Crown AWR, CWI, BWF, CWD, BWC User Manual

USERS’ INFORMATION MANUAL

D

ESIGNED TO

L

EAD

· GAS WATER BOILERS: AWR, CWI, BWF, CWD, BWC

· GAS STEAM BOILER: BSI SERIES

TO THE BOILER OWNER: READ THIS MANUAL IMMEDIATELY AFTER THIS BOILER IS

PLACED IN SERVICE AND RETAIN IT FOR FUTURE REFERENCE.

WARNING: If the information in this

manual is not followed exactly, a re or explosion may result causing property damage,

personal injury or loss of life.

-Do not store gasoline or other ammable vapors and liquids in the vicinity of this or any

other appliance.

-What to do if you smell gas:

· Do not try to light any appliance

· Do not touch any electrical switch; do

not use any phone in your building.

· Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

· If you cannot reach your gas supplier,

call the re department.

-Installation and service must be performed

by a qualied installer, service agency, or the

gas supplier.

AVERTISSEMENT. Assurez-vous de bien

suivre les instructions données dans cette

notice pour réduire au minimum le risque

d’incendie ou d’explosion ou pour éviter

tout dommage matériel, toute blessure ou la

- Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables

dans le voisinage de cet appareil ou de tout

autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE

ODEUR DE GAZ:

· Ne pas tenter d’allumer d’appareils.

· Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones dans le bâtiment où vous vous trouvez.

· Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

· Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service des

incendies.

L’installation et I’entretien doivent être assuréx

par un installateur ou un service d’entretien

PN 980425 REV O

DANGER

THERE ARE NO USER SERVICABLE PARTS ON THIS BOILER. ATTEMPTS TO

SERVICE THIS BOILER BY SOMEONE OTHER THAN A QUALIFIED GAS SERVICE TECHNICIAN COULD VOID THE WARRANTY, CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

• Do not use this boiler if any part has been under water. Immediately call a qualied service technician

to inspect the boiler and to replace any part of the control system and any gas control which has been

under water.

• Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead shut off the gas supply at a location external to the appliance/En cas de

surchauffe ou si l’admission de gaz ne peut étre coupée, ne pas couper ni débrancher l’alimentation

électrique de la pompe. Fermer plutot le robinet d’admission de gaz à l’extérieur de l’appareil.

• This boiler may have parts containing refractory ceramic bers (RCF). See the safety information on

page 11 if this boiler must be serviced or repaired.

CAUTION

Like all central heating appliances, this boiler is equipped with safety devices, which could cause it to shutdown,

requiring service to restore normal operation. Where such a shutdown could result in damage from low temperatures

(such as frozen pipes), do not leave the heating system unattended during cold weather unless alarms or other safeguards are in place to prevent damage.

1) This manual covers the proper care and use of the following boilers:

• AWR “Aruba IV” series gas water boiler

• CWI “Cayman” series gas water boiler

• BWF “Bali” series fan assisted water boiler

• CWD “Cabo2” series gas direct vent water boiler

• BWC “Bimini” series gas condensing direct vent water boiler

• BSI “Bermuda” series gas steam boiler

Most of the information in this manual applies to all of the above boilers. Information that is unique to a particular series is clearly marked with the series to which it applies.

2) Instructions to safely light and shut down this boiler are shown on pages 5 - 7, as well as on a label afxed to the boiler.

WARNING

• In the event that the ame rollout switch opens, the cause of the ame rollout must be diagnosed and cor-

rected by a qualied gas service technician before the boiler is restarted.

• In the event that the ignition system on a CWD or BWC does not permit the boiler to re, there is either

a problem with the igntion system, an occurrence of ame rollout, or a problem with the vent system.

Call a qualied gas service technician to diagnose and correct the problem.

• A “tripped” rollout switch must be replaced by an identical switch having the same temperature setting.

1

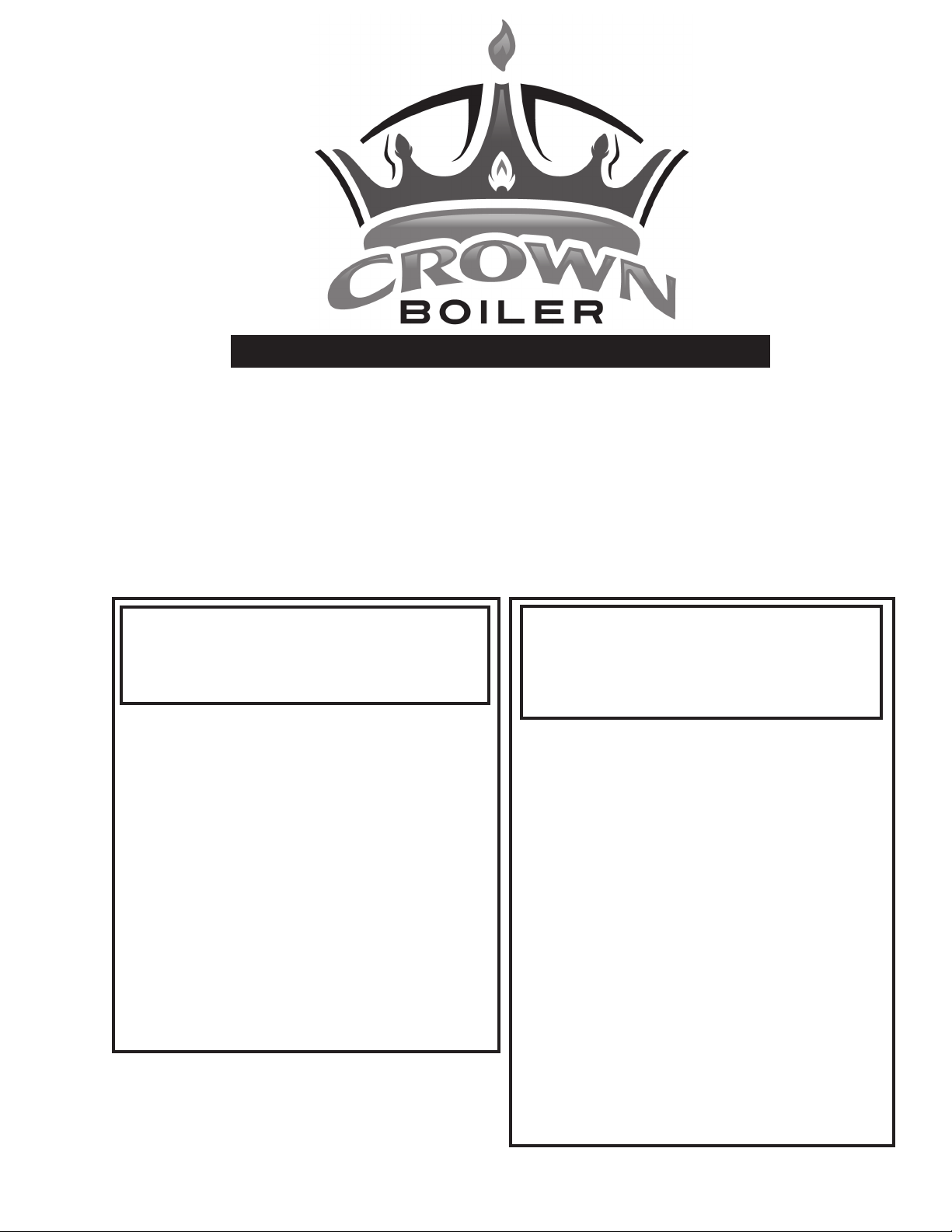

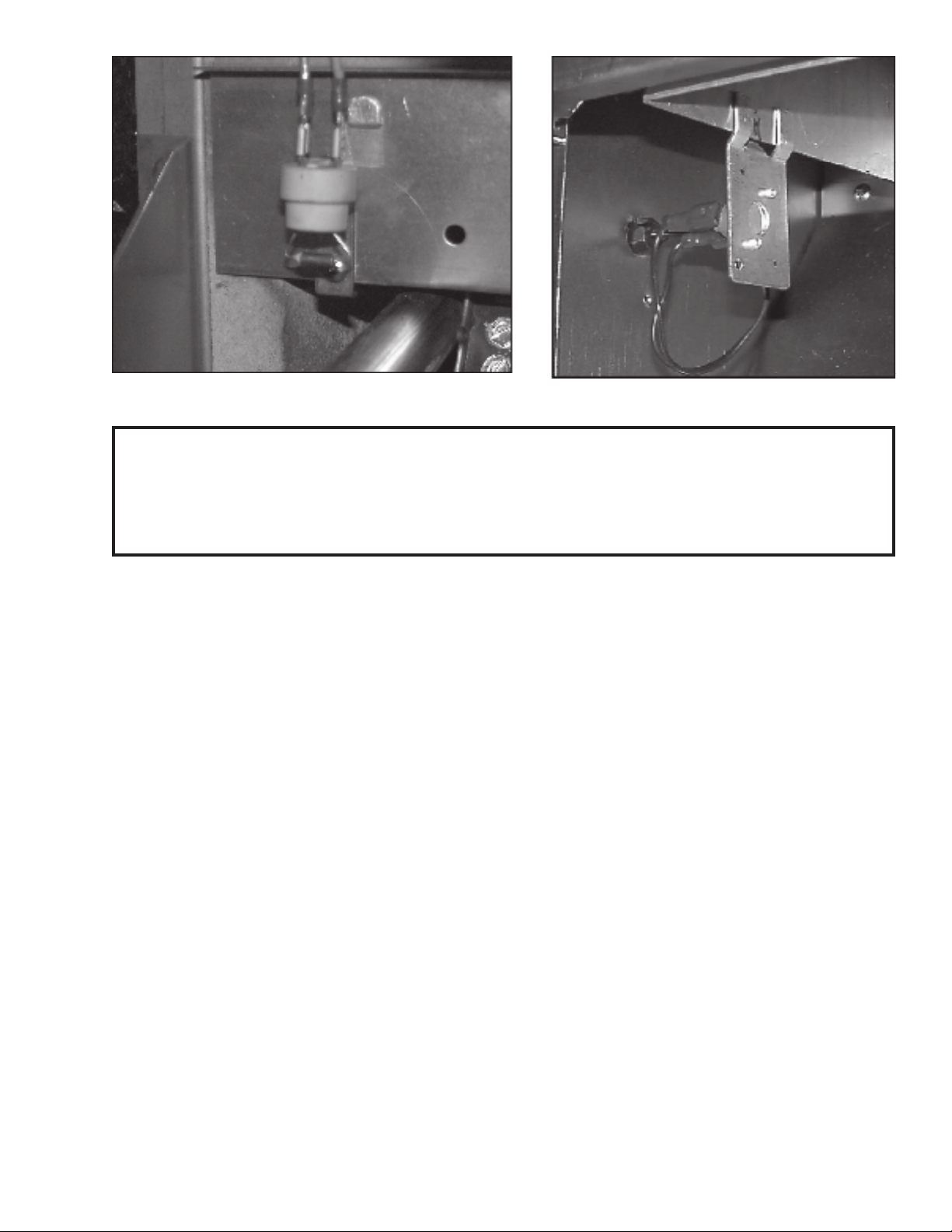

Figure 2: Blocked Vent SwitchFigure 1: Flame Rollout Switch

WARNING

A shutdown of the burners due to the blocked vent switch is an indication that there is a problem with the vent system,

such as a blockage. The blocked vent switch should only be reset after a qualied gas service technician has diagnosed

and corrected the venting problem that caused the blocked vent switch to open.

3) All boilers except the CWD and BWC boilers are equipped with a ame rollout switch (Figure 1). This

switch will shut the burners down in the event that ames exit the burner compartment through the front

opening. The CWD and BWC use an electronic means built into the ignition system to extinguish the

burner/s in the event that ames exit the combustion chamber. If the boiler fails to re, call a qualied

heating service agency to diagnose and correct the problem.

4) The AWR, CWI and BSI boilers are equipped with a blocked vent shut-off switch (Figure 2). This switch

will shut the boiler down in the event that there is an excessive blockage in the vent system. This switch

has a reset button, which must be pressed before the boiler can be restarted.

5) BWF, CWD, BWC Series boilers – These boilers are equipped with a safety feature which will shut

down the burners in the event that there is a blockage in the vent system. In the event that the boiler fails

to function, and the boiler is vented through an outside wall accessible from the ground, inspect the vent

terminal on the outside wall for a blockage such as a bee’s nest or ice. If a blockage is found, the burners

should ignite approximately 30 seconds after the blockage is removed. If no blockage is found, or if the

terminal is inaccessible from the ground, the problem must be diagnosed and corrected by a qualied gas

service technician.

Maintenance

1) Safe reliable operation of this boiler depends upon proper periodic maintenance.

2) The following should be done on a continuous basis:

• Keep the area around the boiler free of objects, which are ammable or which could obstruct the

ow of air into and around the boiler.

2

Loading...

Loading...