Crown SC3013, SC3018, SC3016 Service Manual

Service Manual

W artungshandbuch

Manuel de maintenance

SC3000 Series

Printed in Germany

TABLE OF CONTENT

Page intentionally left blank

Seite absichtlich freigelassen

Page intentionellement laissée blanche

Printed in Germany

TABLE OF CONTENT

Table of content

Table of content........................................................................................................................................ IDX-2230-001

MA – SAFETY

Safety Symbols used in the Manual.........................................................................................................MA-2230-001

General Maintenance and Repair Safety Notes....................................................................................... MA-2230-001

Maintenance and Repair ......................................................................................................................MA-2230-001

Before Leaving the Truck.....................................................................................................................MA-2230-002

Before Carrying out Work on the Truck..............................................................................................MA-2230-002

Before Operating the Truck .................................................................................................................MA-2230-002

Warnings and Labels on the Truck .......................................................................................................... MA-2230-002

ITD – INTRODUCTION

Introduction ...............................................................................................................................................ITD-2230-001

General ..................................................................................................................................................ITD-2230-001

Using the Manual..................................................................................................................................ITD-2230-001

Page Numbers ......................................................................................................................................ITD-2230-003

Operating instruction ...........................................................................................................................ITD-2230-003

Service training ....................................................................................................................................ITD-2230-003

Replacement parts orders ...................................................................................................................ITD-2230-003

Truck Data Numbering Sheet ..............................................................................................................ITD-2230-004

Battery Options ....................................................................................................................................ITD-2230-005

M1 – LUBRICATION AND ADJUSTMENT

Lubrication and Adjustment .................................................................................................................. M1.0-2230-001

Access to Components..................................................................................................................... M1.0-2230-001

Jacking up the Truck......................................................................................................................... M1.0-2230-004

Recommended Lubricants and Oils ................................................................................................ M1.1-1710-001

Lubricants....................................................................................................................................... M1.1-1710-001

Cold Store Trucks........................................................................................................................... M1.1-1710-001

Driver Participation ........................................................................................................................... M1.1-1710-001

Daily Maintenance Log...................................................................................................................... M1.1-1710-001

Inspection and Maintenance Schedule............................................................................................ M1.2-2230-001

T or ques .............................................................................................................................................. M1.9-2230-001

M2 – HYDRAULICS

Hydraulic Symbols ................................................................................................................................. M2.0-0000-001

Hydraulic System ................................................................................................................................... M2.1-2230-001

General ............................................................................................................................................... M2.1-2230-001

Operational Description.................................................................................................................... M2.1-2230-003

Idle Mode ....................................................................................................................................... M2.1-2230-003

Priority Valve .................................................................................................................................. M2.1-2230-003

Steering.......................................................................................................................................... M2.1-2230-003

Lifting.............................................................................................................................................. M2.1-2230-003

Tilting.............................................................................................................................................. M2.1-2230-003

Control Valve ..................................................................................................................................... M2.4-2230-001

Main Relief Valve Setting................................................................................................................ M2.4-2230-001

Maintenance and Repairs............................................................................................................... M2.4-2230-001

Pump Motor ....................................................................................................................................... M2.6-2230-001

Hydraulic Pump ................................................................................................................................. M2.6-2230-001

Commissioning............................................................................................................................... M2.6-2230-001

Bleeding ......................................................................................................................................... M2.6-2230-001

Oil Change ......................................................................................................................................... M2.6-2230-001

M3 – DRIVE UNIT

Truck Drive System ................................................................................................................................ M3.0-2230-001

Gear Unit ............................................................................................................................................ M3.0-2230-001

Removal ......................................................................................................................................... M3.0-2230-001

Printed in Germany

01/99

IDX-2230-001

TABLE OF CONTENT

Drive Motor ........................................................................................................................................ M3.0-2230-001

Removal ......................................................................................................................................... M3.0-2230-001

Design ................................................................................................................................................ M3.1-2230-001

Spur wheel bevel gear assembly ................................................................................................. .... M3.1-2230-001

Pre-assembly of the housing with flange shaft ............................................................................... M3.1-2230-001

Bevel gear spur wheel pinion shaft pre-assembly........................................................................... M3.1-2230-001

Spur wheel flange shaft assembly .................................................................................................. M3.1-2230-001

Bevel gear assembly ...................................................................................................................... M3.1-2230-002

Bevel pinion assembly.................................................................................................................... M3.1-2230-002

Flank tooth bearing ........................................................................................................................... M3.1-2230-003

Correcting the flank tooth bearing................................................................................................... M3.1-2230-003

Reducing the installation path of the conical pinion ........................................................................ M3.1-2230-003

Increasing the installation path of the conical pinion ....................................................................... M3.1-2230-003

Maintenance....................................................................................................................................... M3.1-2230-004

Adding oil........................................................................................................................................ M3.1-2230-004

Types of oil ..................................................................................................................................... M3.1-2230-004

Oil level .......................................................................................................................................... M3.1-2230-004

Oil change ...................................................................................................................................... M3.1-2230-004

M4 – ELECTRICS

Electrical System.................................................................................................................................... M4.0-2230-001

Wire Colour Codes ............................................................................................................................ M4.0-2230-001

Abbreviations .................................................................................................................................... M4.0-2230-002

Electrical Symbols ............................................................................................................................ M4.0-2230-004

Electrical Components........................................................................................................................... M4.2-2230-001

Switch Functions............................................................................................................................... M4.2-2230-001

Brake Switch (BRS) ....................................................................................................................... M4.2-2230-001

Encoder (ENC), Encoder Module (EM) .......................................................................................... M4.2-2230-001

Accelerator Pedal Switch (ACS, POT1) ......................................................................................... M4.2-2230-001

Direction Indicator Switch (DIS)...................................................................................................... M4.2-2230-001

Handbrake Switch (HBS) ............................................................................................................... M4.2-2230-001

Raise Potentiometer (POT2) .......................................................................................................... M4.2-2230-001

Steering Axle Potentiometer (POT3) .............................................................................................. M4.2-2230-001

Tilt (TLT), Sideshift (SSS), Auxiliary Switch (AXS).......................................................................... M4.2-2230-001

Emergency Disconnect .................................................................................................................. M4.2-2230-001

Key Switch (KYS)........................................................................................................................... M4.2-2230-001

Fuses (FU) ..................................................................................................................................... M4.2-2230-001

Seat Switch (SES).......................................................................................................................... M4.2-2230-002

Horn Switch (HNS) ......................................................................................................................... M4.2-2230-002

Electrical Components - Overview................................................................................................... M4.2-2230-002

Zapimos B1S 48/700 Controller ............................................................................................................. M4.3-2230-001

General ............................................................................................................................................... M4.3-2230-001

Main Features .................................................................................................................................... M4.3-2230-001

Protective Devices............................................................................................................................. M4.3-2230-001

Polarity Protection .......................................................................................................................... M4.3-2230-001

Wiring Errors .................................................................................................................................. M4.3-2230-001

Overheating.................................................................................................................................... M4.3-2230-001

Protection ....................................................................................................................................... M4.3-2230-001

Key Terms .......................................................................................................................................... M4.3-2230-001

Shunt or Shunt Resistor (+SH/-SH)................................................................................................ M4.3-2230-001

Volt Motor Negative (VMN)............................................................................................................. M4.3-2230-001

Functional Description...................................................................................................................... M4.3-2230-002

Acceleration / Delay Rate ............................................................................................................... M4.3-2230-002

Travel Switch .................................................................................................................................. M4.3-2230-002

Travel Switch Signal Response ...................................................................................................... M4.3-2230-002

Fault Log ........................................................................................................................................ M4.3-2230-002

Fault Identification .......................................................................................................................... M4.3-2230-002

Sparkless Contactors ..................................................................................................................... M4.3-2230-002

IDX-2230-002

Printed in Germany

01/99

TABLE OF CONTENT

Inversion Braking............................................................................................................................ M4.3-2230-002

Creep Mode.................................................................................................................................... M4.3-2230-002

Slow Travel ..................................................................................................................................... M4.3-2230-002

Steering Controller ......................................................................................................................... M4.3-2230-002

45° Steering Angle.......................................................................................................................... M4.3-2230-003

MOSFET ........................................................................................................................................ M4.3-2230-003

Pedal Braking (Inversion Braking with Battery Supply Regeneration)............................................. M4.3-2230-003

Pulse Width Modulation (PWM)...................................................................................................... M4.3-2230-003

Ramp Start ..................................................................................................................................... M4.3-2230-003

Key Switch ..................................................................................................................................... M4.3-2230-003

Self Test ......................................................................................................................................... M4.3-2230-003

Inverse Travel Alarm....................................................................................................................... M4.3-2230-003

Seat Switch .................................................................................................................................... M4.3-2230-003

Current Limit................................................................................................................................... M4.3-2230-003

Overvoltage.................................................................................................................................... M4.3-2230-003

Overheating.................................................................................................................................... M4.3-2230-003

Low V oltage Reduction................................................................................................................... M4.3-2230-003

ZAPIMOS B1S 48/700 Traction Controller Connections................................................................. M4.3-2230-004

Programmer Connection "B" .......................................................................................................... M4.3-2230-005

Status LED "A" ............................................................................................................................... M4.3-2230-005

Status LED Diagnosis .................................................................................................................... M4.3-2230-005

Control Line Connections................................................................................................................. M4.3-2230-006

Traction Controller .......................................................................................................................... M4.3-2230-006

ZAPIMOS B1S 48/700 Pin Layout ..................................................................................................... M4.3-2230-007

Maintenance....................................................................................................................................... M4.3-2230-008

Cleaning the Traction Controller ..................................................................................................... M4.3-2230-008

Removing / Installing the Traction Controller ................................................................................. M4.3-2230-008

To remove ...................................................................................................................................... M4.3-2230-008

Installing the Traction Controller ..................................................................................................... M4.3-2230-009

Zapimos HP 350A Pump Controller ...................................................................................................... M4.3-2230-200

General ............................................................................................................................................... M4.3-2230-200

Protective Devices............................................................................................................................. M4.3-2230-200

Polarity Protection .......................................................................................................................... M4.3-2230-200

Wiring Errors .................................................................................................................................. M4.3-2230-200

Overheating.................................................................................................................................... M4.3-2230-200

Protection ....................................................................................................................................... M4.3-2230-200

Key Terms .......................................................................................................................................... M4.3-2230-200

Shunt or Shunt Resistor (+SH/-SH)................................................................................................ M4.3-2230-200

Volt Motor Negative (VMN)............................................................................................................. M4.3-2230-200

Functional Description...................................................................................................................... M4.3-2230-201

Acceleration / Delay Rate ............................................................................................................... M4.3-2230-201

Current Limit................................................................................................................................... M4.3-2230-201

Fault Identification .......................................................................................................................... M4.3-2230-201

Fault Log ........................................................................................................................................ M4.3-2230-201

Hydraulic Function Switch .............................................................................................................. M4.3-2230-201

Key Switch ..................................................................................................................................... M4.3-2230-201

Lift Cut-Out ..................................................................................................................................... M4.3-2230-201

Lift Potentiometer ........................................................................................................................... M4.3-2230-201

Lift Potentiometer Response .......................................................................................................... M4.3-2230-201

Low V oltage Reduction................................................................................................................... M4.3-2230-201

MOSFET ........................................................................................................................................ M4.3-2230-201

Overheating.................................................................................................................................... M4.3-2230-201

Overvoltage.................................................................................................................................... M4.3-2230-201

Pulse Width Modulation (PWM)...................................................................................................... M4.3-2230-201

Seat Switch .................................................................................................................................... M4.3-2230-202

Self Test ......................................................................................................................................... M4.3-2230-202

Steer Support ................................................................................................................................. M4.3-2230-202

Printed in Germany

01/99

IDX-2230-003

TABLE OF CONTENT

ZAPIMOS HP 350 A Pump Controller Connections ....................................................................... M4.3-2230-202

Programmer Connection "B" .......................................................................................................... M4.3-2230-203

Status LED "A" ............................................................................................................................... M4.3-2230-203

Status LED Diagnosis .................................................................................................................... M4.3-2230-203

ZAPIMOS HP 350 A Pin Layout........................................................................................................ M4.3-2230-204

Maintenance....................................................................................................................................... M4.3-2230-204

Cleaning the Pump Controller......................................................................................................... M4.3-2230-204

Removing / Installing the Pump Controller ..................................................................................... M4.3-2230-205

To remove ...................................................................................................................................... M4.3-2230-205

Installing the Pump Controller......................................................................................................... M4.3-2230-205

Programmer ............................................................................................................................................ M4.4-2230-001

General ............................................................................................................................................... M4.4-2230-001

Connecting the Programmer ............................................................................................................ M4.4-2230-003

Operating Menu ................................................................................................................................. M4.4-2230-003

General .......................................................................................................................................... M4.4-2230-003

T raction Controller Operating Menu ................................................................................................ M4.5-2230-001

Programmer Start Routine................................................................................................................ M4.5-2230-002

Traction Controller Menu Functions ..................................................................................................... M4.5-2230-003

PROGRAM Menu ............................................................................................................................... M4.5-2230-004

TESTER Menu.................................................................................................................................... M4.5-2230-005

ALARMS Menu................................................................................................................................... M4.5-2230-006

PROGRAM PEDAL Menu .................................................................................................................. M4.5-2230-007

CONFIG Menu .................................................................................................................................... M4.5-2230-008

Pump Controller Operating Menu .................................................................................................... M4.5-2230-009

Menu Functions Pump Controller ......................................................................................................... M4.5-2230-010

PROGRAM Menu ................................................................................................................................M4.5-2230-011

TESTER Menu.................................................................................................................................... M4.5-2230-012

ALARMS Menu................................................................................................................................... M4.5-2230-013

PROGRAM VACC Menu .................................................................................................................... M4.5-2230-014

CONFIG Menu .................................................................................................................................... M4.5-2230-015

Traction Controller Safety Test............................................................................................................ M4.20-2230-001

Pulse Monitor Trip T est (PMT) ........................................................................................................ M4.20-2230-001

Equipment .................................................................................................................................... M4.20-2230-001

T est .............................................................................................................................................. M4.20-2230-001

PMT Safety Test Wiring................................................................................................................... M4.20-2230-002

Battery ................................................................................................................................................... M4.25-2230-001

General ............................................................................................................................................. M4.25-2230-001

Operation ......................................................................................................................................... M4.25-2230-001

Reading the Electrolyte Level......................................................................................................... M4.25-2230-001

Replacing the Battery...................................................................................................................... M4.25-2230-001

Removing the Battery ..................................................................................................................... M4.25-2230-001

Charging the Battery ....................................................................................................................... M4.25-2230-001

Battery Discharge Indicator (BDI) ....................................................................................................... M4.30-2230-001

General ............................................................................................................................................. M4.30-2230-001

Adjusting the Battery Discharge Indicator .................................................................................... M4.30-2230-001

Traction / Pump Motor Maintenance ................................................................................................... M4.35-2230-001

Access.............................................................................................................................................. M4.35-2230-001

M5 – BRAKE

Brake System.......................................................................................................................................... M5.0-2230-001

General ............................................................................................................................................... M5.0-2230-001

Operation ........................................................................................................................................... M5.0-2230-001

Replacing the Brake Disks and Linings........................................................................................... M5.0-2230-002

Preparation..................................................................................................................................... M5.0-2230-002

Brake Disk and Lining Dimensions ................................................................................................. M5.0-2230-003

Removing the Brake Disks and the Friction Plates (Fig. M0362).................................................... M5.0-2230-004

Installation ...................................................................................................................................... M5.0-2230-004

Removing the Handbrake Cable (Fig.M0366)................................................................................. M5.0-2230-006

Installation ...................................................................................................................................... M5.0-2230-006

Printed in Germany

01/99

IDX-2230-004

TABLE OF CONTENT

Adjusting the Operating Brake and Handbrake .............................................................................. M5.0-2230-006

Preparation..................................................................................................................................... M5.0-2230-006

Adjusting the Operating Brake Air Gap........................................................................................... M5.0-2230-006

Operating Brake Test ........................................................................................................................ M5.0-2230-007

Handbrake Adjustment ..................................................................................................................... M5.0-2230-007

M6 – STEERING

Steering ................................................................................................................................................... M6.0-2230-001

Hydraulic System .............................................................................................................................. M6.0-2230-001

Components ...................................................................................................................................... M6.0-2230-001

Removing the Steering Motor .......................................................................................................... M6.0-2230-002

Steering System Hydraulic Diagram................................................................................................ M6.0-2230-002

Steering Axle........................................................................................................................................... M6.1-2230-001

Design ................................................................................................................................................ M6.1-2230-001

Steering Drive Assembly .................................................................................................................. M6.1-2230-001

Wheel hub pre-assembly................................................................................................................ M6.1-2230-001

Steering knuckle pre-assembly ...................................................................................................... M6.1-2230-001

Steering knuckle and wheel hub assembly..................................................................................... M6.1-2230-001

Spur pinion wheel shaft pre-assembly............................................................................................ M6.1-2230-002

Housing Pre-Assembly................................................................................................................... M6.1-2230-002

Setting the Bearing Play ................................................................................................................. M6.1-2230-003

Cylinder Pre-Assembly................................................................................................................... M6.1-2230-006

Fitting the Cylinders........................................................................................................................ M6.1-2230-006

Assembling the Axle Bracket to the Steering Drive......................................................................... M6.1-2230-006

Operational and Leak Test.............................................................................................................. M6.1-2230-006

Maintenance....................................................................................................................................... M6.1-2230-007

General .......................................................................................................................................... M6.1-2230-007

Gear Lubricant................................................................................................................................ M6.1-2230-007

Seals .............................................................................................................................................. M6.1-2230-007

M7 – MAST

Mast ......................................................................................................................................................... M7.0-2230-001

Disassembly ...................................................................................................................................... M7.0-2230-001

Mast Roller Adjustment .................................................................................................................... M7.0-2230-001

Fork Carriage Roller Adjustment...................................................................................................... M7.0-2230-003

Mast Roller Adjustment .................................................................................................................... M7.0-2230-004

Checking the Mast Play .................................................................................................................... M7.0-2230-004

Lift Chain Test......................................................................................................................................... M7.5-2230-001

General ............................................................................................................................................... M7.5-2230-001

Maintenance....................................................................................................................................... M7.5-2230-001

Detailed Chain Testing ...................................................................................................................... M7.5-2230-002

Worn or Missing Plates................................................................................................................... M7.5-2230-002

Pitting and Corrosion ...................................................................................................................... M7.5-2230-002

Protruding or Turned Chain Pins .................................................................................................... M7.5-2230-002

Freedom of Movement and Worn Edges........................................................................................ M7.5-2230-002

Measuring the Chain Elongation..................................................................................................... M7.5-2230-003

Chain T ension................................................................................................................................. M7.5-2230-003

Chain Anchor and Pulleys .............................................................................................................. M7.5-2230-003

Fork Tine Test .................................................................................................................................... M7.6-2230-001

General .......................................................................................................................................... M7.6-2230-001

Fork Identification ........................................................................................................................... M7.6-2230-001

Repairs........................................................................................................................................... M7.6-2230-001

Crack Inspection............................................................................................................................. M7.6-2230-001

V erticality Test ................................................................................................................................ M7.6-2230-002

Fork Blade Warping........................................................................................................................ M7.6-2230-002

Measuring the Fork Tip Width......................................................................................................... M7.6-2230-003

Fork Tine Height Difference ............................................................................................................ M7.6-2230-003

Fork Stop........................................................................................................................................ M7.6-2230-003

Wear............................................................................................................................................... M7.6-2230-004

Printed in Germany

01/99

IDX-2230-005

TABLE OF CONTENT

M8 – CYLINDERS

Cylinders ................................................................................................................................................. M8.0-2230-001

General ............................................................................................................................................... M8.0-2230-001

Plunger Cylinders (Single-Acting Cylinders) .................................................................................. M8.0-2230-001

Piston Cylinder (Double-Acting Cylinder) ....................................................................................... M8.0-2230-002

Maintenance....................................................................................................................................... M8.0-2230-004

Inspection .......................................................................................................................................... M8.0-2230-004

Installing the Piston Seal .................................................................................................................. M8.0-2230-005

General .......................................................................................................................................... M8.0-2230-005

Rod Seal Disassembly Tool............................................................................................................ M8.0-2230-005

Assembly of Small Rod Seals ........................................................................................................ M8.0-2230-005

Assembly of Large Rod Seals ........................................................................................................ M8.0-2230-005

DIA – ELECTRICAL DIAGRAMS

Key............................................................................................................................................................. DIA-2230-001

Connectors .......................................................................................................................................... DIA-2230-001

Contactors ........................................................................................................................................... DIA-2230-001

Abbreviations ...................................................................................................................................... DIA-2230-001

Control Circuit .......................................................................................................................................... DIA-2230-002

Power Circuit ............................................................................................................................................ DIA-2230-003

Connectors ............................................................................................................................................... DIA-2230-004

Traction Controller .............................................................................................................................. DIA-2230-004

Pump Controller .................................................................................................................................. DIA-2230-005

Seat Switch and Steer Pot .................................................................................................................. DIA-2230-006

Control Levers ..................................................................................................................................... DIA-2230-007

B.D.I., Horn and Brake Switches ........................................................................................................ DIA-2230-008

Steer Column ....................................................................................................................................... DIA-2230-009

Star Points ................................................................................................................................................ DIA-2230-010

Panel Wiring.............................................................................................................................................. DIA-2230-011

Power Cables ............................................................................................................................................ DIA-2230-012

Part Numbers for Connectors and Looms ............................................................................................. DIA-2230-013

ZAPI Connectors ................................................................................................................................. DIA-2230-013

MOLEX Connectors............................................................................................................................. DIA-2230-013

DEUTSCH Connectors ........................................................................................................................ DIA-2230-013

Looms .................................................................................................................................................. DIA-2230-013

HYD – HYDRAULIC SCHEMATIC

Hydraulic Schematic ...............................................................................................................................HYD-2230-001

IDX-2230-006

Printed in Germany

01/99

Printed in Germany

SAFETY

Page intentionally left blank

Seite absichtlich freigelassen

Page intentionellement laissée blanche

Printed in Germany

SAFETY

Safety Symbols used in the

Manual

To help guide you through the manual and to highlight

particular danger areas, we have used graphic illustrations:

DANGER

This symbol indicates life-threatening risks

l

Failure to comply with this notice may

result in severe or fatal injuries to

yourself or other people.

WARNING

This symbol indicates the risk of serious

injury and/or serious material damage.

l

Failure to comply with this notice may

result in severe injuries to yourself or

other people and/or serious material

damage.

General Maintenance and Repair Safety Notes

DANGER

Read the safety notices in the truck

Maintenance and Operator's Manuals.

l

Failure to do so could result in severe or

fatal injuries to maintenance personnel

and/or other persons.

Motorised vehicles can be dangerous if maintenance

and service are neglected. For this reason maintenance

and inspections must be carried out at regular short

intervals by trained personnel working to approved

company guidelines.

Maintenance and Repair

1. Maintenance work must only be carried out in

accordance with the test and maintenance program

contained in the present Maintenance Manual and any

applicable service notices.

CAUTION

This symbol indicates the risk of minor

injury and/or minor material damage.

l

Failure to comply with this notice may

result in minor injuries to yourself or

other people and/or minor material

damage.

INFORMATION

Contains additional information with

supplementary notes and hints.

OPTION

OPTION

These items relate to optional features not

supplied with the standard version.

2. Only qualified and authorised personnel may carry

out work on the truck.

3. Always k eep fire extinguishers in good working

condition. Do not approach fluid levels or leaks with a

naked flame.

4. To clean, use a non flammable, non combustable

cleaning solution which is groundwater-neutral.

Only carry out cleaning with an oil separator.

Protect the electrical system from dampness.

5. Keep the service area clean, dry and well-ventilated.

6. Do not allow oil to penetrate the ground or enter the

draining system. Used oil must be recycled. Oil filters

and desiccants must be treated as special waste

products. Relevant applicable regulations must be

followed.

7. Neutralise and thoroughly rinse any spilled battery

fluid immediately .

8. Keep the truck clean. This will facilitate the location

of loose or faulty components.

9. Make sure that capacity and data plates, warnings

and labels are legible at all times.

Printed in Germany

REV .1 10/99

MA-2230-001

1

SAFETY

10. Alterations or modifications b y the o wner or

operator are not permitted without the express written

authorisation from Crown.

11. Only use original Crown spare parts to ensure the

reliability, safety and suitability of the Crown truck.

Before Leaving the Truck

l

l

l

l

l

Stop the truck.

Lower the f ork carriage fully.

Apply the parking brake.

Turn off the travel switch and remove the

key.

Block all wheels when parking on an uneven

surface.

Before Carrying out Work on the Truck

l

Raise the truck to free the drive wheel.

Press the Emergency Stop button and

disconnect the battery.

Warnings and Labels on the Truck

l

l

l

The order and meaning of the warnings and labels on

the truck are described in section 10.9 of the parts

manual.

During regular maintenance check that the

warnings and labels on the truck are

complete and legible.

Clean any illegible labels.

Replace any faulty or missing labels.

l

l

l

Prevent the truck from rolling away.

Before carrying out work on the hoist frame,

the lift mast or on the fork carriage:

Block these parts according to maintenance

instructions in order to prevent them from

dropping.

Only carry out operational testing when there

is sufficient room to manoeuvre, to avoid the

risk of injury to yourself and others.

Before Operating the Truck

l

l

l

Check the safety devices.

Get into the driver's seat.

Check the operation of the lifting device,

travel direction switch, speed control,

steering, warning devices and brakes.

MA-2230-002

2

Printed in Germany

01/99

Printed in Germany

INTRODUCTION

Page intentionally left blank

Seite absichtlich freigelassen

Page intentionellement laissée blanche

Printed in Germany

Introduction

INFORMATION

THIS BOOK IS NOT AN OPERATING MANUAL. IT IS DESIGNED FOR SPECIALIST

PERSONNEL WHO HAVE BEEN TRAINED

AND AUTHORISED BY CROWN FOR THE

WORK DESCRIBED HEREIN.

This manual therefore contains fewer and less detailed

danger warnings than the Operator's Manual, as the latter

is aimed at persons who have very little or no prior

experience at all.

General

The present manual is designed for Customer Service

engineers who wish to familiarise themselves with the

maintenance work required for the various truck

components.

It also contains troubleshooting sections which can be

used to identify and remedy truck faults.

INTRODUCTION

Using the Manual

The Maintenance Manual is written in three independent

language blocks:

Each language block in turn is divided into chapters and

sections. The page numbers in the Maintenance Section

are preceeded by an M.

The table on the following page shows how the manual is

structured.

English, German and French

.

Printed in Germany

01/99

ITD-2230-001

1

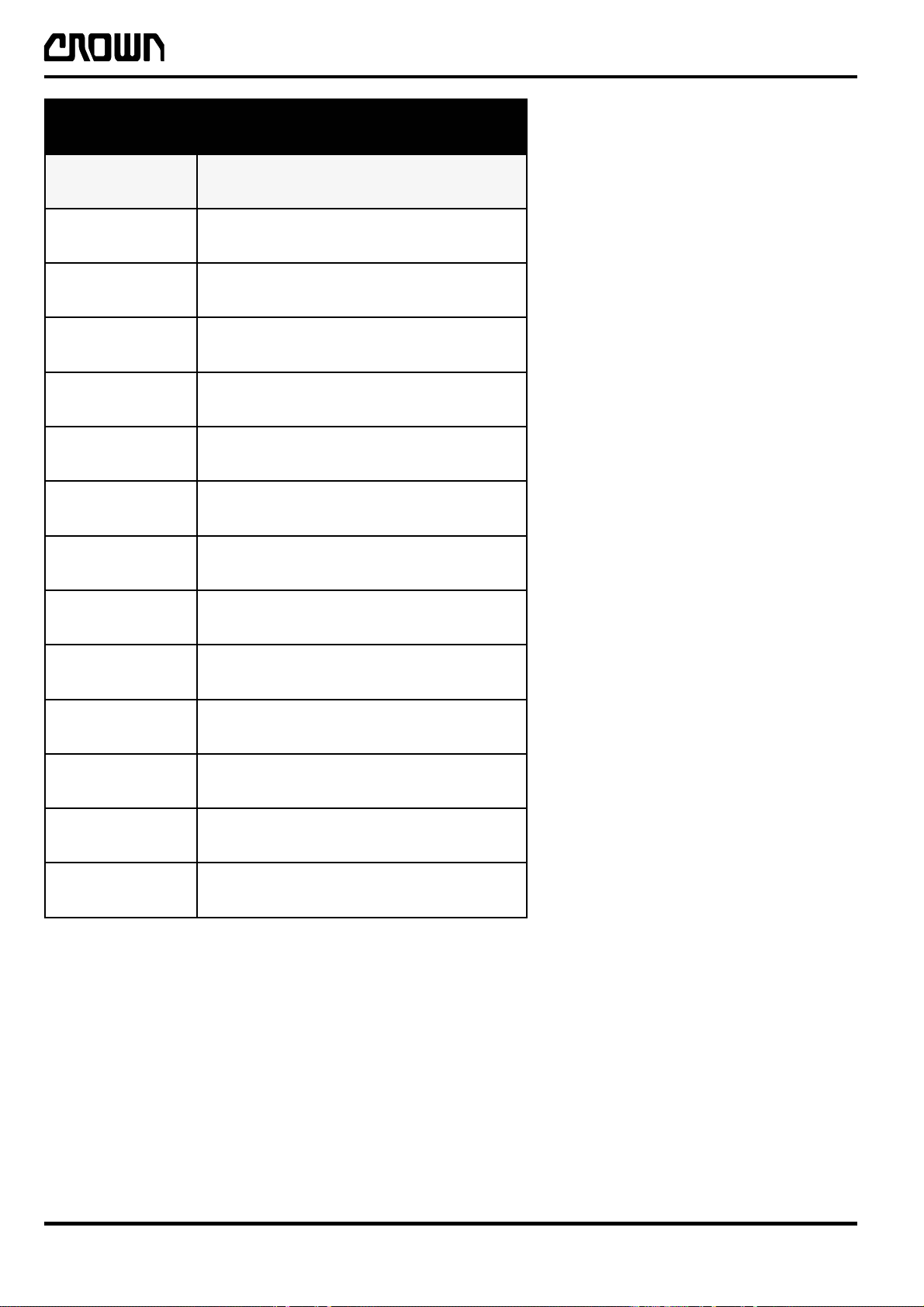

noitceS noitpircseD

XDItnetnoCfoelbaT

AMytefaS

DTInoitcudortnI

1MtnemtsujdAdnanoitacirbuL

2MsciluardyH

INTRODUCTION

ecnanetniaMsnoitceS

3MtinUevirD

4MlacirtcelE

5MekarB

6MgnireetS

7MtsaM

8MrednilyC

AIDsmargaiDlacirtcelE

DYHcitamehcSciluardyH

ITD001B-gb

2

ITD-2230-002

Printed in Germany

01/99

Page Numbers

The page numbers are located on the lower left and right

hand margins of each page and have the following form:

M1.1-2230-001 X

INTRODUCTION

M = Maintenance

Chapter

Section

z. B. 1.2 = Inspection and

Maintenance Plan

Operating instruction

This manual contains no operating instructions. An

operating instructions manual is supplied with the vehicle.

Additional copies can be ordered as required.

With the help of this manual you and your personnel will

be able to ensure the long service life, operational safety

and error free functioning of your CROWN vehicle.

Service training

CROWN offers the appropriate vehicle related training

for service personnel. Details on this training can be

obtained from CROWN on request.

Identical for each language

Section is only once in the manual

Page number

Truck code

Replacement parts orders

When ordering spare parts from this manual please

always give the full description of the vehicle model as

well as the order number. These details enable us to

process your orders in an accurate, quick and reliable

way.

Please refer to the Technical Specifications Sheet for the

utilisable loads, technical data and dimensions for this

series.

Brochures can be obtained from your CROWN dealer or

from the following address:

CROWN Gabelstapler GmbH

Moosacher Str. 52

D-80809 München

T el.: 089/93 00 20

Fax: 089/93 00 2-175

Printed in Germany

01/99

ITD-2230-003

3

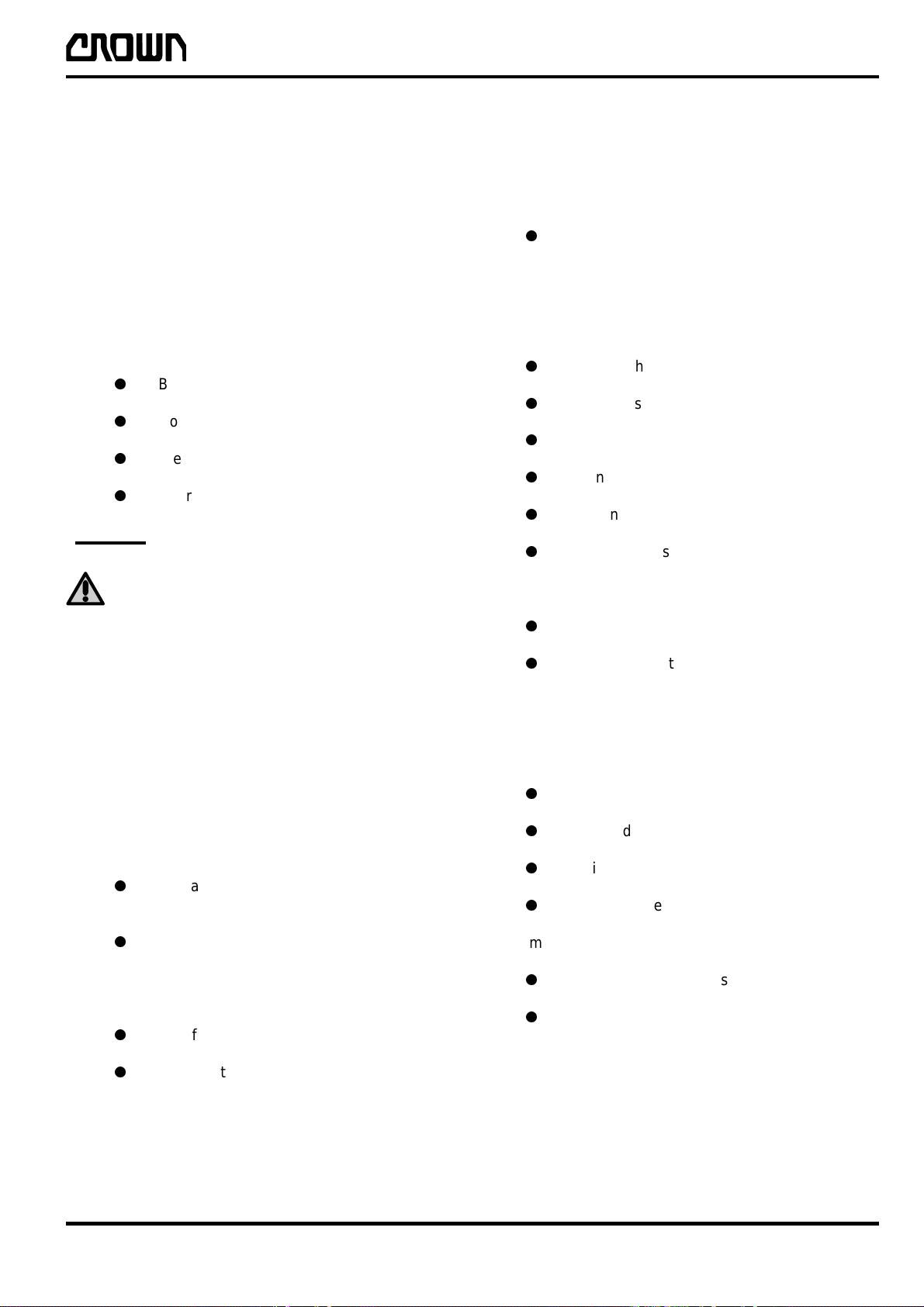

Truck Data Numbering Sheet

1.3SCTL–2–2

INTRODUCTION

Capacity

1.3 = 1250 kg

1.6 = 1600 kg

1.8 = 1800 kg

Model designation

SC = Sitdown Rider

Counterbalance

T = Telescopic

L = Double, part free lift

F = Double, full free lift

T = Triple, full free lift

NOTE

FOR SPECIALS USE THE ACTUAL FIGURES

FOR COLLAPSED / LIFT HEIGHT AND FORK

LENGTH (SEE TABLES ITD002-GB AND

ITD.003-GB).

Example:

Truck with data 1.3SCTL-2-2 designates

l

Capacity 1250 kg

l

Sitdown Rider Counterbalance

l

Telescopic double part free lift mast

l

Collapsed height 1970 mm

l

Lift height 2880 mm

l

Fork length 1000 mm

htgneLkroF

hsaD mm

1009

20001

30511

40021

50221

6006

7008

80731

97601

ITD002-gb

/)mm(thgieHdespalloC

)mm(thgieHgnitfiL

hsaD FTCS/LTCS

10642/0571

20882/0791

30723/5612

40753/5132

50783/5642

60724/5662

70264/0482

80105/5303

90265/0433

010195/5843

hsaD TTCS

10763/0671

20034/0791

35884/5612

45335/5132

55875/5642

65836/5662

70196/0482

85947/5303

98634/3991

011254/4402

116284/5412

2131906/9652

4

ITD-2230-004

ITD003-gb

Printed in Germany

01/99

INTRODUCTION

snoitpOyrettaB

ledoM noitpO hA

1noitpO

h1noitpO

3103CS

2noitpO

h2noitpO

2noitpO

h2noitpO

6103CS

3noitpO

h3noitpO

)mm( )mm(A13534NID

003

063

7811

063

564

004

084

5921

084

026

004

084

5921

084

026

005

006

3041

006

577

726x538x814

726x538x814

487x538x814

487x538x814

726x538x625

726x538x625

487x538x625

487x538x625

726x538x625

726x538x625

487x538x625

487x538x625

726x538x436

726x538x436

487x538x436

487x538x436

epyT

DS

DHS

DS

DHS

DS

DHS

DS

DHS

DS

DHS

DS

DHS

DS

DHS

DS

DHS

3noitpO

005

006

8103CS

h3noitpO

NOTE

ALWAYS SPECIFY MODEL NO. WHEN

ORDERING SPARE PARTS.

Spare parts for model SC3013 option 2/2h

correspond to model SC3016 option 2/2h.

Spare parts for model SC3016 option 3/3h

correspond to model SC3018 option 3/3h.

006

577

726x538x436

726x538x436

3041

487x538x436

487x538x436

DS

DHS

DS

DHS

ITD004-gb

Printed in Germany

01/99

ITD-2230-005

5

Page intentionally left blank

Seite absichtlich freigelassen

Page intentionellement laissée blanche

Printed in Germany

LUBRICATION AND ADJUSTMENT

Printed in Germany

Page intentionally left blank

Seite absichtlich freigelassen

Page intentionellement laissée blanche

Printed in Germany

Lubrication and Adjustment

Access to Components

MAINTENANCE

In the course of regular maintenance the contactor panel,

drive unit, hydraulic system and electrical components

in the chassis can be reached by removing or opening

the panels.

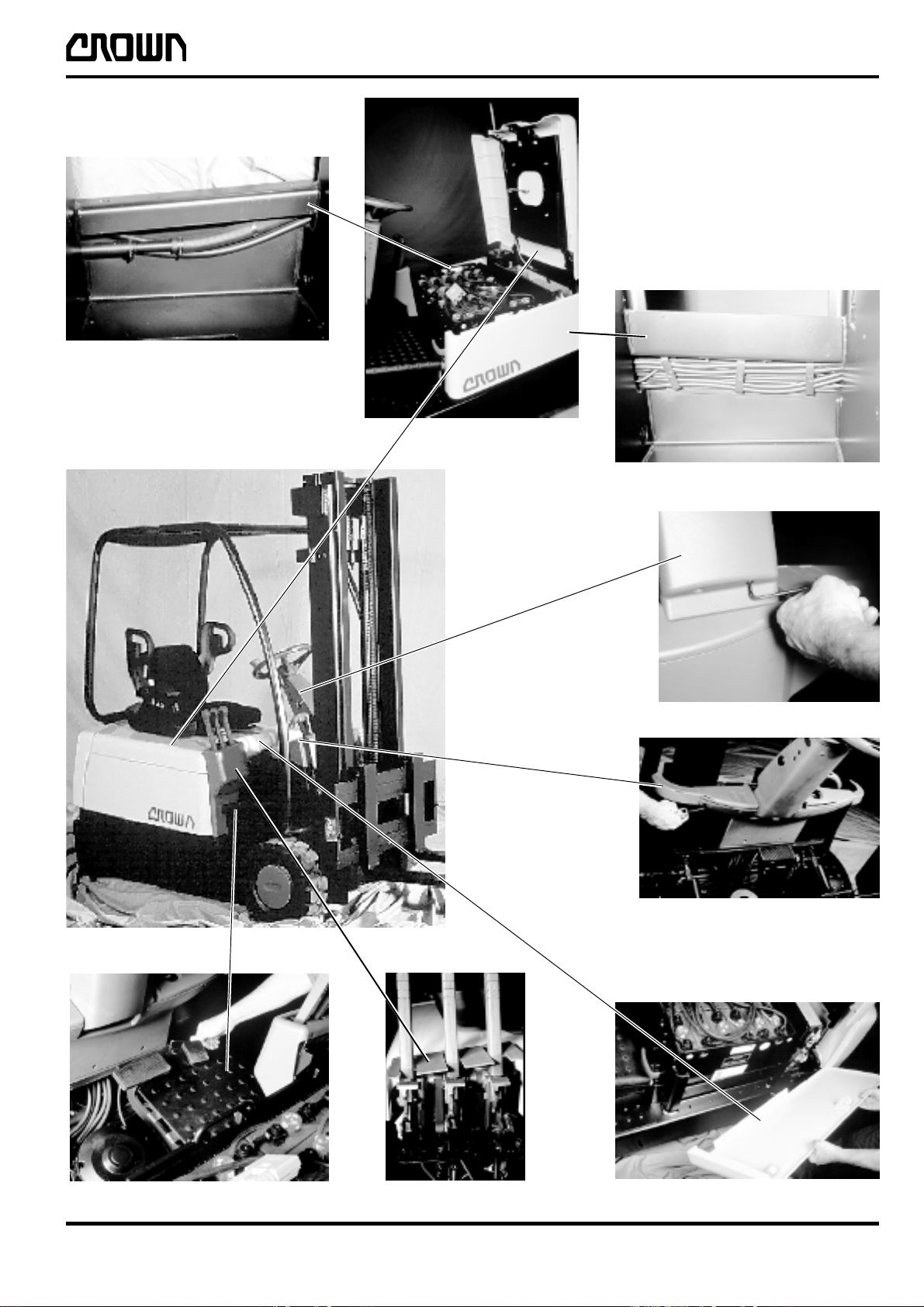

Fig. B: Battery compartment lid

Provides access to:

l

Battery

l

Contactor panel including impulse controls

l

Steering axle and potentiometer

l

Hydraulic motor and pump

CAUTION

WHEN THE BATTERY COMPARTMENT LID

IS OPENED IT CAN TIP OVER IF THE LID

CENTRE OF GRAVITY MOVES OVER THE

PIVOT POINT / ATTACHMENT POINT OF

THE LID.

Fig. C: LH and RH panels (LH illustrated)

l

Lift the side panel out of the attachment

Fig. D: Steering column front panel

Provides access to:

l

Key switch

l

Direction switches

l

Encoder

l

Wiring

l

Steering unit and distributor block

l

Hydraulic lines

To remove:

l

Loosen two hex. socket screws

l

Lift panel slightly and lever out at the bottom

Access:

Pull the handle on the front of the lid and open the

battery compartment lid.

Figs. B1 and B2

Provides access to:

l

Hydraulic lines (Fig. B1) on the right hand side

of the battery compartment.

l

Cable duct (Fig. B2) on the left hand side

of the battery compartment.

Access:

l

Lift off the side panel

l

Remove the battery

Fig. E: Inner dashboard

Provides access to:

l

Handbrake

l

Battery display

l

Wiring

l

Hydraulic lines

To remove:

l

Loosen 6 hex. socket screws

l

Remove panel

Printed in Germany

01/99

M1.0-2230-001

1

MAINTENANCE

Fig. F: Valve and Control Handle Panel

Provides access to:

l

Valve block

l

Switch, potentiometer

l

Control handle mechanism

To remove:

l

Remove the base plate

l

Loosen the two hex. socket screws at the rear

upper section.

l

Remove the single hex. socket screw at the

front below the base plate

l

Lift up the panel

Fig. G: LH and RH base plate (RH illustrated)

Provides access to:

l

Brake pedal and mechanism

l

Brake

l

Accelerator pedal / travel switch and

potentiometer

l

Tilt cylinder attachment (frame)

l

Valve block hydraulic lines

l

Wiring

l

LH and RH drive motor

To remove:

l

Loosen the single hex. socket screw on the

RH base plate

l

Lift out the LH and RH base plates.

2

M1.0-2230-002

Printed in Germany

01/99

MAINTENANCE

B1

M0258

B

M0251

B2

D

M0252

M0257

A

Printed in Germany

M0116

M0253 M0256

01/99

E

CFG

M1.0-2230-003

M0254b

M0259

3

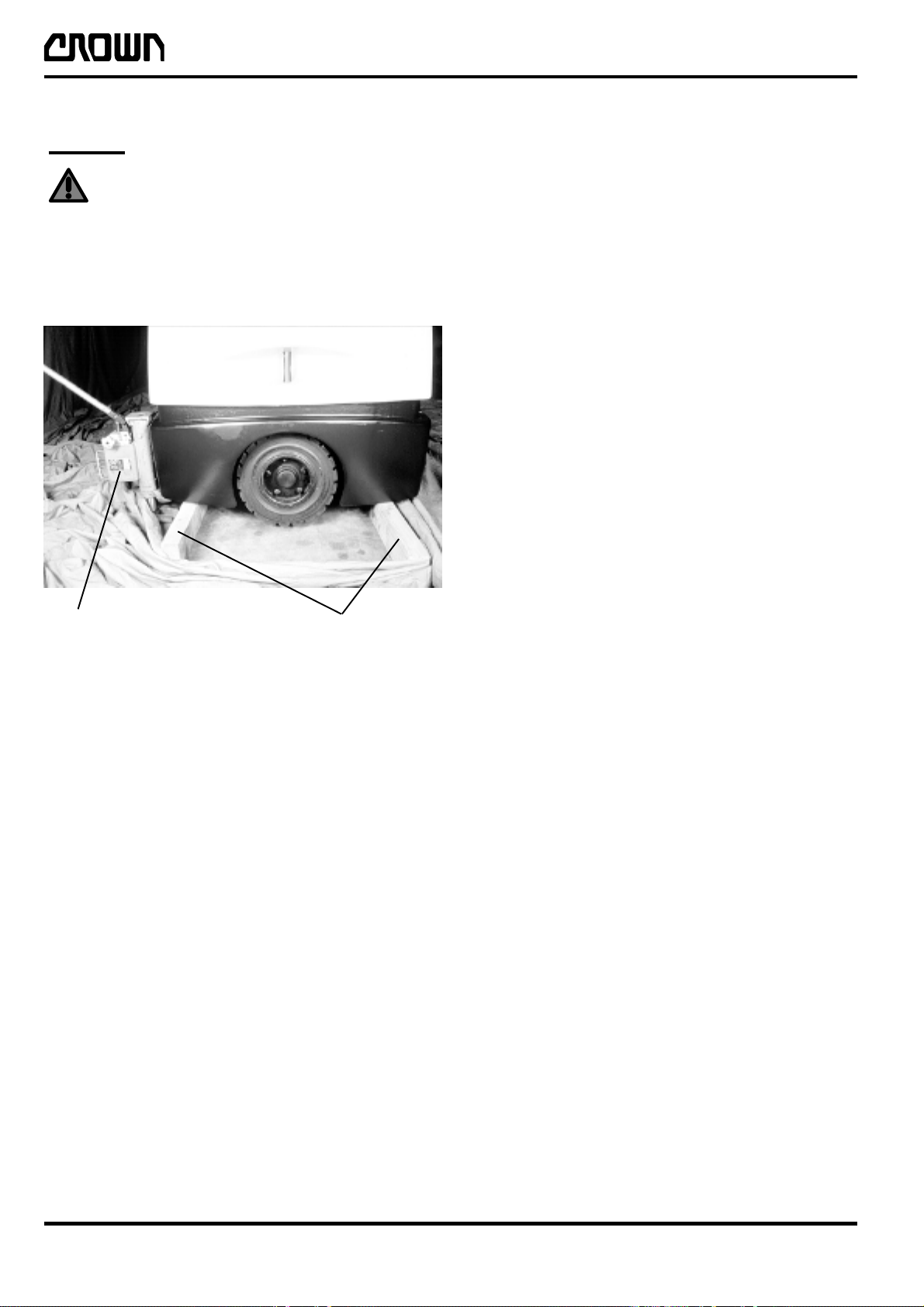

Jacking up the Truck

WARNING

ALWAYS SUPPORT A RAISED TRUCK WITH

WOODEN BLOCKS OR OTHER

APPROPRIATE EQUIPMENT TO RELIEVE

THE JACK.

Apply the jack as shown in Fig. M0262. The same

procedure is used for raising the front section of the truck.

MAINTENANCE

Jack

M0262

Wooden

blocks

4

M1.0-2230-004

Printed in Germany

01/99

Recommended Lubricants and Oils

Lubricants

Only high grade lubricants and oils should be used. These can be obtained from any oil manufacturer . Those listed

on the following page are typical, and any lubricant of the

same grade can be used.

Cold Store Trucks

Special hydraulic oil, lubrication oil and grease must be

used for cold store trucks operating in low temperature

conditions (see table on page M1.1-1710-002). An anticorrosion fluid (Crown no. 078882-002) must be applied

to all screws, washers, nuts, pins, retaining rings etc.

Maintenance schedules should be kept as short as

possible to prevent excessive wear of moving

components.

Driver Participation

MAINTENANCE

By involving the driver in the maintenance schedule, truck

downtimes can be substantially reduced. The driver can

also contribute to determining the maintenance schedule,

thereby saving costs. Crown therefore recommends that

the driver carry out the daily maintenance in accordance

with the table on page M1.2-2230-002.

Daily Maintenance Log

A maintenance log is provided to keep a record of the

extent and time of maintenance performed.

Printed in Germany

01/99

M1.1-1710-001

5

Lubricants and Oil Recommendations

epyTtnacirbuL noitpircseDtcudorP rerutcafunaM .oN-traP-NWORC epyT

MAINTENANCE

2-PLHebularA

esaerG-ML

2AsulugeR

)esoprupitlum(esaerG

2PE

erutarepmetwoL esaerg

)niahc(lionoitacirbuL

erutarepmetwoL

lionoitacirbul

liociluardyH

erutarepmetwoL

liociluardyh

2PEnocaeB

2EexuliboM

XLxanitneR

2LKSebularA

PEpmetoLxerinU

04lawoK

04+sulPXDHebulossE

0421cavleD

626CHSliboM800-200350GG

23FGmatiV

23-SWAnipsyH

23HotuN

42ETD

23sulleT

31JsivinU

AFHoreA

larA

lortsaC

yrutneC

ossE

loxaM

liboM

llehS

larA

liboM

larA

ossE

liboM

larA

lortsaC

ossE

liboM

llehS

larA

liboM

100-200350B

500-200350BB

700-200350G

300-100350D

800-100350DD

lionoissimsnarT

erutarepmetwoL

lionoissimsnart

gnisserdlynivdnarebbuR H

esaerglaicepSSOM

lionoitacirbullasrevinU04AES C

09W58pyH

09W58D-XG

09/58DHebuliboM

09BMxaripS

CHSebuliboMliboM600-200350AA

2

muihtiLgninroCwoD220-200360M

larA

ossE

liboM

llehS

400-200350A

W01-gb

6

M1.1-1710-002

Printed in Germany

01/99

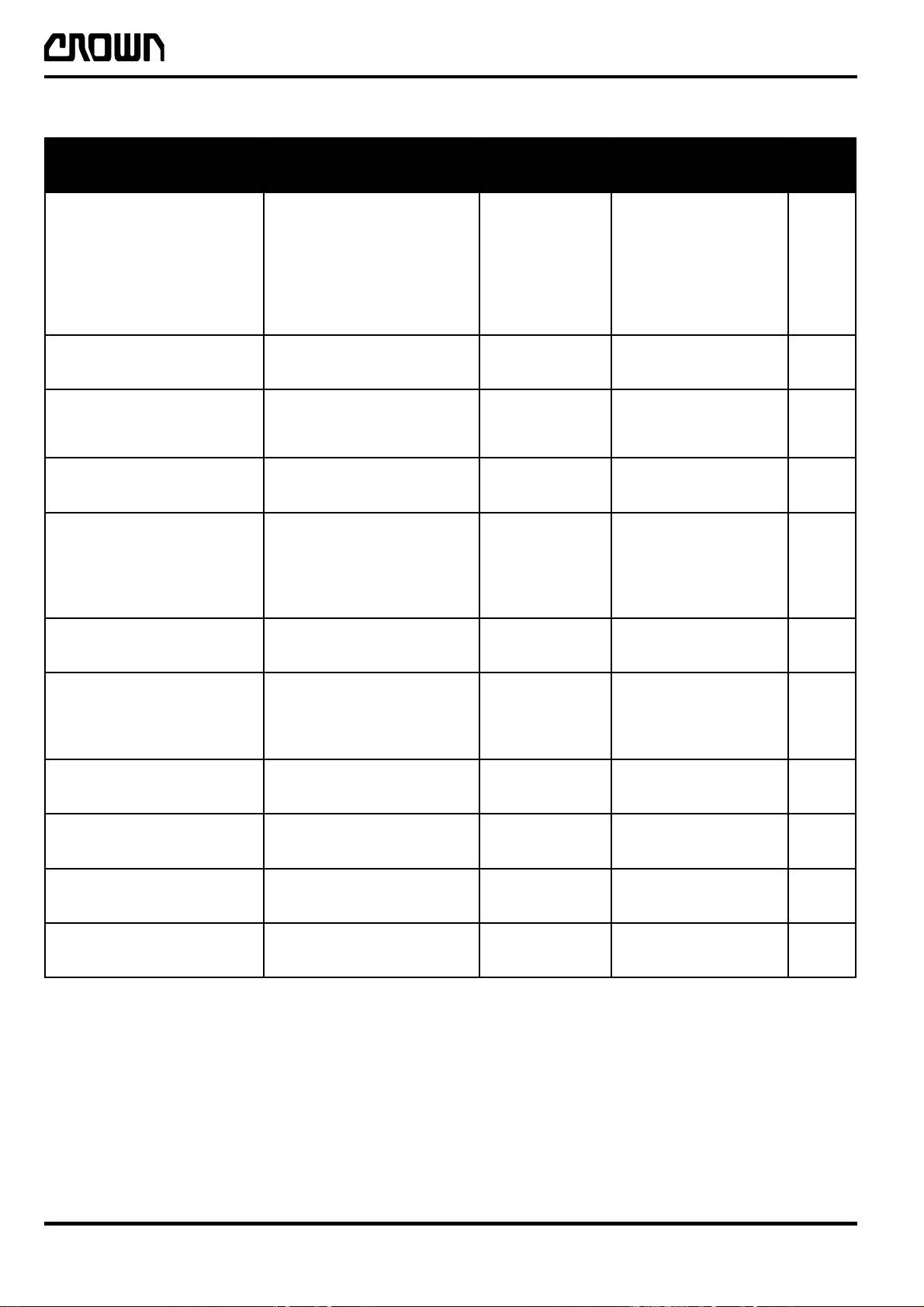

Inspection and Maintenance Schedule

The following inspection and maintenance schedule

assumes single-shift operation under normal operating

conditions. The length of maintenance intervals will

however depend on the particular operating conditions.

In dusty or otherwise extreme environments, including

cold stores, the specified maintenance intervals should

be reduced. The exact periods should be established after

consultation with Crown service personnel.

When performing maintenance work always check for

wear, corrosion and damage and ensure that the parts

are operating correctly and are secure. If in doubt, replace

the component.

Larger maintenance schedule should always include the

work of the next smallest maintenance schedule.

MAINTENANCE

Printed in Germany

01/99

M1.2-2230-001

7

Loading...

Loading...