Page 1

Owner’s Manual and

Service Guide

Original Instruction

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION……………………………………………………...1- 7

OPERATION AND SERVICE INFORMATION……………………………..8-43

Before initial use………………………………………………………………………………….8

Key switch…………………………………………………………………………......................9

Direction selector, accelerator pedal……………………………………………….......................10

Combination brake and park brake pedal, horn, operating the vehicle…………………………..11

Regenerative braking……………………………………………………………………………..12

Diagnostic mode feature, starting and driving, start vehicle on a hill……………………………13

Coasting, sun top and windshield, vehicle cleaning and care……………………………………14

REPAIR

Lifting the vehicle………………………………………………………………………………..15

Wheels and tires………………………………………………………………………………….16

Wheel installation………………………………………………………………………………..17

Light bulb replacement…………………………………………………………………………..18

Service and maintenance…………………………………………………………………………19

Periodic service schedule………………………………………………………….......................20

Tire inspection……………………………………………………………………………………21

Brake……………………………………………………………………………………………..21

Rear axle………………………………………………………………………………………….23

Lubrication……………………………………………………………………………………….24

Hardware…………………………………………………………………………………………25

BA TTERIES AND CHARGING

Safety…………………………………………………………………………………………….26

Battery maintenance……………………………………………………………………………...27

Battery Replacement……………………………………………………………………………..30

Prolonged Storage………………………………………………………………………………..31

Battery charging………………………………………………………………………………….32

Troubleshooting………………………………………………………………………………….34

Hydrometer……………………………………………………………………............................34

Battery Maintenance ………….……………………………………………………....................36

Specific gravity testing…………………………………………………………………………..37

Open-circuit voltage test……………………………………………………………………...... 38

Charging, cleaning……………………………………………………………………………….40

Storage……………………………………………………………………………………………41

Battery terms explained…………………………………………………………………………..42

MAINTENANCEINFORMATION………………………………………......44-56

Troubleshooting………………………………………………………………………………….44

Front/Rear bridge, lubricate the wheel hub bearing, adjust the front

Page 3

wheel bearing…………………………………………………………………………………....45

Correct the toe-in, replace the front shock absorber, replace the front beam………………….. 46

Replace the front spring armor plate…………………………………………………….............47

Replace the wheel hub…………………………………………………………………………..48

Replace the wheel bearing assembly, Replace the rack ball joint, replace the claw…………….49

Replace the steering axle, Rear axle assembly…………………………………………………..50

Remove the shock absorber, Install the shock absorber, Remove the rear spring armor plate,

Assemble the rear spring armor plate, Rear axle maintenance, Check the lubricant level,

Disassemble and assemble of the transaxle………………………………………………………51

Disassemble and replace the oil seal, Install the axle…………………………………………….52

Check the brake pedal and connection…………………………………………………………...54

T est the brake function regularly, Check the wheel brake…………………………………..........55

SPECIFICATION……………………………………………………………....57-60

P ARTS AND ASSEMBLY PROCEDURE……………………………………61-65

Item identification………………………………………………………………………………..62

Assembly procedure……………………………………………………………………………..63

Page 4

SAFETY INFORMATION

Owner’s Manual and Service Guide

1

This manual has been designed to assist in maintaining the vehicle in accordance with procedures developed

by the manufacturer. Adherence to these procedures and troubleshooting tips will ensure the best possible

service from the product. To reduce the chance of personal injury or property damage, the following must by

carefully observed:

GENERAL

Good common sense and prudent driving practices do more to prevent accidents and injury than all of the

warnings and instructions combined. The manufacturer strongly suggests that all users and maintenance

personnel read this entire manual paying particular attention to the CAUTIONS and WARNINGS contained

there in.

Golf cart, Resort cart& Specialty products reserves the right to make design changes without obligation to

make these changes on units previously sold and the information contained in this manual is subject to

change without notice.

Golf cart, Resort cart& Specialty products is not liable for errors in this manual or for incidental or

consequential or consequential damages that result from the use of the material in this manual.

These vehicles are designed and manufactured for off-road use. Some communities may permit these vehicles

to be operated on their streets on a limited basis and in accordance with local ordinances.

With electric powered vehicles, be sure that all electrical accessories are grounded directly to the battery (-)

post. Never use the chassis or body as a ground connection.

Refer to GENERAL SPECIFICATIONS for vehicle seating capacity.

Never modify the vehicle in any way that will alter the weight distribution of the vehicle, decrease its

stability or increase the speed beyond the factory specification. Such modifications can cause serious

personal injury or death.

Vehicles that are capable of higher speeds must limit their speed to no more than the speed of other vehicles

when used in a golf course environment. Additionally, speed should be further moderated by the

environmental conditions, terrain and common sense.

GENERAL OPERATION

Always:

z Use the vehicle in a responsible manner and maintain the vehicle in safe operating condition.

z Read and observe all warnings and operation instruction labels affixed to the vehicle.

z Follow all safety rules established in the area where the vehicle is being operated..

Page 5

SAFETY INFORMATION

Owner’s Manual and Service Guide

2

z Reduce speed to compensate for poor terrain or conditions.

z Apply service brake to control speed on steep grades.

z Maintain adequate distance between vehicles.

z Reduce speed in wet areas.

z Use extreme caution when approaching sharp or blind turns.

z Use extreme caution when driving over loose terrain.

z Use extreme caution in areas where pedestrians are present.

MAINTENANCE

Always:

z Maintain the vehicle in accordance with the manufacturer’s periodic service schedule.

z Ensure that repairs are performed by those that are trained and qualified to do so.

z Follow the manufacturer’s maintenance procedures for the vehicle. Be sure to disable the vehicle before

performing any maintenance. Disabling includes removing the key from the key switch and removal of a

battery wire.

z Insulated any tools used within the battery area in order to prevent sparks or battery explosion caused by

shorting the battery terminals or associated wiring. Remove the batteries or cover exposed terminals

with an insulating material.

z Check the polarity of each battery terminal and be sure to rewire the batteries correctly.

z Use specified replacement parts. Never use replacement parts of lesser quality.

z Use recommended tools.

z Determine that tools and procedures not specifically recommended by the manufacturer will not

compromise the safety of personnel nor jeopardize the safe operation of the vehicle.

z Support the vehicle using wheel chocks and jack stands. Never get under a vehicle that is supported by a

jack. Lift the vehicle in accordance with the manufacturer’s instructions.

z Maintain the vehicle in an area away from exposed flame or persons who are smoking.

z Be aware that a vehicle that is not performing as designed is a potential hazard and must not be operated.

z Test drive the vehicle after any repairs or maintenance. All tests must be conducted in a safe area that is

free of both vehicular and pedestrian traffic.

z Replace damaged or missing warning, caution or information labels.

z Keep complete records of the maintenance history of the vehicle.

Use extreme caution and, if unsure as to the potential for injury, refer the repair or maintenance to a qualified

mechanic.

PART II

FOR THE USER

4 GENERAL SAFETY PRACTICES

4.1 Introduction

Like other machines, golf cart can cause injury if improperly used or maintained. Part II contains

broad safety practices applicable to golf cart operations. Before operation, the user shall establish

such additional specific safety practices as may reasonably be required for safe operation.

4.2 Nameplates, Markings, Capacity, and Modifications

Page 6

SAFETY INFORMATION

Owner’s Manual and Service Guide

3

4.2.1 The user shall maintain in a legible condition all nameplates, warnings and instructions which are

supplied by the manufacturer.

4.2.2 The user shall not perform any modification or addition which affects capacity or safe operation, or

make any change not in accordance with the owner’s manual without the manufacturer’s prior written

authorization. Where authorized modifications have been made, the user shall ensure that capacity,

operation, warning and maintenance instruction plates, tags or decals are changed accordingly.

4.3 Changing and Charging Storage Batteries for Electric Personnel and Burden Carriers

4.3.1 The user shall require battery changing and charging facilities and procedures to be in accordance

with appropriate paragraphs of ANSI/NFPA 505.

4.3.2 The user shall periodically inspect facilities and review procedures to be certain that appropriate

paragraphs of ANSI/NFPA 505, are strictly complied with and shall familiarize carrier operators with

it.

5 OPERATING SAFETY RULES AND PRACTICES

5.1 General

5.1.1 Safeguard the pedestrians at all times. Do not drive Cart in a manner that would endanger anyone.

5.1.2 Riding on the Cart by persons other than the operator is authorized only on personnel seat provided by

the manufacturer.

5.1.3 When a cart is to be left unattended, stop it, apply the parking brake, stop the engine or turn off power,

turn off the control or ignition circuit, and remove the key if provided. Block the wheels if machine is

on an incline.

5.1.4 Use only approved Cart in hazardous locations, as defined in the appropriate safety standards.

5.1.5 Operators shall not add to, or modify, the Cart.

5.2 Traveling

5.2.1 Observe all traffic regulations, including authorized speed limits. Under normal traffic conditions keep

to the right. Maintain a safe distance, based on speed of travel, from a vehicle ahead; and keep the Cart

under control at all times.

5.2.2 Do not pass another vehicle traveling in the same direction at intersections, blind spots, or at other

dangerous locations.

5.2.3 Keep a clear view of the path of travel, observe other traffic and personnel, and maintain a safe

clearance.

5.2.4 Slow down or stop, as conditions dictate, and activate the sound-producing warning device at cross

aisles and when visibility is obstructed at other locations.

5.2.5 Ascend or descend grades slowly.

5.2.6 Under all travel conditions the Cart shall be operated at a speed that will permit it to be brought to a

stop in a safe manner.

5.2.7 Do not indulge in dangerous activities, such as stunt driving or horseplay.

5.2.8 Avoid running over loose objects, potholes, and bumps.

5.2.9 To negotiate turns, reduce speed to improve stability, then turn hand steering wheel or tiller in a smooth,

sweeping motion.

5.3 Loading

5.3.3 At the beginning of each shift during which the Cart will be used, the operator shall check the Cart

condition and inspect the tires, warning devices, lights, battery, speed and directional controllers,

brakes, and steering mechanism. If the Cart is found to be in need of repair or in any way unsafe, the

Page 7

SAFETY INFORMATION

Owner’s Manual and Service Guide

4

matter shall be reported immediately to the design ated auth orit y an d the Cart shall no t b e operat ed unt il

it has been restored to sage operating condition.

5.3.4 Do not make repairs or adjustments unless specifically authorized to do so.

5.3.5 Do not operate a Cart with a leak in the battery.

5.3.6 Do not use open flames for checking electrolyte level in storage battery.

6 MAINTENANCE PRACTICES

6.1 Introduction

6.1.1 Carriers may become hazardous if maintenance is neglected. Therefore, maintenance facilities

trained personnel, and procedures shall be providing such facilities may be on or off the premises.

6.2 Maintenance Procedures

6.2.1 Maintenance and inspection of all Cart shall be performed in conformance with the manufacturer’s

recommendations and the following practices.

(a) A scheduled preventive maintenance, lubrication, and inspection system shall be followed.

(b) Only qualified and authorized personnel shall be permitted to maintain, repair, adjust, and

inspect carriers.

(c) Block chassis before working underneath it.

(d) Operation to check performance of the cart shall be conducted in an authorized area where safe

clearance exists.

(e) Before commencing operation of the cart, follow the manufacturer’s instructions and

recommended procedures.

(f) Avoid fire hazards and have fire protection equipment present in the work area. Do not use an

open flame to check level or leakage of battery electrolyte.

(g) Properly ventilate the work area.

(h) Brakes, steering mechanisms, speed and directional control mechanisms, warning devices, lights,

governors, guards, and safety devices shall be inspected regularly and maintained in a safe

operating condition .

(i) Special cart or devices designed and approved for hazardous area operation shall be inspected to

ensure that maintenance preserves the original approved safe operating features.

(j) Carriers shall be kept in a clean condition to minimize fire hazards and facilitate detection of

loose or defective parts.

(k) Modification and additions which affect capacity and safe machine operation shall not be

performed by the customer or user without manufacturer’s prior written authorization; where

authorized modifications have been made, the user shall ensure that capacity, operation, warning,

and maintenance instruction plates, tags, or decals are changed accordingly.

(l) Care shall be taken to ensure that all replacement parts are interchangeable with the original parts

and of a quality at least equal to that provided in the original equipment.

PART II

MAINTENANCE AND OPERA TIONS

5. GENERAL SAFETY PRACTICES

Introduction

Like other machines, golf cars can cause injury if improperly used or maintained. This section contains broad

safety practices recommended for safe golf car operations. Before operation, the controlling party should

establish such additional specific safety practices as may be reasonably required for safe operations.

Page 8

SAFETY INFORMATION

Owner’s Manual and Service Guide

5

Experience has shown that golf cars which comply with the provisions stated in part II of this standard are

safe when properly operated in accordance with the safety and operation is enhanced when the golf cars are

operated within a specific set of operation instructions, safety rules and practices established to meet actual

operating terrain and conditions.

The safety information contained in part II is intended to provide the controlling party with basic safety

information and to encourage the controlling party to implement a golf car safety program.

It is suggested and recommended that Part II be reprinted in the golf car manufacturer’s operation and service

manuals to encourage safe operations and practices at the controlling party’s facility.

Safety Survey

The controlling party shall perform a safety survey periodically, and as conditions warrant to their premises,

to identify areas where golf cars should not be operated and to identify possible hazards.

Wet area and Loose Terrain or icy terrain

Wet grassy areas and loose terrain may cause a golf car to lose traction and may affect stability. Wet areas and

loose terrain shall be chained or roped off to prevent golf car operations or be identified by a suitable warning

not to operate golf cars in this area due to wet and loose terrain.

Extreme caution should be used when driving on wet or icy terrain. Wet grassy areas or ice may cause a golf

car to lose traction and may affect operator control. Wet or icy areas should be chained or roped off to

prevent golf car operations or be identified by a suitable warning to operators not to operate golf cars in that

area.

Sharp Turns, Blind Corners, Bridge Approaches

Sharp turns, blind spots, bridge approaches and other potentially hazardous areas shall be either chained or

roped off to prevent golf car operations or identified with a suitable warning to the operator of the nature of

the hazard and stating the proper precautions to be taken to avoid the hazard. All turns shall be negotiated at a

reduced speed.

Grades

All grades shall be descended at a reduced speed. Excessive speed while descending grades adversely affects

the stability of the golf car and its ability to stop. In areas where steep grades exist, golf car operations should

be restricted to designated golf car paths and roads where possible. Steep grades shall be identified with a

suitable warning giving the following inform ation: “Warning, steep hill, apply brake to limit speed.”

Avoid parking on steep hills. Avoid sharp turns on grades. Provide flat surface parking areas adjacent to golf

car paths on steep grades.

Golf Car/Pedestrian Interference Areas

Areas where pedestrians and golf cars interfere shall be avoided whenever possible by rerouting the golf car

traffic or the pedestrian traffic to eliminate the interference. If elimination of the interference is not possible

or is highly impractical, signs shall be erected warning pedestrians of the golf car traffic and golf car

operators of the pedestrian traffic and to drive slowly and use extreme caution.

Page 9

SAFETY INFORMATION

Owner’s Manual and Service Guide

6

6. MAINTENANCE

Introduction

Golf cars may become hazardous if maintenance is neglected or improperly performed. Therefore

maintenance facilities, trained personnel and procedures in accordance with the manufacturer’s

recommendations should be provided by the controlling party.

Preventive Maintenance

A regularly scheduled inspection and preventive maintenance program in accordance with the manufacturer’s

recommendations should be established. Such a program will be a valuable tool in providing the golfing

patron with a safe, properly operating golf car and thereby help to avoid accidents.

6.2.1 Personnel

Only qualified, trained and authorized personnel shall be permitted to inspect, adjust and maintain golf cars.

6.2.2 Parts and materials

Only manufacturer’s recommended replacement parts and materials shall be used.

6.2.3 Ventilation

Maintenance and storage areas shall be properly ventilated to avoid fire hazards in accordance with

applicable fire codes and ordinances.

6.2.4 Maintenance Safety Procedures

All maintenance shall be performed in accordance with the manufacturer’s recommended safety procedures

as outlined in the manufacturers operation and service manuals. The following list of recommended safety

procedures are general in nature and in no way supersede the manufacturer’s specific instructions.

6.2.4.1 Following manufacturer’s instructions for immobilizing golf car before beginning any maintenance.

6.2.4.2 Block chassis before working underneath golf car

6.2.4.3 Before performing any maintenance on an electric golf car, disable the electrical system in

accordance with the manufacturer’s instructions.

6.2.4.4 Use only properly insulated tools when working on electrically powered golf cars or around

batteries.

6.2.4.5 The controlling party shall not perform any modification or addition which affects capacity or safe

operation, or make any change not in accordance with owner’s manual without the manufacturers

prior written authorization. Where authorized modifications have been made, the controlling party

shall ensure that capacity, operation, warning and maintenance instruction plates, tags or decals are

changed accordingly.

6.2.4.6 Avoid fire hazards and have fire protection equipment available.

6.2.4.7 Before performing any maintenance on an electric golf car, disconnect the electrical system in

accordance with the manufacturer’s instructions.

6.2.4.8 Use only properly insulated tools when performing maintenance.

6.2.4.9 Periodically inspect and maintain brakes, steering mechanisms, warning devices, governors, safety

decals and all other safety devices and maintain them in a safe operating condition. Do not modify

these devices unless instructed to do so by the manufacturer.

6.2.4.10 After each maintenance or repair, have the golf car driven by qualified and trained personnel to

ensure proper operation and adjustment; perform validation checks in an area that is free of vehicular

and pedestrian traffic

6.2.4.11 Record all maintenance performed in a maintenance record log by date, name of person performing

maintenance and type of maintenance. Controlling Party should periodically inspect maintenance log

Page 10

SAFETY INFORMATION

Owner’s Manual and Service Guide

7

to ensure currency and completeness of entries.

6.2.4.12 The controlling party shall maintain all Danger, Warning and Caution labels, (collectively and

individually “safety labels”); nameplates; serial numbers; and instructions, when supplied by the

manufacturer, in a legible condition.

7. OPERATING SAFETY RULES AND PRACTICES

Operator Qualifications

Only authorized persons shall be allowed to operate golf cars, it is recommended that no persons be

allowed to operate golf cars except those persons who posses a valid motor vehicle drivers license.

The controlling party shall display the operation and safety instructions as recommended by the golf car

manufacturers and the golf course safety rules in a conspicuous place near the golf car rental area or golf car

pick-up area. It is also recommended, as with all motor vehicles, that the warning “Do not operate golf cars

when under the influence of alcohol or drugs.” Be posted in a conspicuous location.

Page 11

OPERATION AND SERVICE INFORMATION

8

Owner’s Manual and Service Guide

OPERATION AND SERVICE INFORMATION

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes,

Cautions and Warnings

Thank you for purchasing this vehicle. Before driving the vehicle, we ask you to spend some time reading

this Owner’s Manual and Service Guide. This guide contains the information that will assist you in

maintaining this highly reliable vehicle.

This vehicle has been designed and manufactured as a “World Vehicle”. Some countries have individual

requirements to comply with their specifications: therefore, some sections may not apply in your country.

Most of the service procedures in this guide can be accomplished using common automotive hand tools.

BEFORE INITIAL USE

Read, understand and follow the safety label on the instrument panel. Be sure you understand how t o operate

the vehicle, its equipment and how to use it safely. Maintaining good performance depends to a large extent

on the operator.

Before a new vehicle is put into operation, the items shown in the INITIAL SERVICE CHART must be

performed (Ref Fig.1).

Vehicle batteries must be fully charged before initial use. Check for correct tire inflation. See GENERAL

SPECIFICARIONS.

Determine and record braking distance required to stop vehicle for future brake performance tests.

Remove the protective clear plastic, that protect the seat bottom and back rest during shipping, before placing

the vehicle in service.

ITEM SERVICE OPERATION

Batteries Charge batteries

Seats Remove protective plastic covering

Brakes Check operation and adjust if necessary

Establish acceptable stopping distance

Tires Check air pressure (see SPECIFICATIONS)

Portable Charger Remove from vehicle and properly mount

Fig.1 Initial Service Chart

Page 12

OPERATION AND SERVICE INFORMATION

9

Owner’s Manual and Service Guide

! WARNING ! To prevent overheating that may cause serious damage to the charger and create the

potential for fire, do not block or obstruct the airways .Portable chargers must be mounted on a

platform above the ground or in such a manner as to permit the maximum air flow underneath and

around the charger.

Portable chargers are shipped with the vehicle. Prior to vehicle or charger operation, chargers must be

removed and mounted on a platform or wall above the ground to permit maximum air flow around and

underneath the charger. If the charger is operated in and outdoor location, rain and sun protection must be

provided.

The power (AC) cord is equipped with a grounded plug. Do not attempt to remove, cut or bend the ground

post.

CONTROLS AND INDICA TORS

Vehicle controls and indicators consist of:

· key/light switch

· direction selector

· state of charge meter

· accelerator pedal

· combination service and park brake pedal

· horn

KEY SWITCH

Located on the dash panel, this switch enables the basic electrical system of the vehicle to be turned on and

off by turning the key. To prevent inadvertent operation of the vehicle when left unattended, the key should

be turned to the ‘OFF’ position and removed (Ref Fig 2).

Fig.2 Key Switch& State of Charger Meter

Page 13

OPERATION AND SERVICE INFORMATION

10

Owner’s Manual and Service Guide

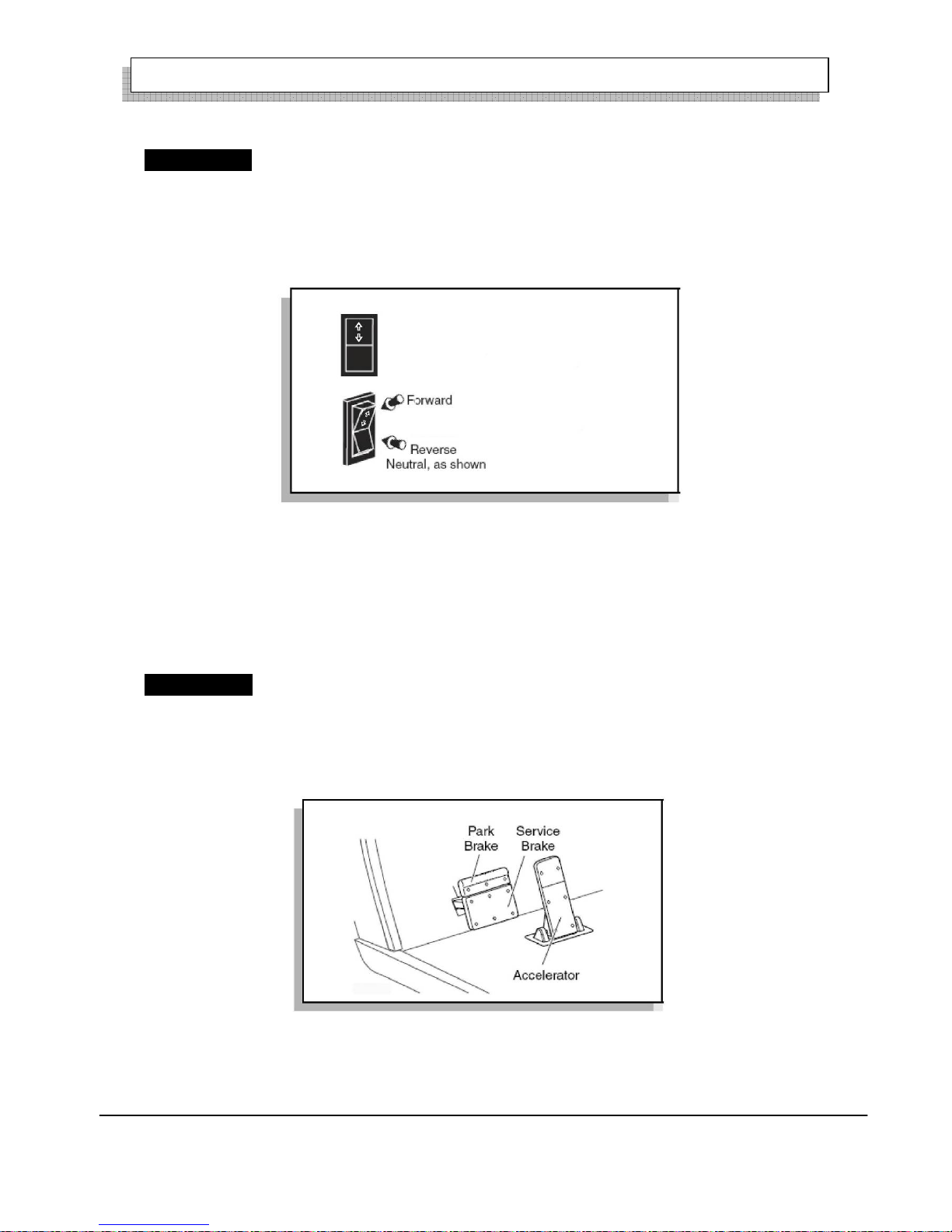

DIRECTION SELECTOR

! WARNING ! To prevent loss of control, do not move direction selector while the vehicle is in motion.

Moving the selector will result in a sudden slowing of the vehicle and the beeping of a warning device.

Located on the dash panel, this switch permits the selection of either ‘F’(forward), ‘R’(reverse) or neutral (the

position between forward and reverse). Vehicle should be left in neutral when unattended (Ref Fig.3).

Fig 3 Direction Selector Types

STATE OF CHARGE METER

Located in the dash, the state of charge meter indicates the amount of usable power in the batteries (Ref Fig.2

on page 2).

ACCELERATOR PEDAL

! WARNING ! Unintentional movement of the accelerator pedal will release the park brake and may

cause the vehicle to move which could result in severe injury or death.

With the key switch ‘ON ’, depressing the accelerator pedal starts the motor. When the pedal is released, the

motor will stop (Ref Fig 4).To stop the vehicle more quickly, depress the service brake.

Fig 4 Accelerator and Brake Controls

If key switch is ‘ON” and park brake is set, depressing the accelerator inadvertently will release the park

brake and will cause the vehicle to move which could cause severe injury or death.

Page 14

OPERATION AND SERVICE INFORMATION

11

Owner’s Manual and Service Guide

Depressing the accelerator pedal will release the park brake if it is engaged. This is a feature to assure the

vehicle is not driven with the park brake engaged. Depressing the accelerator pedal is not the preferred

method of releasing the park brake.

NOTE: Depressing the lower section of the brake pedals the preferred method of releasing the park brake to

assure the longest service life of brake components.

COMBINATION BRAKE AND PARK BRAKE PEDAL

The brake pedal incorporates a park brake feature (Ref Fig.4).To engage, push down on the upper section of

the pedal until it locks in place. The park brake will release when the service brake pedal is depressed. Use

the lower section of the brake pedal to operate the service brake system.

HORN

The horn is operated by pushing the horn button located on (Ref Fig.5)

STEERING WHEEL

Steering should be smooth and consistent on turning right and left .

Fig. 5 Horn Button

OPERA TING THE VEHICLE

! CAUTION ! Improper use of the vehicle or the lack of proper maintenance may result in damage or

decreased performance.

Read and understand the following warnings before attempting to operate the vehicle.

! WARNING ! To reduce the possibility of severe injure or death resulting from loss of vehicle control,

the following warnings must be observed:

When driving vehicle, consider the terrain, traffic conditions and the environmental factors which effect the

terrain and the ability to control the vehicle.

Page 15

OPERATION AND SERVICE INFORMATION

12

Owner’s Manual and Service Guide

Use extra care and reduced speed when driving on poor surfaces, such as loose dirt, wet grass, gravel, etc.

Stay in designated areas and avoid extremely rough terrain.

Maintain a safe speed when driving down hill. Use service brake to control speed when traveling down an

incline. A sudden stop or change of direction may result in loss of control.

Slow down before and during turns. All turns should be made at reduced speed.

! WARNING ! To reduce the possibility of severe injury or death resulting from improper vehicle

operation, the following warnings must be observed:

Refer to GENERAL SPECIFICATIONS for seating capacity.

Depressing accelerator pedal will release foot operated park brake and may cause inadvertent vehicle

movement. Turn the key to the ‘OFF’ position whenever the vehicle is parked.

To prevent inadvertent movement when the vehicle is to be left unattended, engage the park brake, move

direction selector to forward position, turn key to ‘OFF’ position and remove key.

Make sure that the direction selector is in correct position before attempting to start the vehicle.

Always bring the vehicle to a complete stop before shifting the direction selector.

Do not take vehicle out of ‘gear’ while in motion (coast).

Check the area behind the vehicle before operating in reverse.

All occupants must be seated. Keep entire body inside vehicle and hold on while vehicle is in motion.

Regenerative Braking

! WARNING ! To prevent the possibility of loss of control that could cause severe injury or death, use

service brake to control speed.

Pedal-up Braking

Pedal-up Braking is regenerative braking that occurs as following:

a) the accelerator pedal is released for more than one second while the vehicle is moving between 13kph

and the vehicle’s top speed.

b) When pedal-up braking system is activated, the pedal-up braking will slow the vehicle (the warning

beeper will not sound) until the vehicle speed is reduced to 13 kph , the motor generates power which is

returned to the batteries.

Page 16

OPERATION AND SERVICE INFORMATION

13

Owner’s Manual and Service Guide

Walk-Away Feature

Walk-Away limits vehicle movement without driver input, slowing the vehicle to 3kph and sounding an

audible alarm ( reverse beeper).

Example: If all of the following events occur

a) the vehicle has been stopped for more than 1.5 seconds

b) the accelerator pedal has been released for more than one second

c) the vehicle begins to roll above 3kph

the electronic braking will limit speed to approximately 3 kph and the warning beeper will sound. When the

accelerator pedal is depressed, the electronic braking and warning beeper will be overridden and normal

vehicle operation resumes.

Diagnostic Mode Feature

Diagnostic mode eases troubleshooting.

In the unlikely event of certain electrical system failures, the controller will default to a mode that will permit

the vehicle to operate, but at a very reduced speed.

This feature allows the vehicle to be driven back to its storage facility where the problem can be diagnosed.

The controller can be put in diagnostic mode by the technician and the controller will report the failure mode.

ST ARTING AND DRIVING

! WARNING ! To reduce the possibility of roll-back which could result in severe injury or vehicle

damage, do not release the service brake until motor has started.

All vehicle are equipped with an interlock system that disables the controller and prevents the vehicle from

being operated while the charger is connected. The interlock functions even if the DC plug is not fully

connected in the vehicle receptacle. Remove charger plug from vehicle receptacle and properly store cable

prior to moving vehicle.

T o opera te ve hicle:

·Apply the service brake, place the key in the key switch and turn it to the “ON” position.

·Move the direction selector to the direction desired.

·Release the park brake by depressing the service brake pedal until the park releases.

·Slowly depress the accelerator pedal to start the motor. Release service brake when motor starts.

·When the accelerator pedal is released, the motor stops. To stop the vehicle more quickly, depress the

service brake pedal.

Note:

When the direction selector is in the reverse position, a warning signal will sound to indicates that the

vehicle is ready to run in reverse.

Page 17

OPERATION AND SERVICE INFORMATION

14

Owner’s Manual and Service Guide

START VEHICLE ON A HILL

! WARNING ! To reduce the possibility of roll-back which could result in severe injury or vehicle

damage, do not release the service brake until motor has stated.

! CAUTION ! Do not hold vehicle on hill by using accelerator and motor. Leaving motor in a stalled

condition for more than 3-4 seconds will cause permanent damage to motor.

To reduce the possibility of permanent damage to the drive system, it is important to prevent excessive

roll-back when starting the vehicle on a hill.

Place right foot on service brake and release the park brake. Depress accelerator with right foot and release

the service brake by lifting left foot.

COASTING

! WARNING ! To reduce the possibility of severe injury or death from coasting at above

recommended speeds, limit speed with service brake.

On steep hills, it is possible for vehicles to coast at faster than normal speeds that may be encountered on a

flat surface. To prevent loss of vehicle control, speeds should be limited to no more than the maximum speed

on level ground (see vehicle specification). Limit speed by releasing the accelerator and applying service

brake. Severe damage to the drive train components due to excessive speed may result from driving the

vehicle above specified speed. Damage caused by excessive speed may cause a loss of control, is costly, is

considered abuse and will not be covered under warranty.

SUN TOP AND WINDSHIELD

! WARNING ! The sun top does not provide protection from roll over or falling objects.

The windshield does not provide protection from tree limbs or flying objects.

The sun top and windshield provide some protection from the elements; however, they will not keep the

operator and passenger dry in a downpour. The sun top has not been designed to provide roll over protection.

In addition, the sun top does not protect against falling objects nor does the windshield protect against flying

objects and tree limbs. Keep arms and legs inside of vehicle while it is moving.

VECHILE CLEANING AND CARE

VECHILE CLEANING

! WARNING ! To reduce the possibility of severe injury or vehicle damage, read and understand all

instructions supplied by manufacturer of pressure washer.

! CAUTION ! When pressure washing exterior of vehicle, do not use pressure in excess of 700 psi. To

reduce the possibility of cosmetic damage, do not use any abrasive or reactive solvents

It is important that proper techniques and cleaning materials be used. Using excessive water pressure may

Page 18

OPERATION AND SERVICE INFORMATION

15

Owner’s Manual and Service Guide

cause severe injury to operator or bystander, damage to seals, plastics, seat material, body finish or electrical

system. Do not use pressure in excess of 700 psi to wash exterior of vehicle.

Clean windshield with lots of water and a clean cloth. Minor scratches may be removed using a commercial

plastic polish.

Normal cleaning of vinyl seats and plastic or rubber trim requires the use of a mild soap solution applied with

a sponge or soft brush and wipe with a damp cloth.

The painted surfaces of the vehicle provide attractive appearance and durable protection. Frequent washing

with lukewarm or cold water and mild detergent is required to preserve the painted surface.

Occasional cleaning and waxing with non-abrasive products designed for ‘clear coat’ automotive finishes will

enhance the appearance and durability of the painted surfaces.

Corrosive materials used as fertilizers or for dust control can collect on the underbody of the vehicle. These

materials will cause corrosion of underbody parts unless flushed occasionally with plain water. Thoroughly

clean any areas where mud or other debris can collect. Sediment pac ked in clo s ed a rea s sh ou ld be lo o sen ed to

ease it’s removal, taking care not to chip or otherwise damage paint.

REPAIR

LIFTING THE VEHICLE

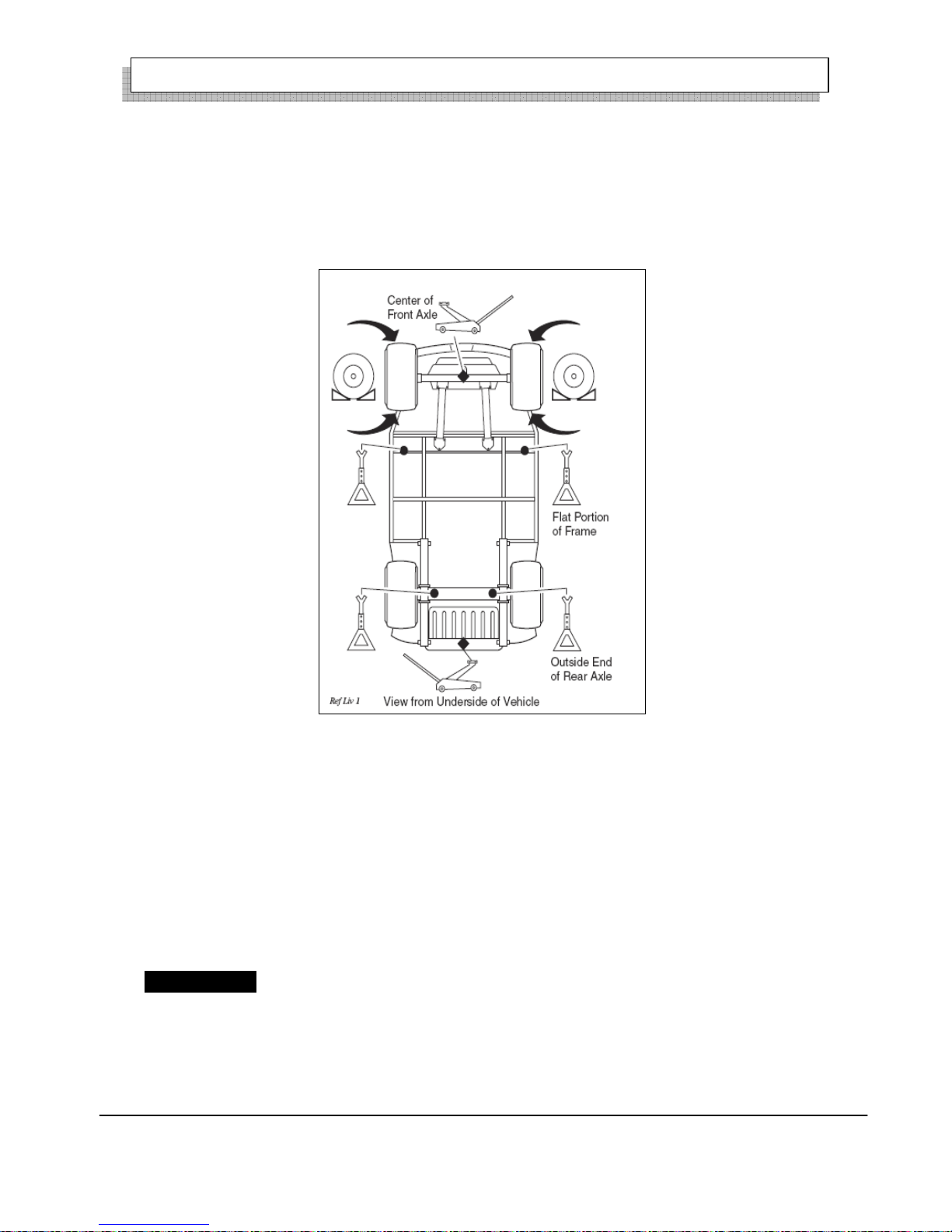

Tool List Qty. Required

Floor jack ………………… 1

Jack stands ……………… 4

Chocks ………………… 4

Some servicing operations may require the front wheels, the rear wheels, or the entire vehicle be raised.

! WARNING ! To reduce the possibility of severe injury or death from a vehicle falling from a jack:

Be sure the vehicle is on a firm and level surface.

Never get under a vehicle while it is supported by a jack.

Use jack stands and test the stability of the vehicle on the stands.

Always place chocks in front and behind the wheels not being raised.

Use extreme care since the vehicle is extremely unstable during the lifting process.

! CAUTION ! When lifting vehicle, position jacks and jack stands at the areas indicated only.

To raise the entire vehicle, install chocks in front and behind each front wheel. Center the jack under the rear

frame crossmember. Raise the vehicle enough to place a jack stand under the outer ends of the rear axle.

Lower the jack and test the stability of the vehicle on the two jack stands.

Place the jack at the center of the front axle. Raise the vehicle enough to place jack stands under the frame

crossmember as indicated.

Page 19

OPERATION AND SERVICE INFORMATION

16

Owner’s Manual and Service Guide

Lower the jack and test the stability of the vehicle on all four jack stands.

If only the front or rear of the vehicle is to be raised, place the chocks in front and behind each wheel not

being raised to stabilize the vehicle.

Lower the vehicle by reversing the lifting sequence.

Fig.6 Lifting the Vehicle

WHEELS AND TIRES

Tire Repair

Tool list Qty. Required

Lug wrench, 3/4”……… ……… 1

Impact socket, 3/4”, 1/2” drive …… 1

Impact wrench, 1/2” ……………… 1

Torque wrench, 1/2”drive………… 1

! WARNING ! A tire explosion can cause severe injury or death. Never exceed inflation pressure

rating on tire sidewall.

To reduce the possibility of tire explosion, pressurize tire with small amount of air applied

intermittently to seat beads. Due to the low volume of the small tires, overinflation can occur in seconds.

Never exceed the tire manufacturer’s recommendation when seating a bead. Protect face and eyes from

escaping air when removing valve core.

Page 20

OPERATION AND SERVICE INFORMATION

17

Owner’s Manual and Service Guide

To reduce the possibility of severe injury caused by a broken socket when removing wheels, use only

sockets designed for impact wrench use.

Use caution when inflating tires. Over inflation could cause the tire to separate from the wheel or cause

the tire to explode, either of which could cause severe injury.

Use caution when inflating tires. Due to the low volume of the small tires, overinflation can occur in seconds.

Over-inflation could cause the tire to separate from the wheel or cause the tire to explode.

Tire inflation should be determined by the condition of the terrain. For outdoor application with major use on

grassy areas, the following should be considered. On hard turf, it is desirable to have a slightly higher

inflation pressure. On very soft turf, a lower pressure reduces the possibility of tires cutting into the turf. For

vehicles being used on paved or hard surfaces, tire inflation pressure should be in the higher allowable range,

but under no condition should inflation pressure be hi gher than recommended on tire sidewall. All four tires

should have the same pressure for optimum handling characteristics. Be sure to install the valve dust cap after

checking or inflating.

NOTE Tire plug tools and plugs are available at most automotive parts outlets and have the advantage of

not requiring the tire be removed from the wheel.

If the tire is flat, remove the wheel and inflate the tire to the maximum recommended pressure for the tire.

Immerse the tire in water to locate the leak and mark with chalk. Insert tire plug in accordance with

manufacturer’s instructions.

! WARNING ! To reduce the possibility of severe injury, be sure mounting/demounting

Machine is anchored to floor. Wear OSHA approved safety equipment when mounting/demounting

tires.

If the tire is to be removed or mounted, the tire changing machine manufacturer’s recommendations must be

followed in order to reduce possibility of severe injury.

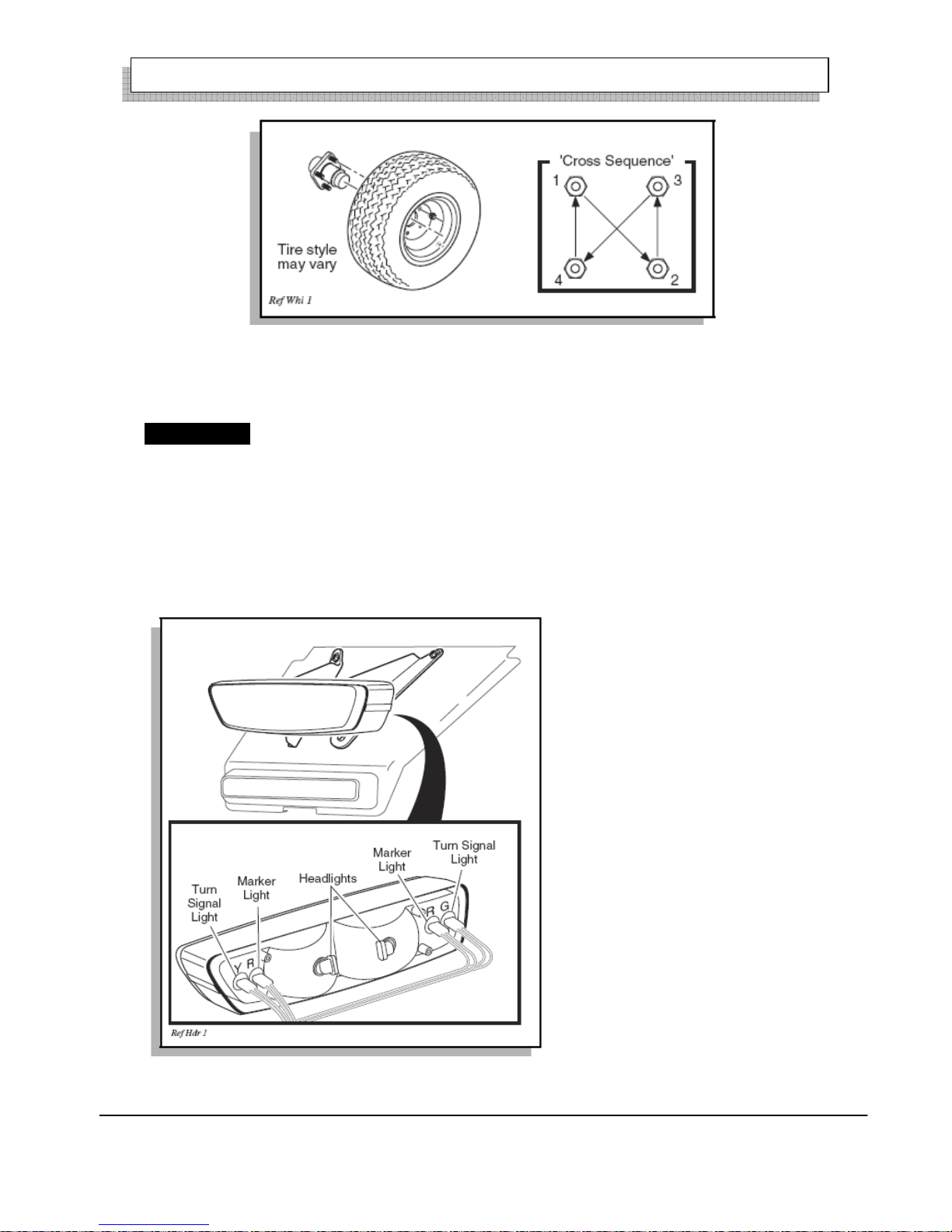

Wheel Installation

! CAUTION ! tTo reduce the possibility of component damage, do not tighten lug nuts to more than

85ft.lbs.(115 Nm) torque.

NOTE It is important to follow the ‘cross sequence’ pattern when installing lug nuts. This will assure even

seating of the wheel against the hub.

With the valve stem to the outside, mount the wheel onto the hub with lug nuts. Finger tighten lug nuts in a

‘cross sequence’ pattern (Ref Fig.7). Tighten lug nuts to 76-102Nm.

Page 21

OPERATION AND SERVICE INFORMATION

18

Owner’s Manual and Service Guide

Fig.7 Wheel Installation

LIGHT BULB REPLACEMENT

! CAUTION ! To reduce the possibility of premature bulb failure, do not touch new bulbs with bare

fingers. Use clean, dry tissue or paper towel to handle the glass portion of the bulb.

For vehicles equipped with lights mounted below cowl, locate bulb socket on backside of light bar (Ref Fig. 8)

and turn bulb socket a quarter turn counterclockwise to unlock and pull out bulb. Insert new bulb and rotate

socket a quarter turn clockwise to secure.

To replace the tail and brake light bulb, remove hardware securing lens and remove lens. (Ref Fig. 9).Install

replacement bulb.

Fig. 8 Headlight, Turn Signal & Marker Light Bulb Replacement

Page 22

OPERATION AND SERVICE INFORMATION

19

Owner’s Manual and Service Guide

Fig. 9 Tail and Brake Light Bulb Replacement

SERVICE AND MAINTENANCE

! WARNING ! To reduce the possibility of severe injury or death from improper servicing techniques:

Do not attempt any type of servicing operations before reading and understanding all notes, cautions and

warnings in this manual.

Any servicing requiring adjustments to be made to the powertrain while the motor is running must be made

with both drive wheels raised and vehicle properly supported on jack stands.

To reduce the possibility of motor damage, never operate vehicle at full throttle for more than 4-5 seconds

while vehicle is in a “no load” condition.

Wear eye protection when working on the vehicle. Use extra care when working around batteries, or using

solvents or compressed air.

To reduce the possibility of causing an electrical arc, which could result in a battery explosion, turn off all

electrical loads from the battery before removing battery wires.

Wrap wrenches with vinyl tape to reduce the possibility of a dropped wrench “shorting out” a battery, which

could result in an explosion.

Reduce the possibility of accidental starting by removing and grounding spark plug wires and disconnecting

battery at negative terminal before servicing.

The electrolyte in a battery is an acid solution which can cause severe burns to the skin and eyes. Treat all

electrolyte spills to the body and eyes with extended flushing with clear water. Contact a physician

immediately.

Page 23

OPERATION AND SERVICE INFORMATION

20

Owner’s Manual and Service Guide

Any electrolyte spills should be neutralized with a solution of 2 teaspoons (10ml) sodium bicarbonate

( braking soda) dissolved in 1 quart ( 1 liters ) of water and flushed with water.

It is in the best interest of both vehicle owner and service technician, to carefully follow the procedures

recommended in this manual. Preventative maintenance, applied at recommended intervals is the best

guarantee for keeping the vehicle both dependable and economical.

This vehicle will give years of satisfactory service, providing it receives regular maintenance. Refer to the

Periodic Service Schedule for appropriate service intervals.

! CAUTION ! To prolong vehicle life, some maintenance items must be serviced more frequently on

vehicles used under severe driving conditions such as extreme temperatures, extreme dust/debris

conditions, frequent use with maximum load.

PERIODIC SERVICE SCHEDULE

NOTE Some maintenance items must be serviced more frequently on vehicles used under severe driving

conditions

DAILY

BEFORE USE:

. Check service brake general operation

. Check park brake function

. Check warning device function in reverse

. Check tire condition

. Check overall vehicle condition

. Recharge batteries to full state of charge after each day’s use

. Inspect charger connector and receptacle at each charge

WEEKLY

TIRES . Examine for cuts, excessive wear and pressure (See GENERAL SPECIFICATIONS)

WHEELS . Check for bent rims, missing or loose lug nuts

MONTHLY - 20 HOURS

BATTERIES

. Clean batteries & terminals. See BATTERY CLEANING.

.Check charge condition and all connections

WIRING . Check all wiring for loose connections and broken insulation

CHARGER / RECEPTACLE . Clean connections, keep receptacles free of dirt and foreign matter

ACCELERATOR . Check for smooth movement

SERVICE BRAKE

(MECHANICAL BRAKES) . Conduct brake performance test

PARK BRAKE . Check brake performance and adjust if required

DIRECTION SELECTOR . Check attachment, tighten if required

Page 24

OPERATION AND SERVICE INFORMATION

21

Owner’s Manual and Service Guide

STEERING ASSEMBLY . Check for abnormal play, tightness of all hardware

TIE ROD/LINKAGES . Check for excessive play, bent components or loose connections

REAR AXLE . Check for leakage, add lubricant level as required

QUARTERLY - 50 HOURS

FRONT AXLE . Check for damage to axle and loose or missing hardware

FRONT SHOCK ABSORBERS . Check for oil leakage and loose fasteners

FRONT SPRINGS . Check for loose hardware, cracks at attachments

FRONT WHEEL ALIGNMENT .Check for unusual tire wear, align if required

PARK BRAKE

. Check for bent/binding linkage rod

. Check for damage or wear to latch arm or catch bracket

. Lubricate as required, use light oil. DO NOT LUBRICATE CABLES OR BRAKE LATCH

REAR SHOCK ABSORBERS . Check for oil leakage, loose mounting hardware

CHARGER PLUG . Clean auxiliary contact (see BATTERY CHARGER MAINTENANCE)

HARDW ARE AND FASTENERS

. Check for loose or missing hardware and components

. Tighten or replace missing hardware

SEMI-ANNUAL - 125 HOURS

DIRECTION SELECTOR . Check for wear and smooth movement (lubricate shaft with light oil if

required)

KING PINS . Check for excessive play and tightness of retaining nuts

STEERING ASSEMBLY . Check bellows and pinion seal for damage or grease leakage

RACK END BALL JOINT . Lubricate, use wheel bearing grease

REAR AXLE . Check for unusual noise and loose or missing mounting hardware

ANNUAL - 250-300 HOURS

FRONT WHEEL BEARINGS . Check and adjust as required, see Technician’s Repair and Service Manual

REAR AXLE . Check lubricant, add lubricant level as required

SERVICE BRAKES

. Clean and adjust

. Check brake shoe linings

TIRE INSPECTION

Tire condition should be inspected per the Periodic Service Schedule. Inflation pressures should be checked

when the tires are cool. Be sure to install the valve dust cap after checking or inflating.

BRAKES

! WARNING ! To reduce the possibility of severe injury or death, always evaluate pedal travel before

operating a vehicle to verify some braking function is present.

All driving brake tests must be done in a safe location with regard for the safety of all personnel.

Page 25

OPERATION AND SERVICE INFORMATION

22

Owner’s Manual and Service Guide

NOTE Over time, a subtle loss of performance may take place , therefore, it is important to establish the

standard with a new vehicle.

The Periodic Brake Performance Test should be performed regularly ( Ref. Fig. 16 ) as an evaluation of

braking system performance. It is useful as a method of identifying subtle loss of performance over time.

Periodic Brake Test for Mechanical Brake

The purpose of this test is to compare the braking performance of vehicle to the braking performance of new

or “known to be good” vehicle or to an established acceptable stopping distance. Actual stopping distances

will be influenced by weather conditions, terrain, rod surface condition, actual vehicle weight (accessories

installed) and vehicle speed. The test is conducted by latching the parking brake to eliminate different pedal

pressures and to include the affects of linkage misadjustment.

Establish the acceptable stopping distance by testing a new or “know to be good” vehicle and recording the

stopping location or stopping distance. For fleets of vehicles, several vehicles should be tested when new and

the range of stopping locations or distances recorded.

NOTE Over time, a subtle loss of performance may take place; therefore, it is important to establish the

standard with a new vehicle.

Drive the vehicle at maximum speed on a flat, dry, clean paved surface ( Ref. Fig 10).Quickly depress the

brake pedal to latch the parking brake at the line or

Page 26

OPERATION AND SERVICE INFORMATION

23

Owner’s Manual and Service Guide

Fig.10 Typical Brake Performance Test

marker in the test area and remove foot from pedal. The vehicle should stop aggressively. The wheel brakes

may or may not lock. Observe the vehicle stopping location or measure the vehicle stopping distance from

the point at which the brakes were latched. The vehicle should stop within the ‘normal’ range of stopping

distances. If the vehicle stops more than 4 ft. ( 3.0m) beyond the accept able stopping dist ance or pull s to one

side, the vehicle has failed the test and should be tested again.

If the vehicle fails the second test, it should immediately be removed from service. The vehicle must be

inspected by a qualified mechanic who should refer to the TROUBLESHOOTING section in the Technician’s

Repair and Service Manual.

REAR AXLE

The only maintenance required for the first three years is the periodic inspection of the lubricant level. The

rear axle is provided with a lubricant level check/fill plug located on the bottom of the differential (Ref Fig.

Page 27

OPERATION AND SERVICE INFORMATION

24

Owner’s Manual and Service Guide

11) (Ref Fig. 12). Unless leakage is evident, the lubricant need only be replaced after three years.

Fig.11 Add, Check and Drain Axle Lubricant-Early Production

Fig.12 Add, Check and Drain Axle Lubricant-Late Production

Checking the Lubricant Level

Clean the area around the check/fill plug and remove plug. The correct lubricant level is just below the

bottom of the threaded hole. If lubricant is low, add lubricant as required. Add lubricant slowly until lubricant

starts to seep from the hole. Install the check/fill plug. In the event that the lubricant is to be replaced, the

vehicle must be elevated and the oil pan removed or the oil siphoned through the check/fill hole.

LUBRICATION

CAUTION Do not use more than 1/2 ~ 3/4 of grease in any grease fitting at any one time. Excess

grease may cause grease seals to fail or grease migration into areas that could damage components.

Putting more than three pumps of grease in a grease fitting could damage grease seals and cause premature

bearing failure (Ref Fig.13 & Fig. 14)

Page 28

OPERATION AND SERVICE INFORMATION

25

Owner’s Manual and Service Guide

Fig.13 Lubrication Points-Early Production

Fig.14 Lubrication Points-Late Production

HARDWARE

Periodically, the vehicle should be inspected for loose fasteners. Fasteners should be tightened in accordance

with the Torque Specifications table (Ref Fig. 15).

Bolt

Grad

e

Bolt size D/MM

6 8 10 12 14 16 18 20

Torque (N·M)

4.8 4-5 10-12 20-25 35-44 54-69 99-108 118-147 167-206

Page 29

OPERATION AND SERVICE INFORMATION

26

Owner’s Manual and Service Guide

5.6 5-7 12-15 25-31 44-54 69-88 108-137 147-186 206-265

6.6 6-8 14-18 29-39 49-64 83-98 127-157 176-216 245-314

8.8 9-12 22-29 44-58 76-102 121-162 189-252 260-347 369-492

10.9

13-1

4

29-35 64-76 108-127 176-206 274-323 372-441 529-637

12.9

15-2

0

37-50 74-88 128-171 204-273 319-425 489-565 622-830

Figure 15

BA TTERIES AND CHARGING

SAFETY

NOTE Always observe the following warnings when working on or near batteries:

! WARNING ! To prevent battery explosion that could result in severe personal injury or

death, keep all smoking materials, open flame or sparks away from the batteries.

Hydrogen gas is formed when charging batteries. Do not charge batteries without adequate ventilation.

A 4% concentration of hydrogen gas is explosive.

Be sure that the key switch is off and all electrical accessories are turned off before starting work on

vehicle.

Never disconnect a circuit under load at a battery terminal.

Batteries are heavy. Use proper lifting techniques when moving them. Always lift the battery with a

commercially available battery lifting device. Use care not to tip batteries when removing or installing

them; spilled electrolyte can cause burns and damage.

The electrolyte in a storage battery is an acid solution which can cause severe burns to the skin and

eyes. Treat all electrolyte spills to the body

and eyes with extended flushing with clear water. Contact a physician immediately.

Always wear a safety shield or approved safety goggles when adding

water or charging batteries.

Any electrolyte spills should be neutralized with a solution of 1/4 cup (60 ml) sodium bicarbonate

(baking soda) dissolved in 1 1/2 gallons (6 liters)

of water and flushed with water.

Overfilling batteries may result in electrolyte being expelled from the battery during the charge cycle.

Page 30

OPERATION AND SERVICE INFORMATION

27

Owner’s Manual and Service Guide

Expelled electrolyte may cause damage to the vehicle and storage facility.

Aerosol containers of battery terminal protectant must be used with extreme care. Insulate metal

container to prevent can from contacting battery terminals which could result in an explosion.

Wrap wrenches with vinyl tape to prevent the possibility of a dropped wrench from ‘shorting out’ a

battery, which could result in an explosion and severe personal injury or death.

Ventilation for electric-powered golf cars shall be provided, to remove the accumulation of flammable

hydrogen gas emitted during the charging process. Because of the highly volatile nature of hydrogen

gas and its propensity to rise and accumulate at the ceiling in pockets, a minimum of 5 air changes per

hour is recommended for multiple vehicles and one air change per hour may be adequate for one

vehicle. The controlling party shall consult applicable fire and safety codes for the specific ventilation

levels required.

The controlling party shall require battery changing and charging facilities and procedures to be in

accordance with applicable ordinances or regulations. The controlling party shall periodically inspect

charging and storage areas or facilities and review procedures to be certain.

BATTERY

A battery is defined as two dissimilar metals immersed in an acid. If the acid is absent or if the metals are not

dissimilar, a battery has not been created. The batteries most commonly used in these vehicles are lead acid.

A battery does not store electricity, but is able to produce electricity as the result of a chemical reaction which

releases stored chemical energy in the form of electrical energy. The chemical reaction takes place faster in

warm conditions and slower in cold conditions. Temperature is important when conducting tests on a battery

and test results must be corrected to compensate for temperature

differences.

As a battery ages, it still performs adequately except that its capacity is diminished. Capacity describes the

time that a battery can continue to provide its design amperes from a full charge.

A battery has a maximum life, therefore good maintenance is designed to maximize the available life and

reduce the factors that can reduce the life of the battery.

BATTERY MAINTENANCE

Tool List Qty. Required

Insulated wrench, 9/16"............................................1

Battery carrier........................................................... 1

Hydrometer................................................................1

Battery maintenance kit P/N 25587-G01..................1

At Each Charging Cycle

Page 31

OPERATION AND SERVICE INFORMATION

28

Owner’s Manual and Service Guide

! WARNING ! To reduce the possibility of fire, never attach a battery charger to a vehicle that is to

be unattended beyond the normal charging cycle. Overcharging could cause damage to the vehicle

batteries and result in extreme overheating. The charger should be checked after 24 hours and

unplugged after the charge cycle is complete.

Before charging the batteries, inspect the plug of the battery charger and vehicle receptacle housing for dirt or

debris.

Charge the batteries after each days use.

Monthly

Inspect all wiring for fraying, loose terminations, corrosion or deterioration of insulation.

Check that the electrolyte level is correct and add suitable water as required.

Clean the batteries and wire terminations.

Electrolyte Level and Water

The correct level of the electrolyte is 1" (25 mm) above the plates in each cell (Ref Fig. 16).

Fig.16 Correct Electrolyte Level

This level will leave approximately 3/4" ( 19.5 mm) of space between the electrolyte and the vent tube. The

electrolyte level is important since any portion of the plates exposed to air will be ruined beyond repair. Of

equal importance is too much water which will result in electrolyte being forced out of the battery due to

gassing and the increase in volume of the electrolyte that results

from the charging cycle.

CAUTION Do not overfill batteries. The charging cycle will expel electrolyte and result in component

damage.

Page 32

OPERATION AND SERVICE INFORMATION

29

Owner’s Manual and Service Guide

A battery being charged will ‘gas’ with the majority of the gassing taking place at the end of the charging

cycle. This gas is hydrogen which is lighter than air. Water and sulfuric acid droplets will be carried out of the

battery vents by the hydrogen gas; however, this loss is minimal. If the battery electrolyte level is too high,

the electrolyte will block the vent tube and the gas will force it out of the vent tube and battery cap. The water

will evaporate but the sulfuric acid will remain where it can damage vehicle components and the storage

facility floor. Sulfuric acid loss will weaken the concentration of acid within the electrolyte and reduce the

life of the battery.

Over the life of the battery, a considerable amount of water is consumed. It is important that the water used be

pure and free of contaminants that could reduce the life of the battery by reducing the chemical reaction. The

water must be distilled or purified by an efficient filtration system. Water that is not distilled should be

analyzed and if required, filtration installed to permit the water to

meet the requirements of the water purity table (Ref Fig.17).

Fig.17 Water Purity Table

Even if the water is colorless, odorless, tasteless and fit for drinking, the water should be analyzed to see that

it does not exceed the impurity levels specified in the table.

Battery Cleaning

CAUTION To prevent battery damage, be sure that all battery caps (if equipped) are tightly installed.

To reduce the possibility of damage to vehicle or floor, neutralize acid before rinsing battery.

To reduce the possibility of damage to electrical components while cleaning, do not use a pressure

washer.

Cleaning should take place per the Periodic Service Schedule (Ref. Fig. 16).

Page 33

OPERATION AND SERVICE INFORMATION

30

Owner’s Manual and Service Guide

When cleaning the outside of batteries and terminals, first spray with a solution of sodium bicarbonate

(baking soda) and water to neutralize any acid deposits before

rinsing with clear water.

Use of a water hose without first neutralizing any acid will move acid from the top of batteries to another area

of the vehicle or storage facility where it will attack the metal

structure or the concrete/asphalt floor. Additionally, conductive residue will remain on the batteries and

contribute to their self discharge.

!WARNING ! To reduce the possibility of battery explosion that could result in severe injury or death,

do not use metallic spray wand to clean battery and keep all smoking materials, open flame or sparks

away from the battery

The correct cleaning technique is to spray the top and sides of the batteries with a solution of sodium

bicarbonate (baking soda) and water. This solution is best applied

with a garden type sprayer equipped with a non metallic spray wand or plastic spray bottle. The solution

should consist of the ingredients shown in the illustration (Ref Fig.18). In addition, special attention should

be paid to metal components adjacent to the batteries which should also be sprayed with the solution.

Fig.18 Preparing Acid Neutralizing Solution

Allow the solution to sit for at least three minutes. Use a soft bristle brush or cloth to wipe the tops of the

batteries to remove any conductive residue. Rinse the entire area

with low pressure clear water. Do not use a pressure washer. All of the items required for complete battery

cleaning and watering (electric vehicles only) are contained in the Battery Maintenance Kit.

Battery Replacement

Remove battery hold downs and cables. Lift out batteries with a commercially available lifting device.

Page 34

OPERATION AND SERVICE INFORMATION

31

Owner’s Manual and Service Guide

If the batteries have been cleaned and any acid in the battery rack area neutralized as recommended, no

corrosion to the battery racks or surrounding area should be present. Any corrosion found should be

immediately removed with a putty knife and a wire brush. The area should be washed with a solution of

sodium bicarbonate (baking soda) and water and thoroughly dried before priming and painting with a

corrosion resistant paint.

The batteries should be placed into the battery racks and the battery hold downs tightened to 45 - 55 in. lbs.

(5 - 6 Nm) torque, to prevent movement but not tight enough to cause distortion of the battery cases.

Inspect all wires and terminals. Clean any corrosion from the battery terminals or the wire terminals with a

solution of sodium bicarbonate (baking soda) and brush clean if

required.

!WARNING! To prevent battery explosion that could result in severe personal injury or death,

extreme care must be used with aerosol containers of battery terminal protectant. Insulate the metal

container to prevent the metal can from contacting battery terminals which could result in an

explosion.

Use care to connect the battery wires as shown (Ref Fig. 19). Tighten the battery post hardware to 50 70 in.

lbs. (6 -8 Nm) torque. Protect the battery terminals and battery wire terminals with a commercially available

protective coating.

Fig.19 Battery Connections

Prolonged Storage

CAUTION Battery charger, controller and other electronic devices need to be disconnected since they

will contribute to the premature discharge of batteries.

During periods of storage, the batteries will need attention to keep them maintained and prevent discharge.

In high temperatures the chemical reaction is faster, while low temperatures cause the chemical reaction to

slow down. A vehicle that is stored at 90° F (32° C) will lose .002 of specific gravity each day. If a fully

Page 35

OPERATION AND SERVICE INFORMATION

32

Owner’s Manual and Service Guide

charged battery has a specific gravity of 1.275, and the battery is allowed to sit unused, it will become

partially discharged. When it reaches 1.240, which it will do in less than twenty days, it should be recharged.

If a battery is left in a discharged state, sulfating takes place on and within the plates. This condition is not

reversible and will cause permanent damage to the battery. In order to prevent damage, the battery should be

recharged. A hydrometer can be used to determine the specific gravity and therefore the state of charge of a

battery.

In winter conditions, the battery must be fully charged to prevent the possibility of freezing (Ref Fig. 29 on

page 23). A fully charged battery will not freeze in temperatures above -75° F (-60° C). Although the

chemical reaction is slowed in cold temperatures, the battery must be stored fully charged, and disconnected

from any circuit that could discharge the battery. For portable chargers, disconnect the charging plug from the

vehicle receptacle. The batteries must be cleaned and all deposits neutralized and removed from the battery

case to prevent self discharge. The batteries should be tested or recharged at thirty day minimum intervals.

BATTERY CHARGING

The battery charger is designed to fully charge the battery set. If the batteries are severely deep cycled, some

automatic battery chargers contain an electronic module

that may not activate and the battery charger will not function. Automatic chargers will determine the correct

duration of charge to the battery set and will shut off when the battery set is fully charged. Always refer to the

instructions of the specific charger used.

Before charging, the following should be observed:

CAUTION Do not overfill batteries. The charging cycle will expel electrolyte and result in component

damage.

z The electrolyte level in all cells must be at the recommended level and cover the plates.

Page 36

OPERATION AND SERVICE INFORMATION

33

Owner’s Manual and Service Guide

Fig.20 Freezing Point of Electrolyte

z The charging must take place in an area that is well ventilated and capable of removing the hydrogen gas

that is generated by the charging process. A minimum of five air exchanges per hour is recommended.

z The charging connector components are in good condition and free from dirt or debris.

z The charger connector is fully inserted into the vehicle receptacle.

z The charger connector/cord set is protected from damage and is located in an area to prevent injury that

may result from personnel running over or tripping over the cord set.

z The charger is automatically turned off during the connect/disconnect cycle and therefore no electrical

arc is generated at the DC plug/receptacle contacts.

NOTE In our chargers, there is a jiggle switch inside charger receptacle. The switch is part of the interlock

system that prevents the vehicle from being driven when the charger plug is inserted in the vehicle charging

receptacle. (Fig 21)

Fig. 21 Jiggle Switch inside of charger receptacle

Page 37

OPERATION AND SERVICE INFORMATION

34

Owner’s Manual and Service Guide

TROUBLESHOOTING

In general, troubleshooting will be done for two distinct reasons. First, a battery that performs poorly and is

outside of the manufacturers specification should be identified in order to replace it under the terms of the

manufacturer’s warranty. Different manufacturers have different requirements. Consult the battery

manufacturer or a manufacturer representative for specific requirements.

The second reason is to determine why a particular vehicle does not perform adequately. Performance

problems may result in a vehicle that runs slowly or in a vehicle that is unable to operate for the time

required.

A new battery must mature before it will develop its maximum capacity. Maturing may take up to 100

charge/discharge cycles. After the maturing phase, the older a battery gets, the lower the capacity. The only

way to determine the capacity of a battery is to perform a load test using a discharge machine following

manufacturer’s recommendations.

A cost effective way to identify a poorly performing battery is to use a hydrometer to identify a battery in a

set with a lower than normal specific gravity. Once the particular cell or cells that are the problem are

identified, the suspect battery can be removed and replaced. At this point there is nothing that can be done to

salvage the battery; however, the individual battery should be replaced with a good battery of the same brand,

type and approximate age.

Hydrometer

A hydrometer (P/N 50900-G1) is used to test the state of charge of a battery cell (Ref Fig. 22). This is

performed by measuring the density of the electrolyte, which is accomplished by measuring the specific

gravity of the electrolyte. The greater the concentration of sulfuric acid, the more dense the electrolyte

becomes. The higher the density, the higher the state of charge.

!WARNING ! To prevent battery explosion that could result in severe personal injury or death, never

insert a metal thermometer into a battery. Use a hydrometer with a built in thermometer

Page 38

OPERATION AND SERVICE INFORMATION

35

Owner’s Manual and Service Guide

Fig.22 Hydrometer

Specific gravity is the measurement of a liquid that is compared to a baseline. The baseline is water which is

assigned a base number of 1.000. The concentration of sulfuric acid to water in a new golf car battery is 1.280

which means that the electrolyte weighs 1.280 times the weight of the same volume of water. A fully charged

battery will test at 1.275 -1.280 while a discharged battery will read in the 1.140 range.

NOTE Do not perform a hydrometer test on a battery that has just been watered.The battery must go

through at least one charge and discharge cycle in order to permit the water to adequately mix with the

electrolyte.

The temperature of the electrolyte is important since the hydrometer reading must be corrected to 80° F (27°

C). High quality hydrometers are equipped with an internal thermometer that will measure the temperature of

the electrolyte and will include a conversion scale to correct the float reading. It is important to recognize that

the electrolyte temperature is significantly different from the ambient temperature if the vehicle has been

operated.

Using A Hydrometer

1. Draw electrolyte into the hydrometer several times to permit the thermometer to adjust to the electrolyte

temperature and note the reading. Examine the color of the electrolyte. A brown or gray coloration indicates a

problem with the battery and is a sign that the battery is nearing the end of its life.

2. Draw the minimum quantity of electrolyte into the hydrometer to permit the float to float freely without

Page 39

OPERATION AND SERVICE INFORMATION

36

Owner’s Manual and Service Guide

contacting the top or bottom of the cylinder.

3. Hold the hydrometer in a vertical position at eye level and note the reading where the electrolyte meets the

scale on the float.

4. ρ25℃ = ρt +0.0007(t-25)

ρ25℃ ——25℃ electrolyte specific gravity ;

ρt ——t℃ electrolyte specific gravity;

5. Test each cell and note the readings (corrected to 80° Fig. 30 Hydrometer F or 27° C). A variation of fifty

points between any two cell readings (example 1.250 -1.200) indicates a problem with the low reading

cell(s).

As a battery ages the specific gravity of the electrolyte will decrease at full charge. This is not a reason to

replace the battery, providing all cells are within fifty points of each other.

Since the hydrometer test is in response to a vehicle exhibiting a performance problem, the vehicle should be

recharged and the test repeated. If the results indicate a weak cell, the battery or batteries should be removed

and replaced with a good battery of the same brand, type and approximate age.

BATTERY MAINTENANCE

Our experience shows that the key to achieving optimum performance and long life is a solid battery

maintenance program using the simple procedures

outlined here.

Equipment:

We recommends the following equipment for use in battery care and maintenance:

Recommended Equipment:

◆ Wrench

◆ Distilled Water

◆ Voltmeter

◆ Hydrometer

◆ Thermometer

◆ Post Cleaner

◆ Baking Soda

◆ Vaseline

◆ Goggles & Gloves

!CAUTION !: Always wear protective clothing, gloves, and goggles

when handling batteries, electrolyte, and charging your battery.

Page 40

OPERATION AND SERVICE INFORMATION

37

Owner’s Manual and Service Guide

Inspection

Batteries should be carefully inspected on a regular basis in order to detect and correct potential problems

before they can do harm. It is a great idea to start this routine when the batteries are first received.

Inspection Guildlines:

1. Examine the outside appearance of the battery.

◆ Look for cracks in the container.

◆ The top of the battery, posts, and connections should be clean, free of dirt, fluids, and corrosion.

◆ Repair or replace any damaged batteries.

2. Any fluids on or around the battery may be an indication that electrolyte spilling, leaching, or leaking out.

◆ Leaking batteries must be repaired or replaced.

3. Check all battery cables and their connections.

◆ Look closely for loose or damaged parts.

◆ Battery cables should be intact; broken or frayed cables can be extremely hazardous.

◆ Replace any cable that looks suspicious.

4. Tighten all wiring connections to the proper specification. Make certain there is good contact with the

terminals.

!WARNING !

◆ Do not smoke near batteries.

◆ Do not overtighten terminals. Doing so can result post breakage, post meltdown, or fire.

Specific Gravity Testing

1. Do not add water at this time.

2. Washing hydrometer with deionized water firstly。,