Page 1

FC 4500

Specifications

FC 4500 Series

Sit-down Rider

Lift Truck

Series

Page 2

FC 4500 Series

14.6"

Sit-down Rider

Lift Truck

Page 3

FC 4500 Series

Specifications

Manufacturer

1

Model

2

Load Capacity*

3

Load Center

4

Power

5

Operator Type

6

Tire Type

7

General Information

Wheels (x = driven)

8

9

Mast (See Mast Chart)

Fork Carriage

12

Forks

13

Tilt

14

Battery Compartment

Headlength

15

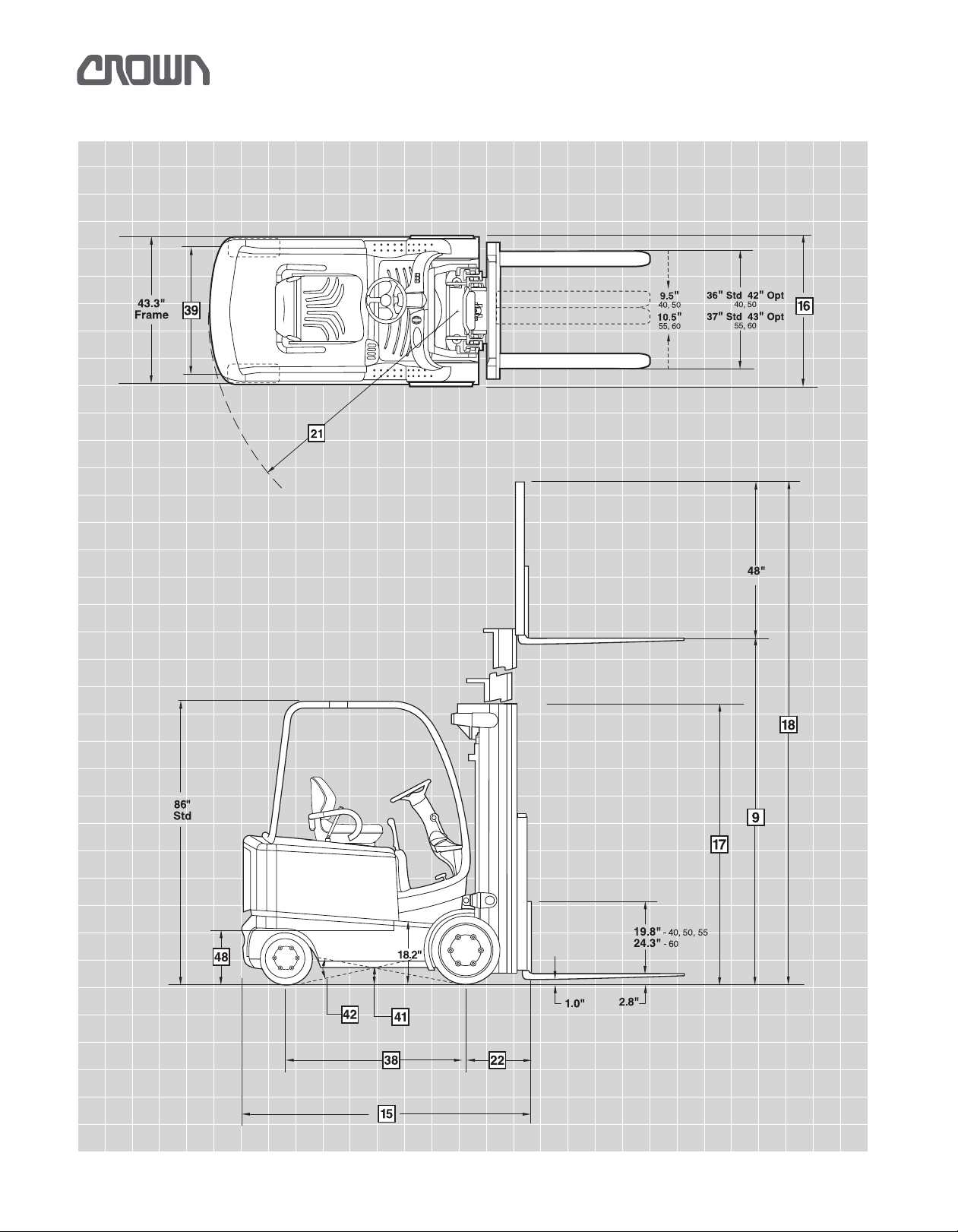

Width Overall

16

Dimensions

17

Height with Load Backrest

18

Turning Radius

21

Load Distance

22

Aisle Width (Add Load + Clear)

23

Speed Travel

24

Speed Lift†† DC

25

AC

Performance

Speed Lower

26

Weight, Less Battery

32

Axle Load with Max Battery,

33

Loaded

Axle Load with Max Battery,

34

Weights

Unloaded

36

Tires

37

Wheelbase

38

Tread/Track Width

39

Ground Clearance, Loaded

40

Chassis

41

Grade Clearance, Loaded

42

Brakes

43

44

45

Battery

46

47

Battery

Battery Floor Height

48

49

Motors

50

Motors

Operating Pressure

51

Fork Face to Load CG

Electric

Number Front/Rear

Lifting Height (MFH)

Free Lift Height

Standard L x W x T

Optional Lengths

F° / B°

Interlocked Fork Height**

Length to Fork Face

Standard Tread

Wide Tread

Mast Collapsed

Mast Extended

Center of Wheel to Fork Face

Right Angle Stack

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded

Front

Rear

Front

Rear

Size Front

Size Rear

Front Standard / Rear

Front Optional / Rear

Lowest Point

Center of Wheelbase

Service

Parking

Type

Capacity - 36V

Capacity - 48V

Weight - Min

Weight - Max

Size - Max

With Rollers / w/o Rollers

Tractor Motor, dia

Lift Motor, dia

For Attachments

Crown Equipment Corporation

FC 4510/15-40 FC 4520/25-40

lb 4000

in 24

36-Volt / 48-Volt

Sit-down Rider Counterbalanced

Cushion

2x / 2

in 188

in 32.2

ITA Class II

in 36 x 4 x 1.8

in 42, 48, 54, 60

degree 5 / 5

in 66

in 27 33

in 77.8 84

in 43.4

in 47.5

in 83

in 236

in 69.1 75.3

in 15.8

in 84.9 91.1

mph 11 / 10.2

mph 9 / 8.3

fpm 110 / 76

fpm 76 / 58

fpm 110 / 92

fpm 104 / 71

fpm 90

lb 7,243 7,195

lb 11,987 11,752

lb 1,886 2,242

lb 4,787 4,851

lb 5,086 5,144

in 21 x 7 x 15

in 16 x 6 x 10.5

in 49.7 54.7

in 36.4 / 36

in 40.5 / 36

in 3

in 4.8

% 38 35

Foot Hydraulic

Hand Electro-hydraulic

Lead Acid

AH 1210 1430

kWh 42.5 50.2

AH 880 1100

kWh 41.2 51.5

lb 2630 2800

lb 3200 4000

Length 27.25 32.94

Width 38.69

Height 22.25

in 17.4 / 17.1

in 11.4

in 7.2

psi Up to 3000

* Optional masts, attachments, longer load dimensions and higher lifting heights may result in derating of the capacity. Contact local dealer.

** Forward tilt restricted to 2° above this height.

† With maintenance-free batteries or batteries with a lid (flat top), consult factory.

†† Based on TT mast.

Page 4

FC 4500 Series

Specifications

Manufacturer

1

Model

2

Load Capacity*

3

Load Center

4

Power

5

Operator Type

6

Tire Type

7

General Information

Wheels (x = driven)

8

9

Mast (See Mast Chart)

Fork Carriage

12

Forks

13

Tilt

14

Battery Compartment

Headlength

15

Width Overall

16

Dimensions

17

Height with Load Backrest

18

Turning Radius

21

Load Distance

22

Aisle Width (Add Load + Clear)

23

Speed Travel

24

Speed Lift†† DC

25

AC

Performance

Speed Lower

26

Weight, Less Battery

32

Axle Load with Max Battery,

33

Loaded

Axle Load with Max Battery,

34

Weights

Unloaded

36

Tires

37

Wheelbase

38

Tread/Track Width

39

Ground Clearance, Loaded

40

Chassis

41

Grade Clearance, Loaded

42

Brakes

43

44

45

Battery

46

47

Battery

Battery Floor Height

48

49

Motors

50

Motors

Operating Pressure

51

Fork Face to Load CG

Electric

Number Front/Rear

Lifting Height (MFH)

Free Lift Height

Standard L x W x T

Optional Lengths

F° / B°

Interlocked Fork Height**

Length to Fork Face

Standard Tread

Wide Tread

Mast Collapsed

Mast Extended

Center of Wheel to Fork Face

Right Angle Stack

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded

Front

Rear

Front

Rear

Size Front

Size Rear

Front Standard / Rear

Front Optional / Rear

Lowest Point

Center of Wheelbase

Service

Parking

Type

Capacity - 36V

Capacity - 48V

Weight - Min

Weight - Max

Size - Max

With Rollers / w/o Rollers

Tractor Motor, dia

Lift Motor, dia

For Attachments

Crown Equipment Corporation

FC 4510/15-50 FC 4520/25-50 FC 4540/45-50

lb 5000

in 24

36-Volt / 48-Volt

Sit-down Rider Counterbalanced

Cushion

2x / 2

in 188

in 32.2

ITA Class II

in 36 x 4 x 1.8

in 42, 48, 54, 60

degree 5 / 5

in 66

in 27 33 36

in 81.2 84 87.1

in 43.4

in 47.5

in 83

in 236

in 71.9 75.4 78.0

in 15.8

in 87.7 91.2 93.8

mph 10.9 / 9.9

mph 8.8 / 8.0

fpm 110 / 70

fpm 76 / 50

fpm 110 / 86

fpm 104 / 66

fpm 90

lb 8,090 7,736 7,454

lb 13,616 13,641 13,456

lb 2,103 1,895 2,097

lb 4,616 5,014 4,829

lb 6,104 5,522 5,724

in 21 x 8 x 15

in 16 x 6 x 10.5

in 49.7 54.7 54.7

in 35.4 / 36

in 39.5 / 36

in 3

in 4.8

% 38 35 35

Foot Hydraulic

Hand Electro-hydraulic

Lead Acid

AH 1210 1430 1650

kWh 42.5 50.2 57.9

AH 880 1100 1210

kWh 41.2 51.5 56.6

lb 2630 2800 3100

lb 3200 4000 4250

Length 27.25 32.94 36.38

Width 38.69

Height 22.25

in 17.4 / 17.1

in 11.4

in 7.2

psi Up to 3000

* Optional masts, attachments, longer load dimensions and higher lifting heights may result in derating of the capacity. Contact local dealer.

** Forward tilt restricted to 2° above this height.

† With maintenance-free batteries or batteries with a lid (flat top), consult factory.

†† Based on TT mast.

Page 5

FC 4500 Series

Specifications

Manufacturer

1

Model

2

Load Capacity*

3

Load Center

4

Power

5

Operator Type

6

Tire Type

7

General Information

Wheels (x = driven)

8

9

Mast (See Mast Chart)

Fork Carriage

12

Forks

13

Tilt

14

Battery Compartment

Headlength

15

Width Overall

16

Dimensions

17

Height with Load Backrest

18

Turning Radius

21

Load Distance

22

Aisle Width (Add Load + Clear)

23

Speed Travel

24

Speed Lift†† DC

25

AC

Performance

Speed Lower

26

Weight, Less Battery

32

Axle Load with Max Battery,

33

Loaded

Axle Load with Max Battery,

34

Weights

Unloaded

36

Tires

37

Wheelbase

38

Tread/Track Width

39

Ground Clearance, Loaded

40

Chassis

41

Grade Clearance, Loaded

42

Brakes

43

44

45

Battery

46

47

Battery

Battery Floor Height

48

49

Motors

50

Motors

Operating Pressure

51

Fork Face to Load CG

Electric

Number Front/Rear

Lifting Height (MFH)

Free Lift Height

Standard L x W x T

Optional Lengths

F° / B°

Interlocked Fork Height**

Length to Fork Face

Standard Tread

Wide Tread

Mast Collapsed

Mast Extended

Center of Wheel to Fork Face

Right Angle Stack

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded

Front

Rear

Front

Rear

Size Front

Size Rear

Front Standard / Rear

Front Optional / Rear

Lowest Point

Center of Wheelbase

Service

Parking

Type

Capacity - 36V

Capacity - 48V

Weight - Min

Weight - Max

Size - Max

With Rollers / w/o Rollers

Tractor Motor, dia

Lift Motor, dia

For Attachments

Crown Equipment Corporation

FC 4520/25-55 FC 4540/45-55

lb 5500

in 24

36-Volt / 48-Volt

Sit-down Rider Counterbalanced

Cushion

2x / 2

in 188

in 32.2

ITA Class II

in 36 x 5 x 1.8

in 42, 48, 54, 60

degree 5 / 5

in 66

in 33 36

in 87.4 90.5

in 45.2

in 48

in 83

in 236

in 78.2 80.9

in 15.8

in 94.0 96.7

mph 10.8 / 9.7

mph 8.8 / 7.8

fpm 110 / 68

fpm 76 / 47

fpm 110 / 81

fpm 104 / 62

fpm 90

lb 8,285 8,166

lb 14,308 14,111

lb 2,277 2,655

lb 4,818 4,622

lb 6,267 6,644

in 21 x 9 x 15

in 16 x 7 x 10.5

in 54.7 54.7

in 36.2 / 36

in 39 / 36

in 3

in 4.8

% 35 35

Foot Hydraulic

Hand Electro-hydraulic

Lead Acid

AH 1430 1650

kWh 50.2 57.9

AH 1100 1210

kWh 51.5 56.6

lb 2800 3100

lb 4000 4250

Length 32.94 36.38

Width 38.69

Height 22.25

in 17.4 / 17.1

in 11.4

in 7.2

psi Up to 3000

* Optional masts, attachments, longer load dimensions and higher lifting heights may result in derating of the capacity. Contact local dealer.

** Forward tilt restricted to 2° above this height.

† With maintenance-free batteries or batteries with a lid (flat top), consult factory.

†† Based on TT mast.

Page 6

FC 4500 Series

Specifications

Manufacturer

1

Model

2

Load Capacity*

3

Load Center

4

Power

5

Operator Type

6

Tire Type

7

General Information

Wheels (x = driven)

8

9

Mast (See Mast Chart)

Fork Carriage

12

Forks

13

Tilt

14

Battery Compartment

Headlength

15

Width Overall

16

Dimensions

17

Height with Load Backrest

18

Turning Radius

21

Load Distance

22

Aisle Width (Add Load + Clear)

23

Speed Travel

24

Speed Lift†† DC

25

AC

Performance

Speed Lower

26

Weight, Less Battery

32

Axle Load with Max Battery,

33

Loaded

Axle Load with Max Battery,

34

Weights

Unloaded

36

Tires

37

Wheelbase

38

Tread/Track Width

39

Ground Clearance, Loaded

40

Chassis

41

Grade Clearance, Loaded

42

Brakes

43

44

45

Battery

46

47

Battery

Battery Floor Height

48

49

Motors

50

Motors

Operating Pressure

51

Fork Face to Load CG

Electric

Number Front/Rear

Lifting Height (MFH)

Free Lift Height

Standard L x W x T

Optional Lengths

F° / B°

Interlocked Fork Height**

Length to Fork Face

Standard Tread

Wide Tread

Mast Collapsed

Mast Extended

Center of Wheel to Fork Face

Right Angle Stack

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded 48V

Empty / Loaded 36V

Empty / Loaded

Front

Rear

Front

Rear

Size Front

Size Rear

Front Standard / Rear

Front Optional / Rear

Lowest Point

Center of Wheelbase

Service

Parking

Type

Capacity - 36V

Capacity - 48V

Weight - Min

Weight - Max

Size - Max

With Rollers / w/o Rollers

Tractor Motor, dia

Lift Motor, dia

For Attachments

Crown Equipment Corporation

FC 4520/25-60 FC 4540/45-60

lb 6000

in 24

36-Volt / 48-Volt

Sit-down Rider Counterbalanced

Cushion

2x / 2

in 180

in 32.2

ITA Class III

in 36 x 5 x 1.8

in 42, 48, 54, 60

degree 5 / 5

in 66

in 33 36

in 87.7 90.8

in 45

in 48

in 83

in 228

in 78.2 80.9

in 16.1

in 94.3 97.0

mph 10.8 / 9.5

mph 8.8 / 7.6

fpm 110 / 66

fpm 76 / 43

fpm 110 / 76

fpm 104 / 57

fpm 90

lb 8,687 8,226

lb 15,364 15,078

lb 2,124 2,248

lb 4,984 4,699

lb 6,503 6,627

in 21 x 9 x 15

in 16 x 7 x 10.5

in 54.7 54.7

in 36.2 / 36

in 39 / 36

in 3

in 4.8

% 35 35

Foot Hydraulic

Hand Electro-hydraulic

Lead Acid

AH 1430 1650

kWh 50.2 57.9

AH 1100 1210

kWh 51.5 56.6

lb 2800 3100

lb 4000 4250

Length 32.94 36.38

Width 38.69

Height 22.25

in 17.4 / 17.1

in 11.4

in 7.2

psi Up to 3000

* Optional masts, attachments, longer load dimensions and higher lifting heights may result in derating of the capacity. Contact local dealer.

** Forward tilt restricted to 2° above this height.

† With maintenance-free batteries or batteries with a lid (flat top), consult factory.

†† Based on TT mast.

Page 7

FC 4500 Series

Mast Chart FC 4500-40/50/55 TL TT QUAD

9

Lifting Height

11

Free Lift Height†

14

Interlocked Fork Ht

17

Mast Collapsed Ht

18

Mast Extended Ht†

Mast Chart FC 4500-60 TL TT

9

Lifting Height

11

Free Lift Height†

14

Interlocked Fork Ht

17

Mast Collapsed Ht

18

Mast Extended Ht†

* Wide tread drive tires recommended. Refer to capacity charts.

† Includes load backrest.

in 126 138 150 188 206 216* 231* 246* 258* 276* 291* 240* 258* 276* 294* 312*

in 5.6 5.6 5.6 32.2 38.2 44.2 50.2 56.2 62.2 68.2 74.2 31.8 39.8 43.8 49.8 55.8

in 78 78 78 66 72 78 84 90 96 102 108 76 82 88 94 100

in 83 89 95 83 89 95 101 107 113 119 125 83 89 95 101 107

in 174 186 198 236 254 264 279 294 306 324 339 288 306 324 342 360

in 118 130 142 180 198 208* 223* 238* 250*

in 5.9 5.9 5.9 32.2 38.2 44.2 50.2 56.2 62.2

in 78 78 78 66 72 78 84 90 96

in 83 89 95 83 89 95 101 107 113

in 166 178 190 228 246 256 271 286 298

Specifications

Standard Features

1. Crown’s Access 1 2 3

Comprehensive

System Control

2. Intrinsic Stability System™

•Travelspeedreduction

when above mast staging

•Forwardtiltinterlock

above staging

•Counterweightexceeds

required standards

•Rampspeedcontrol

3. Operator entry/exit

•18"stepheight

•Largeentry/exit“window”

•Tubularoverheadguard

upright for easy hand hold

•Contouredbattery

seat deck

•Roundedfloorboardedges

•Tiltsteeringwheeland

sculpted column

•Large,unclutteredfloor-

board

4. Operator compartment

design features

•Lowcowlforforkand

floor visibility

•Widevisibilitywindow

between overhead guard

and front pillars

•CrownFlexSeat™-fabric

with hip restraint and

anti-cinch seatbelt.

•Infiniteadjustmentsteering

wheel column

•Fingertipapplied/released

parking brake with tone alert

®

•Nyloncontrol

tactile feedback

•

Natural position for forward/

reverse selector

•Rubberfloormat/rubber

covered pedals

5. AC traction system

6. Exclusive Crown power disc

brake with regenerative

motor plugging

7. Crown-manufactured

lift motor

8. 36/48-volt system

9. Crown display

Battery discharge indicator

•

with lift interrupt and

re-key feature

•

Hour meters/travel

distance/stop watch

•

Pin code access capable

•

Event code display with

five (5) key navigation

•

Access 1 2 3 diagnostics

•

P1, P2, P3 Performance

tuning

10. High visibility mast with

in-line hose routing

11. Waterfall design

overhead guard

12. Lift out or side removal

battery access

13. Battery side retainer

with interlock and

fault identification

14. No tool lift out floorboards

15. 48" high load backrest

16. 350 amp battery connector

handles with

FC 4500 Series

17. Color-coded wiring

18. InfoPoint

Quick Reference Guide

19. Three-spool valve

20. O-ring face seal

hydraulic fittings

21. Battery disconnect handle

22. Lift interrupt

Optional Equipment

1. AC Hydraulics

2. Sideshifter

3. Freezer and corrosion

conditioning

4. UL “EE” rating

5. InfoLink® Ready System

6. TL and quad mast styles

7. Polished and tapered forks

8. Fork lengths

9. Hydraulic valves for

attachments

10. Quick disconnect

hydraulic connectors

11. Attachment pressure

regulator and gauge

12. Special forward tilt

13. Brush wear and motor overtemperature indicators for

DC motors

14. Adjustable armrest

15. Steering spinner knob

16. Keyless on/off switch

17. Work lights

18. Storage tray with

clipboard support

19. Suspension Seat -

fabric or vinyl

®

System with

Technical Information

20. Tilt Position Assist

Urethane covered control

21.

handles with tactile feedback

(3" shorter)

22. Back-up, brake and tail light

23. Strobe lights

24. Audible travel alarm

25. Tow pin

26. Automatic parking brake,

(seat activated)

27. Brake activated

traction cutout

28. Foot operated

directional control

29. Full battery side doors

30. Battery compartment rollers

31. Dock Performance Package

32. Pos/Neg accessory cable

33. Wide tread widths

34. Load backrest heights

35. Drive-in rack

overhead guard

36. Non-marking smooth or

lug rubber tires

37. Work Assist® Accessories

• Clippadandhook

• Accessoryclamp

• Terminalmounting

• Fireextinguisher

• Operatorfan

• Worklights

• Mirrors

38. Battery spacer

39. Crown FlexSeat - vinyl

Page 8

FC 4500 Series

Technical Information

Driveability

The FC 4500 benefits from

Crown’s design and engineering

excellence. Numerous features

improve operator comfort

and productivity.

A low 18" step height first greets

the operator. A low, streamlined

battery cover helps the operator

glide into the truck’s seat. The

overhead guard is shaped to

open up the entry/exit window

and its tubular design provides a

comfortable hand grip location for

a variety of operator heights. The

compact tilt steer column and

steer wheel further facilitate

entry/exit. Tilt column is spring

loaded to easily move up and

away. Floorboard (625-sq in) is

uncluttered and rubber covered

to insulate the operator from

vibration. Sculpted floorboard

design promotes visibility to the

drive tires, which can reduce

product and pallet damage. Brake

pedal effort is reduced. Pedal to

pedal and floor to pedal relationships are refined for comfort.

Better visibility can be seen

everywhere you look. A low

cowl for fork and carriage

visibility, a high visibility mast,

a compact steer column, a

sculpted floorboard and a

“waterfall” overhead guard all

contribute to superior visibility.

Control handles are crafted into

the compartment and “fanned” for

easy selection. They are

urethane covered with tactile

feedback for comfort and easy

selection. Control actuation forces

are minimal and responsive.

Finger applied/released parking

brake with tone alert enhances

operator entry/exit and naturally

encourages its use. Battery

disconnect is easy to reach and

operate. Easy to actuate rockertype switches are conveniently

located to select optional work

lights or fan. A large convex horn

button is housed in the center of

the wheel.

Crown Drive System

Crown has applied the latest

generation AC drive system,

enhanced with Access 1 2 3

®

technology. The demand for

high efficiency systems that

closely match customer torque

requirements is met with this

generation control system.

Drive motor is transversemounted high above the floor

away from dirt and moisture.

Heavy-duty triple reduction, all

gear design operates in oil bath.

Engineered for durability with

reduced vibration and noise.

Crown’s Access 1 2 3

technology provides optimum

performance and control by

offering a communication

interface for both operators

and technicians, intelligent

coordination of lift truck

systems and simplified service

with advanced diagnostics.

The Crown display is used for

easy troubleshooting, access

event history and set performance features. A distribution

panel is conveniently located

with all test points, control

fuses and central wiring for

easy troubleshooting.

Three modes of performance

can be selected to accommodate operator experience or

application requirements.

Crown Power Brake System

Service brakes are located in the

wheel ends with a unique full

circle power disc design.

Hydraulic power is utilized to

actuate a full circle rotor. This

design reduces operator pedal

effort and improves brake

response. Brake service life

is increased due to a

circle friction pad. Access

friction pads for inspection or

replacement is direct and easy,

reducing downtime for brake

maintenance. Parking brake

is activated by a push button

located on the cowl to the right

of the steer wheel column.

Tone alert reminder is standard.

Parking brake is located on the

end of the motor shaft to take

advantage of gear reduction.

Optional seat activated automatic parking brake is available.

Steering

Fully hydrostatic system with

equal area, double-acting

cylinder provides equally responsive steering rate both ways

(4.8 turns lock to lock). Rugged

axle frame; forged spindle and

connecting links eliminate the

need for adjustment. One-piece

forged spindle and kingpin

in tapered roller bearings for

improved life and serviceability.

Spherical bearings with tapered

pins in connecting links eliminate

any play in linkage. All bearing

locations are sealed to exclude

contaminants and are equipped

with lubrication fittings for ease

of service. Axle articulates in

rubber isolation bushing to

improve truck handling and ride.

large full

to the

Crown Manufactured

Mast Assembly

Large, rugged mast trunnion

mount on drive axle and extra

heavy tilt cylinders with self-aligning bushings secure mast.

High visibility mast features

nested-rail design with lift

cylinders positioned behind

the rails. Heavy-duty mast is

engineered to provide smooth

reliable operation. Large hydraulic hose reeves and hose placement are engineered to reduce

hose wear and increase hose

life. Hose routing places hoses

in-line versus side-by-side to

reduce visual interference. Large

lift chains are used for long reliable service life. Large diameter

lift cylinders provide smooth

operation.

Class II and III fork carriages are

available. Optional TL and quad

mast is available.

Hydraulics

Premium hydraulic function

control valve provides precise

metering of lift, tilt and accessory functions. Compensating

section in the valve provides

repeatable function speed

regardless of load condition.

Hydraulic lever actuation is

minimal, reducing stress.

Compensating section also

improves overall system efficiency.

Tilt compensator prevents tilt

from lunging or speeding up when

doing simultaneous functions.

Crown lift/tilt interlock system

provides extended forward tilt

at low fork heights, reduced

forward tilt at elevated heights

to improve truck stability when

forks are elevated.

The control valves’ modular

design allows easy addition of

accessory functions. Maximum

lowering speed is limited by

pressure compensating flow

control valve and velocity fuses.

Integrated hydraulic cylinder

cushions soften mast staging.

You can count on Crown to build lift trucks

designed for safe operation, but that’s

only part of the safety equation. Crown

encourages safe operating practices through

ongoing operator training, safety-focused

supervision, maintenance and a safe working

environment. Go to crown.com and view our

safety section to learn more.

All lift cylinder rams are plated

and retract into the hydraulic oil

for additional corrosion protection when forks are lowered.

The steel oil reservoir is integral

to the frame which helps to dissipate hydraulic oil heat. This

clean, leak-free design includes

suction strainer with separate,

easily accessible fill port and

dipstick with filtered breathers.

Oil is returned through a replaceable spin-on type oil filter.

Batteries

Battery deck lid releases easily

to expose battery for lift out or

side battery removal. Optional

battery rollers for use with

mechanized extraction equipment. A low battery side retainer

is standard. Full battery side

doors are optional.

Other Options

1. Audible travel alarm

2. Flashing lights

Safety considerations and

dangers associated with

audible travel alarms and

flashing lights include:

• Multiplealarmsand/orlights

can cause confusion.

• Workersignorethealarms

and/or lights after day-in and

day-out exposure.

• Operatormaytransferthe

responsibility for “looking out”

to the pedestrians.

• Annoysoperatorsand

pedestrians.

Other Options Available

Contact your local Crown dealer.

Dimensions and performance

data given may vary due to

manufacturing tolerances.

Performance is based on an

average size vehicle and is

affected by weight, condition of

truck, how it is equipped and the

conditions of the operating area.

Crown products and specifications are subject to change

without notice.

Crown Equipment Corporation

New Bremen, Ohio 45869 USA

Tel 419-629-2311

Fax 419-629-3796

crown.com

Because Crown is continually improving its products,

specifications are subject to change without notice.

Crown, the Crown logo, the color beige,

the Momentum symbol, Access 1 2 3,

InfoPoint, Intrinsic Stability System, FlexSeat,

InfoLink and Work Assist are trademarks of

Crown Equipment Corporation.

Copyright 2007-2010 Crown Equipment Corporation

SF14837 Rev. 9/10

Printed in U.S.A.

Loading...

Loading...