Crown PIPSLM Brochure

@crown

@crown

* System® Product Reference

* System® Product Reference

®

®

IQ System P.I.P.-SLM

AUDIO IN

CH-2 CH-1

Programmable

Input Processor

OVERVIEW

An IQ System amplifier is a Crown amplifier (MA Series, CT Series, or Reference Series) that is equipped with an IQ

P.I.P.® Programmable Input Processor

input module. The IQ P.I.P.-SLM is one

such input module. The P.I.P.-SLM includes the “basic” and “SLM” feature

sets, auto-standby and EEPROM

memory backup. The P.I.P.-SLM is fully

PIP2 compatible. The P.I.P.-SLM is an

IQ2 component and requires an IQ

compatible interface for communication with a computer.

CROWN AMPLIFIERS

There are three families of Crown amplifiers which are fully IQ System compatible. They include the Macro-Tech Series for professional PA, the Com-Tech

Series for commercial installations, and

the Reference Series for studio applications. In the case of the P.I.P.-SLM,

however, it should only be installed in a

PIP2 amplifier such as the CT “10” Series.

P.I.P.-SLM PROCESSING

The P.I.P.-SLM allows you to communicate directly with an amplifier whether it

is sitting on a bench next to you or

mounted in rack hanging from a loft.

Before the advent of IQ, it was impossible to directly control and monitor

amplifiers unless you were physically

present at the amplifier. Even then your

abilities were limited by the physical

features of the amplifier. Today you can

control amplifier attenuation in half dB

steps, and control a host of other functions. Unlike other amplifiers, you also

have access to thermal headroom infor-

SLM#.###

AUX

OUT IN

P.I.P.-SLM

mation and visual status of signal level

and distortion.

The P.I.P.-SLM module includes

EEPROM memory backup. This feature

allows the onboard processor to maintain its memory in the event that main

AC power is lost, disconnected, or

switched off at the front panel.

The System and Load Monitor feature

2

set adds the ability to perform reference

and test sweeps and plot results, then

report the results as pass-fail based on

your defined criteria. Additional automation includes auto-standby for energy conservation.

PHYSICAL ATTRIBUTES

All P.I.P.-SLM is about the size of a 3 x

5 card, and the panel face (shown

above) mounts flush with the rear panel

of the amplifier.

Front Panel

• Euro-style 3-pin barrier block audio

input connections per channel.

• Euro-style 4-pin barrier block connector for Crown Bus data loop.

VALUE

ON

124

8163264128

SW1

12345678

TOP VIEW

SW1 Address Switch

Programmable

Input Processor

DATA CROWN BUS

OUTIN

• Euro-style 3-pin barrier block connector to send or receive external control

voltages.

• DSPI (data) LED informs you when the

unit is receiving data, and can also be

used for troubleshooting.

• Dual function memory reset switch is

accessible from the front panel, however it is recessed and unmarked to

prevent unintended operation. Press

once to reset unit to custom default,

press and hold to reset to factory default.

Circuit Boards

• Two multi-layer printed circuit boards.

• Loop address eight segment DIP

switch. Up to 250 IQ amplifiers may

operate on a single data loop.

• PIP2 Jumpers (set to OUT position

when used in a PIP2 amplifier) to compensate output meter scaling depending on amplifier type.

• PIP2 Resistor Packs must be installed

when the module is installed in a PIP

amplifier and must be removed if used

in a non-PIP2 amplifier.

Note: The primary purpose of this module is to support internal load monitoring. This can

only be done with a PIP2 amplifier.

DATA CROWN BUS

SLM#.###

AUDIO IN

CH-2 CH-1

AUX

OUT IN

OUTIN

BOTTOM

View of SW1 Address

Switch

2

SW1

P.I.P.-SLM (Page 1 of 3)

@crown

AMP OUTPUT

VOLTAGE

CH 1

CH 2

* System® Product Reference

®

P.I.P.-SLM (Page 2 of 3)

MONITOR INPUTS

IOC

ODEP

AUX IN

AMP OUTPUT

CURRENT

PIP INPUT

LEVEL

+

-

BALANCED

AUDIO INPUTS

+

-

CH 1

CH 2

CH 1

CH 2

CH 1

CH 2

CONVERTER

BALANCE

TO SINGLE

ENDED CONV.

BALANCE

TO SINGLE

ENDED CONV.

A / D

DDS SINE

WAVE GEN.

DIGITALLY

CONTROLLED

ANALOG

SWITCH

Installation

Before installing the P.I.P.-SLM into the

amplifier you must first configure the

switches, jumpers, and install or remove the PIP2 resistor packs as needed.

When initial configuration is complete,

remove the existing P.I.P. from the amplifier and move the P.I.P. connector to

the P.I.P.-SLM. Set the amplifier sensitivity to the desired position. The ribbon

cable folds up as you insert the module.

IQ MONITORING

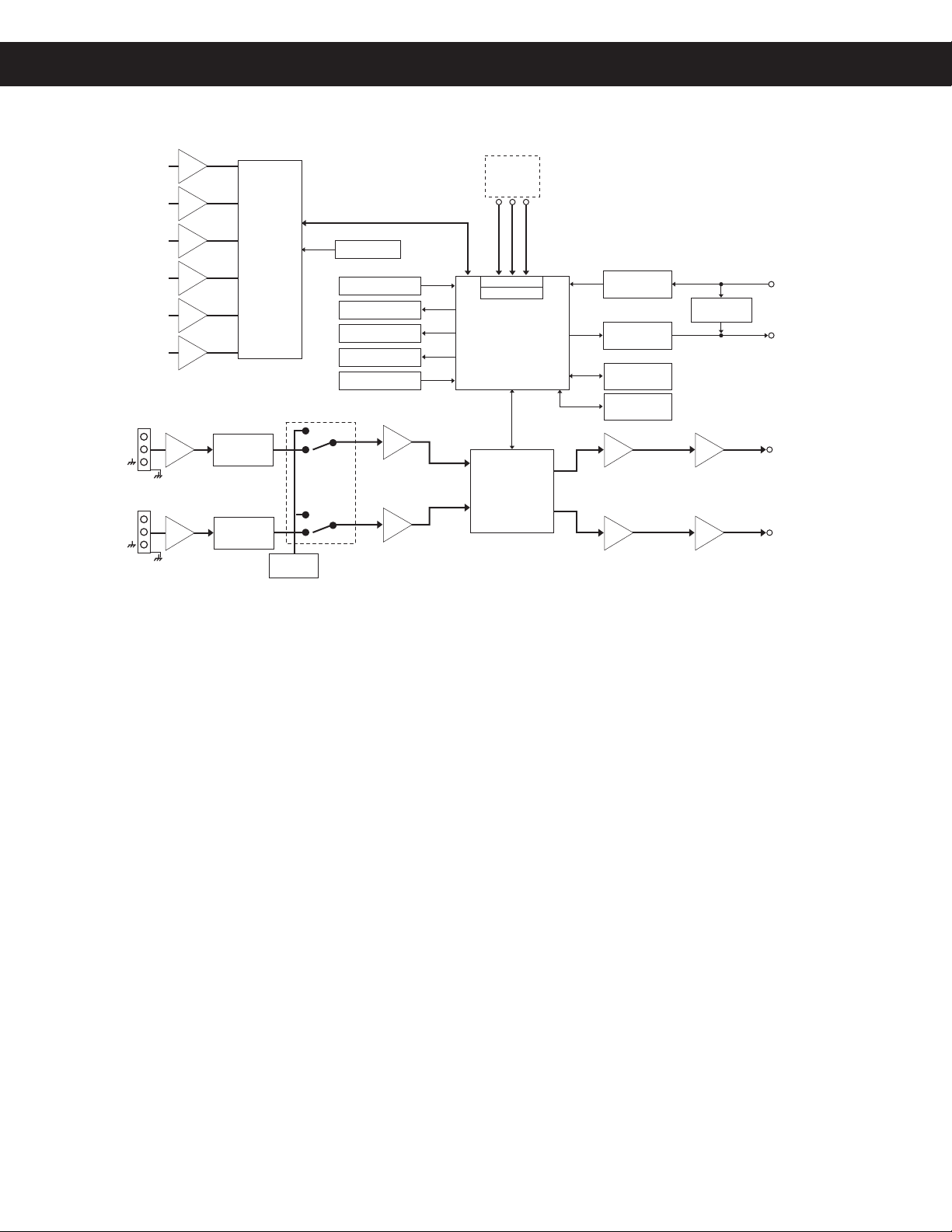

Refer to the P.I.P.-SLM Block Diagram.

• Pre-fade input levels (+20 to –40 dBu).

• Amplifier output signal level (0 to –40

dB re scaled rated output).

• IOC (Input/Output Comparator) indicates distortion >0.05%.

• ODEP (Output Device Emulation Protection). ODEP is an amplifier circuit

that calculates thermal headroom of an

amplifier and is reported in IQ as a percentage of thermal headroom used.

• Aux Port input sense.

REF VOL TAGE

RESET

AUX OUT

REM STANBY

DATA LED

IQ ADDR SWITCH

1

BUFFER

STAGE

2

INPUT MUX

A/D CONV.

MICROCONTROLLER

1

DIGITALLY

CONTROLLED

ANALOG

ATTENUATOR

2

P.I.P .-SLM Basic Block Diagram

IQ CONTROL

Refer to the P.I.P.-SLM Block Diagram.

The P.I.P.-SLM supports the complete

basic feature which consists of:

• Power (high voltage rails).

• Mute.

• Attenuation (0.5 dB steps from 0 to 80

dB).

• Polarity (XLR pins 2 and 3).

• Aux Port output voltage.

• DSPI/Data LED.

• Memory backup.

• User defined default memory.

• Output meter scaling.

AUTO STANDBY

Energy conservation is automated with

this function that allows the amplifier to

idle at a fraction of its normal idle draw.

Per channel with the following variables:

—On-Off

—Threshold (input)

—Turn-off Delay (minutes)

—Turn-on Delay (one switch for both

channels, when on adds a delay based

on address and when off the amplifier

powers up within 8 msec after breaking

threshold)

RECEIVER

OUTPUT

EEPROM

1

BUFFER

STAGE

2

INPUT

DRIVER

8K x 8

8K x 8

RAM

DROP-OUT

RELAY

1

POLARITY INVERT

& OUTPUT BUFFER

2

CROWN BUS

SERIAL

DATA INPUT

CROWN BUS

SERIAL

DATA OUTPUT

CH 1

AUDIO OUTPUTS

CH 2

SLM FUNCTIONS

System and Load monitoring is the major

feature benefit of the P.I.P.-SLM. The

purpose of the SLM function is to verify

repeatability of performance of the audio system. Reference data is first established and subsequent test sweeps

are performed to prove that system

operation is constant. The impedance

response test proves that the load performance is constant while frequency

response proves that the electronics

are a constant. When syncronized with

an external sweep generator (such as

the SLM-8) full system frequency response can be measured.

The signal generator is used to performing sweeps or to produce a constant

tone. To perform a sweep you must

configure the generator and data acquisition. The tolerance criteria you set

determines whether the test will pass or

fail. The following is a complete list of

parameters associated with the SLM

functions:

—Sweep Enable

—Oscillator Enable

Loading...

Loading...