Page 1

®

User's Manual

©2005 Crown Broadcast, a division of International Radio and Electronics, Inc.

25166 Leer Drive, Elkhart, Indiana, 46514-5425 U.S.A.

FM1000A

RF Amplifier Package

(574) 262-8900

i

Page 2

Revision Control

Revision Print Date

Initial Release (Rev. 0) 900413-1 November 1998

Revision 1April 2002

Important Notices

©2005, Crown Broadcast, a division of International Radio and Electronics, Inc.

All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any

form by any means without the written permission of Crown International, Inc.

Printed in U.S.A.

Crown attempts to provide information that is accurate, complete, and useful.

Should you find inadequacies in the text, please send your comments to the

following address:

ii

International Radio and Electronics

25166 Leer Drive, P.O. Box 2000

Elkhart, Indiana, 46515-2000 U.S.A.

Page 3

ContentsContents

Contents

ContentsContents

Section 1—Getting Acquainted

1.1 Your Amplifier Package .......................................................................................1–2

1.2 Amplifier Package Specifications.........................................................................1–3

1.3 Safety Considerations..........................................................................................1–4

1.3.1 Dangers ............................................................................................................1–4

1.3.2 Warnings .......................................................................................................... 1–4

1.3.3 Cautions ...........................................................................................................1–4

Section 2—Installation

2.1 Operating Environment ..................................................................................... 2–2

2.2 Tools Required..................................................................................................2–2

2.3 Unpacking.........................................................................................................2–2

2.4 Preinstallation...................................................................................................2–3

2.4.1 Power Amplifier Modules .............................................................................2–3

2.4.2 Hubble Twist Lock® Connector Wiring ........................................................2–4

2.5 Installation ........................................................................................................2–5

2.6 Remote I/O Connection.....................................................................................2–6

Section 3—Operation

3.1 Initial Power-up Procedures..............................................................................3–2

3.2 Power Switches ................................................................................................3–4

3.2.1 AC Input Circuit Breaker ...............................................................................3–4

3.2.2 DC Power Switch..........................................................................................3–5

3.2.3 Interlock Switch............................................................................................3–5

3.3 Digital Multimeter .............................................................................................3–6

3.4 Fault Indicators ................................................................................................. 3–7

3.5 Fuse Indicators .................................................................................................3–8

Section 4—Principles of Operation

4.1 PA1000 Power Amplifier...................................................................................4–2

4.1.1 Power Modules ............................................................................................4–2

4.1.2 Power Combiner Board ................................................................................4–2

4.1.3 Backplane Assembly.....................................................................................4–3

4.1.3.1 Backplane DC Interconnect Board ........................................................4–3

4.1.3.2 Input Divider Board...............................................................................4–3

4.1.3.3 Output Combiner Board........................................................................4–3

4.1.4 Output Filter & Reflectometer.......................................................................4–3

4.1.5 Metering and Control Board .........................................................................4–4

4.1.6 DC Fuse and Power Distribution Board ........................................................4–4

4.1.7 Cooling Fans.................................................................................................4–4

iii

Page 4

4.2 PS1000 Power Supply ......................................................................................4–4

4.2.1 AC Input Board .............................................................................................4–5

4.2.2 PFC (Power Factor Correcting) Switching Board ..........................................4–5

4.2.3 DC Output Board ..........................................................................................4–6

4.2.4 Cooling Fans.................................................................................................4–6

Section 5—Troubleshooting

5.1 Troubleshooting Flow Chart Analysis ................................................................5–2

5.2 Digital Multimeter Parameters ..........................................................................5–3

5.2.1 In Ref (Input Drive Reference)......................................................................5–3

5.2.2 SWR (Standing Wave Ratio) ........................................................................5–3

5.2.3 ALC (Automatic Level Control) .....................................................................5–3

5.2.4 Power Out ....................................................................................................5–3

5.2.5 PA Temp.......................................................................................................5–4

5.2.6 PA Voltage ....................................................................................................5–4

5.2.7 Tot Current ...................................................................................................5–4

5.2.8 PA1–8...........................................................................................................5–4

5.3 Fault Indicators .................................................................................................5–5

5.3.1 Antenna ........................................................................................................5–5

5.3.2 RF Drive........................................................................................................5–5

5.3.3 PA Temp.......................................................................................................5–5

5.3.3.1 Potential Causes for Non-functioning Cooling Fans..............................5–5

5.3.4 PA DC...........................................................................................................5–6

5.3.5 Multiple Indicators........................................................................................5–6

Section 6—Reference Drawings

6.1 Views ................................................................................................................6–2

6.2 Diagrams and Schematics ................................................................................6–3

Section 7—Service and Support

7.1 Service..............................................................................................................7–2

7.2 24–Hour Support..............................................................................................7–2

7.3 Spare Parts .......................................................................................................7–2

Glossary

Index

iv

Page 5

I

INFORMATION

Section 1—Getting Acquainted

This section provides a general description of the FM1000A

power amplifier system and introduces you to safety conventions

used within this document. Review this material before install-

ing or operating the amplifier and power supply.

Getting Acquainted

1–1

Page 6

I

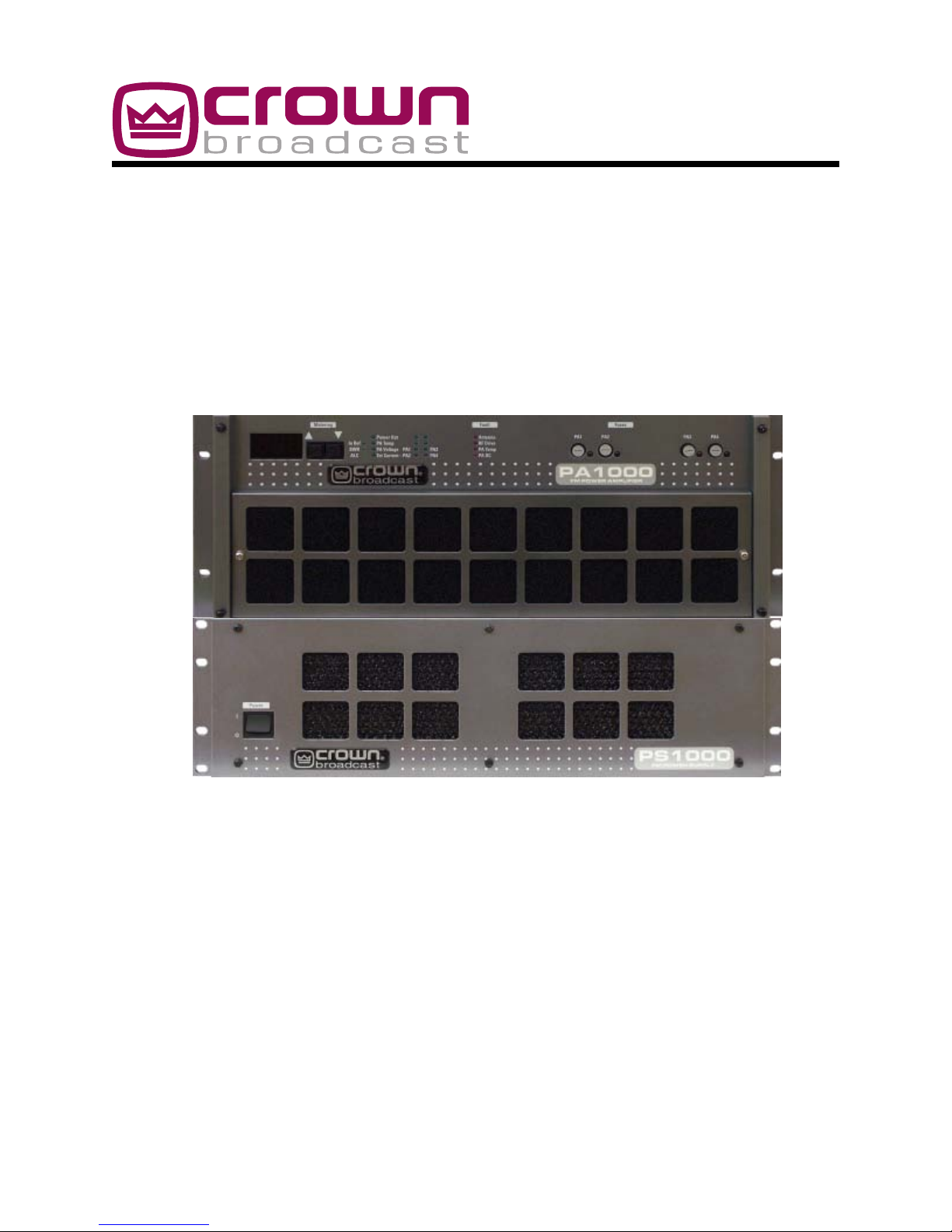

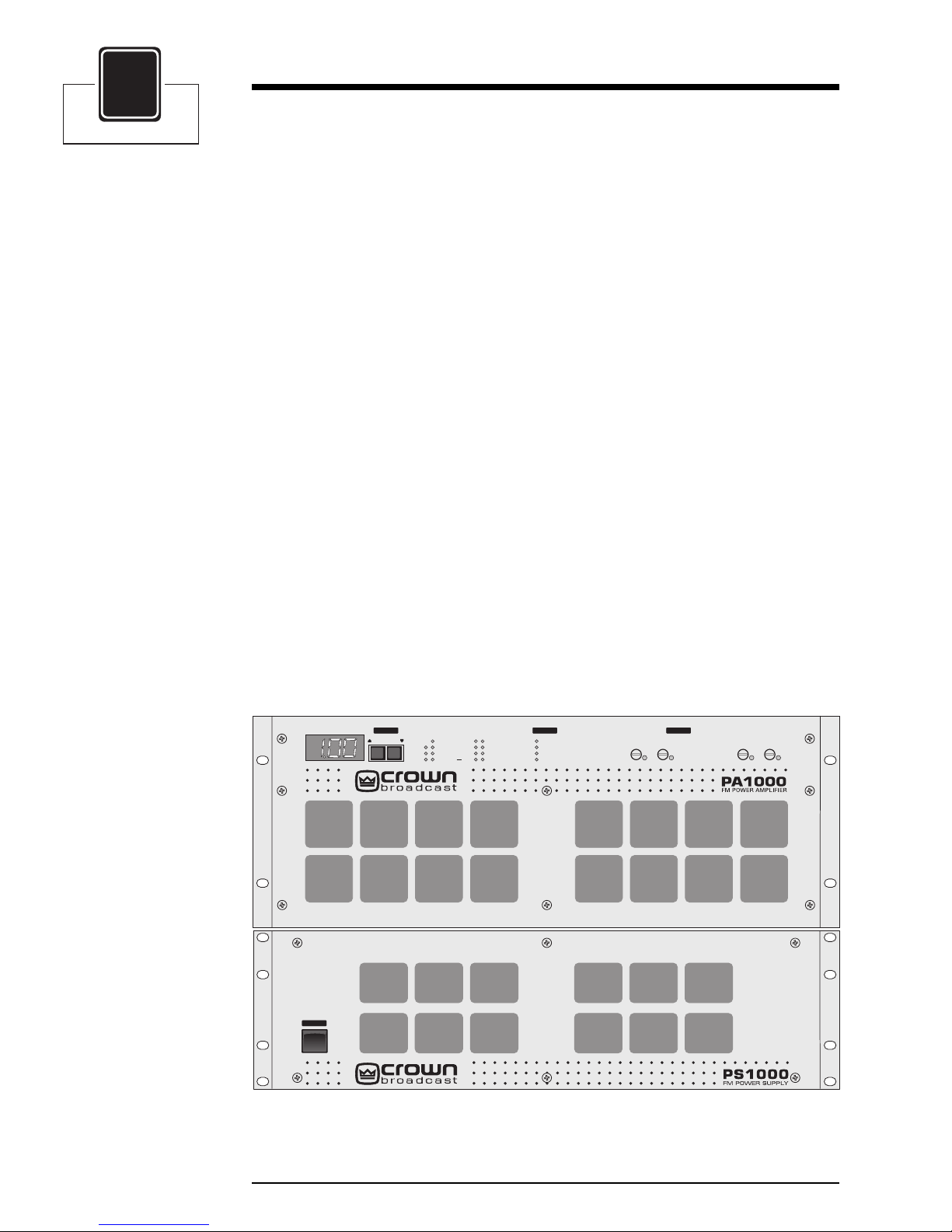

1.1 Your Amplifier Package

The FM1000A is a highly efficient amplifier package designed to set a new standard

in FM transmitter design offering modularity, ease of use, and long-term reliability. The FM1000A package includes a PA1000 amplifier, PS1000 power supply, and

an FM1K accessory pack.

The PA1000 broadband amplifier requires no tuning and typically provides 80% RF

efficiency across the band. The PS1000 power supply is power factor corrected and

90% efficient. Modern MOSFET technology ensures high AC to RF efficiency

(better than 70% overall) and long-term reliability. The unmatched efficiency of

this power amplifier significantly improves your bottom line by providing cooler

operation and lower power costs.

These modular units are uniquely designed to be lightweight and compact for

convenient shipping, and require only seven RU spaces for installation. Installation is made simple with just three interconnections between the amplifier and

power supply. In addition, built-in digital metering and status indicator capabilities enable intuitive operation to further augment the user-friendly design.

Economic long-term reliability is ensured through our carefully engineered solidstate design. The PA1000 features two field-replaceable 500–watt power modules.

This power amplifier delivers 500 to over 1000 watts of RF power output. Use your

existing exciter or purchase the FM1000T which includes our award-winning FM30

exciter for an unbeatable 1 kW transmitter package.

Metering

In Ref

SWR

ALC

Power

I

O

Power Out

PA Temp

PA Voltage

Tot Current

PA1

PA5

PA2

PA6

PA3

PA7

PA4

PA8

®

®

Fault

Antenna

RF Drive

PA Temp

PA DC

PA3

Fuses

PA

4 PA7

PA8

1–2

Illustration 1–1 FM1000A Amplifier Package

FM1000A User’s Manual

Page 7

1.2 Amplifier Package Specifications

RF Power Output:100 to 1100 watts continuous with remote

controlled power adjust

RF Drive Requirement:30 watts for full output

RF Output Impedance: 50 ohms (unbalanced)

Maximum SWR: 1.7:1 (With power foldback at high SWR)

Frequency Range:87–108 MHz

RF Harmonics/Spurious Products: Better than –80 dB

Asynchronous AM S/N Ratio: Better than –55 dB with 100% modulation at

400 Hz, no de-emphasis, no FM modulation

(typically > 60 dB)

Synchronous AM S/N Ratio: Better than –55 dB with 100% modulation at

400 Hz, no de-emphasis, FM

modulation=75 kHz @400 Hz

(typically > 60 dB)

Operating Environment:

Temperature Range: 0°–50°C at sea level

Humidity Range: 0–80% at 20°C (noncondensing)

AC Power:240 Volts AC +10/-15%, 50–60 Hz

Power Consumption: Less than 1400 watts at 1000 watts RF output

typical

Power Factor: .96 typical

Overall Efficiency: 70% typical

RF Output Connector: 7/8 in. EIA flange, 7–16 in DIN optional

Power Amplifier Chassis: 7 x 17.25 x 23 inches (17.78 x 43.82 x

58.42 cm) exclusive of rack ears, but inclusive of connectors

Power Supply Chassis: 5.25 x 17.25 x 23 inches (13.34 x 43.82 x

58.42 cm) exclusive of rack ears

Weight: PA1000—40 pounds (18.1 kg)

RF PA Modules—8 pounds (3.6 kg) each

PS1000—43 pounds (19.5 kg)

Note: System performance is specified using Crown Broadcast

Model FM30 Exciter where applicable.

Getting Acquainted

1–3

Page 8

I

1.3 Safety Considerations

Crown Broadcast assumes the responsibility for providing you a safe product and

safety guidelines during its use. “Safety” means protection to all individuals who

install, operate, and service the transmitter as well as protection of the transmitter

itself. To promote safety, we use standard hazard alert labeling on the product and

in this manual. Follow the associated guidelines to avoid potential hazard.

1.3.1 Dangers

DANGER represents the most severe hazard alert. Extreme bodily harm or death

will occur if DANGER guidelines are not followed.

1.3.2 Warnings

WARNING represents hazards which could result in severe injury or death.

1.3.3 Cautions

CAUTION indicates potential personal injury or equipment or property damage if

the associated guidelines are not followed. Particular cautions in this text also

indicate unauthorized radio-frequency operation.

Type of Hazard

WARNING

Severe shock hazard!

Pictorial Indication

of Hazard

Illustration 1–3 Sample Hazard Alert

Turn power off and

wait approximately 1

minute for capacitors

to discharge before

handling them.

Explanation of

Hazard

1–4

FM1000A User’s Manual

Page 9

®

Section 2—Installation

This section provides important guidelines for installing your

power amplifier and power supply. Review this information carefully for proper installation.

Installation

2–1

Page 10

2.1 Operating Environment

You can install the FM1000A amplifier system in a standard 19–inch component

rack or on a suitable surface such as a bench or desk. In any case, the area should

be as clean and well-ventillated as possible. The power supply must be installed

directly above or below the power amplifier (for the included dressed cables to

reach their respective connectors).

2.2 Tools Required

To install the power supply and power amplifier, you will need the following tools:

❑ Medium phillips screwdriver

❑ Medium flat-blade screwdriver

❑ Small flat-blade screwdriver

❑ 7/16–Inch wrench or nut driver

❑ ESD (Electrostatic Discharge) protection grounding strap and/or mat.

2.3 Unpacking

Before handling any exposed printed circuit boards, ground yourself with an

antistatic strap and/or mat.

CAUTION

Possible equipment damage!

Guard against electrostatic discharge

through electronic components.

The power amplifier, power supply, and two power amplifier modules are packed

and shipped in individual boxes because of their modular nature. (The FM1K

accessory kit is packed inside one of the two power amplifier module boxes.) For

added protection, both the PA1000 amplifier and PS1000 supply are packed in an

inner box and then placed inside an outer box with styrofoam protective corners in

both boxes. You will need to unpack a total of four boxes (plus two inner boxes).

Note: Save the boxes and packaging material that the individual

units are packed in should you need to return them for factory

service.

2–2

FM1000A User’s Manual

Page 11

2.4 Preinstallation

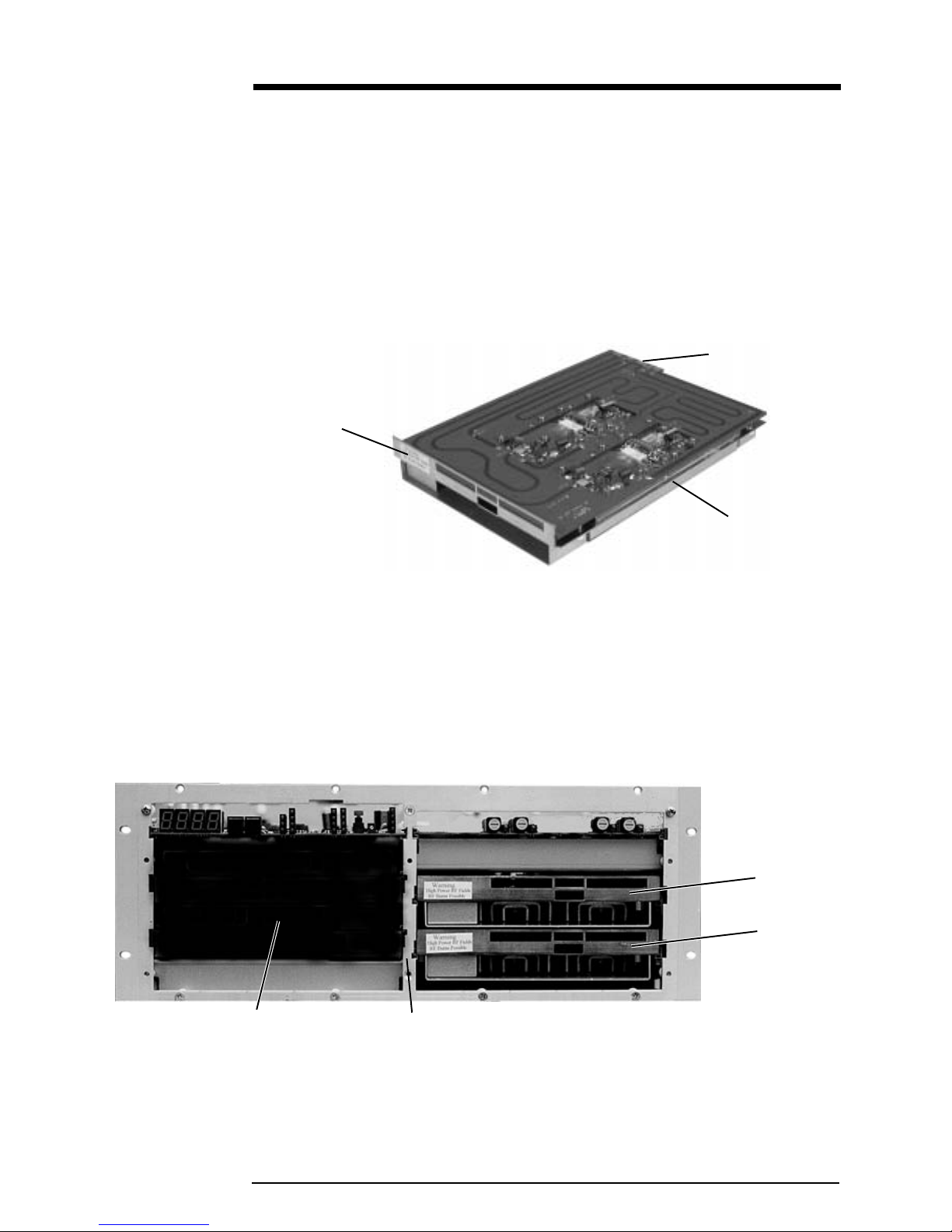

2.4.1 Power Amplifier Modules

The PA1000 incorporates four power amplifiers (two each in two modules). Due to

possible damage during shipment, the power modules have been removed. Follow

these steps to install the modules:

1. Remove the front panel of the PA1000 (four screws).

2. Taking ESD precautions (see page 2–2), unpack the power modules and place

them on your work area with the circuit sides up.

Connector

Warning Label

Slide Rail

3. The warning labels on the front of the modules should all be positioned to the

4. Insert the two power modules, using their slide rails, into the built in chan-

Vacant Cavity

Illustration 2–1 Power Amplifier Module

center of the chassis, also note the position of the connector on the modules

and in the chassis.

nels of the right-side cavity as shown below. Note that the connectors and

warning labels are nearest the middle wall or partition of the PA1000.

Module A

(amps 3 & 4)

Module B

(amps 7 & 8)

Middle Partition

Illustration 2–2 Power Amplifier Module Placement

5. Be sure the modules are pushed in completely so that the connector makes

proper contact.

6. Replace the front panel of the PA1000.

Installation

2–3

Page 12

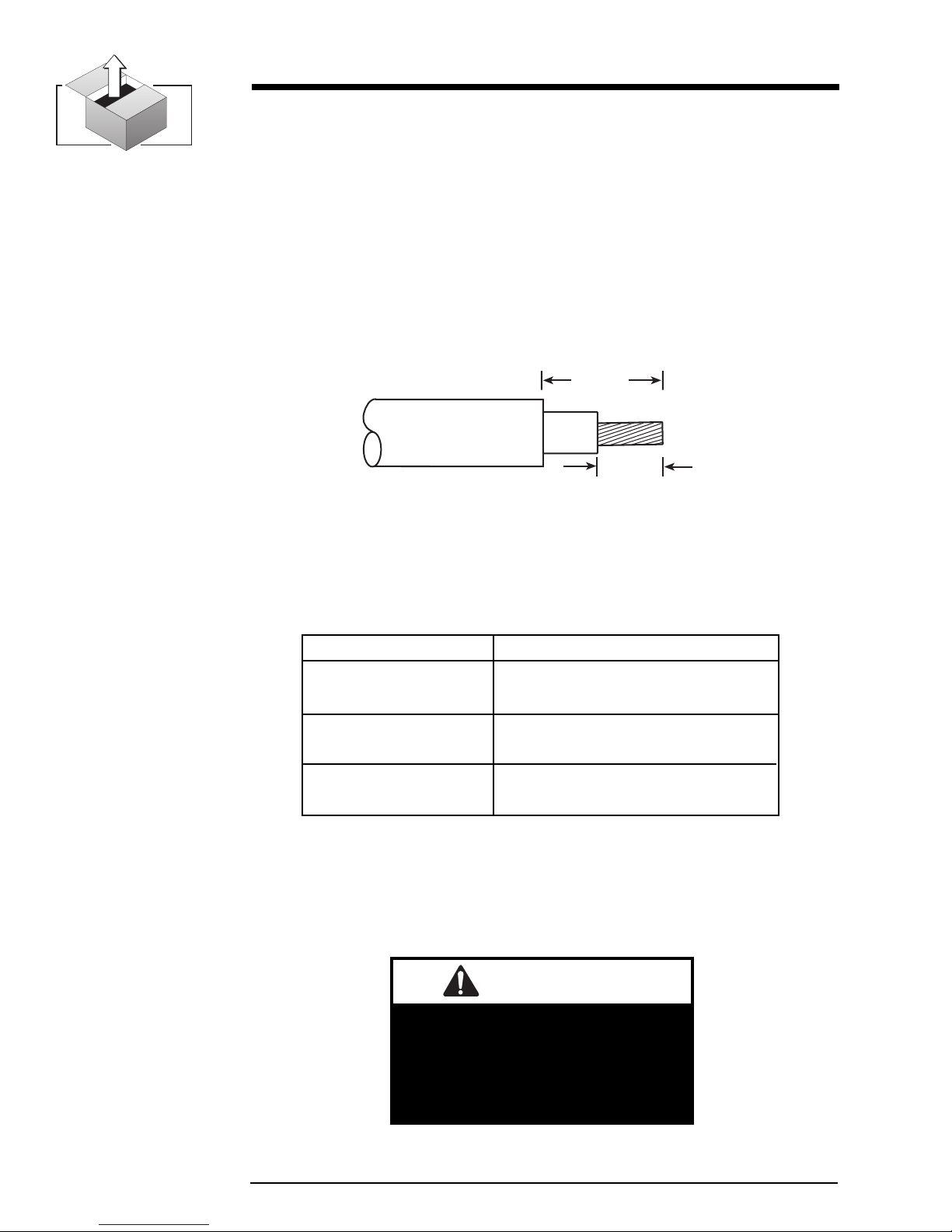

2.4.2 Hubble Twist Lock® Connector Wiring

Prepare the wiring for the Hubble Twist-Lock® connector in the following manner

before connecting to your AC power source:

1. Use round cord with a diameter of 0.385–0.780 inches (10–20 mm), Type SJ

12/3 – 10/3; Type S 16/3 – 10/3.

2. Select conductor size from your National Electrical Code®.

3. Slide the cover onto the cord. Remove insulation from cable and conductors

as shown in Illustration 2–3. Do not tin conductors.

1 Inch

(25 mm)

5/8 Inch

(16 mm)

Illustration 2–3 Cover, Cable & Conductors

4. Loosen terminal screws. Insert conductors fully into proper terminals according to the table below. Take caution that there are no stray wire strands.

Terminal

Green Hex Head Screw

Equipment grounding conductor

Conductor

(green or green/yellow)

Brass Screw

Hot circuit conductor, 240 VAC

(NOT white, NOT green)

Brass/Black Screw

Hot circuit conductor, 240 VAC

(NOT white, NOT green)

5. Tighten terminal screws to 18 pound•inches (2.1 N•m) of torque.

6. Tighten assembly screws to 10 pound•inches (1.1 N•m) of torque.

7. Tighten cord clamp screws to 10 pound•inches (1.1 N•m) of torque.

WARNING

Possible Electric

Shock

Hazard!

2–4

Do not connect AC source until all

other connections are made and

installation is complete.

FM1000A User’s Manual

Page 13

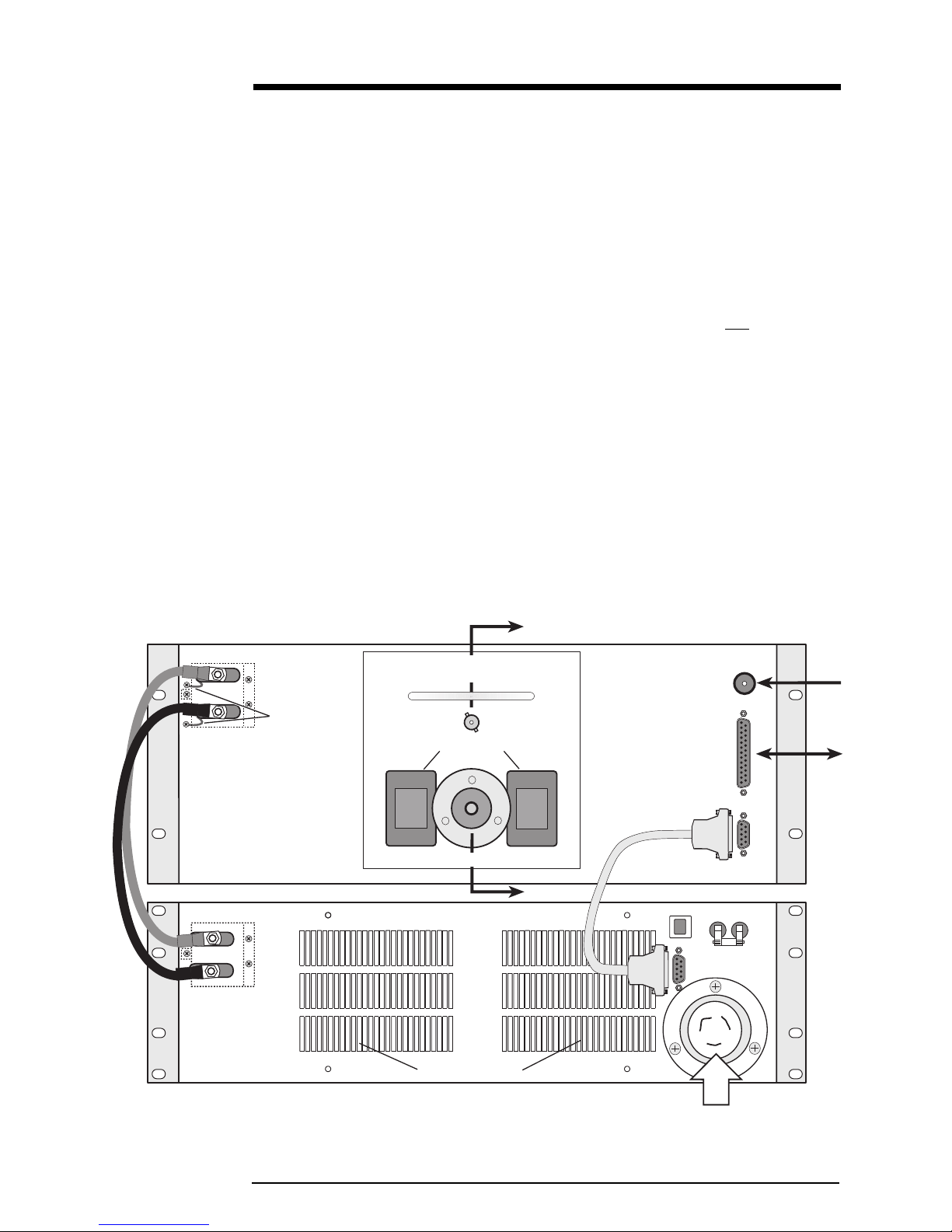

2.5 Installation

1. Mount the units in an appropriate 19–inch wide cabinet. The power supply

must be installed directly below the power amplifier for the included

cables to reach their respective connectors (see illustration 2–4 below).

Note: The PS1000 weighs approximately 40 pounds (18.1 kg); the

PA1000, approximately 43 pounds (19.5 kg). Use help to install.

2. Ensure that the PS1000 power switch is off, the circuit breakers of the 240

VAC source on the back panel are off, and the AC connector is not plugged in.

3. Install the exciter source (such as a Crown Broadcast FM30) according to its

instructions.

4. Connect the RF input cable from the exciter source to the N connector on the

back of the PA1000.

5. Connect the RF output cable (from the antenna) to the 7/8 EIA or 7-16 DIN

connector on the back of the PA1000.

6. Connect one end of the supplied control cable to the 9–pin D-sub connector

on the PA1000.

7. Connect the other end of the control cable to the 9–pin D-sub connector on

the PS1000.

+ DC Input

DC Input

PA1000

+ DC Output

DC Output

PS1000

Ground Screws

RF Monitor

(Optional Connection)

Air Intakes/Filters

RF Output

Air Exhaust Vents

RF Input

Remote I/O

Control

Circuit Breakers

Fans

OFF

Power

Control

OFF

Installation

Illustration 2–4 Rear Panel Connections

240 VA C IN

2–5

Page 14

8. Using the supplied connector, tie together pins 6 and 7 of the Remote I/O

connector. The amplifier will not operate without this connection or a

remote switch on these pins. (See Section 2.6 for Remote I/O connection.)

9. If monitoring of the output signal is desired, connect the RF monitor cable to

the BNC connector on the PA1000.

10. Connect the DC input/output cables between the PA1000 and the PS1000 as

illustrated (Illustration 2–4). The connector end with the ground lead connects to the PA1000. Be sure to attach the ground leads as indicated.

Note: The power lead shield is only grounded at the PA chassis.

11. Install the covers over the DC terminals of the PA1000 and the PS1000 using

hardware form the hardware kit (1/4–inch X 6–32 bolts with lock washers).

12. Connect to your AC power source by inserting the Hubble Twist-Lock connector into the female Hubble connector on the PS1000 and turn to the right

until the connection locks.

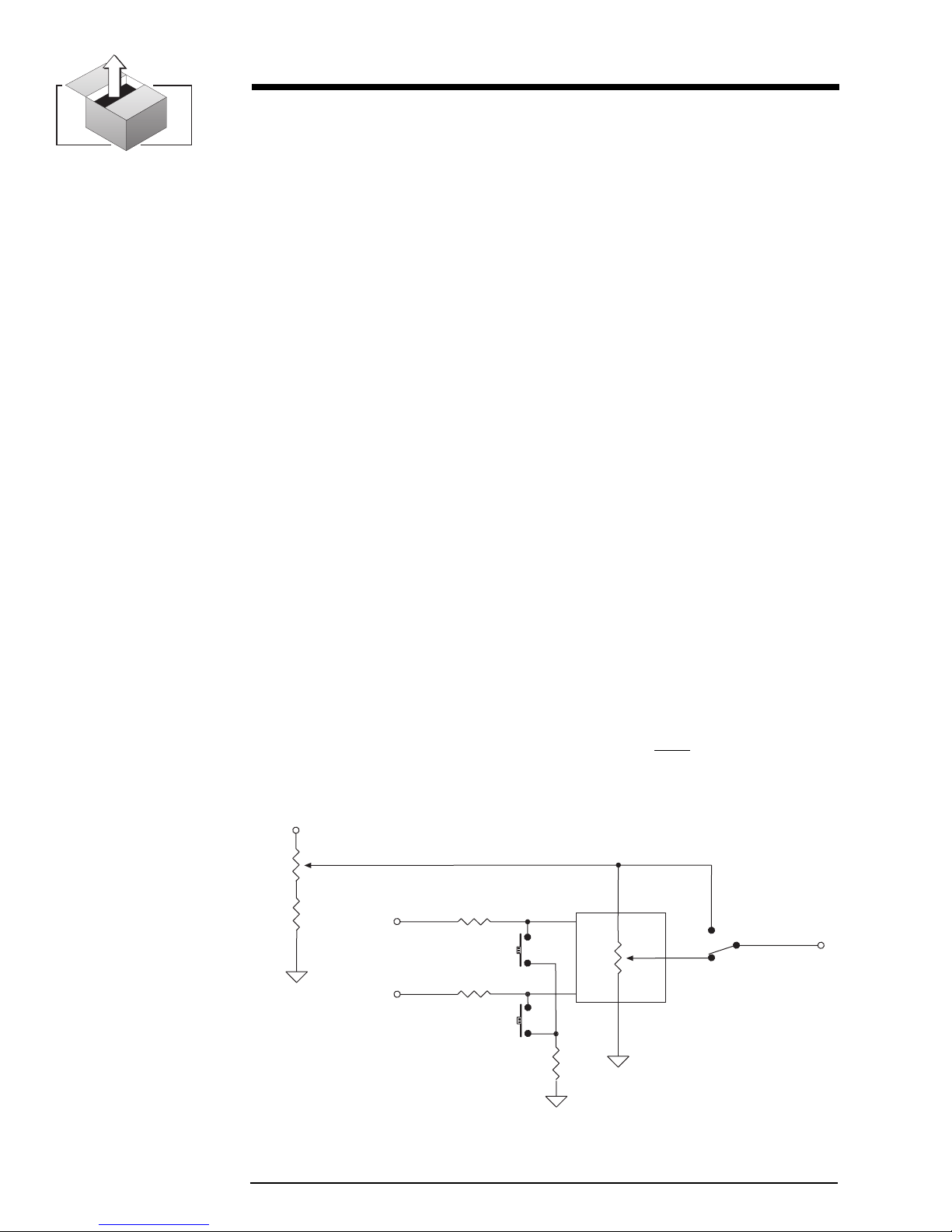

2.6 Remote I/O Connection

The Remote I/O Connector on the back of the PA1000 allows remote control and

monitoring of Certain transmitter functions. There are three basic control functions—AC on/off, RF power level adjustment, and RF down/off.

The AC power on/off remote control function, available at pin 7 of the Remote I/O

Connector, turns DC power to the PA on when the pin is grounded.

The RF power level adjustment remote control function has an internal maximum

limit set on the Metering and Control Board. The Local Power Adjust (R62) sets

the maximum limit of RF power output. The limit is set by placing the Remote/

Local switch (SW5) in the LOCAL position and adjusting the Local Power Adjust to

your desired maximum limit (see illustrations 2–5 and 2–6). However, for any

remote operation to work, the Remote/Local slide switch

must be in the REMOTE

position. Then the on-board remote RAISE and LOWER push buttons and any

external remote switches attached to pins 4 and 15 of the I/O Connector can adjust

+5V

MAXIMUM

R62

LOCAL

POWER

ADJUST

MINIMUM

REMOTE

RAISE POWER

Pin 4

Remote I/O Conn.

REMOTE

LOWER POWER

Pin 15

Remote I/O Conn.

SW3

RAISE

SW4

LOWER

ElectroControl

Circuit

SW5

LOCAL

REMOTE

TANSMITTER

CONTROL

2–6

Illustration 2–5 Local and Remote Functions

FM1000A User’s Manual

Page 15

the level up to that limit and down to zero. When a specific output power level is

set, the Metering and Control Board controls and maintains the setting to keep the

power constant. The location of the Local Power Adjust (R62), the on-board Raise

and Lower switches (SW3 & SW4), and the Local/Remote slide switch (SW5) are

shown below.

Local/Remote

Slide Switch

On-board Remote

Power Adjust

Buttons

Local Power Adjust

Pot

Illustration 2–6 On-board Remote Power & Related Controls

Another remote control function, available at pin 5 of the Remote I/O Connector,

turns RF down/off. Connecting this pin to ground through a resistor allows the

RF power output level of the amplifier to be reduced below the internal limit set by

the Local Power Adjust pot or the remote Raise/Lower settings. However, some

drive power, less than one watt, may still be present at the antenna. Depending on

the resistor used, this pin can serve as a control for optional low power operation.

The remaining remote functions are for monitoring the various

parameters of the PA1000. They are either buffered metering outputs, direct

reading, or latched high/low indications. Further details of these functions are

described in the pin-out table on page 2–8.

Note: If Remote I/O controls are not used, tie pin 7 to pin 6 (GND.).

For remote I/O (Input/Output) connection, connect your remote I/O cable from

your remote control location to the 25–pin (female) D-sub connector on the back

panel of the PA1000. The I/O Connector on the power amplifier is described in the

following diagram:

13

1

The Remote I/O Connector Pinout Table on the next page summarizes the Remote

I/O pin connections.

Installation

25

Illustration 2–7 Remote I/O connector (back panel view)

View from Rear of Cabinet

14

2–7

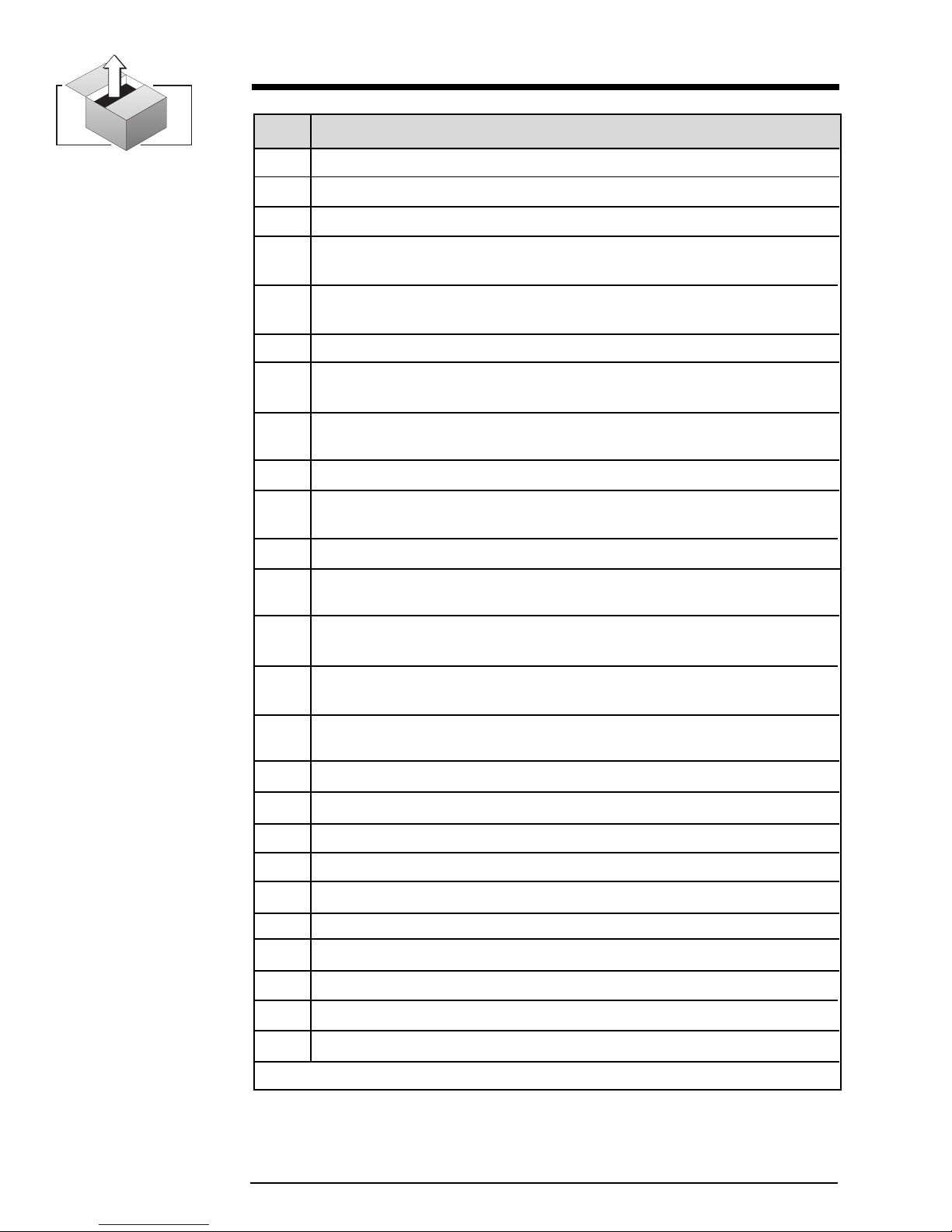

Page 16

Pin # Function

1 PA#8 Current Monitor (a b uff ered metering output with 1 V = 2 A)

2 PA#7 Current Monitor (a b uff ered metering output with 1 V = 2 A)

3 Ground

4 Remote RAISE Po wer (a momentary switch, on this pin, when held lo w will

raise the power le vel 10 watts ev ery 0.5 seconds)

5 Remote RF Po wer Control (a resistor to g round on this pin reduces RF

power output lev el below internal limits. See Section 2.6, page 2–7)

6 Ground

7 Remote AC P o w er On (a latching switch, on this pin, when held low will turn

the AC power supply on)

8 Fault Summary (the voltage from this pin goes to +5 V if any f ault occurs and

drops below 2V when the fault goes aw ay)

9 Ground

10 ALC (the voltage from this pin is a direct reading of automatic level control

voltage, not b uffered)

11 P A Temperature (a buffered metering output with 1 V = 20° C)

12 SWR (a buffered metering output with a calculated reading of standing wave

ratio in VDC)

13 RF Output Power (a buff ered metering output with a calculated reading of

output power of 1 V = 1000 W)

14 Input Power Ref erence (a buff ered metering output with a DC voltage

representing input power)

15 Remote LOWER Power (a momentary s witch, on this pin, when held low will

lower the power le vel 10 watts ev ery 0.5 seconds)

16 P A#6 Current Monitor (a b uff ered metering output with 1 V = 2 A)

17 P A#5 Current Monitor (a b uff ered metering output with 1 V = 2 A)

18 Ground

19 P A#4 Current Monitor (a b uff ered metering output with 1 V = 2 A)

20 P A#3 Current Monitor (a b uff ered metering output with 1 V = 2 A)

21 Ground

22 P A#2 Current Monitor (a b uff ered metering output with 1 V = 2 A)

23 P A#1 Current Monitor (a b uff ered metering output with 1 V = 2 A)

24 P A Total Current Monitor (a buffered metering output with 1 V = 20 A)

25 P A Volts (a buffered metering output with 1 V = 10 V)

Note: PA = Power Amplifier

2–8

Remote I/O Connector Pinout Table

FM1000A User’s Manual

Page 17

This section provides general operating parameters of your power

amplifier system and a detailed description of the front panel

display.

Section 3—Operation

3–1Operation

Page 18

3.1 Initial Power-up Procedures

These steps summarize the operating procedures you should use for the initial

operation of the power amplifier and power supply. More detailed information

follows.

1. Ensure that the external remote control unit is properly connected (See the

Pin Out Description Table, Section 2.6, page 2–8 for proper pin configuration). If not using a remote control unit, pin 7 must be tied to ground pin 6.

2. Connect Antenna.

3. If using an external remote control, enable the power supply via the remote

I/O connector.

4. Turn on (flip up) the AC input circuit breaker located on the rear panel of the

power supply (do not turn on the front panel power switch yet).

Outputs to

PA1000

+ DC Output

DC Output

PS1000

Fan

Circuit Breaker

Fans

Air Exhaust Vents

AC Input

Circuit Breaker

OFF

OFF

Power

Control

240 V AC IN

Illustration 3–1 PS1000 Back Panel Functions

5. Turn on the exciter (a Crown FM30 or equivalent) and adjust its RF power

output level until the In Reference (In Ref) voltage, as indicated on the

PA1000 front panel Digital Multimeter, is between 0.4 and 0.8volts. This is

not a drive dependent amplifier; therefore drive must be at a constant level

regardless of main output power.

Note: The unit will not operate until the exciter is active.

3–2

FM1000A User’s Manual

Page 19

6. Before power-up, place the Local/Remote switch (located on the Metering &

Control board behind the front panel) in the Local position and adjust the

output power limit to the mid-level position using the Local Power Adjust,

also on the Metering & Control board (see Illustration 3–2 below). The unit is

normally shipped with this setting. See Section 2.6 for setting up remote

operation and using the on-board remote buttons and other controls.

7. Turn on the main power switch located on the front panel of the power

supply. (The unit typically takes 30 seconds to power up.)

Local/Remote

Slide Switch

On-board Remote

Power Adjust

Buttons

Local Power Adjust

Pot

Illustration 3–2 Local Power Adjust and Other Controls

Power

I

O

Power Switch

8. Check the PA1000 parameters with the Digital Multimeter for a current (Tot

Current) of 20 to 30 amps and a voltage (PA Voltage) of 25 to 35 volts. If

parameters are within range, increase the Local Power Adjust to the maxi-

Air Intakes/Filters

®

Illustration 3–3 PS1000 Front Panel Functions

mum level of desired operation.

Note: The Local Power Adjust pot is unconventional (CW lowers power).

9.Using an external remote control unit connected to the Remote I/O connector,

adjust the PA1000 to the maximum power set by the Local Power Adjust.

(This prevents adjusting to higher than permitted power levels.)

3–3Operation

Page 20

10. Verify that the following conditions are present as indicated by the PA1000’s

Digital Multimeter:

a. In Ref—Should read between 0.4 and 0.8 volts (0.5 nominal, dependent

upon power input level).

b. SWR—Should read 1.05 to 1.5.

c. ALC—Should read between 4.00 and 6.00 volts for 1.1 kW output (less

for lower output or danger conditions, i.e. high SWR).

d. Power Out—Should read 1.10 for 1.1 kW output.

e. PA Temp—Should read 35 to 50°C with ambient temperature of 25°C.

The remainder of this section describes the functions of the front and rear panel

indicators and switches of the PA1000 and PS1000.

3.2 Power Switches

3.2.1 AC Input Circuit Breaker

The PS1000 supplies power to the PA1000 by converting single-phase 220/240 VAC

into 50 VDC. The PS1000 is protected by a 20 A, double-pole circuit breaker

located on the rear panel. This AC input circuit breaker must be in the “up”

position (as shown below) for operation.

AC Input

Circuit Breaker

Fans

Control

240 V AC IN

Illustration 3–4 AC Input Circuit Breaker

ON

Power

ON

3–4

FM1000A User’s Manual

Page 21

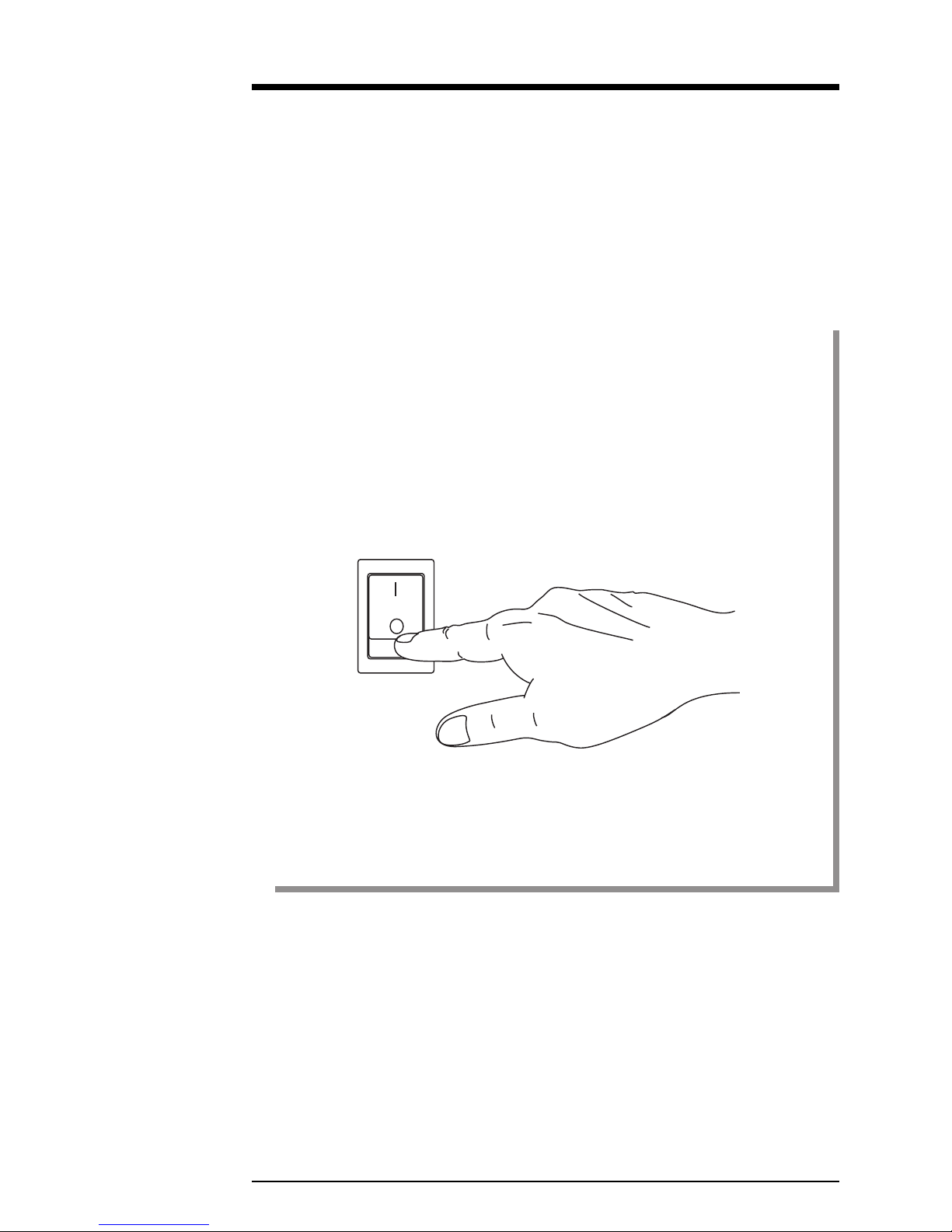

3.2.2 DC Power Switch

The main on/off power switch located on the front panel of the power supply

controls high voltage output. (The control circuit activates this voltage.)

Power

I

O

®

Power Switch

Illustration 3–5 DC Power Switch

3.2.3 Interlock Switch

This switch is located on the fan mounting bracket in the power supply. When the

top cover of the power supply is removed, the Interlock Switch interrupts the

power supply control circuit disabling the high and low voltage supplies.

Lethal voltages are still present on the AC Input Board !

WWARNINGARNING

So, handle with care.

Interlock Switch

Illustration 3–6 Interlock Switch

3–5Operation

Page 22

3.3 Digital Multimeter

The 3–digit numeric display in the upper left corner of the front panel provides

information on the amplifier’s operation. Use the “up” and “down” push-buttons to

select one of the following parameters as indicated by a green LED.

Multimeter Metering Selection Buttons Metering Indicators

Metering

In Ref

SWR

ALC

Power Out

PA Temp

PA Voltage

Tot Current

PA1

PA5

PA2

PA6

PA3

PA7

PA4

PA8

®

Fault

Antenna

RF Drive

PA Temp

PA DC

PA3

Illustration 3–7 Digital Multimeter

In Ref—Input reference is a relative voltage level used to determine input RF

power level. This varies between frequency of operation and input power level.

SWR—Direct reading of the antenna Standing-Wave Ratio (the ratio of the actual

load impedance to the desired 50 ohm load impedance).

ALC—Automatic level control is DC gain control bias used to regulate PA supply

voltage. With the PA power supply at full output voltage, ALC will read about 6.0

volts. When the RF output is being regulated by the RF power control circuit, this

voltage will be reduced, typically reading 5.0 to 6.0 volts. The ALC voltage will be

reduced during PA DC overcurrent, SWR, or overtemperature conditions.

Power Out—Actually reads RF voltage squared, so the accuracy can be affected by

SWR. Tolerance of ± 10% is normal. For exact set-up on site, an external power

meter is recommended.

PA Temp—Highest temperature of all individual RF power amplifier heatsinks in

degrees C.

PA Voltage—Supply voltage of the RF power amplifier.

Tot Current—Sum total current of all individual RF power amplifiers in amperes.

PA1–8—Individual RF amplifier current reading in amperes.

3–6

FM1000A User’s Manual

Page 23

3.4 Fault Indicators

Faults are indicated by illuminated red LED’s when the following occurs:

Antenna—Load SWR exceeds 1.5:1. ALC voltage is reduced to limit the reflected

RF power.

RF Drive—Lack of or insufficient RF drive. If the RF drive fault LED is lit, input

drive must be increased. To achieve full output power, 30 watts of input drive is

required.

CAUTION

Possible equipment damage!

Do not exceed 40 watts of input drive.

Damage to the PA1000 will result if

this level is exceeded.

PA Temp—PA heatsink temperature is greater than 75°C (power foldback will

begin at this point).

PA DC—Power supply current for the PA (power amplifier) is at the preset limit, or

there is a difference of more than 2.5 amps in current between the individual PAs.

When this indicator is on ALC, the voltage is reduced automatically which holds

the supply current to the preset limit.

Fault Indicators

Metering

In Ref

SWR

ALC

Power Out

PA Temp

PA Voltage

Tot Current

PA1

PA5

PA2

PA6

PA3

PA7

PA4

PA8

®

Fault

Antenna

RF Drive

PA Temp

PA DC

PA3

Fuses

PA4

PA7

PA8

Illustration 3–8 Fault Indicators

3–7Operation

Page 24

3.5 Fuse Indicators

The PA1000 consists of two field-replacable power modules with two amplifiers in

each module. Each of the paralleled amplifiers is protected by a 10 ampere

fast-acting fuse. When a fuse opens, the indicator light next to it illuminates.

Fuses 3 and 4 represent amplifiers 1 and 2 on the top right module. Fuses 7 and 8

represent amplifiers 3 and 4 on the lower right power module.

Fuses and Indicators

Power Out

PA Temp

PA Voltage

Tot Current

Fault

PA5

PA1

PA6

PA2

PA7

PA3

PA8

PA4

®

Antenna

RF Drive

PA Temp

PA DC

PA3

Fuses

PA4

PA7

PA8

Illustration 3–9 Fuse Indicators

3–8

FM1000A User’s Manual

Page 25

p

u

e

d

e

r

o

s

n

o

n

o

e

r

e

c

h

do,

n

o

m

o

t

s

e

u

q

c

n

ce

i

i

d

i

s

o

n

u

,

e

s

r

h

c

o

f

e

h

c

o

m

a

i

c

i

d

e

s

on

c

o

d

n

e

v

i

r

c

s

a

e

,

m

do

n

o

m

o

t

s

e

u

q

c

n

ce

i

i

d

i

s

o

n

u

,

e

s

r

ch

o

f

e

h

c

o

m

a

i

c

i

d

e

s

con

o

d

n

e

v

i

r

c

s

a

m

con

o

d

n

e

v

i

r

c

s

a

m

do,

n

o

m

o

t

s

e

u

q

e

n

c

i

i

d

i

s

o

n

u

,

e

s

r

ch

o

f

e

h

c

o

m

a

i

c

i

d

e

s

n

o

c

o

d

n

e

v

i

r

c

s

a

m

e

a

b

b

i

a

n

n

o

n

e

h

'

c

n

o

n

e

t

i

t

a

m

a

l

d

o

n

o

r

n

o

n

e

h

'

c

n

o

n

e

t

i

t

a

m

a

l

t

a

m

a

l

o

n

o

r

e

o

n

e

h

c

n

o

n

e

t

a

m

a

l

o

h

a

l

a

d

i

s

p

o

z

i

o

n

e

d

o

f

a

e

n

u

l

l

a

n

e

l

m

o

n

d

o

r

e

a

l

a

c

i

i

n

s

e

g

n

a

a

n

o

n

p

a

r

l

p

u

e

e

r

s

o

n

e

c

h

e

a

b

b

i

a

n

h

a

l

a

d

i

s

p

o

z

i

o

n

e

d

o

f

a

e

n

u

l

l

a

n

e

l

m

o

n

d

o

r

e

a

l

a

c

i

i

n

s

e

g

n

a

a

n

o

n

p

a

r

l

t

a

c

i

i

i

n

s

e

g

n

a

a

n

o

n

p

a

p

u

e

d

e

r

s

o

n

e

c

h

e

a

b

b

i

a

n

h

a

l

a

d

i

s

p

o

z

i

o

n

e

d

o

'

e

n

u

c

l

l

a

n

e

l

m

o

n

d

o

r

e

t

a

c

i

i

i

n

s

e

g

n

a

a

n

o

n

p

a

m

r

l

o

.

M

n

i

e

d

i

o

f

a

r

e

o

r

l

o

s

.

M

e

d

i

m

a

r

e

s

m

r

l

a

r

e

n

o

f

a

r

l

o

.

M

a

l

e

d

i

r

l

a

re

t

a

c

i

i

i

t

n

s

a

e

m

g

n

a

l

a

on

c

o

d

n

e

v

i

r

c

s

a

do

n

o

m

o

t

s

e

u

q

ce

i

d

i

s

o

n

u

,

e

s

r

e

h

c

o

m

a

i

c

i

d

e

co

o

d

n

e

v

i

r

c

s

a

e

h

c

o

m

a

i

c

i

d

e

on

c

o

d

n

e

v

i

r

c

s

a

a

n

o

n

p

a

r

l

a

r

e

p

u

e

d

e

r

o

s

n

o

n

o

e

r

e

c

,

h

e

a

b

b

i

a

n

n

o

n

e

h

c

c

n

o

n

e

ch

t

i

t

a

m

a

l

n

c

n

o

n

e

h

c

t

i

t

a

m

a

l

o

h

a

l

a

d

i

s

p

o

z

i

o

n

e

d

o

f

a

r

l

o

.

M

'

e

n

u

l

l

a

n

e

l

m

o

n

d

o

r

e

a

l

e

d

a

c

'

e

n

a

c

i

i

i

n

s

e

g

n

a

a

n

o

n

p

a

r

l

a

r

e

u

l

l

a

n

e

l

m

o

n

d

o

r

e

a

l

e

d

i

i

i

n

s

e

g

n

a

a

n

o

n

p

a

r

l

a

r

e

Section 4—Principles of Operation

This section discusses the circuit principles upon which the

power amplifier and power supply function. This information is

not needed for day-to-day operation, but may be useful for advanced users and service personnel.

4–1Principles of Operation

Page 26

m

o

t

o

s

n

n

d

e

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

a

o

i

f

c

i

d

e

n

e

d

v

o

i

s

r

c

s

a

m

o

t

o

s

m

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

h

a

o

i

f

c

i

d

e

n

e

d

v

o

i

s

r

c

s

a

m

n

e

d

v

i

r

c

s

a

m

o

t

o

s

m

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

a

o

i

f

c

i

d

e

n

e

d

v

i

s

r

c

s

a

m

d

v

o

i

r

o

d

i

c

e

h

e

c

o

n

d

o

d

i

c

e

e

c

o

o

c

o

n

d

o

d

i

c

h

e

o

c

o

c

c

o

s

,

n

,

n

n

,

e

n

n

a

m

o

t

o

s

n

m

d

e

o

u

,

q

o

s

n

i

u

d

n

,

i

i

c

e

e

s

r

o

f

o

m

c

h

a

i

e

c

i

d

e

n

e

d

v

o

i

s

r

c

c

o

s

n

a

o

m

c

h

a

m

i

e

c

i

d

e

n

e

d

v

o

i

s

r

c

c

o

s

n

a

m

Introduction

The FM1000A is a solid state RF amplifier package designed to deliver 500 to 1000

watts. The package consists of two separate, compact units—a power supply

(PS1000) and a power amplifier (PA1000). In turn, these units consist of modular

components which provide for efficient operation as well as ease-of-service.

4.1 PA1000 Power Amplifier

The PA1000 power amplifier features adjustable output to deliver 500–1000 watts of

RF output power for broadcast transmission. The amplifier is broadband; no tuning

is required. The design, however, ensures efficient operation. Typical RF efficiency

is 75% to 85% across the FM band.

4.1.1 Power Modules

The primary components of the PA1000 are two, 500–watt power modules. These

power modules are mounted by stacking two in the right cavity of the chassis. The

two slots on the left side are unpopulated.

The chassis of the power modules acts as a heat sink for the MOSFET amplifiers.

There are two power amplifiers mounted to spacer plates on each of the heat sinks,

for a total of four power amplifiers in all. (The power amplifiers are the same as

those utilized in the Crown Broadcast 100, 250, and 500–watt transmitters.)

Power from the amplifiers is combined through a micro-strip combiner to convert

from 50 Ω output impedance for each amplifier to an intermediate impedance and

then return to the 50 Ω output at the Low Pass Filter. This technology eliminates

tuning and adjustments throughout the 88–108 FM band and enables each amplifier

to equally share the power load. The power combiner is also designed to allow a

module to be disconnected from the combiner and removed without adversely

affecting the impedance balance of the unit. With one module removed the impedance change allows the remaining module to continue operation at approximately

one-third of the full output power.

4.1.2 Power Combiner Board

There are two Power Combiner Boards; one attached to each of the two heatsinks

overlapping the amplifiers. Each board takes the power from two amplifiers and

combines it through a parallel quarter-wave transmission line transformer network.

The power is then summed in a common point junction on the Output Combiner

Board.

4–2

FM1000A User’s Manual

Page 27

4.1.3 Backplane Assembly

The backplane assembly is located in the vertical center of the PA1000 behind the

power modules. The Backplane Assembly is the common connection point for the

major sections of the transmitter. This assembly consists of the Input Divider

Board, Output Combiner Board, and Backplane Interconnect Board.

4.1.3.1 Backplane DC Interconnect Board

This board is located nearest the metal inner brace of the chassis. It distributes DC

power to each of the four MOSFET amplifiers, provides the interconnections for

control of the power supply, and enables connection to the remote control interface. The Backplane/DC Interconnect Board contains interconnections from the

Control and Metering Board to the DC Fuse and Power Distribution Board, as well

as power connections to the power amplifier modules.

4.1.3.2 Input Divider Board

The Input Divider Board is the middle board sandwiched between the Backplane DC

Interconnect Board and the Output Combiner Board. It provides the power division

and impedance transformation needed to supply proper drive to each of the four

amplifiers (two modules).

4.1.3.3 Output Combiner Board

The Output Combiner Board is located nearest the Output Filter It consists of a

micro-strip transmission line that combines the output power from the four amplifiers (two modules) so that ultimately, all the power comes together at one common

point junction. Here the currents and voltages of all four power amplifiers are in

phase and producing equal RF output power. From this common point junction,

the Output Combiner Board uses a second quarter-wave transformer to convert the

output power to the 50–ohm impedance needed at the output of the unit.

4.1.4 Output Filter & Reflectometer

The Output Filter/Reflectometer is located behind the Backplane Assembly in the

center of the PA1000. See the accompanying schematic in Section 6 for more

information.

The ninth-order, elliptic, low-pass filter attenuates harmonics generated in the

power amplifier. The capacitors for the filter are circuit board pads. The reflectometer uses printed circuit board traces for micro-strip transmission lines. Transmission line segments (with an impedance of about 100 ohms) on either side of a

50–ohm conductor provide sample voltages representative of the square root of

forward and reverse power. DC voltages, representative of forward and reflected

power, go through a bulkhead Filter Board to the Backplane/DC Interconnect

Board, then to the Metering Board where they are processed for power control and

metering and for SWR metering and protection.

4–3Principles of Operation

Page 28

m

o

t

o

s

n

n

d

e

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

h

a

o

i

f

c

i

d

e

n

e

d

v

o

i

s

r

c

s

a

m

o

t

o

s

m

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

h

a

o

i

f

c

i

d

e

n

e

d

v

o

i

s

r

c

s

a

m

n

e

d

v

i

r

c

s

a

m

o

t

o

s

m

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

a

o

i

f

c

i

d

e

n

e

d

v

i

s

r

c

s

a

m

d

v

o

i

r

o

d

i

c

e

e

c

o

n

d

o

d

i

c

e

e

c

o

o

c

o

n

d

o

d

i

c

h

e

o

c

o

c

c

o

s

,

n

,

n

n

,

e

n

n

a

m

o

t

o

s

n

m

d

e

o

u

,

q

o

s

n

i

u

d

n

,

i

i

c

e

e

s

r

o

f

o

m

c

h

a

i

e

c

i

d

e

n

e

d

v

o

i

s

r

c

c

o

s

n

a

o

m

c

h

a

m

i

e

c

i

d

e

n

e

d

v

o

i

s

r

c

c

o

s

n

a

m

4.1.5 Metering and Control Board

The Metering and Control Board is located above the upper left cavity. This board

supplies readings of voltages and currents, and provides information on the operation of the amplifier.

The Local Power Adjust pot sets the upper limit (maximum) of RF power output.

The on-board RAISE and LOWER push buttons and any external remote control of

the power level is activated within that limit by placing the Local/Remote slide

switch on the board into the Remote position. When a specific output power is set,

the Metering and Control Board controls and maintains the setting keeping power

constant. A long-life battery supplies power to retain the power setting after the

amplifier is turned off.

This board also takes samples from the RF amplifier boards and PS1000 power

supply and processes all the data. It provides SWR readings from the Output Filter

and folds back the amplifier power if the SWR exceeds safe operating limits. Protection circuitry for overcurrent and overtemperature conditions is designed into this

board as well, providing additional precaution against overheating. This board is

fail-safe, like all the other circuit board components in the FM1000A and can be

removed for repair/replacement if necessary.

4.1.6 DC Fuse and Power Distribution Board

This board is located above the right cavity over Power Modules A and B. The DC

Fuse and Power Distribution Board takes power direct from the power supply

through one 80–amp power line, divides it into four separate DC power lines, and

distributes it to the four power amplifiers. Metering resistors in each of the four

power lines monitor the current drawn by each of the four amplifiers to ensure

proper function for monitor and control of the unit.

4.1.7 Cooling Fans

There is a cooling fan located in the back of the PA1000 powered by the PS1000.

The fan operates at 24 volts and is rated at 235 cubic feet per minute. Cool air is

drawn through the heatsinks where a flushing moves the air over the DC Distribution Fuse board, the Control and Metering Board, the Output Filter circuits, and

then out through the air vents on the side panel. If a fan fails, the amplifier will

fold back power to prevent overheating.

4.2 PS1000 Power Supply

The PS1000 supplies power to the PA1000 by converting single-phase 240

VAC into 50 VDC. The PS1000 is protected by a 20 A double-pole circuit breaker.

This highly efficient power supply utilizes switching technology and is power factor

corrected. The PS1000 consists of three printed circuit boards described below.

4–4

FM1000A User’s Manual

Page 29

4.2.1 AC Input Board

The AC Input Board is located on the left side of the PS1000. AC power from the

circuit breaker connects to the AC Input Board where it connects to a ±12 volt DC

power supply and three relays. The ±12 volts is used to close the three relays when

the DC Power Switch on the front panel is switched on. In addition, the ±12 volts

are supplied to the PA1000 for use in the Control and Metering Board. The 240volt AC input to the power supply is connected through a Hubble Twist Lock

connector on the back panel to a 20–amp circuit breaker mounted inside the back

panel.

When the power supply is turned on and enabled, the AC power comes through

torroidal inductors which prevent harmonics and spurious products from feeding

back into the AC power lines. The current flows from the inductors to a bridge

rectifier that converts the current to DC Power, and from there to the PFC Switching Board where the rectified DC is filtered. The filtered DC power is then fed from

the PFC Switching Board through an 80–turn boost inductor and back to the PFC

Switching Board.

4.2.2 PFC (Power Factor Correcting) Switching Board

The PFC Switching Board is located directly behind the cooling fans (front panel) in

the PS1000. This board takes the voltage from the Torroidal Boost Inductor and

sends it to the Boost Switching Transistor. The switching transistor chops the DC

input power at a 25 kHz rate. The chopped voltage is then rectified, filtered, and

sent as DC voltage to a set of four transistors which form a second switching stage.

The second switching stage chops the DC voltage at a 22.5 kHz rate. This chopped

DC power is fed through a blocking capacitor to a transformer on the DC Output

Board. The second switching stage controls the amount of power sent to the DC

Output Board. This ensures that the transformer output voltage and current are

correct for providing the selected RF output power to the amplifier.

4–5Principles of Operation

Page 30

m

o

t

o

s

n

n

d

e

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

h

a

o

i

f

c

i

d

e

n

e

d

v

o

i

s

r

c

s

a

m

o

t

o

s

m

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

h

a

o

i

f

c

i

d

e

n

e

d

v

o

i

s

r

c

s

a

m

n

e

d

v

i

r

c

s

a

m

o

t

o

s

m

e

u

q

o

s

n

i

u

n

,

i

e

s

r

o

m

c

a

o

i

f

c

i

d

e

n

e

d

v

i

s

r

c

s

a

m

d

v

o

i

r

o

d

i

c

e

e

c

o

n

d

o

d

i

c

e

e

c

o

o

c

o

n

d

o

d

i

c

h

e

o

c

o

c

c

o

s

,

n

,

n

n

,

e

n

n

a

m

o

t

o

s

n

m

d

e

o

u

,

q

o

s

n

i

u

d

n

,

i

i

c

e

e

s

r

o

f

o

m

c

h

a

i

e

c

i

d

e

n

e

d

v

o

i

s

r

c

c

o

s

n

a

o

m

c

h

a

m

i

e

c

i

d

e

n

e

d

v

o

i

s

r

c

c

o

s

n

a

m

4.2.3 DC Output Board

The DC Output Board is located in the back of the unit directly behind the PFC

Switching Board. This board rectifies and filters the transformer output voltage

once again to produce the clean DC power required for the power modules. The DC

Output Board also provides the 24–volts that operate the cooling fans in both the

PS1000 and the PA1000. There are two parallel paths from the DC Output Board,

with half the power going through each set of output cables. These cables come

together at the terminal in back of the unit providing the maximum output power

of 50 volts at 60 amperes.

4.2.4 Cooling Fans

There are two cooling fans located in the front section of the PS1000. Their primary function is to cool the semiconductors used in the switching and rectifying

process which are subject to high currents. The fans blow cool air through the

heatsinks and out through the vents on the back and side panels of the PS1000.

The fans have a dedicated circuit breaker located on the back panel of the power

supply.

4–6

FM1000A User’s Manual

Page 31

TROUBLE

TROUBLETROUBLE

Section 5—Troubleshooting

This section describes procedures for service personnel to diagnose and troubleshoot potential fault conditions in the power

amplifier and power supply.

5–1Troubleshooting

Page 32

TROUBLE

TROUBLETROUBLE

5.1 Troubleshooting Flow Chart Analysis

Does your

amplifier have

output power?

Are there any

fault

indicators?

Yes No

Is power

output at the

proper level?

Yes No

Yes No

Yes No

Is exciter delivering

sufficient RF drive?

(Check In Ref meter

reading.)

See Section 3.1

Initial Power-up

procedures.

See Section 3.1

Initial Power-up

procedures.

Do you have

power now?

Yes No

Is your exciter

turned on?

Yes No

Turn the

exciter on.

Antenna:

Section 5.3.1

RF Drive:

Section 5.3.2

PA Temp:

Section 5.3.3

PA DC:

Section 5.3.4

See

See

Secure all

connections to the

PS2000.

See

Ensure AC input

circuit breaker is

flipped up

See

Ensure main

power switc h is

turned on.

Call Support—

See Section 8

5–2

FM1000A User’s Manual

Page 33

5.2 Digital Multimeter Parameters

The following procedures are general in nature; for in-depth service, and repair see

the Service & Support section of this manual.

WWARNINGARNING

Lethal voltages present!

Only technically qualified

individuals shoud attempt

troubleshooting or service

procedures

If any abnormal readings are displayed for any of the following parameters on the

Digital Multimeter, try troubleshooting in the following manner:

5.2.1 In Ref (Input Drive Reference)

If this indication of drive level is not between 0.4 and 0.8 volts, then:

.

q Check the exciter to ensure proper power input level of 25–30 watts.

q Check RF input cable for secure connection.

5.2.2 SWR (Standing Wave Ratio)

If the SWR is over 1.5:1, then look for:

q effects of inclement weather such as icing on the antenna and feed line.

q for moisture in the feedline.

q insecure antenna connections.

5.2.3 ALC (Automatic Level Control)

If this indication is not between 4.00 and 6.00 volts for 1.1 kW output, then:

q Check for overheating (see PA Temp fault LED).

q Check for overcurrent (see PA DC fault LED).

q Check for high SWR (see Antenna fault LED).

5.2.4 Power Out

This reading is user adjustable, but for full output should read 1.10 for 1.1 kW.

q If lower than desired, check for proper input drive, and/or proper adjustment

of the Local Power Control (see section 3.1 #6).

5–3Troubleshooting

Page 34

TROUBLE

TROUBLETROUBLE

5.2.5 PA Temp

The meter should read between 35–50°C with an ambient temperature of 25°C. If

temperature is 75°C or above, then check and do the following:

❑ Ambient temperature higher than 50°C; reduce temperature.

❑ Restricted air flow; remove any obstructions, clean dirty air filters by using

mild detergent and warm water.

❑ Possible antenna mismatch; check for icing, moisture in the feedline, and

secure antenna connections.

❑ Overcurrent: If PA DC fault indicator is flashing, monitor the current for a

proper level—the total current and the current of individual Power Amps.

5.2.6 PA Voltage

Supply voltage to the RF power amplifiers should be 50 V. If it is not check:

❑ drive level to ensure proper power level input of 30 watts

❑ for high SWR

❑ for overcurrent; check PA DC fault indicator and if flashing, check current for

proper levels (total and individual Power Amps)

❑ for overtemperature; ambient temperature higher than 50°C; reduce tempera-

ture. Check air flow; remove any obstructions and clean dirty air filters.

5.2.7 Tot Current

If total current reading is over 35 amperes, then check or do the following:

❑ Reduce power output; check all fault indicators and troubleshoot accordingly.

❑ If one or more of the 250–watt power modules has failed; replace.

❑ High SWR; check for icing, moisture in the feedline, and secure antenna

connections.

5.2.8 PA1–8

If there is 2.5 amps or more difference between the individual PA current readings

(7 to 9 amps typical), then check the following:

❑ Failed/faulty power module (reading directly correlates to failed power mod-

ule); replace.

❑ Blown individual power amplifier fuses 1–8; replace as indicated by red LED.

❑ Reduced power output; check all fault indicators and troubleshoot accordingly.

5–4

FM1000A User’s Manual

Page 35

5.3 Fault Indicators

If one of the LED fault indicators is illuminated red, troubleshoot using the following suggestions:

5.3.1 Antenna

Antenna mismatch.

❑ Effects from inclement weather conditions such as icing.

❑ Check for moisture in the feedline.

❑ Secure antenna connections.

5.3.2 RF Drive

Denotes lack of or insufficient drive level.

❑ Ensure proper drive level of 25–30 watts input power.

❑ Check RF input cable for secure connection.

5.3.3 PA Temp

Temperature has reached the internal preset limit for safe operation (75°C).

❑ Ambient temperature higher than 50°C; reduce temperature.

❑ Restricted air flow; remove any obstructions, clean dirty air filters by using

mild detergent and warm water.

❑ Antenna mismatch; check for icing, moisture on the feedline, and secure

antenna connections.

❑ Overcurrent; check PA DC fault indicator, if flashing monitor current for

proper levels (total and individual Power Amps).

❑ Faulty DC Output Board; replace (see Section 7, Service & Support).

❑ Faulty or non-functioning cooling fan; determine the cause for malfunction

in the following section.

5.3.3.1 Potential Causes for Non-functioning Cooling Fans

The PA1000 has one and the PS1000 has two cooling fans each. All three fans are

powered by the same circuit of the PS1000. There are two potential causes for a

non-functioning fan or fans:

1. If a single fan does not operate, the fan is faulty and must be replaced. (See

Section 7, Service & Support.)

2. If none of the fans operate, a blown circuit breaker, a short circuit in the

PS1000, or a damaged winding on the main transformer of the DC Output

Board (in the PS1000) is the cause. In this case, do one of the following:

5–5Troubleshooting

Page 36

TROUBLE

TROUBLETROUBLE

a. The circuit breaker is located on the rear panel of the power supply. If the

breaker has popped out, reset it by pushing it in. If the breaker continues

to trip, check for a short circuit.

b. Check each fan with a volt-ohm meter by disconnecting and testing it for a

short circuit. Replace the fan/fans as needed (see Section 7).

c.If none of the fans have short circuits, there is damage on the

winding of the transformer. It will have to be replaced (see Section 7).

5.3.4 PA DC

Discrepancy in current between the individual amplifiers, or in total current.

❑ There is a difference of current greater than 2.5 amps between any one of the

4 individual amplifiers. This could occur as a result of a blown or faulty power

module, or a blown fuse; replace as appropriate (see Section 7, Service &

Support).

❑ There is too much total current—power foldback will occur above maximum

total amperage of 35 amps due to antenna mismatch. Examine the antenna

for arcing and moisture. Also, check output power for proper current; the RF

detection circuit could malfunction causing an overcurrent situation.

5.3.5 Multiple Indicators

Call your Crown Broadcast service representative. See Section 7, Service and

Support, for contact information.

®

s

e

s

u

t

l

u

a

g

n

i

r

e

t

e

M

e

R

n

I

R

W

S

C

L

A

r

e

w

o

P

I

O

F

a

n

n

e

t

n

A

5

A

P

1

A

P

t

u

O

r

e

w

o

P

e

v

i

r

D

F

R

6

A

P

2

A

P

p

m

e

T

A

P

f

p

m

e

T

A

P

7

A

P

3

A

P

e

g

a

t

l

o

V

A

P

C

D

A

P

8

A

P

4

A

P

t

n

e

r

r

u

C

t

o

T

®

®

F

8

A

P

7

A

P

6

A

P

5

A

P

4

A

P

3

A

P

2

A

P

1

A

P

5–6

FM1000A User’s Manual

Page 37

Section 6—Reference Drawings

The illustrations in this section may be useful for making

adjustments, taking measurements, troubleshooting, or

understanding the circuitry of your RF power amplifier and

power supply.

6–1Reference Drawings

Page 38

6.1 Views

Metering

In Ref

SWR

ALC

Power

I

O

Power Out

PA Temp

PA Voltage

Tot Current

PA1

PA5

PA2

PA6

PA3

PA7

PA4

PA8

®

®

Fault

Antenna

RF Drive

PA Temp

PA DC

PA3

Fuses

PA

4 PA7

PA8

Illustration 6–1 Front View

+ DC Input

DC Input

PA1000

+ DC Output

DC Output

PS1000

Ground Screws

RF Monitor

(Optional Connection)

Air Intakes/Filters

RF Output

Air Exhaust Vents

RF Input

Remote I/O

Control

Circuit Breakers

OFF

Fans

OFF

Power

Control

240 VA C IN

6–2

Illustration 6–2 Back View

FM1000A User’s Manual

Page 39

6.2 Diagrams and Schematics

30 W Exciter

(Crown FM30)

RF Input

Excitation

1 kW RF

Power Output

PA1000

Power Amplifier

Remote I/O

Connector

Power Supply

Control

0–50 VDC

PA Supply

PS1000

Power Supply

240 VAC

50/60 Hz Input Power

Single Phase

Illustration 6–3 FM1000A Block Diagram

6–3Reference Drawings

Page 40

6–4

FM1000A User’s Manual

Illustration 6–4 PS1000 Block Diagram

240 VAC

AC

CIRCUIT

BREAKER

AC INPUT

NEUTRAL

GROUND

AC

INPUT

CCA

POWER

SWITCH

RECTIFIER

PFC &

CONTROL

CCA

DC

OUTPUT

CCA

+ 0 to 50 VDC

RETURN

PS CONTROL

9-PIN

DSUB

220 VDC

+/ 12 VDC

VOLTAGE

BOOST

INDUCTOR

360 VDC

360 VDC

CONTROL

Page 41

6–8

FM1000A User’s Manual

Illustration 6–5 PA1000 Block Diagram

Page 42

6–13

Reference Drawings

Backplane Distribution

Note: All bypass capacitors are 0.01 mf

Page 43

6–14

FM1000A User's Manual

Ribbon Cables and Connectors

Ribbon Cables and Connectors

Page 44

6–16

FM1000A User's Manual

Notes:

Page 45

Section 7—Service and Support

We understand that you may need various levels of support or

that the product could require servicing at some point in time.

This section provides information for both of these scenarios.

Service and Support

7–1

Page 46

7.1 Service

The product warranty (see opposite page) outlines our responsibility for defective

products. Before returning a product for repair or replacement (our choice), call

our Customer Service department using the following telephone number:

(866) 262-8917

Our Customer Service Representative will give you further instructions regarding

the return of your product. Use the original shipping carton or a new one obtained

from Crown. Place shipping spacers between the slide-out power amplifier assembly and the back panel.

Please fill out the Factory Service Instructions sheet (page 7–5) and include it with

your returned product.

7.2 24–Hour Support

In most instances, what you need to know about your product can be found in this

manual. There are times when you may need more in-depth information or even

emergency-type information. We provide 24–hour technical assistance on your

product via a toll telephone call.

For emergency help or detailed technical assistance, call

(866) 262-8917

You may be required to leave a message at this number but your call will be

returned promptly from our on-call technician.

7.3 Spare Parts

To obtain spare parts, call Crown Broadcast Sales at the following number.

(866) 262-891

You may also write to the following address:

Service Manger

International Radio and Electronics Company, Inc.

25166 Leer Drive

Elkhart, Indiana, U.S.A. 46514-5425

7–2

FM1000A User's Manual

Page 47

Crown Broadcast Three Year Limited Product Warranty

SUMMARY OF WARRANTY

Crown Broadcast, IREC warrants its broadcast products to the ORIGINAL PURCHASER of a NEW Crown

Broadcast product, for a period of three (3) years after shipment from Crown Broadcast. All products are

warranted to be free of defects in materials and workmanship and meet or exeed all specifications published

by Crown Broadcast. Product nameplate with serial number must be intact and not altered in any way. This

warranty is non - transferable. This warranty in its entirety is the only warranty offered by Crown Broadcast. No

other warranties, expressed or implied, will be enforceable.

EXCLUSIONS

Crown Broadcast will not warranty the product due to misuse, accident, neglect and improper installation or

operation. Proper installation included A/C line surge supression, lightning protection and proper grounding of

the entire transmitter, and any other recommendations designated in the Instruction manual. This warranty

does not extend to any other products other than those designed and manufactured by Crown Broadcast. This

warranty does not cover any damage to any accessory such as loads, transmission line or antennas resulting

from the use or failure of a Crown Broadcast transmitter. Warranty does not cover any loss of revenue resulting

from any failure of a Crown Broadcast product, act of God, or natural disaster.

Procedure for Obtaining Warranty Service

Crown Broadcast will repair or service, at our discretion, any product failure as a result of normal intended use.

Warranty repair can only be performed at our plant facility in Elkhart, Indiana USA or at a factory authorized

service depot. Expenses in remedying the defect will be borne by Crown Broadcast, including two-way ground

transportation cost within the continental United States.

Prior to returning any product or component to Crown Broadcast for warranty work or repair, a Return

Authorization (RA) number must be obtained from the Crown Broadcast Customer Service Department.