Page 1

■ Cast iron sectional heat exchanger

Commercial, Forced Draft

Hot Water or Steam Boiler

Commercial, Forced Draft

Hot Water or Steam Boiler

For Businesses, Institutions,

Apartments and other

commercial buildings

For Businesses, Institutions,

Apartments and other

commercial buildings

Commercial Hot Water

or Steam Boiler

Commercial Hot Water

or Steam Boiler

and push nipples

■ Vertical flue design

■ Easily assembled with short individual draw rods

■ Optional tankless heater for domestic hot water

■ Top or rear vent connections

■ Side clean out plates

■ Optional Return Temperature Control (RTC)

■ Sizes from 342,000 to 1,852,000 BTU/hr output

Heat exchanger constructed

and tested in accordance with

ASME Section IV standard.

Page 2

Ten reasons why you need

Commercial Hot Water

or Steam Boiler

Commercial Hot Water

or Steam Boiler

the Series 24 commercial boiler

1. Optimum for large installations –

Available in ten sizes from 342,000 to

1,852,000 BTU/hr output.

2. Gas, oil or combination gas/oil fired –

Customer’s preference in the choice of

fuels for economy and availability may be

an important part of the purchase decision.

3. Hot water or steam – The Series 24

has been designed to meet a wide variety

of installations.

4. Tankless heater available for domestic

hot water – Convenient for small spaces or

difficult installations that preclude a separate

water heater. Finned copper coil heats water

fast, and piping is easier to install.

5. Cast iron construction – Cast iron heat

exchanger sections and push nipples provide

long life. Cast iron resists the effect of

petroleum-based chemicals such as corrosion

inhibitors, pump lubricants and antifreeze. Cast

iron push nipples are important because they

expand and contract at the same rate as the

sections they join, which provides integrity to

the entire assembly.

6. Convenient delivery in sections – Delivery

is available in easily handled sections that can

be maneuvered through doorways and down

stairs making this boiler ideal for installations

where the boiler room is not readily accessible.

7. Easy assembly – Once in place, the sections

are easily assembled using a 3/4-inch drive

ratchet with a 1-1/16-inch-deep socket and

a wrench. Short draw rods pass through the

sections’ reinforced lugs, resulting in fast,

strain-free assembly.

8. Versatile venting options – The Series 24

is a forced draft boiler that eliminates the need

for high chimneys or draft inducers. Uniquely,

the boiler can be vented from either the top or

rear for maximum installation flexibility. Rear

outlet venting requires only 6-1/2 feet of

vertical clearance from floor to ceiling.

9. Hassle-free maintenance – All regular

maintenance access areas are located on the

left side, allowing the Series 24 to be installed

9 inches from the right sidewall. Removable

jacket panels and flue cover plates simplify

access to the heating surfaces.

10. It’s a CROWN! Satisfied customers are

our goal. So, all CROWN boilers employ the

latest technology for performance and safety.

We offer a wide range of products to meet

each customer’s individual needs, and we

offer competitive pricing, attractive warranties

and optional extended coverage.

Page 3

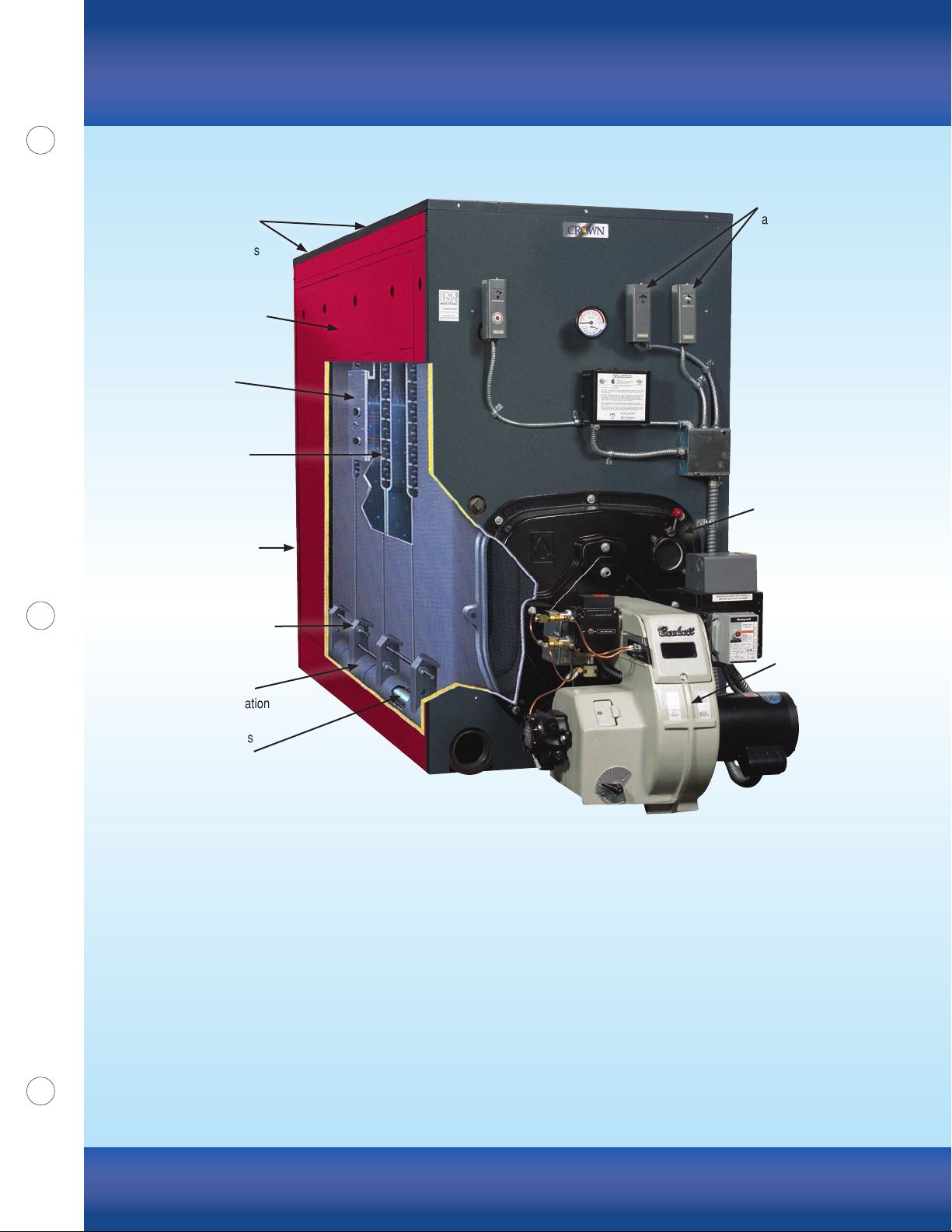

Top or rear flue outlet

with adjustable lock-type

damper includes

tapping for outlet

pressure readings

Left side jacket

panels and cleanouts

for easy access to

all flue surfaces

Tankless heater

for domestic

hot water

Cast iron vertical

flue design with

p

inned heating

s

urface achieves

maximum heat transfer

Rear cover includes

flame observation

port and plugged

tapping for over-fi

draft readings

R

einforced lugs and

individual draw rods

f

or easy assembly

Wet base

construction for

improved circulation

re

Front mounted

controls for easy

adjustment and

maintenance

Burner mounting

plate with flame

observation port

Your choice

of a Beckett

gas or oil burner

Cast iron nipples

ensure integrity

of section assembly

Standard Equipment

All Boilers – Sections unassembled, flush

insulated jacket, burner mounting plate, burner

adapter plate, rear flue damper (top outlet

optional), flue canopy, rear observation port cover,

target wall (V-903A), and miscellaneous plugs,

bushings and fittings.

Steam Trim – 15 PSI safety valve, L404A

pressuretrol, gauge glass assembly, steam gauge.

Water Trim – 30 PSI safety relief valve, L4006A

high limit, pressure temperature gauge.

Oil Boilers – Flange mounted flame retention

oil burner furnished with 2 stage fuel unit, primary

control and dual oil valves.

Gas Boilers – Flange mounted gas burner

with standard controls meeting the latest UL

requirements, dual gas valves and electronic

ignition.

Optional Equipment

Top outlet flue damper, tankless heaters, 50 PSI

relief valves (water), and combustion and

hydronic controls to meet ASME CSD-1.

Page 4

Series 24 Dimensions (in inches)

SAFETY/RELIEF

VALVE

‘F’ O.D. COLLAR

(STD. REAR OUTLET)

3

‘C’

‘A’

4

‘D’

INSULATED

JACKET

COMBINATION

LABEL

RATING

LABEL

� HIGH

PRESSURE

LIMI

T CONTROL/MR

� HIGH

PRESSURE

LIMI

T CONTROL/MR

NWL

57

MM#67 LWCO

LOWEST

PERMISSIBLE

W

ATER LEVEL

PLATE

(STEAM ON

LY)

FLOOR

FRONT VIEW

(STEAM)

LEFT SIDE VIEW

(STEAM)

FRONT VIEW

(WATER)

BURNER

MOUNTING

PLATE

‘H’‘G’6

(TYP)

1

REMOVABLE SIDE

PANELS

OVER-FIRE

PRESSURE SENSING;

NPT PLUGGED

REAR OBSERV

ATION

PORT

COVER

REAR FLUE

OUTLET W/

DAMPER

T

ANKLESS HEATERS

(‘E’ MAXIMUM ALLOWABLE)

‘B’

4” SUPPLY

(TYP)

TOP VIEW

BREECHING PRESSURE

SENSING;

PLUGGED (REAR OUTLET)

3

/8

-16

BREECHING PRESSURE

SENSING;

PLUGGED (TOP OUTLET)

3

/8

-16

1

8

13

1

2

3

1

8

6

1

2

16

STD.

1

8

16

1

8

1

8

41

1

2

9

1

4

47

3

8

4

1

4

4

1

4

23

1

2

32

1

8

3

1

2

16

5

8

3” RETURN

(4 PLACES)

FLAME

OBSERV

ATION

PORT

TEMPER

ATURE/

PRESSURE GUAGE

STEAM GUAGE

GUAGE

GLASS

SET

RATING LABEL

OPERATING

LIMIT

OPERATING

LIMIT

RETURN

TEMPERATURE

CONTROL

ASME DAT

A

LABEL

‘F’

O.D.

CO

LLAR

(OPTIONAL

T

OP OUTLET)

ASME DATA

LABEL

COMBINATION LABEL

INSTALLER/

SERVICE

LABEL

� PROBE TYPE

LOW

WATER

CU

T-OFF

BREECHING PRESSURE

SENSING;

PLUGGED (REAR OUTLET)

3

/8

-16

IN

IN

OUT

OUT

OUT

(TYP)

12” MIN

THREE HEATER MANIFOLDTWO HEATER MANIFOLD

FOUR HEATER MANIFOLD

FOR JACKET

REMOVAL

IN

1

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

4

4

5

MAXIMUM FLUTE BURNER BECKETT

1

APPROX.

NUMBER NUMBER NUMBER OF OUTLET MOUNTING K.D. BLR.

BOILER OF OF STEAM HEATERS DIAMETER PLATE WIDTH CF OIL CG GAS SHIPPING

MODEL SECTIONS ‘A’ ‘B’ RISERS ‘C’ ‘D’ ‘E’ ‘F’ ‘G’ ‘H’ ‘H’ WEIGHT LB.

24-03 3 18-1/4 12 1 – 9-1/8 1 7 8 9-3/4 20-7/8 1363

24-04 4 24-1/4 18 1 – 12-1/8 1 7 8 11-3/4 21-5/8 1675

24-05 5 30-1/4 24 1 – 15-1/8 1 8 8 11-3/4 21-5/8 1987

24-06 6 36-1/4 30 1 – 18-1/8 2 8 4 20-5/8 21-5/8 2273

24-07 7 42-1/4 36 2 – 21-1/8 2 8 4 20-5/8 28-5/8 2589

24-08 8 48-1/4 42 2 – 24-1/8 2 10 4 20-5/8 28-5/8 2901

24-09 9 54-1/4 48 2 – 27-1/8 3 10 4 21-1/8 29-1/8 3282

24-10 10 60-1/4 54 2 – 30-1/8 3 10 4 21-1/8 29-1/8 3614

24-11 11 66-1/4 60 2 – 33-1/8 3 12 4 22-5/8 29-1/8 3925

24-12 12 72-1/4 66 3 30 36-1/8 4 12 4 22-5/8 29-1/2 4252

● Not supplied as

standard equipment

Tankless Heater

Ratings in GPM

NUMBER OF 24 TANKLESS

BOILER

MODEL 1 2 3 4

24-03 6.75 — — —

24-04 7.5 — — —

24-05 7.5 — — —

24-06 7.5 15 — —

24-07 7.5

24-08 7.5 15 — —

24-09 7.5 15 22.5 —

24-10 7.5 15 22.5 —

24-11 7.5 15 22.5 —

24-12 7.5 15 22.5 30

Continuous draw heated from 40°F to 140°F

with 200°F boiler water.

HEATERS INSTALLED

15 — —

Multi-Heater Manifold

ITEMS DESCRIPTION

1 1-1/4” Copper Elbow

2 1-1/2” x 1-1/4” x 1-1/4” Copper Tee

3 2” x 1-1/2” x 1-1/4” Copper Tee

4 2” x 2” x 1-1/4” Copper Tee

5 1-1/4” Copper x MIP Adapter

Notes:

1. It is important that tankless heater sections

be correctly located in the boiler. Refer to

installation manual.

Pressure drop across each T-4 tankless

2.

heater = 5.25 PSI at 7.5 GPM fl

3. Locate heater control in heater identified as

ow rate.

Page 5

Burner Mounting Plates and Adapter Plates

FRONT VIEW

SIDE VIEWS

4” STANDARD

IDENTIFICATION NUMBER

‘A’

DIA

HOLE

‘B’ DIA

BOLT CIRCLE

‘C’

(REF)

4 8

8” EXTENDED

CAST IRON BURNER MOUNTING PLATES

STANDARD BURNER

ADAPTER PLATE

Commercial Hot Water or Steam BoilerCommercial Hot Water or Steam Boiler

FRONT VIEW BACK VIEW

F E

J2

J2

J1

J1

Q

K

M

G

T

B

P

P

N

S

A

D

C

BECKETT (“CF” SERIES) BURNER ADAPTER PLATE

I.D. ‘A’ ‘B’ ‘C’

BOILER MODEL PART NO. NO. DIA. DIA. REF.

24-03 THRU 24-05 330400 920 4-3/4 10 7-1/16

24-06 THRU 24-08 330401 921 6-1/8 10 7-1/16

24-09 THRU 24-12 330402 922 6-3/4 10 7-1/16

BECKETT (“CG” SERIES) BURNER ADAPTER PLATE

I.D. ‘A’ ‘B’ ‘C’

BOILER MODEL PART NO. NO. DIA. DIA. REF.

24-03 THRU 24-06 330400 920 4-3/4 10 7-1/16

24-07 THRU 24-08 330401 921 6-1/8 10 7-1/16

24-09 THRU 24-11 330403 923 7-1/4 10 7-1/16

24-12 330404 924 8-1/8 10 7-1/16

Note:

1. A burner adapter plate is needed for each boiler.

Control Tappings

TAPPING SIZE

LOCATION (IN.) STEAM BOILER W

A 4 Supply Supply

B 4

Supply (24-07 thru 24-12)

C 3 Blow-Off Valve Return

D 3 Return

Return (24-12)

E 3 Plug Blow-Off / Drain Valve

F 3 Plug Plug

G 1-1/2 Safety Valve / Surface Skim Tap Relief Valve

J1 1 Plug Plug

J2 1 Float L.W.C.O. Plug

K 3/4 Plug Probe L.W.C.O.

M 3/4 Operating Pressure Limit Control Operating Temperature Limit Control

N 3/4

Limit Control / Manual Reset Limit Control/Manual Reset

P 1/2 Gauge Glass/#67 L.W.C.O. Plug

Q 1/2

Gauge (Bush to 1/4”)

S 3/4 Tankless Heater Control Tankless Heater Control

T 3/4 Firing Rate Pressure Control Firing Rate Temperature Control

Plug (24-03 thru 24-06)

Plug (24-03 thru 24-11)

Hi Pressure Hi Temperature

Steam Gauge (Bush to 1/4”)

Temperature/Pressure

ATER BOILER

Plug

Series 24 Minimum Piping

Recommendations – Water Boiler

Impact of System Piping – Many hot water systems

are zoned. Some also use mixing valves to control the water

temperature in the system.

flow through the boiler to vary dramatically, depending on

the status of the zones or mixing valves. In addition, the

large water content of many commercial systems has the

potential to subject the boiler to operation with low return

temperatures for an extended period of time.

can shorten the life of a boiler due to thermal shock or flue

gas condensation.

Crown’s 3 Recommendations – On the following

pages, CROWN provides three basic recommendations

for near-boiler piping that are intended to maximize the

life expectancy of the boiler by protecting it from flue gas

condensation and thermal shock. Each protects the boiler

by making sure that both of the following conditions are met:

■ The flow through the boiler is high enough to

ensure a temperature rise of less than 40°F

These features can cause the

These factors

■ The return temperature does not fall below 135°F

for an extended period of time.

RTC Return Temperature Control – Piping

Recommendation 3 makes use of CROWN’s optional

TC (Return Temperature Control). This control provides an

R

economical and effective way of protecting the boiler from

thermal shock and condensation. It can be incorporated into

most hot water systems with minimal modifications to the

system design and operation. When this option is used on

multiple Series 24s, one R

The CROWN RTC is also available with an outdoor reset

option. This provides additional energy savings by

modulating system water temperature to match the

building load requirements.

TC is required for each boiler.

Page 6

Series 24 Minimum Piping Recommendations – Water Boiler

DRAIN VALVE

(SEE NOTE 4)

24-03 THRU 24-11 (W/20°F DROP)

24-03 THRU 24-12 (W/40°F DROP)

24-12 (W/20°F DROP)

DRAIN

VALVE

(SEE NOTE 4)

REAR OF

BOILER

REAR OF

BOILER

3” x 12” NIPPLE

AND BELL REDUCER

(SEE NOTE 3)

SUPPLY

RETURN

2

RETURN

RETURN

HEADER

RETURN

BRANCH

2

2A

23

2

1

2B

1

SUPPLY

1

BOILER CIRCUL

ATOR

(BY OTHERS - SEE NOTE 5)

DRAIN VALVE

(SEE NOTE 4)

SUPPLY

SYSTEM PUMP

CLOSELY

SPACED

TEES

MAX

4D

D

REAR OF

BOILER

RETURN

RETURN HEADER

RETURN BRANCH

2

2A

2B

23

2

1

24-12 (W/20°F DROP)

BOILER CIRCULATOR

(BY OTHERS - SEE NOTE 5)

DRAIN VALVE

(SEE NOTE 4)

SUPPLY

SYSTEM PUMP

CLOSELY

SPACED

TEES

MAX

4D

BOILER CIRCUL

ATOR

(BY OTHERS - SEE NOTE 5)

DRAIN VALVE

(SEE NOTE 4)

SUPPLY

SYSTEM PUMP

CLOSELY

SPACED

TEES

MAX

4D

D

REAR OF

BOILER

RETURN

3” x 12” NIPPLE

AND BELL REDUCER

(SEE NOTE 4)

REAR OF

BOILER

RETURN

RETURN HEADER

RETURN BRANCH

2

2

2A

2B

1

23

2

1

24-03 THRU 24-11 (W/20°F DROP)

24-03 THRU 24-12 (W/40°F DROP)

24-12 (W/20°F DROP)

Recommendation 1 is used

when the load is constant and

not varied due to mixing or

multiple zones. Use when:

■ system return water is not

less than 135° F for

prolonged periods of time

■ system flow does not impact

flow through the boiler

Recommendation 2 is a primary-secondary piping method

that maintains a constant flow through the boiler by using a

secondary boiler circulator. This arrangement isolates the

boiler from flow variations but does not safe-guard against

cold return water temperatures. Use when:

■ system return water is not less than 135° F

for prolonged periods of time

■ system flow does not impact flow through the

boiler (i.e. zoning, mixing)

PIPE SIZING AND NOTES FOR RECOMMENDATIONS 1 AND 2

RETURN PIPING SIZE (IN)

SUPPLY RETURN RETURN

PIPING HEADER BRANCH

SIZE (IN) (1) RETURN (2) (2A) (QTY.) SIZE (2B)

BOILER 20°F 40°F 20°F 40°F 20°F 20°F

MODEL DROP DROP DROP DROP DROP DROP

24-03 2 1-1/2 2 1-1/2 – –

24-04 2 1-1/2 2 1-1/2 – –

24-05 2 1-1/2 2 1-1/2 – –

24-06 2-1/2 1-1/2 2-1/2 1-1/2 – –

24-07 2-1/2 2 2-1/2 2 – –

24-08 2-1/2 2 2-1/2 2 – –

24-09 3 2 3 2 – –

24-10 3 2-1/2 3 2-1/2 – –

24-11 3 2-1/2 3 2-1/2 – –

24-12 4 2-1/2 4 2-1/2 3 (2) 3

Notes:

1. All piping is schedule 40.

2. Pipe sizes listed are based on a 20° F or 40°F differential (temperature drop).

Select one to match application.

When specified return piping is less than 3”, install 3” x 12” nipple and appropriate

3.

size bell reducer directly into boiler return tapping as shown.

Drain valve—ball valve preferable, gate valve acceptable alternative

4.

(supplied by others).—Minimum valve size per ASME code is 3/4 ” NPT.

Page 7

Recommendation 3 is used when the return water temperature goes below 135°F for prolonged periods of

24-03 THRU 24-11 (W/20°F DROP)

24-03 THRU 24-12 (W/40°F DROP)

BOILER CIRCULAT

OR

(BY OTHERS - SEE NOTE 5)

DRAIN VALVE

(SEE NOTE 4)

SUPPLY

DIVERTING

V

ALVE & ACTUATOR

SUPPLY

1

1

3

2

2

SYSTEM

PUMP

CLOSELY

SPACED

TEES

D

MAX

4D

REAR OF

BOILER

RETURN

RETURN

RETURN

SENSOR

(SEE NOTE 7)

3” x 12” NIPPLE

AND BELL REDUCER

(SEE NOTE 4)

SEE NOTE 6

SEE NOTE 5

24-03 THRU 24-11 (W/20°F DROP)

24-03 THRU 24-12 (W/40°F DROP)

24-12 (W/20°F DROP)

BOILER CIRCULAT

OR

(BY OTHERS - SEE NOTE 5)

DRAIN VALVE

(SEE NOTE 4)

SUPPLY

DIVERTING

V

ALVE & ACTUATOR

SUPPLY

1

BOILER CIRCULATOR

(BY OTHERS - SEE NOTE 5)

DRAIN VALVE

(SEE NOTE 4)

SUPPLY

1

1

3

DIVERTING

V

ALVE & ACTUATOR

3

2

2

SYSTEM

PUMP

CLOSELY

SPACED

TEES

D

MAX

4D

REAR OF

BOILER

REAR OF

BOILER

RETURN

RETURN

RETURN

SENSOR

(SEE NOTE 7)

RETURN

SENSOR

(SEE NOTE 7)

3” x 12” NIPPLE

AND BELL REDUCER

(SEE NOTE 4)

SEE NOTE 6

SEE NOTE 5

SUPPLY

1

2B

2A

RETURN BRANCH

SYSTEM

PUMP

CLOSELY

SPACED

TEES

D

MAX

4D

2

2

RETURN

RETURN HEADER

RETURN

SEE NOTE 6

SEE NOTE 5

24-07 THRU 24-11

24-03 THRU 24-06

(SEE NOTE 4)

(SEE NOTE 4)

(SEE NOTE 5)

(SEE NOTE 5)

(SEE NOTE 5)

(SEE NOTE 3)

SEE NOTE 2

(SEE NOTE 3)

RISER

WATER LINE

EQUALIZER

CLOSE NIPPLE

24” MIN.

18” MIN.

HARTFORD LOOP

(REQ’D ON GR

AVITY

RETURN SYSTEM)

REAR OF BOILER

BLOW-OFF/

DRAIN

VALVE

(SEE NOTE 3)

2” TO 4”

SUPPLY

1

1

1

3

4

4

4

3

2

2

2

2

2

2

‘A’

‘A’

‘B’

HEADER

(SEE NOTE 4)

24-07 THRU 24-11

(SEE NOTE 4)

(SEE NOTE 5)

(SEE NOTE 5)

SEE NOTE 2

(SEE NOTE 3)

RISER

WATER LINE

EQUALIZER

CLOSE NIPPLE

24” MIN.

18” MIN.

HARTFORD LOOP

(REQ’D ON GRAVITY

RETURN SYSTEM)

REAR OF BOILER

BLOW-OFF/

DRAIN

VALVE

(SEE NOTE 3)

2” TO 4”

SUPPLY

1

1

3

3

4

4

2

2

2

2

‘A’

‘A’

‘B’

RETURN

HEADER

(SEE NOTE 4)

24-12

(SEE NOTE 5)

SEE NOTE 2

RISER

WATER LINE

EQUALIZER

CLOSE NIPPLE

24” MIN.

18” MIN.

HARTFORD LOOP

(REQ’D ON GRAVITY

RETURN SYSTEM)

REAR OF BOILER

BLOW-OFF/

DRAIN

VALVE

(SEE NOTE 3)

DRAIN VALVE

(WET RETURN)

2” TO 4”

SUPPLY

1

3

4

2

2

‘A’

‘B’

RETURN

HEADER

(SEE NOTE 4)

time. This is also primary-secondary piping, but includes the addition of a 3-way valve, return water sensor and

boiler-mounted RTC Return Temperature Control.

PIPE SIZING AND NOTES FOR RECOMMENDATION 3

RETURN PIPING SIZE (IN)

SUPPLY RETURN RETURN

PIPING HEADER BRANCH

SIZE (IN) (1) RETURN (2) (2A) (QTY.) SIZE (2B)

BOILER 20°F 40°F 20°F 40°F 20°F 20°F

MODEL DROP DROP DROP DROP DROP DROP

24-03 2 1-1/2 2 1-1/2 – –

24-04 2 1-1/2 2 1-1/2 – –

24-05 2 1-1/2 2 1-1/2 – –

24-06 2-1/2 1-1/2 2-1/2 1-1/2 – –

24-07 2-1/2 2 2-1/2 2 – –

24-08 2-1/2 2 2-1/2 2 – –

24-09 3 2 3 2 – –

24-10 3 2-1/2 3 2-1/2 – –

24-11 3 2-1/2 3 2-1/2 – –

24-12 4 2-1/2 4 2-1/2 3 (2) 3

Notes:

1. All piping is schedule 40.

2. Pipe sizes listed are based on a 20° F or 40°F differential (temperature drop).

Select one to match application.

When specified return piping is less than 3”, install 3” x 12” nipple and appropriate

3.

size bell reducer directly into boiler return tapping as shown.

Drain valve—ball valve preferable, gate valve acceptable alternative

4.

(supplied by others).—Minimum valve size per ASME code is 3/4” NPT.

5. Maximum linear feet of pipe from 3-way bypass port to sensor location = 11 feet.

Bypass line shall be the same diameter as return

6. Minimum linear feet of pipe from point of mixing (where bypass meets return line)

to sensor location = 4 feet.

Install special 3” x 12” nipple with 1/4” NPT side tapping closest to boiler.

7.

Where applicable, use bell reducer to adapt to recommended return pipe size.

Proper boiler circulator sizing is listed in RTC literature.

8.

A.

Series 24 Minimum Piping Recommendations – Steam Boiler

RISER

RISER HEADER

BOILER (QTY.) & SUPPLY RETURN EQUALIZER

MODEL SIZE (1) (2) (3) (4) ‘A’ ‘B’

24-03 (1) 3” 3” 1-1/2” 2” – –

24-04 (1) 4” 4” 2” 2” – –

24-05 (1) 4” 4” 2” 2” – –

24-06 (1) 4” 4” 2-1/2” 2-1/2” – –

24-07 (2) 4” 6” 2-1/2” 2-1/2” 36” –

24-08 (2) 4” 6” 2-1/2” 2-1/2” 42” –

24-09 (2) 4” 6” 2-1/2” 2-1/2” 48” –

24-10 (2) 4” 6” 3” 3” 54” –

24-11 (2) 4” 6” 3” 3” 60” –

24-12 (3) 4” 6” 3” 3” 30” 36”

PIPING SIZE (IN)

SPACING (IN)

Notes:

1. All piping is schedule 40.

2. To prevent condensate from being trapped in header, do not reduce equalizer elbow at header

connection.

Drain/blowoff valve—ball valve preferable, gate valve acceptable alternative (supplied by others).

3.

• Mininim valve size per ASME code is 3/4” NPT 24-03/24-05; 1” NPT 24-06/24-10;

24-11/24-12.

1-1/4” NPT

• Increasing the valve size will improve the blowdown operation

•

In all cases, piping connection blowoff valve to boiler should be full size to the point of discharge.

4. For pumped return systems, see Series 24 installation manual.

Page 8

Series 24 Specifications

Commercial Hot Water or Steam BoilerCommercial Hot Water or Steam Boiler

BURNER HEATING WATER BOILER WEIGHT

NET I=B=R RATING INPUT SURFACE NET

GROSS (SQ. FT.) FIREBOX IN (GAL.) (LBS.) VENT

BOILER HORSE- OUTPUT SQ. FT. MBH MBH OIL GAS VOLUME FIREBOX DIA.

MODEL POWER (MBH) STEAM STEAM WATER (GPH) (MBH) STEAM WATER (CU. FT.) (“W.C.”) STEAM WATER STEAM WATER (IN.)

24-03 10.2 342 1071 257 297 3.05 438 34.2 37.0 3.2 .33 44.5 66.0 1439 1618 7

24-04 14.1 471 1471 353 410 4.10 594 48.6 54.3 4.8 .38 53.0 75.0 1811 1995 7

24-05 18.9 634 1983 476 551 5.50 792 63.0 71.5 6.4 .31 61.5 84.0 2184 2372 8

24-06 23.8 797 2492 598 693 6.90 990 77.5 88.8 7.9 .38 70.0 93.0 2557 2749 8

24-07 28.0 937 2929 703 815 8.10 1174 91.9 106.0 9.5 .36 78.5 102.0 2930 3126 8

24-08 32.5 1087 3396 815 945 9.40 1358 106.3 123.3 11.0 .35 87.0 111.0 3303 3503 10

24-09 39.3 1316 4146 995 1148 11.40 1641 120.7 140.5 12.6 .35 95.5 120.0 3676 3880 10

24-10 45.0 1505 4788 1149 1309 13.00 1867 135.1 157.8 14.2 .40 104.0 129.0 4048 4257 10

24-11 50.5 1690 5429 1303 1470 14.60 2093 149.5 175.0 15.7 .45 112.5 138.0 4421 4634 12

24-12 55.3 1852 5983 1436 1610 16.00 2320 164.0 192.3 17.3 .49 121.0 147.0 4794 5011 12

Notes:

1. Trim suffix S = Steam Boiler W = Water Boiler

Fuel suffix

2. I=B=R net ratings shown are based on piping and pick-up allowances which vary from 1.333 to 1.289 for steam and 1.15 for water. Consult manufacturer for installations having unusual piping and pick-up

requirements, such as intermittent system operation, extensive piping systems, etc. The I=B=R burner capacity in GPH is based on oil having a heat value of 140,000 BTU per gallon.

3. Firebox volume does not include added volume of 8” extended burner mounting plate (BMP). If 8” BMP is specified (refer to Figure 1), add 0.7 cu. ft. to volume listed above.

4. Boiler ratings are based on 12.5% CO2 (oil) and 9.7% CO2 (natural gas), + .10” (inches) water column pressure at boiler flue outlet. Ratings shown above apply at altitudes up to 1000 feet on oil and 2,000

feet on gas. For altitudes above those indicated, the ratings should be reduced at the rate of 4% for each 1000 feet above sea level.

Maximum

Standard Safety (Relief) V

N = Natural Gas O = Oil

Allowable Working Pressure: Steam Boiler – 15 PSI, Water Boiler – 50 PSI

alve Set Pressure: Steam Boiler – 15 PSI, Water Boiler – 30 PSI

Beckett Gas Burners (Natural Gas)

PRESSURE

CONTENT w/ WATER

Beckett Oil Burners

Min. Inlet Gas

Boiler Burner Rate STD. Motor Pressure Train

Model Model Control Voltage H.P. (in W.C.) Size

24-03 CG10.1S On/Off 120/60/1 1/3 3.2 1”

24-04 CG10.4S On/Off 120/60/1 1/3 3.6 1”

24-05 CG10.5S On/Off 120/60/1 1/3 4.3 1-1/4”

24-06 CG10.6S On/Off 120/60/1 1/3 4.4 1-1/2”

24-07 CG15.3S Lo/Hi/Lo 120/60/1 1/2 4.0 1-1/2”

24-08 CG15.4S Lo/Hi/Lo 120/60/1 1/2 4.4 1-1/2”

24-09 CG25.2S Lo/Hi/Lo 120/60/1 3/4 4.3 1-1/2”

24-10 CG25.3S Lo/Hi/Lo 120/60/1 3/4 4.9 1-1/2”

24-11 CG25.4S Lo/Hi/Lo 120/60/1 3/4 4.9 1-1/2”

24-12 CG50.2S Lo/Hi/Lo 208-240/60/1 2 3.9 1-1/2”

Minimum gas pressures shown are for standard burners only.

See manual for minimum gas pressure when other size gas trains are used.

AVAILABLE FROM

Boiler Burner Rate STD. Motor

Model Model Control Voltage H.P.

24-03 CF500 On/Off 120/60/1 1/3

24-04 CF800 On/Off 120/60/1 1/3

24-05 CF800 On/Off 120/60/1 1/3

24-06 CF1400 Lo/Hi/Lo 120/60/1 1/2

24-07 CF1400 Lo/Hi/Lo 120/60/1 1/2

24-08 CF1400 Lo/Hi/Lo 120/60/1 1/2

24-09 CF2300A Lo/Hi/Lo 120/60/1 3/4

24-10 CF2300A Lo/Hi/Lo 120/60/1 3/4

24-11 CF2500 Lo/Hi/Lo 240/60/1 2

24-12 CF2500 Lo/Hi/Lo 240/60/1 2

Since 1949, homeowners have depended on us

for quality, value and service.

3633 I Street, P.O. Box 14818

Philadelphia, PA 19134

Phone: (215) 535-8900 Fax: (215) 535-9736

www.crownboiler.com

S24-12/05 (25M)

PN980521

Loading...

Loading...