Page 1

RC

RC 5500 Series

AC Traction

Service & Parts Manual

Crown 2007 PF15343 3/07

Page 2

New Bremen, Ohio 45869 USA

H

Phone 419/629-2311

crown.com

ow to Order Service Parts

To obtain fast, efficient service when ordering repair parts for your Crown Material Handling Equipment, please

follow this simple procedure:

1. Address all orders to your local Crown dealer.

2. Specify model and serial number of truck, which is shown on the serial number plate.

3. List the quantity needed.

4. List the part number and description, as shown in this Service Manual.

5. Show billing and shipping address.

6. Suggest fastest routing.

Your authorized Crown dealer stocks a large number of standard service parts. In addition, he has a factory trained Service Department to serve you.

Our Local Crown Dealer Is

NAME

ADDRESS

CITY

STATE ZIP

TELEPHONE

The information in this manual is the latest available at the time of printing for the unit with which it was shipped.

Should there be any variation due to vendor changes or special options on your unit, contact your Crown dealer

or Crown at the above address.

Crown 1986 Printed in U.S.A.

PF7609 Rev. 4/01

Page 3

.

Page 4

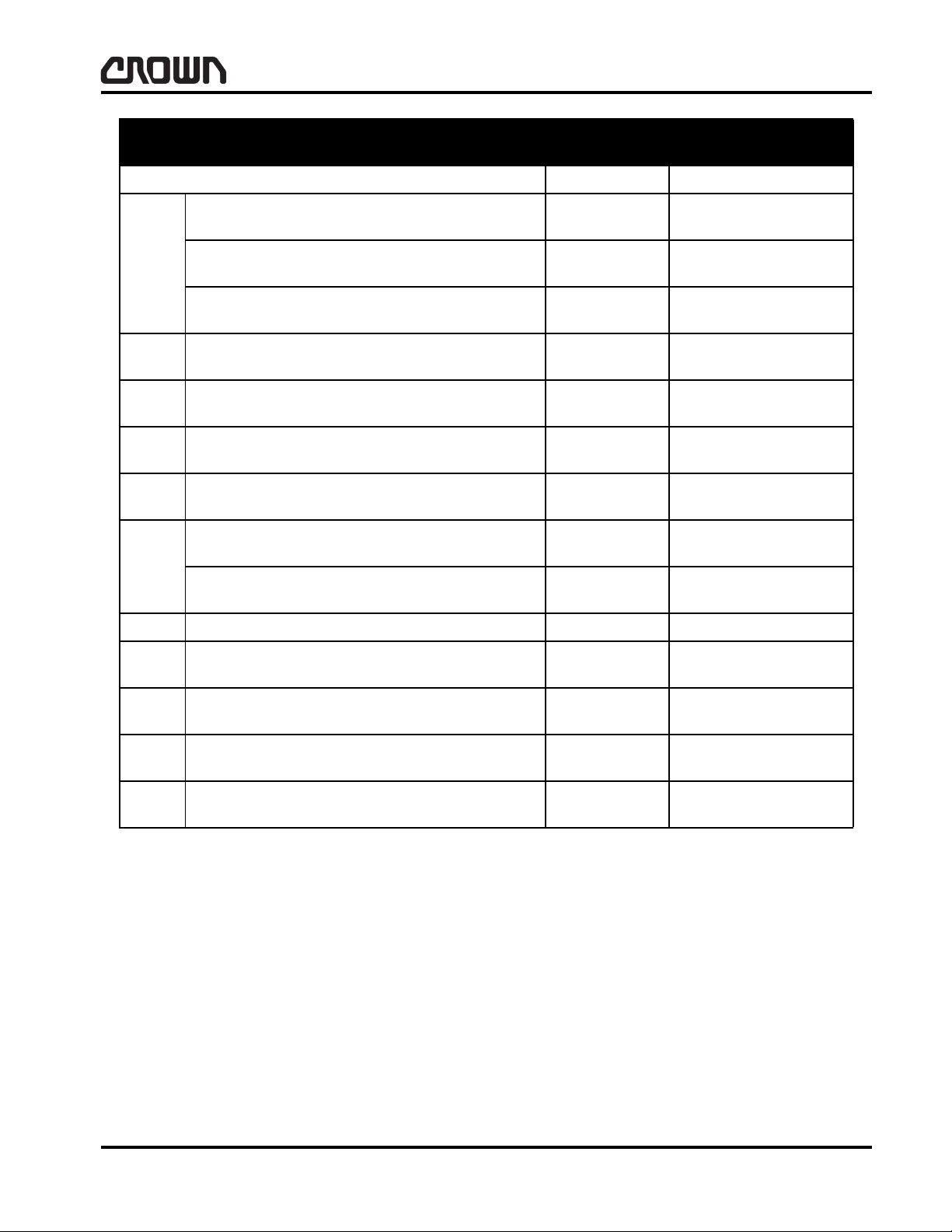

TABLE OF CONTENTS

I

Page 5

Notes:

II

Page 6

TABLE OF CONTENTS

SAFETY PAGE

General Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . .3

Control of Hazardous Energy . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Lockout/Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Battery Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lockout - Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Brake Release Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 7

Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Hydraulic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Towing Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Towing by Pulling in

Power Unit First Direction . . . . . . . . . . . . . . . . . . . . . . . . .9

Towing by Pulling

in the Forks First Direction . . . . . . . . . . . . . . . . . . . . . . .10

Towing by Lifting Truck and

Pulling in Power Unit First Direction . . . . . . . . . . . . . . . . .10

Towing by Lifting Truck and

Pulling in the Forks First Direction . . . . . . . . . . . . . . . .10

Lifting and Blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Blocking Masts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Disconnecting Tilt Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Removing Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning of Material Handling Equipment . . . . . . . . . . . . . . . .17

Cleaning Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TABLE OF CONTENTS

INTRODUCTION PAGE

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Operater Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Service Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

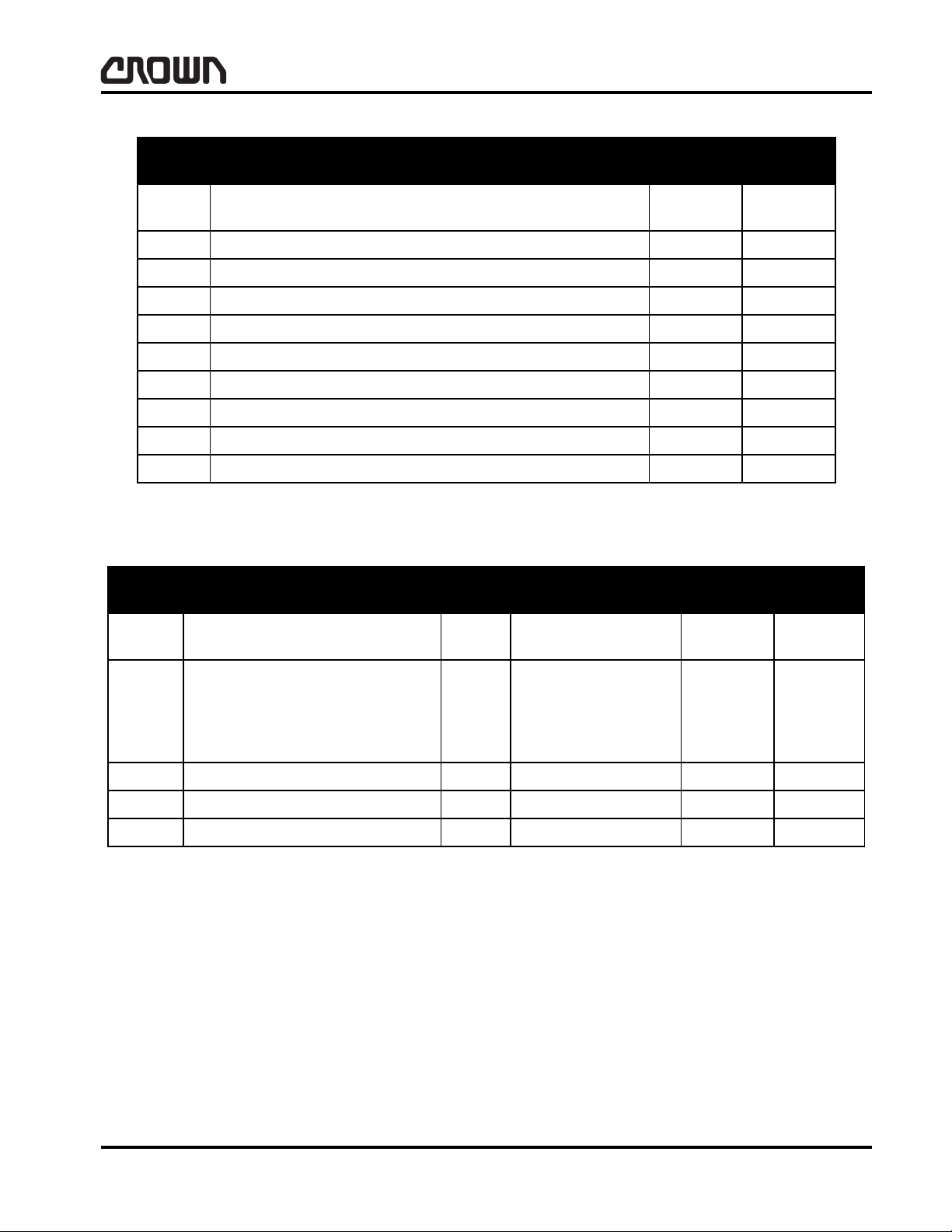

LUBRICATION & ADJUSTMENT PAGE

Lubrication and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Lubrication and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .33

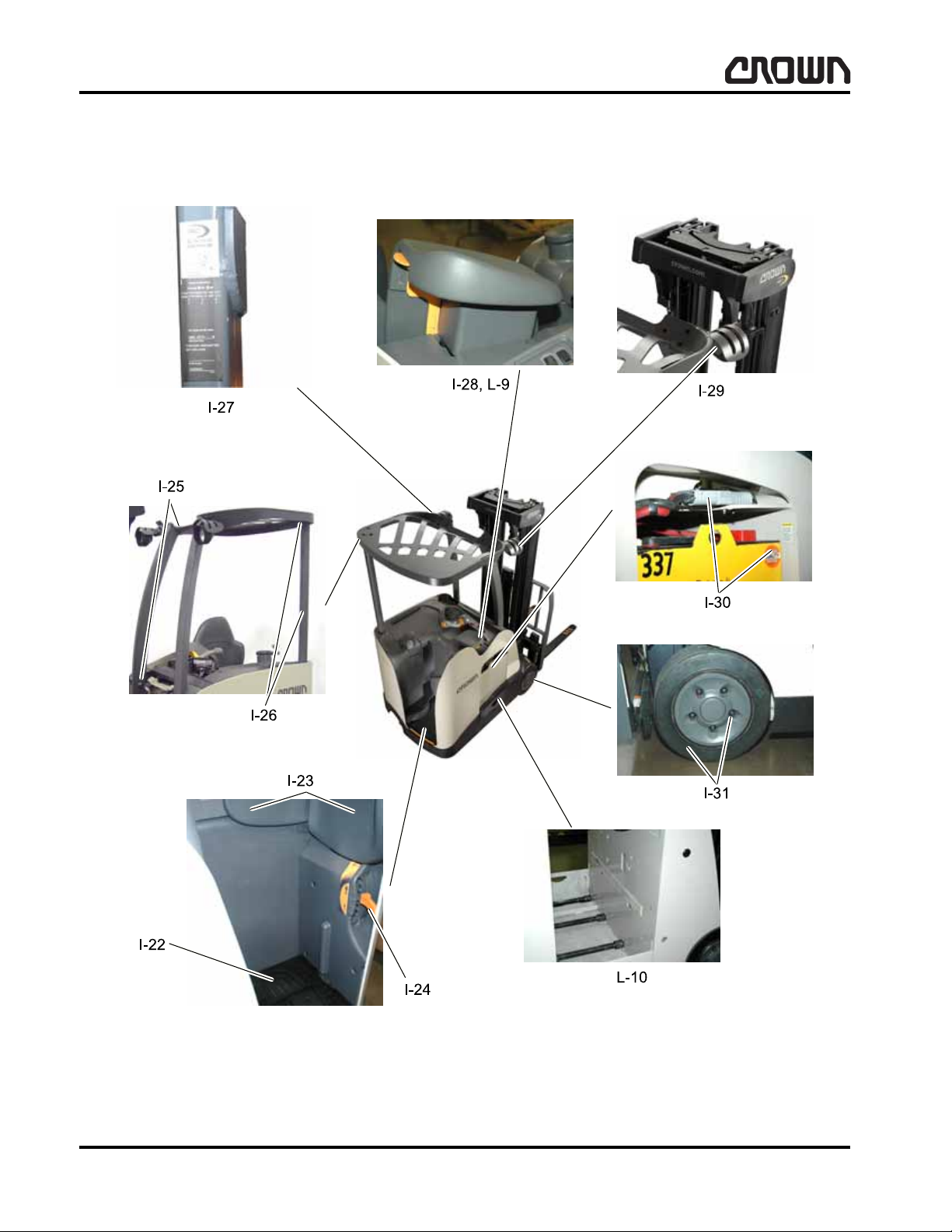

Component Accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Componentry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

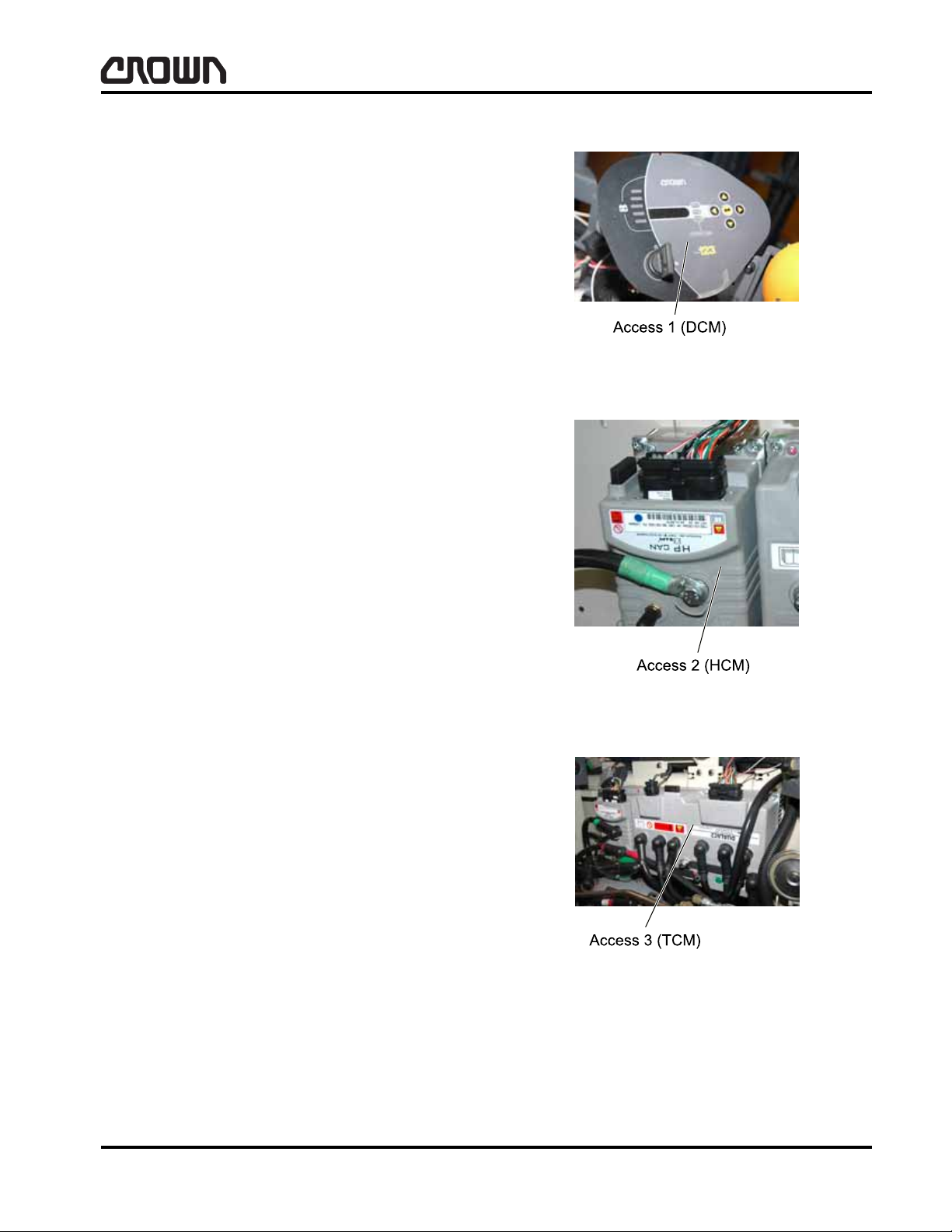

Access 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Access 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Access 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

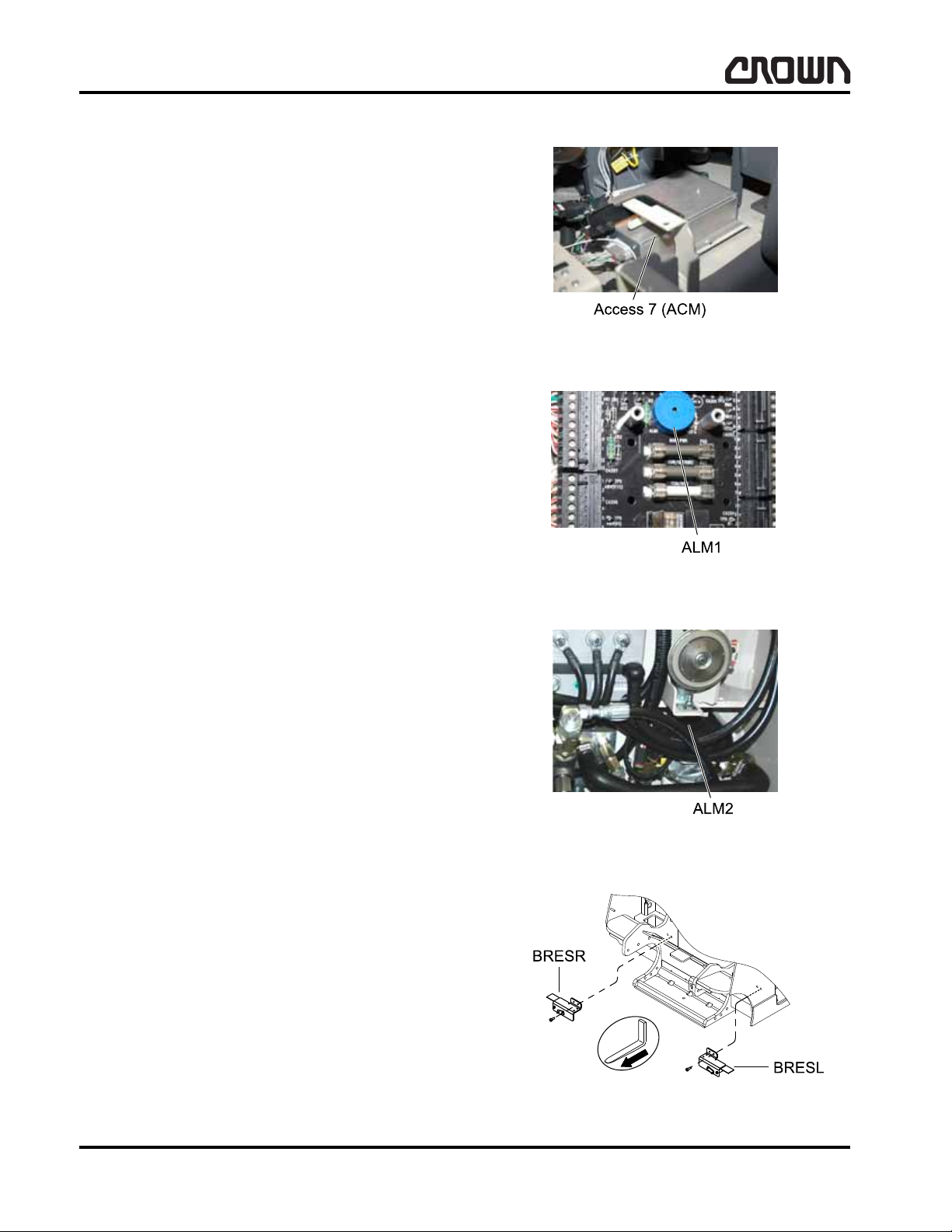

Access 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

ALM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

ALM2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

III

Page 7

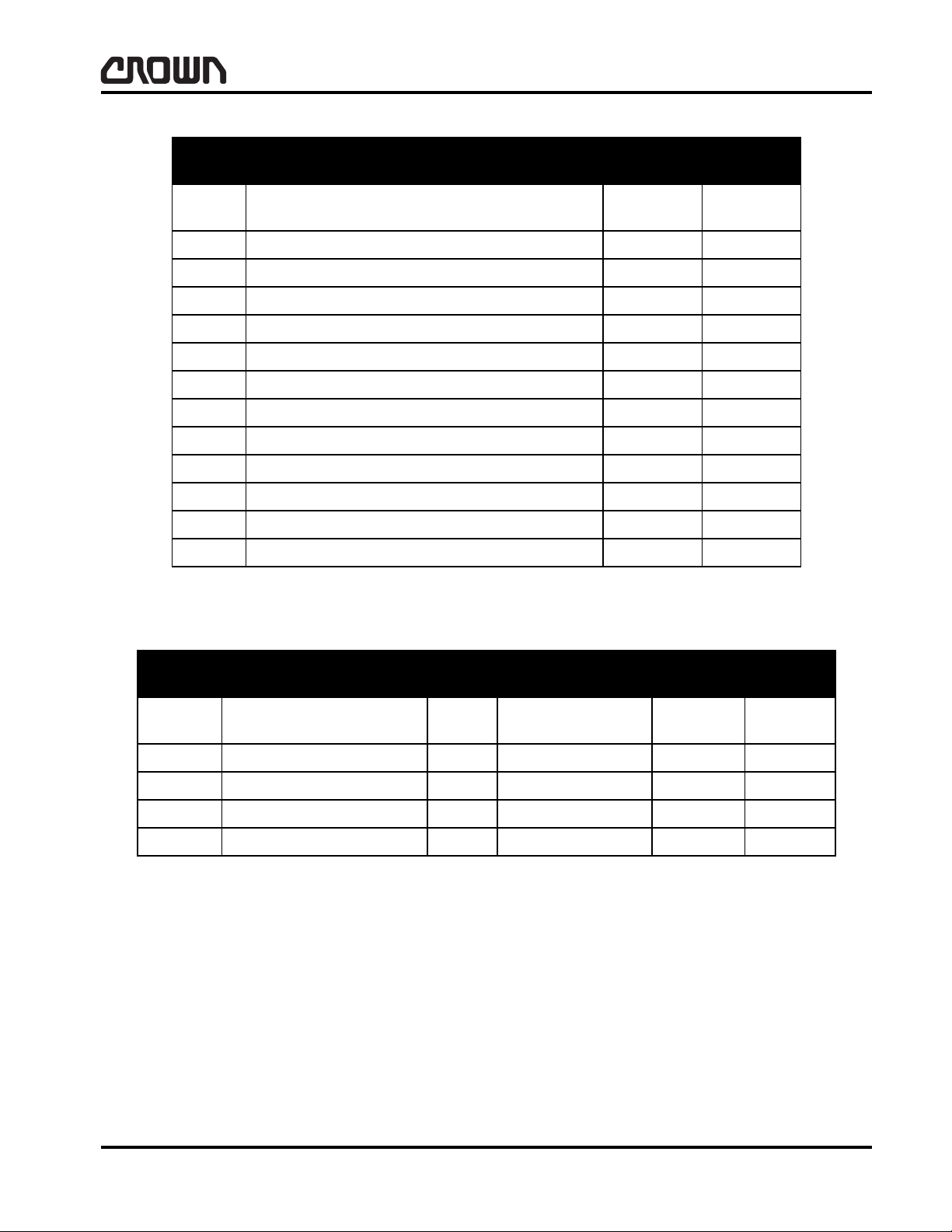

TABLE OF CONTENTS

BRESL, BRESR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

BRKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

BRK1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

BRK2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CBVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

CBVR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

CVR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DMS1, DMS2, DMS3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

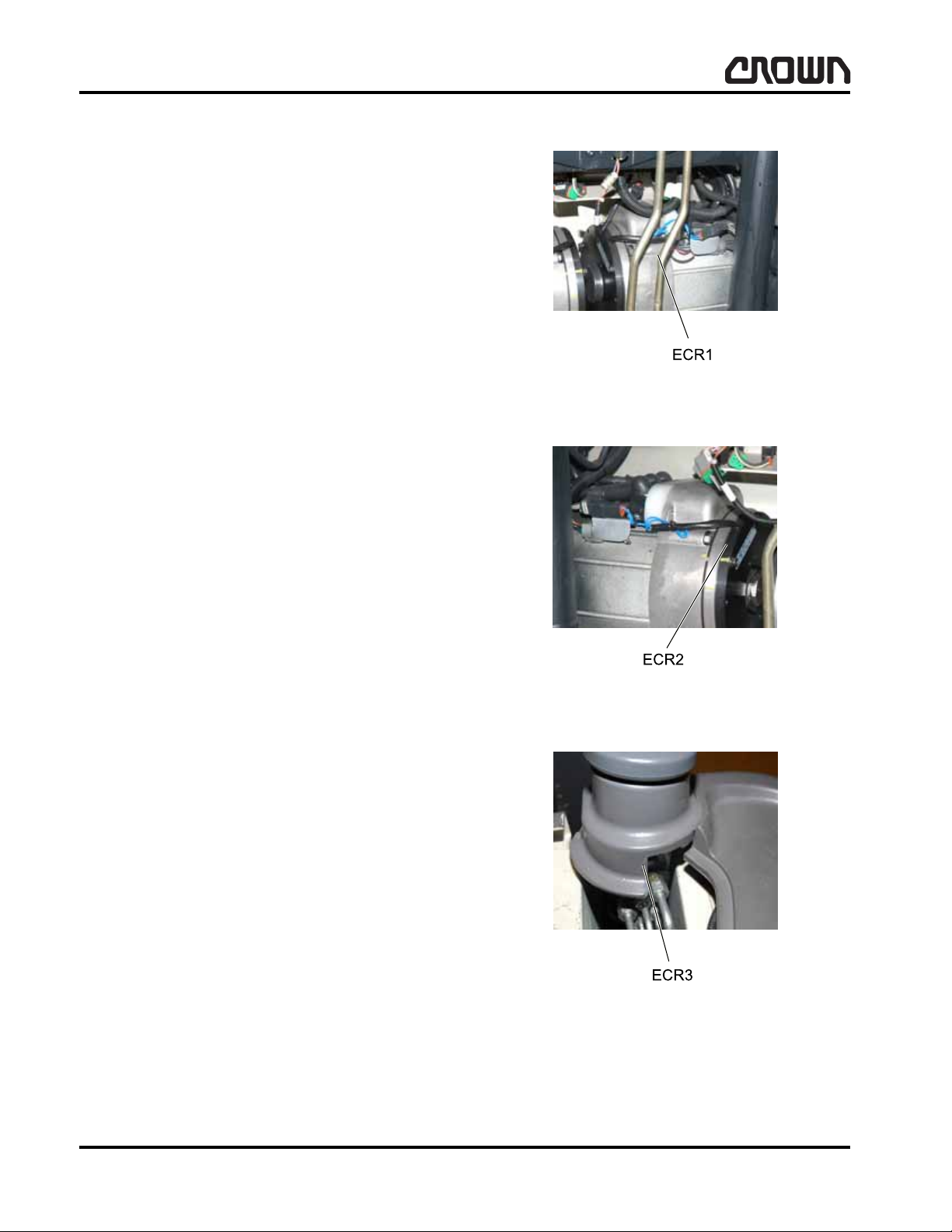

ECR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ECR2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ECR3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ECR4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

EDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

ENLS, ENSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

FNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

FAN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

FAN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

FS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

FU1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

FU2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

FU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

FU4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

FU5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

FU13/FU14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

HGTS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

HGTS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

HGTS3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

HGTS4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

HN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

HNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

K1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

K2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

KYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

LCV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

LGT1, LGT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

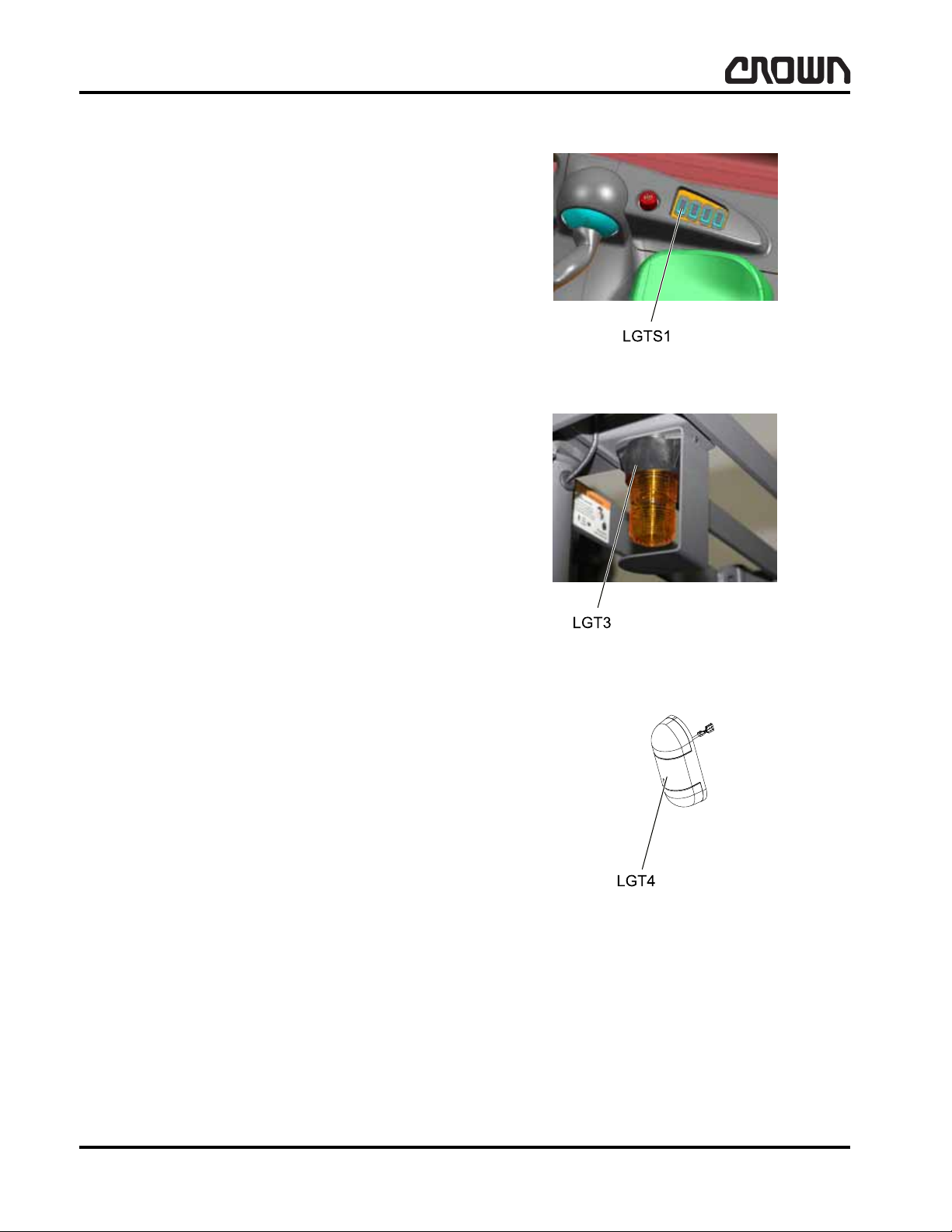

LGTS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

LGT3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

LGT4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

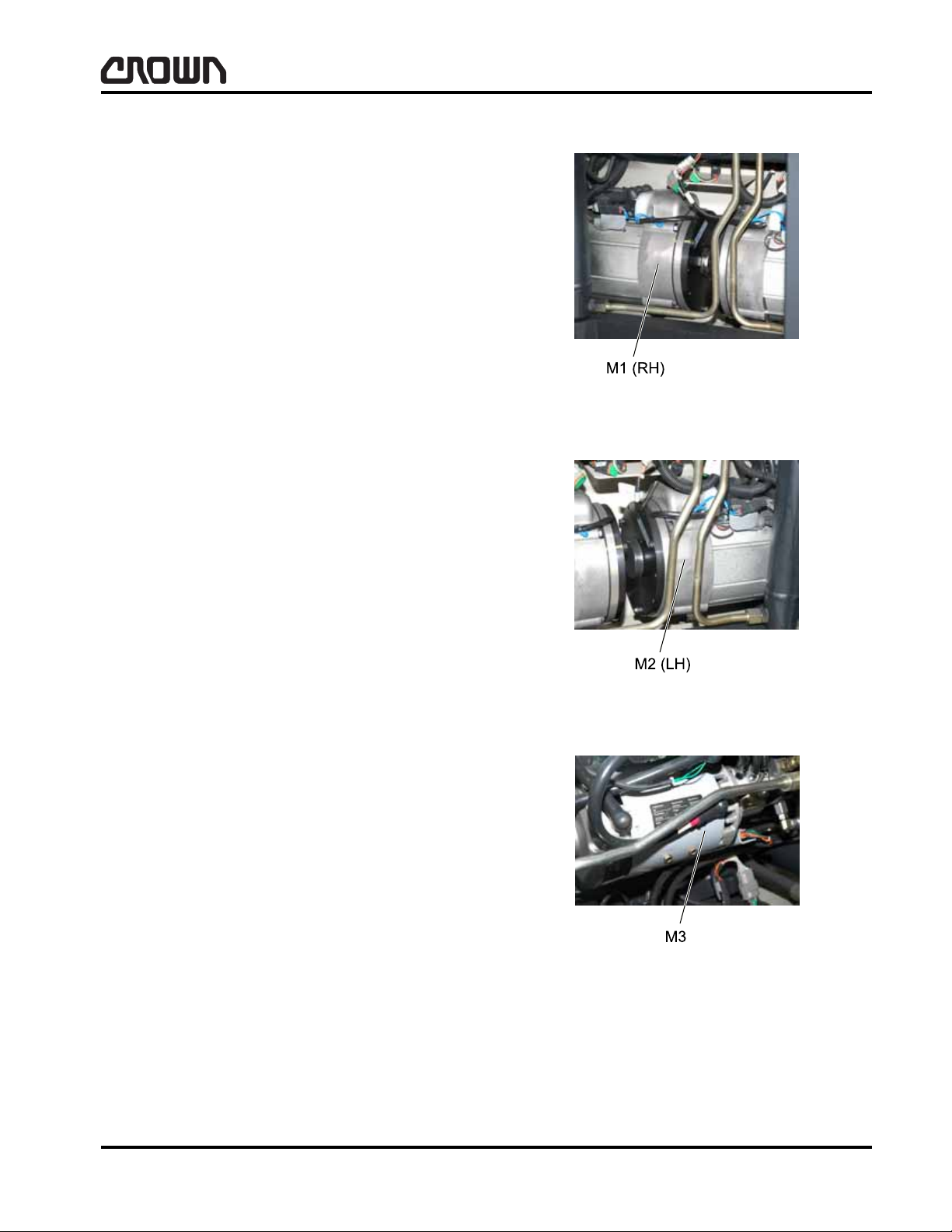

M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

ORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

POT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

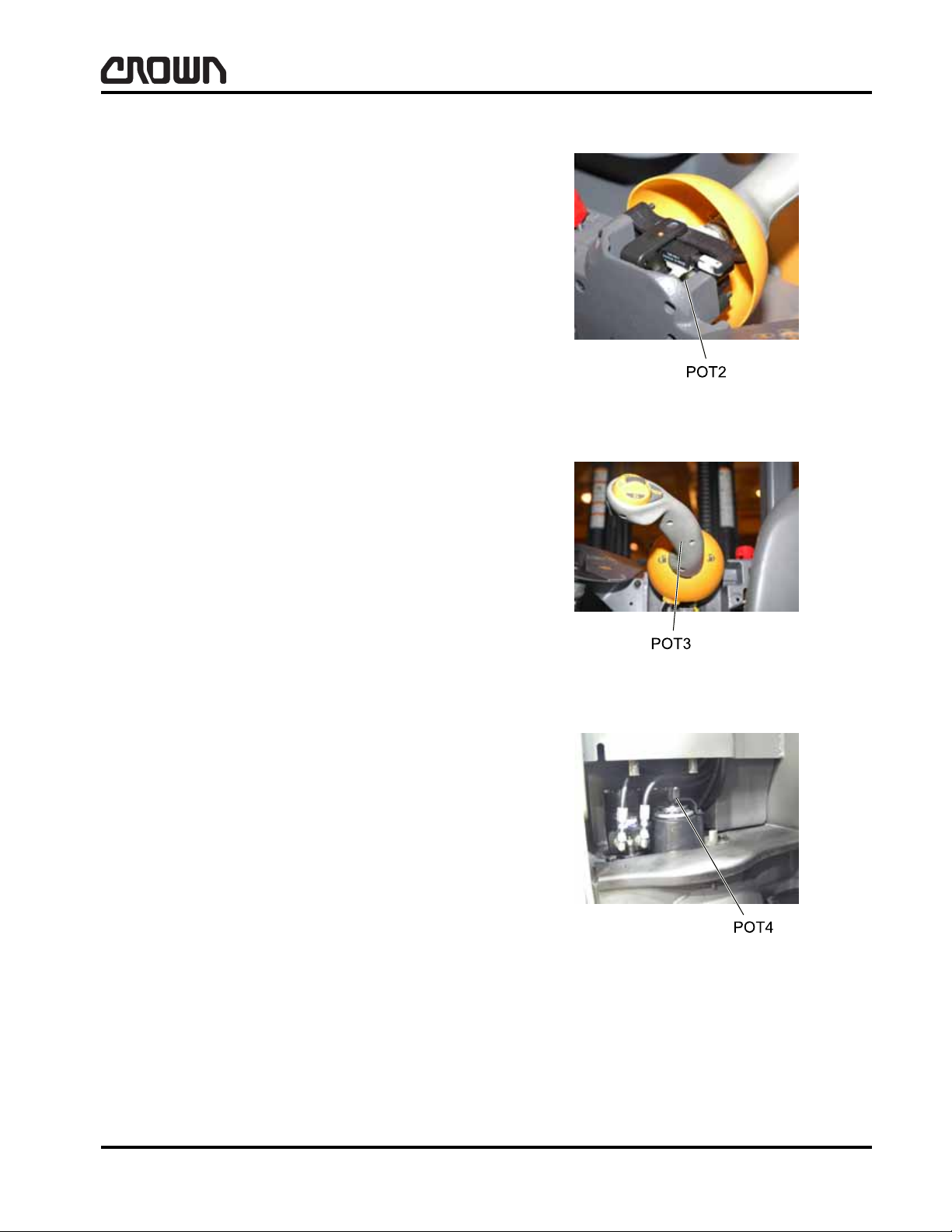

POT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

POT3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

POT4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

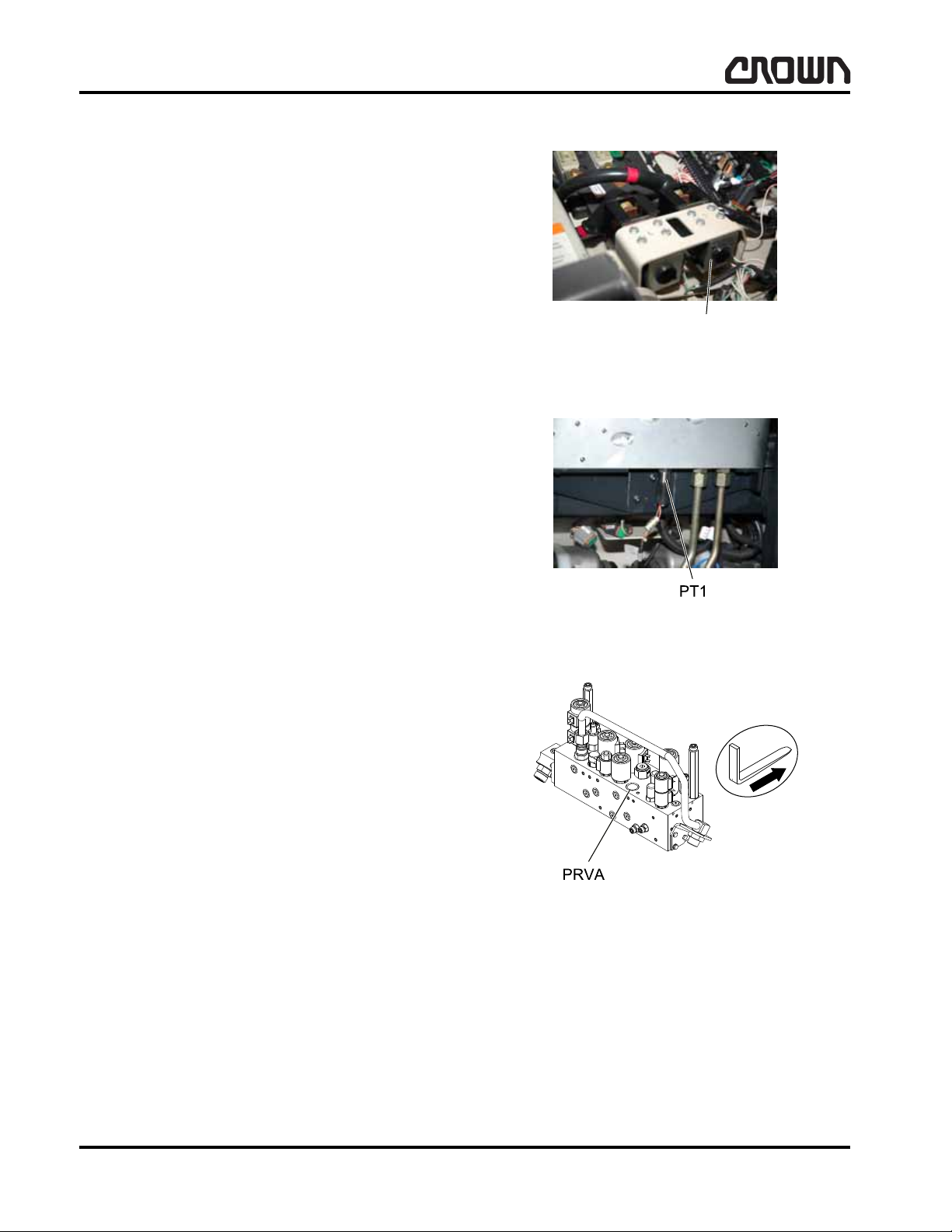

P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PRVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

RPS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

RPS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

IV

Page 8

RS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

RVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

RVM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

SSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

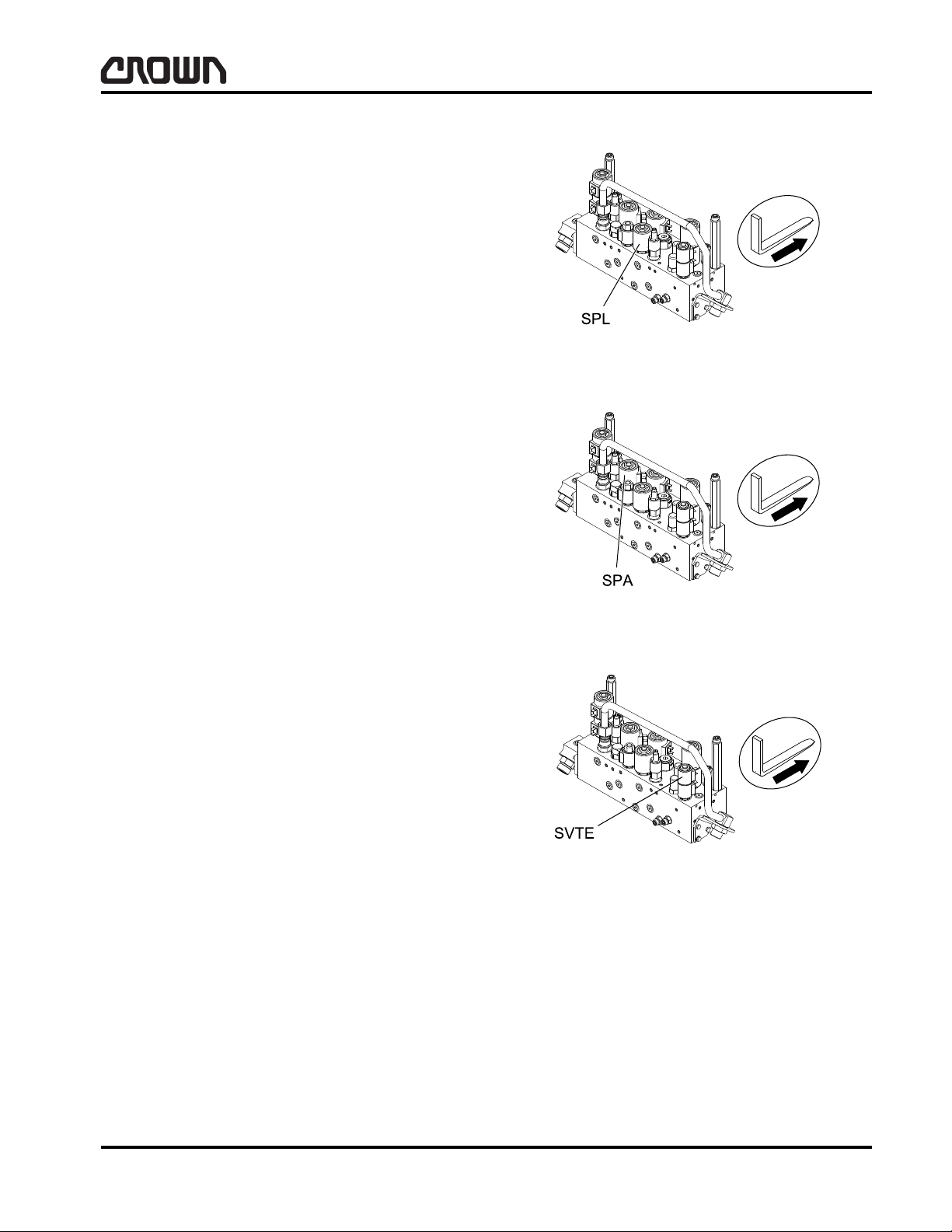

SPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SPA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

SVTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

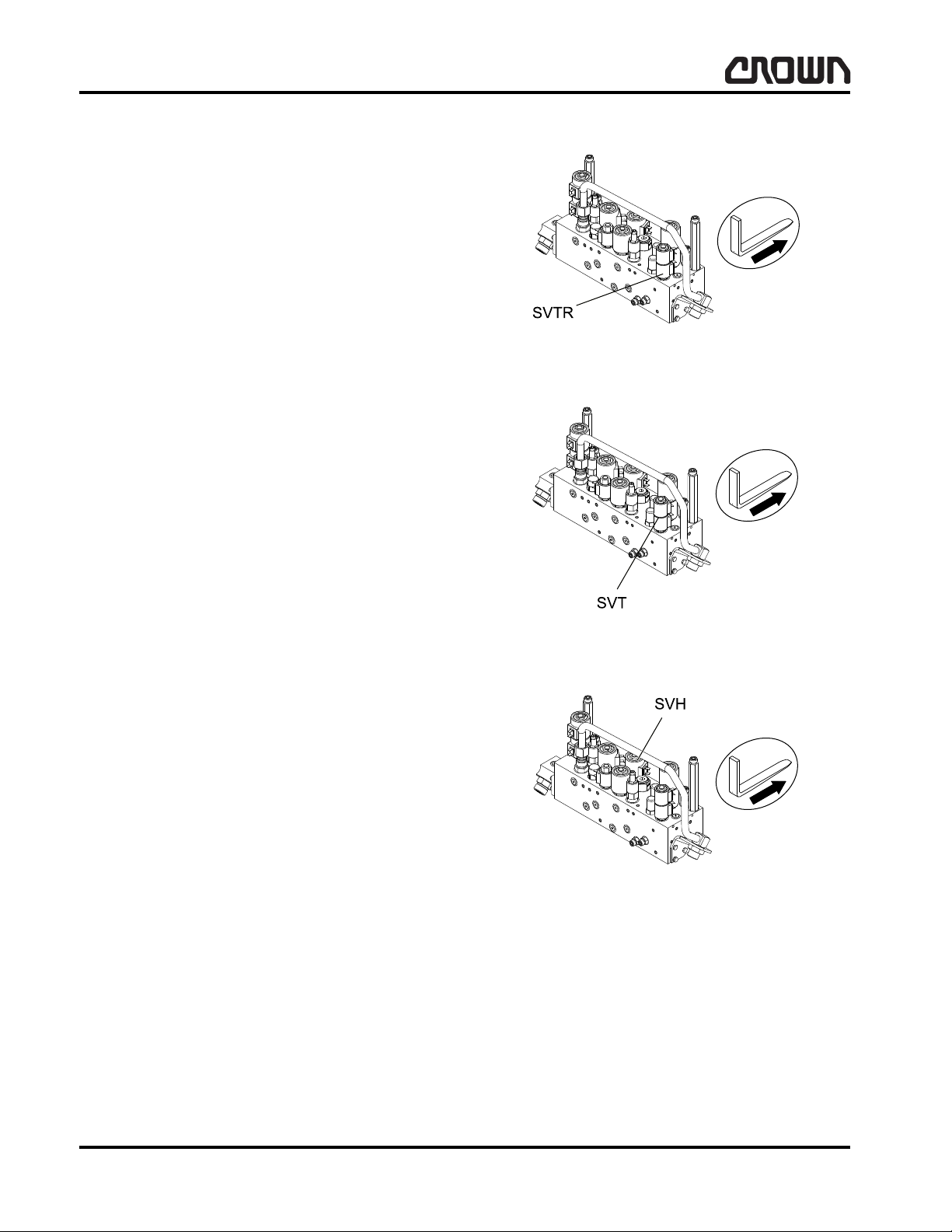

SVTR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

SVT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

SVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

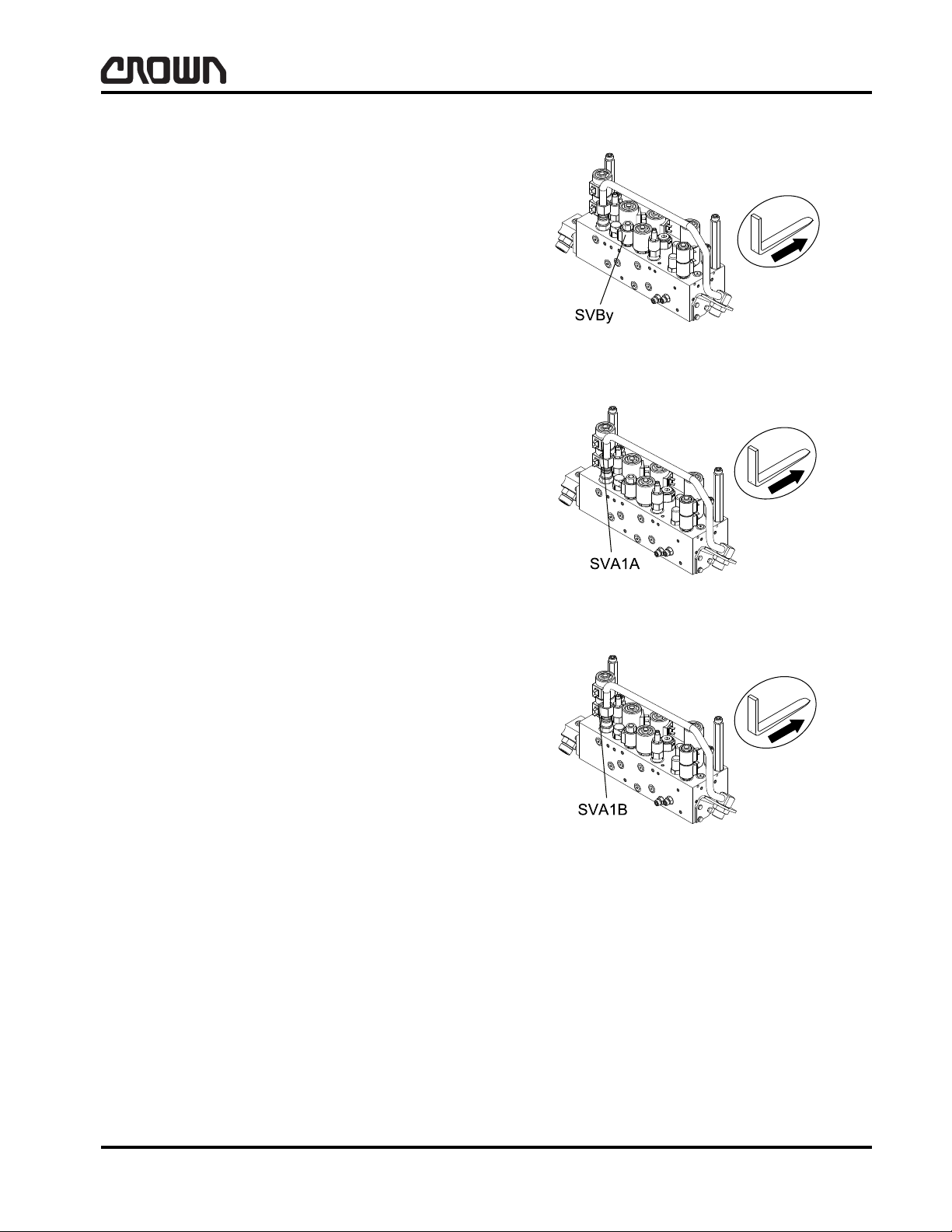

SVBy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SVA1A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SVA1B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SVA2A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SVA2B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SVA3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

TBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

TDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

TR1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

TR2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

TS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

TS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

TS3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Metric Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

TABLE OF CONTENTS

HYDRAULIC PAGE

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Hydraulic Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Lift Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Tilt Drift Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Steering Slip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

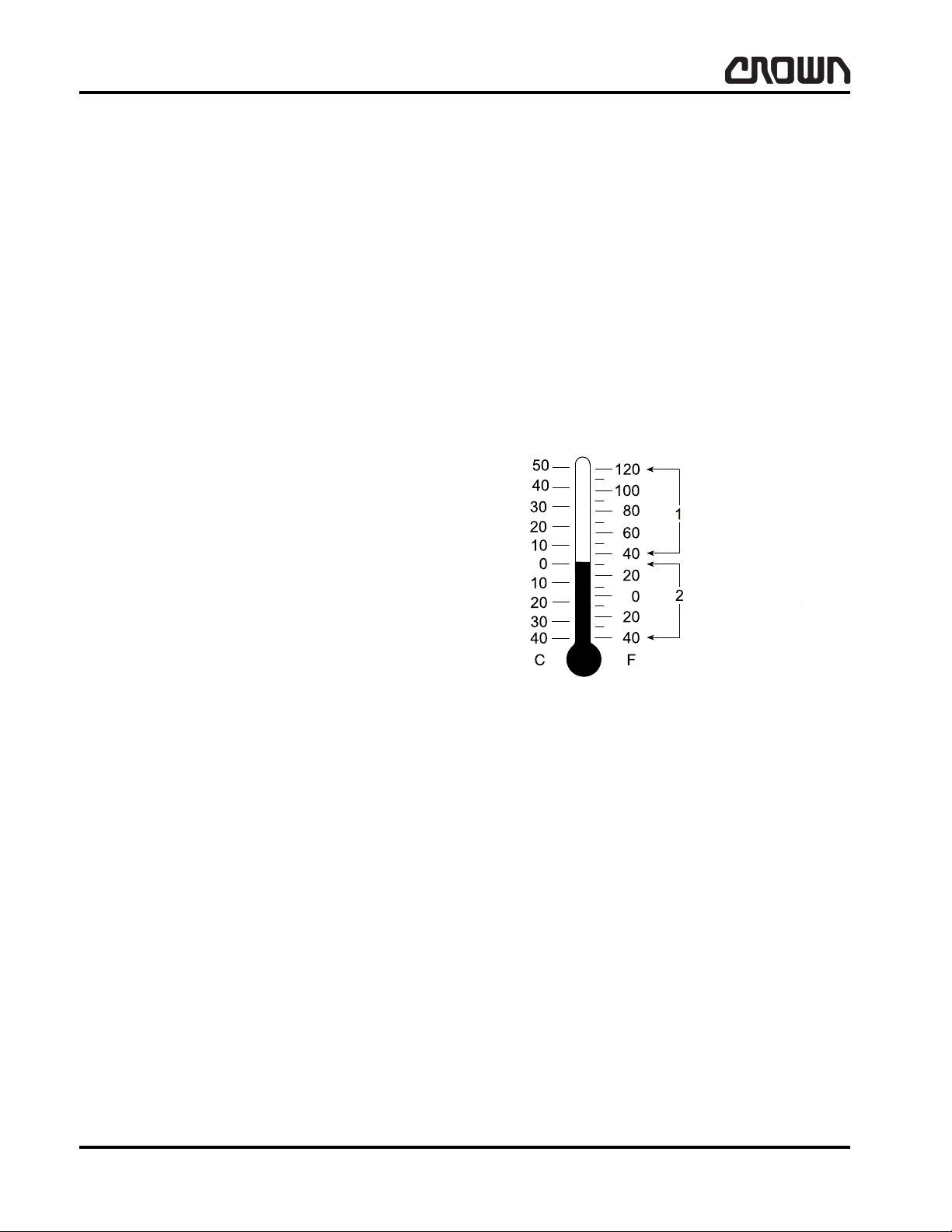

Freezer Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Hydraulic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Steering Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Hoist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Lift Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Lower Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Tilt and Accessory Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Tilt Down Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Tilt Back Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Tilt Position Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Sideshift - Left Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Sideshift - Right Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Fourth Hydraulic Function (Second Accessory) . . . . . . . . . . . 91

Fifth Hydraulic Function (Third Accessory) . . . . . . . . . . . . . . . 91

V

Page 9

TABLE OF CONTENTS

Accessory Clamp Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Attachment Setup - General . . . . . . . . . . . . . . . . . . . . . . . . . 93

Attachment Setup - Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Hydraulic Schematic Symbols . . . . . . . . . . . . . . . . . . . . . . . . . 97

Pump Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Pump Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Parts Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Priority Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Pump Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Start Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

DRIVE UNIT PAGE

Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Inspect Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Drive Unit Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Drive Tire Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Traction Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Traction Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . 109

Traction Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . 109

Drive Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Drive Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Drive Unit Sub-Assembly Removal . . . . . . . . . . . . . . . . . . . .111

Drive Unit Gear Assembly Replacement/Installation . . . . . . 113

ELECTRICAL PAGE

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Wiring Color Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

ACCESS 123...System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

ACCESS 1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Operator Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Message Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Timer - Message Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Trip - Message Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Bdi - Message Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Hours - Message Mode . . . . . . . . . . . . . . . . . . . . . . . . . 135

Odometer - Message Mode . . . . . . . . . . . . . . . . . . . . . . 135

Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Bleed Quick Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . 136

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Relief Pressure Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

VI

Page 10

Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Analyzer Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

A1 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

A2 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

A3 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

A4 Test Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Hour Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

Control Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Traction Drive Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Basics of System Operation . . . . . . . . . . . . . . . . . . . . . . . . . 197

Control Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Power Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Hydraulic Control Module - AC/DC . . . . . . . . . . . . . . . . . . . . 199

Basics of System Operation . . . . . . . . . . . . . . . . . . . . . . . . . 199

Accessory Control Module . . . . . . . . . . . . . . . . . . . . . . . . . .199

Basics of System Operation . . . . . . . . . . . . . . . . . . . . . . . . . 199

Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Battery Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Battery Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Battery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Pump Motor and Brush Inspection . . . . . . . . . . . . . . . . . . . .209

Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Event Code 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Event Code 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Event Code 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Event Code 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Event Code 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Event Code 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Event Code 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Event Code 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Event Code 108 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Event Code 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Event Code 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Event Code 111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Event Code 112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Event Code 113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Event Code 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Event Code 199 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Event Code 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Event Code 201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

TABLE OF CONTENTS

VII

Page 11

TABLE OF CONTENTS

Event Code 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Event Code 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Event Code 203 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Event Code 203 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Event Code 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Event Code 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Event Code 206 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Event Code 207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Event Code 208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Event Code 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Event Code 212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Event Code 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Event Code 214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Event Code 215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Event Code 216 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Event Code 217 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Event Code 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Event Code 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Event Code 220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Event Code 221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Event Code 222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Event Code 223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Event Code 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Event Code 300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Event Code 301 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Event Code 302 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Event Code 303 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Event Code 304 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Event Code 305 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Event Code 306 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Event Code 307 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Event Code 308 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Event Code 309 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Event Code 310 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Event Code 311-313 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Event Code 314 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Event Code 315 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Event Code 316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Event Code 318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Event Code 319 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Event Code 399 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Event Code 700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Event Code 701 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Event Code 702 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Event Code 703 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Event Code 704 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Event Code 705 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Event Code 706 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Event Code 707 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Event Code 708 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Event Code 709 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Event Code 710 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Event Code 711 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Event Code 712 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

VIII

Page 12

Event Code 713 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Event Code 714 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Event Code 715 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Event Code 716 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Event Code 717 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Event Code 718 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Event Code 719 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Event Code 720 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Event Code 721 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Event Code 722 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Event Code 723 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Event Code 724 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Event Code 726 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Event Code 727 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Event Code 728 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Event Code 729 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Event Code 730 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Event Code 731 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Event Code 732 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Event Code 733 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Event Code 734 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Event Code 735 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Event Code 736 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Event Code 737 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Event Code 738 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Event Code 739 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Event Code 740 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Event Code 741 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Event Code 742 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Event Code 743 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Event Code 744 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Event Code 745 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Event Code 746 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Event Code 747 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Event Code 748 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Event Code 749 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Event Code 750 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Event Code 751 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Event Code 752 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Event Code 753 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Event Code 754 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Event Code 755 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Event Code 799 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

TABLE OF CONTENTS

IX

Page 13

TABLE OF CONTENTS

BRAKE PAGE

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Service Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Plugging Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Service Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Stopping Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Parking Brake Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Electric Parking Brake Release Procedures . . . . . . . . . . . . 301

Releasing Parking Brake Using Operator Display . . . . . . . . 301

Releasing Parking Brake Using Truck Battery . . . . . . . . . . . 302

Releasing Parking Brake Using External Power Source . . . 302

Brake Switch Adjustment (BRKS) . . . . . . . . . . . . . . . . . . . . 303

Parking Brake Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

STEERING PAGE

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Hydrostatic Steering Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Forward and Reverse Steering . . . . . . . . . . . . . . . . . . . . . . 309

Steer Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Steer Command Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 310

Housing to Yoke Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 311

Steer Motor to Axle Housing Assembly . . . . . . . . . . . . . . . . 312

Wheel Assemblies to Steer Axle (Metallic Shield) . . . . . . . . 313

Wheel Assemblies to Steel Axle (Oil Seal) . . . . . . . . . . . . . 314

Hydraulic Steer Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Steer Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Motor Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

LIFTING MECHANISM PAGE

Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Fork Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Mast Flaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

TT (Triple Telescopic Full Free Lift) Mast . . . . . . . . . . . . . . . 321

Mast Testing (Assembled) . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Mast Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Mast Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

Removal From Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Mast Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Quad (Four Stage) Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Mast Flaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Mast Testing (Assembled) . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Mast Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Mast Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

Carriage Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Carriage Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Lift Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

X

Page 14

Lift Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

Rust and Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

Cracked Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

Tight Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Protruding or Turned Pins . . . . . . . . . . . . . . . . . . . . . . . .335

Chain Side Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

Lift Chain Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .336

Lift Chain Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Chain Anchors and Pulleys . . . . . . . . . . . . . . . . . . . . . . . 337

Leaf Chain Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . .337

Disconnect Procedures: . . . . . . . . . . . . . . . . . . . . . . . . . .337

Fork Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Abrasion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .339

Overloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .341

Fatigue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Bent or Twisted Forks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Hanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .343

TABLE OF CONTENTS

CYLINDERS PAGE

Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Mast Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Mast Cylinder Inspection . . . . . . . . . . . . . . . . . . . . . . . . .349

Mast Cylinder Disassembly . . . . . . . . . . . . . . . . . . . . . . . 349

Mast Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

Mast Cylinder Reassembly . . . . . . . . . . . . . . . . . . . . . . .351

Mast Cylinder Bleeding and Flushing Procedures . . . . . .351

Mast Cylinder Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Mast Cylinder Flushing . . . . . . . . . . . . . . . . . . . . . . . . . .352

Carriage Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .353

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .353

Carriage Cylinder Disassembly . . . . . . . . . . . . . . . . . . . . 354

Carriage Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . .354

Carriage Cylinder Reassembly . . . . . . . . . . . . . . . . . . . .356

Carriage Cylinder Bleeding and Flushing Procedures . . . 356

Carriage Cylinder Bleeding . . . . . . . . . . . . . . . . . . . . . . . 356

Carriage Cylinder Flushing . . . . . . . . . . . . . . . . . . . . . . .356

Tilt Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Tilt Cylinder Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . .357

Tilt Cylinder Disassembly . . . . . . . . . . . . . . . . . . . . . . . . .358

Rod Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .358

Tilt Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Tilt Cylinder and Rod Reassembly . . . . . . . . . . . . . . . . . .358

Tilt Cylinder Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .359

Tilt Cylinder Shimming . . . . . . . . . . . . . . . . . . . . . . . . . . .359

Tilt Cylinder Bleeding and Flushing Procedures . . . . . . .360

Tilt Cylinder Bleeding and Flushing . . . . . . . . . . . . . . . . .361

Sideshifter Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Sideshifter Cylinder Inspection . . . . . . . . . . . . . . . . . . . . . . . 363

Sideshifter Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . . 364

Sideshifter Cylinder Disassembly . . . . . . . . . . . . . . . . . . . . . 365

Sideshifter Cylinder Reassembly . . . . . . . . . . . . . . . . . . . . . 366

XI

Page 15

TABLE OF CONTENTS

PLATFORM PAGE

Sideshifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Sideshifter Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 369

Sideshifter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

Sideshifter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Bearing Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Supply Circuit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Sideshift Circuit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

GLOSSARY PAGE

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

WIRING DIAGRAMS PAGE

Introduction to Diagram Usage . . . . . . . . . . . . . . . . . . . . . . . 391

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Pictorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Electrical Diagrams Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Electrical Schematic - AC Lift . . . . . . . . . . . . . . . . . . . . . . . . 394

Electrical Schematic - DC Lift . . . . . . . . . . . . . . . . . . . . . . . . 395

Distribution Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Multi-Task Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

Accessory Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Traction Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Hydraulic Control Module - AC Lift . . . . . . . . . . . . . . . . . . . . 401

Hydraulic Control Module - DC Lift . . . . . . . . . . . . . . . . . . . . 402

Motors and Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Console and Overhead Guard . . . . . . . . . . . . . . . . . . . . . . . . 404

Floorboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

Hydraulics, Height & Load Sense . . . . . . . . . . . . . . . . . . . . . 406

Freezer Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

Power Cables - AC Lift (ANSI Trucks) . . . . . . . . . . . . . . . . . . 408

Power Cable - AC Lift w/Rapid Charge . . . . . . . . . . . . . . . . . 409

Power Cable - AC Lift (Euro Trucks) . . . . . . . . . . . . . . . . . . . 410

Power Cables - DC Lift (ANSI Trucks) . . . . . . . . . . . . . . . . . . 411

Power Cable - DC Lift w/Rapid Charge . . . . . . . . . . . . . . . . . 412

Power Cable - DC Lift (Euro Trucks) . . . . . . . . . . . . . . . . . . . 413

InfoLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Wire Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 415

HYDRAULIC SCHEMATIC PAGE

Entire Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

XII

Page 16

POWER UNIT PARTS PAGE

Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

Armrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Suspended Floorboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .434

FlexRide Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .438

Entry Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Counterweight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .446

Overhead Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .448

Battery Retainers, Spacers, Rollers . . . . . . . . . . . . . . . . . . . .454

HYDRAULIC PARTS PAGE

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 460

Mast Plumbing - TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .464

Mast Plumbing - Quad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

DC Lift Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .474

Pump Motor - AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 476

Pump Motor - DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

Pump Motor - AC “EE” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480

Valve Assembly 1 Low Flow Accessory . . . . . . . . . . . . . . . . 482

Valve Assembly W/2 High Flow Accessories . . . . . . . . . . . . 486

Chain Slack Valve - Quad Mast . . . . . . . . . . . . . . . . . . . . . . . . 490

Manifold Crossover Relief . . . . . . . . . . . . . . . . . . . . . . . . . . . .492

Carriage Hydraulics - TT/Quad . . . . . . . . . . . . . . . . . . . . . . . .494

TABLE OF CONTENTS

DRIVE UNIT PARTS PAGE

Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500

AC Traction Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .502

AC Traction Motor - EE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .504

Drive Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

ELECTRICAL PARTS PAGE

Electrical Components - Power Unit . . . . . . . . . . . . . . . . . . .510

Contactor Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518

Contactor Panel - EE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 520

Distribution Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 524

Distribution Panel - Freezer/Corrosion . . . . . . . . . . . . . . . . .526

Distribution Panel - EE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 528

Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .530

Multi-T ask Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 532

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 538

Battery Retainer Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

Tilt Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

Access 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 548

Control Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

Overhead Guard - Strobe Light . . . . . . . . . . . . . . . . . . . . . . . .552

Overhead Guard - Worklights . . . . . . . . . . . . . . . . . . . . . . . . . 554

Work Lights - TT Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

Work Lights - Quad Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

Strobe Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 560

XIII

Page 17

TABLE OF CONTENTS

BRAKE PARTS PAGE

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 564

STEERING PARTS PAGE

Steering Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 568

Steer Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 570

Steer Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 574

Steer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 576

Steer Tire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 578

LIFTING MECHANISM PARTS PAGE

Mast - TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 582

Mast - Quad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 590

Fork Carriage - TT Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

Fork Carriage - Quad Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . 602

Yoke - TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

5th Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

Yoke Quad Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

Lift Chain - TT Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 610

Lift Chain - Quad Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612

Load Backrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 616

Fork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 618

CYLINDER PARTS PAGE

Mast Cylinder - TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 624

Carriage Cylinder - TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 626

Mast Cylinder - Quad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 628

Carriage Cylinder - Quad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 630

Tilt Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 632

Sideshifter Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 636

PLATFORM PARTS PAGE

Sideshifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 640

LABELS AND DECALS PAGE

Work Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 646

Work Assist Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 648

InfoLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 654

Labels & Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 656

Labels & Decals Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 662

Labels & Decals InfoPoint/Access . . . . . . . . . . . . . . . . . . . . 666

Labels & Decals RC 5500C . . . . . . . . . . . . . . . . . . . . . . . . . . . 670

XIV

Page 18

SAFETY

1

Page 19

Notes:

2

Page 20

SAFETY

WARNING

General Maintenance Instructions

General Maintenance Instructions

TO PREVENT SERIOUS RISK OF INJURY TO

YOURSELF AND OTHERS OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS

Power industrial trucks may become hazardous if adequate maintenance is neglected. Therefore, adequate

maintenance facilities, trained personnel and procedures should be provided.

Maintenance and inspection shall be performed in conformance with the following practices:

1. A scheduled planned maintenance, lubr ica tio n,

and inspection system should be followed.

2. Only qualified and authorized personnel shall be

permitted to maintain, repair, adjust and inspect

truck.

3. Before leaving the truck—

– Stop truck.

– Fully lower the load engaging means.

– Place directional controls in neutral.

– Apply the parking brake.

– Turn off power (power disconnect).

– Remove key.

– Block the wheels if truck is on an incline.

4. Before working on truck—

– Raise drive wheel free of floor or disconnect

power sources.

– Use chocks or other positive positioning de-

vices.

– Block load engaging means, inter masts, or

chassis before working under them.

– Operation to check performance of truck or at-

tachments shall be conducted in an authorized

safe clearance area.

5. Before starting to operate truck—

– Be in operating position.

– Apply brake.

– Place directional control in neutral.

– Before operating truck, check functions of lift

systems, directional control, speed control, steering, warning devices, brakes and any attachments

if any used.

6. Avoid fire hazards and have fire protection equipment present. Do not use an open flame to check

level, or for leakage of electrolyte and fluids or oil.

Do not use open pans of fuel or flammable cleaning fluids for cleaning parts.

7. Keep shop well ventilated, clean and dry.

8. Brakes, steering mechanisms, control mechanisms, lift overload devices, guards, and safety devices shall be inspected regularly and maintained

in a safe operating condition.

– All guards must be installed to factory configuration and condition before operating truck. Do not

operate truck if any guards or fasteners are damaged, improperly installed or missing.

9. Capacity, operation and maintenance instruction

plates or decals shall be maintained in legible condition.

10. All parts of lift mechanisms shall be inspected to

maintain them in safe operating condition.

11. All hydraulic systems shall be regularly inspected

and maintained in conformance with good practice.

Cylinders, valves, and other similar parts shall be

checked to assure that “drift” has not developed to

the extent that it would create a hazard.

12. Batteries, motors, controllers, limit switches, protective devices, electrical conductors, and connections shall be maintained in conformance with

good practice. Special attention shall be paid to the

condition of electrical insulation.

13. Trucks shall be kept in a clean condition to minimize fire hazards and facilitate detection of loose

or defective parts.

Crown 1976 PF2821-1 Rev. 10/08

MA-04.0-001

05 Rev. 10/08

3

Page 21

SAFETY

General Maintenance Instructions

14. Modifications and additions which affe ct cap a city

and safe truck operation shall not be performed b y

the customer or user without manufacturers prior

written approval. Capacity, operation and maintenance plates or decals shall be changed accordingly.

– Adding electrical devices (radio, terminal,

lights, etc.) or changing existing components or

wiring can affect truck operation and could cause

an accident. Contact authorized Crown personnel

before adding to or changing the electrical system

in any way.

– For EE rated trucks, adding electrical devices

could cause a fire or explosion, as well as void the

EE rating. Written approval must be obtained from

Crown prior to adding electrical device(s). Prior to

use, inspection of installed device(s) must be performed by an appropriate nationally recognized

testing laboratory (i.e. Underwriters Laboratories

Inc) or the Authority Having Jurisdiction (see NFPA

505).

15. Care shall be taken to assure that all replacement

parts are interchangeable with the original parts

and of equal quality to that provided in the original

equipment.

16. Be sure that any equipment added to the truck (terminal, fan, clipboard, etc.) is positioned so that it

does not block your vision or interfere with safe and

efficient operation of the truck.

For further information pertaining to operating and

maintenance procedures:

• All trucks except Series B and Tow Tractors, refer

to current ASME B56.1.

• Series B trucks, refer to current ASME B56.10.

• Tow Tractors, refer to current ASME B56.9.

05 Rev. 10/08

4

MA-04.0-002

Crown 1976 PF 2821-2 Rev. 10/08

Page 22

SAFETY

CAUTION

CAUTION

Control of Hazardous Energy

Control of Hazardous Energy

Lockout/Tagout

In the interest of safety and to ensure compliance with

OSHA Regulations, (Standards - 29 CFR), control of

hazardous energy (lockout/tagout) - 1910.147, Crown

has developed guidelines for proper energy control

when performing service and maintenance on the

truck. Before performing any service or maintenance,

review appropriate sections in this service manual for

additional procedures to be followed.

In addition, Crown recommends that all mechanics

wear appropriate protective items, such as safety

glasses, work gloves, and steel-toed shoes, whenever

performing service or maintenance work on Crown

equipment.

Battery

Safety Rules

• Wear protective clothing, such as, rubber apron,

gloves, boots and full-face shield when per forming

any maintenance on batteries. Do not allow electrolyte to come in contact with eyes, skin, clothing

or floor. If electrolyte comes in contact with eyes,

flush immediately and thoroughly with clean water .

Obtain medical attention immediately. Should electrolyte be spilled on skin, rinse promptly with clean

water and wash with soap. A baking soda solution

(one pound to one gallon of water) will neutralize

acid spilled on clothing, floor or any other surface.

Apply solution until bubbling stops and rinse with

clean water.

• Keep vent plugs firmly in place at all times except

when adding water or taking hydrometer readings.

• Do not bring any type of flame, spark, etc., near the

battery. Gas formed while the battery is charging,

is highly explosive. This gas remains in the cells

long after charging has stopped.

• Do not allow dirt, cleaning solution or other foreign

material to enter cells. Impurities in electrolyte has

a neutralizing effect reducing available charge.

• If battery repair is planned, follow the battery man-

ufacturer's instructions concerning repair practices

and procedures.

Battery Care

Only qualified and experienced personnel should perform maintenance and repair on batteries.

• Make certain the charger being used matches the

voltage and amperage of the truck battery. This

voltage is listed on the truck serial plate.

• Before disconnecting or connectin g batte r i es to a

charger , make sure charger is "OFF". If an attempt

is made to do this while charger is "ON", serious

injury to you, the battery and charger could result.

• Never use a match or lighter. Battery fumes are ex-

plosive.

• Make certain battery used meets weight, size and

voltage requirements of truck (refer to seria l plate).

NEVER operate truck with an undersized battery.

Charging

Never smoke or bring flame near the battery. Gas

formed during charging is highly explosive and can

cause serious injury.

Consult the charger manufacturer's manual covering

your charger for hints on operation and maintenance.

• Do not lay metallic or conductive objects on bat-

tery. Arcing will result.

Crown 2006 PF15396-1 Rev. 9/07

MA-1055-100

03 Rev. 9/07

5

Page 23

SAFETY

CAUTION

CAUTION

CAUTION

Control of Hazardous Energy

Battery Removal

When removing the battery, move truck to area intended for battery care. Floor must be level. Turn key

switch or toggle switch to "OFF" position and remove

key. Disconnect battery and lockout or tagout truck as

described in Lockout - Tagout in this section. Never

move battery partially from truck without roller stand in

place. Lower load engaging means completely. If battery is removed with load engaging means raised, use

hoist attached to mast to provide tip over protection. Do

not allow any metallic object to come in contact with the

top of the battery cells. This may cause a short circuit

when removing, transporting the battery. Use an insulator (such as plywood) to cover the top of the battery

before and during removal.

Make certain same battery or battery of equal weight is

loaded into truck for truck stability. See nameplate for

minimum battery weight.

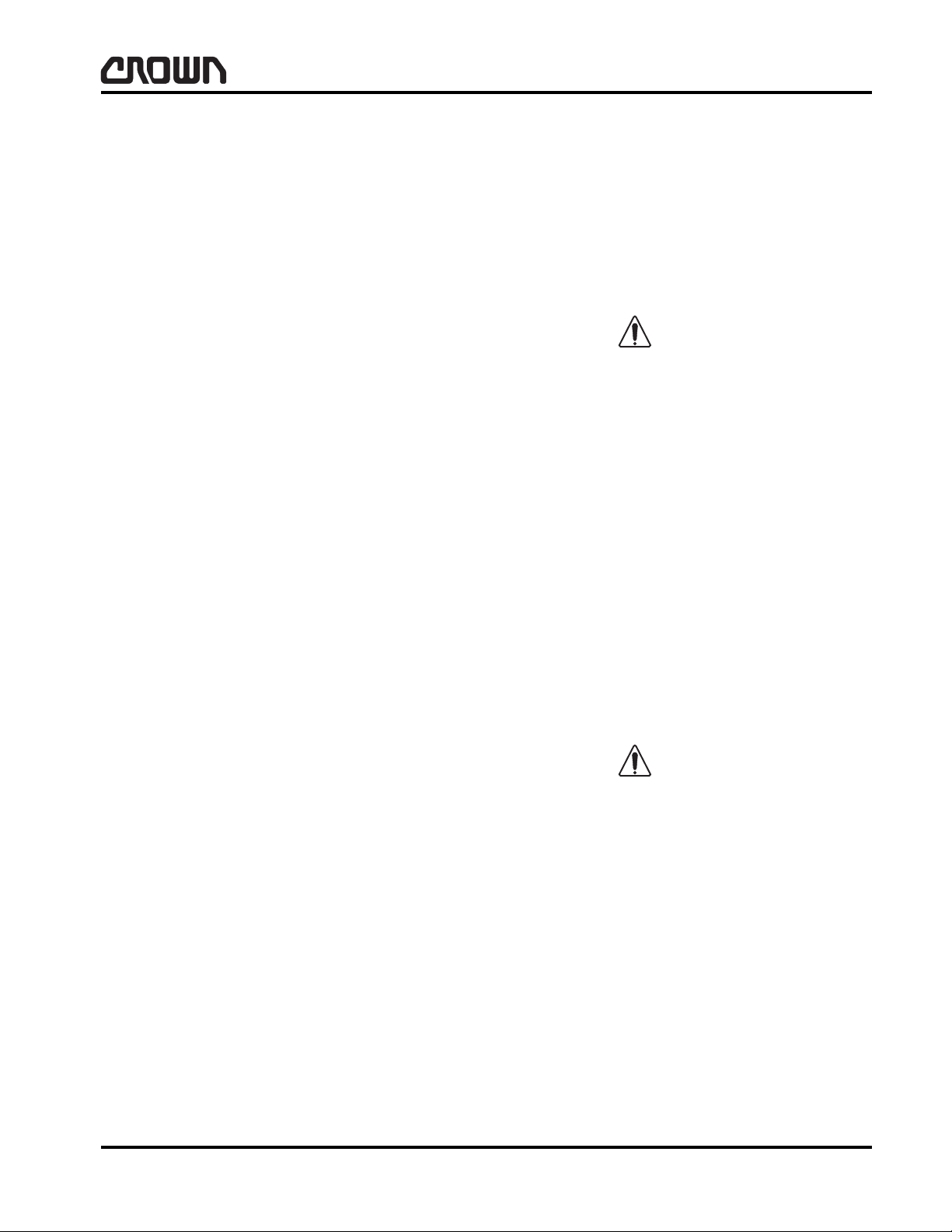

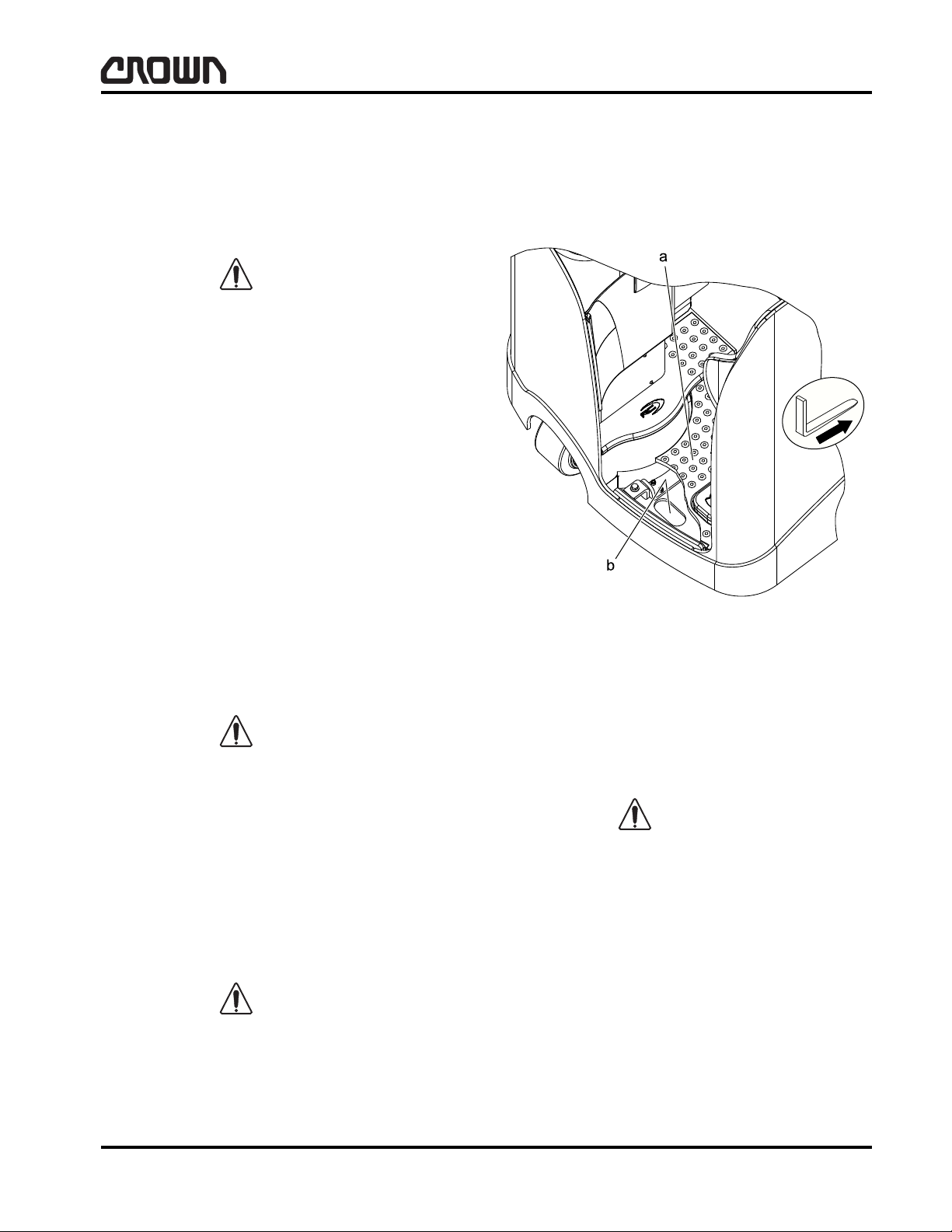

Lockout - Tagout

Always turn key switch to "OFF", remove key and apply

tag to multi-function control handle Item 1 and/or steering tiller Item 2 with cable tie warning others truck is

being serviced.

Figure 8251

Battery Installation

When installing the battery, move truck to area intended for battery care. Floor must be level. Turn key

switch or toggle switch to "OFF" position and remove

key. Lockout or tagout truck as described in Lockout Tagout in this section. If battery was removed with load

engaging means raised, use hoist attached to mast to

provide tip over protection. Do not allow any metallic

object to come in contact with the top of the battery

cells. This may cause a short circuit when transporting

or installing the battery. Use an insulator (such as plywood) to cover the top of the battery before and during

installation.

Figure 16925-01

a

Multi-function Control Handle

b

Steering Tiller

When maintenance is to be performed and th e bat tery

will be left in the truck, remove the main power fuses

and install a commercially available lockout device on

the battery connector.

When maintenance is performed and the battery is removed from the truck, remove main power fuses, install

a lockout device on the trucks battery connector if possible, or if possible install a tag with a cable tie on the

trucks battery connector so it cannot be removed easily

warning that the truck is not available for operation.

03 Rev. 9/07

6

MA-1055-101

Crown 2006 PF15396-2 Rev. 9/07

Page 24

Brake Release Instructions

WARNING

CAUTION

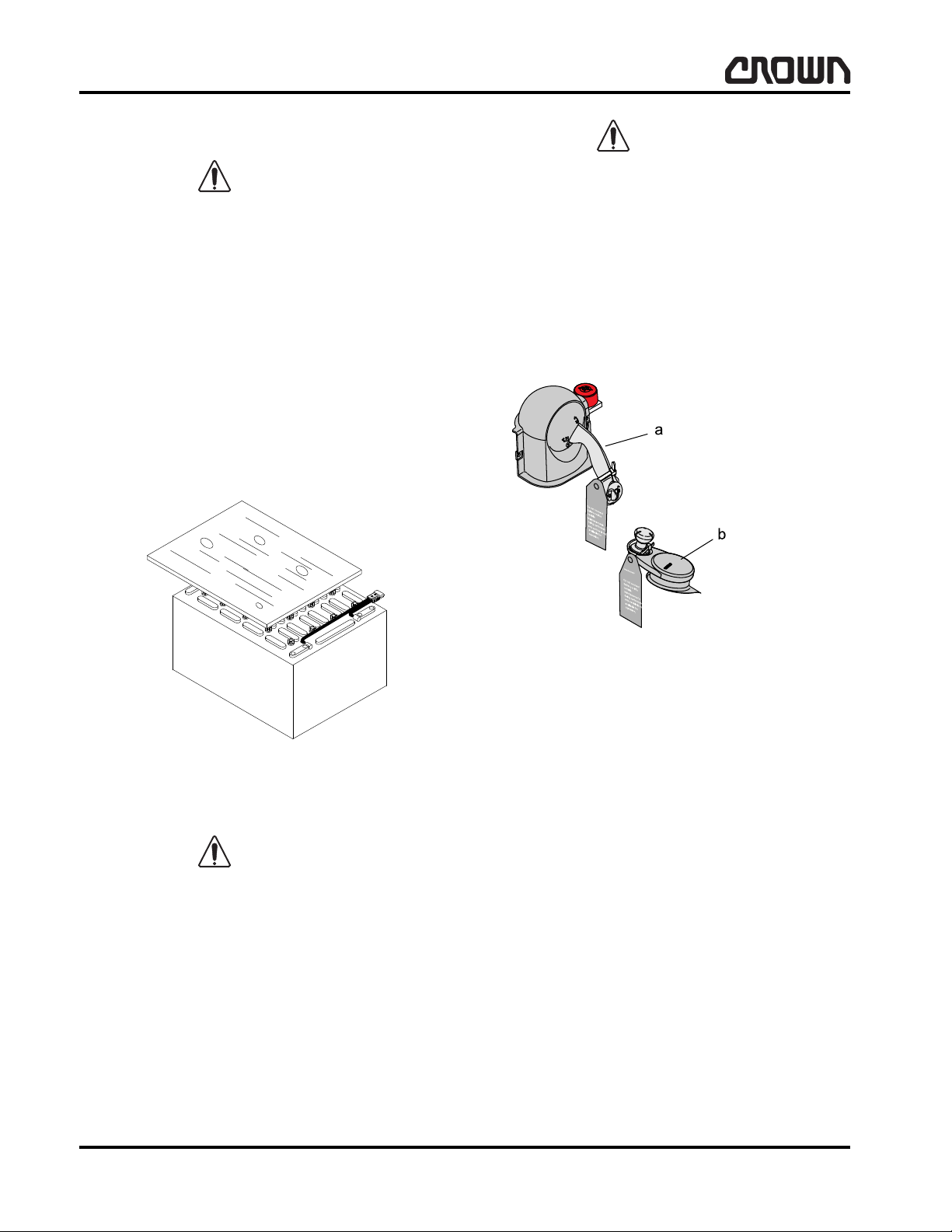

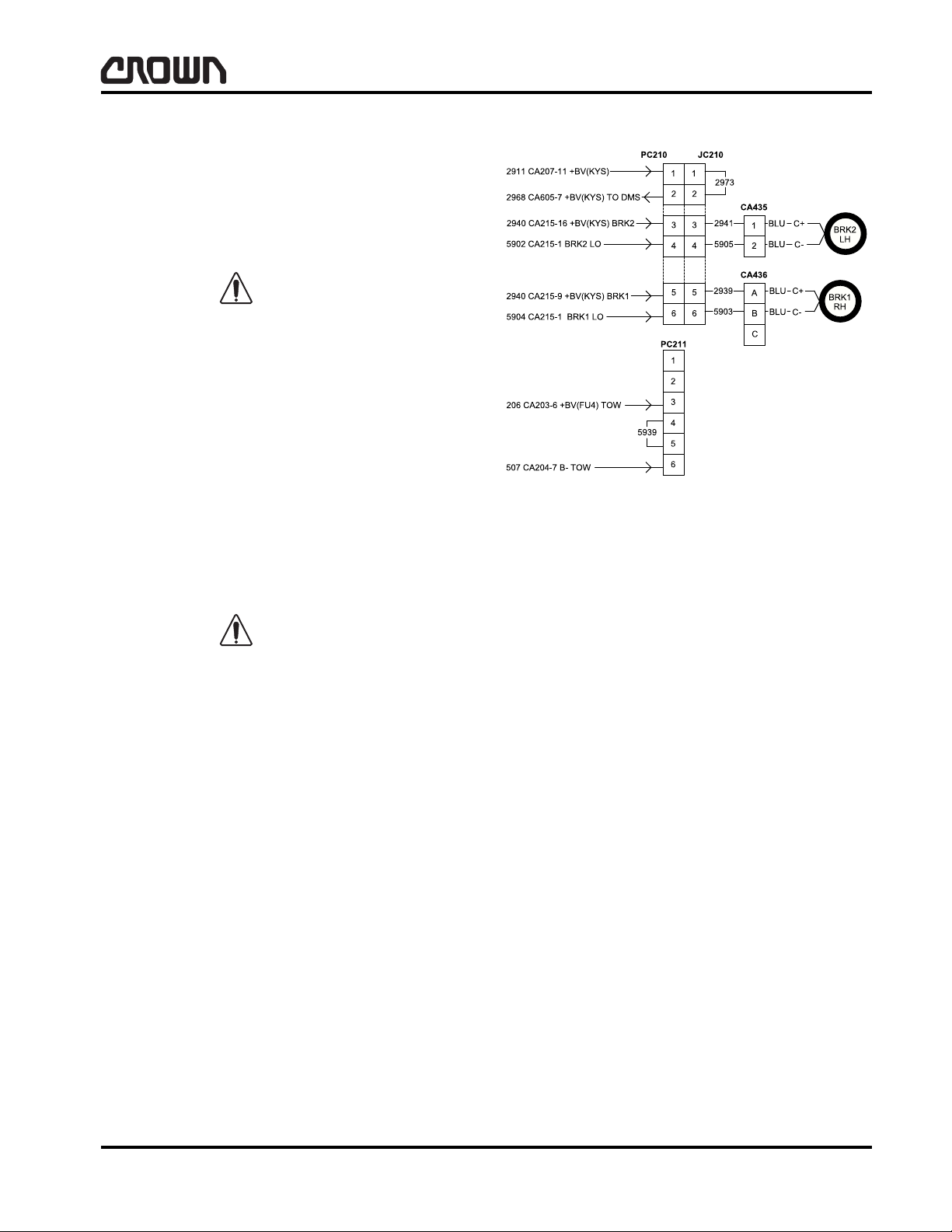

Tow Condition Note:

- Disconnect PC210 From JC210

- Connect PC211 Into JC210

RC 5500 series trucks ship with sprin g applied/e lectrically released brakes. Power m ust be applied to the

brake circuit to release brakes for towing/unloading.

Equipment required: Crown wire harness part number

139956-001 or equivalent.

Extreme care must be taken when using this method to

release the brakes. With brakes released on uneven

surfaces, vehicle will roll.

No battery installed method

1. Open vehicle "desktop" cover and disconnect harness connector CA210 (near power fuses).

2. Plug harness (139956-001) into harness plug

JC210.

SAFETY

Control of Hazardous Energy

3. Apply 18-24 volts (DC) to harness to release

brakes.

4. Once vehicle has been moved, remove power to

harness and reconnect CA210.

Do not apply more than 28 volts (DC) to brake release

harness. Brake coil damage will occur.

Battery installed method

1. With battery unplugged from vehicle, unplug harness connector CA210 (located under desktop

cover).

2. Plug JC210 into PC211 (located in same area) on

vehicle.

3. Plug battery into vehicle battery connector to release brakes.

4. Once vehicle has been moved, disconnect battery

and reconnect CA210.

Figure 16926

Crown 2006 PF15396-3 Rev. 9/07

MA-1055-102

03 Rev. 9/07

7

Page 25

SAFETY

WARNING

Truck Modules

Control of Hazardous Energy

Capacitance

Due to capacitance voltage present in the traction motor controller and lift motor controller, whenever performing maintenance which may permit contact with

the bus bars and associated power cables, discharge

the capacitors.

• Move truck to a secure non-traffic maintenance

area with a level floor.

• Lockout or tagout truck as described in Lockout -

Tagout in this section.

• Disconnecting the battery will discharge the capac-

itors. Once the dash display flashes, the capacitors

are discharged. T wo alternative methods of discharging these capacitors are to disconnect the

battery and hold the key switch in the "start" position for 10 seconds or disconnect the battery and

connect a 200 ohm, 2 watt resistor betw ee n th e

positive and negative terminals on the controller.

• Turn key switch to "OFF", remove key.

Hydraulic

AVOID HIGH PRESSURE FLUIDS – Escaping fluid

under pressure can penetrate the skin causing serious

injury. Relieve pressure before disconnecting hydraulic

lines. Tighten all connections before applying pressure. Keep hands and body away from pin holes which

eject fluids under high pressure. Use a piece of cardboard or paper to search for leaks. Do not use your

hand.

Any fluid injected into the skin under high pressure

should be considered as a serious medical emergency

despite an initial normal appearance of the skin. There

is a delayed onset of pain, and serious tissue d amage

may occur. Medical attention should be sought immediately by a specialist who has had experience with this

type of injury.

When maintenance is to be performed on the hydraulic

system, make certain the hydraulic system is not under

pressure by:

• Move truck to a secure non-traffic maintenance

area with a level floor.

• No load on forks.

• Completely lower load engaging means (mast) or,

if required for maintenance, block mast sections at

the appropriate height as described in Mast of this

section.

• Lockout or tagout truck as described in Lockout -

Tagout in this section.

• Depressurize hydraulic reservoir by momentarily

opening cap on reservoir before disconnecting any

hydraulic lines or components.

• Operate hydraulic levers to remove any hydraulic

pressure that may be present.

Figure 16927

03 Rev. 9/07

8

MA-1055-103

Crown 2006 PF15396-4 Rev. 9/07

Page 26

SAFETY

WARNING

WARNING

WARNING

WARNING

Control of Hazardous Energy

Towing Truck

Refer to the following guidelines when towing the truck:

Towing by Pulling in

Power Unit First Direction

• Towed truck must always maintain three contact

points with floor and/or towing device.

• Do not make sharp turns when lifting/towing truck.

• Towed vehicle forks should be empty and no more

than 305 mm (12.0 in) off floor. If possible, tilt forks

back and center sideshifter.

• Extreme care must be taken when using this

method to release the brakes. With brakes released on uneven surfaces, vehicle will roll.

• Provide a safe distance for truck to coast to stop.

• Excessive acceleration by towing vehicle, or drag

caused by towed vehicle (i.e., brake drag, drive

unit drag, wheel drag, etc.) will greatly increase requirements to pull or push a vehicle.

Preparing Truck For Towing:

• When attaching towing device to lift truck to be

towed, a slotted hole has been provided on rear

bottom side of power unit. Firmly attach tow device

in this area. Fasten so as not to loosen or disengage during towing.

• Power must be applied to the brake circuit to re-

lease brakes for towing. Refer to Brake Release

Instructions in this section.

• Turn power OFF.

Truck will be difficult to steer. Use extreme caution.

• Driver will be required to steer truck, as there is no

power assist from hydraulics. Truck will coast to

stop.

Towing Device Requirements:

• Towing device/vehicle must have pulling/braking

capacity greater than 3600 kg (8000 lb).

• Brakes on towed truck will not operate.

Towing mechanism attachment must not intrude more

than 40 mm (1.6 in) into floorboard cavity. Failure to

observe this WARNING could result in damage to floorboard components.

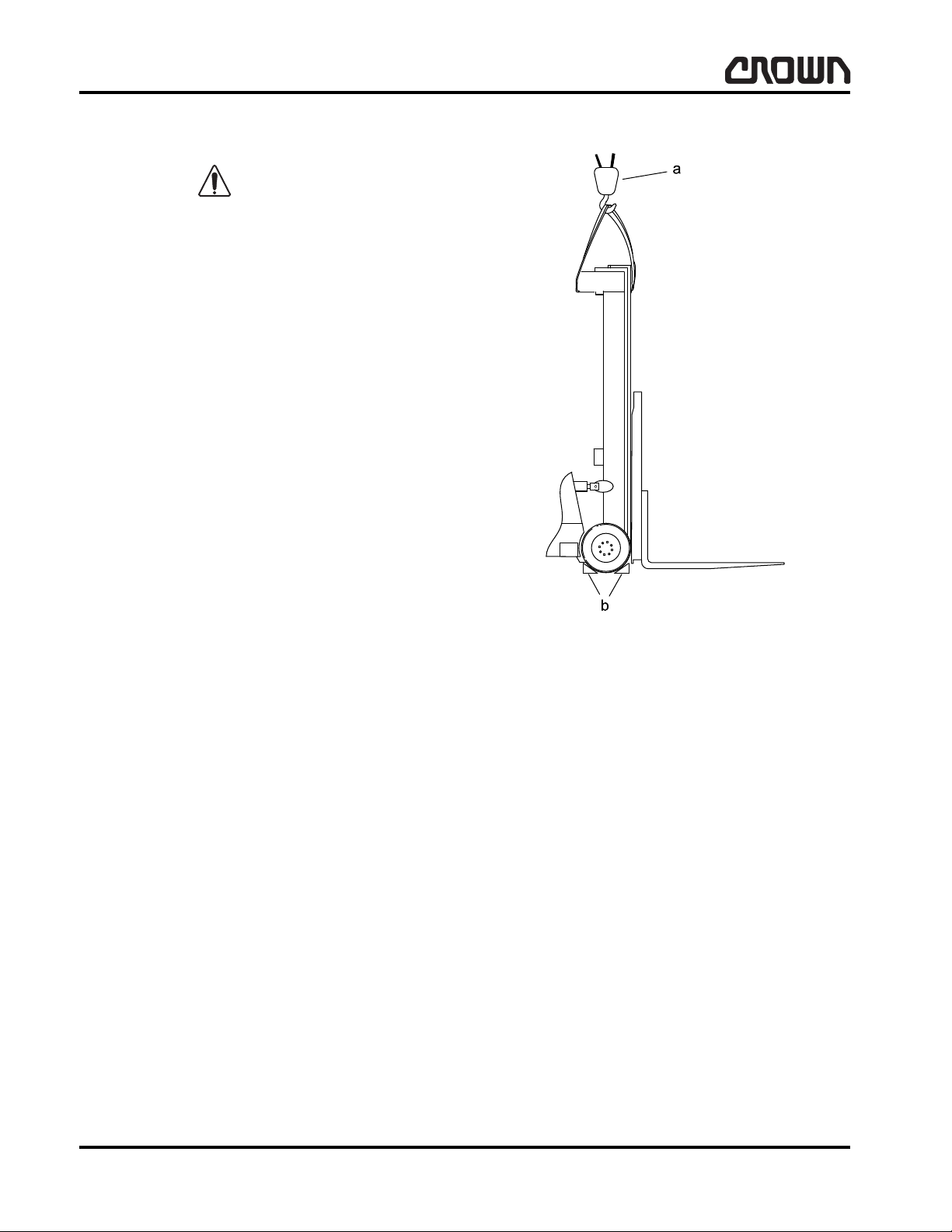

Figure 18645

a

Floorboard (cutout to show slotted hole)

b

Slotted Hole

Towing Guidelines:

• Maximum travel speed while towing truck is

3.2 kph (2 mph).

Truck will be difficult to steer. Use extreme caution.

• Driver will be required to steer truck, as there is no

power assist from hydraulics.

• Truck will coast to stop.

• Operator actions: see WARNINGS above.

Crown 2006 PF15396-5 Rev. 9/07

MA-1055-104

03 Rev. 9/07

9

Page 27

SAFETY

WARNING

WARNING

WARNING

WARNING

Control of Hazardous Energy

Towing by Pulling

in the Forks First Direction

Towing by pulling in the forks first direction is not

recommended.

Towing by Lifting Truck and

Pulling in Power Unit First Direction

• Do not lift towed truck higher than 51 mm (2.0 in)

off floor.

• Towed truck must always maintain three contact

points with floor and/or towing device.

• Do not make sharp turns when lifting/towing truck.

• Towed vehicle forks should be empty and no more

than 305 mm (12.0 in) off floor. If possible, tilt forks

back and center sideshifter.

• Extreme care must be taken when using this

method to release the brakes. With brakes released on uneven surfaces, vehicle will roll.

Towing Guidelines:

• Maximum travel speed while towing truck is

3.2 kph (2 mph).

Truck will be difficult to steer. Use extreme caution.

• No operator should be on lifted and towed truck.

• Operator actions: see WARNINGS above.

Towing by Lifting Truck and

Pulling in the Forks First Direction

Towing by lifting truck and pulling in the forks first

direction is not recommended.

Preparing Truck For Towing:

• Power must be applied to the brake circuit to re-

lease brakes for towing. Refer to Brake Release

Instructions in this section.

• Turn power OFF.

Towing Device Requirements:

• Towing device must have lifting capacity of

2268 kg (5000 lb) at load position at slot opening in

bottom of power unit.

• Towing device must have pulling/pushing/braking

capacity greater than 3600 kg (8000 lb).

• Ensure that a stem or ball capable of stated pulling/

pushing/braking capacity, and of such a design as

to prevent disengagement during towing oper ation,

is used.

• When attaching towing device to lift truck to be

towed, engage in slot located in rear , lower portion

of power unit skirt.

03 Rev. 9/07

10

MA-1055-105

Crown 2006 PF15396-6 Rev. 9/07

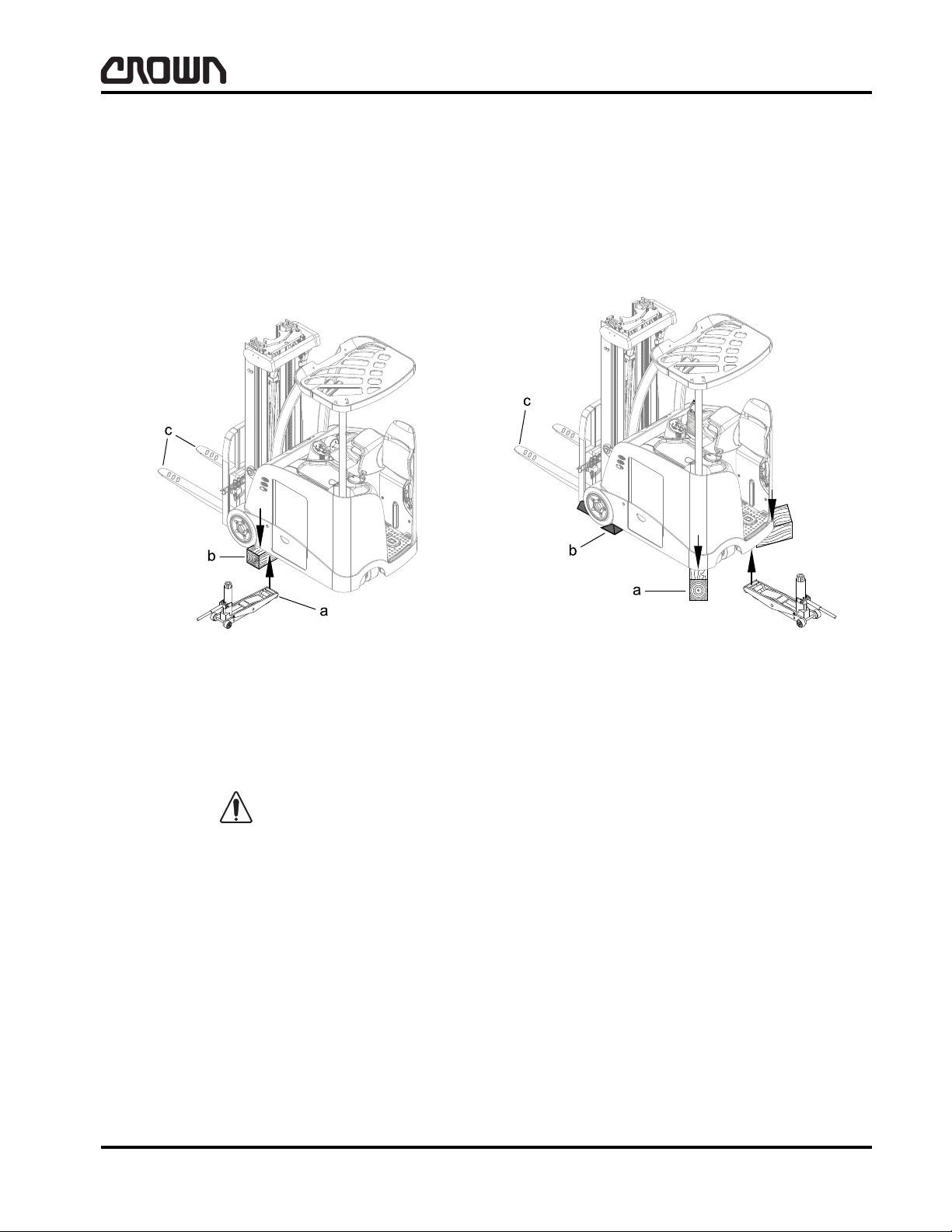

Page 28

SAFETY

WARNING

NOTE

Side

Steer

Wheel

Control of Hazardous Energy

Lifting and Blocking

Move truck to a secure non-traffic maintenance

•

area with a level floor.

• No load on forks.

• Lockout or tagout truck as described in Lockout -

Tagout in this section.

NOTES:

• Hydraulic Jack Capacity: 3620 kg (8000 lb)

• Crown Part Number: 122599

• Collapsed Height Minimum: 60 mm (2.25 in)

• Raised Height Maximum: 400 mm (16 in)

Figure 16928-01

a

Use Serated Pads on Jack and Position Jack 75 mm (3.0 in)

Inward on a Flat Surface

b

Hardwood Block One Side of Truck Only to Height as

Required – Not to Exceed 162 mm (8.0 in)

c Do Not Raise Forks More than 380 mm (15 in) from Floor

Truck stability decreases dramatically if truck skirt is

raised more than 140 mm (5.5 in) or 15°. Attach sling

and overhead lifting device to all cross members of the

mast to prevent truck from tipping over when raising

one side of the truck.

Figure 16929-01

a

Use Hardwood Blocks to Set Height as Required – Not to

Exceed 162 mm (8.0 in)

b

Wheel Chock Both Drive Wheels

c Do Not Raise Forks More than 380 mm (15 in) from Floor

Position hardwood blocks as shown when lifting and

blocking the truck.

Crown 2006 PF15396-7 Rev. 9/07

MA-1055-106

03 Rev. 9/07

11

Page 29

SAFETY

Control of Hazardous Energy

Mast

Blocking Masts

Use 100 x 100 mm (4 x 4 in) or bigger hardwood blocks

of appropriate length for supporting mast channels.

Block both mast rails of each stage to maintain stability .

Remove any carriage mounted accessory (i.e., carton

clamp, etc.) except sideshifters before blocking masts.

These accessories add significant weight to the mast.

• Move truck to a secure non-traffic maintenance

area with a level floor.

• Chock wheels (refer to Lifting and Blocking in this

section).

• Connect battery.

• Raise forks and position blocks under second

stage mast as shown.

• Using a clamp or ratchet tie down, secure blocks to

mast channel as shown.

• Lower mast and position appropriate length blocks

under third stage mast as shown.

• Lower mast and position appropriate length block

under fourth stage mast (or inner) on quad ma st as

shown.

• Using a clamp or ratchet tie down, secure blocks to

mast channel or second stage block as shown.

• Lower fork carriage until carriage rests on stops or

place blocks under carriage and lower until weight

rests on blocks.

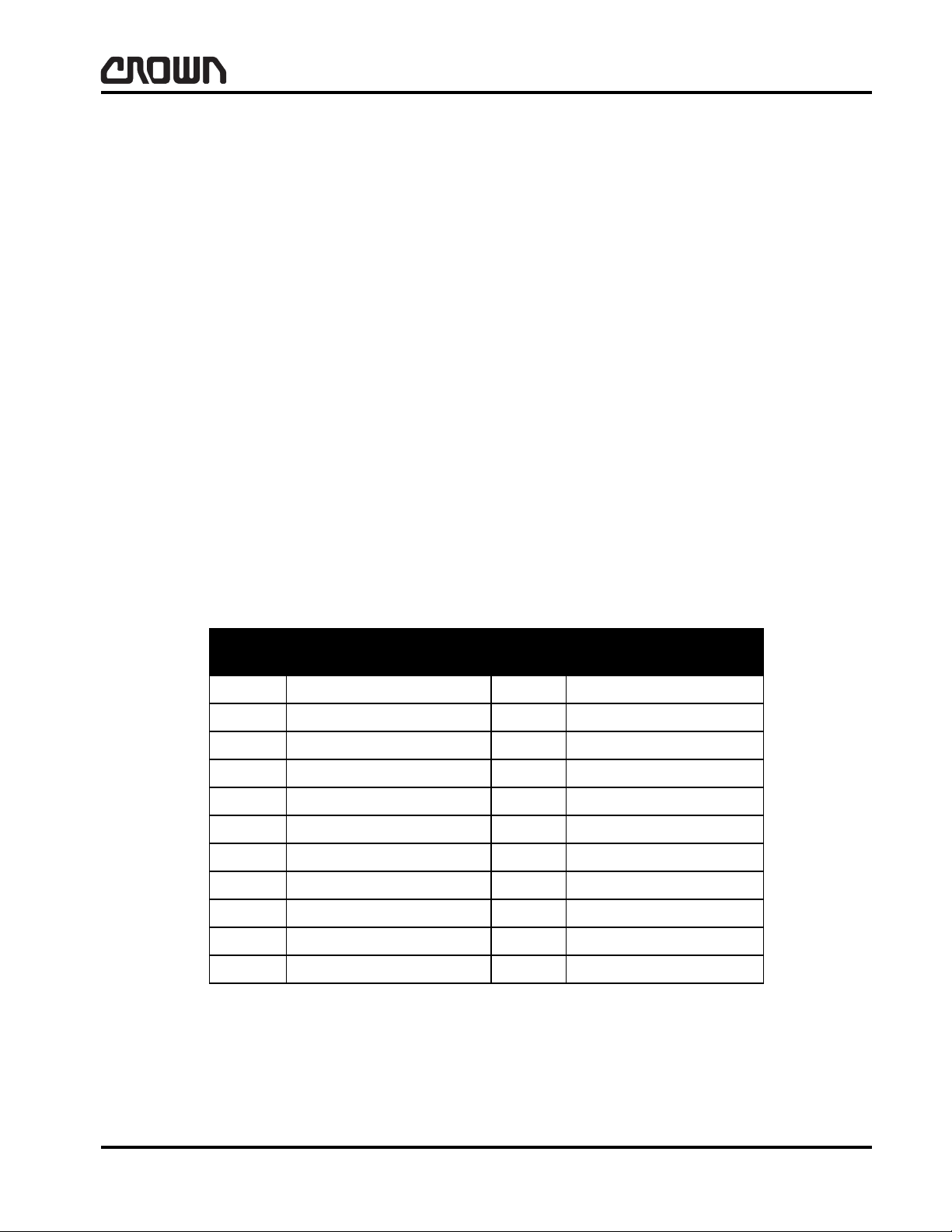

• Lockout or tagout truck as described in Lockout -

Tagout in this section.

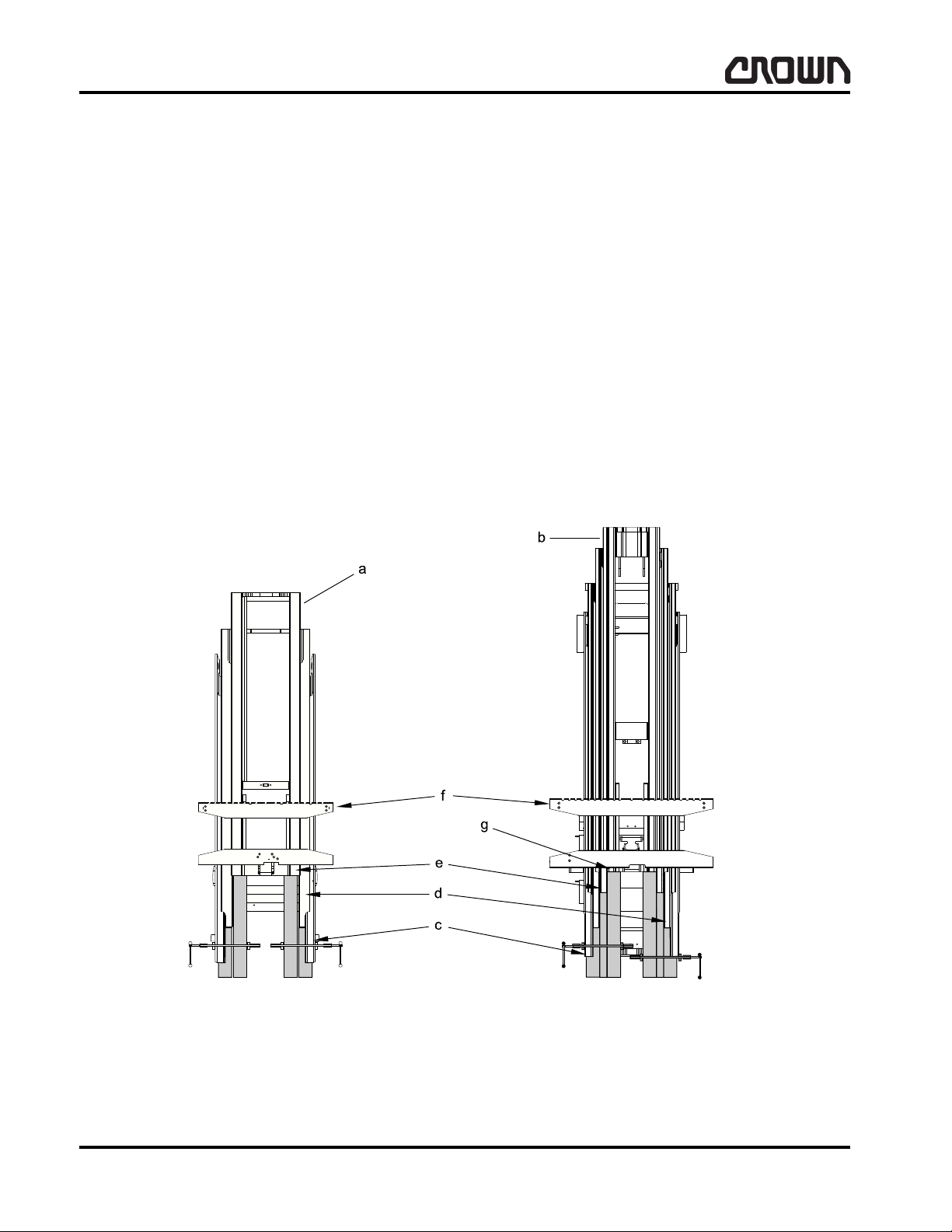

a

TT Mast e Third Stage Mast

b

Quad Mast f Fork Carriage (Shown Raised Slightly for Clarity)

c Second Stage Mast g Fourth Stage Mast (or Inner)

d First Stage Mast (Mainframe or Outer Mast)

MA-1055-107

03 Rev. 9/07

12

Figure 16930-01

Crown 2006 PF15396-8 Rev. 9/07

Page 30

SAFETY

Control of Hazardous Energy

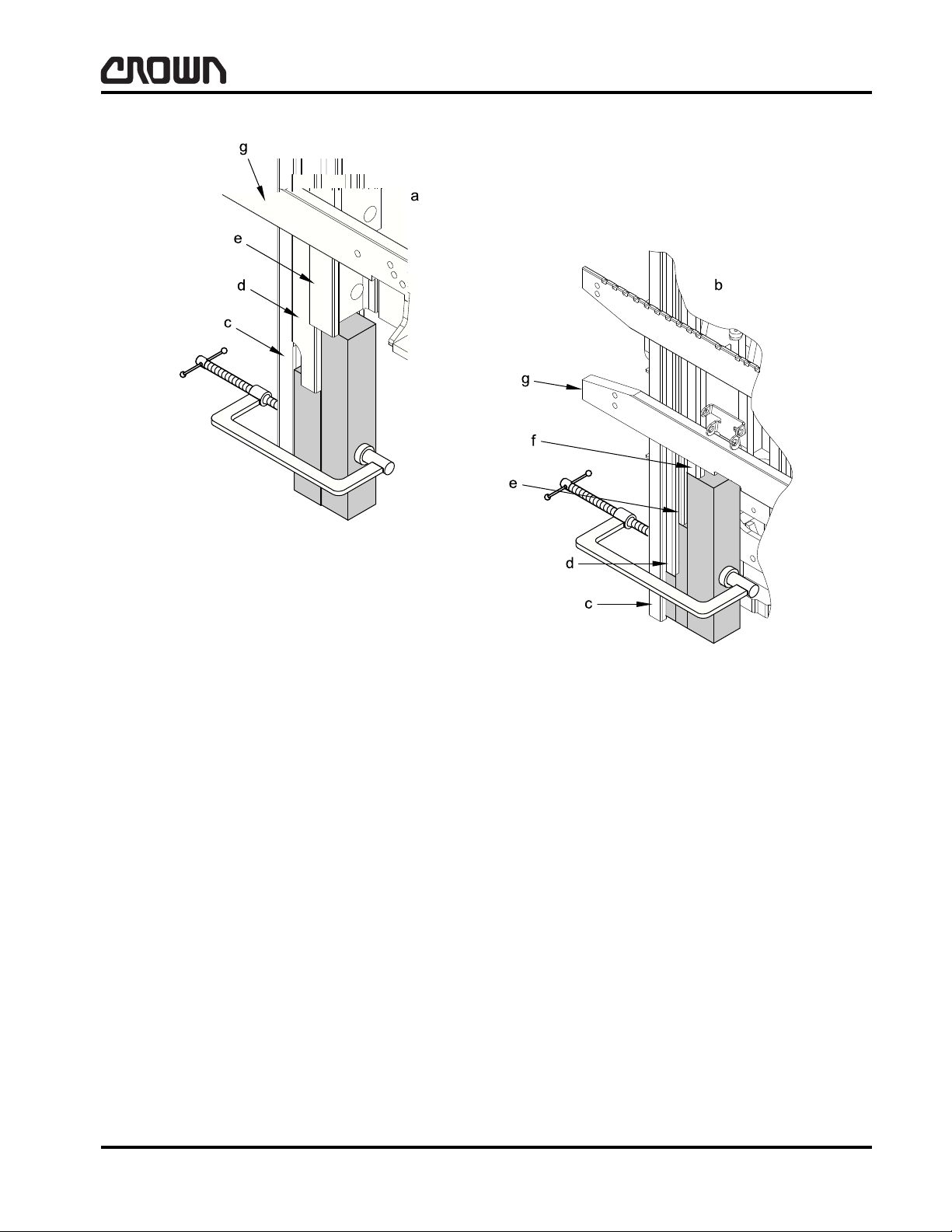

a

TT Mast e Third Stage

b

Quad Mast f Fourth Stage (or Inner Mast)

c First Stage (Mainframe or Outer Mast) g Fork Carriage

d Second Stage

Figure 16931-01

Crown 2006 PF15396-9 Rev. 9/07

MA-1055-108

03 Rev. 9/07

13

Page 31

SAFETY

WARNING

Control of Hazardous Energy

Disconnecting Tilt Cylinder

Wear appropriate items, such as safety glasses and

steel-toed shoes whenever performing maintenance

work. Do not place fingers, hands or arms through

mast or position them at pinch points.

In this section you may be required to lift and block the

truck and mast or raise and lower different components

for removal and installation. Make sure lifting device

and sling are sufficiently rated to withstand the weight

being lifted. Never work under or around a truck that is

not properly secured. Refer to truck Data Plate for truck

weight information.

It will be necessary to disconnect and remove the battery from the truck, disconnect tilt cylinders from the

mast, disconnect electrical connections and hydraulic

lines. "Control of Hazardous Energy" section provides

information for performing the above procedures along

with some additional information on other procedures

dealing with truck maintenance. This section should be