Crown SP 3400 series Maintenance Manual

SP 3400 Series

Maintenance Manual

M

Order Number: 812563-006

Revision: A • Printed in Germany

This master manual is subject to continual updates.

It is meant exclusively for businesses authorized by CROWN.

It is not permitted to pass on the contents or copies thereof to third parties.

CROWN Gabelstapler GmbH & Co. KG

– European Headquarter –

Moosacher Str. 52

80809 München

Germany

Phone +49 (0)89 93 00 2 – 0

Fax +49 (0)89 93 00 2 – 133

All rights reserved under international and Pan-American Copyright Agreement.

Copyright 2006

CROWN Equipment Corporation

Printed in Germany

TABLE OF CONTENTS

I

Notes:

Printed in Germany

II

TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PAGE SER-NR. CUT REV.

Symbols Used in the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fork direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . 4

Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Parking the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Working on the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Starting the Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning and Instruction Decals on the Truck . . . . . . . . . . . . . 5

Control of Hazardous Energy . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Battery Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lockout - Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Depressurising the hydraulic system . . . . . . . . . . . . . . . . 10

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lifting and Blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Raising the Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Raising the Drive Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Blocking Masts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INTRODUCTION PAGE SER-NR. CUT REV.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Service Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ordering Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Using the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Data Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Truck Data Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LUBRICATION & ADJUSTMENT PAGE SER-NR. CUT REV.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Componentry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ALM1

Status Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

BRES1, BRES2 (Option)

Battery Restraint Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 40

BRK1

SP 3400 04/2006 • Printed in Germany

TOC-7534

III

TABLE OF CONTENTS

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

BRS1

Brake Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CHS1, CHS2

Chain Slack Switches (TT Mast Only) . . . . . . . . . . . . . . . . 42

CHS3, CHS4

Chain Slack Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

CV1

Check Valve (only 3427 / 3422) . . . . . . . . . . . . . . . . . . . . . 42

CV2

Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

CV3

Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Cylinder

Free Lift (TT Mast Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cylinder

Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

DCM

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

DPS

Display Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DTS1

Drive / Tow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ECR1

Steering Command Encoder . . . . . . . . . . . . . . . . . . . . . . .44

ECR2

Steering Feedback Encoder . . . . . . . . . . . . . . . . . . . . . . . 44

ECR3

Traction Speed Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ECR4

Lift Height Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ED1

Emergency Disconnect Main Contactor . . . . . . . . . . . . . . .46

ED2

Emergency Disconnect Traction & Steering Contactor . . . 46

EDS

Emergency Disconnect Switch . . . . . . . . . . . . . . . . . . . . . 46

Fan

Operator Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

FILTER

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

FNS

Fan Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

FS

Forward Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

FU1

Lights and Fan Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU2

Control Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

FU3

Options Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU4

Manual Brake Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU5

TOC-7534

IV

SP 3400 04/2006 • Printed in Germany

TABLE OF CONTENTS

Brake Outer Coil Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU6

Brake Inner Coil Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU8

Pump Motor 1 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU9

Pump Motor 2 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FU10

Steer Module Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

FU11

Freezer Condition Power Unit Fuse . . . . . . . . . . . . . . . . . 50

FU12

Freezer Condition Platform Fuse . . . . . . . . . . . . . . . . . . . 50

FU13

Traction Motor Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

GCM

Guidance Control Module . . . . . . . . . . . . . . . . . . . . . . . . . 50

GTS1, GTS2, GTS3, GTS4

Side Gate Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

GTS5, GTS6 (SAA Only - not shown)

Rear Gate Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

GUS

Guidance Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

HN1

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

HN2

Back-Up or Travel Alarm . . . . . . . . . . . . . . . . . . . . . . . . . 52

HNS1

Horn Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

HSLCS

High Speed Lower Cutout Switch . . . . . . . . . . . . . . . . . . . 52

HSRCS

High Speed Raise Cutout Switch . . . . . . . . . . . . . . . . . . . 52

HTS24

610 mm (24 in.) Height Limit Switch . . . . . . . . . . . . . . . . . 54

HTS60

1525 mm (60 in.) Height Limit Switch . . . . . . . . . . . . . . . . 54

HTS120

3050 mm (120 in.) Height Limit Switch . . . . . . . . . . . . . . . 54

HTS150

3810 mm (150 in.) Height Limit Switch . . . . . . . . . . . . . . . 54

HTS180

4570 mm (180 in.) Height Limit Switch . . . . . . . . . . . . . . . 56

K1

Power Up Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

K2

Module Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

K5

Steer Motor Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

K11

Freezer Condition Relay . . . . . . . . . . . . . . . . . . . . . . . . . . 56

K12

Freezer Condition Relay . . . . . . . . . . . . . . . . . . . . . . . . . . 56

KYS

SP 3400 04/2006 • Printed in Germany

TOC-7534

V

TABLE OF CONTENTS

Key Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

LCS1

Lower Cutout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LGS1

Dome Light Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LGS2

Work Light Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LGS3

Spot Light Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LGT1

Strobe or Flashing Light . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LGT2, 5

Work Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LGT3, 6

Dome Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

LGT4, 7

Spot Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

LOS1

Low Speed Lower Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 60

LOS2

High Speed Lower Switch . . . . . . . . . . . . . . . . . . . . . . . . . 60

M1

Traction Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

M2

Power Steering Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

M3

Lift Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

M4

Lift Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

MRC1

Traction Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

MVL

Manual Valve Lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

ORS1

Override Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

P1

Low Speed Lift Pump Contactor . . . . . . . . . . . . . . . . . . . .62

P1 PUMP

Low Speed Lift Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

P2

High Speed Lift Pump Contactor . . . . . . . . . . . . . . . . . . . . 62

P2 PUMP

High Speed Lift Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

POT1

Traction Request Potentiometer . . . . . . . . . . . . . . . . . . . . 64

PS1

Light Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PS2

Light Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PVL

Proportional Lowering Valve . . . . . . . . . . . . . . . . . . . . . . .64

RAS1

Low Speed Raise Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 64

RAS2

TOC-7534

VI

SP 3400 04/2006 • Printed in Germany

TABLE OF CONTENTS

High Speed Raise Switch . . . . . . . . . . . . . . . . . . . . . . . . . 64

RCS1, RCS2

Raise Cutout Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

RES1

Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES2, RES3

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES4, RES5

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES6, RES7

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES8, RES9

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES10

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES11

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 66

RES12

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES13

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES14

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES15, RES19

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES16

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES17

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES18

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 68

RES20, RES21

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 70

RES30

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 70

RES31

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 70

RES32

Freezer Condition Heater . . . . . . . . . . . . . . . . . . . . . . . . . 70

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

RGS1, RGS2

Rail Guide Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

RS

Reverse Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

RV1

Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SB10

Suppressor Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SB11

Suppressor Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SB21

Suppressor Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SB30

Suppressor Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SP 3400 04/2006 • Printed in Germany

TOC-7534

VII

TABLE OF CONTENTS

SCM

Steering Control Module . . . . . . . . . . . . . . . . . . . . . . . . . .72

Sensor Bar Load Wheel

Wire Guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Sensor Bar Steer Wheel

Wire Guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Strainer

Suction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Test Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

THS2

Power Unit Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

THS3

Platform Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

ZSS

Zone Select Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Skids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

HYDRAULIC SYSTEM PAGE SER-NR. CUT REV.

Hydraulic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Hydraulic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Lift Circuit - One Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Relief Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Accumulator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Lift Circuit - Two Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Low Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

High Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Relief Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Accumulator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Lower Circuit - One Speed/Two Speed Lower . . . . . . . . . . . .88

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Manual Lower Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Lift Circuit - One Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Lifting Fork Lift Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Relief Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Accumulator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Lift Circuit - Two Speed Lift W/Lifting Forks . . . . . . . . . . . . . . 96

Low Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

High Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Relief Valve Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Accumulator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Lower Circuit - One Speed/Two Speed Lower . . . . . . . . . . . .99

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Manual Lower Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Hydraulic Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . 103

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Lift Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Freezer Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Hydraulic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Pump - Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Oil Seal Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

TOC-7534

VIII

SP 3400 04/2006 • Printed in Germany

TABLE OF CONTENTS

Oil Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Pump Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Parts Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Pump Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Lift/Lower Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Relief Valve- RV1 Operation . . . . . . . . . . . . . . . . . . . . . . . . 112

Adjustment (1.25 Trucks) . . . . . . . . . . . . . . . . . . . . . . . . 112

Relief Valve- RV1 & RV2 Operation . . . . . . . . . . . . . . . . . . 113

Adjustment (1.0 Trucks) . . . . . . . . . . . . . . . . . . . . . . . . . 113

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Precharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Hydraulics Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . 118

DRIVE UNIT PAGE SER-NR. CUT REV.

Drive Tire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Drive Unit Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Oil Pump Disassembly (Refer to Illustrations 1895 & 13131) 124

Oil Pump Assembly (Refer to Illustrations 1895 & 13131) . . 125

Drive Unit Removal & Installation (Refer to Illustration 3272) 126

ELECTRICAL SYSTEM PAGE SER-NR. CUT REV.

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Wiring Color Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Basic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Motor Monitoring System (MMS) . . . . . . . . . . . . . . . . . . . . . . 136

Overtemperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Brushwear Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Some Troubleshooting Basics . . . . . . . . . . . . . . . . . . . . 139

Check the Event Code Listing . . . . . . . . . . . . . . . . . . . . 139

No Event Code? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

To Locate Malfunctioning Components . . . . . . . . . . . . . 139

Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Event Code 201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Event Code 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Event Code 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Event Code 208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Event Code 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Event Code 210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Event Code 211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Event Code 212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Event Code 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Event Code 215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Event Code 216 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Event Code 217 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

SP 3400 04/2006 • Printed in Germany

TOC-7534

IX

TABLE OF CONTENTS

Event Code 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Event Code 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Event Code 221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Event Code 222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Event Code 223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Event Code 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Event Code 227 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Event Code 228 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Event Code 311 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Event Code 312 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Event Code 313 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Event Code 314 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Event Code 315 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Event Code 316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Event Code 317 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Event Code 318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Event Code 319 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Event Code 321 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Event Code 322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Event Code 323 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Event Code 324 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Event Code 326 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Event Code 327 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Event Code 328 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Event Code 331 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Event Code 332 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Event Code 333 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Event Code 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Event Code 335 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Event Code 336 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Event Code 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Event Code 339 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Event Code 341 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Event Code 342 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Event Code 343 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Event Code 344 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Event Code 345 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Event Code 346 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Event Code 347 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Event Code 348 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Event Code 349 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Event Code 351 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Event Code 352 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Event Code 353 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Event Code 354 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Event Code 355 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Event Code 356 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Event Code 357 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Event Code 358 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Event Code 362 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Event Code 363 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Event Code 364 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Event Code 365 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Event Code 366 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

TOC-7534

X

SP 3400 04/2006 • Printed in Germany

TABLE OF CONTENTS

Event Code 367 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Event Code 368 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Event Code 369 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Event Code 371 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Event Code 372 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Event Code 373 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Event Code 374 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Event Code 375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Event Code 376 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Event Code 377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Event Code 378 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Event Code 379 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Event Code 381 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Event Code 382 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Event Code 383 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Event Code 384 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Event Code 385 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Event Code 386 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Event Code 387 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Event Code 388 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Event Code 391 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Event Code 392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Event Code 393 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Event Code 394 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Event Code 396 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Event Code 397 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Event Code 398 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Event Code 399 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Event Code 411 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Event Code 412 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Event Code 413 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Event Code 414 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Event Code 415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Event Code 416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Event Code 417 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Event Code 418 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Event Code 419 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Event Code 421 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Event Code 422 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Event Code 423 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Event Code 424 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Event Code 425 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Event Code 426 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Event Code 427 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Event Code 428 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Event Code 429 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Event Code 431 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Event Code 432 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Event Code 433 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Event Code 434 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Event Code 435 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Event Code 436 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Event Code 437 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Event Code 438 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

SP 3400 04/2006 • Printed in Germany

TOC-7534

XI

TABLE OF CONTENTS

Event Code 439 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Event Code 441 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Event Code 442 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

If: Fault persists.

Then replace GCM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Event Code 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Event Code 801 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Event Code 802 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Event Code 803 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Event Code 804 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Event Code 805 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Event Code 806 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Event Code 807 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Event Code 808 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Event Code 809 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Event Code 810 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Event Code 811 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Event Code 812 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Event Code 813 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Event Code 814 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Event Code 827 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Event Code 828 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Event Code 829 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Event Code 831 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Event Code 832 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Event Code 833 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Event Code 834 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Event Code 835 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Event Code 836 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Event Code 837 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Event Code 838 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Tune Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Service Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Service Terminal Operation . . . . . . . . . . . . . . . . . . . . . . . . .252

Keyboard Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Truck Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

Lift Cutouts or Zone Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Truck Option Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

P.M. Interval Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Hourmeter Reset Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Wire Guidance Calibration Menus . . . . . . . . . . . . . . . . . . . . 260

Traction Setups/Calibration Menus . . . . . . . . . . . . . . . . . . . . 261

Traction Setups/Features Menus . . . . . . . . . . . . . . . . . . . . . 262

Features/Travel Alarm Menus . . . . . . . . . . . . . . . . . . . . . . . . 263

Traction Setups/Performance Menus . . . . . . . . . . . . . . . . . . 264

Traction Setups/Performance Menus (cont'd) . . . . . . . . . . . .265

System Information Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 270

View Enable Config Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Truck Monitors Menus / View Encoder Counts Menu . . . . . .272

View Switch Status Menus / View System Constants Menus 273

View Hardware Outputs Menus . . . . . . . . . . . . . . . . . . . . . . 275

View Hourmeter Data Menus / View Wire Guide Sensors Menus 276

TOC-7534

XII

SP 3400 04/2006 • Printed in Germany

TABLE OF CONTENTS

Traction Analyzer Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Status Analyzer Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Traction Inputs Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

View Switches Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Traction Outputs Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Wire Guidance System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Guidance Module (GCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Line Driver Output.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Sensor Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Checking Truck Steering System . . . . . . . . . . . . . . . . . . . . . 292

Truck Steering System Components . . . . . . . . . . . . . . . . . . 293

Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Contact Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Coil Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Steering Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Acceleration Potentiometer (POT1)s . . . . . . . . . . . . . . . 300

Directional Switches (FS & RS) . . . . . . . . . . . . . . . . . . . 301

Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 302

FS and RS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Actuator Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Potentiometer (POT1) . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Cam Torsion Spring, Stop . . . . . . . . . . . . . . . . . . . . . . . 304

Twist Grip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

RAS1, RAS2, LOS1, LOS2, HNS, EDS . . . . . . . . . . . . . 306

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Battery Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Placing battery on charge: . . . . . . . . . . . . . . . . . . . . . . . 312

Removing battery from charge: . . . . . . . . . . . . . . . . . . . 312

Battery Stop Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Battery Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

SP 3400 04/2006 • Printed in Germany

TOC-7534

XIII

TABLE OF CONTENTS

BRAKE SYSTEM PAGE SER-NR. CUT REV.

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Braking Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Brake Force Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .321

BRAKE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Air Gap Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Torque Gap Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Rotor and Brake Pad Replacement . . . . . . . . . . . . . . . . . 325

Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

STEERING PAGE SER-NR. CUT REV.

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Steering Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Steering Wheel Direction Indicator . . . . . . . . . . . . . . . . . . . . 331

Steering Wheel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .332

Steering Motor Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

LIFTING MECHANISM PAGE SER-NR. CUT REV.

Lift Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Freedom of Movement of Chain Links . . . . . . . . . . . . . . . . . 339

Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Chain Anchor and Pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Worn Connection Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Protruding or Turned Chain Pins . . . . . . . . . . . . . . . . . . . . . 340

Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Chain Lateral Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Uneven Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Misaligned Lift Components . . . . . . . . . . . . . . . . . . . . . . . . . 341

Lift Chain Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Separating Lift Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Tools and Equipment Required . . . . . . . . . . . . . . . . . . . . 343

Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

FEM / ISO Forks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .345

Fork Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

FEM / ISO Fork Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .346

Inspection Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Crack Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Fork Blade Warping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Fork Tip Straightness Test . . . . . . . . . . . . . . . . . . . . . . . . 347

Measuring the Fork Tip Height . . . . . . . . . . . . . . . . . . . . .347

Fork Tine Height Difference . . . . . . . . . . . . . . . . . . . . . . .347

Fork Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .348

Fork Blade Abrasion Check . . . . . . . . . . . . . . . . . . . . . . . 348

Platform Fork Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Fork Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Fork Blade Abrasion Check . . . . . . . . . . . . . . . . . . . . . . . 349

Overloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

TOC-7534

XIV

SP 3400 04/2006 • Printed in Germany

TABLE OF CONTENTS

Bent or Twisted Forks . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Hanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

CYLINDERS PAGE SER-NR. CUT REV.

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

For your personal protection: . . . . . . . . . . . . . . . . . . . . . . . . 355

General Instructions for Repairing Hydraulic Components 355

Rod Seal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Large Rod Seal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 356

Small Seal Rod Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Rod Seal Assembly, Sealing Lip First . . . . . . . . . . . . . . . . . 358

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Mast, Free Lift and Auxiliary Fork Cylinders . . . . . . . . . . . . 359

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Accessing Rod Packing- Mast Cylinder . . . . . . . . . . . . . 361

Accessing Rod Packing - Free Lift Cylinder . . . . . . . . . . 362

Accessing Rod Packing- Auxiliary Fork Cylinder . . . . . . 362

Rod Packing Replacement . . . . . . . . . . . . . . . . . . . . . . . 362

Mast Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 364

Auxiliary Fork Cylinder Removal . . . . . . . . . . . . . . . . . . . 365

Free Lift Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . 365

Free Lift, Mast and Auxiliary Fork Cylinder Assembly . . 366

Free Lift, Mast and Auxiliary Fork Cylinder Installation . . 366

PLATFORM PAGE SER-NR. CUT REV.

Safety Shield Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Floor Mat Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Forks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Fork Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Fork Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Pallet Grab (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Release Handle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 372

Pedal Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372

Pallet Grab Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Operator Compartment Gates . . . . . . . . . . . . . . . . . . . . . . . . 375

Spring Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Operator Egress System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Platform Removal & Shimming . . . . . . . . . . . . . . . . . . . . . . . 377

Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

Platform Removal and Shimming, TL Mast . . . . . . . . . . . . . 378

Shimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

Removing the Platform for Shimming . . . . . . . . . . . . . . . 378

Platform Removal & Shimming TT Mast . . . . . . . . . . . . . . . 381

Removing the Platform for Shimming . . . . . . . . . . . . . . . 382

ELECTRICAL COMPONENTS PAGE SER-NR. CUT REV.

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

SP 3400 04/2006 • Printed in Germany

TOC-7534

XV

TABLE OF CONTENTS

SCHEMATIC DIAGRAMS PAGE SER-NR. CUT REV.

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Schematic, Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Schematic with Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

Platform, Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Platform, Auxiliary Fork Lift . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Distribution Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .404

Traction, Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .405

Traction, Auxiliary Fork Lift . . . . . . . . . . . . . . . . . . . . . . . . . . 406

Display Module (DCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Traction Module (MRC1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Steering Module (SCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

Traction Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

Guidance Control Module (GCM) . . . . . . . . . . . . . . . . . . . . . . 411

Lights, Fan, Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . .412

Freezer Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Order Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .415

Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 416

Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .418

Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Platform with Auxiliary Lift Fork . . . . . . . . . . . . . . . . . . . . . . . 420

HYDRAULIC SCHEMATIC PAGE SER-NR. CUT REV.

Single Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Two Speed Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Single Speed Lift With Lifting Forks . . . . . . . . . . . . . . . . . . . 425

Two Speed Lift With Lifting Forks . . . . . . . . . . . . . . . . . . . . .426

TL Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

TT Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

TOC-7534

XVI

SP 3400 04/2006 • Printed in Germany

Printed in Germany

SAFETY

1

Notes:

Printed in Germany

2

Symbols Used in the Manual

Safety Symbols

To provide guidance and clearly identify potential

hazard points, we have used graphic illustrations in the

manuall:

SAFETY

SYMBOLS USED IN THE MANUAL

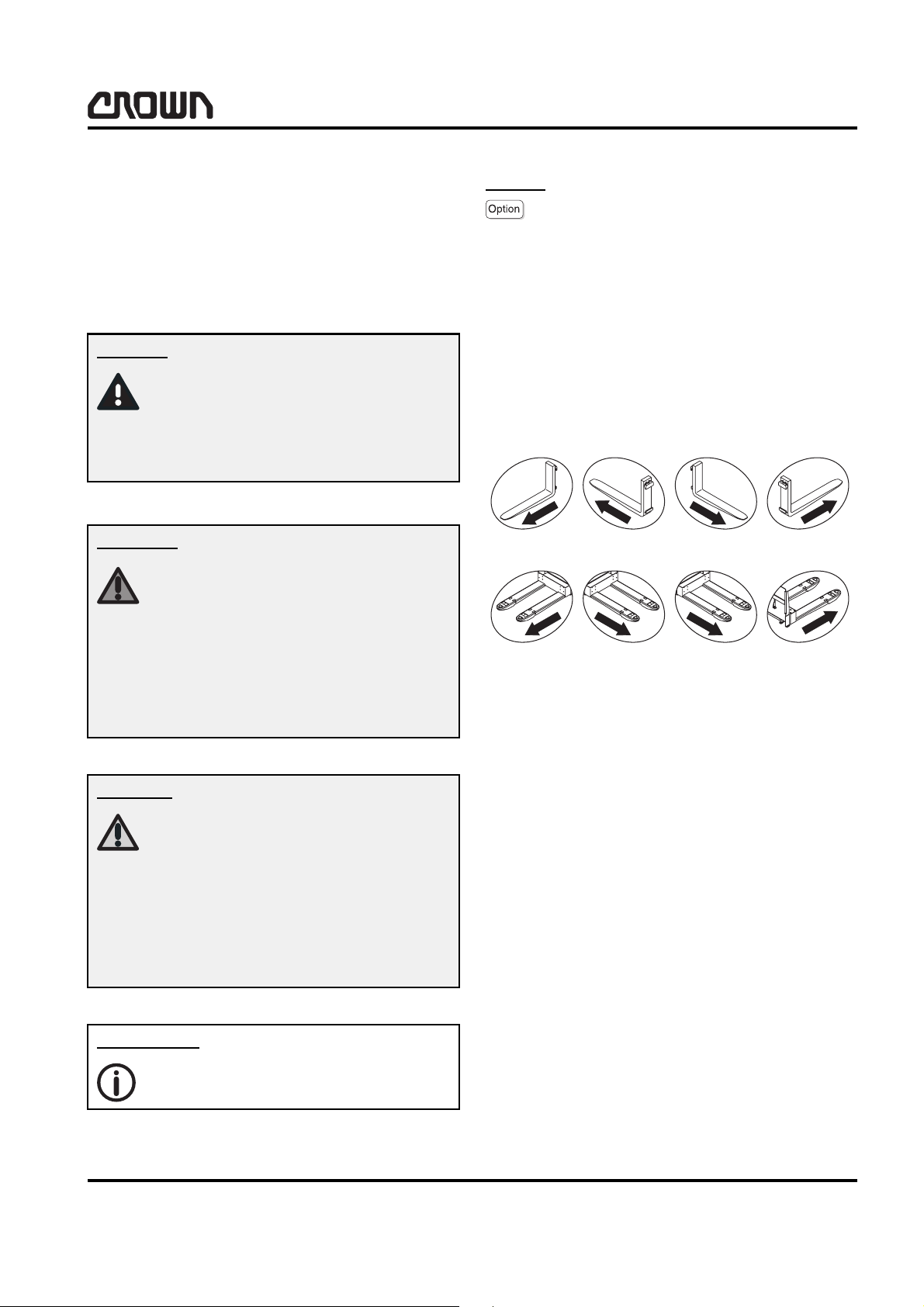

Option

General Symbols

This symbol is used with text describing optional equipment. This is not included with the standard version.

Danger!

This symbol indicates a danger to life.

You or other people could be seriously

or fatally injured if you fail to comply

with this safety instruction.

Warning!

This symbol represents risk of injury

and/or potentially significant material

damage.

You or other people could be seriously

injured and/or significant material damage could occur if you fail to comply

with this safety instruction.

Caution!

Fork direction

This symbols are used to show the direction of view in

a figure. The direction of the forks is used as reference.

This symbol represents potential minor

injuries and/or potential minor material

damage.

You or other people could be slightly

injured and/or minor material damage

could occur if you fail to comply with

this safety instruction.

Information

This symbol is used with additional information and instructions.

SP 3400 04/2006 • Printed in Germany

MA-0000

Rev. 1 1/06

3

SAFETY

GENERAL SAFETY INSTRUCTIONS

General Safety Instructions

Maintenance and Repair Instructions

Danger!

Observe the safety instructions in the

maintenance manual and the truck operator manual.

Failure to do so could result in serious

or even fatal injuries to maintenance

and other personnel.

Motorised trucks can become hazardous if maintenance and servicing work are neglected. For this reason maintenance and inspections must be performed

at sufficiently short intervals. There must be suitably

trained personnel and proper guidelines at your place

of work.

• Do not allow oils to penetrate the ground or the

drain system. Used oil must be recycled correctly.

Oil filters and dehumidifying inserts must be

treated as special waste. Observe the local authority regulations.

• Immediately neutralize and thoroughly rinse any

spilled battery fluid.

• Keep the truck clean. This will facilitate tracing

loose or faulty components.

• Maintain the legibility of the data capacity plate and

data plate, warning and instruction decals.

• Truck modifications and additions may only be per-

formed with Crown’s prior written approval.

• The reliability, safety and suitability of Crown

trucks can only be ensured by using original Crown

parts.

Maintenance and Repair

•

Always carry out work in accordance with the test

and maintenance schedule enclosed in these

maintenance instructions and any applicable service bulletins.

• Only qualified and authorized personnel may carry

out work on the truck.

• Keep fire protection equipment at hand and do not

use a naked flame to check fluid levels or to test for

leaks.

• Use groundwater neutral, non-flammable solvents

for cleaning. Always perform cleaning work over an

oil separator. Protect the electrical system against

damp.

• Keep the work place and battery charging station

clean, dry and well ventilated.

Before Parking the Truck

•

Brake until the truck comes to rest.

• Lower the fork carriage fully.

• Apply the parking brake.

• Switch off the truck and remove the key.

• When parking on a slope or incline always chock

all wheels.

Before Working on the Truck

•

Jack up the truck so that the drive wheel is clear of

the ground. Apply the Emergency Disconnect and

disconnect the battery.

MA-0000

4

SP 3400 04/2006 • Printed in Germany

• Prevent the truck from rolling away and lowering.

• When working on the mast, fork carriage or lifting

mast always apply a chock to prevent accidental

lowering.

• Allow sufficient room for manoeuvre when testing

the truck, to avoid endangering yourself and other

people.

Before Starting the Truck

•

Test the safety mechanisms.

• Get into the travel position.

SAFETY

GENERAL SAFETY INSTRUCTIONS

• Test the lifting mechanism, travel direction switch,

speed control, steering, warning mechanism and

brakes.

Warning and Instruction Decals on the Truck

In the course of periodic maintenance work, check that

the warning and instruction decals on the truck are

complete and legible.

• Clean any dirty decals.

• Replace any faulty or missing decals.

• A description and the location of the warning and

instruction decals used on the truck are given in

chapter 10.9 of the parts manual.

SP 3400 04/2006 • Printed in Germany

MA-0000

5

Notes:

Printed in Germany

6

SAFETY

CONTROL OF HAZARDOUS ENERGY

Control of Hazardous Energy

In the interest of safety Crown has developed guidelines for proper energy control when performing service and maintenance on the SP 3400.

Before performing any service or maintenance on

the SP 3400, review the appropriate sections in this

service manual for additional procedures to be followed.

In addition, Crown recommends that all mechanics

wear appropriate protective items, such as safety

glasses, work gloves, and steel toed shoes, whenever

performing service or maintenance work on Crown

equipment.

Battery

Warning

[one pound to one US gallon of water] will neutralise acid spilled on clothing, the floor or any other

surface. Apply solution until bubbling stops and

rinse with clean water.

• Keep vent plugs firmly in place at all times except

when adding water or taking hydrometer readings.

• Do not bring any type of flame, spark, etc., near the

battery. Gas formed while the battery is charging is

highly explosive. This gas remains in the cells long

after charging has stopped.

• Do not lay metallic or conductive objects on the

battery. Arcing will result.

• Do not allow dirt, cleaning solution or other foreign

materials to enter cells. Impurities in electrolyte

have a neutralising effect, reducing the available

charge.

Only qualified and experienced personnel should perform maintenance and

repair on batteries.

Follow the battery’s and charger manufacturer’s instructions concerning

practices and procedures for charging,

maintenance and repair.

Safety Rules

• Wear protective clothing such as a rubber apron,

gloves, boots and a full-face shield when performing any maintenance on batteries.

• Do not allow electrolyte to come in contact with

eyes, skin, clothing or floor. If electrolyte comes in

contact with eyes, flush immediately and thoroughly with clean water. Obtain medical attention

immediately.

Make certain the charger being used matches the voltage and amperage of the truck battery. This voltage is

listed on the truck data plate.

Before disconnecting or connecting batteries to a

charger, make sure the charger is “OFF”. If an attempt

is made to do this while the charger is “ON”, serious

injury to you and damage to the battery and charger

could result.

Make sure that the battery used meets the weight, size

and voltage requirements of the truck (refer to data

plate). Never operate the truck with an undersized

battery.

• Should electrolyte be spilled on skin, rinse

promptly with clean water and wash with soap. A

baking soda solution (0.120 kg to 1 litre of water)

SP 3400 04/2006 • Printed in Germany

MA-7534

7

SAFETY

CONTROL OF HAZARDOUS ENERGY

Battery Removal.

Warning

When removing the battery, move truck

to area intended for battery care. Floor

must be level. Turn key switch or toggle switch to “off” position and remove

key. Disconnect battery and lockout or

tagout truck as described in Battery Lockout/Tagout in this section. Never

move battery partially from truck without roller stand in place. Lower load engaging means completely. If battery is

removed with load engaging means

raised, use hoist attached to mast to

provide tipover protection. Do not allow any metallic object to come into

contact with the top of the battery cells.

This may cause a short circuit when removing and transporting the battery.

Use an insulator (such as plywood) to

cover the top of the battery before and

during removal.

Battery Installation

Warning

Make sure that the battery used meets

the weight, size and voltage requirements of the truck (refer to data plate).

NEVER operate truck with an undersized battery.

Warning

When installing the battery, move truck

to area intended for battery care. Floor

must be level. Turn key switch or toggle switch to “off” position and remove

key. Lockout or tagout truck as described in Battery - Lockout/Tagout in

this section. If battery was removed

with load engaging means raised, use

hoist attached to mast to provide

tipover protection. Do not allow any

metallic object to come in contact with

the top of the battery cells. This may

cause a short circuit when transporting

or installing the battery. Use an insulator (such as plywood) to cover the top

of the battery before and during installation.

MA-7534

WARNING

Do not connect

battery to this

vehicle.

Maintenance is

being performed

and vehicle is not

available for

operation.

8251

8262

Lockout - Tagout

Always turn key switch to “off”, remove key and apply

tag to steering wheel or twist grip with cable tie, warning others that the truck is being serviced (Figure

8262).

When maintenance is to be performed and the battery

will be left in the truck:

Disconnect battery, remove the main power fuses and

install a commercially available lockout device on the

battery connector. When maintenance is performed

and the battery is removed from the truck, remove the

main power fuses, install a lockout device on the

truck’s battery connector if possible, or if possible install a tag with a cable tie on the trucks battery connector so it cannot be removed easily, warning that the

truck is not available for operation.

SP 3400 04/2006 • Printed in Germany

8

SAFETY

CONTROL OF HAZARDOUS ENERGY

Brake

Danger

Extreme care must be taken when using the Drive/Tow switch to release the

brakes!

The truck will be free-wheeling and the

brake pedal in the operator compartment will have no effect on braking.

Brakes will only be applied when DTS1

is moved from the Tow to the Drive position.

The brakes can be released through the use of the

Drive/Tow switch (DTS1) during a maintenance situation. When using this method to release the brakes,

the truck will not have brakes available for stopping. The truck will not have traction control and

the power steering system will not work.

8. Disconnect brake harness from distribution panel

and connect to original connection, CA407.

DTS1

Brake Harness Connection

PC407

1. Lockout or tagout truck as described in Battery Lockout/Tagout in this section.

2. Chock wheels or make sure truck is secured by

some means to keep it from rolling away.

3. When towing the truck make sure all operators are

informed of the truck’s lack of braking.

4. Move switch DTS1 from the Drive position to the

Tow position.

5. Insert brake harness, PC407, to distribution panel.

6. Move truck to area intended for maintenance.

7. Move DTS1 from the Tow to the Drive position.

Disconnect battery.

12367

SP 3400 04/2006 • Printed in Germany

MA-7534

9

SAFETY

CONTROL OF HAZARDOUS ENERGY

Capacitance

Due to capacitance voltage present in the Access 3

module, whenever performing maintenance which may

permit contact with the bus bars and associated power

cables, discharge the capacitors.

1. Move truck to a secure non traffic maintenance

area with a level floor.

2. Lockout or tagout truck as described in Battery Lockout/Tagout in this section. Disconnect battery.

3. Turn and hold the key switch to the “start” position

for 30 seconds. Voltage lowered below 1 V.

4. Turn key switch to “off”, remove key.

Or allow 5 minutes after battery disconnect for capacitors to discharge.

Hydraulic System

Warning

Avoid high pressure fluids!

Escaping fluid under pressure can penetrate the skin causing serious injury.

Relieve pressure before disconnecting

hydraulic lines. Tighten all connections

before applying pressure. Keep hands

and body away from pin holes which

eject fluids under high pressure. Use a

piece of cardboard or paper to search

for leaks. Do not use your hand.

Any fluid injected into the skin under

high pressure should be considered as

a serious medical emergency despite

an initial normal appearance of the

skin. There is a delayed onset of pain,

and serious tissue damage may occur.

Medical attention should be sought immediately by a specialist who has had

experience with this type of injury.

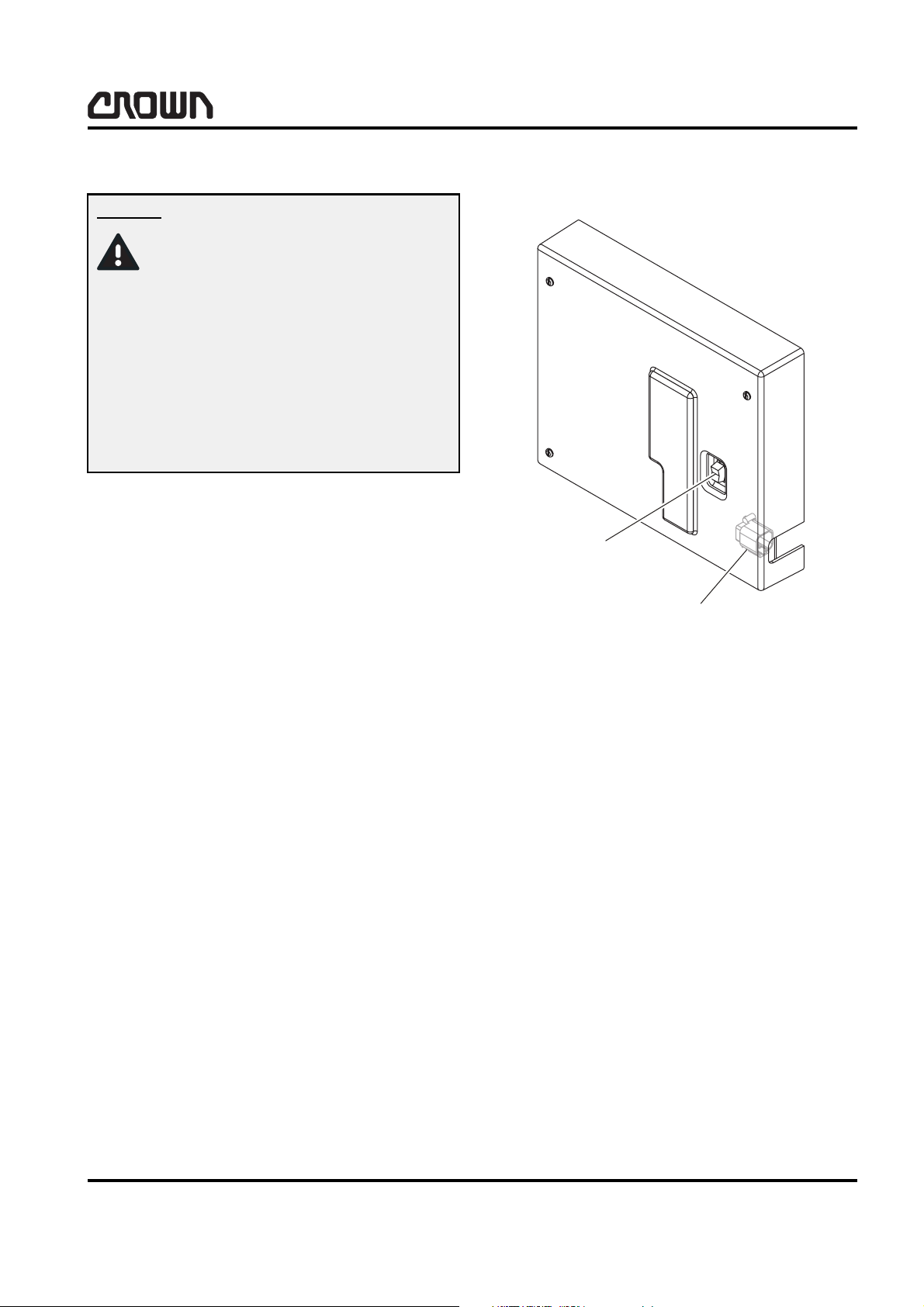

Access 3

Depressurising the hydraulic system

When maintenance is to be performed on the hydraulic

system, to make sure the hydraulic system is not under

pressure:

5. Move truck to a secure non traffic maintenance

¨

12368

area with a level floor.

6. No load on forks.

7. Completely lower load engaging means (mast) or,

if required for maintenance, block mast sections at

appropriate height as described in Mast of this section.

8. Lockout or tagout truck as described in Battery Lockout/Tagout in this section.

9. Open power unit doors and locate the lift manifold.

MA-7534

10

SP 3400 04/2006 • Printed in Germany

10. Open the manual lower valve to remove hydraulic

pressure.

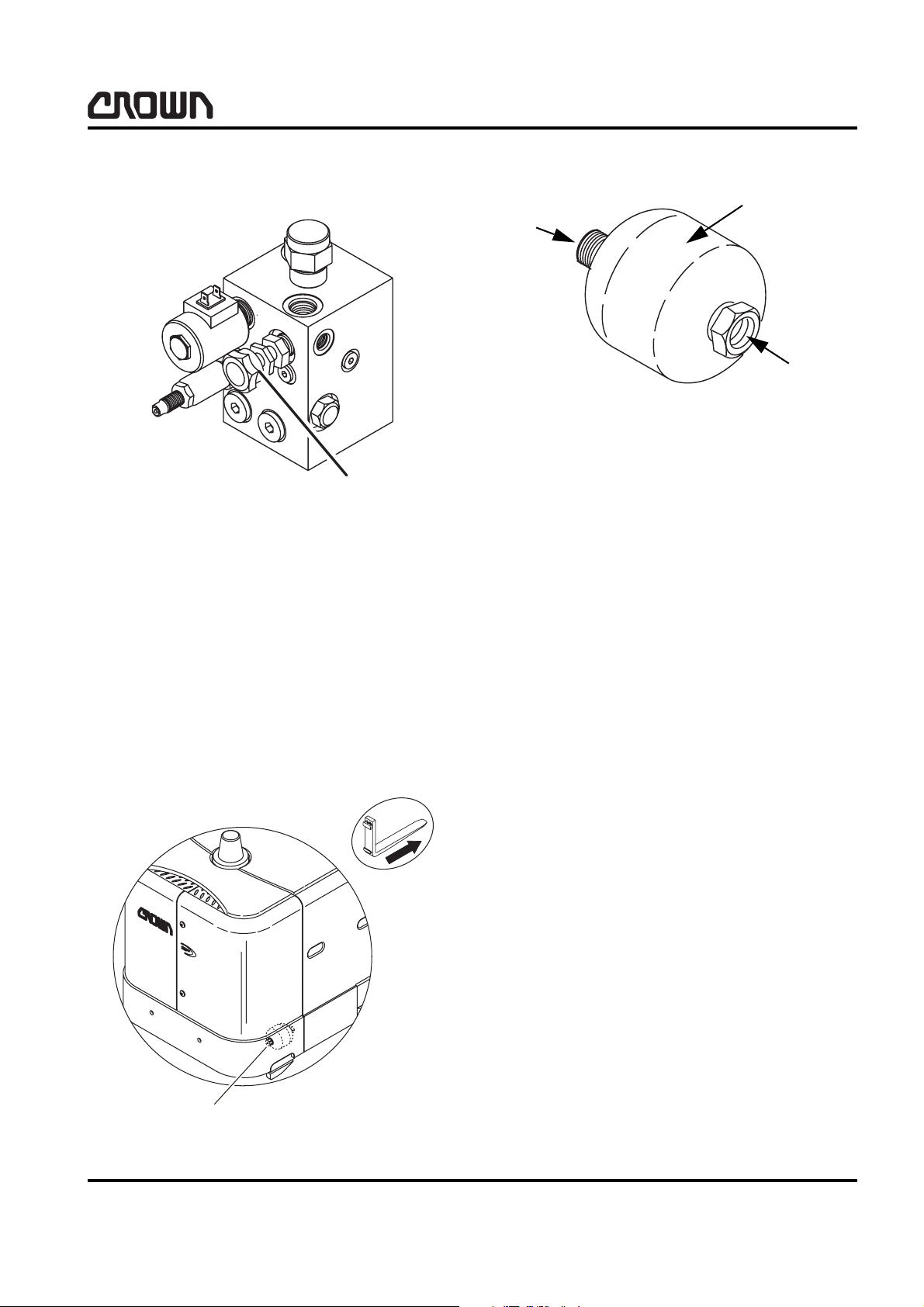

T

CV3

PCL

MVL

ACC

CV2

C1

PVL

CV1

SAFETY

CONTROL OF HAZARDOUS ENERGY

1

3

2

8266-EU

Manual Lower Valve

12369-EU

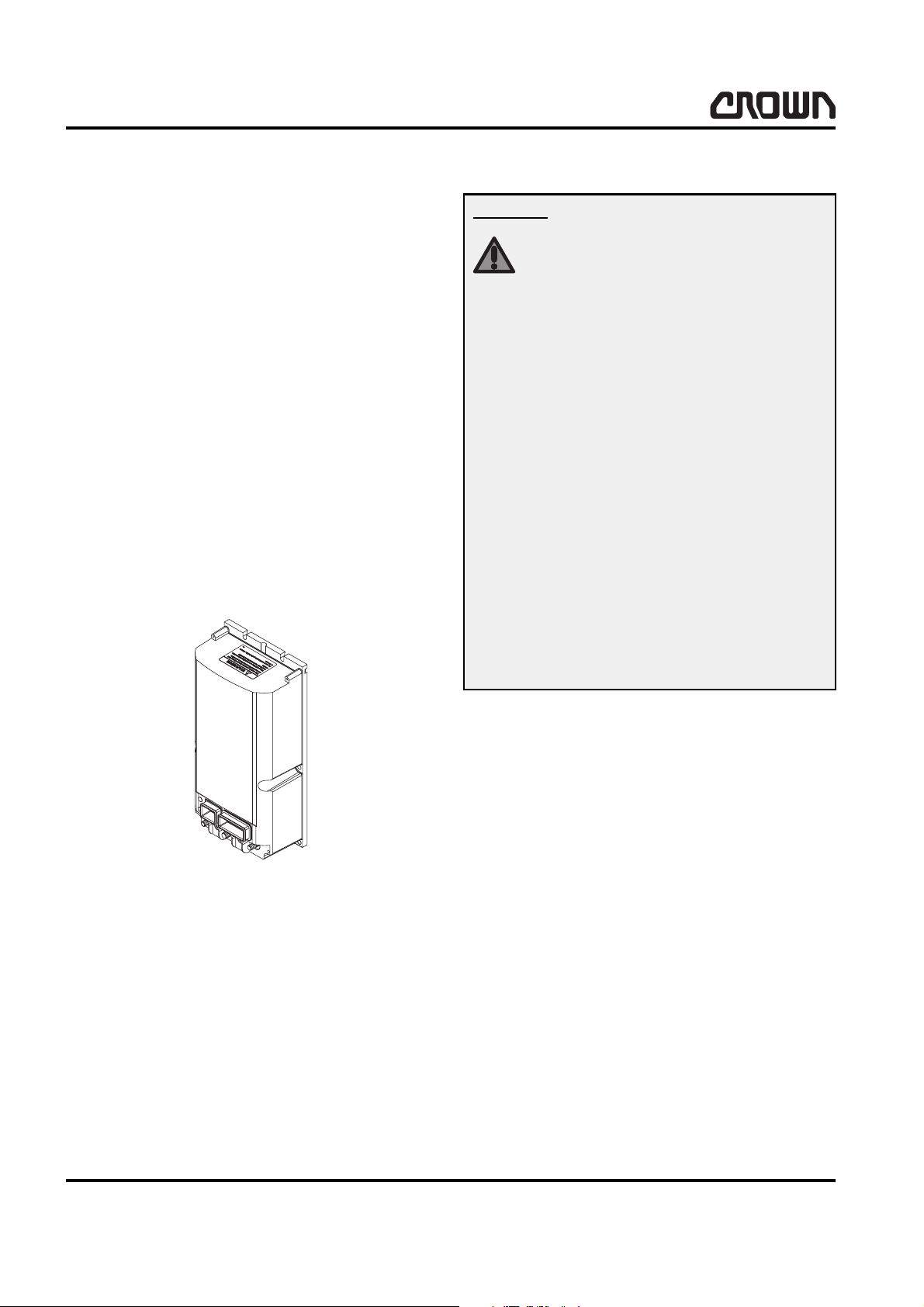

Accumulator

The accumulator (hydraulic system shock absorber)

contains a charge of inert gas such as dry nitrogen. Do

not tamper with the gas valve on the accumulator in an

attempt to reduce the amount of this charge. Use accumulator charging equipment and procedures as described in chapter 2 of this manual.

1 Accumulator

2 Hydraulic Line Connection

3Gas Valve

Accumulator

SP 3400 04/2006 • Printed in Germany

10575-EU

MA-7534

11

SAFETY

CONTROL OF HAZARDOUS ENERGY

Lifting and Blocking

Required tools

• Hydraulic Jack

Capacity 3 620 kg (8 000 lbs), Crown part

number: 12259

Minimum collapsed height: 60 mm (2.25 inch)

Maximum raised height: 400 mm (16 inch)

• Jack Stand

Capacity 4 500 kg (10 000 lbs). Commercially

available.

• Appropriately sized hard wood blocks and wedges.

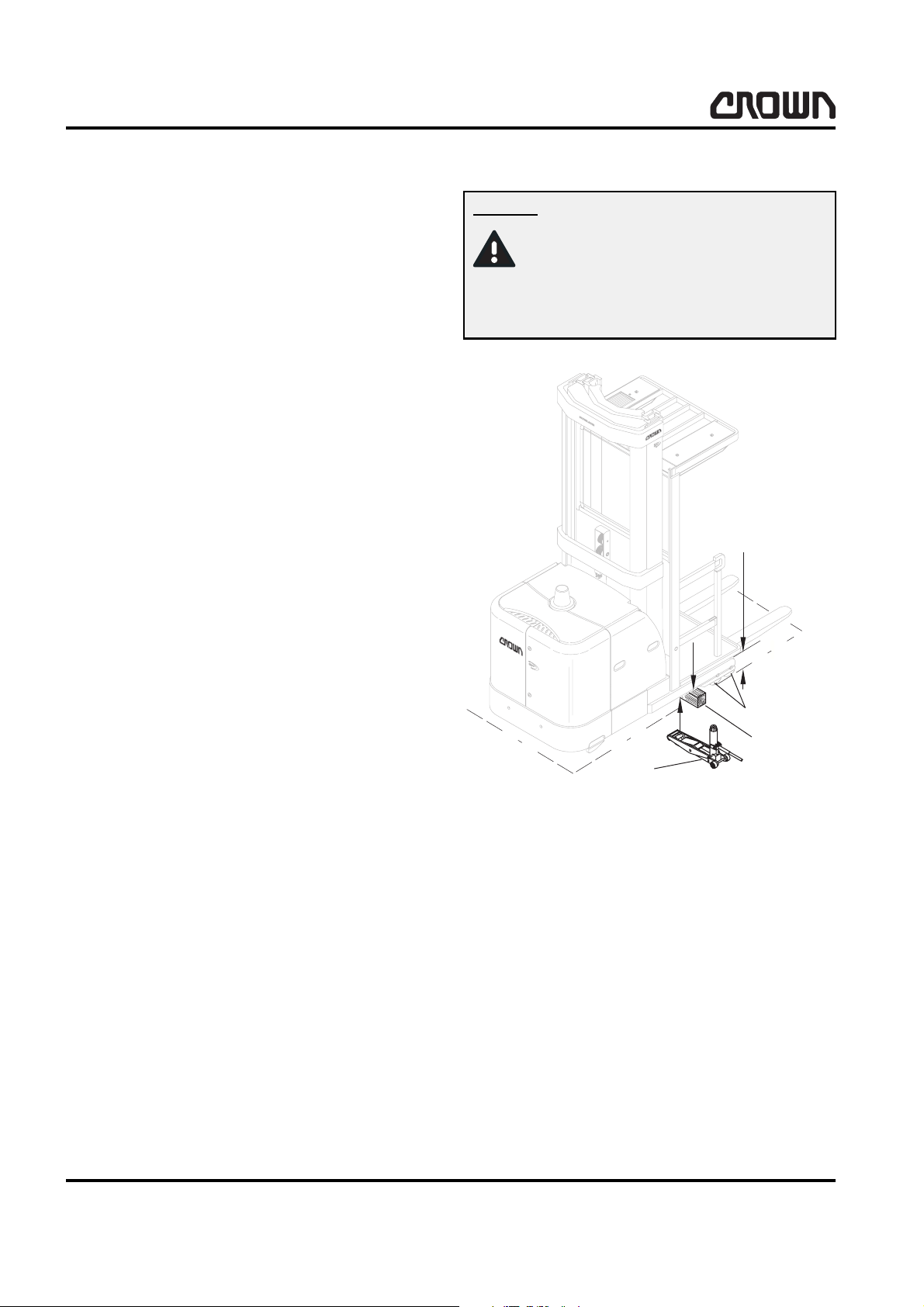

Raising the Side

Danger

Risk of tipover!

Truck stability decreases dramatically

if load wheels are raised more than

13 mm (0.5 inch).

max. 150 mm

(6 inch)

1

2

3

10576-EU

1. Move truck to a secure, traffic-free maintenance

area with a level floor.

2. No load on forks.

3. Raise the platform to max. 150 mm (6 inch) from

floor (Figure 10576-EU).

4. Lockout or tagout truck as described in Battery Lockout/Tagout in this section.

5. Attach a sling and an overhead lifting device to all

cross members of the mast to prevent the truck

from accidental tipping over.

MA-7534

12

SP 3400 04/2006 • Printed in Germany

Loading...

Loading...