Page 1

Micro-Tech 2400 Amplifier Service Manual

POWER AMPLIFIER

SERVICE MANUAL

MICRO-TECH®-2400

©1995 by CROWN INTERNATIONAL, INC.

Mailing Address:

P.O. Box 1000

Elkhart, IN U.S.A. 46515-1000

Shipping Address:

57620 C.R. 105

Elkhart, IN U.S.A. 46517

Micro-Tech®, ODEP® and Crown® are registered trademarks of Crown International, Inc.

K-SVCMT24

7-95

1

Page 2

Micro-Tech 2400 Amplifier Service Manual

The information furnished in this manual does not include all of the details of design, production, or variations

of the equipment. Nor does it cover every possible situation which may arise during installation, operation or

maintenance. If you need special assistance beyond the scope of this manual, please contact the Crown

Technical Support Group.

Mail: P.O. Box 1000 Elkhart IN 46515-1000

Shipping: 57620 C.R. 105 Elkhart IN 46517

Phone: (800) 342-6939/(219) 294-8200

FAX: (219) 294-8301

CAUTION

TO PREVENT ELECTRIC SHOCK DO

NOT REMOVE TOP OR BOTTOM

COVERS. NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE

PERSONNEL. DISCONNECT

POWER CORD BEFORE REMOVING

REAR INPUT MODULE TO ACCESS

GAIN SWITCH.

WARNING

TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT EXPOSE THIS

EQUIPMENT TO RAIN OR MOISTURE!

AVIS

À PRÉVENIR LE CHOC

ÉLECTRIQUE N’ENLEVEZ

PAS LES COUVERTURES.

RIEN DES PARTIES

UTILES À L’INTÉRIEUR.

DÉBRANCHER LA BORNE

AVANT D’OUVRIR LA

MODULE EN ARRIÈRE.

2

Page 3

Micro-Tech 2400 Amplifier Service Manual

Table of Contents

Introduction .............................................................4

Scope......................................................................4

Warranty..................................................................4

Parts Information ..................................................... 5

Specifications..........................................................6

Voltage Conversion ................................................. 7

Circuit Theory .......................................................... 8

Electrical Checkout Procedures............................13

Parts List (Non-Module) ........................................ 16

Module Information ...............................................19

M46330-3 Fuse Module ........................................ 20

Q43327-8 Display Module .................................... 20

Q43354-2 Output Module .....................................21

Q43328-6 Main Module.........................................22

Q43399-7 Main Module.........................................26

3

Page 4

Micro-Tech 2400 Amplifier Service Manual

Introduction

This manual contains service information on Crown

power amplifiers. It is designed to be used in conjunction with the applicable Owner's Manual. However,

some important information is duplicated in this Service Manual in case the Owner's Manual is not readily

available.

NOTE: THE INFORMATION IN THIS MANUAL IS INTENDED

FOR USE BY AN EXPERIENCED TECHNICIAN ONLY!

SCOPE

This Service Manual includes several sections. These

sections include Parts Information, Specifications,

Voltage Conversion, Circuit Theory, Electrical Test

Procedures, Non-Module Parts Lists, and Module

Parts Lists. Schematics are attached. Note that component parts with circuit board comprise a complete

module. Module part numbers are always associated

with a specific circuit board, although an unpopulated

circuit board may be built up with different parts to

create different modules. Note that Crown does not

sell blank (unpopulated) circuit boards.

Each of the compact audio power amplifiers are

designed for professional or commercial use. Providing high power amplification from 20Hz to 20KHz with

minimum distortion, they feature balanced inputs with

bridged and parallel monophonic capability. Specific

features vary depending on model family.

WARRANTY

Each Owner's Manual contains basic policies as related to the customer. In addition it should be stated

that this service documentation is meant to be used

only by properly trained service personnel. Because

most Crown products carry a 3 Year Full Warranty

(including round trip shipping within the United States),

all warranty service should be referred to the Crown

Factory or Authorized Warranty Service Center. See

the applicable Owner’s Manual for warranty details. To

find the location of the nearest Authorized Service

Center or obtain instructions for receiving Crown Factory Service please contact the Crown Technical Support Group (within North America) or your Crown/

Amcron Importer (outside North America).

Crown

Technical Support Group

Factory Service

Parts Department

Mailing Address:

PO Box 1000

Elkhart, IN USA 46515-1000

Shipping Address:

57620 C.R. 105

Elkhart, IN USA 46517

Phone: (219) 294-8200

Toll Free: (800) 342-6939

FAX: (219) 294-8301

4

Page 5

Micro-Tech 2400 Amplifier Service Manual

Parts Information

GENERAL INFORMATION

Later sections include both mechanical and electrical

parts lists for this product. The parts listed are current

as of the date printed. Crown reserves the right to

modify and improve its products for the benefit of its

customers.

PART NUMBERING SYSTEMS

As of the printing of this manual, Crown is using two

numbering systems. The elder system always uses

eight characters. The first character is a letter. Common letters used are C, D, H, M, P, and Q. The second

through sixth characters are numbers. The numbers

build sequentially (for each prefix letter) as new parts

are added to our parts inventory system. (In some

cases there will be a space then a four character

number after the prefix letter; the space is considered

a character.) The seventh character is usually a hyphen, though it may be a letter to indicate a revision or

special note. The last character is called a check-digit,

and is useful to Crown for internal tracking.

Crown is in the process of converting to a new part

number system. Length may vary from eight to twelve

characters. There is still a letter prefix, then five

numbers. These five numbers identify a type of part.

The seventh character is a hyphen. Remaining characters identify the details of the type of part identified

by the first part of the number.

STANDARD AND SPECIAL PARTS

Many smaller electrical and electronic parts used by

Crown are stocked by and available from electronic

supply houses. However, some electronic parts that

appear to be standard are actually special. A part

ordered from Crown will assure an acceptable replacement. Structural items such as modules and

panels are available from Crown only.

shipment on a C.O.D. or pre-payment (check or credit

card) basis.

TERMS

Normal terms are pre-paid. Net-30 Days applies to

only those firms having pre-established accounts with

Crown. If pre-paying, the order must be packed and

weighed before a total bill can be established, after

which an amount due will be issued and shipment

made upon receipt of pre-payment. New parts returned for credit are subject to a 10% re-stocking fee,

and authorization from the Crown Parts Department

must be obtained before returning parts for credit.

Crown is not a general parts warehouse. Parts sold by

the Crown Parts Department are solely for servicing

Crown/Amcron products. Part prices and availabil-

ity are subject to change without notice.

Crown

Parts Department

Mailing Address:

PO Box 1000

Elkhart, IN USA 46515-1000

Shipping Address:

57620 C.R. 105

Elkhart, IN USA 46517

ORDERING PARTS

When ordering parts, be sure to give the product

model, and include a description and part number

(CPN/DPN) from the parts listing. Price quotes are

available on request.

SHIPMENT

Shipment will be normally made by UPS or best other

method unless you specify otherwise. Shipments are

made to and from Elkhart, Indiana USA, only. Established accounts with Crown will receive shipment

freight prepaid and will be billed. All others will receive

Phone: (219) 294-8210

or: (219) 294-8211

Toll Free: (800) 342-6939

FAX: (219) 294-8301

5

Page 6

Micro-Tech 2400 Amplifier Service Manual

Specifications

Unless noted otherwise, all specifications are based

on driving an 8 ohm load per channel, both channels

driven, the sensitivity switch in the 26dB position, the

AC supply is 120VAC at 60Hz. Crown specifications

are guaranteed through the warranty period (normally

3 years). Because our testing methods are more stringent than our published specifications, every Crown

amplifier will exceed its published specifications.

POWER

Power

8 Ohm Stereo—520W/Ch

4 Ohm Stereo—800W/Ch

2 Ohm Stereo—1050W/Ch

8 Ohm Bridge Mono—1585W

4 Ohm Bridge Mono—2070W

2 Ohm Parallel Mono—1530W

1 Ohm Parallel Mono—2080W

Load Impedances: Rated for 16, 8, 4, 2, and 1 (parallel

mono only) Ohm operation; safe with all types of loads,

even totally reactive loads.

AC Mains: 120VAC at 60 Hz with standard three-wire

grounded connector for North American units; 100VAC,

120VAC, 220VAC, and 240VAC at 50 or 60 Hz when

equipped with universal transformers, applicable fan

assembly, and other applicable hardware with country specific power cord.

PERFORMANCE

Frequency Response: ±0.1dB from 20 Hz to 20 kHz at 1

Watt.

Phase Response: ±10° from 10 Hz to 20 kHz at 1 Watt.

Signal to Noise Ratio: A-weighted, better than 105 dB

below full rated output. Better than 100 dB below full

rated output from 20 Hz to 20 kHz.

Total Harmonic Distortion (THD): <0.05% from 20 Hz to

1 kHz, increasing linearly to 0.1% at 20 kHz at 500W.

I.M. Distortion: <0.05% from less than 164 milliwatts to

520 W at 26 dB gain.

Slew Rate: >13V per microsecond. (Slew rates are

limited to useful levels for ultrasonic/RF protection.)

Damping Factor: >1000 from 10 Hz to 400 Hz.

DC Offset: <10 millivolts.

Input Impedance: Nominally 20K ohms balanced; 10K

ohms unbalanced.

Output Impedance: <10 milliohms in series with <2

microhenries.

Protection Systems: Output Device Emulation Protec-

tion (ODEP) limits drive in the event of dangerous

dynamic thermal conditions without interrupting power.

Current limiting for shorted load protection. DC/LF and

common mode output current Fault circuitry to mute

audio. Delay of 4 seconds from turn on mutes amplifier

to prevent dangerous turn-on transients. A high voltage circuit breaker in each main transformer primary

and a low voltage power supply fuse in fan primary.

Slew rate limiting to prevent RF burn out.

MECHANICAL

Input Connectors: Balanced 1/4 inch phone jacks. Op-

tional XLR inputs with MT-XLR accessory.

Output Connectors: Color-coded 5-way binding posts

on 3/4 inch centers; spaced 3/4 inch apart.

Front Panel Controls: A front panel rocker switch used

to power the amplifier on and off.

Back Panel Controls: A three-position switch which

selects Stereo, Bridge-Mono, or Parallel-Mono mode.

A rotary potentiometer for each channel used to

control output level. A ground lift switch used to isolate

the phone jack input grounds from the chassis (AC)

ground. And a push button circuit breaker for each

channel used to protect the power supplies.

Internal Controls: A three-position switch selects 0.775V,

1.4V, or 26 dB voltage gain input sensitivity.

Indicators: Amber Enable indicator shows on/off status

of low-voltage power supply. An Amber ODEP indicator for each channel shows the reserve energy status.

If no reserve energy is available the indicator will dim

in proportion to ODEP limiting.

Construction: Black splatter-coat steel chassis with

specially designed flow-through ventilation system.

Mounting: Standard EIA 310 front-panel rack mount

with supports for supplemental rear corner mounting.

Dimensions: 19 inches wide, 3.5 inches high, 16 inches

deep behind front mounting surface.

6

Weight: 46 lbs, 14 oz. Shipping; 55 lbs, 12 oz.

Page 7

Micro-Tech 2400 Amplifier Service Manual

Voltage Conversion

The 120 Volt 60 Hz version, sold in the United States,

is not voltage selectable. It does not have a voltage

selection board. This version is to be used only with

120 Volts and only with 60Hz.

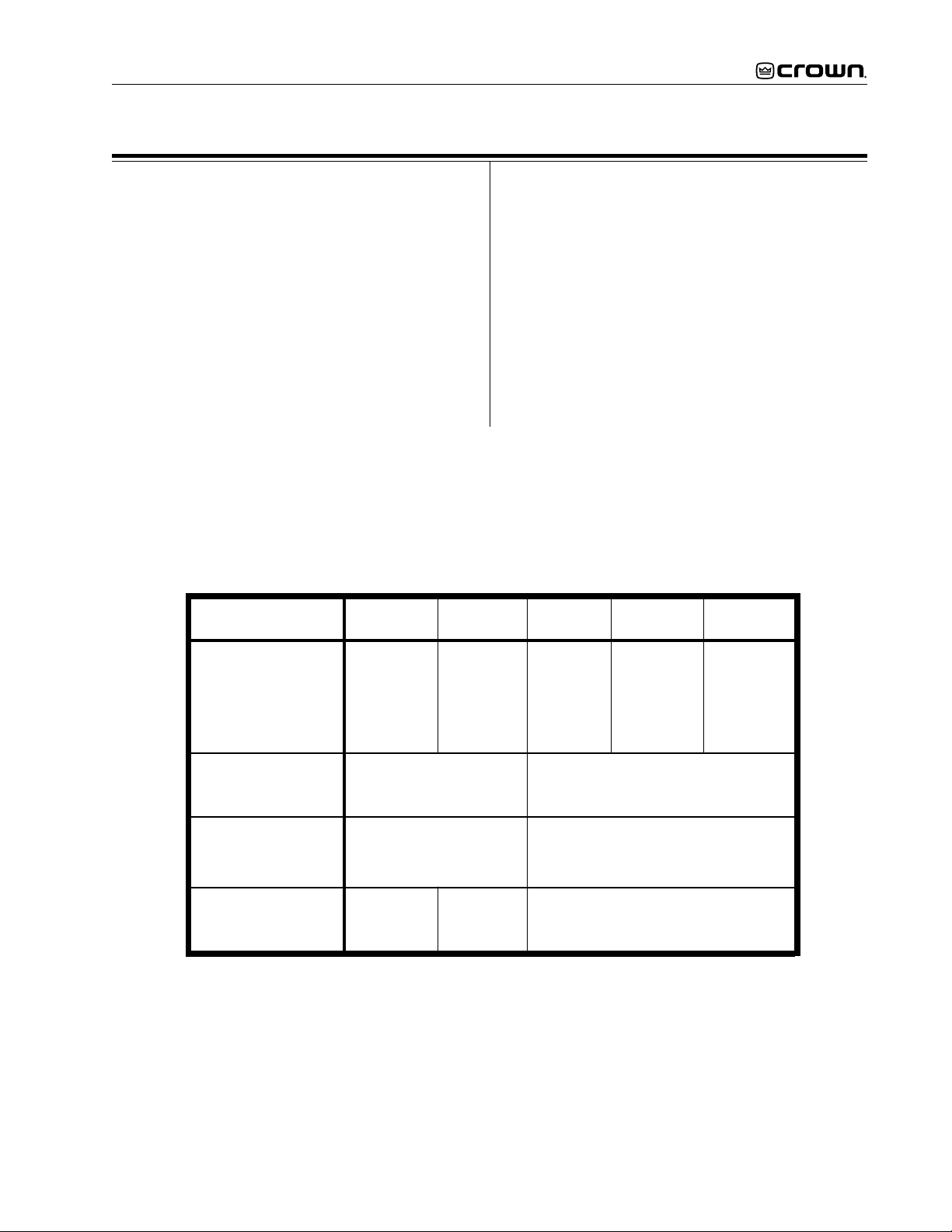

All other versions of the Micro Tech 2400 use a voltage selection board. The following chart indicates

different configurations of jumpers for different voltages. Note that the circuit breakers, fuse and

transmotor may need to be changed to accommodate different voltages. Versions with the voltage selection board may be used at 50 or 60 Hz.

VOLTAGE SELECTION BOARD

100V

P8—B

B—E

Jumpers

Circuit Breakers

CB100/CB200

Fuse

F1

Transmotor

TF1

Note: "P" locations are on the Fuse Board

P9—F

C—F

C 9508-0

15 Amp

A10285-10

1 Amp

H43068-8

P8—A

P9—F

H43407-8

120V

A—D

C—F

200V

P8—B

C—E

P9—F

220V/230V

P8—B

C—D

P9—F

C 8041-3

7.5 Amp

A10285-7

.5 Amp

H43408-6

240V

P8—A

C—D

P9—F

7

Page 8

Micro-Tech 2400 Amplifier Service Manual

Theory

OVERVIEW

It should be noted that over time Crown makes improvements and changes to their products for various

reasons. This manual is up to date as of the time of

writing. For additional information regarding these

amplifiers, refer to the applicable Technical Notes

provided by Crown for this product.

This section of the manual explains the general operation of a typical Crown power amplifier. Topics covered include Front End, Grounded Bridge, and ODEP.

Due to variations in design from vintage to vintage

(and similarities with other Crown products) the theory

of operation remains simplified.

FEATURES

Micro Tech amplifiers utilize numerous Crown innovations including grounded bridge and ODEP technologies. Cooling techniques make use of the what is

essentially air conditioner technology. Air flows bottom to top, and front to side. Air flows a short distance

across a wide heatsink. This type of air flow provides

significantly better cooling than the “wind tunnel”

technology used by many other manufacturers. Output transistors are of the metal can type rather than

plastic case. This allows for a significantly higher

thermal margin for the given voltage and current

ratings. All devices used are tested and graded to

ensure maximum reliability. Another electronic technique used is negative feedback. Almost all power

amplifiers utilize negative feedback to control gain

and provide stability, but Crown uses multiple nested

feedback loops for maximum stability and greatly

improved damping. Most Crown amplifiers have damping in excess of 1000 in the bass frequency range. This

feedback, along with our compensation and ultra-low

distortion output topology, make Crown amplifiers

superior.

Features specific to the Micro Tech Series’ include two

seperate power transformers (one for each channel),

a full time full speed fan which also serves as the low

voltage transformer, slew rate limiting, and audio

muting for delay or protective action. This amplifier

can operate in either a Bridged or Parallel Mono mode

as well as dual (stereo). A sensitivity switch allows

selection of input voltage required for rated output.

Level controls are mounted on the rear panel and are

of the rotary type. Front panel indicators let the user

know the status of the low voltage power supply

(enable), and an ODEP indicator for each channel

which shows the reserve energy status. In general, the

packaging of this model is designed for maximum

watt/price/weight/size value with user friendly features.

For additional details refer to the specification section,

or to the applicable Owner’s Manual.

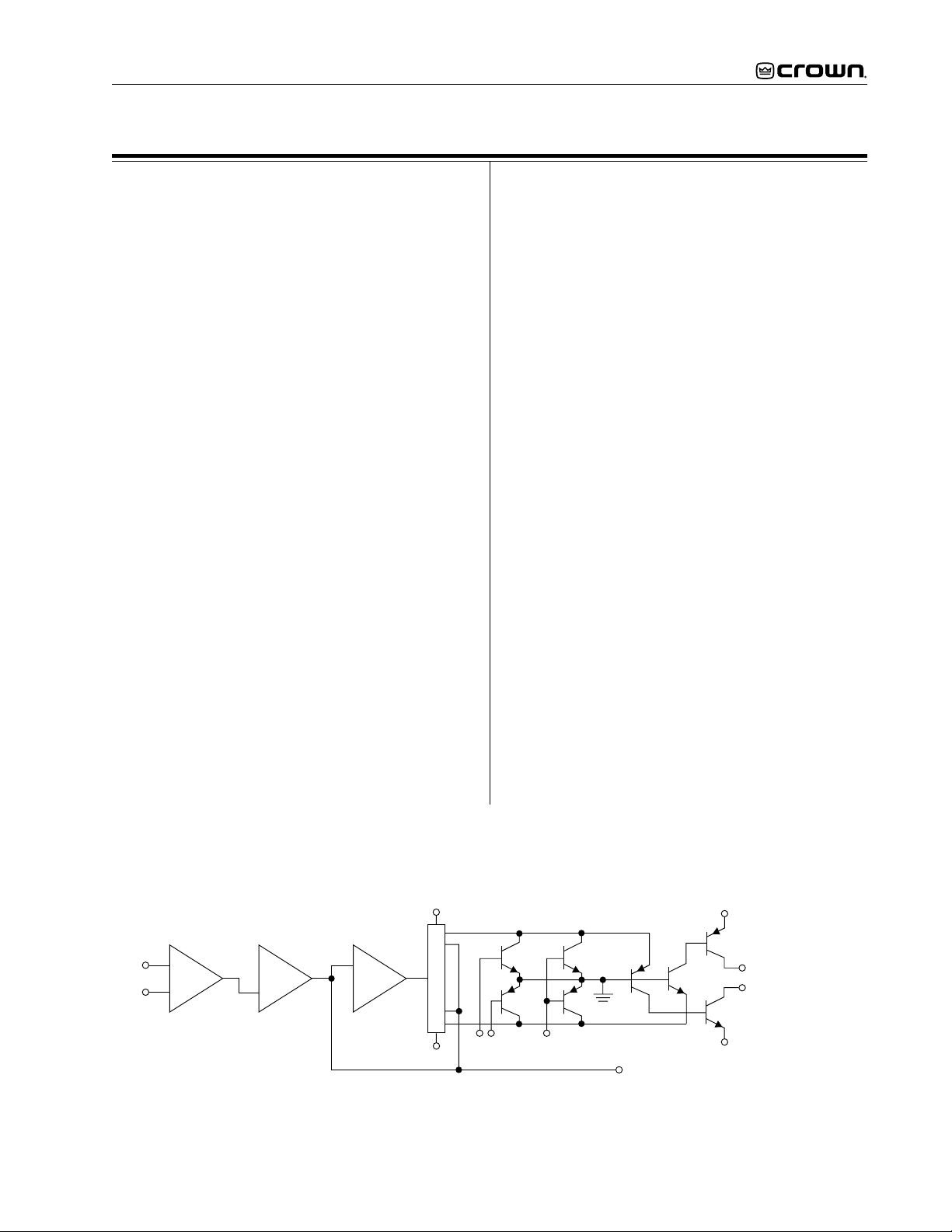

FRONT END OPERATION

The front end is comprised of three stages: Balanced

Gain Stage (BGS), Variable Gain Stage (VGS), and

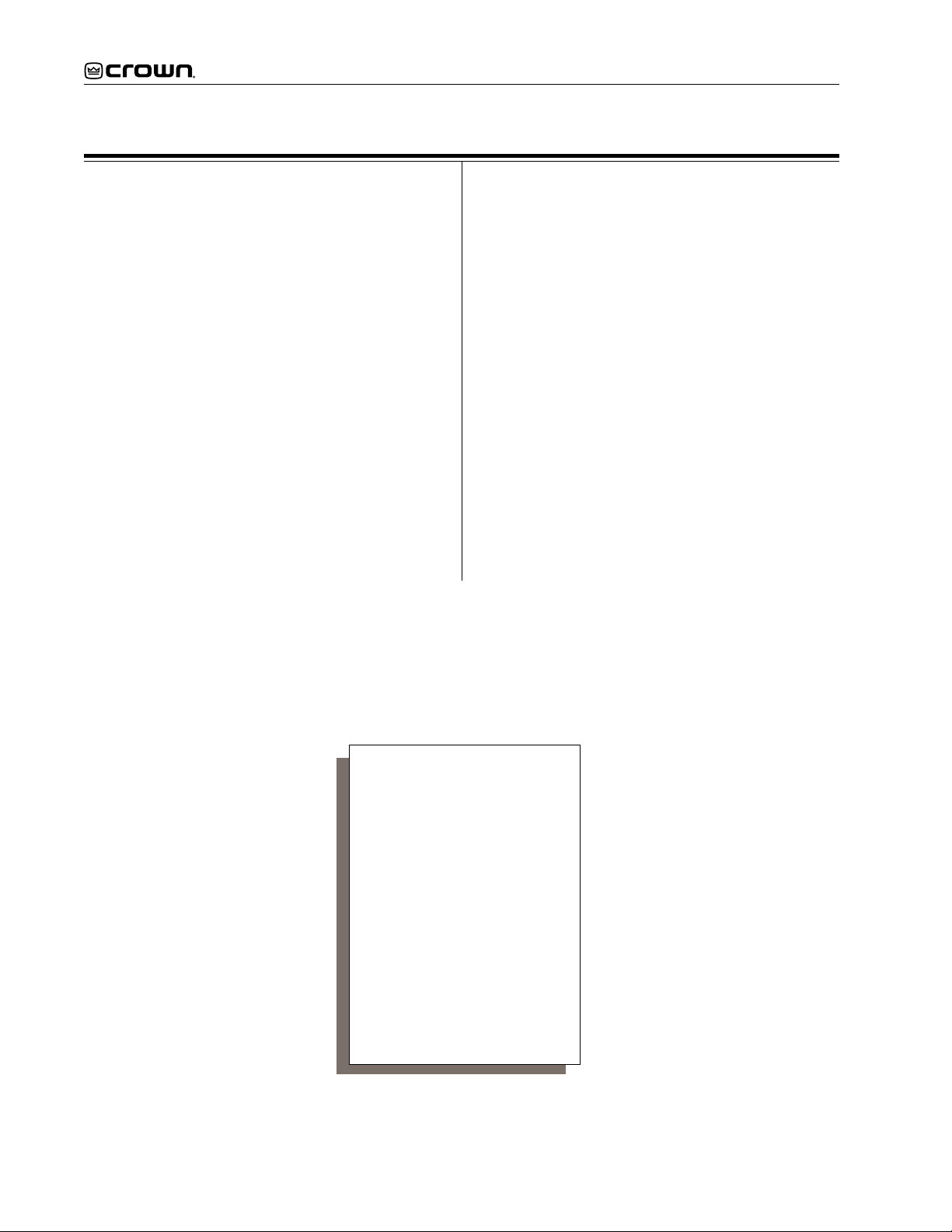

the Error Amp. Figure 1 shows a simplified diagram of

a typical front end with voltage amplification stages.

Balanced Gain Stage (BGS)

Input to the amplifier is balanced. The shield may be

isolated from chassis ground by an RC network to

interrupt ground loops via the Ground Lift Switch. The

non-inverting (hot) side of the balanced input is fed to

the non-inverting input of the first op-amp stage. The

inverting (negative) side of the balanced input is fed

to the inverting input of the first op-amp stage. A

potentiometer is provided for common mode rejection

adjustment. Electrically, the BGS is at unity gain.

(From an audio perspective, however, this stage

actually provides +6dB gain if a fully balanced signal

is placed on its input.) The BGS is a non-inverting

stage. It’s output is delivered to the Variable Gain

Stage.

Variable Gain Stage (VGS)

From the output of the BGS, the signal goes to the VGS

where gain is determined by the position of the Sensitivity Switch, and level is determined by the level

control. VGS is an inverting stage with the input being

fed to its op-amp stage. Because gain after this stage

is fixed at 26dB (factor of 20), greater amplifier sensitivity is achieved by controlling the ratio of feedback to

input resistance. The Sensitivity Switch sets the input

impedance to this stage and varies the gain such that

the overall amplifier gain is 26 dB, or is adjusted

appropriately for 0.775V or 1.4V input to attain rated

output.

Error Amp

The inverted output from the VGS is fed to the noninverting input of the Error Amp op-amp stage through

an AC coupling capacitor and input resistor. Amplifier

output is fed back via the negative feedback (NFb)

loop resistor. The ratio of feedback resistor to input

resistor fixes gain from the Error Amp input to the

output of the amplifier at 26 dB. Diodes prevent

overdriving the Error Amp. Because the Error Amp

8

Page 9

Micro-Tech 2400 Amplifier Service Manual

Theory

amplifies the difference between input and output

signals, any difference in the two waveforms will

produce a near open loop gain condition which in turn

results in high peak output voltage. The output of the

Error Amp, called the Error Signal (ES) drives the

Voltage Translators.

VOLTAGE AMPLIFICATION

The Voltage Translator stage separates the output of

the Error Amp into balanced positive and negative

drive voltages for the Last Voltage Amplifiers (LVAs),

translating the signal from ground referenced ±15V to

±Vcc reference. LVAs provide the main voltage amplification and drive the High Side output stages. Gain

from Voltage Translator input to amplifier output is a

factor of 25.2.

Voltage Translators

A voltage divider network splits the Error Signal (ES)

into positive and negative drive signals for the balanced voltage translator stage. These offset reference

voltages drive the input to the Voltage Translator

transistors. A nested NFb loop from the output of the

amplifier mixes with the inverted signal riding on the

offset references. This negative feedback fixes gain at

the offset reference points (and the output of the Error

Amp) at a factor of -25.2 with respect to the amplifier

output. The Voltage Translators are arranged in a

common base configuration for non-inverting voltage

gain with equal gain. They shift the audio from the

±15V reference to VCC reference. Their outputs drive

their respective LVA.

Also tied into the Voltage Translator inputs are ODEP

limiting transistors and control/protection transistors.

The ODEP transistors steal drive as dictated by the

ODEP circuitry (discussed later). The control/protection transistors act as switches to totally shunt audio to

ground during the turn-on delay, or during a DC/LF or

Fault protective action.

Last Voltage Amplifiers (LVAs)

The Voltage Translator stage channels the signal to

the Last Voltage Amplifiers (LVA's) in a balanced

configuration. The +LVA and -LVA, with their push-pull

effect through the Bias Servo, drive the fully complementary output stage. The LVAs are configured as

common emitter amplifiers. This configuration provides sufficient voltage gain and inverts the audio. The

polarity inversion is necessary to avoid an overall

polarity inversion from input jack to output jack, and it

allows the NFb loop to control Error Amp gain by

feeding back to its non-inverting input (with its polarity

opposite to the output of the VGS). With the added

voltage swing provided by the LVAs, the signal then

gains current amplification through the Darlington

emitter-follower output stage.

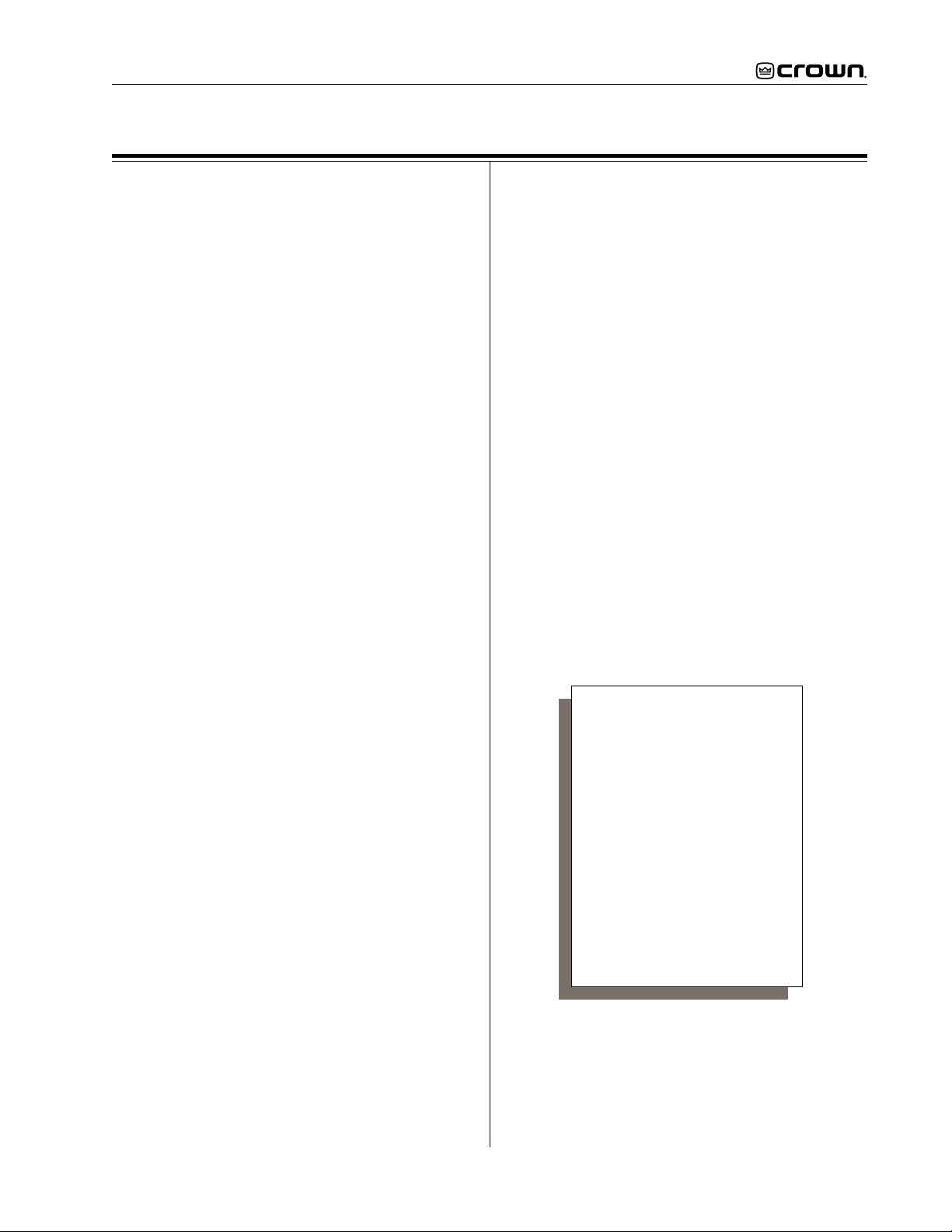

GROUNDED BRIDGE TOPOLOGY

Figure 2 is a simplified example of the grounded

bridge output topology. It consists of four quadrants

of three deep Darlington (composite) emitter-follower

stages per channel: one NPN and one PNP on the

High Side of the bridge (driving the load), and one

NPN and one PNP on the Low Side of the bridge

(controlling the ground reference for the rails). The

output stages are biased to operate class AB+B for

ultra low distortion in the signal zero-crossing region

and high efficiency.

Audio

Inputs

BGS VGS Error

Amp

+

-

+

-

+

-

Figure 1. Typical Amplifier Front End and Voltage Amplification Stages.

+15V

Voltage Divider

+

-15V

-

ODEP

Q100

Q103

Mute

Q121

Q122

NFb Loop

Voltage

Translators

Q101

Q102

+VCC

Q105

NPN Outputs (+HS)

PNP Outputs (-HS)

Q110

-VCC

LVA's

9

Page 10

Micro-Tech 2400 Amplifier Service Manual

Theory

High Side (HS)

The High Side (HS) of the bridge operates much like

a conventional bipolar push-pull output configuration.

As the input drive voltage becomes more positive, the

HS NPN conducts and delivers positive voltage to the

load. Eventually the NPN devices reach full conduction and +Vcc is across the load. At this time the HS

PNP is biased off. When the drive signal is negative

going, the HS PNP conducts to deliver -Vcc to the load

and the HS NPN stage is off.

The output of the +LVA drives the base of predriver

device. Together, the predriver and driver form the

first two parts of the three-deep Darlington and are

biased class AB. They provide output drive through

the bias resistor, bypassing the output devices, at

levels below about 100mW. An RLC network between

the predriver and driver provide phase shift compensation and limit driver base current to safe levels.

Output devices are biased class B, just below cutoff.

At about 100mW output they switch on to conduct high

current to the load. Together with predriver and driver,

the output device provide an overall class AB+B

output.

The negative half of the HS is almost identical to the

positive half, except that the devices are PNP. One

difference is that the PNP bias resistor is slightly

greater in value so that PNP output devices run closer

to the cutoff level under static (no signal) conditions.

This is because PNP devices require greater drive

current.

HS bias is regulated by Q18, the Bias Servo. Q18 is a

Vbe multiplier which maintains approximately 3.3V

Vce under static conditions. The positive and negative

halves of the HS output are in parallel with this 3.3V.

With a full base-emitter on voltage drop across

predrivers and drivers, the balance of voltage results

in approximately .35V drop across the bias resistors in

the positive half, and about .5V across the bias resistor

in the negative half. Q18 conduction (and thus bias) is

adjustable.

A diode string prevents excessive charge build up

within the high conduction output devices when off.

Flyback diodes shunt back-EMF pulses from reactive

loads to the power supply to protect output devices

from dangerous reverse voltage levels. An output

terminating circuit blocks RF on output lines from

entering the amplifier through its output connectors.

Low Side (LS)

The Low Side (LS) operates quite differently. The

power supply bridge rectifier is not ground referenced, nor is the secondary of the main transformer.

In other words, the high voltage power supply floats

with respect to ground, but ±Vcc remain constant with

10

+

+Vcc (Positive Rail)

Input

signal

HIGH SIDE LOW SIDE

Load

(speaker)

-Vcc (Negative Rail)

Inverting Op-amp

-

Figure 2. Crown Patented Grounded Bridge Topology

Page 11

Micro-Tech 2400 Amplifier Service Manual

Theory

respect to each other. This allows the power supply to

deliver +Vcc and -Vcc from the same bridge rectifier

and filter as a total difference in potential, regardless

of their voltages with respect to ground. The LS uses

inverted feedback from the HS output to control the

ground reference for the rails (±Vcc). Both LS quadrants are arranged in a three-deep Darlington and are

biased AB+B in the same manner as the HS.

When the amplifier output swings positive, the audio is

fed to an op-amp stage where it is inverted. This

inverted signal is delivered directly to the bases of the

positive (NPN) and negative (PNP) LS predrivers. The

negative drive forces the LS PNP devices on (NPN

off). As the PNP devices conduct, Vce of the PNP

Darlington drops. With LS device emitters tied to

ground, -Vcc is pulled toward ground reference.

Since the power supply is not ground referenced (and

the total voltage from +Vcc to -Vcc is constant) +Vcc

is forced higher above ground potential. This continues until, at the positive amplifier output peak, -Vcc =

0V and +Vcc equals the total power supply potential

with a positive polarity. If, for example, the power

supply produced a total of 70V from rail to rail (±35VDC

measured from ground with no signal), the amplifier

output would reach a positive peak of +70V.

Conversely, during a negative swing of the HS output

where HS PNP devices conduct, the op-amp would

output a positive voltage forcing LS NPN devices to

conduct. This would result in +Vcc swinging toward

ground potential and -Vcc further from ground potential. At the negative amplifier output peak, +Vcc = 0V

and -Vcc equals the total power supply potential with

a negative polarity. Using the same example as above,

a 70V supply would allow a negative output peak of 70V. In summary, a power supply which produces a

total of 70VDC rail to rail (or ±35VDC statically) is

capable of producing 140V peak-to-peak at the amplifier output when the grounded bridge topology is

used. The voltage used in this example are relatively

close to the voltages of the PB-1/460CSL.

Low side bias is established by a diode string which

also shunts built up charges on the output devices.

Bias is adjustable via potentiometer. Flyback diodes

perform the same function as the HS flybacks. The

output of the LS is tied directly to chassis ground via

ground strap.

OUTPUT DEVICE EMULATION PROTECTION

(ODEP)

To further protect the output stages, a specially developed ODEP circuit is used. It produces a complex

analog output signal. This signal is proportional to the

always changing safe-operating-area margin of the

output transistors. The ODEP signal controls the Voltage Translator stage by removing drive that may

exceed the safe-operating-area of the output stage.

ODEP senses output current by measuring the voltage dropped across LS emitter resistors. LS NPN

current (negative amplifier output) and +Vcc are

sensed, then multiplied to obtain a signal proportional

to output power. Positive and negative ODEP voltages

are adjustable via two potentiometers. Across ±ODEP

are a PTC and a thermal sense (current source). The

PTC is essentially a cutoff switch that causes hard

ODEP limiting if heatsink temperature exceeds a safe

maximum, regardless of signal level. The thermal

sense causes the differential between +ODEP and –

ODEP to decrease as heatsink temperature increases.

An increase in positive output signal output into a load

will result in –ODEP voltage dropping; an increase in

negative output voltage and current will cause +ODEP

voltage to drop. A complex RC network between the

±ODEP circuitry is used to simulate the thermal barriers between the interior of the output device die

(immeasurable by normal means) and the time delay

from heat generation at the die until heat dissipates to

the thermal sensor. The combined effects of thermal

history and instantaneous dynamic power level result

in an accurate simulation of the actual thermal condition of the output transistors.

The total effect is to deliver a peak to peak voltage to

the speaker load which is twice the voltage produced

by the power supply. Benefits include full utilization of

the power supply (it conducts current during both

halves of the output signal; conventional designs

require two power supplies per channel, one positive

and one negative), and never exposing any output

device to more than half of the peak to peak output

voltage (which does occur in conventional designs).

11

Page 12

Micro-Tech 2400 Amplifier Service Manual

Theory

BALANCED

INPUTS

+VOLTAGE

TRANSLATOR

VGSBGS

-1

ERROR

AMP

OUTPUT

DEVICE

EMULATION

PROTECTION

-VOLTAGE

TRANSLATOR

+LVA

-1

HIGH SIDE

BIAS

SERVO

-LVA

-1

MAIN NEGATIVE FEEDBACK (NFb) LOOP

LOW SIDE

-1

INVERTING

BRIDGE

BALANCE

BIAS

DIODE

STRING

POSITIVE

HIGH SIDE

OUTPUT

NPN STAGE

NEGATIVE

HIGH SIDE

OUTPUT

PNP STAGE

POSITIVE

LOW SIDE

OUTPUT

NPN STAGE

NEGATIVE

LOW SIDE

OUTPUT

PNP STAGE

12

Figure 3. Typical Crown Amplifier Basic Block Diagram (One Channel Shown)

Page 13

Micro-Tech 2400 Amplifier Service Manual

Electrical Checkout Procedures

GENERAL INFORMATION

The following test procedures are to be used to verify

operation of this amplifier. DO NOT connect a load or

inject a signal unless directed to do so by the procedure. These tests, though meant for verification and

alignment of the amplifier, may also be very helpful in

troubleshooting. For best results, tests should be

performed in order.

All tests assume that AC power is from a regulated 120

VAC source. Test equipment includes an oscilloscope, a DMM, a signal generator, loads, and I.M.D.

and T.H.D. noise test equipment.

STANDARD INITIAL CONDITIONS

Level controls fully clockwise.

Stereo/Mono switch in Stereo.

Sensitivity switch in 26 dB fixed gain position.

It is assumed, in each step, that conditions of the

amplifier are per these initial conditions unless otherwise specified.

TEST 1: DC OFFSET

Spec: 0 VDC, ±10 mV.

Initial Conditions: Controls per standard, inputs shorted.

Procedure: Measure DC voltage at the output connec-

tors (rear panel). There is no adjustment for output

offset. If spec is not met, there is an electrical malfunction. Slightly out of spec measurement is usually due

to U104/U204 out of tolorance.

TEST 2: OUTPUT BIAS ADJUSTMENT

Spec: 300 to 320 mVDC.

Initial Conditions: Controls per standard, heatsink tem-

perature less than 40°C.

Procedure: Measure DC voltages on the output module

across R02, adjust R26 if necessary. Measure DC

voltages on the output module across R21, adjust R23

if necessary. Repeat for second channel.

TEST 3: ODEP VOLTAGE ADJUSTMENT

Spec: Bias Per Chart, ±0.1V DC.

Initial Conditions: Controls per standard, heatsink at

room temperature 20 to 30°C (68 to 86°F). Note: This

adjustment should normally be performed within 2

minutes of turn on from ambient (cold) conditions. If

possible measure heatsink temperature, if not measure ambient room temperature. Use this information

when referencing the following chart.

°F °C V

–ODEP

V

+ODEP

66 18.9 –10.31 10.31

68 20.0 –10.26 10.26

70 21.1 –10.20 10.20

72 22.2 –10.14 10.14

74 23.3 –10.09 10.09

76 24.4 –10.03 10.03

77 25.0 –10.00 10.00

78 25.6 –9.97 9.97

80 26.7 –9.91 9.91

82 27.8 –9.86 9.86

84 28.9 –9.80 9.80

86 30.0 –9.74 9.74

88 31.1 –9.69 9.69

90 32.2 –9.63 9.63

92 33.3 –9.57 9.57

94 34.4 –9.51 9.51

–ODEP Procedure: Measure pin 6 of U100 and, if

necessary, adjust R121 to obtain V

as specified

–ODEP

above. Measure pin 6 of U200 and, if necessary,

adjust R221 to obtain V

as specified above.

–ODEP

+ODEP Procedure: Measure pin 6 of U103 and, if

necessary, adjust R132 to obtain V

as specified

+ODEP

above. Measure pin 6 of U203 and, if necessary,

adjust R232 to obtain V

as specified above.

+ODEP

TEST 4: AC POWER DRAW

Spec: 100 Watts maximum quiescent.

Initial Conditions: Controls per standard.

Procedure: With no input signal and no load, measure

AC line wattage draw. If current draw is excessive,

check for high AC line voltage or high bias voltage.

TEST 5: COMMON MODE REJECTION

Spec at 100 Hz: –70 dB.

Spec at 20 kHz: –50 dB.

Initial Conditions: Controls per standard.

Procedure: No load. Inject a 0 dBu 100 Hz sine wave

into each channel, one channel at a time, with inverting

and non-inverting inputs shorted together. At the

output measure less than –44 dBu. Inject a 0 dBu 20

kHz sine wave into each channel, one channel at a

time, with inverting and non-inverting inputs shorted

together. At the output measure less than –24 dBu.

Adjust R921 or R1021, if necessary, to obtain the

required measurements.

13

Page 14

Micro-Tech 2400 Amplifier Service Manual

Electrical Checkout Procedures

TEST 6: VOLTAGE GAIN

Spec 26dB Gain: Gain of 20.0 ±3%.

Spec 0.775V Sensitivity: ±6%.

Spec 1.4V Sensitivity: +12%/–6%.

Initial Conditions: Controls per standard.

Procedure: No load connected. Inject a 0.775 VAC 1

kHz sine wave with the Sensitivity Switch in the 26 dB

position. Measure 15.5 VAC ±0.5 VAC at the amplifier

output. Inject a 0.775 VAC 1 kHz sine wave with the

Sensitivity Switch in the 0.775V position. Measure 64.5

VAC ±3.9 VAC at the amplifier output. Inject a 1.4 VAC

1 kHz sine wave with the Sensitivity Switch in the 1.4V

position. Measure 64.5 VAC +7.7/-3.9 VAC at the

amplifier output. Return the Sensitivity Switch to the 26

dB position.

TEST 7: PHASE RESPONSE

Spec: ±10° from 10 Hz to 20 kHz at 1 Watt.

Initial Conditions: Controls per standard, 8 ohm load on

each channel.

Procedure: Inject a 1 kHz sine wave and adjust for 1

Watt output (2.8 VAC). Check input and output signals

against each other, input and output signals must be

within 10° of each other.

TEST 8: LEVEL CONTROLS

Spec: Level controlled by level controls.

Initial Conditions: Controls per standard.

Procedure: No Load. Inject a 1 kHz sine wave. With

level controls fully clockwise you should see full gain.

As controls are rotated counterclockwise, observe

similar gain reduction in each channel. When complete, return level controls to fully clockwise position.

TEST 9: CURRENT LIMIT

Spec: Current Limit at 38 Amps, ±3 Amps

Initial Conditions: Controls per standard.

Procedure: Load each channel to 1 Ohm. Inject a 1 kHz

differentiated (or 10% duty cycle) square wave. See

figure 4. Increase output level until current limit occurs. Current limit should occur at 38 ±3 Amps (38

Vpk) with output device Vce less than 40 Vpk. Observe clean (no oscillations) current clipping.

In

.047 uF

Figure 4. Differentiator Circuit

Out

1K Ohm

TEST 10: SLEW RATE & 10 KHZ SQUARE WAVE

Spec: 17 - 25 V/µS.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 10

kHz square wave to obtain 64 volts peak-to-peak at

each output. Observe the slope of the square wave. It

should typically measure 17 to 25 V/µS. Also, the

square wave must not include overshoot, ringing, or

any type of oscillation.

TEST 11: CROSSTALK

Spec: -60dB at 20 kHz.

Initial Conditions: Controls per standard. Terminate

input of channel not driven with 600 ohms.

Procedure: 8 ohm load on each channel. Inject a 20 kHz

sine wave into the Channel 1 input and increase output

level to 62 VAC. Measure less than 62 mVAC at the

output of Channel 2. Inject a 20 kHz sine wave into the

Channel 2 input and increase output level to 62 VAC.

Measure less than 62 mVAC at the output of Channel

1.

TEST 12: OUTPUT POWER

Spec at 8 Ohm Stereo: >= 520W at 0.1% THD.

Spec at 4 Ohm Stereo: >= 800W at 0.1% THD.

Spec at 2 Ohm Stereo: >= 934W at 0.1% THD.

International 8 Ohm Stereo: >=515W at 0.1% THD.

International 4 Ohm Stereo: >=745W at 0.1% THD.

International 2 Ohm Stereo: >=925W at 0.1% THD.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 1 kHz

sine wave and measure at least 64.5 VAC at the output

of each channel. Load each channel to 4 ohms. Inject

a 1 kHz sine wave and measure at least 56.6 VAC.

Load each channel to 2 ohms. Inject a 1 kHz sine wave

and measure at least 43.2 VAC. All power measurements must be at less than 0.1% THD.

TEST 13: REACTIVE LOADS

Spec: No oscillations. Safe with all types of loads.

Initial Conditions: Controls per standard.

Procedure Capacitive: Load each channel to 8 ohms in

parallel with 2 µF. Inject a 20 kHz sine wave with 55

VAC output for 10 seconds.

Procedure Inductive: Load each channel to 8 ohms in

parallel with 159 µHenries. Inject a 1 kHz sine wave

with 35.8 VAC output for 10 seconds.

Procedure Torture: Load each channel with the primary

(red and black leads) of a DC-300A transformer (D

5781-6). Inject a 15 Hz sine wave at sufficient output

level to cause 3 to 5 flyback pulses, for 10 seconds.

14

Page 15

Micro-Tech 2400 Amplifier Service Manual

Electrical Checkout Procedures

Procedure Short: Inject a 60 Hz sine wave at 5 VAC

minimum output. After establishing signal, short the

output for 10 seconds.

TEST 14: ODEP LIMITING

Spec: No oscillation on ODEP Limiting wave form;

either channel controls limiting in Parallel Mono Mode.

Initial Conditions: Controls per standard; rag or other

obstruction blocking fan so that it does not turn.

Procedure: Load the amplifier to 4 ohms on each

channel. Inject a 60 Hz sine wave and adjust for 35

Vrms at the output. After a few minutes observe a wave

form similar to Figure 5. Remove the input signal from

both channels and allow the amplifier to cool for a few

minutes. Switch the amplifier to Parallel Mono and

remove the load from Channel 1. Inject the signal into

Channel 1 and observe that ODEP limiting occurs at

the output of both channels. Remove the load from

Channel 2, and install the load on Channel 1. Again,

observe that both channels limit. Return all amplifier

controls to standard initial conditions. Remove the fan

obstruction.

TEST 16: SIGNAL TO NOISE RATIO

Spec: 100 dB below rated 8 ohm power 20 Hz to 20

kHz. 105 dB A-Weighted.

Initial Conditions: Controls per standard. Short inputs.

Procedure: Load each channel to 8 ohms. Measure

less than 645 µV at the output of each channel (20 Hz20 kHz bandpass filter).

TEST 17: TURN ON TRANSIENTS

Spec: No dangerous transients.

Initial Conditions: Controls per standard.

Procedure: From an off condition, turn on the amplifier

and monitor the output noise at the time of turn on.

Note: Turn on noise may increase significantly if the

amplifier is cycled off and on.

TEST 18: TURN OFF TRANSIENTS

Spec: No dangerous transients.

Initial Conditions: Controls per standard.

Procedure: From an on condition, turn off the amplifier

and monitor the output noise at the time of turn off.

Note: Turn off noise may increase significantly if the

amplifier is cycled off and on.

TEST 19: INTERMODULATION DISTORTION

Spec at 0 dB Output: 0.01%.

Spec at –35 dB Output: 0.05%.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a

SMPTE standard IM signal (60 Hz and 7 kHz sine

wave mixed at 4:1 ratio). Set the 60 Hz portion of the

sine wave to 51.5 Volt RMS. Set the 7 kHz portion to

25%. With an IM analyzer measure less than 0.01%

IMD. Repeat test at –35 dB (reference 51.5 Volt RMS,

60 Hz portion) and measure less than 0.05% IMD.

Figure 5. ODEP Limiting Wave Form

TEST 15: LF PROTECTION

Spec: Amplifier mutes for low frequency.

Initial Conditions: Controls per standard.

Procedure: No load. Inject a 0.5 Hz 6 volt peak-to-peak

square wave, or a 2 Hz 6VAC sine wave into each

channel and verify that each channel cycles into mute.

TEST 20: CLIPPING

Spec: No protective action during test.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 1

kHz sine wave at each input and drive output 6 dB into

clip for 10 seconds. The amplifier should not activate

any protective circuits (ODEP, Fault, or LF Protection).

POST TESTING

After completion of testing, if all tests are satisfactory,

the amplifier controls should be returned to the positions required by customer. If conditions are unknown

or unspecified, factory settings are as follows:

Level Controls: 9 to 11 O’Clock.

Sensitivity Switch: 0.775V U.S., 1.4V International.

Stereo/Mono Switch: Stereo.

Ground Lift: Lift.

Power: Off.

15

Page 16

Micro-Tech 2400 Amplifier Service Manual

Parts List (Non-Module)

SUPPLIMENTAL ITEMS

CPN ITEM QTY

D 4137-2 Nylon Thumbscrew Washer 4

C 3342-0 Feet, Black Self-Stick 4

A10087-71012 10-32 .75 Machine (Rack Screw) 4

K80603-2 MT Series Owners Manual 1

POWER SUPPLY

CPN ITEM QTY

D 7975-2 Power Cord (US Models) 1

A10793-0503G Power Cord (European plug) 1

D 8633-6 Power Transformer (120V 60 Hz only) 2

D 8631-0 Power Transformer (Universal Volt) 2

C 9508-0 Circuit Breaker, 15A (100V-120V) 2

C 8041-3 Circuit Breaker, 7.5A (200V-240V) 2

A10285-10 Fuse, 1A 3AG (100V-120V) 1

A10285-7 Fuse, .5A AGC (200V-240V) 1

H43409-4 Transmotor (120V 60 Hz Only) 1

H43408-6 Transmotor (200V-240V Only) 1

H43068-8 Transmotor (100V Only) 1

H43407-8 Transmotor (120V 50 Hz) 1

A10101-19 Fiber Washer, 500ODX195ID (Universal Volt Only) 2

D 8299-6 Fish Paper Insulation (Universal Volt Only) 2

H43403-7 Universal Volt Wires (Universal Volt Only) 2

P10178-5 Terminal Jumper Board Ch 2 (Universal Volt Only) 1

P10432-6 Terminal Jumper Board Ch 1 (Universal Volt Only) 1

A10089-11032 10-32 x 2 PNHD Screw (Mounts Transformers) 8

A10094-8 #10 Int Tooth Lockwasher 8

A10099-7 #10 Nylon Shoulder Washer 8

C 7062-0 6-32 x 5/16 undercut Flthd Mscr (XMotor Asm) 2

C 9938-9 Fan Blade, 4.5 Inch CCW 1

D 8439-8 Fan Bracket 1

D 8639-3 6300µF 150V Electrolytic Capacitor 2

C 8752-5 35A 400V Bridge Rectifier 2

D 8438-0 Capacitor Bracket 2

D 6764-1 Shoulder Washer (Cap Asm) 4

C 9870-4 10-32 x .38 Screw (Cap Asm) 4

A10098-5 1/4" Belleville Spring Washer (Cap Asm) 4

A10095-4 #10 External Star Lockwasher (Cap Asm) 4

H43469-8 Blue Wires, Cap Asm 2

H43470-6 Red Wires, Cap Asm 2

OUTPUT ASSEMBLY (ONE PER CHANNEL)

CPN ITEM QTY (PER CHANNEL)

C 8187-4 NPN Output Device 6

C 8188-2 PNP Output Device 6

C 8573-5 PNP Driver Transistor, TO-3P (2SA1186) 2

C 8574-3 NPN Driver Transistor, TO-3P (2SC2837) 2

16

Page 17

Micro-Tech 2400 Amplifier Service Manual

Parts List (Non-Module)

OUTPUT ASSEMBLY CONT. (ONE PER CHANNEL)

CPN ITEM QTY(PER CHANNEL)

D 7665-9 Clip, TO-3P Mounting 2

D 7666-7 Bracket, TO-3P Heatsink 2

C 8813-5 Q318/Q418 Bias Servo MPSA18/MPS8097 1

B 5842-8 Tubing, #23 TFE Thin Wall Red (For C 8813-5) Request in Inches

C 5826-0 S100/S200 Thermal Sense LM334Z 1

B 5464-1 Tubing, #24 Teflon Thin Wall (For C 5826-0) Request in Inches

D 8774-8 PTC Thermal Sensor 95DEGC 1

A10315-1 Screw, 6-32-.56 Hex Washer Head 12

C 9491-9 Screw, 6-32-.312 Taptite Pan Ph 29

D 7796-2 Silpad Insulator (Between Chassis and Heatsinks) 1

D 7797-0 Output Thru-Hole Pad Insulator 1

D 8197-2 Paper Shroud 1

C 9387-9 Rivet, Plastic 2

F12019-0 Diode Heatsink Slug (Under diodes on Module) 1

M21322J8 Heatsink, Copper 3/4" with fins 2

BACK PANEL ASSEMBLY

CPN ITEM QTY

M21417J6 Back Panel (US Model) 1

M21423J4 Back Panel (European Model) 1

F10787J3 Back Cover Plate 1

C 2823-0 Dual Binding Post Assembly 2

D 7600-6 G round Strap, Dual Bannana 1

D 7975-2 20A Power Cord (US Models) 1

A10793-0503G European Power Cord 1

F11160-3 Strain Relief for US Models 1

A10214-7 Strain Relief, European Model 1

A10086-70806 8-32 X .37 Round Head Machine Screw 2

A10094-6 #8 Internal Star Lockwasher 4

A11376-6130J 13 Inch Black 12 Gauge output wire 1

A11376-6235J 23.5 Inch Black 12 Guage output wire 1

A11394-6160E 16 Inch Red 12 Guage output wire 1

A11394-6235E 23.5 Inch Red 12 Guage output wire 1

A11390-6130E 13 Inch Black 22 Guage wire 1

CHASSIS FRONT ASSEMBLY

CPN ITEM QTY

A10090-70806 Screw, 8-32-.375 Mach Ph Oval (Grille) 3

A10090-70808 Screw, 8-32-.5 Mach Ph Oval (End Caps) 4

A10101-5 Washer, Nylon (Grille) 3

A10173-1 Clip, Grille Filter 3

D 6944-9 Air Filter 1

D 8052J8 End Cap 2

F12435J7 Grille 1

D 8635-1 MT-2400 Front Panel Overlay 1

17

Page 18

Micro-Tech 2400 Amplifier Service Manual

Parts List (Non-Module)

MAIN CHASSIS ASSEMBLY

CPN ITEM QTY

D 8501-5 Cover , Top 1

D 8548-6 Cover, Bottom 1

A10110-70605 Screw, 6-32-.312 Taptite Ph (Covers) 16

M21447J3 Main Chassis 1

MISCELLANEOUS

CPN ITEM QTY

A10110-70812 8-32 x .750 Taptite Pnhd Screw 2

A10094-3 Washer, #6 Black Star 3

A10109-10822 Screw, 8-18-1.375 Pan Ph 2

A10192-1 Snap Bushing .5 4

C 6912-7 Tension Retainer Board Support 2

C 6913-5 Spacer Nut, 1 inch 2

C 6914-3 Spacer Nut, .75 inch 2

C 8812-7 5.5" Cable Tie 27

C 1813-2 7.5" Cable Tie & Clamp 2

C 5894-8 15" Cable Tie 1

D 7622-0 16.5" 16 Pin Ribbon Cable 1

C 7351-7 10-12 Ga Splice Connector 2

C 9491-9 Screw, 6-32 x .312 Pan Head 11

D 7784-8 Label, Sensitivity Switch 1

D 8251-7 Label, F1 Fuse Replacement 1

D 8069-4 Insulator, Fuse Board 1

18

Page 19

Micro-Tech 2400 Amplifier Service Manual

Module Information

MODULE HISTORY

The Micro Tech 2400 amplifier was introduced in

January of 1995. Since then there have been several

updates and revisions, some of which called for new

modules. The following is a list of all modules used up

to this date, July 1995.

OUTPUT MODULES: (left and right are identical)

Q43354-2

Original Output Module, still in production. Uses

P10429-2 board.

MAIN MODULES:

Q43328-6

Original Main Module on D 8679-9 board. Used until

6-14-95.

Q43399-7

Main Module on D 8827-4 board.

FUSE MODULE:

M46330-3

Fuse board on P10425-0 board.

DISPLAY MODULE:

Q43327-8

Display module on D 8030-5 board.

19

Page 20

Micro-Tech 2400 Amplifier Service Manual

M46330-3 Fuse Module & Q43327-8 Display Module Parts List

M46330-3 FUSE MODULE

2 C 5060-6 PC Mount Fuse Clip

11 C 7817-7 Tab, AMP .25 Faston PC Mount

1 P10425-0 MT-2400 Fuse Board

For replacement fuse see Power Supply Parts List on page 16.

Q43327-8 DISPLA Y MODULE

CAPACITORS

C503 C603 C 6806-1 .01µF

C507 C607 C 6809-5 220pF

C701 C 6802-0 .47µF

C702 C 6802-0 .47µF

DIODES

D701 C 3533-4 1N966B

D702 C 3533-4 1N966B

LED'S

E502 E602 C 4342-9 Amber, MV5153

E701 C 4342-9 Amber, MV5153

CONNECTOR

J3 C 4508-5 Socket, IC DIP 16 Pin

TRANSISTORS

Q504 Q604 C 3625-8 2N4125

RESISTORS

R508 R608 A10266-1351 1.3M

R509 R609 A10266-7551 7.5M

R510 R610 A10266-4751 4.7M

R511 R611 A10266-4741 470K

R512 R612 A10266-2221 2.2K

R513 R613 A10266-1522 1.5K .5W

R514 R614 A10266-1001 10 Ohm

R615 A10266-1522 1.5K .5W

R702 A10266-5111 510 Ohm

R707 A10266-5111 510 Ohm

INTEGRATED CIRCUITS

U502 C 5070-5 TL072CP

BOARD

1 D 8030-5 MT Display Board

20

Page 21

Micro-Tech 2400 Amplifier Service Manual

Q43354-2 Output Module Parts List (P10429-2 Board)

Q43354-2 Output Module for MT-2400. For Schematic See

J0658-5

CAPACITORS

C01 C 8511-5 .047µF

C02 C 8426-6 .1µF

C03 C 8426-6 .1µF

C04 C 6806-1 .01µF

C05 C 6806-1 .01µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

C43 C 7697-3 .01µF 500V

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2941-0 1N5402

D06 C 2941-0 1N5402

D07 C 2941-0 1N5402

D08 C 2941-0 1N5402

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

D13 C 2851-1 1N4004

D14 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

RESISTORS

R00 A10266-7501 75

R01 A10266-1011 100

R02 C 7778-1 5.6 flame proof

R03 C 6486-2 .2 5W

R04 C 6486-2 .2 5W

R05 C 6486-2 .2 5W

R06 C 6486-2 .2 5W

R07 C 6486-2 .2 5W

R08 C 6486-2 .2 5W

R09 C 7779-9 22 flame proof

R10 A10266-1011 100

R11 C 7317-8 2.7 5W

R12 A10266-2R74 2.7 2W

R13 A10266-7501 75

R14 A10266-2R74 2.7 2W

R15 C 6486-2 .2 5W

R16 C 6486-2 .2 5W

R17 C 6486-2 .2 5W

R18 C 6486-2 .2 5W

R19 C 6486-2 .2 5W

R20 C 6486-2 .2 5W

R21 C 7778-1 5.6 flame proof

R22 C 7779-9 22 flame proof

R23 C 6844-2 250 Pot LS Bias

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS Bias

R27 A10266-3911 390

R28 A10266-1331 13K

R29 A10266-5101 51

R30 A10265-10201 102

R41 A10266-2201 22

R42 A10266-2201 22

R43 A10266-2201 22

TRANSISTORS

Q17 C 8508-1 NPN 2SC3298B

Q19 C 8509-9 PNP 2SA1306B

Note: Q18, S100/200, Driver and Output Transistors

are not included with the module. See the Output

Assembly Parts List on pages 16 & 17.

MISC.

Board P10429-2

Jumpers C 5868-2 0 Ohm Jumper (11)

Clips D 6414-3 Q17/19 Hold Down

P500 P600 C 9828-2 12 Pin Header

21

Page 22

Micro-Tech 2400 Amplifier Service Manual

Q43328-6 Main Module Parts List (D8679-9 Board)

Q43328-6 MT-2400 ORIGINAL MAIN MODULE

Use Schematic J 0658-5

CAPACITORS

C1 C 3913-8 470µF

C2 C 3913-8 470µF

C4 C 6802-0 .47µF

C5 C 6806-1 .01µF

C6 C 6806-1 .01µF

C7 C 8897-8 .1µF

C8 C 5362-6 2.2uF

C100 C200 C 5311-3 22µF

C101 C201 C 9464-6 10pF

C102 C202 C 8576-8 100uF

C103 C203 C 6805-3 .022µF

C104 C204 C 6805-3 .022µF

C105 C205 C 6812-9 47pF

C106 C206 C 6812-9 47pF

C107 C207 C 8897-8 .1µF

C108 C208 C 6814-5 12pF

C109 C209 C 8576-8 100µF

C110 C210 C 5362-6 2.2µF

C112 C212 C 9991-8 1µF

C113 C213 C 9992-6 47µF

C114 C214 C 8854-9 100µF

C115 C215 C 8854-9 100µF

C116 C216 C 9992-6 47µF

C117 C217 C 9991-8 1µF

C118 C218 C 6814-5 12pF

C119 C219 C 6802-0 .47µF

C122 C222 C 6811-1 100pF

C123 C223 C 6812-9 47pF

C124 C224 C 6812-9 47pF

C129 C229 C 6814-5 12pF

C130 C230 C 6813-7 27pF

C132 C232 C 6806-1 .01µF

C133 C233 C 6813-7 27pF

C134 C234 C 6805-3 .022µF

C135 C235 C 6805-3 .022µF

C136 C236 C 6808-7 470pF

C137 C237 C 6808-7 470pF

C138 C238 C 6813-7 27pF

C139 C239 C 6813-7 27pF

C140 C240 C 6812-9 47pF

C141 C241 C 6812-9 47pF

C144 C244 C 8576-8 100µF

C145 C245 C 6812-9 47pF

C146 C246 C 6812-9 47pF

C147 C247 C 6806-1 .01µF

C148 C248 C 6810-3 180pF

C149 C249 C 6808-7 470pF

C150 C250 C 6806-1 .01µF

C151 C251 C 6806-1 .01µF

C152 C252 C 6950-7 82pF 5%

C153 C253 C 8897-8 .1µF

C154 C254 A10434-104JD .1µF 250V

C155 C255 C 8897-8 .1µF

C156 C256 C 8897-8 .1µF

C158 C258 C 6805-3 .022uF

C159 C259 C 6805-3 .022uF

C160 C260 C 8897-8 .1uF

C161 C261 C 8897-8 .1uF

DIODES

D1 C 2851-1 1N4004

D2 C 2851-1 1N4004

D3 C 2851-1 1N4004

D4 C 2851-1 1N4004

D5 C 2851-1 1N4004

D6 C 2851-1 1N4004

D7 C 2851-1 1N4004

D100 D200 C 3181-2 1N4148

D101 D201 C 3181-2 1N4148

D102 D202 C 3824-7 1N970B

D103 D203 C 3181-2 1N4148

D104 D204 C 3181-2 1N4148

D108 D208 C 3181-2 1N4148

D109 D209 C 3181-2 1N4148

D110 D210 C 3181-2 1N4148

D111 D211 C 5061-4 1N3070

D112 D212 C 3181-2 1N4148

D113 D213 C 3181-2 1N4148

D120 D220 C 3181-2 1N4148

D121 D221 C 3181-2 1N4148

D122 D222 C 3181-2 1N4148

D123 D223 C 5061-4 1N3070

D124 D224 C 3181-2 1N4148

D125 D225 C 3181-2 1N4148

D126 D226 C 5061-4 1N3070

D127 D227 C 5061-4 1N3070

D128 D228 C 5061-4 1N3070

D129 D229 C 3181-2 1N4148

D130 D230 C 3181-2 1N4148

D131 D231 C 3181-2 1N4148

D132 D232 C 3181-2 1N4148

D133 D233 C 3181-2 1N4148

D134 D234 C 3181-2 1N4148

LED's

E100 E200 C 9857-1 RED

E101 E201 C 9857-1 RED

22

Page 23

Micro-Tech 2400 Amplifier Service Manual

Q43328-6 Main Module Parts List Cont. (D8679-9 Board)

RESISTOR NETWORKS

N101 N201 D 7944-8 Res. Net.

N102 N202 D 6082-8 Res. Net.

TRANSISTORS

Q100 Q200 D 2961-7 2N3859A

Q101 Q201 C 3578-9 MPSA93

Q102 Q202 C 3810-6 MPSA43

Q103 Q203 C 3786-8 PN4250

Q105 Q205 C 3578-9 MPSA93

Q106 Q206 C 3625-8 2N4125

Q107 Q207 C 3786-8 PN4250

Q108 Q208 C 5891-4 MTS105

Q109 Q209 D 2961-7 2N3859A

Q110 Q210 C 3810-6 MPSA43

Q112 Q212 C 3625-8 2N4125

Q113 Q213 C 3625-8 2N4125

Q115 Q215 D 2962-5 MPS8097

Q116 Q216 C 3786-8 PN4250

Q117 Q217 D 2961-7 2N3859A

Q118 Q218 D 2961-7 2N3859A

Q119 Q219 C 3625-8 2N4125

Q120 Q220 C 3625-8 2N4125

Q123 Q223 C 7458-0 2N4123

Q124 Q224 C 3625-8 2N4125

Q125 Q225 C 3786-8 PN4250

Q126 Q226 C 5891-4 MTS105

Q127 Q227 C 3625-8 2N4125

Q128 Q228 C 7458-0 2N4123

Q129 Q229 C 3625-8 2N4125

Q130 Q230 C 7458-0 2N4123

Q131 Q231 C 3625-8 2N4125

Q132 Q232 C 3625-8 2N4125

Q133 Q233 C 3625-8 2N4125

Q134 Q234 C 3625-8 2N4125

Q135 Q235 C 7458-0 2N4123

Q136 Q236 C 7458-0 2N4123

Q137 Q237 C 3625-8 2N4125

RESISTORS

R1 A10265-53621 53.6K 1%

R2 C 7340-0 24 5W

R3 C 7340-0 24 5W

R4 A10265-46421 46.4K 1%

R5 OPEN

R7 A10266-4331 43K

R8 A10265-75021 75K 1%

R10 OPEN

R17 A10265-75021 75K 1%

R18 A10266-4331 43K

R100 R200 C 7409-3 5K Lin. Vol.

R101 R201 A10265-49911 4.99K 1%

R102 R202 A10266-5111 510

R103 R203 A10265-10031 100K 1%

R104 R204 A10266-2721 2.7K

R105 R205 A10266-2721 2.7K

R106 R206 A10266-1231 12K

R107 R207 A10266-6831 68K

R108 R208 A10265-80601 806

R109 R209 A10266-5601 56

R110 R210 A10266-6831 68K

R111 R211 A10266-1231 12K

R112 R212 A10266-5131 51K

R113 R213 A10266-4721 4.7K

R114 R214 A10266-4721 4.7K

R115 R215 A10266-3341 330K

R116 R216 A10266-2751 2.7M

R117 R217 A10265-46421 46.4K 1%

R118 R218 A10265-28701 287 1%

R119 R219 A10265-68101 681 1%

R120 R220 A10265-28701 287 1%

R121 R221 C 5062-2 100K Pot

R122 R222 A10266-2741 270K

R123 R223 A10266-2732 27K .5W

R124 R224 A10266-6821 6.8K

R125 R225 C 8836-6 100 .5W FP

R126 R226 C 8836-6 100 .5W FP

R127 R227 A10266-6821 6.8K

R128 R228 A10266-1331 13K

R129 R229 A10265-10031 100K 1%

R130 R230 A10265-10031 100K 1%

R131 R231 A10266-1331 13K

R132 R232 C 5062-2 100K Pot

R133 R233 A10266-2741 270K

R134 R234 A10266-2732 27K .5W

R135 R235 A10266-1012 100 .5W

R136 R236 A10266-6821 6.8K

R137 R237 A10266-1012 100 .5W

R138 R238 A10266-6821 6.8K

R139 R239 A10265-80601 806 1%

R140 R240 A10266-5601 56

R141 R241 A10266-1541 150K

R142 R242 A10266-1541 150K

R143 R243 A10266-4711 470

R144 R244 A10266-4711 470

R145 R245 A10266-4711 470

R146 R246 A10266-1231 12K

R147 R247 C 8836-6 100 .5W FP

R148 R248 A10266-2721 2.7K

R149 R249 C 8836-6 100 .5W FP

R150 R250 A10266-2721 2.7K

R151 R251 A10266-1231 12K

R152 R252 A10265-11521 11.5K 1%

23

Page 24

Micro-Tech 2400 Amplifier Service Manual

Q43328-6 Main Module Parts List Cont. (D8679-9 Board)

R153 R253 A10124-24 JUMPER

R154 R254 A10266-5601 56

R155 R255 A10266-1321 1.3K

R156 R256 A10266-1321 1.3K

R157 R257 A10266-1321 1.3K

R158 R258 A10265-11321 11.3K

R159 R259 A10265-10011 1K 1%

R160 R260 A10266-5601 56

R161 R261 A10266-4701 47

R162 R262 A10266-4701 47

R163 R263 A10266-5601 56

R164 R264 A10266-4711 470

R165 R265 A10266-4711 470

R166 R266 A10266-4711 470

R167 R267 A10265-10011 1K 1%

R168 R268 A10265-10011 1K 1%

R170 R270 A10265-10011 1K 1%

R171 R271 A10265-10011 1K 1%

R173 R273 A10266-5601 56

R174 R274 A10265-24921 24.9K 1%

R175 R275 A10265-78711 7.87K 1%

R176 R276 A10265-24921 24.9K 1%

R177 R277 A10265-19121 19.1K 1%

R179 R279 A10266-1321 1.3K

R180 R280 A10266-4711 470

R181 R281 A10266-4721 4.7K

R182 R282 A10266-2201 22

R184 R284 A10266-4741 470K

R186 R286 A10266-2751 2.7M

R187 R287 A10266-3321 3.3K

R188 R288 A10266-3321 3.3K

R189 R289 A10266-2731 27K

R190 R290 A10266-2051 2M

R193 R293 A10265-10021 10K 1%

R194 R294 A10265-10031 100K 1%

R195 R295 A10266-3021 3K

R196 R296 A10266-4721 4.7K

R197 R297 A10265-10021 10K 1%

R198 R298 A10266-4721 4.7K

R199 R299 A10265-10021 10K 1%

R300 R400 A10265-10031 100K 1%

R301 R401 A10265-10031 100K 1%

R911 R1011 A10266-1521 1.5K

R912 R1012 A10266-4711 470

R913 R1013 A10265-10031 100K 1%

R914 R1014 A10266-5141 510K

R915 R1015 A10266-2201 22

R916 R1016 A10266-2201 22

R917 R1017 A10266-10021 10K

R918 R1018 A10266-10021 10K

R919 R1019 A10266-10021 10K

R920 R1020 A10266-10021 10K

R921 R1021 C 9079-2 200 Pot

R922 R1022 A10265-68101 681 1%

R923 R1023 A10265-35711 3.57K 1%

R924 R1024 A10265-60401 604 1%

R925 R1025 A10265-10031 100K 1%

R926 R1026 A10265-60401 604 1%

R927 R1027 A10265-10031 100K 1%

R928 R1028 A10265-35711 3.57K 1%

R929 R1029 A10266-1241 120K

R930 R1030 A10266-1241 120K

R931 R1031 A10266-3921 3.9K

R932 R1032 A10265-10021 10K 1%

R933 R1033 A10266-4731 47K

R934 R1034 A10265-10021 10K 1%

R935 R1035 A10266-4731 47K

R936 R1036 A10265-10021 10K 1%

R937 R1037 A10265-10021 10K 1%

R938 R1038 A10265-10021 10K 1%

R939 R1039 A10266-4731 47K

R940 R1040 A10266-4731 47K

R941 R1041 A10266-4731 47K

R942 R1042 A10266-4731 47K

SWITCHES

S2 C 7325-1 Ground Lift

S3 C 7960-5 Sensitivity

S4 C 6781-6 Ster eo/Mon

TEST POINTS

TP1 TP2 C 6564-6 HDR

INTEGRATED CIRCUITS

U1 C 5095-2 UA7815

U2 C 5096-0 UA7915

U100 U200 C 6911-9 UPA75

U101 U201 C 6411-0 H11C2

U102 U202 C 4345-2 LM339

U103 U203 C 6910-1 UPA76

U104 U204 C 7558-7 MC33079P

MISC.

Board D 8679-9

Socket C 3450-1 14 Pin (4)

U1X, U2X C 9494-3 Heatsinks

HW1-4 C 8812-7 5.5" Cbl Tie

HW5-9 C 9944-7 Nyl. Spacer

J1 C 7593-4 5 Pin HDR

J2 C 4508-5 16 Pin

J11 C 7526-4 3 Pin HDR

J100 J200 C 6777-4 Ph Jack, (2)

Cover C 6778-2 Ph Jk CVR

24

Page 25

Micro-Tech 2400 Amplifier Service Manual

Q43328-6 Main Module Parts List Cont. (D8679-9 Board)

J500 J800 D 8681-5 10 In. RBN

J600 J700 D 8680-7 6 In. RBN

HW5-8 C 8812-7 5.5" Cbl Tie

Z1-Z5 OPEN

25

Page 26

Micro-Tech 2400 Amplifier Service Manual

Q43399-7 Main Module Parts List (D8827-4 Board)

Q43399-7 MT-2400 MAIN MODULE

Use Schematic J 0691-6

CAPACITORS

C1 C 3913-8 470µF

C2 C 3913-8 470µF

C4 C 6802-0 .47µF

C5 C 6806-1 .01µF

C6 C 6806-1 .01µF

C7 C 8897-8 .1µF

C8 C 5362-6 2.2uF

C100 C200 C 5311-3 22µF

C101 C201 C 9464-6 10pF

C102 C202 C 8576-8 100uF

C103 C203 C 6805-3 .022µF

C104 C204 C 6805-3 .022µF

C105 C205 C 6812-9 47pF

C106 C206 C 6812-9 47pF

C107 C207 C 8897-8 .1µF

C108 C208 C 6814-5 12pF

C109 C209 C 8576-8 100µF

C110 C210 C 5362-6 2.2µF

C112 C212 C 8991-9 .47µF

C113 C213 C 8996-9 15µF

C114 C214 C 8854-9 100µF

C115 C215 C 8854-9 100µF

C116 C216 C 8986-9 15µF

C117 C217 C 8991-9 .47µF

C118 C218 C 6814-5 12pF

C119 C219 C 6802-0 .47µF

C122 C222 C 6811-1 100pF

C123 C223 C 6812-9 47pF

C124 C224 C 6812-9 47pF

C129 C229 C 6814-5 12pF

C130 C230 C 6813-7 27pF

C133 C233 C 6813-7 27pF

C134 C234 C 6805-3 .022µF

C135 C235 C 6805-3 .022µF

C136 C236 C 6808-7 470pF

C137 C237 C 6808-7 470pF

C138 C238 C 6813-7 27pF

C139 C239 C 6813-7 27pF

C140 C240 C 6812-9 47pF

C141 C241 C 6812-9 47pF

C144 C244 C 8576-8 100µF

C145 C245 C 6812-9 47pF

C146 C246 C 6812-9 47pF

C147 C247 C 6806-1 .01µF

C148 C248 C 6810-3 180pF

C149 C249 C 6808-7 470pF

C150 C250 C 6806-1 .01µF

C151 C251 C 6806-1 .01µF

C152 C252 C 6950-7 82pF 5%

C153 C253 C 8897-8 .1µF

C154 C254 A10434-104JD .1µF 250V

C155 C255 C 8897-8 .1µF

C156 C256 C 8897-8 .1µF

C158 C258 C 6805-3 .022uF

C159 C259 C 6805-3 .022uF

C160 C260 C 8897-8 .1uF

C161 C261 C 8897-8 .1uF

C113X C213X OPEN

C116X C216X OPEN

DIODES

D1 C 2851-1 1N4004

D2 C 2851-1 1N4004

D3 C 2851-1 1N4004

D4 C 2851-1 1N4004

D5 C 2851-1 1N4004

D6 C 2851-1 1N4004

D7 C 2851-1 1N4004

D100 D200 C 3181-2 1N4148

D101 D201 C 3181-2 1N4148

D102 D202 C 3824-7 1N970B

D103 D203 C 3181-2 1N4148

D104 D204 C 3181-2 1N4148

D105 D205 C 2851-1 1N4004

D106 D206 C 2851-1 1N4004

D108 D208 C 3181-2 1N4148

D109 D209 C 3181-2 1N4148

D110 D210 C 3181-2 1N4148

D111 D211 C 5061-4 1N3070

D112 D212 C 3181-2 1N4148

D113 D213 C 3181-2 1N4148

D120 D220 C 3181-2 1N4148

D121 D221 C 3181-2 1N4148

D122 D222 C 3181-2 1N4148

D123 D223 C 5061-4 1N3070

D124 D224 C 3181-2 1N4148

D125 D225 C 3181-2 1N4148

D126 D226 C 5061-4 1N3070

D127 D227 C 5061-4 1N3070

D128 D228 C 5061-4 1N3070

D129 D229 C 3181-2 1N4148

D130 D230 C 3181-2 1N4148

D131 D231 C 3181-2 1N4148

D132 D232 C 3181-2 1N4148

D133 D233 C 3181-2 1N4148

D134 D234 C 3181-2 1N4148

LED's

E100 E200 C 9857-1 RED

E101 E201 C 9857-1 RED

26

Page 27

Micro-Tech 2400 Amplifier Service Manual

Q43399-7 Main Module Parts List Cont. (D8827-4 Board)

RESISTOR NETWORKS

N101 N201 D 7944-8 Res. Net.

N102 N202 D 6082-8 Res. Net.

TRANSISTORS

Q100 Q200 D 2961-7 2N3859A

Q101 Q201 C 3578-9 MPSA93

Q102 Q202 C 3810-6 MPSA43

Q103 Q203 C 3786-8 PN4250

Q105 Q205 C 3578-9 MPSA93

Q106 Q206 C 3625-8 2N4125

Q107 Q207 C 3786-8 PN4250

Q108 Q208 C 5891-4 MTS105

Q109 Q209 D 2961-7 2N3859A

Q110 Q210 C 3810-6 MPSA43

Q112 Q212 C 3625-8 2N4125

Q113 Q213 C 3625-8 2N4125

Q115 Q215 D 2962-5 MPS8097

Q116 Q216 C 3786-8 PN4250

Q117 Q217 D 2961-7 2N3859A

Q118 Q218 D 2961-7 2N3859A

Q119 Q219 C 3625-8 2N4125

Q120 Q220 C 3625-8 2N4125

Q123 Q223 C 7458-0 2N4123

Q124 Q224 C 3625-8 2N4125

Q125 Q225 C 3786-8 PN4250

Q126 Q226 C 5891-4 MTS105

Q127 Q227 C 3625-8 2N4125

Q128 Q228 C 7458-0 2N4123

Q129 Q229 C 3625-8 2N4125

Q130 Q230 C 7458-0 2N4123

Q131 Q231 C 3625-8 2N4125

Q132 Q232 C 3625-8 2N4125

Q133 Q233 C 3625-8 2N4125

Q134 Q234 C 3625-8 2N4125

Q135 Q235 C 7458-0 2N4123

Q136 Q236 C 7458-0 2N4123

Q137 Q237 C 3625-8 2N4125

Q138 Q238 C 3810-6 MPSA42

Q139 Q239 C 3578-9 MPSA93

RESISTORS

R1 A10265-53621 53.6K 1%

R2 C 7340-0 24 5W

R3 C 7340-0 24 5W

R4 A10265-46421 46.4K 1%

R5 OPEN

R7 A10266-4331 43K

R8 A10265-75021 75K 1%

R10 OPEN

R11 OPEN

R12 OPEN

R17 A10265-75021 75K 1%

R18 A10266-4331 43K

R100 R200 C 7409-3 5K Lin. Pot.

R101 R201 A10265-49911 4.99K 1%

R102 R202 A10266-5111 510

R103 R203 A10265-10031 100K 1%

R104 R204 A10266-2721 2.7K

R105 R205 A10266-2721 2.7K

R106 R206 A10266-1231 12K

R107 R207 A10266-6831 68K

R108 R208 A10265-80601 806

R109 R209 A10266-5601 56

R110 R210 A10266-6831 68K

R111 R211 A10266-1231 12K

R112 R212 A10266-5131 51K

R113 R213 A10266-4721 4.7K

R114 R214 A10266-4721 4.7K

R115 R215 A10266-3341 330K

R116 R216 A10266-2751 2.7M

R117 R217 A10265-46421 46.4K 1%

R118 R218 A10265-28701 287 1%

R119 R219 A10265-68101 681 1%

R120 R220 A10265-28701 287 1%

R121 R221 C 5062-2 100K Pot

R122 R222 A10266-2741 270K

R123 R223 A10266-2732 27K .5W

R124 R224 A10266-6821 6.8K

R125 R225 C 8836-6 100 .5W FP

R126 R226 C 8836-6 100 .5W FP

R127 R227 A10266-6821 6.8K

R128 R228 A10266-1331 13K

R129 R229 A10265-10031 100K 1%

R130 R230 A10265-10031 100K 1%

R131 R231 A10266-1331 13K

R132 R232 C 5062-2 100K Pot

R133 R233 A10266-2741 270K

R134 R234 A10266-2732 27K .5W

R135 R235 C 8836-6 100 .5W FP

R136 R236 A10266-6821 6.8K

R137 R237 C 8836-6 100 .5W FP

R138 R238 A10266-6821 6.8K

R139 R239 A10265-80601 806 1%

R140 R240 A10266-5601 56

R141 R241 A10266-1541 150K

R142 R242 A10266-1541 150K

R143 R243 A10266-4711 470

R144 R244 A10266-4711 470

R145 R245 A10266-4711 470

R146 R246 A10266-1231 12K

R147 R247 C 8836-6 100 .5W FP

R148 R248 A10266-2721 2.7K

27

Page 28

Micro-Tech 2400 Amplifier Service Manual

Q43399-7 Main Module Parts List Cont. (D8827-4 Board)

R149 R249 C 8836-6 100 .5W FP

R150 R250 A10266-2721 2.7K

R151 R251 A10266-1231 12K

R152 R252 A10265-11521 11.5K 1%

R153 R253 A10124-24 JUMPER

R154 R254 A10266-5601 56

R155 R255 A10266-1321 1.3K

R156 R256 A10266-1321 1.3K

R157 R257 A10266-1321 1.3K

R158 R258 A10265-11321 11.3K

R159 R259 A10265-10011 1K 1%

R160 R260 A10266-5601 56

R161 R261 A10266-4701 47

R162 R262 A10266-4701 47

R163 R263 C10166-4 56 FP

R164 R264 A10266-4711 470

R165 R265 A10266-4711 470

R166 R266 A10266-4711 470

R167 R267 A10265-10011 1K 1%

R168 R268 A10265-10011 1K 1%

R169 R269 OPEN

R170 R270 A10265-10011 1K 1%

R171 R271 A10265-10011 1K 1%

R172 R272 OPEN

R173 R273 C10166-4 56

R174 R274 A10265-24921 24.9K 1%

R175 R275 A10265-78711 7.87K 1%

R176 R276 A10265-24921 24.9K 1%

R177 R277 A10265-19121 19.1K 1%

R179 R279 A10266-1321 1.3K

R180 R280 A10266-4711 470

R181 R281 A10266-4721 4.7K

R182 R282 A10266-2201 22

R184 R284 A10266-4741 470K

R186 R286 A10266-2751 2.7M

R187 R287 A10266-3321 3.3K

R188 R288 A10266-3321 3.3K

R189 R289 A10266-2731 27K

R190 R290 A10266-2051 2M

R193 R293 A10266-1031 10K

R194 R294 A10265-10031 100K 1%

R195 R295 A10266-3021 3K

R196 R296 A10266-4721 4.7K

R197 R297 A10265-10021 10K 1%

R198 R298 A10266-4721 4.7K

R199 R299 A10265-10021 10K 1%

R300 R400 A10265-10031 100K 1%

R301 R401 A10265-10031 100K 1%

R911 R1011 A10266-1521 1.5K

R912 R1012 A10266-4711 470

R913 R1013 A10266-1041 100K

R914 R1014 A10266-5141 510K

R915 R1015 A10266-2201 22

R916 R1016 A10266-2201 22

R917 R1017 A10266-10021 10K

R918 R1018 A10266-10021 10K

R919 R1019 A10266-10021 10K

R920 R1020 A10266-10021 10K

R921 R1021 C 9079-2 200 Pot

R922 R1022 A10265-68101 681 1%

R923 R1023 A10265-35711 3.57K 1%

R924 R1024 A10265-60401 604 1%

R925 R1025 A10266-1041 100K

R926 R1026 A10265-60401 604 1%

R927 R1027 A10266-1041 100K

R928 R1028 A10265-35711 3.57K 1%

R929 R1029 A10266-1241 120K

R930 R1030 A10266-1241 120K

R931 R1031 A10266-3921 3.9K

R932 R1032 A10266-1031 10K

R933 R1033 A10266-4731 47K

R934 R1034 A10266-1031 10K

R935 R1035 A10266-4731 47K

R936 R1036 A10266-1031 10K

R937 R1037 A10266-1031 10K

R938 R1038 A10266-1031 10K

R939 R1039 A10266-4731 47K

R940 R1040 A10266-4731 47K

R941 R1041 A10266-4731 47K

R942 R1042 A10266-4731 47K

R943 R1043 A10266-1031 10K

R944 R1044 A10266-1031 10K

R945 R1045 A10266-4701 47

R946 R1046 A10266-2031 20K

R947 R1074 A10266-2031 20K

SWITCHES

S2 C 7325-1 Gnd Lift

S3 C 7960-5 Sensitivity

S4 C 6781-6 Ster eo/Mon

TEST POINTS

TP1 TP2 C 6564-6 HDR

INTEGRATED CIRCUITS

U1 C 5095-2 UA7815

U2 C 5096-0 UA7915

U100 U200 C 6911-9 UPA75

U101 U201 C 6411-0 H11C2

U102 U202 C 4345-2 LM339

U103 U203 C 6910-1 UPA76

U104 U204 C 7558-7 MC33079P

U100A U200A OPEN

28

Page 29

Micro-Tech 2400 Amplifier Service Manual

Q43399-7 Main Module Parts List Cont. (D8827-4 Board)

U103A U203A OPEN

MISC.

Board D 8827-4

Socket C 3450-1 14 Pin

HW9-10 C 9494-3 Heatsinks

HW11-15 C 9944-7 Nyl. Spacer

J1 C 7593-4 5 Pin HDR

J2 C 4508-5 16 Pin

J11 C 7526-4 3 Pin HDR

J12 Not Used

J100 J200 C 6777-4 Ph. Jack

Cover C 6778-2 Ph Jk CVR

J101 J201 Not Used

J500 J800 D 8681-5 10 In. RBN

J600 J700 D 8680-7 6 In. RBN

HW5-8 C 8812-7 5.5" Tie, (4)

Z1-Z5 OPEN

29

Loading...

Loading...