Page 1

SW Series Manual

!

!

Overhead Electric Infrared Heater

Installation, Operation, Maintenance and Parts

1, 2 and 3 Lamp Units

All persons involved with the installation, operation and maintenance of the heater system must read and

understand the information in this manual.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read and understand the installation, operating

and maintenance instructions thoroughly before installing or servicing this equipment.

C R O W N V E R I T Y I N C .

37 Adams Boulevard, Brantford, Ontario, Canada N3S 7V8

tel 519.751.1800 or 888.505.7240 fax 519.751.1802 e-mail info@crownverity.com web www.crownverity.com

Page 2

SW Series Manual

3

Contents

1.0 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Model Number Designation Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Available Models and Operational Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Clearance to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Signs and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Standards, Certifications and Government Regulations. . . . . . . . . . . . . . . . . . . . . . . . 8

2.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Heater Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lamp Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Outdoor Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.0 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Heater Assembly Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Parts Listing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.0 Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2

Page 3

SW Series Manual

!

!

!

!

!

!

1.0 Safety • Safety Symbols • Applications

1.0 Safety

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, serious injury or death. Read and understand the installation,

operating and maintenance instructions thoroughly before installing or servicing this

equipment. Only trained, qualified personnel with proper electrical experience may

install or service this equipment.

Safety Symbols

Safety is the most important consideration during installation, operation and maintenance of the infrared

heater. You will see the following symbols and signal words when there is a hazard related to safety or

property damage.

Warning indicates a potentially hazardous situation

!

WARNING

which, if not avoided, could result in death or injury.

Caution indicates a potentially hazardous situation

CAUTION

NOTICE

which, if not avoided, could result in minor or

moderate injury.

Notice indicates a potentially hazardous situation

which, if not avoided, could result in property

damage.

Applications

Commercial / Industrial (Indoors & Outdoors)

Infrared heaters are designed and certified for use in industrial and commercial buildings such as

warehouses, manufacturing plants, aircraft hangars and vehicle maintenance shops. For maximum safety,

the building must be evaluated for potential hazards before installing the heater system. A critical safety

factor to consider before installation is the clearance to combustibles.

Outdoor Residential Only

This heater is NOT approved for use in an indoor residential application. This includes, but not limited to,

attached garages, living quarters, solariums, etc. Consult the local fire marshal and/or insurance provider

if unsure of your application.

WARNING

Not For Residential Use.

Installation of this infrared heater system in residential indoor spaces, RV’s, mobile homes,

etc. may result in property damage, fire, serious injury or death.

3

Page 4

5

1.0 Safety • Model Number Designation Chart • Available Models

Model Number Designation Chart

SW Series Manual

Series Material Type

SW-24

SW-33

SW-46

Model Configuration Examples:

SW-24B1-C16R, or SW-33S2-G25W

B= Black Powder Coat

or

S= Stainless Steel

Lamp

Qty.

1

2

3

Voltage Code

A= 120 VAC

B= 208 VAC

C= 240 VAC

D= 277 VAC

G= 480 VAC

H= 575 VAC

Lamp Wattage

Code

16

25

36

38

Lamp Type (Color)

R= Ruby Lamp

W= Standard Lamp

Available Models and Operational Specifications

Series Lamp Qty. Voltage; Phase Amperes Watts BTU/h

120; 1ph 13.33

208; 1ph 7.69

240; 1ph 6.67

480; 1ph 3.33

208; 1ph 15.38

480; 1ph 6.67

208; 1 or 3ph 23.08

480; 1 or 3ph 10.00

208; 1ph 12.02

240; 1ph 10.42

480; 1ph 5.21

208; 1ph 24.04

480; 1ph 10.42

480; 1ph 7.60 3,650 12,454

575; 1ph 6.60 3,800 12,978

480; 1ph 15.21 7,300 24,909

575; 1ph 13.22 7,600 25,955

480; 1 or 3ph 22.81 10,950 37,636

575; 1 or 3ph 19.83 11,400 38,933

1,600 5,459

3,200 10,919240; 1ph 13.33

4,800 16,378240; 1 or 3ph 20.00

2,500 8,530

5,000 17,065240; 1ph 20.83

SW-24

SW-33

SW-46

1

2

3

1

2

3 480; 1 or 3ph 15.625 7,500 25,590

1

2

3

or

4

Page 5

SW Series Manual

!

Clearance to Combustibles

Placement of explosive objects, flammable objects, liquids and vapors close to the heater

may result in explosion, fire, property damage, serious injury or death. Do not store, or use,

explosive objects, liquids and vapor in the vicinity of the heater.

Failure to comply with the published clearances to combustibles could result in personal

injury, death and/or property damage.

The outside surfaces of the heater are hot during operation and after operation. If contact is

made, permanent skin damage may occur. Do not move, handle, or service the unit during

operation or while hot.

Signs shall be posted specifying the maximum permissible stacking height in order to

maintain clearances to combustibles.

WARNING

!

CAUTION

1.0 Safety • Clearance to Combustibles

Hazards Include:

For maximum safety the building must be evaluated for hazards before installing the heater system.

Examples include, but are not limited to:

• Gas and electrical lines

• Combustible and explosive materials

• Chemical storage areas

• Areas of high chemical fume concentrations

• Provisions for accessibility to the heater

• Adequate clearances around air openings

• Vehicle parking areas

A critical safety factor to consider before installation is the clearances to combustibles. Clearance to

combustibles is defined as the minimum distance you must have between the indicated surface and the

combustible item. Considerations must also be made for moving objects around the infrared heater. The

following is a partial list of items to maintain clearances from:

• Vehicles with lifts or cranes

• Storage areas with stacked materials

• Lights

• Sprinkler heads

• Overhead doors and tracks

• Dirty, contaminated environment

Combustible Items Include: Moving Objects Include:

• Wood • Overhead doors

• Paper • Vehicles on lifts

• Fabric • Cranes

• Chemicals • Hoists

• Wall or roof insulation • Car wash equipment

When installing the infrared heater system, the minimum clearances to combustibles must be maintained.

These distances are shown in Chart 1.1 and on the heater. If you are unsure of the potential hazards,

consult your local fire marshal, fire insurance carrier or other qualified authorities on the installation of

infrared heaters for approval of the proposed installation.

5

Page 6

7

1.0 Safety • Clearance to Combustibles

Chart 1.1 • Clearance to Combustibles in Inches (see Figure 1.1)

Side

Model

Wattage

Mounting

Angle

Front Behind* End Top Below

0° 24 24 24 6 40

1,600

45° 40 24 24 10 40

0° 24 24 24 6 46

2,500

45° 46 24 24 10 46

0° 24 24 24 6 56

3,200

45° 56 24 24 10 56

3,650

3,800

0° 24 24 24 6 62

45° 62 24 24 10 62

0° 24 24 24 6 72

4,800

45° 72 24 24 10 72

0° 24 24 24 6 72

5,000

45° 72 24 24 10 72

0° 24 24 24 6 84

7,300

45° 84 24 24 10 84

7,500

7,600

10,950

11,400

0° 24 24 24 6 84

45° 84 24 24 10 84

0° 24 24 24 6 96

45° 96 24 24 10 96

*A minimum clearance of 36 inches must be maintained from behind another heater.

SW Series Manual

NOTE: Ensure that building materials with a low heat tolerance (i.e, awnings, fabrics, plastics, sprinklers,

insulation, etc.) are protected against degradation. This may require the heater to be mounted at a

distance in excess of the published clearances to combustibles. Contact the material manufacturer for

specific details.

Figure 1.1 • Clearance to Combustibles

SIDE

END

TOP

TOP VIEW • 0°

SIDE

BELOW

END VIEW

0° Mounting Angle

END

TOP

FRONT

BEHIND

BELOW

END VIEW

45° Mounting Angle

6

Page 7

SW Series Manual

SAMPLE

1.0 Safety • Safety Signs and Labels

Safety Signs and Labels

It is important to provide warnings to alert individuals to potential hazards and safety actions. Signs should

state the hazards for the particular application and be legible to the building occupants. Consult the

factory or a factory representative for additional information on signage compliance.

Safety warning labels must be maintained on the infrared heater. Illustrations of the safety labels, and their

locations, are pictured below. When no longer legible, they must be replaced. Contact either your local

distributor or the product manufacturer for obtaining replacement signs or labels.

Top View

F/N: LLECL001 - Clearance to Combustibles Label

F/N: LL01 - Clearance Safety Tag

(Affix adjacent to heater’s controller)

L1

LAMP NO. 1

LAMP NO. 2

NOTE: USE COPPER CONDUCTORS ONLY

(Located inside raceway)

DETROIT RADIANT INFRARED RADIANT ELECTRIC HEATER

FOR INDOOR COMMERCIAL/INDUSTRIAL USE.

FOR PROTECTED AND UNPROTECTED OUTDOOR USE.

NOT FOR INDOOR RESIDENTIAL USE!

MODEL NO.

SW-24B1-C16R

PHASE:

Single

FREQUENCY:

50/60 Hz

AMPERES

6.67

DESIGN COMPLIES WITH:

UL2021 1997 & C22.2 No. 46-M1988 - Electric Air - Heaters

DETROIT RADIANT PRODUCTS COMPANY

21400 HOOVER ROAD - WARRE N, MI

(586) 756-0950 - www.drp-co.com

VOLTAGE

240

MININMUM

MOUNTING ANGLE:

0 Degrees

MAXIMUM

MOUNTING ANGLE:

45 Degrees

Serial No. 10 10 DETR 021400 0001

CAUTION

- VERIFY SUPPLY VOLTAGE -

DISCONNECT FROM ELECTRICAL SUPPLY

L2

BEFORE SERVICING THIS HEATER.

THIS APPLIANCE MUST BE PROPERLY

GROUNDED TO THE ELECTRICAL SOURCE.

Electrical Label

WATTAGE

1600

VERSION

11/1020

STANDARD LAMP:

EL-083

ALTERNATE LAMP:

EL-073

Rating Plate

LLWEL02-1M-03/11 (CDS)

7

Page 8

9

1.0 Safety • Standards, Certifications and Government Regulations

SW Series Manual

Standards, Certifications and Government Regulations

Installation of this infrared heater must comply with all applicable local, state and national specifications,

regulations and building codes. Contact the local building inspector and/or fire marshal for guidance.

The heater must be electrically grounded in accordance with the following codes:

United States: Refer to National Electrical Code®, ANSI/NFPA 70 (latest edition).

Wiring must conform to the latest edition of National Electrical

Code®, local ordinances, and any special diagrams from the manufacturer.

Canada: Refer to Canadian Electrical Code CSA C22.1 Part 1 (latest edition).

Crown Verity units comply or are certified by one or more of the following organizations or

standards:

• CSA 22.2 #46 - M1988

• UL 2021, 1997

8

Page 9

SW Series Manual

!

!

!

2.0 Installation • Design

2.0 Installation

WARNING

Read and understand, the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

Design

To ensure a safe, properly designed heating system, a layout should be developed for the correct

placement of the infrared heater(s).

Aside from safety factors such as clearance to combustibles (see Chart 1.1 on page 6), you should also

take into consideration the environment (e.g., cold/drafty, average, protected), heat coverage (sq. ft.)

needed, heater centers, the distance behind a person or work station(s). Also, the effective infrared

surface temperature of a person or object may be diminished with wind above 5 mph. Wind barrier(s)

may be required. Most importantly, clearance to combustibles must always be maintained! Refer to

hazards on page 5.

When positioning the heaters, keep in mind combustible materials, lights, sprinkler heads, overhead

doors, storage area with stacked materials, gas and electrical lines, parked vehicles, cranes, etc. Refer to

Page 6 for minimum clearance to verify that a safe installation exists.

This installation manual, along with national, state, provincial and local codes, address these issues. It is

critical that you read, understand and follow all guidelines and instructions. Always inspect and evaluate

the mounting conditions, application, and wiring.

When heated, materials high in hydrocarbons (solvents, paint thinner, mineral spirits, formaldehydes, etc.)

can evaporate and/or degrade. This may result in odors or fumes being emitted into the environment. To

correct this problem, clean the area and/or introduce additional ventilation. Heaters installed and serviced

in accordance with the installation manual do not emit foul odors into the environment.

IMPORTANT: Fire sprinkler heads must be located at an appropriate distance from the heater to avoid

an inadvertent discharge. This distance may exceed the published clearance to combustibles. Certain

applications may require the use of high temperature sprinkler heads or relocation of the heaters.

CAUTION

Fire sprinkler systems containing propylene glycol, antifreeze or other potentially flammable substances

shall not be used in conjunction with this heater without careful consideration for and avoidance of

inadvertent discharge hazards. For further information consult NFPA 13. Always observe applicable state

and local codes.

9

Page 10

11

2.0 Installation • Design

SW Series Manual

Chart 2.1 • Outdoor Comfort Heating Application Chart

(Dim A)

Recommended

Series Lamp Qty.

1 8-10 17 x 15 6.3

SW-24

SW-33

SW-46

Heater installation shall comply with all IOPM, NEC, ANSI/NFPA-70, CEC, and local restrictions.

2 8-10 17 x 16 11.8

3 10-12 21 x 21 10.9

1 8-10 18 x 15 9.3

2 10-12 22 x 20 11.4

3 10-12 22 x 21 16.2

1 10-12 22 x 19 8.7

2 12-14 27 x 24 11.3

3 12-14 27 x 25 16.2

Mounting Height (Ft.)*

Coverage of Heater

Length x Width (Ft.) Watts per Square Foot

Chart 2.2 • Indoor Spot Heating Application Chart

(Dim A)

Recommended

Series Lamp Qty.

1 8-10 21 x 19 4.0

SW-24

SW-33

SW-46

When comfort heating people, two heaters should be used to heat both sides of the individual. Heater installation shall

comply with all IOPM, NEC, ANSI/NFPA-70, CEC and local restrictions.

2 8-10 21 x 20 7.6

3 10-12 25 x 23 8.4

1 8-10 22 x 19 6.0

2 10-12 26 x 24 8.0

3 10-12 26 x 25 11.5

1 10-12 26 x 25 5.6

2 12-14 31 x 26 9.0

3 12-14 31 x 27 13.1

Mounting Height (Ft.)*

Coverage of Heater

Length x Width (Ft.) Watts per Square Foot

*Clearance to combustibles must be maintained at all times. Factory recommended mounting heights are listed as a

guideline. If infrared heaters are mounted too low or too high, they may result in discomfort or lack of heat.

Figure 2.1 • Heating Application

36” Min.

Dim A

10

Page 11

SW Series Manual

!

2.0 Installation • Heater Mounting

Heater Mounting

WARNING

Improper suspension of the infrared heater may result in collapse and being crushed.

Always suspend from a permanent part of the building structure that can support the total

force and weight of the heater.

Failure to maintain minimum clearance to combustibles may result in fire and/or explosion,

property damage, serious injury or death. Always maintain minimum clearances and post

signs or provided tags (F/N: LL01) adjacent to heaters controller. Signs should state the

hazards for the particular application and be legible to the building occupants. Consult the

factory or a factory representative for additional information on signage compliance.

The heater can be suspended with chains or rigid threaded rod. Local codes, or conditions that would

cause the unit to move (e.g., wind drafts, blowers, crane rails, etc.), may require rigid threaded rod.

Consult all applicable codes before installation.

The heater must be level from side to side and may be 0° to 45° on horizontal. Refer to figures 2.2 and

2.3.

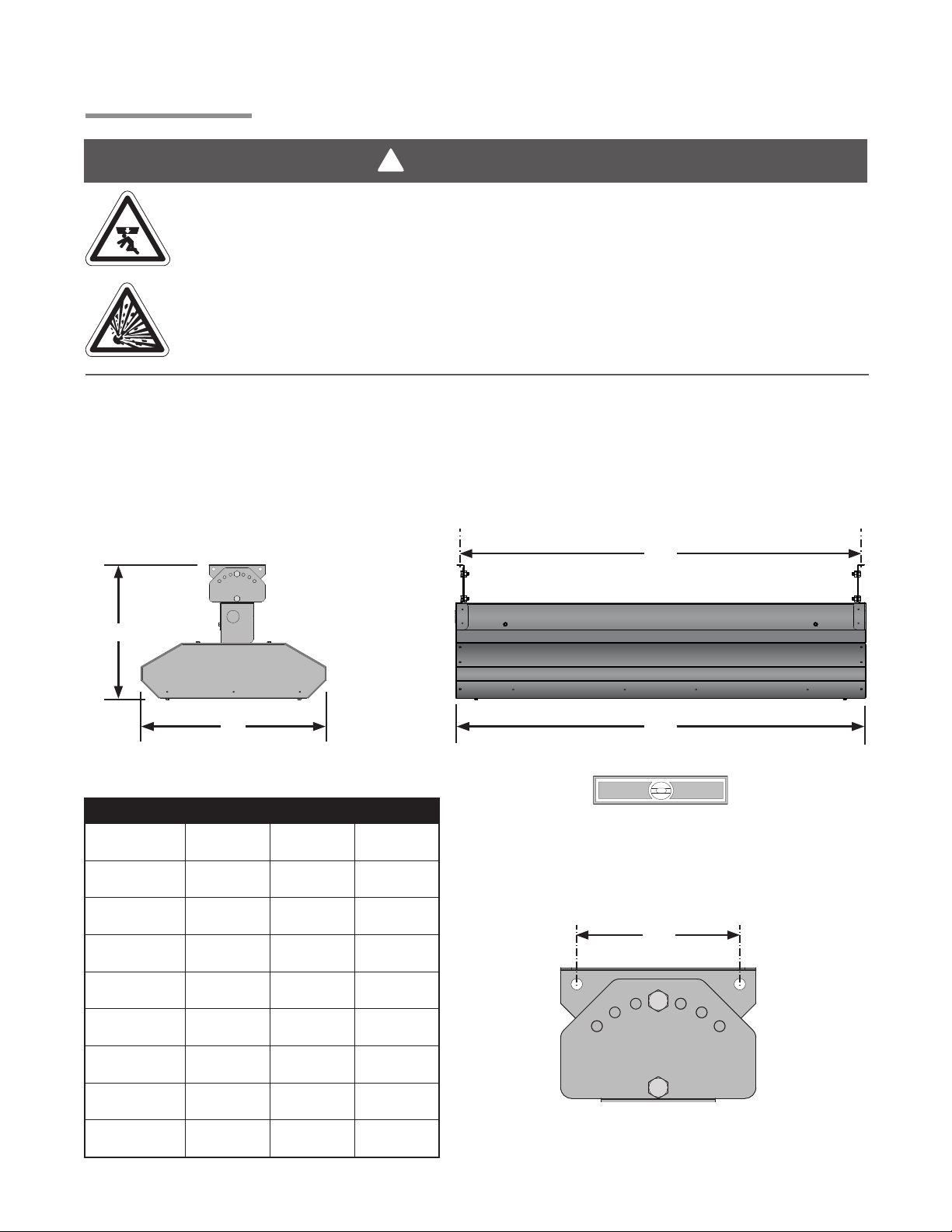

Figure 2.2 • Heater Dimensions

10.50

B

Chart 2.3 • Physical Dimensions (inches)

Model No. A B C

SW-24-X1 23.50 9.25 24.00

SW-24-X2 23.50 15.00 24.00

SW-24-X3 23.50 20.75 24.00

SW-33-X1 32.50 9.25 33.00

SW-33-X2 32.50 15.00 33.00

A

(Center of Mounts)

C

Mount Heater Level

- Side to Side -

Figure 2.3 • Mounting Centers

3.75

SW-33-X3 32.50 20.75 33.00

SW-46-X1 45.50 9.25 46.00

SW-46-X2 45.50 15.00 46.00

SW-46-X3 45.50 20.75 46.00

11

Page 12

13

2.0 Installation • Heater Mounting

SW Series Manual

Top Channel Assembly

Attach the mounting brackets to the top wire raceway. On each end, place (1) 1/4” x 1/2” bolt through

1

the bottom hole of the mounting bracket and through the bottom hole of the top wire raceway.

Place (1) 1/4” lock nut on each bolt. Do not tighten completely. Refer to figure 2.4.

NOTE: The mounting brackets are NOT required for chain suspension.

Adjust wire raceway to desired mounting angle

2

On each side, place (1) 1/4” x 1/2” bolt through slot in the mounting bracket and the hole in the top wire

3

raceway. Place (1) 1/4” lock nut on each bolt and tighten.

Tighten lock nuts from Step 1.

4

Hook heater body into mounted wire raceway. Unit will hang freely by the “T” hinge, leaving both

5

hands free to wire unit. Refer to figure 2.4.

Run supplied high temperature wires out to field supplied junction box. DO NOT make connections

6

inside the wire raceway

Close wire raceway using the (4) #8-32 x 3/8” grounding screws provided in hardware pack.

7

Figure 2.4 • Top Channel Assembly

Wire Raceway

#8-32 x 3/8”

Grounding

Screw

#8-32 x 3/8” Grounding Screw

1/4” x 1/2” Bolt

T-Hinge

12

Page 13

SW Series Manual

!

2.0 Installation • Lamp Installation

Lamp Installation

CAUTION

Disconnect power prior to installing or replacing supplied quartz lamp(s). The elements can and should

be installed prior to mounting the heater.

Remove the service access panels and open lamp retainers.

1

Position heating elements in “U” slots at the ends of the reflector. When utilizing the ruby lamps, the

2

lamp adapter plates (EL-006) must first be removed.

Close lamp retainers to secure the heating element in the slot (see Figure 2.5).

3

Carefully wrap the heating element pigtail one revolution clockwise around terminal screws (see Figure

4

2.6). NOTE: Cut excess pigtail off at terminal to prevent lead from touching metal parts. Avoid

handling the quartz glass as much as possible. Quartz glass should be wiped off with alcohol using a

clean cloth.

Tighten the terminal screws (see Figure 2.6). CAUTION: Do not pull pigtail too tightly that pressure is

5

being placed on the heating element. Maintain a 1/2” slack in the pigtail.

Reinstall service access panels using sheet metal screws as removed in Step 1.

6

Figure 2.5 • Lamp Installation

Lamp Retainers

Figure 2.6 • Lamp Installation

Terminal Screws

Cut off excess

Lamp Adapter Plates (EL-006)

Wrap pigtail clockwise

around terminal screw

1/2” slack on pigtail

NOTE: SW Series heaters are designed for use with Quartz lamp infrared heating elements only. They

are NOT intended to be used with straight metal rod heating elements. Replace lamps with parts

from Crown Verity only.

13

Page 14

15

!

2.0 Installation • Outdoor Application • Electrical

SW Series Manual

Totally Exposed Outdoor Applications

!

CAUTION

For totally exposed outdoor applications (not ceiling protected) ensure connections are made as illustrated

in Figure 2.7

Figure 2.7 • Exposed Outdoor Application

6”

Minimum

NOTE: All conduit, conduit fittings, and junction boxes are field supplied. Must be NEMA Type 4x or

equivalent. Heater must be suspended from mounting brackets.

Electrical

WARNING

Electric Shock

Field wiring to the heater must be connected and grounded in accordance with national,

state, provincial, local codes and to the guidelines in the this manual. In the United States

refer to the most current revisions to the ANSI/NFPA 70 Standard and in Canada refer to

the most current revisions the CSA C22.1 Part I Standard.

Disconnect power to heater before servicing.

Failure to follow these instructions can result in death or electrical shock

This fixture is equipped with high temperature silicone lead wires to make connections to branch circuit.

Remove the wire-ties prior to making electrical connections.

Wiring connections should always be through one of the knockouts in the top wire raceway. Wire

connections must also be made outside the of the top wire raceway. Consult the factory, or a qualified

electrician for details on staging.

Supply wires must be a copper conductor type, with a minimum size of 10AWG.

Infrared heater must be connected to the earthing conductor (green wire) installed by the factory.

See above for use in Totally Exposed Outdoor Applications.

14

Page 15

SW Series Manual

LAMP NO. 1

L1

L2

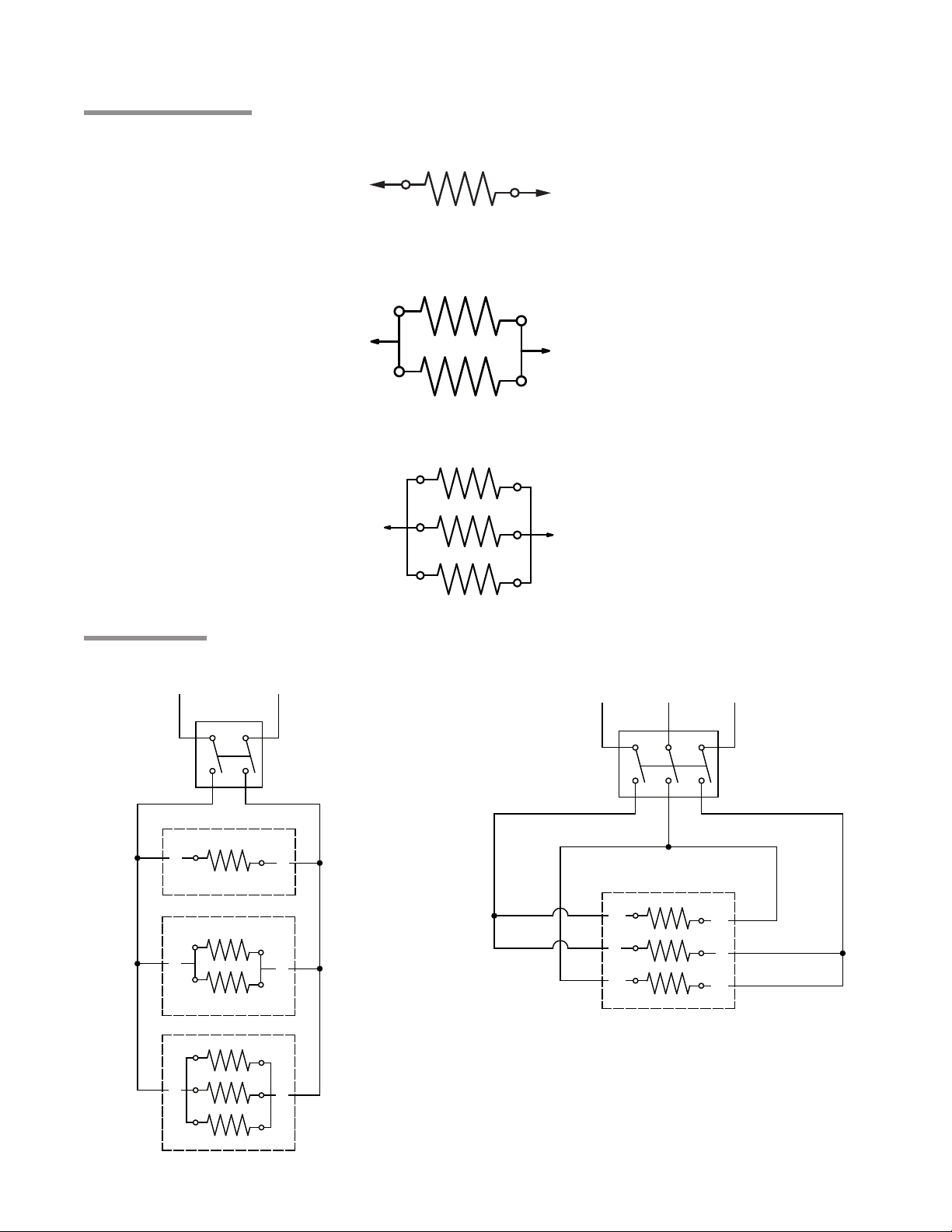

SINGLE LAMP UNIT

DOUBLE LAMP UNIT

TRIPLE LAMP UNIT

CONTROL

DEVICE

L1 L2

L1

L2

L1

L2

L1

L2

Wiring Diagrams

Figure 2.8 • SW Wiring Diagram • Units with 1 Lamp

Figure 2.9 • SW Wiring Diagram • Units with 2 Lamps

2.0 Installation • Wiring Diagrams

L1

LAMP NO. 1

LAMP NO. 2

L2

Figure 2.10 • SW Wiring Diagram • Units with 3 Lamps

LAMP NO. 1

L1

LAMP NO. 2

LAMP NO. 3

L2

Field Wiring

Figure 2.11 • Single Phase Service Figure 2.12 • Three Phase Service

L1 L3

CONTROL

L2

DEVICE

TRIPLE LAMP UNIT

L1

L1

L3

L3

L2

L2

15

Page 16

17

3.0 Maintenance • Maintenance Checks & Log

SW Series Manual

3.0 Maintenance

It is recommended that the following become a standard yearly procedure to obtain maximum operating

efficiency and trouble free operation.

During long periods of non-usage, remove or cover heater with a polyethylene bag and disconnect from

power supply. If further service to the heater is desired, contact your representative or the factory.

Clean reflector surface with a damp cloth.

1

Ensure heater is secure on all hanging points.

2

Maintain clearance to combustibles at all times. Immediately remove objects in violations of the

3

published clearance to combustibles.

Check electrical wires and connections for wear or any kind of damage.

4

16

Page 17

SW Series Manual

3.0 Maintenance • Troubleshooting Guide

Troubleshooting Guide

Turn Heater on from power source.

Does the heating

lamps turn on?

Yes

No

Are the heating lamps

Key

physically damaged?

Start

Question

Yes

Process

Question

Replace heating lamp(s).

No

Are the heating lamps

wired as indicated in

the manual?

No

Rewire lamps as indicated

in this manual.

Yes

Find the source of the electrical problem between panel and heater.

Corrective

Action

Is there a sufficient

amount of heat?

Yes

Is there too much heat?

No

No

Is the supply voltage correct for the

model type on the rating label?

Yes

Is the heater mounted within the

recommended height?

Yes

Mount heater within the

recommended mounting heights.

No

No

Yes

Supply correct voltage

Heater size and/or quantity of

heaters, may be incorrect for

application.

Troubleshooting ends.

17

Page 18

19

3.0 Maintenance • Heater Assembly Components

SW Series Manual

Heater Assembly Components

For complete information on SW Series replacement parts, visit www.crownverity.com For discontinued

models, consult the factory.

Figure 3.1 • Components

016

028

057

058

059

027

037

026

031

033

034

035

051

001

020

023

021

002

003

004

012

013

014

022

024

006

038

025

070-088

152, 153, 154

252, 253, 254

352, 353, 354

155

255

355

106

206

306

18

Page 19

SW Series Manual

Electric Parts Listing

Chart 3.2 • General Parts List

3.0 Maintenance • Heater Assembly Components

Part

No.

EL-001 Ceramic Insulating Base EL-072 Lamp; 2500W 208V Clear

EL-002 Reflector, 24 Inch Model EL-073 Lamp; 1600W 240V Clear

EL-003 Reflector, 33 Inch Model EL-074 Lamp; 2500W 240V Clear

EL-004 Reflector, 46 Inch Model EL-075 Lamp; 1600W 480V Clear

EL-006 Lamp Adaptor Plate EL-076 Lamp; 2500W 480V Clear

EL-012 Reflector Channel, 24 Inch Model EL-077 Lamp; 3650W 480V Clear

EL-013 Reflector Channel, 33 Inch Model EL-078 Lamp; 3800W 575V Clear

EL-014 Reflector Channel, 46 Inch Model EL-080 Lamp; 1600W 120V Ruby

EL-016 Mounting Brackets EL-081 Lamp; 1600W 208V Ruby

EL-020 Brass Strip with three (3) #10-32 holes EL-082 Lamp; 2500W 208V Ruby

EL-021 #10-32 x 3/8 Brass Panhead MS EL-083 Lamp; 1600W 240V Ruby

EL-022 #10-32 x 1-1/4" Stainless Steel Pan Head MS EL-084 Lamp; 2500W 240V Ruby

EL-023 #10-32 Keps Nut EL-085 Lamp; 1600W 480V Ruby

EL-024 #10 medium Split Lock Washer, Stainless Steel EL-086 Lamp; 2500W 480V Ruby

EL-025 #10-32 x 3/4 SS pan Head #2 Phillips Machine Screw EL-087 Lamp; 3650W 480V Ruby

EL-026

EL-027 1/4 - 20 x 1/2 inch bolt for bracket

EL-028 1/4-20 Nut

EL-029 1/4 Split lock washer

EL-030 Stainless Steel Rivet

EL-031 Green Ground Screw

EL-033 Wire, length for 33, 12 Gauge (specify color) Double Lamp Model Parts List

EL-034 Wire, Length for 24 12 Gauge (specify color)

EL-035 Wire, length for 46 12 Gauge (specify color)

EL-036 Snap-on Fork Terminal for connector

EL-037 Wire Bushing, 2201

EL-038 #8 Stainless Steel Sheet Metal Screw

EL-051 Ceramic Insulating Base Assembly Triple Lamp Model Parts List

EL-057 Wire Raceway Cover Assembly, 24 Inch Model

EL-058 Wire Raceway Cover Assembly, 33 Inch Model

EL-059 Wire Raceway Cover Assembly, 46 Inch Model

EL-070 Lamp; 1600W 120V Clear

EL-071 Lamp; 1600W 208V Clear

Description Part

No.

#10 Hex head with Star Washer, Self Threading, Fine

threads 3/8

EL-088 Lamp; 3800W 575V Ruby

EL-106 Service Access Panel, Single Lamp

EL-152 Single Lamp Shell Assembly, 24 Inches

EL-153 Single Lamp Shell Assembly, 33 Inches

EL-154 Single Lamp Shell Assembly, 46 Inches

EL-155 Single Lamp Chassis Assembly

EL-206 Service Access Panel, Double Lamp

EL-252 Double Lamp Shell Assembly, 24 Inches

EL-253 Double Lamp Shell Assembly, 33 Inches

EL-254 Double Lamp Shell Assembly, 46 Inches

EL-255 Double Lamp Chassis Assembly

EL-306 Service Access Panel, Triple Lamp

EL-352 Triple Lamp Shell Assembly, 24 Inches

EL-353 Triple Lamp Shell Assembly, 33 Inches

EL-354 Triple Lamp Shell Assembly, 46 Inches

EL-355 Triple Lamp Chassis Assembly

Description

Single Lamp Model Parts List

Visit our website www.crownverity.com for further part related technical data.

19

Page 20

SW Series Manual4.0 Limited Warranty

4.0 Limited Warranty

One-Year Limited Warranty. Crown Verity (hereinafter referred to as the Company) warrants to the original

purchaser or original user that all Crown Verity Infrared Heaters sold by it and all parts thereof are free from

defects in material or workmanship under normal use and service. The Company’s sole obligation under this

warranty shall be limited to furnishing replacement parts, F.O.B. Brantford Ontario, for 12 months from the date of

initial installation of the heater, but not to exceed 18 months from the date of shipment by the Company of the

heaters, for any parts which the Company’s examination shall disclose to its satisfaction to be defective. Defective

parts are to be returned to the Company, transportation charges prepaid.

General Conditions. The warranties set out in this certificate are the exclusive remedy of the original owner or

user in lieu of all other warranties written, oral or implied (including any warranty of merchantability or fitness for

the purpose) and all other obligations or liabilities on the part of the Company, and the Company neither assumes

nor authorizes any person to assume for it any other obligation or liabilities on the part of the Company, and the

Company neither assumes nor authorizes any person to assume for it any other obligation or liability in connection

with the sale, installation or use of the heater or any parts thereof.

The Company will not be responsible for labor charges for the analysis of a defective condition in the heater

or for the installation of replacement parts. The warranties provided herein will not apply if the input of the

heater exceeds the rated input at time of manufacturing or if the heater in the judgment of the Company has

been subjected to misuse, excessive dust, improper conversion, negligence, accident, corrosive atmospheres,

excessive thermal shock, excessive vibration, physical damage to the heater, alterations by unauthorized service

personnel, operation contrary to the Company’s instructions or if the serial number has been altered, defaced, or

removed. The Company shall not be liable for any default or delay in the performance of these warranties caused

by contingency beyond its control, including war, government restriction or restraints, strikes, fire, flood, short or

reduced supply of raw materials, or parts.

The warranties herein shall be null and void if the heater is not installed by a competent heating contractor and/

or if the heater is not installed according to Company instructions, normal industry practices and/or if the heater

is not maintained and repaired according to Company’s instructions. Normal product degradation and wear (rust,

oxidation, etc.) does not constitute a material defect and applicable warranty claim.

Written permission is required for the return of any parts or equipment and any such return must be made on the

basis of transportation charges prepaid. Shipment may be refused unless prior written permission is obtained and

goods returned prepaid.

C R O W N V E R I T Y I N C .

37 Adams Boulevard, Brantford, Ontario, Canada N3S 7V8

tel 519.751.1800 or 888.505.7240 fax 519.751.1802 e-mail info@crownverity.com web www.crownverity.com

Loading...

Loading...