Crown PZM-10, PZM-11, PZM-180, PZM-185, PZM-2LV Brochure

...

Te c h M a d e S i m p l e

Tech Made Simple

The Crown® PRESSURE ZONE MICROPHONE® (PZM®)

THE PROBLEM

Recording engineers often must place microphones near hard refl ective surfaces. Some situations where this occurs are recording drama or opera with

microphones near the stage fl oor, recording a piano with the mics near the open

lid, or recording an instrument surrounded by refl ective baffl es.

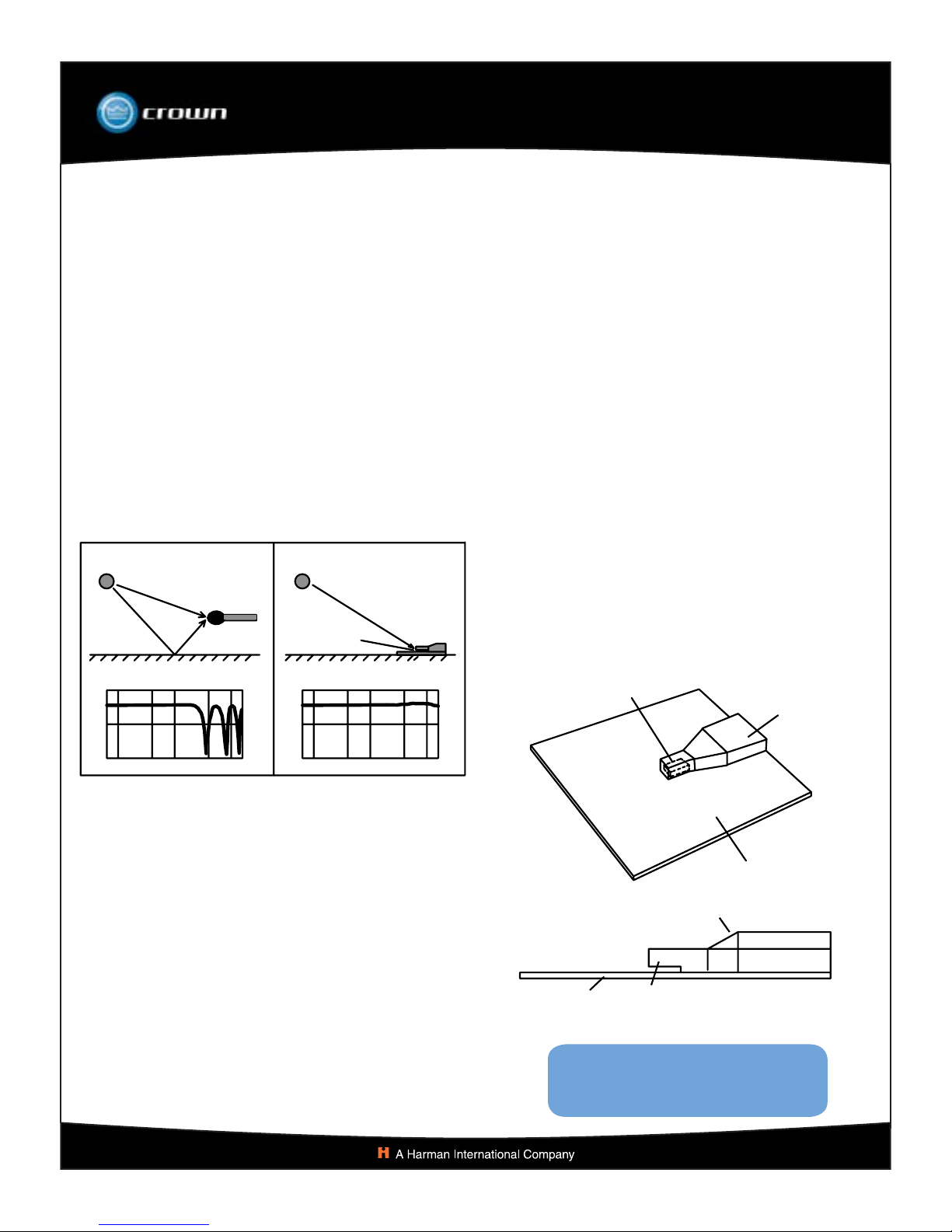

In these situations, sound travels from the sound source to the microphone

via two paths: directly from the source to the microphone, and refl ected off

the surface (Figure 1, left). Note that the refl ected sound travels a longer

distance than the direct sound, so the refl ected sound is delayed relative to the

direct sound. When the direct and delayed sounds combine at the microphone

diaphragm, this results in phase cancellations of various frequencies. A series

of peaks and dips is created in the net frequency response. This is called a

comb-fi lter effect. It colors the tone quality and gives an unnatural sound.

To solve this problem, we need to shorten the delay of the refl ected sound so that

it arrives at the mic at the same time as the direct sound.

SOUND

SOURCE

DIRECT SOUND

MIC

SURFACE

RESULTING FREQUENCY RESPONSE

dB

REFLECTED

SOUND

SOUND

SOURCE

DIRECT SOUND

REFLECTED

SOUND

RESULTING FREQUENCY RESPONSE

dB

BOUNDARY

MIC

Typical applications for PZMs are:

• grand piano (taped to the underside of the lid)

• ambience miking (on the fl oor or walls)

• stereo recording of orchestras, symphonic bands and small ensembles

(mounted on a panel)

• drum set

The PZM was invented in 1978 by audio consultant Ed Long and recording

engineer Ron Wickersham. Ken Wahrenbrock marketed the fi rst PZM prototypes,

and Crown started manufacturing PZMs in 1980.

PZM BENEFITS

• Eliminates phase cancellations, giving a clear, natural sound.

• 6 dB higher sensitivity and 6 dB better signal-to-noise ratio (improved

“reach”).

• Unchanging tone quality as the sound source moves.

• Lack of off-axis coloration.

• Small size, inconspicuous.

• Hemispherical polar pattern. It can be shaped by the addition of panels near

the mic capsule.

TO LEARN MORE

Go to www.crownaudio.com and click on Microphones. Then select Document

Library. Look under Microphone Application Guides to fi nd the

Crown Boundary Microphone Application Guide.

MIC CAPSULE

CAPSULE

HOLDER

FREQUENCY

FREQUENCY

Figure 1. Conventional mic vs. a PZM

THE PZM SOLUTION

A new kind of microphone was developed to solve the problem of phase

interference from sound refl ections: the Pressure Zone Microphone or PZM.

In a PZM, the diaphragm can he placed as close to the surface as desired.

Then the direct and refl ected waves arrive at the microphone at the same

time, in phase (Figure 1, right). This eliminates phase cancellations and

results in a smooth frequency response. The diaphragm is mounted in the

“pressure zone” just above the plate, a region where the direct and refl ected

waves are effectively in-phase.

This special microphone was designed to be used on surfaces such as

fl oors, walls, tables, or even piano lids. It includes a miniature omnidirectional condensermic capsule, which is mounted face-down next to a soundrefl ecting plate. The microphone diaphragm is parallel with and very close to

the refl ecting surface (Figure 2).

BOUNDARY PLATE

CAPSULE

HOLDER

SIDE VIEW

PLATE

MIC CAPSULE

Figure 2. PZM construction

1718 W. Mishawaka Rd, Elkhart, Indiana 46517-9439 USA Tel:

Crown and PZM are registered trademarks of Crown International

©2005 by Crown Audio, Inc.

574-294-8000

136367-2 2/05

Loading...

Loading...