Page 1

Power Base-1 & 460CSL Amplifier Service Manual

POWER AMPLIFIER

SERVICE MANUAL

POWER BASE-1® & 460CSL

©1995 by CROWN INTERNATIONAL, INC.

Mailing Address:

P.O. Box 1000

Elkhart, IN U.S.A. 46515-1000

Shipping Address:

57620 C.R. 105

Elkhart, IN U.S.A. 46517

™

CSL™ is a trademark and Power Base-1,® ODEP® and Crown® are registered trademarks of Crown International, Inc.

K-SVCPB1

1-95

1

Page 2

Power Base-1 & 460CSL Amplifier Service Manual

Table of Contents

Introduction .............................................................4

Scope......................................................................4

Warranty..................................................................4

Parts ........................................................................ 5

Specifications..........................................................6

Voltage Conversion ................................................. 7

Circuit Theory .......................................................... 8

Test Procedures.................................................... 13

Mechanical Parts Listing .......................................17

Module Information ...............................................20

Q42576-1 Output Module (Original) .....................21

Q42661-1 Output Module (#2) .............................. 22

Q42718-9 Output Module (#3) .............................. 23

Q42885-6 Output Module (TO-3P)........................24

Q42967-2 Output Module (THC)...........................25

Q43200-7 Output Module (THC #2)......................26

Q42552A0 Main Module (Original)........................27

Q42664-5 Main Module (Service Only) ................. 29

Q42682-7 Main Module (#2) .................................31

Q42776-7 Main Module (3rd Gain) ....................... 34

Q42953-2 Main Module (3rd Gain PB-1) .............. 37

Q43060-5 Main Module (THC) ..............................40

3

Page 3

Power Base-1 & 460CSL Amplifier Service Manual

Specifications

Unless noted otherwise, all specifications are based

on driving an 8 ohm load per channel, both channels

driven, the sensitivity switch in the 26dB position, the

AC supply is 120VAC at 60Hz. Crown specifications

are guaranteed through the warranty period (normally

3 years). Because our testing methods are more stringent than our published specifications, every Crown

amplifier will exceed its published specifications.

POWER

Power

8 Ohm Stereo—205W/Ch

4 Ohm Stereo—230W/Ch

8 Ohm Bridge Mono—430W

4 Ohm Parallel Mono—425W

Load Impedances: Rated for 16, 8, 4, and 2 (parallel

mono only) Ohm operation; safe with all types of loads,

even totally reactive loads.

AC Mains: 120VAC at 60 Hz with standard 3 wire

grounded 15A connector with single voltage transformer and fan for North American units; 100VAC,

120VAC, 220VAC, and 240VAC at 50 or 60 Hz when

equipped with universal transformer, applicable fan,

and other applicable hardware with country specific

power cord. Note that at 50 Hz fan speed is reduced.

PERFORMANCE

Frequency Response: ±0.1dB from 20 Hz to 20 kHz at 1

Watt.

Phase Response: ±10° from 10 Hz to 20 kHz at 1 Watt.

Signal to Noise Ratio: Better than 105 dB (A-weighted)

below max. average power from 20 Hz to 20 kHz.

Total Harmonic Distortion (THD): <0.05% from 20 Hz to

1 kHz, increasing linearly to 0.1% at 20 kHz at 170W.

I.M. Distortion: <0.05% from 10 milliwatts to 170W at 26

dB gain.

Slew Rate: >13V per microsecond.

Damping Factor: >1000 from 10 Hz to 400 Hz.

Input Impedance: Nominally 20K ohms balanced; 10K

ohms unbalanced.

Output Impedance: <10 milliohms in series with <2

microhenries.

Protection Systems: Output Device Emulation Protec-

tion (ODEP) limits drive in the event of dangerous

dynamic thermal conditions without interrupting power.

Current limiting for shorted load protection. DC/LF and

common mode output current Fault circuitry to mute

audio. Delay of 4 seconds from turn on mutes amplifier

to prevent dangerous turn-on transients. High voltage

fuse in main transformer primary and low voltage fuse

in fan primary. Slew rate limiting to prevent RF burn

out.

MECHANICAL

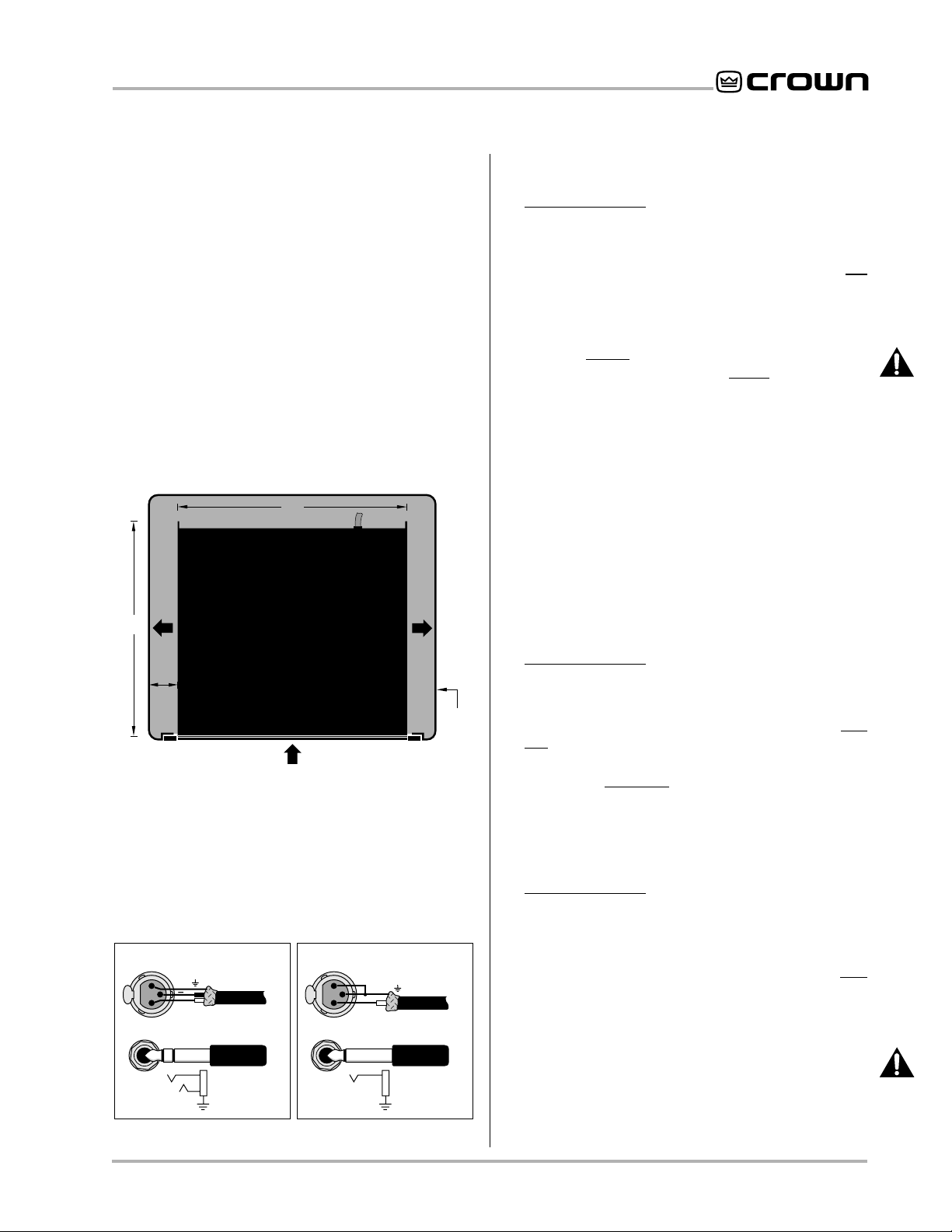

Input Connectors: Balanced 1/4 inch phone jacks.

Output Connectors: Color-coded 5-way binding posts

on 3/4 inch centers; spaced 3/4 inch apart.

Front Panel Controls: A rocker on/off power switch.

Back Panel Controls: A three-position switch which

selects Stereo, Bridge-Mono, or Parallel-Mono mode;

a two position input ground-lift switch, and level controls for each channel.

Internal Controls: A three-position switch selects 0.775V,

1.4V, or 26 dB voltage gain input sensitivity (all units

manufactured with D 7911-7 main module or later;

earlier models only allowed for 0.775V or 26 dB gain).

Indicators: Red Enable indicator shows on/off status of

low-voltage power supply.

Construction: Black splatter-coat steel chassis with

specially designed flow-through ventilation system.

Mounting: Standard EIA 310 front-panel rack mount

with supports for supplemental rear corner mounting.

Dimensions: 19 inches wide, 3.5 inches high, 16 inches

deep behind front mounting surface.

DC Offset: <10 millivolts.

6

Weight: 30 lbs.

Page 4

Power Base-1 & 460CSL Amplifier Service Manual

Voltage Conversion

PB/CSL Universal Fuse Board

BLU

BRN

P19

P20

P10

P9

P8

P7

P16

P15

P14

P13

P12

P11

P6

P5

P4

P3

P2

P1

P22

100V Connections:

P10 to P15

P11 to P14

P7 to P12

120V Connections:

P10 to P16

P11 to P14

P7 to P13

220V Connections:

P10 to P15

P9 to P14

P8 to P13

240V Connections:

P10 to P16

P9 to P14

P8 to P13

For list of applicable

transformer, fuse F100,

fanformer, and power

cord refer to voltageparts cross-reference.

F1F100

P18

S1 Power Switch

P17

Note: The only versions of this

product produced at the Crown

Factory with international voltage capabilities built in are CSL

versions built specifically for

sale outside the United States.

P21

Specific parts are required for the PB-1/460CSL in

order to be used at different international line voltages. Refer also to Mechanical Parts Lists.

100V AC Mains:

10A Fuse A10285-26

0.5A Low Voltage Supply Fuse A10285-7

Power Transformer (Universal) D 7598-2

Transmotor 120V 50 Hz H43055-5

120V AC Mains:

10A Fuse A10285-26

0.5A Low Voltage Supply Fuse A10285-7

Power Transformer (Universal) D 7598-2

Power Transformer (United States) D 6589-2

Transmotor 120V 50 Hz H43055-5

Transmotor 120V 60 Hz H43065-4

220V to 240V AC Mains:

5A Fuse A10285-21

0.5A Low Voltage Supply Fuse A10285-7

Power Transformer D 7598-2

Transmotor 120V 50 Hz H43055-5

7

Page 5

Power Base-1 & 460CSL Amplifier Service Manual

Theory

OVERVIEW

It should be noted from the outset that the PB-1 and

460CSL amplifiers are electrically and mechanically

identical products. The only differences, from a service perspective, are cosmetic. For the purposes of

servicing the products, it should also be known that

the CSL version has been on the market since 1992.

Since the PB amplifiers have been in production since

the mid-1980’s there are a number of electrical and

mechanical parts associated with the older PB models

only. It is also important to realize that over time Crown

has introduced numerous improvements to PB/CSL

amplifiers. Though often changes are minor, and are

made for a variety of reasons, a few changes have had

a significant impact on the operation of the circuitry.

This manual is up to date as of the time of writing. For

additional information regarding these amplifiers, refer to the applicable Technical Notes provided by

Crown for this product.

This section of the manual explains the general operation of a typical Crown power amplifier. Topics covered include Front End, Grounded Bridge, and ODEP.

Due to variations in design from vintage to vintage

(and similarities with other products Crown) the theory

of operation remains simplified.

FEATURES

Power Base/CSL amplifiers utilize numerous Crown

innovations including grounded bridge and ODEP

technologies. Cooling techniques make use of the

what is essentially air conditioner technology. Air flows

bottom to top, and front to side. Air flows a short

distance across a wide heatsink. This type of air flow

provides significantly better cooling than the “wind

tunnel” technology used by many other manufacturers. Output transistors are of the metal can type rather

than plastic case. This allows for a significantly higher

thermal margin for the given voltage and current

ratings. All devices used are tested and graded to

ensure maximum reliability. Another electronic technique used is negative feedback. Almost all power

amplifiers utilize negative feedback to control gain

and provide stability, but Crown uses multiple nested

feedback loops for maximum stability and greatly

improved damping. Most Crown amplifiers have damping in excess of 1000 in the bass frequency range. This

feedback, along with our compensation and ultra-low

distortion output topology, make Crown amplifiers

superior.

Features specific to the Power Base/CSL Series’ in-

clude a single core transformer (one primary with two

independent ungrounded secondaries), a full time full

speed fan which also serves as the low voltage

transformer, slew rate limiting, and audio muting for

delay or protective action. This amplifier can operate

in either a Bridged or Parallel Mono mode as well as

dual (stereo). A sensitivity switch allows selection of

input voltage required for rated output. Level controls

are rear mounted. The only indicator provided tells the

operator that the low voltage supply is energized. In

general, the packaging of this model is designed for

maximum watt/price/weight/size value. It is the most

basic grounded bridge amplifier now available from

Crown.

For additional details refer to the specification section,

or to the applicable Owner’s Manual.

FRONT END OPERATION

The front end is comprised of three stages: Balanced

Gain Stage (BGS), Variable Gain Stage (VGS), and

the Error Amp. Figure 1 shows a simplified diagram of

a typical front end with voltage amplification stages.

Balanced Gain Stage (BGS)

Input to the amplifier is balanced. The shield may be

isolated from chassis ground by an RC network to

interrupt ground loops (early models did not have the

Ground Lift feature) via the Ground Lift Switch. The

non-inverting (hot) side of the balanced input is fed to

the non-inverting input of the first op-amp stage. The

inverting (negative) side of the balanced input is fed

to the inverting input of the first op-amp stage. A

potentiometer is provided for common mode rejection

adjustment. Electrically, the BGS is at unity gain.

(From an audio perspective, however, this stage

actually provides +6dB gain if a fully balanced signal

is placed on its input.) The BGS is a non-inverting

stage. It’s output is delivered to the Variable Gain

Stage.

Variable Gain Stage (VGS)

Note: Older models only had two front end stages.

The functions of this stage were combined, primarily,

with those of the third.

From the output of the BGS, the signal goes to the VGS

where gain is determined by the position of the Sensitivity Switch, and level is determined by the level

control. VGS is an inverting stage with the input being

fed to its op-amp stage. Because gain after this stage

is fixed at 26dB (factor of 20), greater amplifier sensi-

8

Page 6

Power Base-1 & 460CSL Amplifier Service Manual

Theory

tivity is achieved by controlling the ratio of feedback to

input resistance. The Sensitivity Switch sets the input

impedance to this stage and varies the gain such that

the overall amplifier gain is 26 dB, or is adjusted

appropriately for 0.775V or 1.4V input to attain rated

output. Note that earlier models (before main modules

built with D 7911-7 board) did not support the 1.4V

sensitivity.

Error Amp

The inverted output from the VGS is fed to the noninverting input of the Error Amp op-amp stage through

an AC coupling capacitor and input resistor. Amplifier

output is fed back via the negative feedback (NFb)

loop resistor. The ratio of feedback resistor to input

resistor fixes gain from the Error Amp input to the

output of the amplifier at 26 dB. Diodes prevent

overdriving the Error Amp. Because the Error Amp

amplifies the difference between input and output

signals, any difference in the two waveforms will

produce a near open loop gain condition which in turn

results in high peak output voltage. The output of the

Error Amp, called the Error Signal (ES) drives the

Voltage Translators.

VOLTAGE AMPLIFICATION

The Voltage Translator stage separates the output of

the Error Amp into balanced positive and negative

drive voltages for the Last Voltage Amplifiers (LVAs),

translating the signal from ground referenced ±15V to

±Vcc reference. LVAs provide the main voltage amplification and drive the High Side output stages. Gain

from Voltage Translator input to amplifier output is a

factor of 25.2.

Voltage Translators

A voltage divider network splits the Error Signal (ES)

into positive and negative drive signals for the balanced voltage translator stage. These offset reference

voltages drive the input to the Voltage Translator

transistors. A nested NFb loop from the output of the

amplifier mixes with the inverted signal riding on the

offset references. This negative feedback fixes gain at

the offset reference points (and the output of the Error

Amp) at a factor of -25.2 with respect to the amplifier

output. The Voltage Translators are arranged in a

common base configuration for non-inverting voltage

gain with equal gain. They shift the audio from the

±15V reference to VCC reference. Their outputs drive

their respective LVA.

Also tied into the Voltage Translator inputs are ODEP

limiting transistors and control/protection transistors.

The ODEP transistors steal drive as dictated by the

ODEP circuitry (discussed later). The control/protection transistors act as switches to totally shunt audio to

ground during the turn-on delay, or during a DC/LF or

Fault protective action.

Last Voltage Amplifiers (LVAs)

The Voltage Translator stage channels the signal to

the Last Voltage Amplifiers (LVA's) in a balanced

configuration. The +LVA and -LVA, with their push-pull

effect through the Bias Servo, drive the fully complementary output stage. The LVAs are configured as

common emitter amplifiers. This configuration provides sufficient voltage gain and inverts the audio. The

polarity inversion is necessary to avoid an overall

polarity inversion from input jack to output jack, and it

Audio

Inputs

BGS VGS Error

Amp

+

-

+

-

+

-

Figure 1. Typical Amplifier Front End and Voltage Amplification Stages.

+15V

Voltage Divider

+

-15V

-

ODEP

Q100

Q103

Mute

Q121

Q122

NFb Loop

Voltage

Translators

Q101

Q102

+VCC

Q105

NPN Outputs (+HS)

PNP Outputs (-HS)

Q110

-VCC

LVA's

9

Page 7

Power Base-1 & 460CSL Amplifier Service Manual

Theory

allows the NFb loop to control Error Amp gain by

feeding back to its non-inverting input (with its polarity

opposite to the output of the VGS). With the added

voltage swing provided by the LVAs, the signal then

gains current amplification through the Darlington

emitter-follower output stage.

GROUNDED BRIDGE TOPOLOGY

Figure 2 is a simplified example of the grounded

bridge output topology. It consists of four quadrants

of three deep Darlington (composite) emitter-follower

stages per channel: one NPN and one PNP on the

High Side of the bridge (driving the load), and one

NPN and one PNP on the Low Side of the bridge

(controlling the ground reference for the rails). The

output stages are biased to operate class AB+B for

ultra low distortion in the signal zero-crossing region

and high efficiency.

High Side (HS)

The High Side (HS) of the bridge operates much like

a conventional bipolar push-pull output configuration.

As the input drive voltage becomes more positive, the

HS NPN conducts and delivers positive voltage to the

load. Eventually the NPN devices reach full conduction and +Vcc is across the load. At this time the HS

PNP is biased off. When the drive signal is negative

going, the HS PNP conducts to deliver -Vcc to the load

and the HS NPN stage is off.

The output of the +LVA drives the base of predriver

device. Together, the predriver and driver form the

first two parts of the three-deep Darlington and are

biased class AB. They provide output drive through

the bias resistor, bypassing the output devices, at

levels below about 100mW. An RLC network between

the predriver and driver provide phase shift compensation and limit driver base current to safe levels.

Output devices are biased class B, just below cutoff.

At about 100mW output they switch on to conduct high

current to the load. Together with predriver and driver,

the output device provide an overall class AB+B

output.

The negative half of the HS is almost identical to the

positive half, except that the devices are PNP. One

difference is that the PNP bias resistor is slighter

greater in value so that PNP output devices run closer

to the cutoff level under static (no signal) conditions.

This is because PNP devices require greater drive

current.

HS bias is regulated by Q18, the Bias Servo. Q18 is a

Vbe multiplier which maintains approximately 3.3V

Vce under static conditions. The positive and negative

halves of the HS output are in parallel with this 3.3V.

With a full base-emitter on voltage drop across

predrivers and drivers, the balance of voltage results

in approximately .35V drop across the bias resistors in

10

+

+Vcc (Positive Rail)

Input

signal

HIGH SIDE LOW SIDE

Load

(speaker)

-Vcc (Negative Rail)

Inverting Op-amp

-

Figure 2. Crown Patented Grounded Bridge Topology

Page 8

Power Base-1 & 460CSL Amplifier Service Manual

Theory

the positive half, and about .5V across the bias resistor

in the negative half. Q18 conduction (and thus bias) is

adjustable.

A diode string prevents excessive charge build up

within the high conduction output devices when off.

Flyback diodes shunt back-EMF pulses from reactive

loads to the power supply to protect output devices

from dangerous reverse voltage levels. An output

terminating circuit blocks RF on output lines from

entering the amplifier through its output connectors.

Low Side (LS)

The Low Side (LS) operates quite differently. The

power supply bridge rectifier is not ground referenced, nor is the secondary of the main transformer.

In other words, the high voltage power supply floats

with respect to ground, but ±Vcc remain constant with

respect to each other. This allows the power supply to

deliver +Vcc and -Vcc from the same bridge rectifier

and filter as a total difference in potential, regardless

of their voltages with respect to ground. The LS uses

inverted feedback from the HS output to control the

ground reference for the rails (±Vcc). Both LS quadrants are arranged in a three-deep Darlington and are

biased AB+B in the same manner as the HS.

When the amplifier output swings positive, the audio is

fed to an op-amp stage where it is inverted. This

inverted signal is delivered directly to the bases of the

positive (NPN) and negative (PNP) LS predrivers. The

negative drive forces the LS PNP devices on (NPN

off). As the PNP devices conduct, Vce of the PNP

Darlington drops. With LS device emitters tied to

ground, -Vcc is pulled toward ground reference.

Since the power supply is not ground referenced (and

the total voltage from +Vcc to -Vcc is constant) +Vcc

is forced higher above ground potential. This continues until, at the positive amplifier output peak, -Vcc =

0V and +Vcc equals the total power supply potential

with a positive polarity. If, for example, the power

supply produced a total of 70V from rail to rail (±35VDC

measured from ground with no signal), the amplifier

output would reach a positive peak of +70V.

Conversely, during a negative swing of the HS output

where HS PNP devices conduct, the op-amp would

output a positive voltage forcing LS NPN devices to

conduct. This would result in +Vcc swinging toward

ground potential and -Vcc further from ground potential. At the negative amplifier output peak, +Vcc = 0V

and -Vcc equals the total power supply potential with

a negative polarity. Using the same example as above,

a 70V supply would allow a negative output peak of 70V. In summary, a power supply which produces a

total of 70VDC rail to rail (or ±35VDC statically) is

capable of producing 140V peak-to-peak at the amplifier output when the grounded bridge topology is

used. The voltage used in this example are relatively

close to the voltages of the PB-1/460CSL.

The total effect is to deliver a peak to peak voltage to

the speaker load which is twice the voltage produced

by the power supply. Benefits include full utilization of

the power supply (it conducts current during both

halves of the output signal; conventional designs

require two power supplies per channel, one positive

and one negative), and never exposing any output

device to more than half of the peak to peak output

voltage (which does occur in conventional designs).

Low side bias is established by a diode string which

also shunts built up charges on the output devices.

Bias is adjustable via potentiometer. Flyback diodes

perform the same function as the HS flybacks. The

output of the LS is tied directly to chassis ground via

ground strap.

OUTPUT DEVICE EMULATION PROTECTION

(ODEP)

To further protect the output stages, a specially developed ODEP circuit is used. It produces a complex

analog output signal. This signal is proportional to the

always changing safe-operating-area margin of the

output transistors. The ODEP signal controls the Voltage Translator stage by removing drive that may

exceed the safe-operating-area of the output stage.

ODEP senses output current by measuring the voltage dropped across LS emitter resistors. LS NPN

current (negative amplifier output) and +Vcc are

sensed, then multiplied to obtain a signal proportional

to output power. Positive and negative ODEP voltages

are adjustable via two potentiometers. Across ±ODEP

are a PTC and a thermal sense (current source). The

PTC is essentially a cutoff switch that causes hard

ODEP limiting if heatsink temperature exceeds a safe

maximum, regardless of signal level. The thermal

sense causes the differential between +ODEP and –

ODEP to decrease as heatsink temperature increases.

An increase in positive output signal output into a load

will result in –ODEP voltage dropping; an increase in

negative output voltage and current will cause +ODEP

voltage to drop. A complex RC network between the

11

Page 9

Power Base-1 & 460CSL Amplifier Service Manual

Theory

±ODEP circuitry is used to simulate the thermal barriers between the interior of the output device die

(immeasurable by normal means) and the time delay

from heat generation at the die until heat dissipates to

the thermal sensor. The combined effects of thermal

history and instantaneous dynamic power level result

in an accurate simulation of the actual thermal condition of the output transistors.

BALANCED

INPUTS

+VOLTAGE

TRANSLATOR

VGSBGS

-1

ERROR

AMP

OUTPUT

DEVICE

EMULATION

PROTECTION

-VOLTAGE

TRANSLATOR

+LVA

-1

HIGH SIDE

BIAS

SERVO

-LVA

-1

MAIN NEGATIVE FEEDBACK (NFb) LOOP

LOW SIDE

-1

INVERTING

BRIDGE

BALANCE

BIAS

DIODE

STRING

POSITIVE

HIGH SIDE

OUTPUT

NPN STAGE

NEGATIVE

HIGH SIDE

OUTPUT

PNP STAGE

POSITIVE

LOW SIDE

OUTPUT

NPN STAGE

NEGATIVE

LOW SIDE

OUTPUT

PNP STAGE

12

Figure 3. Typical Crown Amplifier Basic Block Diagram (One Channel Shown)

Page 10

Power Base-1 & 460CSL Amplifier Service Manual

Checkout Procedures

GENERAL INFORMATION

The following test procedures are to be used to verify

operation of this amplifier. DO NOT connect a load or

inject a signal unless directed to do so by the procedure. These tests, though meant for verification and

alignment of the amplifier, may also be very helpful in

troubleshooting. For best results, tests should be

performed in order.

All tests assume that AC power is from a regulated 120

VAC source. Test equipment includes an oscilloscope, a DMM, a signal generator, loads, and I.M.D.

and T.H.D. noise test equipment.

STANDARD INITIAL CONDITIONS

Level controls fully clockwise.

Stereo/Mono switch in Stereo.

Sensitivity switch in 26 dB fixed gain position.

It is assumed, in each step, that conditions of the

amplifier are per these initial conditions unless otherwise specified.

TEST 1: DC OFFSET

Spec: 0 VDC, ±10 mV.

Initial Conditions: Controls per standard, inputs shorted.

Procedure: Measure DC voltage at the output connec-

tors (rear panel). There is no adjustment for output

offset. If spec is not met, there is an electrical malfunction. Slightly out of spec measurement is usually due

to U104/U204 out of tolorance.

The following is a list of ODEP Bias Voltages VS.

Temperature.

°F °C V

–ODEP

V

+ODEP

66 18.9 –10.31 11.41

68 20.0 –10.26 11.36

70 21.1 –10.20 11.30

72 22.2 –10.14 11.24

74 23.3 –10.09 11.19

76 24.4 –10.03 11.13

77 25.0 –10.00 11.10

78 25.6 –9.97 11.07

80 26.7 –9.91 11.01

82 27.8 –9.86 10.96

84 28.9 –9.80 10.90

86 30.0 –9.74 10.84

88 31.1 –9.69 10.79

90 32.2 –9.63 10.73

92 33.3 –9.57 10.67

94 34.4 –9.51 10.61

–ODEP Procedure: Measure pin 6 of U100 and, if

necessary, adjust R121 to obtain V

as specified

–ODEP

above. Measure pin 6 of U200 and, if necessary,

adjust R221 to obtain V

as specified above.

–ODEP

+ODEP Procedure: Measure pin 6 of U103 and, if

necessary, adjust R132 to obtain V

as specified

+ODEP

above. Measure pin 6 of U203 and, if necessary,

adjust R232 to obtain V

as specified above.

+ODEP

TEST 2: OUTPUT BIAS ADJUSTMENT

Spec: 300 to 310 mVDC.

Initial Conditions: Controls per standard, heatsink tem-

perature less than 40°C.

Procedure: Measure DC voltages on the output module

across R31, adjust R26 if necessary. Measure DC

voltages on the output module across R32, adjust R23

if necessary. Repeat for second channel.

TEST 3: ODEP VOLTAGE ADJUSTMENT

Spec: Cold Bias Per Charts Below ±0.1V DC.

Initial Conditions: Controls per standard, heatsink at

room temperature 20 to 30°C (68 to 86°F). Note: This

adjustment should normally be performed within 2

minutes of turn on from ambient (cold) conditions. If

possible measure heatsink temperature, if not measure ambient room temperature. Use this information

when referencing the chart below.

13

Page 11

Power Base-1 & 460CSL Amplifier Service Manual

Checkout Procedures

TEST 4: AC POWER DRAW

Spec: 90 Watts maximum quiescent.

Initial Conditions: Controls per standard.

Procedure: With no input signal and no load, measure

AC line wattage draw. If current draw is excessive,

check for high AC line voltage or high bias voltage.

TEST 5: COMMON MODE REJECTION

Spec at 100 Hz: –70 dB.

Spec at 20 kHz: –50 dB.

Initial Conditions: Controls per standard.

Procedure: No load. Inject a 0 dBu 100 Hz sine wave

into each channel, one channel at a time, with inverting

and non-inverting inputs shorted together. At the

output measure less than –44 dBu. Inject a 0 dBu 20

kHz sine wave into each channel, one channel at a

time, with inverting and non-inverting inputs shorted

together. At the output measure less than –24 dBu.

Adjust R921 or R1021, if necessary, to obtain the

required measurements. (In older units the adjustments are done using N100/N200.)

TEST 6: VOLTAGE GAIN

Spec: ±3% when the Sensitivity Switch is set for 26dB

gain, ±6% when the Sensitivity Switch is set for 0.775V

or 1.4V sensitivity.

Initial Conditions: Controls per standard.

Procedure: No load connected. Inject a 0.775 VAC 1

kHz sine wave with the Sensitivity Switch in the 26 dB

position. Measure 15.5 VAC ±0.07 VAC at the amplifier output. Inject a 0.775 VAC 1 kHz sine wave with the

Sensitivity Switch in the 0.775V position. Measure 39.9

VAC ±1.2 VAC at the amplifier output. Inject a 1.4 VAC

1 kHz sine wave with the Sensitivity Switch in the 1.4V

position. Measure 39.9 VAC ±1.2 VAC at the amplifier

output. Return the Sensitivity Switch to the 26 dB

position.

TEST 7: PHASE RESPONSE

Spec: ±10° at 1 Watt.

Initial Conditions: Controls per standard, 8 ohm load on

each channel.

Procedure: Inject a 1 kHz sine wave and adjust for 1

Watt output (2.8 VAC). Check input and output signals

against each other, input and output signals must be

within 10° of each other.

Procedure: No Load. Inject a 1 kHz sine wave. With

level controls fully clockwise you should see full gain.

As controls are rotated counterclockwise, observe

similar gain reduction in each channel. When complete, return level controls to fully clockwise position.

TEST 9: CURRENT LIMIT

Spec: Current Limit at 13 ±2 Amps

Initial Conditions: Controls per standard.

Procedure: Load each channel to 1 Ohm. Inject a 1 kHz

differentiated (or 10% duty cycle) square wave and

increase output level until current limit occurs. Current

limit should occur at 11 ±1 Amps. Observe clean (no

oscillations) current clipping.

TEST 10: SLEW RATE & 10 KHZ SQUARE WAVE

Spec: >13V/µS.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 10

kHz square wave to obtain 40 volts peak-to-peak at

each output. Observe the slope of the square wave. It

should typically measure 17 to 25 V/µS. Also, the

square wave must not include overshoot, ringing, or

any type of oscillation.

TEST 11: CROSSTALK

Spec: <33 mVAC at 20 kHz.

Initial Conditions: Controls per standard. Short input of

channel not driven.

Procedure: 8 ohm load on each channel. Inject a 20 kHz

sine wave into the Channel 1 input and increase output

level to 37.4 VAC. Measure less than 33 mVAC at the

output of Channel 2. Inject a 20 kHz sine wave into the

Channel 2 input and increase output level to 37.4 VAC.

Measure less than 33 mVAC at the output of Channel

1.

TEST 12: OUTPUT POWER

Spec at 8 Ohm Stereo: 205W at 0.1% THD.

Spec at 4 Ohm Stereo: 230W at 0.1% THD.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 1 kHz

sine wave and measure at least 40.5 VAC at the output

of each channel. Load each channel to 4 ohms. Inject

a 1 kHz sine wave and measure at least 30.3 VAC. All

power measurements must be at less than 0.1% THD.

TEST 8: LEVEL CONTROLS

Spec: Level controlled by level controls.

Initial Conditions: Controls per standard.

14

TEST 13: REACTIVE LOADS

Spec: No oscillations. Safe with all types of loads.

Initial Conditions: Controls per standard.

Page 12

Power Base-1 & 460CSL Amplifier Service Manual

Checkout Procedures

Procedure Capacitive: Load each channel to 8 ohms in

parallel with 2 µF. Inject a 20 kHz sine wave with 30

VAC output for 10 seconds.

Procedure Inductive: Load each channel to 8 ohms in

parallel with 159 µHenries. Inject a 1 kHz sine wave

with 15 VAC output for 10 seconds.

Procedure Torture: Load each channel with the primary

(red and black leads) of a DC-300A transformer (D

5781-6). Inject a 10 Hz sine wave at sufficient output

level to cause 3 to 5 flyback pulses, for 10 seconds.

Procedure Short: Inject a 60 Hz sine wave at 5 VAC.

After establishing signal, short the output for 10 seconds.

TEST 14: ODEP LIMITING

Spec: No oscillation on ODEP Limiting wave form;

either channel controls limiting in Parallel Mono Mode.

Initial Conditions: Controls per standard; rag or other

obstruction blocking fan so that it does not turn.

Procedure: Load the amplifier to 2 ohms on each

channel. Inject a 60 Hz sine wave and adjust for 15

Vrms at the output. After a few minutes observe a wave

form similar to Figure 4. Remove the input signal from

both channels and allow the amplifier to cool for a few

minutes. Switch the amplifier to Parallel Mono and

remove the load from Channel 1. Inject the signal into

Channel 1 and observe that ODEP limiting occurs at

the output of both channels. Remove the load from

Channel 2, and install the load on Channel 1. Again,

observe that both channels limit. Return all amplifier

controls to standard initial conditions. Remove the fan

obstruction.

TEST 15: LF PROTECTION

Spec: Amplifier mutes for low frequency.

Initial Conditions: Controls per standard.

Procedure: No load. Inject a 0.5 Hz 6 volt peak-to-peak

square wave into each channel and verify that each

channel cycles into mute.

TEST 16: SIGNAL TO NOISE RATIO

Spec: 100 dB (105 dB A-weighted) below rated 8 ohm

power.

Initial Conditions: Controls per standard. Short inputs.

Procedure: Load each channel to 8 ohms. Measure

less than 400 µV at the output of each channel (or –100

dB from reference of +34.25 dBu).

TEST 17: TURN ON TRANSIENTS

Spec: No dangerous transients.

Initial Conditions: Controls per standard.

Procedure: From an off condition, turn on the amplifier

and monitor the output noise at the time of turn on.

Note: Turn on noise may increase significantly if the

amplifier is cycled off and on.

TEST 18: TURN OFF TRANSIENTS

Spec: No dangerous transients.

Initial Conditions: Controls per standard.

Procedure: From an on condition, turn off the amplifier

and monitor the output noise at the time of turn off.

Note: Turn off noise may increase significantly if the

amplifier is cycled off and on.

TEST 19: INTERMODULATION DISTORTION

Spec at 0 dB Output: 0.01%.

Spec at –35 dB Output: 0.05%.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a

SMPTE standard IM signal (60 Hz and 7 kHz sine wave

mixed at 4:1 ratio) at 200 Watts (32.4 VAC). With an IM

analyzer measure less than 0.01% IMD. Repeat test at

–35 dB (reference 200 Watts or 32.4 VAC) and measure less than 0.05% IMD.

Figure 4. ODEP Limiting Wave Form

TEST 20: CLIPPING

Spec: No protective action during test.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 1 kHz

sine wave at each input and drive output 6 dB into clip

for 10 seconds. The amplifier should not activate any

protective circuits (ODEP, Fault, or LF Protection).

POST TESTING

After completion of testing, if all tests are satisfactory,

the amplifier controls should be returned to the positions required by customer. If conditions are unknown

or unspecified, factory settings are as follows:

15

Page 13

Power Base-1 & 460CSL Amplifier Service Manual

Mechanical (Non-Module) Parts

SUPPLIMENTAL ITEMS

CPN ITEM QTY

D 4137-2 Nylon Thumbscrew Washer 4

C 3342-0 Feet, Black Self-Stick 4

A10087-71012 10-32 .75 Machine (Rack Screw) 4

120VAC/60HZ NORTH AMERICA PRODUCT ONLY

CPN ITEM QTY

A10285-26 Fuse, 10A 3AB (120V Units) 1

A10285-7 Fuse, .5A AGC 1.25x.25 (LVPS) 1

D 6589-2 PB-1 Power Transformer 1

A10101-19 Washer, Fiber (XFMR Assby) 2

H42873-2 Fanformer Assembly 1

P10391-4 Fuse Board (U.S. Only) 1

P10426-6 Fuse Board (International Only) 1

FANFORMER MECHANICAL ASSEMBLY

CPN ITEM QTY

C 7062-0 Screw, 6-32-5/16 Flat Mach 2

C 9939-7 Fan Blade, 4 inch CCW 1

D 8439-8 Fan Bracket 1

FILTER CAPACITOR MOUNTING ASSEMBLY (ONE PER CHANNEL)

CPN ITEM QTY

A10095-4 Washer, #10 Ext. Lock 2

A10098-5 Belleville Spring Washer 2

C 7015-8 C126/C226 7800µF 90V 1

C 8752-5 D117/D217 35A 400V Bridge Rectifier 1

C 9870-4 Screw, 10-32-.38 Pan 2

D 6764-1 Washer, Shoulder 2

D 8438-0 Bracket, Capacitor Mounting 1

FUSE BOARD ASSEMBLY

CPN ITEM QTY

C 5060-6 Fuse Clip, PC Mount #926 4

P10391-4 Fuse Board 1

LED ASSEMBLY

CPN ITEM QTY

C 4342-9 Enable LED, Amber 1

P10068B4 LED Board 1

17

Page 14

Power Base-1 & 460CSL Amplifier Service Manual

Mechanical (Non-Module) Parts

OUTPUT ASSEMBLY (ONE PER CHANNEL)

CPN ITEM QTY

A10100-4 Washer, #6 Flat Zinc 2

A10315-1 Screw, 6-32-.56 Hex Washer Head 12

C 4751-1 NPN Output Device 2

C 5826-0 S100/S200 Thermal Sense LM334Z 1

C 6492-0 PNP Output Device 2

C 7326-9 Solder Lug, #6 Tin 2

C 8573-5 PNP Driver Device TO-3P 2

C 8574-3 NPN Driver Device TO-3P 2

C 8813-5 Q318/Q418 Bias Servo MPSA18/MPS8097 1

C 9491-9 Screw, 6-32-.312 Taptite Pan Ph 13

D 7665-9 Clip, TO-3P Mounting 2

D 7666-7 Bracket, TO-3P Heatsink 2

D 7796-2 Silpad Insulator 1

D 7797-0 Output Thru-Hole Pad Insulator 1

D 8264-0 PTC Thermal Sensor 1

F12019-0 Diode Heatsink Slug 1

F12469-7 Heatsink, Aluminum 2

Output Module (See Module List) 1

BACK PANEL ASSEMBLY

CPN ITEM QTY

A10214-7 Strain Relief (Power Cord) 1

C 2823-0 Dual Binding Post Assembly 1

D 7074-4 Power Cord (3-14 15A USA) 1

M21208J9 Back Panel 1

A10019-8 Nut, #8 32-2 Captive 2

CHASSIS FRONT ASSEMBLY

CPN ITEM QTY

A10031-1 Nut, 8-32 Captive 4

A10090-70806 Screw, 8-32-.375 Mach Ph Oval (Grille) 3

A10090-70808 Screw, 8-32-.5 Mach Ph Oval 4

A10101-5 Washer, Nylon (Grille) 3

A10110-70605 Screw, 6-32-.312 Taptite Ph (Cover) 20

A10173-1 Clip, Grille Filter 3

D 6944-9 Air Filter 1

D 8465J2 End Cap 2

D 8501-5 Cover , Top 1

D 8548-6 Cover, Bottom 1

F10962-3 Front Panel Overlay PB-1 1

F11978J7 Front Panel Overlay 460CSL 1

F12435J7 Grille 1

18

Page 15

Power Base-1 & 460CSL Amplifier Service Manual

Mechanical (Non-Module) Parts

MAIN CHASSIS ASSEMBLY

CPN ITEM QTY

A10086-11008 Screw, 10-32-.5 Mach Rd Ph 4

A10086-70806 Screw, 8-32-.37 Mach Rd Ph 2

A10089-11032 Screw, 10-32-2 Mach Pan Ph 4

A10094-3 Washer, #6 Black Star 3

A10094-6 Washer, #8 Black Star 4

A10094-8 Washer, #10 Tooth Lock 10

A10099-7 Washer, #10 Nylon Shoulder 4

A10100-16 Washer 4

A10102-8 Nut, 10-32 Hex Zinc 6

A10109-10822 Screw, 8-18-1.375 Pan Ph 2

A10110-70812 Screw, 8-32-.75 Taptite Pan Ph 2

A10192-1 Snap Bushing .5 4

C 1811-6 Tie Wrap 4

C 3163-0 Solder Lug #6 505 1

C 6487-0 Power Switch 22A Rocker 2 Pole 1

C 6912-7 Tension Retainer Board Support 2

C 6913-5 Spacer Nut, 1 inch 2

C 6914-3 Spacer Nut, .75 inch 2

C 9491-9 Screw, 6-32-.312 Taptite Pan 4

C 9953-8 Screw, 6-20-.312 Taptite Pan Black 6

D 7340-9 Label, F1 Fuse Replacement 1

D 7600-6 Ground Strap (DBP to Chassis) 1

D 7784-8 Label, Sensitivity Switch 1

D 8003-2 Label, F200 Fuse Replacement 1

D 8069-4 Insulator, Fuse Board 1

F10787J3 Back Panel Plate 1

F10963-1 Transformer Plate 1

M21059J6 Chassis 1

Main Module (See Module List) 1

19

Page 16

Power Base-1 & 460CSL Amplifier Service Manual

Module Information

MODULE HISTORY

Since its introduction in 1986, the PB-1 has gone

through a number of updates and revisions. Over the

course of its history some of these changes have

resulted in upgrading to newer modules. What follows

is a historical breakdown of PB-1 modules. It should

also be noted that the 460CSL was introduced in 1992

and therefor modules obsoleted before that time were

never used in the CSL version.

OUTPUT MODULES:

Q42576-1

Original output module. No longer available.

Q42661-1

Through hole output module. No longer available.

Q42718-9

Output module: 4 resistor small predriver. PB-1 Only.

Last output module for PB-1 for use with TO-220

package driver transistors.

Q42885-6

TO-3P Driver Output module. Not for use in THC units,

not retrofittable into TO-220 driver transistor units.

Q42967-2

THC Output module with TO-3P drivers. Not retrofittable

to any older units. Does not require special main

module for THC ODEP recompensation. Also improved bias stability.

Q43200-7

THC #2 Output Module. Replaces Q42967-2 only.

Electrically identical, but larger screw head plates

prevent shorting which could occur with the first THC

output module.

MAIN MODULES:

Q42552A0

This was the original main board. It offered 2 front end

gain stages and was also used in the PB-1, MT-600/

LX, MT-1200/LX. It did not include ground lift, but did

offer a choice of .775V or 26 dB voltage gain sensitivities. No longer available.

Q42664-5

Service replacement for Q42552A0 for PB-1. No longer

available.

Q42682-7

Main #2. Upgraded board from Q42552A0 for PB-1.

No longer available.

Q42776-7

Universally usable PC board, finished module used in

MT-600/1200, MA-600/1200, and PB-1. Added third

gain stage and ground lift switch. For use in the PB-1

install two level pots (C 7409-3) and remove R187 and

R287. Can replace all older modules. Use this module

to replace this or any previous module. This module

can also be used to replace the Q42953-2 module put

into production later. Note that if this module is being

used to replace an older module, you may have to

slide the ground lift switch to the left (ground lift

position) and clip off the plastic switch protrusion in

order for the module to properly fit in the unit.

Q42953-2

PB-1 main module to replace Q42776-7. This or the

Q42776-7 module may be used with TO-3P driver

transistor output modules, and with or without Through

Hole Chassis (THC) in this amplifier.

Q43060-5

THC main module built on D 7993-5 circuit board. On

this module the boost circuit has been deleted, the

third position (1.4V) is added to the Sensitivity Switch,

and additional fault circuitry has been added to the

module. Although it is possible to modify any older unit

to accept this module, it is recommended that the

Q42776-7 be used to replace main modules in all older

units, and this module be used only as a replacement

for itself.

20

Page 17

Power Base-1 & 460CSL Amplifier Service Manual

Q42576-1 Output Module Parts List (P10137-1 Board)

Q42576-1 Output Module (4 Resistor Original) for PB-1:

CAPACITORS

C01 C 3978-1 .047µF

C02 C 6804-6 .1µF

C03 C 6804-6 .1µF

C04 C 3996-3 .0047µF

C05 C 6807-9 .001µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

C43 C 6806-1 .01uF

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2851-1 1N4004

D06 C 2851-1 1N4004

D07 C 2851-1 1N4004

D08 C 2851-1 1N4004

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

TRANSISTORS

Q17 C 3810-6 NPN MPSA43

Q19 C 3578-9 PNP MPSA93

RESISTORS

R00 A10266-7501 75

R01 A10266-4711 470

R02 C 7778-1 5.6

R03 C 6486-2 .2 5W

R08 C 6486-2 .2 5W

R09 C 7779-9 22

R10 A10266-4711 470

R11 C 1001-4 2.7 1W

R12 C 1001-4 2.7 1W

R13 A10266-7501 75

R14 C 1001-4 2.7 1W

R15 C 6486-2 .2 5W

R20 C 6486-2 .2 5W

R21 C 7778-1 5.6

R22 C 7779-9 22

R23 C 6844-2 250 Pot LS Bias

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS Bias

R27 A10266-3911 390

R28 A10266-1331 13K

R30* A10265-10201* 102*

MISC.

Board P10137-1

Jumpers C 5868-2 0 Ohm Jumper (8)

Clips D 6414-3 Q17/19 Hold Down

J500 J600 C 7057-0 10 Pos. Connector

Note: R30 is 102 Ohms in most units, though in some

cases a different value may be used to match the

installed S100/S200 LM334 (C5826-0) device grade.

This is the standard value and is used with the most

common LM334 grade, green. If the LM334 is marked

with a blue dot, R30 should be a 107 Ohm resistor

(A10265-10701); if it is marked with a yellow dot then

R30 should be a 100 Ohm resistor (A10265-10001).

21

Page 18

Power Base-1 & 460CSL Amplifier Service Manual

Q42661-1 Output Module Parts List (P10137-1 Board)

Q42661-1 Output Module (4 Resistor #2) for PB-1:

CAPACITORS

C01 C 3978-1 .047µF

C02 C 6804-6 .1µF

C03 C 6804-6 .1µF

C04 C 3996-3 .0047µF

C05 C 6807-9 .001µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2851-1 1N4004

D06 C 2851-1 1N4004

D07 C 2851-1 1N4004

D08 C 2851-1 1N4004

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

TRANSISTORS

Q17 C 3810-6 NPN MPSA43

Q19 C 3578-9 PNP MPSA93

RESISTORS

R00 A10266-7501 75

R01 A10266-4711 470

R02 C 7778-1 5.6

R07 D 6600-7 .19 5W

R09 C 7779-9 22

R10 A10266-4711 470

R11 C 1001-4 2.7 1W

R12 C 1001-4 2.7 1W

R13 A10266-7501 75

R14 C 1001-4 2.7 1W

R15 D 6600-7 .19 5W

R16 D 6600-7 .19 5W

R19 D 6600-7 .19 5W

R21 C 7778-1 5.6

R22 C 7779-9 22

R23 C 6844-2 250 Pot LS Bias

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS Bias

R27 A10266-3911 390

R28 A10266-1331 13K

R30* A10265-10201* 102*

MISC.

Board P10137-1

Jumpers C 5868-2 0 Ohm Jumper (4)

Clips D 6414-3 Q17/19 Hold Down

J500 J600 C 7057-0 10 Pin Header

Note: R30 is 102 Ohms in most units, though in some

cases a different value may be used to match the

installed S100/S200 LM334 (C5826-0) device grade.

This is the standard value and is used with the most

common LM334 grade, green. If the LM334 is marked

with a blue dot, R30 should be a 107 Ohm resistor

(A10265-10701); if it is marked with a yellow dot then

R30 should be a 100 Ohm resistor (A10265-10001).

22

Page 19

Power Base-1 & 460CSL Amplifier Service Manual

Q42718-9 Output Module Parts List (P10233-8 Board)

Q42718-9 Output Module (4 Resistor #3) for PB-1:

CAPACITORS

C01 C 3978-1 .047µF

C02 C 3218-2 .22µF

C03 C 3218-2 .22µF

C04 C 8534-7 .0047µF

C05 C 6807-9 .001µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2851-1 1N4004

D06 C 2851-1 1N4004

D07 C 2851-1 1N4004

D08 C 2851-1 1N4004

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 1.3µH Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

TRANSISTORS

Q17 C 3810-6 NPN MPSA43/42

Q19 C 3578-9 PNP MPSA93

RESISTORS

R00 A10266-7501 75

R01 A10266-4711 470

R07 D 6600-7 .19 5W

R10 A10266-4711 470

R11 A10266-2R73 2.7 1W

R12 A10266-1204 12 2W

R13 A10266-7501 75

R14 A10266-1204 12 2W

R15 D 6600-7 .19 5W

R16 D 6600-7 .19 5W

R19 D 6600-7 .19 5W

R23 C 6844-2 250 Pot LS Bias

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS Bias

R27 A10266-3911 390

R28 A10266-1331 13K

R30* A10265-10201* 102*

R31 C 7778-1 5.6 .5W Flame Proof

R32 C 7778-1 5.6 .5W Flame Proof

R33 C 7779-9 22 .5W Flame Proof

R34 C 7779-9 22 .5W Flame Proof

R35 A10266-1204 12 2W

R36 A10266-1204 12 2W

R37 A10266-1204 12 2W

R38 A10266-1204 12 2W

R39 A10266-1204 12 2W

R40 A10266-1204 12 2W

MISC.

Board P10233-8

Jumpers C 5868-2 0 Ohm .25W

Clips D 6414-3 Q17/Q19 Hold Down

J500 J600 C 7057-0 10 Pin Header

*Note: R30 is 102 Ohms in most units, though in some

cases a different value may be used to match the

installed S100/S200 LM334 (C5826-0) device grade.

This is the standard value and is used with the most

common LM334 grade, green. If the LM334 is marked

with a blue dot, R30 should be a 107 Ohm resistor

(A10265-10701); if it is marked with a yellow dot then

R30 should be a 100 Ohm resistor (A10265-10001).

23

Page 20

Power Base-1 & 460CSL Amplifier Service Manual

Q42885-6 Output Module Parts List (P10305-4 Board)

Q42885-6 Output Module (4 Resistor TO-3P Drivers) for

PB-1/460CSL:

CAPACITORS

C01 C 8511-5 .047µF

C02 C 7964-7 .22µF

C03 C 7964-7 .22µF

C04 C 8534-7 .0047µF

C05 C 6807-9 .001µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

C43 C 6806-1 .01uF

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2851-1 1N4004

D06 C 2851-1 1N4004

D07 C 2851-1 1N4004

D08 C 2851-1 1N4004

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

TRANSISTORS

Q17 C 3810-6 NPN MPSA43

Q19 C 3578-9 PNP MPSA93

RESISTORS

R00 A10266-7501 75

R01 A10266-4711 470

R04 D 6600-7 .19 5W

R07 D 6600-7 .19 5W

R10 A10266-4711 470

R11 C 1001-4 2.7 1W

R12 C 3931-0 12 2W

R13 A10266-7501 75

R16 D 6600-7 .19 5W

R19 D 6600-7 .19 5W

R23 C 6844-2 250 Pot LS Bias

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS Bias

R27 A10266-3911 390

R28 A10266-1331 13K

R29 C 6402-9 51 OHM

R30* A10265-10201* 102*

R31 C 7778-1 5.6 flame proof

R32 C 7778-1 5.6 flame proof

R33 C 7779-9 22 flame proof

R34 C 7779-9 22 flame proof

R35 C 3931-0 12 2W

R36 C 3931-0 12 2W

R37 C 3931-0 12 2W

R38 C 3931-0 12 2W

R39 C 3931-0 12 2W

R40 C 3931-0 12 2W

MISC.

Board P10305-4

Jumpers C 5868-2 0 Ohm Jumper (7)

Clips D 6414-3 Q17/19 Hold Down

J500 J600 C 7057-0 10 Pos. Connector

BEAD C 8341-7 Over emitter of Q19

Note: R30 is 102 Ohms in most units, though in some

cases a different value may be used to match the

installed S100/S200 LM334 (C5826-0) device grade.

This is the standard value and is used with the most

common LM334 grade, green. If the LM334 is marked

with a blue dot, R30 should be a 107 Ohm resistor

(A10265-10701); if it is marked with a yellow dot then

R30 should be a 100 Ohm resistor (A10265-10001).

24

Page 21

Power Base-1 & 460CSL Amplifier Service Manual

Q42967-2 Output Module Parts List (P10341-9 Board)

Q42967-2 Output Module for Through Hole Chassis (THC)

PB-1/460CSL units:

CAPACITORS

C01 C 8511-5 .047µF

C02 C 7964-7 .22µF

C03 C 7964-7 .22µF

C04 C 8534-7 .0047µF

C05 C 8534-7 .0047µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

C43 C 6806-1 .01µF

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2851-1 1N4004

D06 C 2851-1 1N4004

D07 C 2851-1 1N4004

D08 C 2851-1 1N4004

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

TRANSISTORS

Q17 C 3810-6 NPN MPSA43

Q19 C 3578-9 PNP MPSA93

RESISTORS

R00 A10266-7501 75

R01 A10266-4711 470

R04 D 6600-7 .19 5W

R07 D 6600-7 .19 5W

R10 A10266-4711 470

R11 A10266-2R73 2.7 1W

R12 A10266-1204 12 2W

R13 A10266-7501 75

R14 A10266-1204 12 2W

R16 D 6600-7 .19 5W

R19 D 6600-7 .19 5W

R23 C 6844-2 250 Pot LS Bias

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS Bias

R27 A10266-3911 390

R28 A10266-1331 13K

R29 A10266-5101 51

R30* A10265-10201* 102*

R31 C 7778-1 5.6 .5W Flame Proof

R32 C 7778-1 5.6 .5W Flame Proof

R33 C 7779-9 22 .5W Flame Proof

R34 C 7779-9 22 .5W Flame Proof

R35 A10266-1204 12 2W

R36 A10266-1204 12 2W

R37 A10266-1204 12 2W

R38 A10266-1204 12 2W

R39 A10266-1204 12 2W

R40 A10266-1204 12 2W

MISC.

Board P10341-9

Jumpers C 5868-2 0 Ohm (Qty 7)

Clips D 6414-3 Q17/Q19 Hold Down

J500 J600 C 7057-0 10 Pin Header

*Note: R30 is 102 Ohms in most units, though in some

cases a different value may be used to match the

installed S100/S200 LM334 (C5826-0) device grade.

This is the standard value and is used with the most

common LM334 grade, green. If the LM334 is marked

with a blue dot, R30 should be a 107 Ohm resistor

(A10265-10701); if it is marked with a yellow dot then

R30 should be a 100 Ohm resistor (A10265-10001).

25

Page 22

Power Base-1 & 460CSL Amplifier Service Manual

Q43200-7 Output Module Parts List (P10397-1 Board)

Q43200-7 Output Module (THC #2) for PB-1/460CSL Units:

CAPACITORS

C01 C 8511-5 .047µF

C02 C 7964-7 .22µF

C03 C 7964-7 .22µF

C04 C 8534-7 .0047µF

C05 C 8534-7 .0047µF

C06 C 6806-1 .01µF

C07 C 6807-9 .001µF

C08 C 6810-3 180pF

C09 C 6809-5 220pF

C43 C 6806-1 .01µF

DIODES

D01 C 2851-1 1N4004

D02 C 2851-1 1N4004

D03 C 2851-1 1N4004

D04 C 2851-1 1N4004

D05 C 2851-1 1N4004

D06 C 2851-1 1N4004

D07 C 2851-1 1N4004

D08 C 2851-1 1N4004

D09 C 2851-1 1N4004

D10 C 2851-1 1N4004

D11 C 2851-1 1N4004

D12 C 2851-1 1N4004

INDUCTORS

L00 C 6592-6 Output Coil

L01 C 3510-2 470µH

L02 C 3510-2 470µH

TRANSISTORS

Q17 C 3810-6 NPN MPSA43

Q19 C 3578-9 PNP MPSA93

RESISTORS

R00 A10266-7501 75

R01 A10266-4711 470

R04 D 6600-7 .19 5W

R07 D 6600-7 .19 5W

R10 A10266-4711 470

R11 A10266-2R73 2.7 1W

R12 A10266-1204 12 2W

R13 A10266-7501 75

R14 A10266-1204 12 2W

R16 D 6600-7 .19 5W

R19 D 6600-7 .19 5W

R23 C 6844-2 250 Pot LS

R24 A10266-1331 13K

R25 A10266-2221 2.2K

R26 C 6844-2 250 Pot HS

R27 A10266-3911 390

R28 A10266-1331 13K

R29 A10266-5101 51

R30* A10265-10201* 102*

R31 C 7778-1 5.6 .5W Flame Proof

R32 C 7778-1 5.6 .5W Flame Proof

R33 C 7779-9 22 .5W Flame Proof

R34 C 7779-9 22 .5W Flame Proof

R35 A10266-1204 12 2W

R36 A10266-1204 12 2W

R37 A10266-1204 12 2W

R38 A10266-1204 12 2W

R39 A10266-1204 12 2W

R40 A10266-1204 12 2W

MISC.

Board P10397-1

Jumpers C 5868-2 0 Ohm (Qty 7)

Clips D 6414-3 Q17/Q19 Hold Down

J500 J600 C 7057-0 10 Pin Header

26

*Note: R30 is 102 Ohms in most units, though in some

cases a different value may be used to match the

installed S100/S200 LM334 (C5826-0) device grade.

This is the standard value and is used with the most

common LM334 grade, green. If the LM334 is marked

with a blue dot, R30 should be a 107 Ohm resistor

(A10265-10701); if it is marked with a yellow dot then

R30 should be a 100 Ohm resistor (A10265-10001).

Page 23

Power Base-1 & 460CSL Amplifier Service Manual

Q42552A0 Main Module Parts List (D 6304B2 Board)

Q42552A0 Main Module (Original) for PB-1:

CAPACITORS

C1 C 4303-1 1000uF

C2 C 3913-8 470uF

C3 C 4303-1 1000uF

C4 C 6802-0 .47uF

C100 C200 C 5053-1 18uF

C101 C201 C 2821-4 10pF

C103 C203 C 6805-3 .022uF

C104 C204 C 6805-3 .022uF

C105 C205 C 6950-7 82pF

C106 C206 C 6950-7 82pF

C108 C208 C 6812-9 47pF

C112 C212 C 6803-8 .12uF

C113 C213 C 6802-0 .47uF

C114 C214 C 3729-8 100uF 16V

C115 C215 C 3729-8 100uF 16V

C116 C216 C 6802-0 .47uF

C117 C217 C 6803-8 .12uF

C118 C218 C 6812-9 47pF

C122 C222 C 6811-1 100pF

C124 C224 C 6809-5 220pF

C125 C225 C 3729-8 100uF 16V

C127 C227 C 3729-8 100uF 16V

C133 C233 C 6814-5 12pF

C134 C234 C 6805-3 .022uF

C135 C235 C 6805-3 .022uF

C136 C236 C 6808-7 470pF

C137 C237 C 6808-7 470pF

C138 C238 C 6814-5 12pF

C139 C239 C 6814-5 12pF

C140 C240 C 6812-9 47pF

C141 C241 C 6812-9 47pF

C142 C242 C 5162-0 3-12pF Trim

D112 D212 C 3181-2 1N4148

D113 D213 C 3181-2 1N4148

D114 D214 C 3181-2 1N4148

D115 D215 C 3181-2 1N4148

D120 D220 C 3181-2 1N4148

D121 D221 C 3181-2 1N4148

D122 D222 C 3181-2 1N4148

D123 D223 C 3181-2 1N4148

NETWORK RESISTORS

N100 N200 D 4669-4 Balanced Input Trim

N101 N201 D 6081-0 Resistor Network-B

N102 N202 D 6082-8 Resistor Network-C

TRANSISTORS

Q100 Q200 D 2961-7 SEL 2N3859A

Q101 Q201 C 3578-9 MPSA93

Q102 Q202 C 3810-6 MPSA43/A42

Q103 Q203 C 3786-8 PN4250A

Q104 Q204 C 3625-8 2N4125

Q105 Q205 C 3578-9 MPSA93

Q106 Q206 C 3625-8 2N4125

Q107 Q207 C 3786-8 PN4250A

Q108 Q208 D 2961-7 SEL 2N3859A

Q109 Q209 D 2961-7 SEL 2N3859A

Q110 Q210 C 3810-6 MPSA43/A42

Q111 Q211 D 2961-7 SEL 2N3859A

Q112 Q212 C 3625-8 2N4125

Q113 Q213 C 3625-8 2N4125

Q115 Q215 D 2962-5 MPS8097

Q116 Q216 C 3786-8 PN4250A

Q117 Q217 D 2961-7 SEL 2N3859A

Q118 Q218 D 2961-7 SEL 2N3859A

Q119 Q219 C 3625-8 2N4125

Q120 Q220 C 3625-8 2N4125

DIODES

D1 C 2851-1 1N4004

D2 C 2851-1 1N4004

D3 C 2851-1 1N4004

D4 C 2851-1 1N4004

D5 C 2851-1 1N4004

D6 C 2851-1 1N4004

D7 C 2851-1 1N4004

D104 D204 C 2851-1 1N4004

D105 D205 C 2851-1 1N4004

D106 D206 C 2851-1 1N4004

D107 D207 C 2851-1 1N4004

D108 D208 C 3181-2 1N4148

D109 D209 C 3181-2 1N4148

D110 D210 C 3181-2 1N4148

D111 D211 C 3181-2 1N4148

RESISTORS

R1 A10265-10031 100K 1%

R5 A10266-3321 3.3K

R100 R200 C 6893-9 5K POT

R101 R201 A10265-49911 4.99K

R102 R202 A10266-1021 1K

R103 R203 A10265-10031 100K 1%

R104 R204 A10266-2721 2.7K

R105 R205 A10266-2721 2.7K

R106 R206 A10266-1231 12K

R107 R207 A10266-4731 47K

R108 R208 A10266-1021 1K

R109 R209 A10266-8201 82 OHM

R110 R210 A10266-4731 47K

R112 R212 A10266-5131 51K

R113 R213 A10266-4721 4.7K

27

Page 24

Power Base-1 & 460CSL Amplifier Service Manual

Q42552A0 Main Module Parts List (D 6304B2 Board)

R114 R214 A10266-4721 4.7K

R115 R215 A10266-5141 510K

R116 R216 A10266-3351 3.3M

R118 R218 A10266-2711 270 OHM

R119 R219 A10266-3011 300 OHM

R120 R220 A10266-2711 270 OHM

R121 R221 C 5062-2 100K TRIMMER

R122 R222 A10266-2741 270K

R123 R223 A10266-1831 18K

R124 R224 A10266-6821 6.8K

R125 R225 C 7782-3 100 OHM

R126 R226 C 7782-3 100 OHM

R127 R227 A10266-6821 6.8K

R128 R228 A10266-1031 10K

R129 R229 A10266-1041 100K

R130 R230 A10266-1041 100K

R131 R231 A10266-1031 10K

R132 R232 C 5062-2 100K TRIMMER

R133 R233 A10266-2741 270K

R134 R234 A10266-1831 18K

R135 R235 C 7782-3 100 OHM

R136 R236 A10266-6821 6.8K

R137 R237 C 7782-3 100 OHM

R138 R238 A10266-6821 6.8K

R139 R239 A10266-1021 1K

R140 R240 A10266-8201 82 OHM

R141 R241 A10266-1541 150K

R142 R242 A10266-1541 150K

R146 R246 A10266-1031 10K

R147 R247 C 7781-5 200 OHM

R148 R248 A10266-2721 2.7K

R149 R249 C 7781-5 200 OHM

R150 R250 A10266-2721 2.7K

R151 R251 A10266-1031 10K

R152 R252 A10266-1231 12K

R154 R254 A10266-1011 100 OHM

R156 R256 A10266-1321 1.3K

R157 R257 A10266-1321 1.3K

R158 R258 A10266-9121 9.1K

R159 R259 A10266-1031 10K

R161 R261 A10266-4701 47 OHM

R162 R262 A10266-4701 47 OHM

R165 R265 A10265-53611 5.36K 1%

R146 R246 A10265-53611 5.36K 1%

R167 R267 A10266-1021 1K

R168 R268 A10265-95301 953 OHM

R170 R270 A10266-1021 1K

R171 R271 A10265-95301 953 OHM

SWITCHES

S3 C 6841-8 4PDT

S100 C 6781-6 6P3T

IC’S

U1 C 5095-2 MC7815

U2 C 5096-0 MC7915

U100 U200 C 6500-0 UPA77 PNP

U103 U203 C 6910-1 UPA76 NPN

U104 U204 C 6900-2 MC34084P

MISC.

Board D 6304A4 or D 6304B2

J9 C 6871-5 6-Cond Snap Mate

J100 J200 C 6777-4 PHONE JACK

J500 J800 D 6619-7 10" RIBBON ASSY

J600 J700 D 6620-5 6" RIBBON ASSY

MOUNTS U1, U2:

(2) C 1889-2 6-32 NUT

(2) C 2176-3 6-32 X .5 SCREW

(2) C 5341-0 HEATSINK

(2) C 5594-4 STAR WASHER

MOUNTS U104, U204:

(2) C 3450-1 14 Pin Socket

COVERS FOR J100, J200:

(2) C 6778-2 Cover, Phone Jack

Additional Parts

(1) C 4508-5 16 PIN SOCKET

(1) C 5061-4 1N3070 DIODE

(1) C 6851-7 5-Pos Header

(1) C 7077-8 3-Cond Wire Retain

C 6899-6 Wire Posts

28

Page 25

Power Base-1 & 460CSL Amplifier Service Manual

Q42664-5 Main Module Parts List (D 6910-0 Board)

Q42664-5 Main Module (Service Replacement For Original) for PB-1:

CAPACITORS

C1 C 4303-1 1000uF

C2 C 3913-8 470uF

C3 C 4303-1 1000uF

C4 C 6802-0 .47uF

C100 C200 C 5311-3 22uF

C101 C201 C 2821-4 10pF

C103 C203 C 6805-3 .022uF

C104 C204 C 6805-3 .022uF

C105 C205 C 6950-7 82pF

C106 C206 C 6950-7 82pF

C108 C208 C 6812-9 47pF

C112 C212 C 6803-8 .12uF

C113 C213 C 6802-0 .47uF

C114 C214 C 3729-8 100uF 16V

C115 C215 C 3729-8 100uF 16V

C116 C216 C 6802-0 .47uF

C117 C217 C 6803-8 .12uF

C118 C218 C 6812-9 47pF

C122 C222 C 6811-1 100pF

C123 C223 C 6811-1 100pF

C124 C224 C 6809-5 220pF

C125 C225 C 3729-8 100uF 16V

C127 C227 C 3729-8 100uF 16V

C128 C228 C 6803-8 .12uF

C133 C233 C 6814-5 12pF

C134 C234 C 6805-3 .022uF

C135 C235 C 6805-3 .022uF

C136 C236 C 6808-7 470pF

C137 C237 C 6808-7 470pF

C138 C238 C 6814-5 12pF

C139 C239 C 6814-5 12pF

C140 C240 C 6812-9 47pF

C141 C241 C 6812-9 47pF

C242 C 5162-0 3-12pF Trim

D109 D209 C 3181-2 1N4148

D110 D210 C 3181-2 1N4148

D111 D211 C 5061-4 1N3070

D112 D212 C 3181-2 1N4148

D113 D213 C 3181-2 1N4148

D114 D214 C 3181-2 1N4148

D115 D215 C 3181-2 1N4148

D120 D220 C 3181-2 1N4148

D121 D221 C 3181-2 1N4148

D122 D222 C 3181-2 1N4148

D123 D223 C 5061-4 1N3070

NETWORK RESISTORS

N100 N200 D 4669-4 Balanced Input Trim

N101 N201 D 6081-0 Resistor Network-B

N102 N202 D 6082-8 Resistor Network-C

TRANSISTORS

Q100 Q200 D 2961-7 SEL 2N3859A

Q101 Q201 C 3578-9 MPSA93

Q102 Q202 C 3810-6 MPSA43/A42

Q103 Q203 C 3786-8 PN4250A

Q104 Q204 C 3625-8 2N4125

Q105 Q205 C 3578-9 MPSA93

Q106 Q206 C 3625-8 2N4125

Q107 Q207 C 3786-8 PN4250A

Q108 Q208 D 2961-7 SEL 2N3859A

Q109 Q209 D 2961-7 SEL 2N3859A

Q110 Q210 C 3810-6 MPSA43/A42

Q111 Q211 D 2961-7 SEL 2N3859A

Q112 Q212 C 3625-8 2N4125

Q113 Q213 C 3625-8 2N4125

Q115 Q215 D 2962-5 MPS8097

Q116 Q216 C 3786-8 PN4250A

Q117 Q217 D 2961-7 SEL 2N3859A

Q118 Q218 D 2961-7 SEL 2N3859A

Q119 Q219 C 3625-8 2N4125

Q120 Q220 C 3625-8 2N4125

DIODES

D1 C 2851-1 1N4004

D2 C 2851-1 1N4004

D3 C 2851-1 1N4004

D4 C 2851-1 1N4004

D5 C 2851-1 1N4004

D6 C 2851-1 1N4004

D7 C 2851-1 1N4004

D104 D204 C 2851-1 1N4004

D105 D205 C 2851-1 1N4004

D106 D206 C 2851-1 1N4004

D107 D207 C 2851-1 1N4004

D108 D208 C 3181-2 1N4148

RESISTORS

R1 A10265-10031 100K 1%

R5 A10266-3323 3.3K 1W

R100 R200 C 6893-9 5K POT

R101 R201 A10265-49911 4.99K

R102 R202 A10266-1021 1K

R103 R203 A10265-10031 100K 1%

R104 R204 A10266-2721 2.7K

R105 R205 A10266-2721 2.7K

R106 R206 A10266-1231 12K

R107 R207 A10266-4731 47K

R108 R208 A10266-1021 1K

R109 R209 A10266-8201 82 OHM

29

Page 26

Power Base-1 & 460CSL Amplifier Service Manual

Q42664-5 Main Module Parts List (D 6910-0 Board)

R110 R210 A10266-4731 47K

R111 R211 A10266-1231 12K

R112 R212 A10266-5131 51K

R113 R213 A10266-4721 4.7K

R114 R214 A10266-4721 4.7K

R115 R215 A10266-5141 510K

R116 R216 A10266-3351 3.3M

R117 R217 A10266-4731 47K

R118 R218 A10266-2711 270 OHM

R119 R219 A10266-3011 300 OHM

R120 R220 A10266-2711 270 OHM

R121 R221 C 5062-2 100K TRIMMER

R122 R222 A10266-2741 270K

R123 R223 A10266-1831 18K

R124 R224 A10266-6821 6.8K

R125 R225 C 7782-3 100 OHM

R126 R226 C 7782-3 100 OHM

R127 R227 A10266-6821 6.8K

R128 R228 A10266-1031 10K

R129 R229 A10266-1041 100K

R130 R230 A10266-1041 100K

R131 R231 A10266-1031 10K

R132 R232 C 5062-2 100K TRIMMER

R133 R233 A10266-2741 270K

R134 R234 A10266-1831 18K

R135 R235 C 7782-3 100 OHM

R136 R236 A10266-6821 6.8K

R137 R237 C 7782-3 100 OHM

R138 R238 A10266-6821 6.8K

R139 R239 A10266-1021 1K

R140 R240 A10266-8201 82 OHM

R141 R241 A10266-1541 150K

R142 R242 A10266-1541 150K

R146 R246 A10266-1031 10K

R147 R247 C 7781-5 200 OHM

R148 R248 A10266-2721 2.7K

R149 R249 C 7781-5 200 OHM

R150 R250 A10266-2721 2.7K

R151 R251 A10266-1031 10K

R152 R252 A10266-1231 12K

R154 R254 A10266-1011 100 OHM

R156 R256 A10266-1321 1.3K

R157 R257 A10266-1321 1.3K

R158 R258 A10266-9121 9.1K

R159 R259 A10266-1031 10K

R161 R261 A10266-4701 47 OHM

R162 R262 A10266-4701 47 OHM

R165 R265 A10265-53611 5.36K 1%

R146 R246 A10265-53611 5.36K 1%

R167 R267 A10266-1021 1K

R168 R268 A10265-95301 953 OHM

R170 R270 A10266-1021 1K

R171 R271 A10265-95301 953 OHM

SWITCHES

S3 C 6841-8 4PDT

S100 C 6781-6 6P3T

IC’S

U1 C 5095-2 MC7815

U2 C 5096-0 MC7915

U100 U200 C 6911-9 UPA75 PNP

U103 U203 C 6910-1 UPA76 NPN

U104 U204 C 6900-2 MC34084P

MISC.

BOARD D 6304B2

J1 C 7593-4 5 PIN HEADER

J2 C 4508-5 16 PIN SOCKET

J9 C 7527-2 6 PIN HEADER

J10 C 7592-6 4 PIN HEADER

J11 C 7077-8 WIRE RET AINER

J100 J200 C 6777-4 PHONE JACK

J500 J800 D 6619-7 10" RIBBON ASSY

J600 J700 D 6620-5 6" RIBBON ASSY

MOUNTS U1, U2:

(2) C 1889-2 6-32 NUT

(2) C 2176-3 6-32 X .5 SCREW

(2) C 5341-0 HEATSINK

(2) C 5594-4 STAR WASHER

MOUNTS U104, U204:

(2) C 3450-1 14 Pin Socket

COVERS FOR J100, J200:

(2) C 6778-2 Cover, Phone Jack

Additional Parts

(1) C 7077-8 3-Cond Wire Retain

30

Page 27

Power Base-1 & 460CSL Amplifier Service Manual

Q42682-7 Main Module Parts List (D 6910-0 Board)

Q42682-7 Main Module (#2) for PB-1:

CAPACITORS

C1 C 4303-1 1000uF

C2 C 3913-8 470uF

C3 C 4303-1 1000uF

C4 C 6802-0 .47uF

C5 OPEN

C6 OPEN

C100 C200 C 5311-3 22uF

C101 C201 C 2820-6 5pF

C103 C203 C 6805-3 .022uF

C104 C204 C 6805-3 .022uF

C105 C205 C 6812-9 47pF

C106 C206 C 6812-9 47pF

C108 C208 C 6814-5 12pF

C112 C212 C 6803-8 .12uF

C113 C213 C 6802-0 .47uF

C114 C214 C 3729-8 100uF 16V

C115 C215 C 3729-8 100uF 16V

C116 C216 C 6802-0 .47uF

C117 C217 C 6803-8 .12uF

C118 C218 C 6814-5 12pF

C122 C222 C 6811-1 100pF

C123 C223 C 6812-9 47pF

C124 C224 C 6812-9 47pF

C125 C225 C 3729-8 100uF 16V

C127 C227 C 3729-8 100uF 16V

C128 C228 C 7706-2 .1uF

C129 OPEN

C130 C 6814-5 12pF

C133 C233 C 6814-5 12pF

C134 C234 C 6805-3 .022uF

C135 C235 C 6805-3 .022uF

C136 C236 C 6808-7 470pF

C137 C237 C 6808-7 470pF

C138 C238 C 6814-5 12pF

C139 C239 C 6814-5 12pF

C140 C240 C 6812-9 47pF

C141 C241 C 6812-9 47pF

C242 C 5162-0 3-12pF Trim

C144 C244 C 5362-6 2.2uF

C145 C245 C 6814-5 12pF

C146 C246 C 6809-5 220pF

C147 C247 C 6806-1 .01uF

C148 C248 C 6810-3 180pF

C149 C249 C 6808-7 470pF

C150 C250 OPEN

C151 C251 OPEN

C152 C252 C 6809-5 220pF

C153 C253 C 5362-6 2.2uF

DIODES

D1 C 2851-1 1N4004

D2 C 2851-1 1N4004

D3 C 2851-1 1N4004

D4 C 2851-1 1N4004

D5 C 2851-1 1N4004

D6 C 2851-1 1N4004

D7 C 2851-1 1N4004

D104 D204 C 2851-1 1N4004

D105 D205 C 2851-1 1N4004

D106 D206 C 2851-1 1N4004

D107 D207 C 2851-1 1N4004

D108 D208 C 3181-2 1N4148

D109 D209 C 3181-2 1N4148

D110 D210 C 3181-2 1N4148

D111 D211 C 5061-4 1N3070

D112 D212 C 3181-2 1N4148

D113 D213 C 3181-2 1N4148

D114 D214 C 3181-2 1N4148

D115 D215 C 3181-2 1N4148

D120 D220 C 3181-2 1N4148

D121 D221 C 3181-2 1N4148

D122 D222 C 3181-2 1N4148

D123 D223 C 5061-4 1N3070

NETWORK RESISTORS

N100 N200 D 4669-4 Balanced Input Trim

N101 N201 D 6081-0 Resistor Network-B

N102 N202 D 6082-8 Resistor Network-C

TRANSISTORS

Q100 Q200 D 2961-7 SEL 2N3859A

Q101 Q201 C 3578-9 MPSA93

Q102 Q202 C 3810-6 MPSA43/A42

Q103 Q203 C 3786-8 PN4250A

Q104 Q204 C 3625-8 2N4125

Q105 Q205 C 3578-9 MPSA93

Q106 Q206 C 3625-8 2N4125

Q107 Q207 C 3786-8 PN4250A

Q108 Q208 D 2961-7 SEL 2N3859A

Q109 Q209 D 2961-7 SEL 2N3859A

Q110 Q210 C 3810-6 MPSA43/A42

Q111 Q211 D 2961-7 SEL 2N3859A

Q112 Q212 C 3625-8 2N4125

Q113 Q213 C 3625-8 2N4125

Q115 Q215 D 2962-5 MPS8097

Q116 Q216 C 3786-8 PN4250A

Q117 Q217 D 2961-7 SEL 2N3859A

Q118 Q218 D 2961-7 SEL 2N3859A

Q119 Q219 C 3625-8 2N4125

Q120 Q220 C 3625-8 2N4125

Q121 Q221 C 3786-8 PN4250A

31

Page 28

Power Base-1 & 460CSL Amplifier Service Manual

Q42682-7 Main Module Parts List (D 6910-0 Board)

RESISTORS

R1 A10265-53621 53.6K 1%

R2 OPEN

R3 OPEN

R4 A10265-46421 46.4K 1%

R5 A10266-3323 3.3K 1W

R10 OPEN

R100 R200 C 7409-3 5K POT

R101 R201 A10265-49911 4.99K

R102 R202 A10266-1021 1K

R103 R203 A10265-10031 100K 1%

R104 R204 A10266-2721 2.7K

R105 R205 A10266-2721 2.7K

R106 R206 A10266-1231 12K

R107 R207 A10266-6831 68K

R108 R208 A10266-1021 1K

R109 R209 A10266-8201 82 OHM

R110 R210 A10266-6831 68K

R111 R211 A10266-1231 12K

R112 R212 A10266-5131 51K

R113 R213 A10266-4721 4.7K

R114 R214 A10266-4721 4.7K

R115 R215 A10266-5141 510K

R116 R216 A10266-3351 3.3M

R117 R217 A10266-4731 47K

R118 R218 A10266-2711 270 OHM

R119 R219 A10266-3011 300 OHM

R120 R220 A10266-2711 270 OHM

R121 R221 C 5062-2 100K TRIMMER

R122 R222 A10266-2741 270K

R123 R223 A10266-1831 18K

R124 R224 A10266-6821 6.8K

R125 R225 C 7782-3 100 OHM

R126 R226 C 7782-3 100 OHM

R127 R227 A10266-6821 6.8K

R128 R228 A10266-1031 10K

R129 R229 A10266-1041 100K

R130 R230 A10266-1041 100K

R131 R231 A10266-1031 10K

R132 R232 C 5062-2 100K TRIMMER

R133 R233 A10266-2741 270K

R134 R234 A10266-1831 18K

R135 R235 C 7782-3 100 OHM

R136 R236 A10266-6821 6.8K

R137 R237 C 7782-3 100 OHM

R138 R238 A10266-6821 6.8K

R139 R239 A10266-1021 1K

R140 R240 A10266-8201 82 OHM

R141 R241 A10266-1541 150K

R142 R242 A10266-1541 150K

R146 R246 A10266-1031 10K

R147 R247 C 7781-5 200 OHM

R148 R248 A10266-2721 2.7K

R149 R249 C 7781-5 200 OHM

R150 R250 A10266-2721 2.7K

R151 R251 A10266-1031 10K

R152 R252 A10266-1231 12K

R153 R253 C 5869-2 ZERO OHM

R155 R255 OPEN

R156 R256 A10266-1321 1.3K

R157 R257 A10266-1321 1.3K

R158 R258 A10266-9121 9.1K

R159 R259 A10266-1031 10K

R161 R261 A10266-4701 47 OHM

R162 R262 A10266-4701 47 OHM

R167 R267 A10266-1021 1K

R168 R268 A10265-95301 953 OHM

R169 R269 OPEN

R170 R270 A10266-1021 1K

R171 R271 A10265-95301 953 OHM

R172 R272 OPEN

R174 R274 A10265-38311 3.83K 1%

R175 R275 A10265-24311 2.43K 1%

R176 R276 A10266-1041 100K

R177 R277 C 5062-2 TRIM POT

R178 R278 A10266-1231 12K

R179 R279 A10266-4731 47K

R180 R280 A10266-4711 470 OHM

R181 R281 A10266-4721 4.7K

R182 R282 A10266-2201 22 OHM

R183 R283 A10266-2051 2M

SWITCHES

S3 C 7363-2 4PDT

S100 C 6781-6 6P3T

IC’S

U1 C 5095-2 MC7815

U2 C 5096-0 MC7915

U100 U200 C 6911-9 UPA75 PNP

U103 U203 C 6910-1 UPA76 NPN

U104 U204 C 6900-2 MC34084P

INTERCONNECTS

J1 OPEN

J2 C 4508-5 16 PIN SOCKET

J9 C 7527-2 6 PIN HEADER

J10 C 7592-6 4 PIN HEADER

J11 C 7526-4 3 PIN HEADER

J100 J200 C 6777-4 PHONE JACK

J500 J800 D 6619-7 10" RIBBON ASSY

J600 J700 D 6620-5 6" RIBBON ASSY

32

Page 29

Q42682-7 Main Module Parts List (D 6910-0 Board)