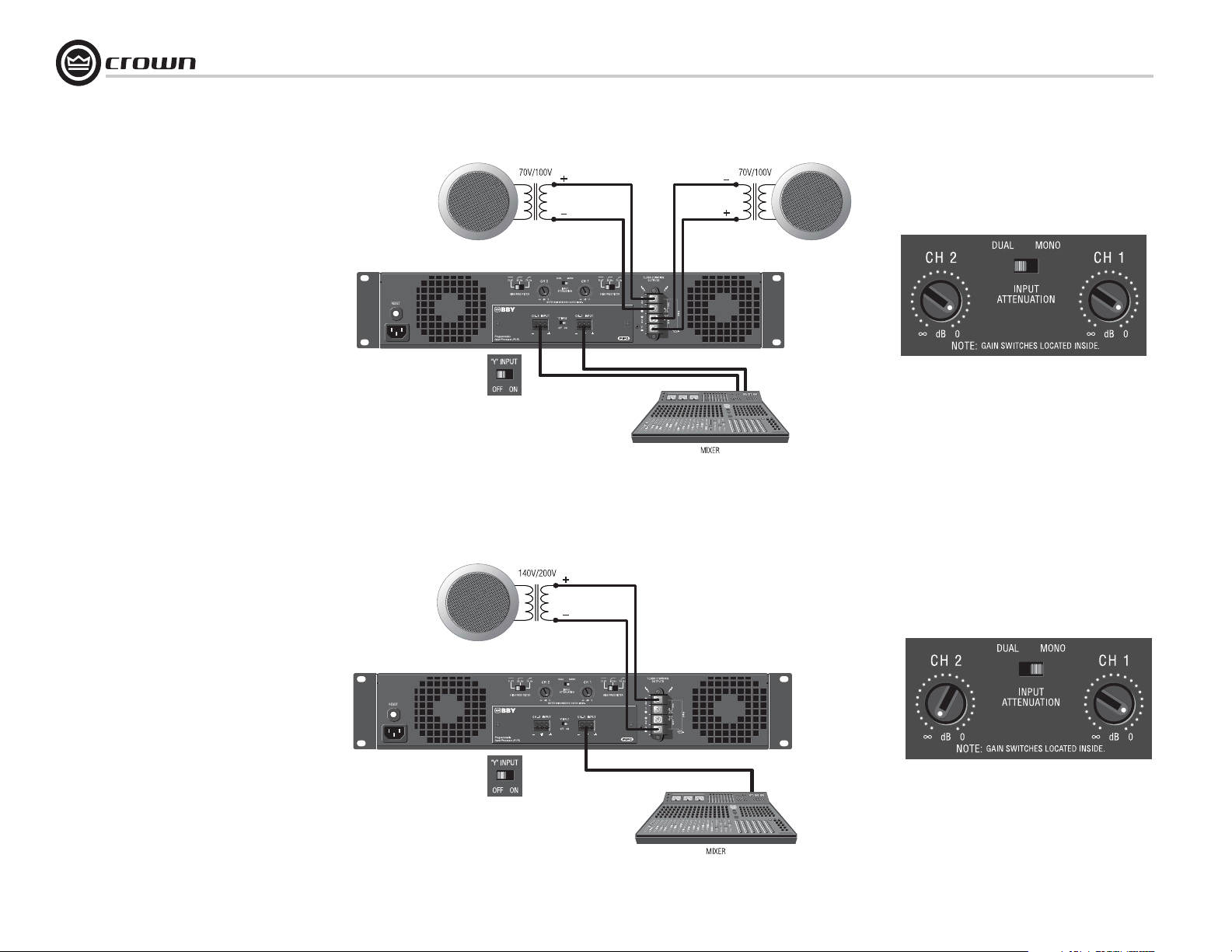

3 Setup

3.6.3 Dual 70V/100V Mode

Typical input and output wiring, along with Attenuator and Mode Switch settings are shown in Figures 3.10 and 3.11. Make sure the Mode switch is

set to the “Dual” position when operating in Dual

mode.

INPUTS: Connect input wiring to both channels.

OUTPUTS: In Dual Mode, the CTs 600/1200 can

power 25/50/70V lines; the CTs 2000/3000 can

power 25/50/70/100V lines. Connect each channel of output connectors to speakers that have the

appropriate transformers.

.

CTs 2-Channel Power Amplifiers

Figure 3.12 Attenuator and Mode-Switch

Settings for 70V/100V Operation

3.6.4 Bridge-Mono 140V/200V Mode

Typical input and output wiring, along with Attenuator and Mode Switch settings are shown in Figures 3.12 and 3.13. Make sure the Mode switch is

set to the “Mono” position when operating in

Bridge-Mono mode.

INPUTS: Connect input wiring to Channel 1 only.

OUTPUTS: In Bridge-Mono mode, the CTs 600/

1200 can power 140V lines; the CTs 2000/3000

can power 140V and 200V lines. Connect speakers with 140V or 200V transformers across the

positive terminals of the channel pair. Do not use

the negative terminals of the channel pair when

the pair is being operated in Bridge-Mono mode.

Refer to Section 3.5 for output connector pin

assignments.

NOTE: When operating in Bridge-Mono

mode, turn down (full CCW) the Input

Attenuator for Channel 2. The Channel-1

Input Attenuator works both channels.

page 10

Figure 3.11 System Wiring and Y-Switch Setting for 70V/100V Operation

Figure 3.13 System Wiring and Y-Switch Setting for 140V/200V Operation

Always route the input and output wires in

separate bundles.

Figure 3.14 Attenuator and Mode-Switch

Settings for 140V/200V Operation

Operation Manual

Page 11

CTs 2-Channel Power Amplifiers

3 Setup

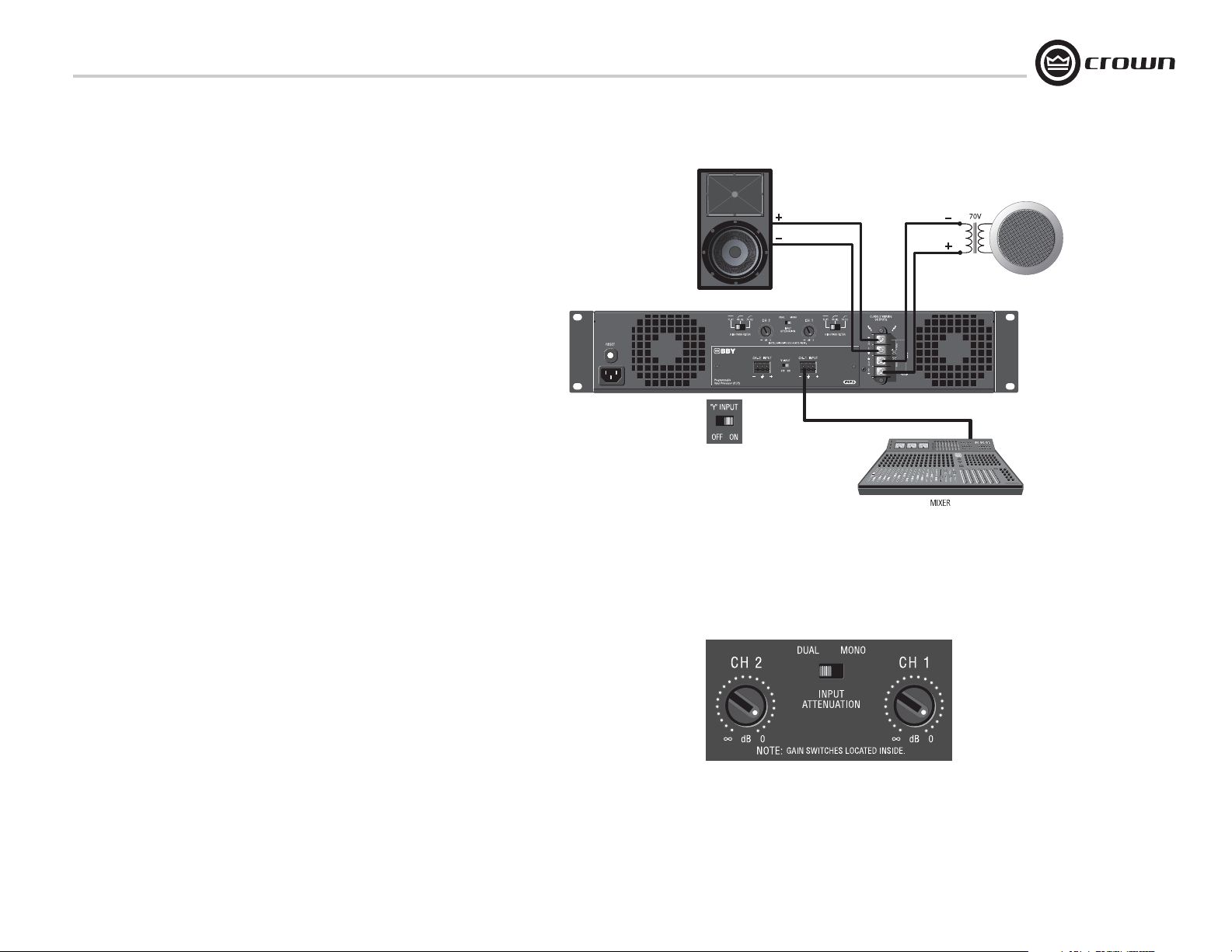

3.6.5 Dual Mode with “Y” Input

See Figure 3.14. This configuration feeds a mono

signal to both Channel 1 and Channel 2. In the

example in Figure 3.14, Channel 1 is driving a lowimpedance loudspeaker and Channel 2 is driving a

loudspeaker with a 70V transformer.

INPUTS:

Connect the signal to the Channel 1 input. On the

back panel, set the “Y” Input Switch to ON.

OUTPUTS:

Connect the Channel 1 speaker’s positive (+) lead

to Channel 1 positive terminal of amp; repeat for

negative (–).

Connect the Channel 2 speaker’s positive (+) lead

to Channel 2 positive terminal of amp; repeat for

negative (–).

See Figure 3.15. Turn up both Input Attenuators and

set the Mode Switch to Dual.

NOTE: When the “Y” Input Switch is on, the Channel 2 input can be used to daisy-chain to another

amplifier.

Figure 3.15 System Wiring for “Y” Input Mode

Operation Manual

Always route the input and output wires in

separate bundles.

Figure 3.16

Attenuator and Mode-Switch

Settings for “Y” Input Mode

page 11

Page 12

3 Setup

CTs 2-Channel Power Amplifiers

page 12

3.7 Connect to AC Mains

On the back panel, check whether your amplifier is labeled

for 120V or 220-240V AC mains. Connect your amplifier

to the corresponding AC mains power source (power outlet) with the supplied AC power cordset. First, connect the

IEC end of the cordset to the IEC connector on the amplifier. Then, with the amplifier in the OFF position, plug the

other end of the cordset into the AC mains.

WARNING: The third prong of this connector

(ground) is an important safety feature. Do not

attempt to disable this ground connection by

using an adapter or other methods.

Amplifiers don’t create energy. The AC mains voltage and

current must be sufficient to deliver the power you expect.

Check the amplifier’s back-panel label which specifies the

required AC mains voltage and frequency. The AC mains

voltage must be no more than 15% above the required

voltage, and no less than 25% below the required voltage.

The AC mains frequency must be within the required frequency range. If you are unsure of the output voltage of

your AC mains, please consult your electrician.

3.8 Startup Procedure

Use the following procedure when first turning on your

amplifier:

1. Turn down the level of your audio source.

2. Turn down the level controls of the amplifier.

3. Turn on the “Power” switch. The Power indicator

should glow. Wait for the “Ready” LED to illuminate.

4. Turn up the level of your audio source to an optimum

level.

5. Turn up the Level controls on the amplifier until the

desired loudness or power level is achieved. Verify

that the Signal LED is flashing.

6. Turn down the level of your audio source to its normal

range.

If you ever need to make any wiring or installation

changes, don’t forget to turn off the amplifier and disconnect the power cord.

For help with determining your system’s optimum gain

structure (signal levels) please refer to the Crown Ampli-

fier Application Guide, available online at

www.crownaudio.com.

4 Operation

4.1 Precautions

Your amplifier is protected from internal and external

faults, but you should still take the following precautions

for optimum performance and safety:

1. Before use, your amplifier first must be configured for

proper operation, including input and output wiring

hookup. Improper wiring can result in serious operating difficulties. For information on wiring and configuration, please consult the Setup section of this

manual or, for advanced setup techniques, consult

Crown’s Amplifier Application Guide available online

at www.crownaudio.com.

2. Use care when making connections, selecting signal

sources and controlling the output level. The load you

save may be your own!

3. Do not short the ground lead of an output cable to the

input signal ground. This may form a ground loop

and cause oscillations.

4. Never connect the output to a power supply,

battery or power main. Electrical shock may

result.

5. Tampering with the circuitry, or making unauthorized

circuit changes may be hazardous and invalidates all

agency listings.

6. Do not operate the amplifier with the red Clip LEDs

constantly flashing.

7. Do not overdrive the mixer, which will cause clipped

signal to be sent to the amplifier. Such signals will be

reproduced with extreme accuracy, and loudspeaker

damage may result.

8. Do not operate the amplifier with less than the rated

load impedance. Due to the amplifier’s output protection, such a configuration may result in premature

clipping and speaker damage.

Remember: Crown is not liable for damage that results

from overdriving other system components.

Operation Manual

Page 13

CTs 2-Channel Power Amplifiers

4 Operation

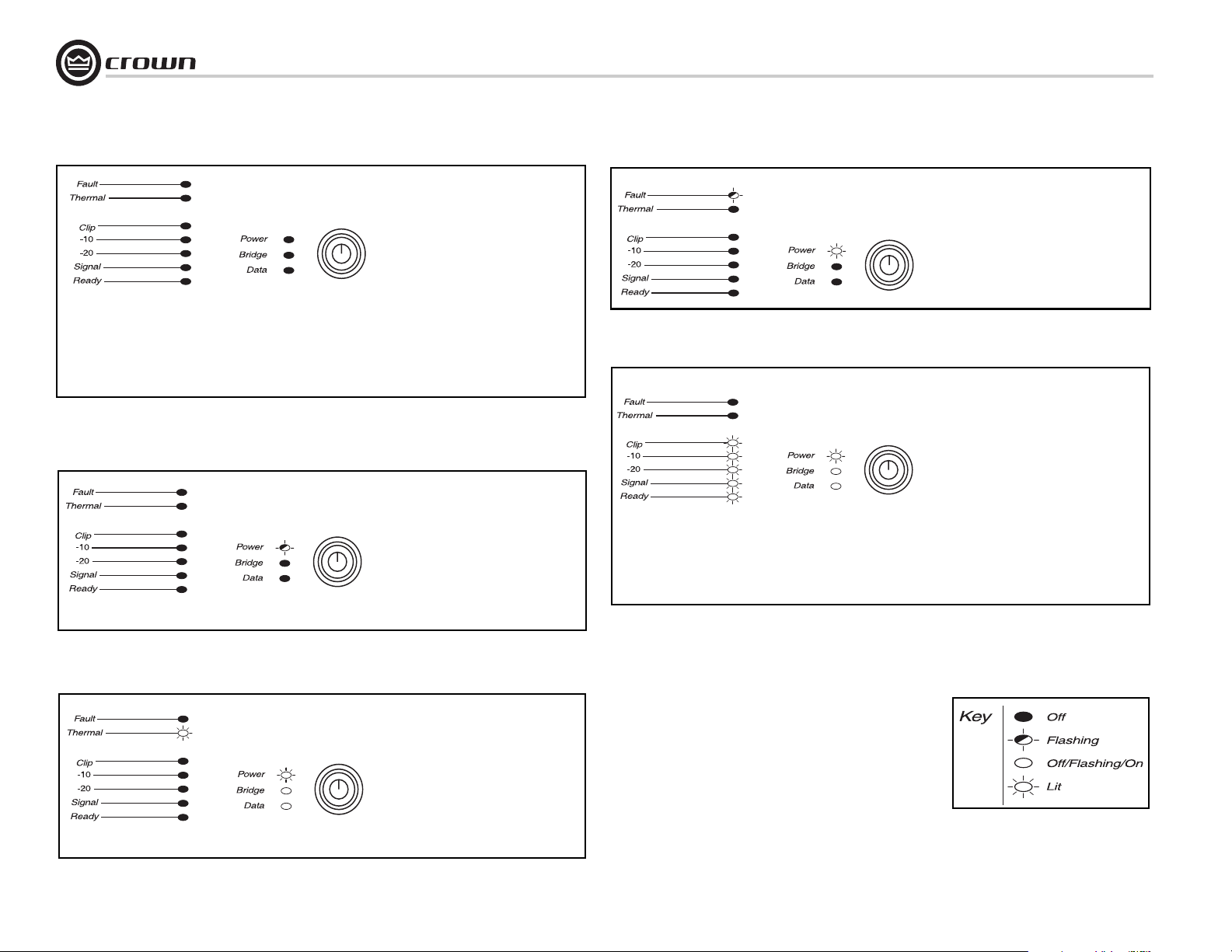

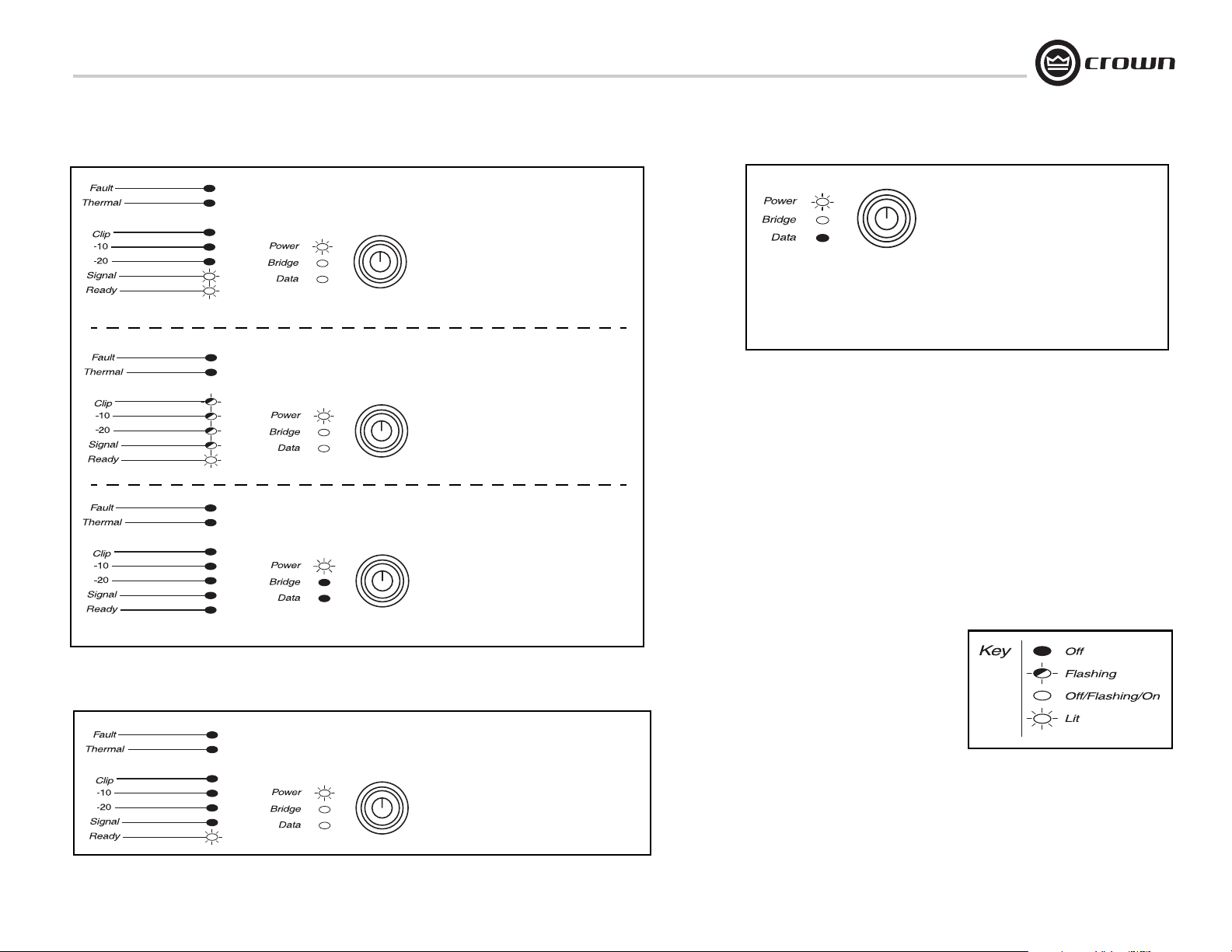

4.2 Front Panel Controls

and Indicators

A. Fault Indicator

Red LED, one per channel, flashes when

the amplifier output channel has stopped

operating. Usually this means that the

amplifier must be serviced.

B. Thermal Indicator

Red LED, one per channel, illuminates

when the channel has shut down, or is

very near shutting down, due to thermal

stress or overload.

C. Ready Indicator

Green LED, one per channel, illuminates

when the channel is initialized and ready to

produce audio output. Indicator is off when

the channel is set to standby mode via the

IQ system.

Signal Indicators

Three green LEDS per channel indicate the

amplifier’s input and output signal levels.

From bottom to top the LEDs are:

D. Signal: input signal is above –40 dBu.

E. –20 dB: amplifier output is within 20 dB of

clipping.

F. –10 dB: amplifier output is within 10 dB of

clipping.

G. Clip Indicator

Red LED, one per channel, illuminates

when the channel’s output signal reaches

the onset of audible clipping. The Clip

Indicator also will illuminate during Thermal Level Control (TLC) limiting or when

the input compressor/limiter is protecting

the amplifier from input overload.

H. Cooling Vents

Front-to-rear forced airflow.

I. Power Indicator

Blue LED indicates AC power has been

applied and is within the safe operating

range of the power supply. The LED will

flash when the AC line voltage is approximately 15% above or 25% below the nominal rated value.

J. Data Indicator

Yellow LED indicates IQ Loop data activity

This LED is driven by the IQ-PIP2 module

via the PIP2

flashes only when the installed PIP module

is polled for data, or is polled to see

whether it is online.

K. Bridge Mode Indicator

Yellow LED illuminates when the rearpanel Mode Switch is set to the “Bridge”

position

L. Power Switch

Push-on / push-off switch.

interface. Note: Data indicator

Operation Manual

Figure 4.1 CTs 600 front panel.

page 13

Page 14

4 Operation

CTs 2-Channel Power Amplifiers

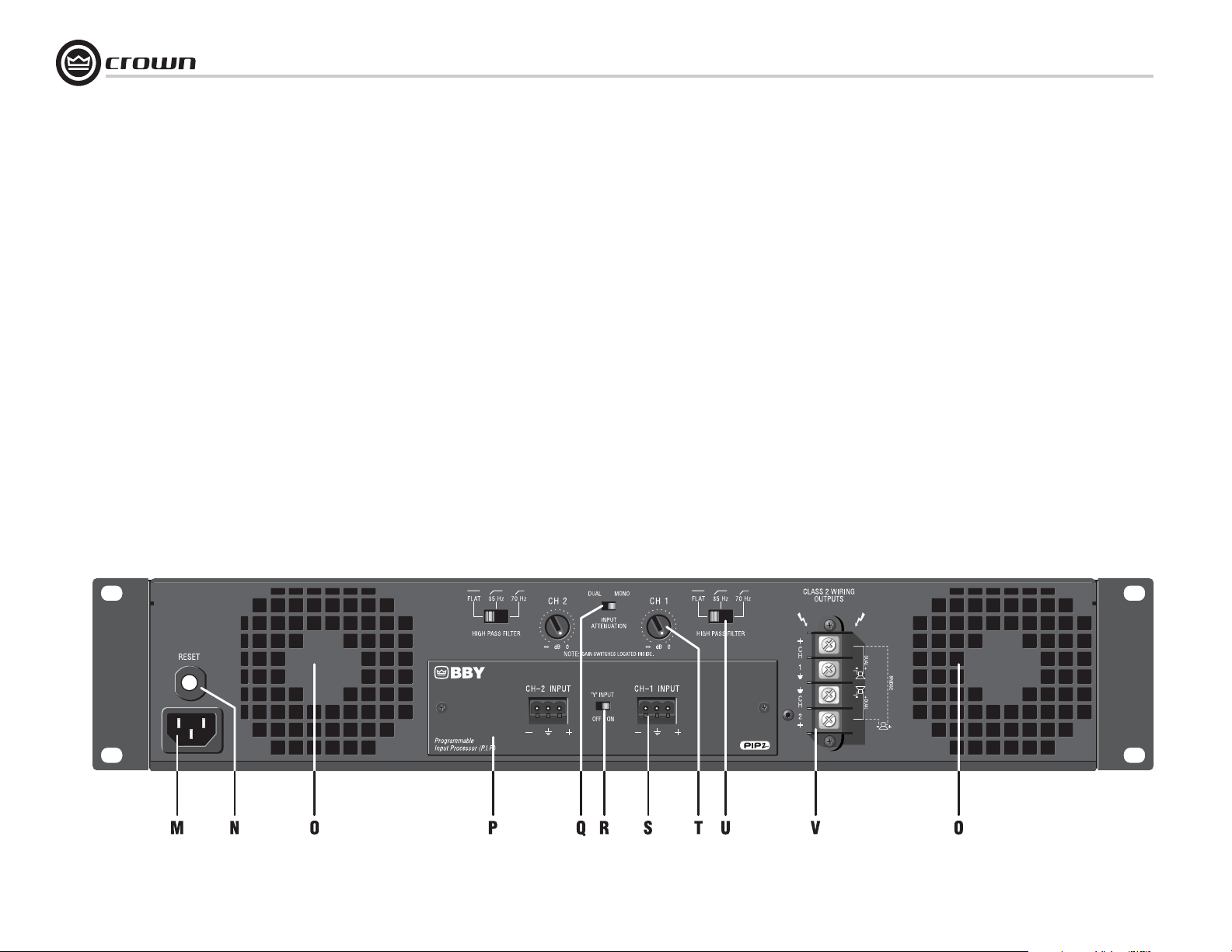

4.3 Back Panel Controls

and Connectors.

CTs 2000/3000 back panel is shown.

CTs 600/1200 look slightly different near

the Reset button.

M. Power Cord Connector

Standard 15 amp IEC inlet. A circuit

breaker located near the IEC power inlet

protects the amplifier from excessive AC

current draw.

N. Reset Switch

Resets the circuit breaker that protects the

power supply.

O. Ventilation Grille

Air flow is front to back. Do not block the

ventilation grilles.

P. PIP ™ Input Panel

PIP2-BBY module includes two balanced

3-pin removable barrier connectors. The

“Y” Input Switch is described under

letter R.

Sensitivity Switches

Behind the input panel are the Input Sensitivity Switches. One 3-position switch per

channel selects various sensitivity settings. See Section 5.2.4 for details and

diagram.

Q. Mode Switch

This two-position switch is used to select

the amplifier’s mode of operation: Dual or

Bridge Mono.

Dual mode is used for 2/4/8 ohms, for 70V

operation with the CTs 600/1200, and for

70/100V operation with the CTs 2000/

3000.

Bridge mode is used for 4/8/16 ohms, for

140V operation with the CTs 600/1200,

and for 100/140/200V operation with the

CTs 2000/3000.

R. “Y” Input Switch

When set to ON, this switch parallels the

input signals of the two channels, for use

when the input signal is mono. The amplifier’s channel outputs are still independent.

The “Y” Input Switch also can be used to

daisy-chain the signal to another amplifier.

See Section 3.6.5 for details.

S. Input Connectors

Balanced 3-pin terminal block connectors,

one per channel.

T. Channel Level Controls

One 21-position detented rotary attenuator

per channel, ranging from –100 dB to 0 dB

gain.

U. High-Pass Filter

One 3-position switch per channel selects

between OFF, 35Hz and 70Hz 3rd-order filters.

V. Speaker Connectors

One four-pole touch-proof terminal strip.

Accepts up to 10 AWG terminal forks.

Output Cover (not shown)

This covers the output connectors, protecting users from the connectors’ potentially high voltage. This cover is required

for Class 2 wiring installations. See Section 3.5 for details on removing covers that

have two holes.

page 14

Figure 4.2 CTs 2000 and 3000 Back Panel Controls and Connectors

Operation Manual

Page 15

CTs 2-Channel Power Amplifiers

5 Advanced Features

and Options

NOTE: For detailed information about

these Crown amplifier features, please

consult the Crown Amplifier Application

Guide, available on the Crown website

at www.crownaudio.com

5.1 Protection Systems

Your Crown amplifier provides extensive protection and diagnostic capabilities, including

thermal level control, fault indicators, highpass filtering, DC protect, AC under/over voltage protection, inrush limiting, and variablespeed fans.

5.1.1 Thermal Level Control (TLC)

If the amplifier becomes too hot for safe operation, the light will shine brightly and TLC will

engage the input compressor. By compressing

the input, the amplifier will not generate as

much heat and will have a chance to cool down.

The degree of compression is proportional to

the amount of overheating. This feature allows

the show to go on, rather than having the

amplifier shut down.

5.1.2 Junction Temperature Simulation (JTS) (CTs 600/1200 only)

JTS circuitry simulates the operation of the

amplifier’s output transistors, and compares it

against the transistors known Safe Operation

Area (SOA). If JTS sees that more power is

about to be asked of the output devices than

they are capable of delivering under the present

conditions, JTS immediately limits the drive

level until it falls within the SOA. Limiting is

proportional and kept to an absolute minimumonly what is required to prevent the possibility

of output transistor damage.

This level of protection enables Crown to

increase output transistor utilization while also

greatly increasing amplifier reliability.

5.1.3 Fault

The amplifier will light the Fault LED if the

amplifier output stage stops operating. If this

happens, see Section 8 for servicing information.

5.1.4 High-Pass Filters

Very low frequency signals contain no useful

musical energy, waste valuable amplifier power

and headroom, and can be damaging to your

speakers. Your Crown amplifier provides highpass filters to remove these signals from each

channel’s output.

On the back panel are two 3-position 3rd-order

high-pass filter switches (one per channel) with

selections of Off, 35Hz and 70 Hz.

5.1.5 Low-Pass Filters

Gaussian-approximation ultrasonic filters prevent ultrasonic feedback and HF burnout in

drivers. This type of filter preserves transient

reponse better than a Butterworth filter.

5.1.6 AC Under/Over Voltage

Protection

If the AC line voltage drops below 25% or rises

above 15% of the nominal operating voltage of

the amplifier, the amplifier’s power supply turns

off and the blue Power LED flashes. The amplifier will turn back on when the AC line voltage

returns to safe operating levels (within +15% /

-25%).

5.1.7 Circuit Breaker

A circuit breaker located near the IEC power

inlet protects the amplifier from excessive AC

current draw.

5.1.8 DC Output Servo

The output servo circuit protects your drivers

by eliminating DC offset, even in the presence

of very large asymmetrical signals.

5.1.9 Inrush Limiting

A soft-start circuit in the power supply minimizes the amplifier’s current draw during

power-on.

5.1.10 Variable-speed Fans

Two continuously variable speed fans direct the

airflow through the amplifier for cooling.

5.2 Advanced Features

5.2.1 Switching Power Supply

Crown’s Switching Power Supply minimizes

the amplifier’s weight.

Typical non-switching power supplies require

large, heavy transformers in order to produce

the required power at the output stage. These

transformers must be large to operate at 50 to

60 Hz (standard AC supplied by the power

company).

By contrast, switching power supplies can

operate with a much smaller (and lighter) transformer because they first convert the AC up to a

much higher frequency, thereby reducing

waste.

The power supply is voltage-specific, allowing

use in regions using 120V or 240V.

5.2.2 Input Compressor

Prevent input/output overload.

5.2.3 Sleep Circuit

Lowers standby power consumption by shutting down the high-voltage supplies during idle

periods.

NOTE: By default, the sleep circuit is not active

on the CTs 600/1200, but may be activated as a

service option.

Operation Manual

page 15

Page 16

5 Advanced Features

and Options

5.2.4 Input Sensitivity Switches

To access the Input Sensitivity Switches, turn off the amplifier and remove the

PIP2-BBY Input Panel. The switches are in the top surface of the cavity behind the

Input Panel. One 3-position switch per channel selects among these settings: CTs

600/1200: 1.4V (8/4 ohms), 26 dB gain, and 1.4V (70V operation). CTs 2000/

3000: 1.4V (8/4 ohms), 26 dB gain, and 1.4V (70V) / 2V (100V). The Specifications

chapter lists the input sensitivity for the 26 dB gain setting.

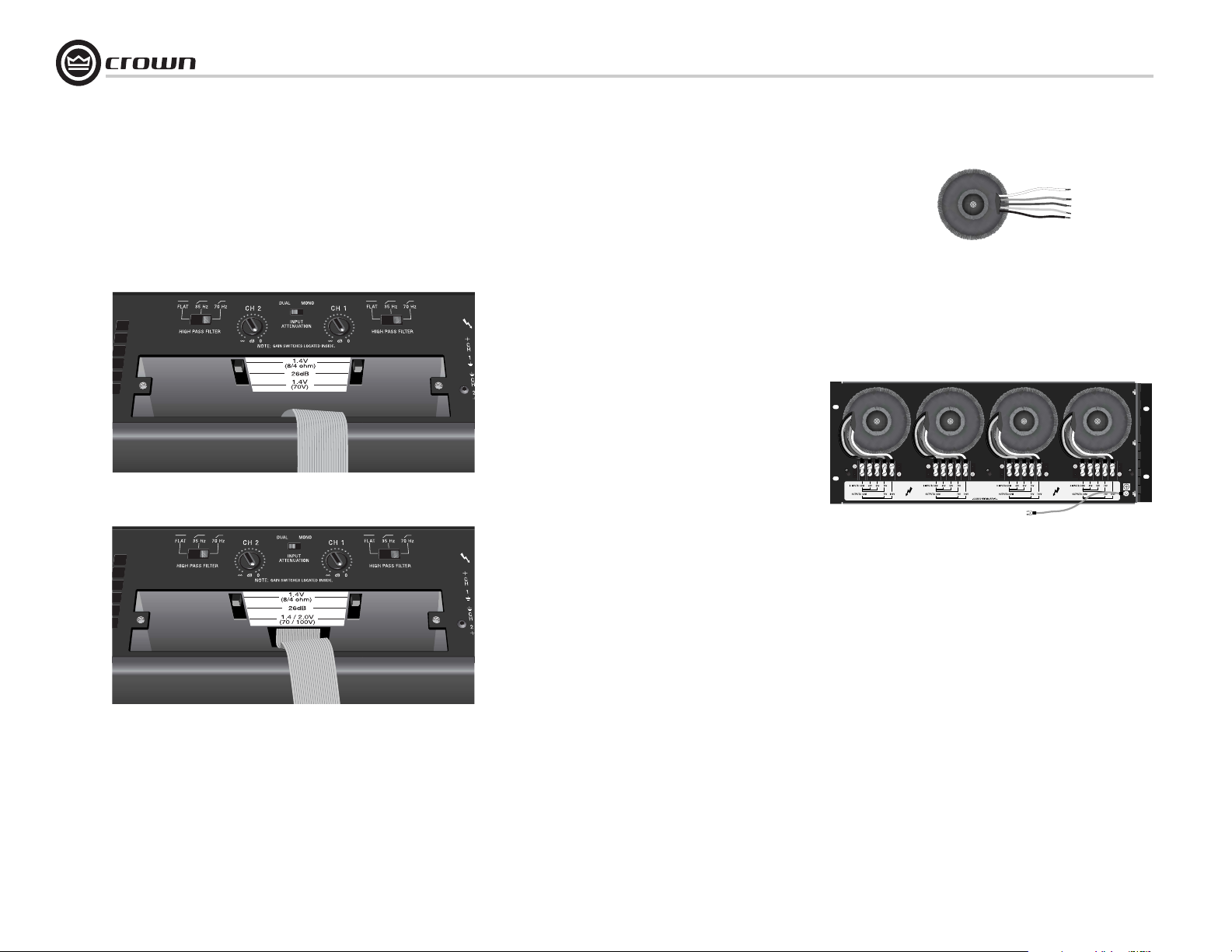

Figure 5.1 Input Sensitivity Switches for CTs 600/1200

5.3 Options

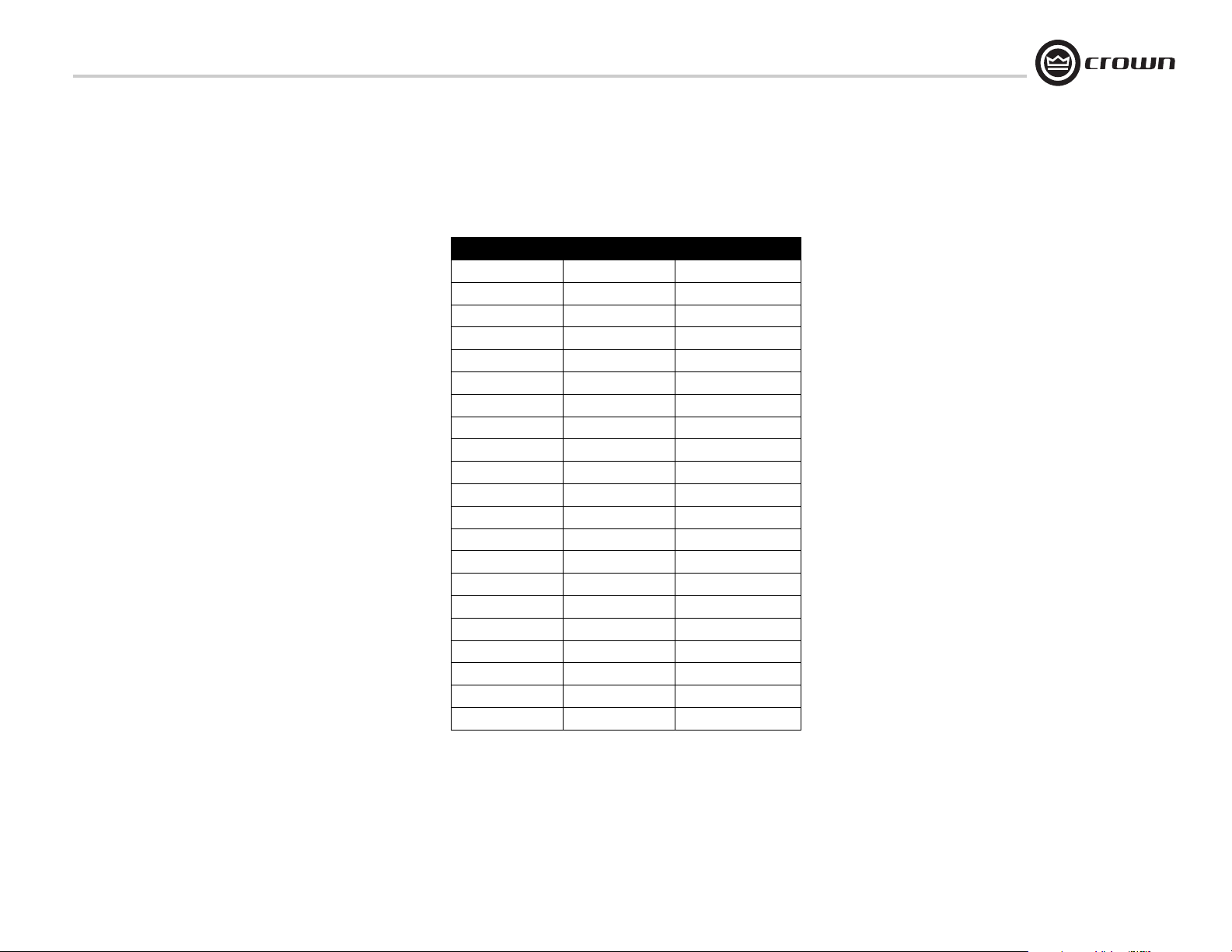

T-170V: See Figure 5.3. This is an autoformer that

allows 100V output from the CTs 600/1200, and

allows other amplifiers without direct constant voltage

output to be easily integrated into distributed systems.

TP-170V: See Figure 5.4. This is a rack-mountable

panel with four autoformers as described above.

PIP Modules

Versatile PIP (Programmable Input Processor) modules provide flexible expansion features that can be

added to customize the amplifier. PIP modules plug

into the connector inside the back panel of the amplifier. PIP modules are available with features ranging

from error-driven compressor/limiters to crossovers to

IQ control. Your amplifier is a PIP2 amplifier, which

means it can take advantage of the many advanced features found in PIP2 modules. The CTs Series 2-channel models do not accept earlier PIP

Visit the Crown website at www.crownaudio.com, or

contact Crown Customer Service, for descriptions of

available PIP and PIP2 modules.

modules.

CTs 2-Channel Power Amplifiers

Figure 5.3 170V

page 16

Figure 5.4 TP-170V (back view)

Figure 5.2 Input Sensitivity Switches for CTs 2000/3000

Operation Manual

Page 17

CTs 2-Channel Power Amplifiers

5 Advanced Features

and Options

5.3.1 Nominal Attenuation Settings

The signal level for each input can be attenuated accurately by

adjusting the 21-step Level Control (see Section 4.3). Figure 5.5

shows the attenuation in dB for each detent. The setting of the

input-sensitivity switch varies the actual attenation as shown.

The accuracy of the attenuation varies with the setting. Expected

tolerances are:

Potentiometer steps 0-6 dB: ± 1 dB

Potentiometer steps 6-12 dB: ± 1.5 dB

Potentiometer steps 12-24 dB: ± 3 dB

Potentiometer steps 24-54 dB: ± 6 dB

Detent 26 dB 4/8 ohm or 70/100V

0 (full CW) 0.0 0.0

10.5 0.5

21.0 1.5

32.0 3.5

43.0 5.0

54.0 6.5

65.0 8.0

76.0 9.5

87.011.0

98.013.0

10 9.0 14.5

11 10.5 16.0

12 12.0 18.0

13 13.5 20.0

14 15.0 22.0

15 18.0 24.0

16 21.0 26.0

17 24.0 30.0

18 36.0 42.0

19 48.0 54.0

20 (full CCW) OFF OFF

Operation Manual

Figure 5.5 Attenuation vs. Detent of Level Controls for CTs 2-Channel Amplifiers

page 17

Page 18

6 Troubleshooting

CTs 2-Channel Power Amplifiers

CONDITION: Power indicator is

off.

POSSIBLE REASON

• The amplifier has lost AC power.

• The amplifier’s Power switch is off.

• The amplifier is not plugged into the

power receptacle.

• The amplifier output level is so high that

the power supply circuit breaker has

tripped. Allow the unit to cool. Turn down

the Level controls. Press the Reset Switch

on the back panel.

CONDITION: Power indicator is

flashing.

POSSIBLE REASON:

• The AC line voltage has dropped below

25% or has risen above 15% of the nominal line voltage of the power supply.

CONDITION: Fault indicator is

flashing.

POSSIBLE REASON:

• The amplifier channel has stopped operating. Refer the unit to an authorized Crown

Service Center.

CONDITION: Distorted sound.

POSSIBLE REASON:

• Load is wired incorrectly or Stereo/Mono

mode switch is set incorrectly. Check both.

• Input is overlaoded by a signal level that is

too high. Turn down your amplifier level

controls, or turn down the input signal, until

the clip light goes out.

Note: If the signal sounds distorted even though

the Clip LED is off, the input signal may be distorted before it reaches the amplifier input. Check

gain staging and output levels of the mixer or

preamp.

page 18

CONDITION: Thermal indicator is

on.

POSSIBLE REASON:

• The amplifier is becoming too hot for safe

operation. Allow amplifier to cool. Check

for loads less than 2 ohms, and for

excessive input levels. Check for proper

ventilation and proper mode-switch setting.

“Off/Flashing/On” above means that

the LED can be off, or flashing, or on.

Operation Manual

Page 19

CTs 2-Channel Power Amplifiers

6 Troubleshooting

CONDITION: No sound, even though

the amp has power. Power LED is on with-

out flashing and the amp is receiving an input signal. Signal indicator is flashing.

POSSIBLE REASON:

• Speakers not connected.

• Open circuit due to speaker failure.

• There is a short on the amplifier output. First

disconnect your speakers from the affected

channel(s) one by one to determine if one of

the loads is shorted.

• Ready LED is off. Channel has been set to

standby mode via the IQ system.

CONDITION: Data indicator not flashing, even though PIP module is

installed and host computer IQ software is active.

POSSIBLE REASON:

• Cable between computer and PIP module is

broken or not connected.

Note: Data indicator flashes only when the installed

PIP2 module is polled for data, or is polled to see

whether it is online.

Operation Manual

CONDITION: No input signal. Signal

indicator is not flashing even though audio is

applied, and the channel is ready..

POSSIBLE REASON:

• Input signal level is very low.

• Level controls are turned down.

“Off/Flashing/On” above means that

the LED can be off, or flashing, or on.

page 19

Page 20

7 Specifications

Minimum Guaranteed Power

(20 Hz - 20 kHz)

2-ohm Dual (per ch.) 150W 250W 1000W 1500W

4-ohm Dual (per ch.) 300W 600W 1000W 1500W

8-ohm Dual (per ch.) 300W 600W 1000W 1250W

16-ohm Dual (per ch.) 300W 300W 625W 625W

70V Dual (per ch.) 300W 600W 1000W 1500W

100V Dual (per ch.) 300W* 600W* 1000W 1500W

4-ohm Bridge 300W 500W 2000W 3000W

8-ohm Bridge 600W 1200W 2000W 3000W

16-ohm Bridge 600W 1200W 2000W 2500W

100V Bridge 600W* 1200W* 2000W 3000W

140V Bridge 600W 1200W 2000W 3000W

200V Bridge 600W* 1200W* 2000W 3000W

Performance CTs 600 CTs 1200 CTs 2000 CTs 3000

Frequency Response (at 1 watt, 20 Hz - 20 kHz) ± 0.25 dB ± 0.25 dB ± 0.25 dB ± 0.25 dB

Signal to Noise Ratio (ref. rated power, 20 Hz to 20 kHz, A-weighted) < 105 dB < 105 dB < 105 dB < 105 dB

Total Harmonic Distortion (THD) at full rated power, from 20 Hz to 20 kHz < 0.1% < 0.1% < 0.35% < 0.35%

Intermodulation Distortion (IMD) 60 Hz and 7 kHz at 4:1, from –40 dB to

full rated power

Damping Factor:

10 Hz to 100 Hz > 3000 > 3000 > 3000 > 3000

Crosstalk (below rated power)

20 Hz to 1kHz > 80 dB > 80 dB > 80 dB > 80 dB

Common Mode Rejection (CMR) (20 Hz to 1 kHz, typical) 50 dB 50 dB 50 dB 50 dB

DC Output Offset < 2 mV < 2mV < 2 mV < 2 mV

Input Impedance nominally balanced, nominally unbalanced 10 k ohms, 5 k ohms 10 k ohms, 5 k ohms 10 k ohms, 5 k ohms 10 k ohms, 5 k ohms

CTs 2-Channel Power Amplifiers

CTs 600

Power at 0.1% THD

< 0.1% < 0.1% < 0.35% < 0.35%

CTs 1200

Power at 0.1% THD

CTs 2000

Power at 0.35% THD

CTs 3000

Power at 0.35% THD

page 20

* With T-170V or TP-170V.

Operation Manual

Page 21

CTs 2-Channel Power Amplifiers

7 Specifications

Performance CTs 600 CTs 1200 CTs 2000 CTs 3000

Maximum Input Level

Before input compression

Absolute maximum

Load Impedance (Note: Safe with all types of loads)

Stereo

+20 dBu

+ 32 dBu

2, 4, 8, 16 ohms and 70V

+20 dBu

+ 32 dBu

2, 4, 8, 16 ohms and 70V

+20 dBu

+ 32 dBu

2, 4, 8, 16, 70V,

and 100V

+20 dBu

+ 32 dBu

2, 4, 8, 16, 70V,

and 100V

Bridge Mono

Voltage Gain (at maximum level setting)

8/4 Ohm Operation

26 dB

70V Operation

100V Operation

Input Sensitivity

2/4/8 ohms

70V

100 V

26 dB gain

Required AC Mains (+15%, – 25%) 120V/60 Hz, 230V/50 Hz 120V/60 Hz, 230V/50 Hz 120V/60 Hz, 230V/50 Hz 120V/60 Hz, 230V/50 Hz

Power Draw at Idle (120 VAC mains) 24W (Standby Mode) 24W (Standby Mode) 35W (Standby Mode) 35W (Standby Mode)

Overall Group Delay < 120 usec < 120 usec < 120 usec < 120 usec

Cooling Continuously variable speed

Dimensions

Width

Height

Depth

Net Weight

Shipping Weight

4, 8, 16 and 140V

35:1 (31 dB)

20:1 (26 dB)

50:1 (34 dB)

1.4V

1.4V

4 ohm load: 1.74V.

8 ohm load: 2.46V

forced air, front-to-back airflow

19 in. (48.3 cm.)

3.5 in. (8.9 cm.)

14.25 in. (36.2 cm.)

22.8 lb (10.3 kg),

27.7 lb (12.6 kg)

4, 8, 16 and 140V

50:1 (34 dB)

20:1 (26 dB)

50:1 (34 dB)

1.4V

1.4V

4 ohm load: 2.46V.

8 ohm load: 3.47V

Continuously variable speed

forced air, front-to-back airflow

19 in. (48.3 cm.)

3.5 in. (8.9 cm.)

14.25 in. (36.2 cm.)

23.4 lb (10.6 kg),

2 8 . 3 l b ( 1 2 . 8 k g )

4, 8, 16, 140V , 200V

63.9:1 (36 dB)

20:1 (26 dB)

50:1 (34 dB)

50:1 (34 dB)

1.4V

1.4V

2.0V

4 ohm load: 3.17V.

8 ohm load: 4.48V

Continuously variable speed

forced air, front-to-back airflow

19 in. (48.3 cm.)

3.5 in. (8.9 cm.)

14.25 in. (36.2 cm.)

27.0 lb (12.2 kg)

32.0 lb (14.5 kg)

4, 8, 16, 140V, 200V

71.4:1 (37 dB)

20:1 (26 dB)

50:1 (34 dB)

50:1 (34 dB)

1.4V

1.4V

2.0V

4 ohm load: 3.88V.

8 ohm load: 5.01V

Continuously variable speed

forced air, front-to-back airflow

19 in. (48.3 cm.)

3.5 in. (8.9 cm.)

14.25 in. (36.2 cm.)

27.7 lb (12.6 kg)

32.7 lb (14.8 kg)

Operation Manual

page 21

Page 22

7 Specifications

CTs 2-Channel Power Amplifiers

page 22

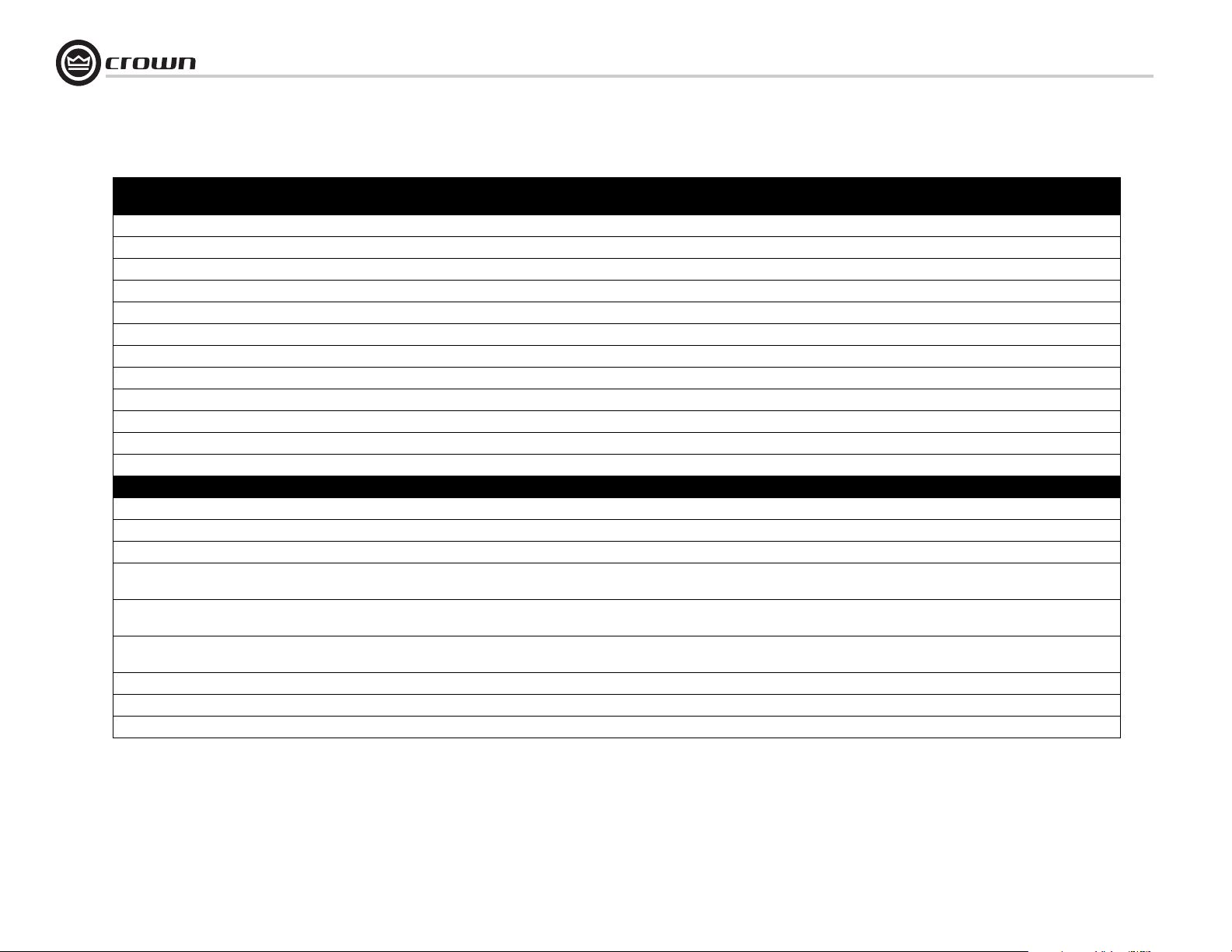

Figure 7.1 CTs 600/1200 Typical Frequency Response (1 W, 8 ohms)

Figure 7.3

CTs 600/1200

Typical Damping Factor

vs. Frequency

Figure 7.2 CTs 600/1200 Typical Crosstalk vs. Frequency

Operation Manual

Page 23

CTs 2-Channel Power Amplifiers

7 Specifications

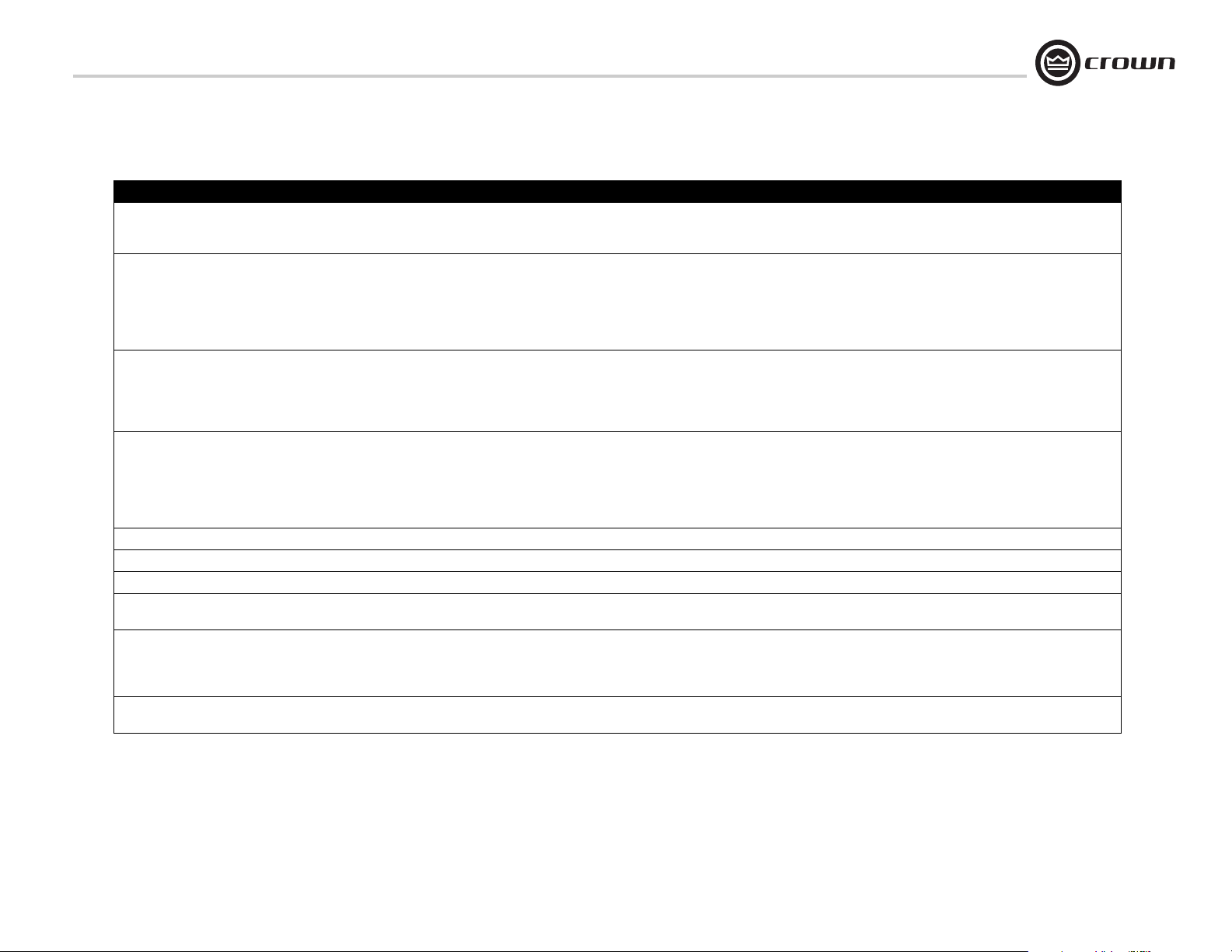

Figure 7.4 CTs 2000/3000 Typical Frequency Response (1W)

Operation Manual

Figure 7.5 CTs 2000/3000 Typical Crosstalk vs. Frequency

Figure 7.6

CTs 2000/3000

Typical Damping Factor

vs. Frequency

page 23

Page 24

8 Service

CTs 2-Channel Power Amplifiers

Crown amplifiers are quality units that rarely require

servicing. Before returning your unit for servicing,

please contact Crown Technical Support to verify

the need for servicing.

This unit has very sophisticated circuitry which

should only be serviced by a fully trained technician. This is one reason why each unit bears the following label:

CAUTION: To prevent electric shock, do not

remove covers. No user serviceable parts

inside. Refer servicing to a qualified technician.

8.1 Worldwide Service

Service may be obtained from an authorized service

center. (Contact your local Crown/Amcron representative or our office for a list of authorized service

centers.) To obtain service, simply present the bill of

sale as proof of purchase along with the defective

unit to an authorized service center. They will handle

the necessary paperwork and repair.

Remember to transport your unit in the original factory pack.

8.2 US and Canada Service

Service may be obtained in one of two ways: from

an authorized service center or from the factory. You

may choose either. It is important that you have your

copy of the bill of sale as your proof of purchase.

8.2.1 Service at a US or Canada Service Center

This method usually saves the most time and effort.

Simply present your bill of sale along with the

defective unit to an authorized service center to

obtain service. They will handle the necessary

paperwork and repair. Remember to transport the

unit in the original factory pack. A list of authorized

service centers in your area can be obtained from

the Crown website at www.crownaudio.com, or by

calling Crown Factory Service.

8.2.2 Factory Service

To obtain factory service, fill out the service

information page found in the back of this manual and send it along with your proof of pur-

chase and the defective unit to the Crown

factory.

For warranty service, we will pay for ground shipping both ways in the United States. Contact Crown

Factory Service to obtain prepaid shipping labels

prior to sending the unit. Or, if you prefer, you may

prepay the cost of shipping, and Crown will reimburse you. Send copies of the shipping receipts to

Crown to receive reimbursement.

Your repaired unit will be returned via UPS ground.

Please contact us if other arrangements are

required.

8.2.3 Factory Service Shipping

Instructions:

1. Before sending a Crown product to the factory

for service, first call the Crown Service Department for a return authorization (RA) number.

2. Be sure to fill out the service information form

that follows and enclose it with your shipment,

either inside the box or in a packing slip envelope securely attached to the outside of the

shipping carton. Do not send the service information form separately. If you are sending the

unit from a Shipping Center, we recommend

taping the form to the product. We also recommend recording the serial number and model

before shipping for your reference.

3. Keep a copy of the serial number and model.

To ensure the safe transportation of your unit to

the factory, ship it in an original factory packing

container. If you don’t have the original carton,

you may obtain a product service foam-inplace shipping pack from Crown Factory Service at the number listed below. For non-warranty service, you may also provide your own

shipping pack, however we still recommend

using a Crown Supplied Shipping Container.

Minimum recommended requirements for

materials are as follows: 275 P.S.I. burst test

Double-Wall carton that allows for 2-inch solid

Styrofoam on all six sides of unit or 3 inches of

plastic bubble wrap on all six sides of unit;

securely seal the package with an adequate car-

ton sealing tape. Do not use light boxes or

“peanuts.” Damage caused by poor packing

cannot be covered under warranty.

4. Do not ship the unit in any kind of cabinet

(wood or metal). Ignoring this warning may

result in extensive damage to the unit and the

cabinet. Accessories are not needed—do not

send the product documentation, cables and

other hardware.

If you have any questions, please contact Crown

Factory Service.

Crown Factory Service

1718 W. Mishawaka Rd.,

Elkhart, Indiana 46517 U.S.A.

Telephone: 574-294-8200

800-342-6939 (North America,

Puerto Rico, and Virgin Islands only)

Facsimile:

574-294-8301 (Technical Support)

574-294-8124 (Factory Service)

Internet:

http://www.crownaudio.com

8.2.4 Crown’s Profit Protection Plan

In the United States, your CTs series amplifier is

also covered by Crown’s advance-replacement

Profit Protection Plan, an enhancement to Crown’s

exceptional Three-Year, No-Fault, Full Warranty.

Crown’s Profit Protection Plan guarantees replacement of your covered amplifier should it fail at any

time during the original three-year warranty period

following the date of original purchase.

Simply contact your local Crown dealer or distributor with model and serial number information to initiate a claim. Your dealer will supply full details on

return procedures for the defective unit as well as

standard and optional delivery times and methods

for the replacement amplifier. Before any claim will

be honored, Crown Factory Service will verify that

there is a problem with the unit.

For more information on the Profit Protection Plan,

please contact Crown Factory Service or your local

Crown representative.

page 24

Operation Manual

Page 25

CTs 2-Channel Power Amplifiers

YEAR

3

9 Warranty

UNITED STATES & CANADA

SUMMARY OF WARRANTY

Crown International, 1718 West Mishawaka

Road, Elkhart, Indiana 46517-4095 U.S.A. warrants to you, the ORIGINAL PURCHASER and

ANY SUBSEQUENT OWNER of each NEW Crown

product, for a period of three (3) years from the

date of purchase by the original purchaser (the

“warranty period”) that the new Crown product is

free of defects in materials and workmanship. We

further warrant the new Crown product regardless of the reason for failure, except as excluded

in this Warranty.

ITEMS EXCLUDED FROM THIS

CROWN WARRANTY

This Crown Warranty is in effect only for failure of

a new Crown product which occurred within the

Warranty Period. It does not cover any product

which has been damaged because of any intentional misuse, accident, negligence, or loss which

is covered under any of your insurance contracts.

This Crown Warranty also does not extend to the

new Crown product if the serial number has been

defaced, altered, or removed.

WHAT THE WARRANTOR WILL DO

We will remedy any defect, regardless of the reason for failure (except as excluded), by repair,

replacement, or refund. We may not elect refund

unless you agree, or unless we are unable to provide replacement, and repair is not practical or

cannot be timely made. If a refund is elected,

then you must make the defective or malfunctioning product available to us free and clear of

all liens or other encumbrances. The refund will

be equal to the actual purchase price, not includ-

ing interest, insurance, closing costs, and other

finance charges less a reasonable depreciation

on the product from the date of original purchase. Warranty work can only be performed at

our authorized service centers or at the factory.

Warranty work for some products can only be

performed at our factory. We will remedy the

defect and ship the product from the service center or our factory within a reasonable time after

receipt of the defective product at our authorized

service center or our factory. All expenses in

remedying the defect, including surface shipping

costs in the United States, will be borne by us.

(You must bear the expense of shipping the

product between any foreign country and the port

of entry in the United States including the return

shipment, and all taxes, duties, and other customs fees for such foreign shipments.)

HOW TO OBTAIN WARRANTY

SERVICE

You must notify us of your need for warranty service within the warranty period. All components

must be shipped in a factory pack, which, if

needed, may be obtained from us free of charge.

Corrective action will be taken within a reasonable time of the date of receipt of the defective

product by us or our authorized service center. If

the repairs made by us or our authorized service

center are not satisfactory, notify us or our authorized service center immediately.

DISCLAIMER OF CONSEQUENTIAL

AND INCIDENTAL DAMAGES

YOU ARE NOT ENTITLED TO RECOVER FROM

US ANY INCIDENTAL DAMAGES RESULTING

FROM ANY DEFECT IN THE NEW CROWN

PRODUCT. THIS INCLUDES ANY DAMAGE TO

ANOTHER PRODUCT OR PRODUCTS RESULTING FROM SUCH A DEFECT. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATIONS

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WARRANTY ALTERATIONS

No person has the authority to enlarge, amend,

or modify this Crown Warranty. This Crown

Warranty is not extended by the length of time

which you are deprived of the use of the new

Crown product. Repairs and replacement parts

provided under the terms of this Crown Warranty shall carry only the unexpired portion of

this Crown Warranty.

DESIGN CHANGES

We reserve the right to change the design of any

product from time to time without notice and with

no obligation to make corresponding changes in

products previously manufactured.

LEGAL REMEDIES OF PURCHASER

THIS CROWN WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, YOU MAY ALSO HAVE

OTHER RIGHTS WHICH VARY FROM STATE TO

STATE. No action to enforce this Crown Warranty shall be commenced after expiration of the

warranty period.

THIS STATEMENT OF WARRANTY SUPERSEDES

ANY OTHERS CONTAINED IN THIS MANUAL

FOR CROWN PRODUCTS 12/01

Operation Manual

page 25

Page 26

CTs 2-Channel Power Amplifiers

YEAR

3

9 Warranty

SUMMARY OF WARRANTY

Crown International, 1718 West Mishawaka Road,

Elkhart, Indiana 46517-4095 U.S.A. warrants to

you, the ORIGINAL PURCHASER and ANY SUBSEQUENT OWNER of each NEW Crown1 product,

for a period of three (3) years from the date of purchase by the original purchaser (the “warranty

period”) that the new Crown product is free of

defects in materials and workmanship, and we

further warrant the new Crown product regardless

of the reason for failure, except as excluded in this

Warranty.

1 Note: If your unit bears the name “Amcron,” please substitut e

it for the name “Crown” in this warranty.

ITEMS EXCLUDED FROM THIS

CROWN WARANTY

This Crown Warranty is in effect only for failure

of a new Crown product which occurred within

the Warranty Period. It does not cover any product which has been damaged because of any

intentional misuse, accident, negligence, or loss

which is covered under any of your insurance

contracts. This Crown Warranty also does not

extend to the new Crown product if the serial

number has been defaced, altered, or removed.

WORLDWIDE EXCEPT USA & CANADA

WHAT THE WARRANTOR WILL DO

We will remedy any defect, regardless of the reason for failure (except as excluded), by repair,

replacement, or refund. We may not elect refund

unless you agree, or unless we are unable to provide replacement, and repair is not practical or

cannot be timely made. If a refund is elected, then

you must make the defective or malfunctioning

product available to us free and clear of all liens

or other encumbrances. The refund will be equal

to the actual purchase price, not including interest, insurance, closing costs, and other finance

charges less a reasonable depreciation on the

product from the date of original purchase. Warranty work can only be performed at our authorized service centers. We will remedy the defect

and ship the product from the service center

within a reasonable time after receipt of the defective product at our authorized service center.

HOW TO OBTAIN WARRANTY

SERVICE

You must notify your local Crown importer of

your need for warranty service within the warranty

period. All components must be shipped in the

original box. Corrective action will be taken within

a reasonable time of the date of receipt of the

defective product by our authorized service center.

If the repairs made by our authorized service center are not satisfactory, notify our authorized service center immediately.

DISCLAIMER OF CONSEQUENTIAL

AND INCIDENTAL DAMAGES

YOU ARE NOT ENTITLED TO RECOVER FROM US

ANY INCIDENTAL DAMAGES RESULTING FROM

ANY DEFECT IN THE NEW CROWN PRODUCT.

THIS INCLUDES ANY DAMAGE TO ANOTHER

PRODUCT OR PRODUCTS RESULTING FROM

SUCH A DEFECT.

WARRANTY ALTERATIONS

No person has the authority to enlarge, amend, or

modify this Crown Warranty. This Crown Warranty

is not extended by the length of time which you are

deprived of the use of the new Crown product.

Repairs and replacement parts provided under the

terms of this Crown Warranty shall carry only the

unexpired portion of this Crown Warranty.

DESIGN CHANGES

We reserve the right to change the design of any

product from time to time without notice and with

no obligation to make corresponding changes in

products previously manufactured.

LEGAL REMEDIES OF PURCHASER

No action to enforce this Crown Warranty shall be

commenced after expiration of the warranty period.

THIS STATEMENT OF WARRANTY SUPERSEDES

ANY OTHERS CONTAINED IN THIS MANUAL FOR

CROWN PRODUCTS. 7/01

page 26

Operation Manual

Page 27

CTs 2-Channel Power Amplifiers

Crown Factory Service Information

Shipping Address: Crown Factory Service, 1718 W. Mishawaka Rd., Elkhart, IN 46517

Phone: 1-800-342-6939 or 1-574-294-8200 Fax: 1-574-294-8124

Owner’s Name : ________________________________________________________________________________________________________________________________________________________________

Shipping Address: ______________________________________________________________________________________________________________________________________________________________

Phone Number: ________________________________Fax Number: ________________________________ Email ________________________________________________________________________________

Model: __________________________________________________________________________________ Serial Number: ________________________________________________________________________

Purchase Date : ________________________________________________________________________________________________________________________________________________________________

NATURE OF PROBLEM

(Be sure to describe the conditions that existed when the problem occurred and what attempts were made to correct it.)

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

Other equipment in system: ___________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________

If warranty has expired, payment will be: ! Cash/Check ! Visa ! Master Card ! C.O.D. ! Purchase Order for Crown Dealer

Card Number:___________________________________ Exp. Date:___________________

Signature:______________________________________________________________________

ENCLOSE THIS PORTION WITH THE UNIT. DO NOT MAIL SEPARATELY.

Operation Manual

page 27

Page 28

Page 29

Addendum To Operation Manual

Note: This addendum pertains to Section 3 - Setup

Section 5 - Advanced Features and Options

Section 9 - Service

2561953A

REV. A Printed 8/03

Printed in U.S.A.

It is important that you review this addendum

before reviewing the Operation

Manual.

Section 3

With reference to the DUAL/MONO mode switch:

Dual mode allows each amplifier channel to operate independently like a stereo amplifier.

Installation is intuitive - input Channel 1 feeds output Channel 1 and input Channel 2 feeds

output Channel 2. To put the amplifier into the Dual mode, turn it off, slide the DUAL/

MONO switch to DUAL, and properly connect the output wiring.

The MONO switch setting is the BRIDGE-MONO mode and is used to drive loads with a

total impedance of at least 4 ohms. For distributed loudspeaker systems, 140 volts (twice the

normal 70- volt output) is produced. To put the amplifier into the Bridge-Mono mode, turn it

off, and slide the DUAL/MONO switch to MONO. Both outputs will receive the signal from

Channel 1 with the output of Channel 2 inverted so it can be bridged with the Channel 1

output. Please note that there is no provision for paralleling the outputs to obtain a

single high-powered 70-volt constant voltage output.

Section 5

Federal Signal will not offer the T- 170V, TP- 170V, or PIP Modules as indicated in Section

5.3 -Options.

Section 9

For any service related issues, please contact Crown Technical Support. Return the unit to

Crown Factory Service, or to a Crown authorized service center if repairs need to be made.

Page 30

MODELS AR2000-M, AR2000-P AND AR2000-Z

AUDIO ROUTER DEVICES

2561533C

REV. C 12/01

Printed in U.S.A.

INSTALLATION AND SERVICE INSTRUCTIONS

Page 31

INSTALLATION AND SERVICE INSTRUCTIONS

FOR

MODELS AR2000-M, AR2000-P AND AR2000-Z, AUDIO ROUTER DEVICES

SAFETY MESSAGE TO INSTALLERS

People’s safety depends on your safe installation

of our products. It is important to read, understand

and follow all instructions shipped with this product.

Selection of mounting location for this device, its

controls and routing of wiring should be made by the

Facilities Engineer and the Safety Engineer. Listed

below are other important safety instructions and

precautions you should follow.

• This unit must be installed and maintained

by a qualified electrician in accordance with

the National Electrical Code (NFPA 70) or

other national or local codes, under the

direction of the local authority having jurisdiction.

• Do not connect this unit to system wiring

when circuits are energized.

• For optimum sound distribution do not

overload the output lines.

• All audio devices produce loud sounds which,

in certain circumstances, may cause permanent hearing loss. Take appropriate precautions such as wearing hearing protection.

Recommendations in OSHA Sound Level

Standard (29 CFR 1910) should not be exceeded.

• After installation and completion of initial

system test, provide a copy of this instruction

sheet to all personnel responsible for operation, periodic testing and maintenance of this

equipment.

I. GENERAL.

1-1. GENERAL DESCRIPTION.

This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

The Model AR2000-M (see figure 1-1) Audio

Router, is a UL listed and cUL certified central

control device that is capable of routing a selected

audio input to specific zones. It can control signals to

speakers designed for 25Vrms line operation or

70Vrms line operation. It can also control 1Vrms

signals intended to be amplified with a separate

amplification device. The AR2000-M has a public

address (PA) function so voice messages or instructions can be announced over the Audio Router system

through an optional Model MSB-1 or MNC-1 Micro-

phone. The unit can also be used to play background

music generated from an external source over the

Audio Router system.

The Model AR2000-M is an audio multiplexing

device. It is capable of handling two inputs from any

of three different selected source voltages of 1, 25 or

70 volts. The unit has 8 selectable zones which either

the A or the B source is routed to. There is an all call

button that selects all zones. There are also 8 programmable presets on the unit. The presets are

initiated by the front panel buttons or by remote

contacts wired to the back panel. The front panel

also has a monitor speaker jack. A microphone jack

is also available for use with a MSB-1. The microphone has priority over the two user supplied

sources. The telephone feature is protected by an 8

key password. Options available allow changing the

password and recording a message for broadcasting.

Commands entered via the telephone key pad allow

the user to send a message to specified zones. The