Page 1

P.I.P.-RPA

P.I.P.-RPAT

© 2002 by Crown Audio, Inc., P.O. Box 1000, Elkhart, IN 46515-1000 U.S.A.

Telephone: 574-294-8000. Fax: 574-294-8329. Trademark Notice: PIP is a

trademark and Crown and P.I.P. are registered trademarks of Crown

International. Other trademarks are the property of their respective owners.

125658-4

Printed on

recycled paper.

7/02

Page 2

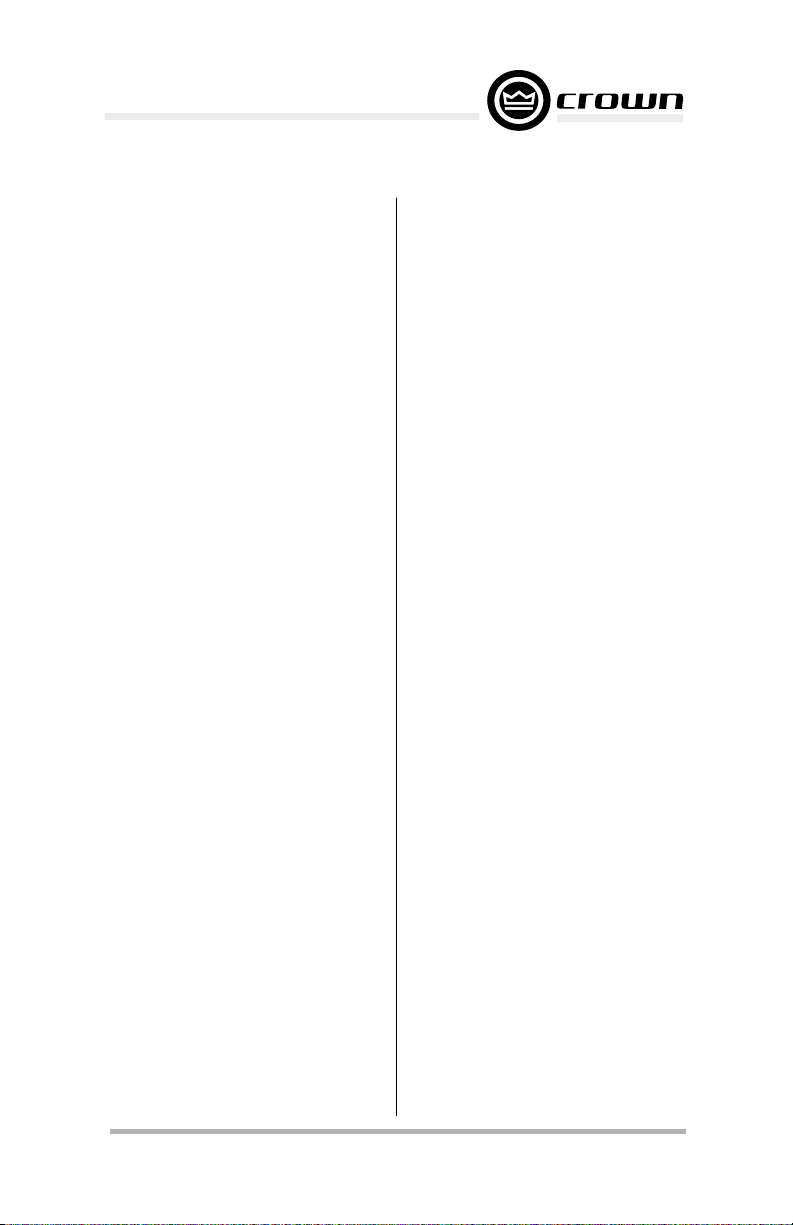

Fig. 1.1 P.I.P.-RPA

P.I.P.-RPA

Page 2

Reference Manual

Page 3

P.I.P.-RPA

1 Welcome

Thank you for purchasing the Crown

®

P.I.P.

-RPA accessory.

ules are designed to install quickly

into the rear panel of many Crown

amplifiers. PIP stands for “Programmable Input Processor.” Their versatile features expand the capabilities of

your amplifier and enable you to customize it for your particular needs.

The P.I.P.-RPA adds the features of a

remote-controlled 4-input 2-output

mixer to the input of your amplifier.

Each of the four main audio inputs is

balanced and can accept signal levels ranging from low-level microphones to line-level devices. Phantom power is available for microphones. The P.I.P.-RPAT also has1:1

isolation transformers for each input.

Unbalanced “Audio Bus” inputs and

outputs, similar to “Aux Send” and

“Aux Return” on a typical mixer, are

provided. The Audio Bus inputs allow an almost unlimited number of

sources to be connected at each

amplifier input. The Audio Bus outputs allow the mixed signal of Channel 1 and 2 to be fed to other amplifiers or components.

Mixing the input signals of the P.I.P.RPA is accomplished remotely using

a two-wire remote control to control

the VCA (voltage-controlled amplifier) of each input. The remote control

can be a fixed resistor for a fixed

attenuation or a 10 K potentiometer

(pot) for variable attenuation. A 10

PIP

™

mod-

VDC source is conveniently provided

on the PIP for the remote. If no attenuation is desired, the 10 V source must

be connected directly to the remote

control input. Up to 84 dB of attenuation is available with each VCA. If

desired, more than one input can be

controlled by the same remote control.

A “voice-over” feature is provided so

Inputs A and C can have priority over

Inputs B and D. When activated, the

voice-over circuitry causes the lowpriority inputs to “duck” by a preset

attenuated level. The input priority

(and signal routing) is programmed

with an 8-segment DIP switch on the

top circuit board of the PIP

ion “Tie” feature, controlled remotely,

enables you to tie one channel to the

other. Using it, the audio from one or

more inputs can be directed to both

outputs and their priorities linked.

.

A compan-

Feature Summary

❏ Remote-controlled mixing of 4

balanced mic/line inputs with up to

84 dB of attenuation.

❏ Adjustable input sensitivity.

❏ Phantom power available for mics.

❏ Audio Bus inputs and outputs.

❏ 10 V provided for remote-controls.

❏ Voice-over capability with adjust-

able sensitivity and duck level.

❏ Ch. 1 and 2 can be tied together.

❏ 1:1 isolation transformers (P.I.P.-

RPAT).

Reference Manual

Page 3

Page 4

P.I.P.-RPA

Fig. 2.1 Facilities

2 Facilities

A. Input Mode Switches

These gold-plated three-position

switches select the mode of each

main audio input: mic-level, line-level,

or mic-level with phantom power.

B. Input Level Controls

The level of each main audio input

can be adjusted with these level controls. They have a range of 36 dB.

Page 4

Using them, you can compensate for

a wide range of input signal levels.

C. Barrier Connectors

All connections are made using these

screw-down barrier-block connectors.

Important:

unless the wire ends are first tinned.

Strip no more than

of insulation from the wire ends.

Do not use stranded wire

1

/4 inch (6.4 mm)

Reference Manual

Page 5

P.I.P.-RPA

Main Audio Inputs

There are four balanced main audio

inputs. Inputs A and B are normally

fed to Ch. 1 of the amplifier. Inputs C

and D are normally fed to Ch. 2. Each

input remains off (attenuated 84 dB)

until a positive DC voltage greater

than 5 V is applied to the corresponding remote input (10 V results

in no attenuation).

Remote Inputs / 10 V Output

There is a remote control input for

each main audio input and a 10 VDC

supply output for feeding them (see

Section 3.6). Each main audio input is

normally off (attenuated 84 dB) until a

positive DC voltage greater than 5 V is

connected to the corresponding remote input. If the 10 V supply is

strapped directly to a remote input,

the main audio input will have no

attenuation.

Audio Bus Input / Output

There is also an unbalanced audio

bus input and output for each channel. Each bus input and output pair

shares a common ground connection. The bus outputs contain the

mixed audio signals from Inputs A–D

which feed the corresponding amplifier channel.

Note: The audio bus outputs are

inverted. The mating bus inputs correct this by again inverting the signal.

Tie Input

Finally there is a “Tie” input which is

a logic input and can be switched on

by feeding a positive DC voltage to it.

It enables the audio inputs and voiceover priorities of Ch. 1 to be “tied” to

Ch. 2 and vice versa.

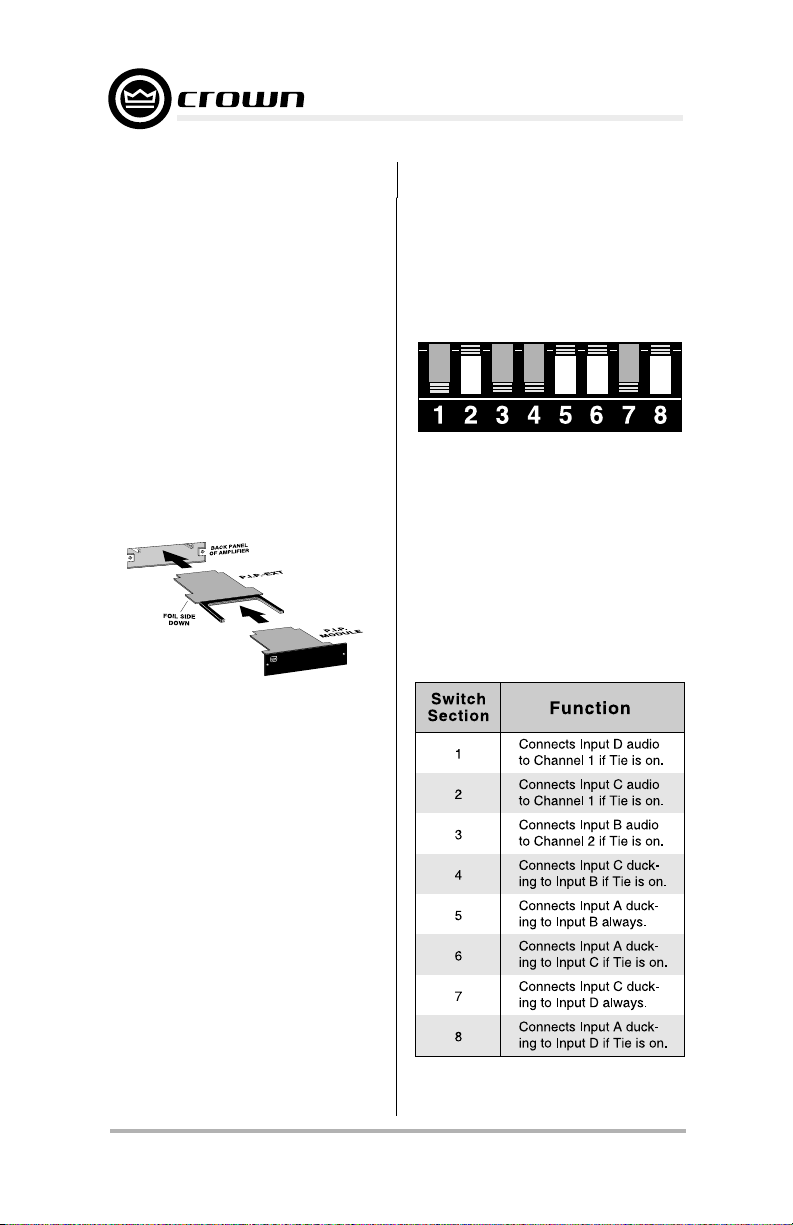

D. Routing/Priority Switch

This 8-segment DIP (dual in-line

package) switch is comprised of eight

individual switches. Flipping them

down toward the bottom circuit board

turns them off. Flipping them up toward the top circuit board turns them

on. The DIP switch is used to program the routing and priority of each

main audio input. See Section 3.1.

E. Duck Level Controls

The “duck level” is the amount of

attenuation applied to a lower priority

input when a higher priority input is

activated. The first control (closest to

the front panel of the PIP) sets the

duck level triggered by Input A and

the third control sets the duck level

triggered by Input C. The attenuation

range is 0 to 70 dB.

F. Voice-Over Sensitivity

Controls

The “voice-over sensitivity” is the level

required from an input signal before

the “duck” circuit is activated, causing lower-priority inputs to duck to a

preset attenuation level. The second

control (closest to the front panel)

sets the sensitivity of Input A and the

fourth control sets the sensitivity of

Input C. The voice-over sensitivity

controls have a range of 26 dB.

Reference Manual

Page 5

Page 6

P.I.P.-RPA

3 Installation

This section provides general installation instructions. For additional information on using Crown PIP modules, visit the Crown website at

www.crownaudio.com.

The internal controls of the P.I.P.RPA must be set prior to installation.

Note: An accessory, a PIP extender

card (P.I.P.-EXT), is available if you

prefer to make the voice-over and

duck level adjustments while the PIP

is operating. This allows you to test

your settings and easily make

changes while you fine-tune the installation.

Fig. 3.1 P.I.P.-EXT Accessory

3.1 Setting the

InputRouting/Priority

Switch

The routing/priority switch serves two

purposes. First, it works together with

the Tie function to control audio signal routing. Second, it sets the priority of Inputs B, C and D (Input A

always has the highest priority. Input

C always has the second highest

priority.)

The routing/priority switch is the 8segment DIP switch shown in Figures 2.1 and 3.2. Notice that it is

mounted upside-down to the underside (component side) of the top

circuit board.

Normally the mix of Inputs A and B feeds

Channel 1 of the amplifier and the mix of

Inputs C and D feeds Channel 2. This

can be changed by the routing/priority

switch when the Tie function is turned on

(see Section 3.7).

Fig. 3.2 Priority/Routing DIP Switch

(Inverted for Readability)

When the Tie function is on, the audio

from Input A is automatically fed to

both Channels 1 and 2. The audio

from the remaining inputs can also

be tied to both channels using the

routing/priority switch. The first three

switch sections control the routing of

Inputs B–D as shown in Figure 3.3.

Fig. 3.3 Routing/Priority DIP

Switch Functions

Page 6

Reference Manual

Page 7

P.I.P.-RPA

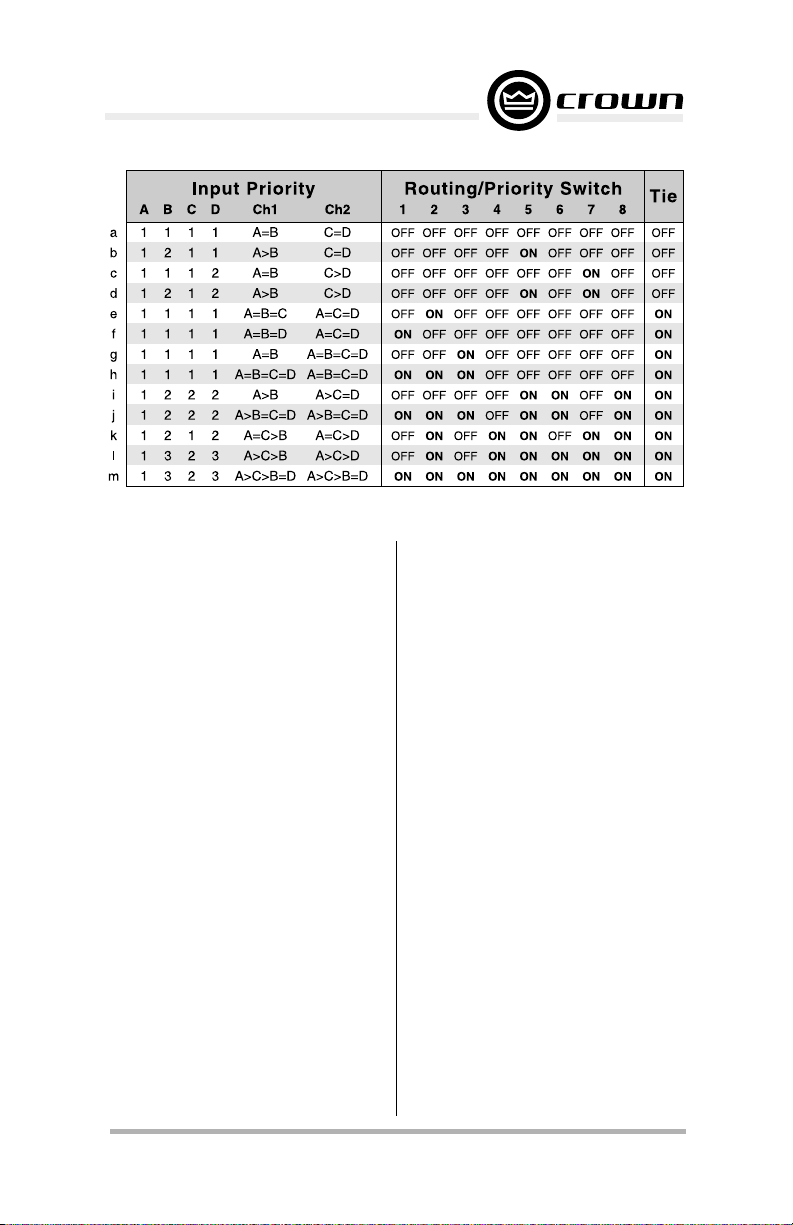

Fig. 3.4 Sample Routing/Priority DIP Switch Settings

The priority of each input determines

whether it will override or “duck” under another input. For example, you

can feed background music into Input B and a paging mic into Input A.

By setting the priority of Input B lower

than Input A, the background music

will be automatically attenuated when

someone uses the paging mic.

The table in Figure 3.4 shows some

common settings for the switch and

what they mean—it does not show

every possible combination. The

highest priority is 1 and the lowest

priority is 3. Notice that Input A is

always set to priority 1. Input C is

usually set to priority 1 unless the

channels are tied together. The reason for this is because only Inputs A

and C have voice-over sensing circuitry. Since the other inputs do not

have this sensing capability they must

have a lower priority.

As mentioned earlier, the routing/

priority switch works in conjuction

with the Tie function. The table in

Figure 3.3 shows that all the DIP

switch sections except 5 and 7 function only when the Tie function is on.

The Tie function is designed to be

remotely controlled and is fully described in Section 3.7. If you have no

desire to control it remotely and want

to leave it on, simply install a jumper

between the 10-V output and the Tie

input on the front panel of the PIP

3.2 Setting the Duck Level

If you gave all four main audio inputs

the same priority you can skip to

Section 3.4. When two or more inputs

have a different priority, the duck

level is the attenuation level the lowpriority inputs will duck when the

voice-over circuitry is activated.

The duck circuits have an attack time

of 15 milliseconds and a decay time

of 1.5 seconds. This means the duck

circuit needs only 15 milliseconds to

attenuate the low-priority input(s)

when the voice-over circuit triggers

it. However, when the voice-over circuit is no longer activated, the duck

circuit waits about 1.5 seconds be-

Reference Manual

Page 7

Page 8

P.I.P.-RPA

fore it removes the attenuation. The

result is a fast transition when the

duck circuit is activated and a slower,

smooth transition when it is deactivated.

The duck level controls have a wide

0–70 dB range as shown in Figure

3.6. (The setting numbers in the table

in Figure 3.6 refer to the tick marks on

the duck level pot in Figure 3.5.)

Fig. 3.5 Duck/Voice-Over Control

(Inverted for Readability)

Note:Note:

Note: Since Inputs A and C have

Note:Note:

independent ducking circuitry, they

Fig. 3.6 Duck Level Settings

may be used to provide two different

ducking levels for lower priority inputs. For example, assume the routing/priority switch has been set to the

“l” setting (as shown in Figure 3.4)

and the Tie function has been turned

on. This setting makes Input A priority

1, Input C priority 2, and Inputs B and

D priority 3. If the ducking level for A

is 70 dB, and the ducking level for C

is 46, Inputs B, C and D will all duck 70

dB when there is a signal over the

sensitivity threshold on A. Inputs B

and D will duck 46 dB when a signal

on Input C surpasses its threshold. In

this scenario, background music on B

and D would be pulled under by a

normal page on Input C, and Input A

could be reserved for emergency announcements.

3.3 Setting the Voice-Over

Sensitivity

If you gave all four main audio inputs

the same priority, skip to Section 3.4.

When two or more inputs have a

different priority, the voice-over sensitivity circuits set the points at which

Input A and C will activate their respective ducking circuits.

Only Inputs A and C have signalsensing capability so they will always have the highest priorities.

Each voice-over sensitivity circuit

senses the input signal level after the

input level control (the pot accessed

through the front panel of the PIP)

and before the remote-controlled attenuator. This is shown in the block

diagram in Figure 3.19. This means

that the remote attenuation setting

does

not affect the duck level.

Figures 2.1 and 3.5 show voice-over

sensitivity controls. They look identi-

Page 8

Reference Manual

Page 9

P.I.P.-RPA

cal to the duck level controls. Figure

3.7 shows how the control can increase the relative sensitivity.

When the control is set to position 1

(0 dB) it is so insensitive the voiceover circuit will almost never trigger.

When it is set to position 12, the

sensitivity is increased 26 dB.

Fig. 3.7 Voice-Over

Sensitivity Settings

Setting the voice-over sensitivity is

simply a matter of gradually turning

up the sensitivity control until it is set

too high, then backing it down a little

to an optimum setting. This will require you to install and remove the

P.I.P.-RPA several times while the

sensitivity setting is refined. If you

prefer not to repeatedly install and

remove the PIP from the amplifier

you can purchase our P.I.P.-EXT accessory, an extender card which will

allow you to connect the PIP outside

the amplifier so you can make adjustments to it during system operation.

The exact procedure for setting the

voice-over sensitivity will vary de-

pending upon your particular application. The steps we provide are for

a common scenario which shows the

principles involved. If you need more

information please contact our Technical Support Group at 800/342-6939,

or contact your local representative.

For the sake of simplicity our example will describe how to set just

one of the two voice-over sensitivity

controls. We will also assume that

you do not have a P.I.P.-EXT. The

procedure involves turning up the

voice-over sensitivity until it is triggered by the ambient noise level

then backing off a little so that only an

audio signal triggers it.

Procedure

Example: Input B will be fed a line-

level background music signal and

will be assigned a priority of 2 by the

routing/priority switch. Input A will be

fed a mic-level signal from a paging

mic which requires phantom power.

The paging mic will automatically override the background music whenever

it is used. The routing/priority switch

will be set to setting “b” to accomplish

this (refer to Figure 3.4).

1. Set the input mode switch (Figure

3.8) to the appropriate setting for

each input. Input A should be set to

“PHAN” for the phantom powered

microphone and Input B should be

set to “LINE” for the line-level feed.

2. Set the input level controls of

Inputs A and B for the required

system gain (Figure 3.8).

3. Refer to Section 3.5 and connect

the audio cables to the

appropriate inputs (A and B).

Audio signals will be needed next

to adjust the voice-over circuit of

Reference Manual

Page 9

Page 10

Fig. 3.8 Steps 1 & 2

Input A.

4. If you haven’t yet done so, adjust

the duck level per Section 3.2.

5. Turn the voice-over sensitivity

control of Input A to its middle

setting

(setting 6 in Figure 3.5).

6. Turn off the power amplifier and

unplug its power cord. Refer to

Section 3.4 and install the PIP

into the amplifier. Reconnect

power to the amplifier and turn it

on.

7. With the ambient noise level of

Input A at a maximum, check to

see if Input B has ducked.

8. Turn off the power amplifier,

unplug its power cord and remove

the PIP again.

9. Adjust the voice-over sensitivity control in the following manner: If Input B has NOT yet ducked

increase the voice-over sensitivity

control one mark. If it HAS ducked,

decrease the voice-over sensitivity control one mark.

10.Repeat steps 6 through 9 until the

setting has been found where the

voice-over sensitivity control just

begins to allow Input B to duck.

Back off the sensitivity control

1

/4 turn from this point. The voice

over circuit should now trigger on

a legitimate signal and not noise.

Notice in Figure 3.7 that turning the

P.I.P.-RPA

voice-over sensitivity control fully

counterclockwise (setting 0) will turn

the circuit off.

The voice-over sensitivity control has

26 dB of adjustable range. Since the

voice-over circuitry follows the input

mode switch and input level control,

the actual sensitivity level can vary

widely. To increase the relative sensitivity of the voice-over circuit, turn

up the input level control and turn

down the amplifier level or the remote controlled attenuator. Remember, the remote controlled attenuator

is located after the voice-over circuit

so it can be used to reduce the gain

added with the input level control. If

less relative voice-over sensitivity is

desired, do just the opposite: Turn

down the input level control and turn

up the amplifier level control or the

remote-controlled attenuator. (Refer

to Figure 3.7.)

3.4 Installation

Procedures

CAUTION: Before connecting this or

any PIP to your amplifier, it is important to turn its level controls

down, turn it off and

remove the AC powerremove the AC power

remove the AC power.

remove the AC powerremove the AC power

Don’t touch the circuitry while the

amp is plugged in. Even though the

amplifier is off, there could still be

enough energy remaining to cause

electric shock.

You may need a phillips screwdriver

to remove the existing PIP module or

panel from your amplifier.

1. Turn down the level controls (full

counterclockwise), turn off the

amplifier and unplug it from the AC

power source.

Page 10

Reference Manual

Page 11

P.I.P.-RPA

L

E

N

A

P

K

C

A

B

R

E

I

F

I

L

P

M

A

F

O

.

P

.

I

.

P

U

D

O

M

Fig. 3.9 Installation into a

Standard PIP Amplifier

FROM AMPLIFIER

P

I

P

A

R

E

T

P

A

D

A

2

B

A

18 PIN (B)

B

20 PIN (A)

Fig.3.10 PIP2 Input Adapter

Connection

L

E

N

A

P

K

C

A

B

2

IP

P

F

O

R

IE

IF

L

P

M

A

R

E

T

P

A

D

A

2

IP

P

.

.I.P

P

U

D

O

M

Fig. 3.11 Installation into a

PIP2 Amplifier

2. Remove the existing PIP module

or panel (two screws). For

PIP2

amplifiers, this may involve

disconnecting the PIP from a PIP2

input adapter (see Figures 3.10

and 3.11). If a PIP2 input adapter is

already present, do not remove

the ribbon cables from the

adapter. Otherwise you will have

to reconnect them in the next step.

3.

Standard PIP Amplifiers

: Align the

edges of the P.I.P.–RPA in the PIP

card rails and firmly push the unit

E

L

in until it is seated against the

mounting bracket (see Figure 3.9).

PIP2 Amplifiers:

(Requires a PIP2

input adaptor. Crown part number

Q43528-1.) Connect the PIP2 input

adapter to the two input cables of

the amplifier (see Figure 3.10).

Notice that the PIP2 input adapter

should be positioned with the PIP

edge connector on top and facing

away from the amplifier. The 20pin cable (A) is connected first

then the 18-pin cable (B) is

connected. Both ribbon cables

should extend below the PIP2

input adapter.

Next, insert the edge connector of

the P.I.P.–RPA into the PIP2 input

adapter (see Figure 3.11) and

insert the assembly into the PIP

opening in the back of the

amplifier.

E

L

4. Secure the P.I.P.–RPA with the two

screws and lock washers

provided. (The lock washers are

important because they bond the

PIP to the chassis ground of the

amplifier.)

5. Connect input and output wiring.

6. Plug in the amplifier and turn it on.

Adjust its level controls to a

desired setting.

Do not tamper with the circuitry. Circuit changes made by unauthorized

personnel, or unauthorized circuit

modifications are not allowed.

Remember: Crown is not liable for

any damage resulting from overdriving other components in your sound

system.

Reference Manual

Page 11

Page 12

P.I.P.-RPA

Figure 3.12 shows how to wire a

balanced and unbalanced source or

daisy-chain output to the barrier block

connectors.

Important: If the amplifier is used in

either Bridged-Mono or Parallel-Mono

mode, you

fier level control off (fully counterclockwise). The input and level control of Ch. 2 are not defeated in mono

mode so any signal applied to Ch. 2

will beat against the signal in Ch. 1.

Refer to the amplifier

Manual

Bridged-Mono or Parallel-Mono

modes of operation.

Fig. 3.12 Main Audio Input Wiring

must turn the Ch. 2 ampli-

Reference

for more information about

3.5 Wiring the Audio

Inputs

Because the gain of a Crown amplifier equipped with a P.I.P.-RPA can

be quite high (as much as 90 dB) it is

very important to exercise care when

routing the input and output cables.

We strongly recommended that balanced audio input wiring be used.

Important: Use shielded wire for mic

input cables and avoid routing them

near the output cables or noise and/

or feedback oscillation may occur. It

is wise to take similar precautions

with line-level input cables too.

To avoid hum, do not route the input

cables near power cables.

Figure 3.12 above shows how to connect the audio cables to the main

audio inputs for both balanced and

unbalanced sources. It is important

not to strip away too much insulation

from the wires before attaching them

because the screw terminals are so

close to the front panel. We recommend you strip away only

mm) of insulation. Also, if stranded

wire is used, first tin the ends before

inserting them in the connector.

Important: If the amplifier is used in

either Bridged-Mono or Parallel-Mono

mode, you

fier level control off (fully counterclockwise). The input and level control of Ch. 2 are not defeated in mono

mode, so any signal fed into Ch. 2 will

beat against the signal in Ch. 1. As a

result, you should not use Input C or

D unless the Tie function is on and

you are mixing them into Ch.1.Please

refer to your amplifier’s Reference

Manual for more information about

Bridged-Mono or Parallel-Mono

modes of operation.

must turn the Ch. 2 ampli-

1

/4 inch (6.4

Ground Isolation

If present, ground loop problems can

be reduced by unsoldering or cutting and removing the ground jumper

shown in Figures 3.13 and A.1.

The jumper, labelled Z1, is located

on the underneath side of the top

circuit board just in front of the priority DIP switch. When it is removed,

Page 12

Reference Manual

Page 13

P.I.P.-RPA

the signal ground is isolated from the

chassis ground by a 82-ohm resistor

and 0.1-microfarad capacitor as

shown below:

Fig. 3.13 Locating the

Ground Isolation Jumper

3.6 Wiring the Remote

Control Inputs

Each input has an attenuator which is

remote controlled and is located in

the circuit after the input mode, input

level control, and voice-over/ducking circuitry. See Figure 3.19.

switch to maximum attenuation. A

10-V source is provided on the PIP

module for your convenience, but an

external source can also be used.

A 10-Kohm, C-taper audio pot is suggested for remote lines (see Appendix A-1). Crown’s RPA-RMT is ideal.

Linear pots will work, but are less

precise at higher output levels. Connect the pot between the PIP’s

output and the remote input (Figure

3.16).

10-V

Fig. 3.14 Ground Isolation

The attenuator is a voltage-controlled

amplifier (VCA) which is operated by

a DC voltage range of 5 to 10 V. It has

zero attenuation when it receives 10

V. It has a maximum attenuation of

84 dB when it receives 5 V or less

(see Figure 3.15). If the VCA receives a voltage over 10 V, it will also

Reference Manual

Fig. 3.15 Remote Control

Resistance/Voltage

Page 13

Page 14

Note: The 10 V output can also be wired

directly to the remote

inputs to turn them

on with no attenuation.

Fig. 3.16 Remote Control & Tie Function Wiring

P.I.P.-RPA

If variable controls aren’t required, the

10-V output can be connected directly to the remote control input for

no attenuation, or a resistor can be

used for a fixed attenuation level. The

table in Figure 3.15 shows how much

attenuation is achieved with different

remote-control resistance values. The

corresponding voltage is also provided. The input can also be easily

switched on or off if a switch or relay

is added to the remote control input.

A resistance of greater than 10 K

ohms or a remote input voltage of

less than +5V is not recommended.

If a remote control wire is opened or

shorted to ground, the control will

default to maximum attenuation.

3.7 The Tie Input

The Tie function is provided to “tie” the

audio signal and input priorities of

Channel 1 and 2 together. This enables all four inputs to be mixed into

Page 14

one or both channels of the amplifier.

Whenever the Tie function is enabled,

the audio from Input A is automatically connected to Channel 2. The

routing/priority DIP switch also affects the Tie function. The tables in

Figure 3.3 and 3.4 show how the

audio from each input and their respective priorities are controlled by

the routing/priority switch when the

Tie function is on.

The Tie function is controlled by a

TTL logic level circuit and is designed to be controlled remotely. It is

turned on when 4.2 V or more is

detected at the Tie input connector

on the front panel of the PIP Simply

connect a switch between the 10-V

output and the Tie input as shown in

Figure 3.16 to control it. If desired,

the Tie func-tion can be permanently

enabled by placing a jumper across

the 10-V output and Tie input in place

of the switch.

Reference Manual

Page 15

P.I.P.-RPA

3.8 Using the Audio Bus

The audio bus inputs and outputs are

provided so additional signals can

be added to the mixed bus (input) of

each channel or the mixed (output)

signals can be fed to other components or amplifiers (see Section A.4

in the Appendix). As such they are

very similar to the “Aux Return” and

“Aux Send” connections on a typical

mixer.

One common use for the audio bus

inputs is to “stack” multiple P.I.P-RPAs.

For example, by interconnecting the

audio bus inputs and outputs of two

P.I.P.-RPAs (as shown in Figure 3.17)

you can create an 8x2 mixer.

Fig. 3.17 Stacking Two P.I.P.-RPAs

The audio bus inputs are actually

“current” inputs so a 10 K ohm

source resistor (1/4 watt) is required

for connection.

most unlimited number of sources to

be connected. The best place to

locate the 10-K resistor is at the input

connector since this results in the

lowest noise. This is shown in Figure

3.18. No resistor is required for connection to the audio bus outputs.

Since the audio bus inputs and outputs are unbalanced, two things

should be considered: First, the input

grounds are always “lifted” from the

This allows an al-

Fig. 3.18 Audio Bus Wiring

chassis ground. Second, in-line isolation transformers should be added for

long input or output wire runs.

Note: Only the mixed audio signal

from Inputs A, B, C, and D appear at

the audio bus outputs. Any signal fed

into the audio bus inputs will

appear at the audio bus outputs (to

avoid a feedback loop).

Important: The polarity of the audio bus outputs is inverted. The

mating audio bus inputs perform the

necessary polarity inversion so that

all inputs to the amplifier are the

same polarity. When using the audio

bus output to drive another component the signal should be connected

to the (–) in put and ground.

not

4 Specifications

General

Note:

All specifications referenced

to a 0.775-V input signal.

Signal to Noise:

dB from 20 Hz to 20 kHz. Mic: Nominally –115 dB equivalent input noise,

20 Hz to 20 kHz (Rs=300Ω).

Line: Nominally 80

Reference Manual

Page 15

Page 16

P.I.P.-RPA

Frequency Response:

30 Hz to 15 kHz without isolation

transformers. ±0.5 dB from 50 Hz to

15 kHz with isolation transformers.

Harmonic Distortion (THD): Less

than 0.1% THD from 20 Hz to 20 kHz.

Less than 0.5% THD from 30 Hz to 15

kHz at +10 dB.

Common Mode Rejection: Better

than 50 dB from 20 Hz to 10 kHz.

Better than 45 dB from 10 to 20 kHz.

P.I.P.-RPA(T) better than 40 dB from

10 to 20 kHz.

Crosstalk: Line: Better than –60 dB

from 20 Hz to 20 kHz. Mic: Better

than –42 dB.

Controls: One input mode switch

and one input level control for each

main audio input (A–D) located on

front panel of the PIP. One 8-segment priority DIP switch located on

the component side of the top circuit

board. One voice-over sensitivity and

duck level control each for Input A

and C, located on the component

side of the top circuit board.

Connectors: Buchanan-type screwdown barrier connectors.

Dimensions: 6

(16.2 x 4.8 x 9.8 cm).

±0.5 dB from

3

/8 x 17/8 x 37/8 in.

Main Audio Inputs

Four independent AC-coupled balanced audio inputs are provided,

A–D. They are switchable as mic,

line, or mic with phantom power

inputs. Each input channel also includes a remote-controlled attenuator. A routing/priority switch assigns

an override priority to each input.

Inputs A and C each have sensing

circuitry which can be used to acti-

vate an attenuation (duck) circuit to

override other inputs.

Nominal Input Impedance:

11.4 K ohms balanced. Mic: 1.4 K

ohm balanced.

Phantom Power:

with a 2 K ohm output impedance.

Recommended Source Impedance: Mic or Line: 600 ohms or less,

balanced or unbalanced.

Maximum Input Level:

dB. Mic: +16 dB.

Nominal Gain:

0–36 dB with user-accessible gain

pots. Mic: Adjustable from 20–56 dB.

18 VDC at 9 mA

Line: Adjustable from

Line:

Line: +36

Remote Control Inputs

One remote input for the attenuator

of each main audio input (A–D). Two

wire format requiring a 10 K ohm

potentiometer across the 10 V output

and the remote input terminals. Nominal input impedance of 10 K ohms. A

10 VDC source is used to control the

attenuator (VCA). +10 V at the remote input yields 0 dB attenuation

and +5 V or less yields a maximum

84 dB attenuation. A control voltage

of less than +5V is not recommended.

Tie Input

A logic input which “ties” the audio

and input priorities of the main audio

inputs (A–D) together. The audio routing and priority status is set by the

priority DIP switch on the top circuit

board. Input impedance is 430 K

ohms. Minimum voltage to force Tie

function on: 4.2 V. Maximum allowable voltage for Tie to be off: 2.4 V.

Page 16

Reference Manual

Page 17

P.I.P.-RPA

10 V Output

A 10 VDC ± 50 mV current-limited

output is provided for use with the

remote control inputs and the Tie input. It has a 75-ohm output impedance.

Audio Bus

Audio Bus Inputs:

dent unbalanced current summing

input for each output channel of the

One indepen-

PIP There is unity gain into either

input when a 10 K ohm source resistor is used.

Audio Bus Outputs:

dent unbalanced output for each output channel of the PIP, representing

the mix of the A–D main audio inputs.

Suggested for use with 10 K ohm or

greater input impedance. The output

impedance is 75 ohms. Capable of

driving a 600-ohm line to +18 dB.

One indepen-

Reference Manual

Page 17

Page 18

P.I.P.-RPA

Page 18

Fig. 3.19 Circuit Block Diagram

Reference Manual

Page 19

P.I.P.-RPA

Appendix

Important:

instructions on how to modify the

P.I.P.–RPA to accommodate special

needs. Only a competent technician

should attempt to make these modifications. Other than the ones described here, no other modifications

are approved by Crown. If you have

any questions or need further technical assistance, please contact the

Crown Technical Support Group at

800-342-6939, or contact your local

representative.

This Appendix includes

A.1 Custom Remote Control

This section describes (1) how to

avoid problems with audio taper pots,

and (2) how to get full-range control

with pot values other than 10 K ohm.

A pot with an audio or log taper is

called an “Autoper” pot. C-taper pots

are similar to A-type pots except the

tape is reversed. The P.I.P.-RPA is

designed to use C-taper pots for

remote level controls.

Crown’s RPA-RMT is the best remote

control because of its C-taper. Common A-taper sliders can be flipped to

create the C-taper, but A-taper rotary pots can’t be flipped. Linear

pots are not recommended.

Reference Manual

Fig. A.1 Scaling Resistors and Jumpers

Page 19

Page 20

P.I.P.-RPA

Pots other than 10 K ohm will work

best if you change the scaling resistors to match the pot value. For example, use a 20 K resistor for a 20 K

pot. Do not exceed 50 K. The scaling

resistor locations are shown in Figure A.1. Resistor R65 is used for

Input A, R74 for Input B, R79 for Input

C, and R89 for Input D.

Remove the

from the top and bottom circuit boards

to access the scaling resistors. With

the panel removed, separate the circuit boards by pulling them straight

apart. Take care not to bend the long

connector pins which connect the

two boards. For more help, contact

Crown’s Technical Support Group at

800-294-6939.

front panel (4 screws)

A.2 Master Remote Control

If desired, the attenuation of more

than one input can be controlled with

just one master remote control pot. In

fact, all of them can be controlled

from one pot. One input will be the

master and all others grouped with it

will be slaves. The procedure is

simple:

1. Select which input you want to use

as the master input. Connect the

remote control pot to it. (Input A is

the master in Figure A.2.)

2. Remove the appropriate scaling

resisters from all but the master

input. (Figure A.1.)

3. Jumper the master remote pot to

all the slave remote control inputs.

To control the level of Inputs A and C

with the pot for Input A, remove the

Input C scaling resistor (R79) and

add a jumper between the A and C

remote inputs as shown in Figure

A.2.

A.3 Limiting Remote

Attentuation

Depending upon the installation, it

may be desirable to limit the maximum remote attenuation. For example, you may want to decrease

the sensitivity of the remote control

pot so it must be rotated farther for a

given amount of attenuation. You may

also want to prevent someone from

turning a microphone down too low.

Figure A.3 shows a simple way to do

this by placing a resistor in parallel

with the 10 K remote control pot.

Fig. A.2 Master/Slave

Remote Control Wiring

Page 20

Fig. A.3 Adding an Attenuation Limit

Resistor Parallel to the Remote Pot

Reference Manual

Page 21

P.I.P.-RPA

The table in Figure A.4 shows the

resistor value to use for different maximum attenuation values.

Note:

The values in Figure A.4 are for

use with a 10 K remote control pot

only. If a different value pot is used,

the following equation will solve for

the correct resistor value:

“R

” is the value of the limit resistor in

L

kilohms. “VL” is the minimum desired

remote control voltage in volts. It can

be found by selecting the maximum

desired attenuation from either Figure A.4 or 3.15 and reading the voltage required for that attenuation. “RP”

is the value of the pot used for the

remote control in kilohms.

Remember:

value other than 10 K ohms is used,

the scaling resistor will also have to

be changed as described in Section

A.1.

If a remote control pot

A.4 Signal Processing

It is possible to use the audio bus

inputs and outputs as a processor

loop for a compressor, limiter or

equalizer. To do this, remove resistor

R97 for Channel 1 and R110 for Channel 2. They are located on the top

circuit board and are shown in Figures A.1 and 3.19. Section A.1 contains brief instructions for gaining

access to the component side of the

top circuit board.

After the components are removed,

use the audio bus output to drive the

input of the external processor (remember, these are unbalanced

lines). Connect the output of the external processor to the audio bus

input through the specified 10 K resistor (see Section 3.8). See Section

4 for the input and output capabilities

of the audio bus.

Fig. A.4 Remote Control Limit

Resistor Value/Max Attenuation

Reference Manual

Page 21

Page 22

Loading...

Loading...