Page 1

INSTALLATION and OPERATION MANUAL

Self-Priming Centrifugal Pumps

Series: B4, B6, B9, B12,

B19*, B21*, SB4,

SB6, SB9, SB12,

SB19*, SB21*,

BH7, SBH7

Universal Drive

IMPORTANT! Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

change product without prior written notifi cation.

A Crane Co. Company

420 Third Street 83 West Drive, Bramton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com

Form No. 099811-Rev. H

Page 2

TABLE OF CONTENTS

A. SPECIFICATIONS

B4, SB4, B6, SB6, B9, SB9, SERIES PUMPS.................................................4

B12, SB12, BH7, SBH7 SERIES PUMPS........................................................5

B19, SB19, B21, SB21, SERIES PUMPS ........................................................6

B. GENERAL INFORMATION

(Receiving, Storage, Service Centers) .............................................................7

C. INSTALLATION RECOMMENDATIONS ..........................................................7

D. OPERATION RECOMMENDATIONS ..............................................................7 - 8

E. PREVENTATIVE MAINTENANCE ...................................................................8 - 9

TROUBLE SHOOTING ....................................................................................10 - 11

F. REPLACEMENT PARTS ..................................................................................11

B4, B6, B9, CROSS-SECTION ........................................................................12

PARTS LIST ...................................................................................................13

SB4, SB6, SB9 CROSS-SECTION ..................................................................14

PARTS LIST ...................................................................................................15

SAFETY FIRST ............................................................................................... 3

B12 CROSS-SECTION ....................................................................................16

PARTS LIST ...................................................................................................17

SB12 CROSS-SECTION .................................................................................18

PARTS LIST ...................................................................................................19

BH7 CROSS-SECTION ...................................................................................20

PARTS LIST ...................................................................................................21

SBH7 CROSS SECTION .................................................................................22

PARTS LIST ...................................................................................................23

B19, B21 CROSS-SECTION ...........................................................................24

PARTS LIST ...................................................................................................25

SB19, SB21 CROSS-SECTION .......................................................................26

PARTS LIST ...................................................................................................27

WARRANTY ...................................................................................................28

START-UP REPORT for Electric Motor Drive ..................................................29 - 30

START-UP REPORT for Engine Driven Pumps ...............................................31 - 32

RETURNED GOODS POLICY

WARRANTY REGISTRATION

Other brand and product names are trademarks or registered trademarks of their respective holders.

® CROWN is a registered trademark of Crane Pumps & Systems, Inc

® Tefl on is a registered trademark of E.I. Dupont de Nemours and Company

® Crane-Carb is a registered trademark of John Crane International

1997, 1998, 2002, 2/06, 9/06 Alteration Rights Reserved

2

Page 3

SAFETY FIRST!

Please Read This Before Installing Or Operating Pump.

This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information,

observe the following symbols:

IMPORTANT! Warns about hazards that can result

in personal injury or Indicates factors concerned with

assembly, installation, operation, or maintenance which

could result in damage to the machine or equipment if

ignored.

CAUTION ! Warns about hazards that can or will cause minor

personal injury or property damage if ignored. Used with symbols

below.

WARNING ! Warns about hazards that can or will cause serious

personal injury, death, or major property damage if ignored. Used

with symbols below.

Hazardous fl uids can

cause fi re or explosions,

burnes or death could

result.

Biohazard can cause

serious personal injury.

Rotating machinery

Amputation or severe

laceration can result.

Toxic Fumes Breathing can cause

nausea, fainting or death

Extremely hot - Severe

burnes can occur on contact.

Hazardous fl uids can Hazard-

ous pressure, eruptions or explosions could cause personal

injury or property damage.

Hazardous voltage can

shock, burn or cause death.

Eye protectiong required

WARNING! - DO NOT wear loose clothing that may

become entangled in the impeller or other moving parts.

Always wear appropriate safety gear, such as safety

glasses, when working on the pump or piping.

WARNING! - Keep clear of suction and discharge

openings. DO NOT insert fi ngers in pump with power

connected.

Always wear eye protection when working on pumps.

Make sure lifting handles are securely fastened each

time before lifting. DO NOT operate pump without safety

devices in place. Always replace safety devices that

have been removed during service or repair. Secure the

pump in its operating position so it can not tip over, fall

or slide.

DO NOT exceed manufacturers recommendation for

maximum performance, as this could cause the motor

to overheat.

WARNING! If Engine driven, never operate in an

enclosed building or area where exhaust gases can

accumulate. Never operate near a building where

exhaust gases can seep inside. Never operate in a

pit or sump without making provisions for adequate

ventilation.

WARNING! Do not breathe exhaust fumes when

working in the area of the engine. (Exhaust gases are

odorless and deadly poison.)

Only qualifi ed personnel should install, operate and repair

pump. Any wiring of pumps should be performed by a qualifi ed

electrician.

WARNING ! - To reduce risk of electrical shock, pumps

and control panels must be properly grounded in

accordance with the National Electric Code (NEC) or

the Canadian Electrical Code (CEC) and all applicable

state, province, local codes and ordinances. Improper

grounding voids warranty.

WARNING! - To reduce risk of electrical shock, always

disconnect the pump from the power source before

handling or servicing. Lock out power and tag.

WARNING! Operation against a closed

discharge valve will cause premature bearing

and seal failure on any pump, and on end

suction and self priming pump the heat build

may cause the generation of steam with resulting dangerous

pressures. It is recommended that a high case temperature

switch or pressure relief valve be installed on the pump body.

CAUTION! Pumps build up heat and pressure

during operation-allow time for pumps to cool

before handling or servicing.

WARNING! - DO NOT pump hazardous materials

(fl ammable, caustic, etc.) unless the pump is specifi cally

designed and designated to handle them.

CAUTION! - Do not block or restrict discharge hose, as

discharge hose may whip under pressure.

WARNING! Allow exhaust system to cool before

touching.

Never add fuel to the tank while the engine is running.

Stop engine and allow to cool.

Do not smoke while refueling the engine

Do not refuel near open fl ame

Carefully read instruction manuals supplied by engine

manufacture before attempting to assemble, operate

or service the engine or any part. The “WARNING”

statements indicate potentially hazardous conditions for

operator or equipment.

WARNING! Products Returned Must Be Cleaned,

Sanitized, Or Decontaminated As Necessary Prior

To Shipment, To Insure That Employees Will Not Be

Exposed To Health Hazards In Handling Said Material.

All Applicable Laws And Regulations Shall Apply.

Bronze/brass and bronze/brass fi tted pumps may

contain lead levels higher than considered safe for

potable water systems. Lead is known to cause cancer

and birth defects or other reproductive harm. Various

government agencies have determined that leaded

copper alloys should not be used in potable water

applications. For non-leaded copper alloy materials of

construction, please contact factory.

IMPORTANT! - Crane Pumps & Systems, Inc. is not

responsible for losses, injury, or death resulting from a

failure to observe these safety precautions, misuse or

abuse of pumps or equipment.

3

Page 4

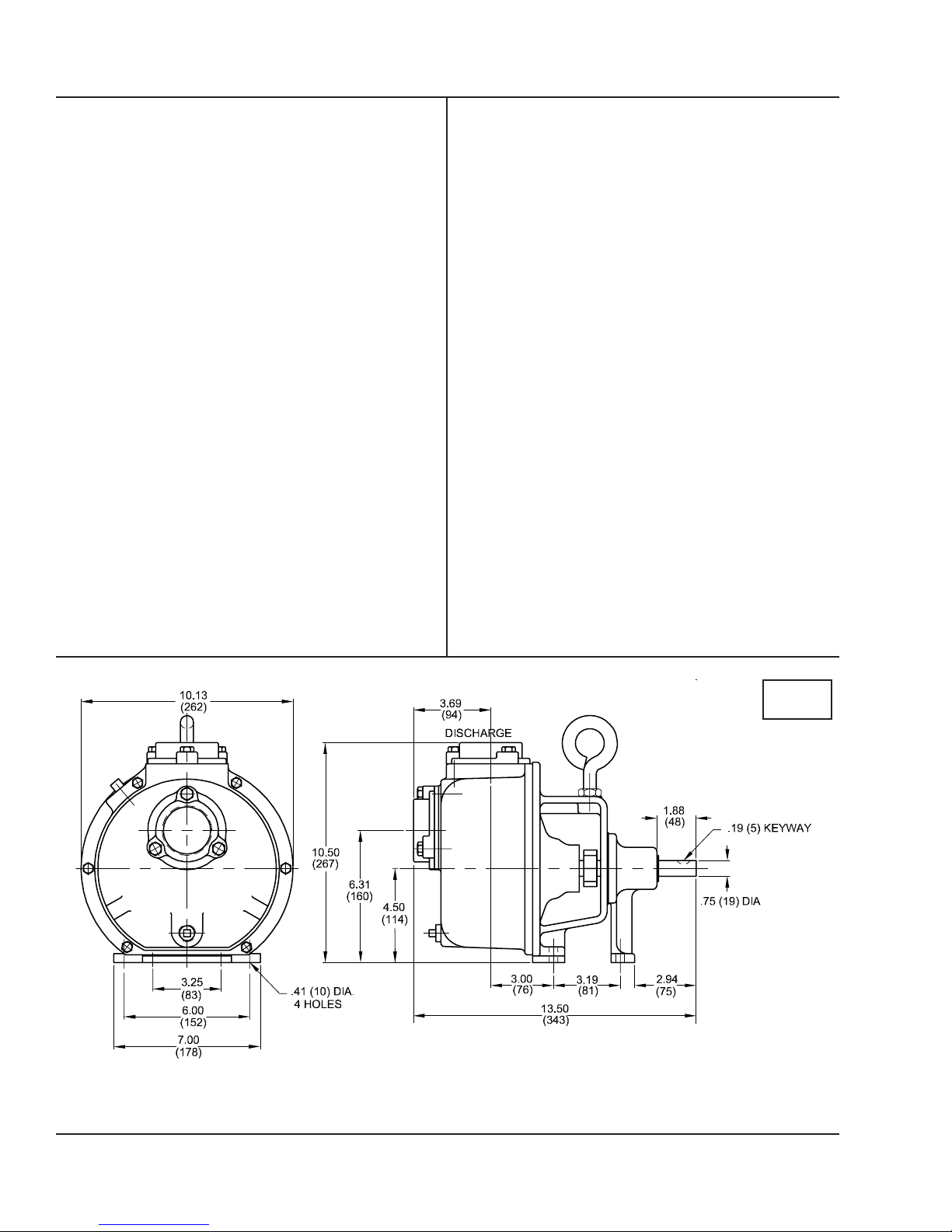

SECTION: A - PUMP SPECIFICATIONS: B4, B6, B9, SB4, SB6, SB9

SUCTION/DISCHARGE:

B4, SB4, B6, SB6 ...............1½” x 1½" NPT, Female

B9, SB9 ...............................2" X 2" NPT Female

LIQUID TEMPERATURE ....160°F (71°C) Continuous

VOLUTE/WEARPLATE ....... B-Cast Iron ASTM A-48, Class 30

SB - 316 Stainless Steel,

Replaceable

CASE...................................B-Cast Iron ASTM A-48, Class 30

SB - 316 Stainless Steel

PEDESTAL ..........................Cast Iron ASTM A-48, Class 30

IMPELLER: Design:

B4 & SB4 ......Open Type, Passes 1/4" Solids

B6 & SB6 .......Open Type, Passes 3/8" Solids

B9 & SB9 .......Open Type, Passes 1/2" Solids

Material .........B-Cast Iron ASTM A-48, Class 30

SB - 316 Stainless Steel

Dynamically Balanced, ISO G6.3

IMPELLER SHAFT ...........Stainless Steel

LOCKING COLLAR ............Stainless Steel. Serves as Shaft

Slinger

SQUARE RINGS ................B - Buna-N

SB - Viton®

HARDWARE .......................B - Corrosion Resistant Steel

SB - Stainless Steel

PAINT .................................B - Air Dry Enamel

SB - Two Part Epoxy

SEAL:B Design ...........Single Mechanical

Lubrication .........Grease, with Self-Feeding Lubricator

Material ..........Rotating Faces - Carbon

Stationary Faces - Ceramic

Elastomer - Buna-N

Hardware - 300 Series Stainless

SB Design ...........Single Mechanical

Lubrication .....Pumped Fluid

Material ..........Rotating Faces - Carbon

Stationary Faces - Ceramic

Elastomer - Viton

Hardware - 300 Series Stainless

BEARING: B4, SB4, B6, SB6

Design ............Single Row, Ball

Lubrication .....Grease

Load ...............Radial & Thrust

BEARING: B9, SB9

Design ............Double Row, Ball

Lubrication .....Grease

Load ...............Radial & Thrust

CHECK VALVE:

Material .........B - Valve Flap-Neoprene

SB - Valve Flap - Viton

Weight-Cast Iron ASTM A-48,

Class 30

OPTIONAL EQUIPMENT ....Seal Material, Case Heater,

Stainless Hardware; High Temperature Control; Flex Coupled

Assy., with Base & OSHA Guard; Right Hand V-Belt Drive

Assy., Left Hand V-Belt Drive Assy., and In-Line Vertical V-

Belt Drive Assy., with Base, Motor Adjusting Base & OSHA

Guard.

inches

(mm)

IMPORTANT !

1.) DO NOT USE FOR PUMPING FLUIDS WITH A FLASH POINT OF LESS THAN 100°F.

2.) MAKE CERTAIN THAT PUMP AND/OR MOTOR ASSEMBLY AND CONTROLS HAVE THE APPROPRIATE RATINGS FOR THE GIVEN APPLICATION

AREA CLASSIFICATION. (ie DIVISION I, AGENCY LISTING ETC.)

4

Page 5

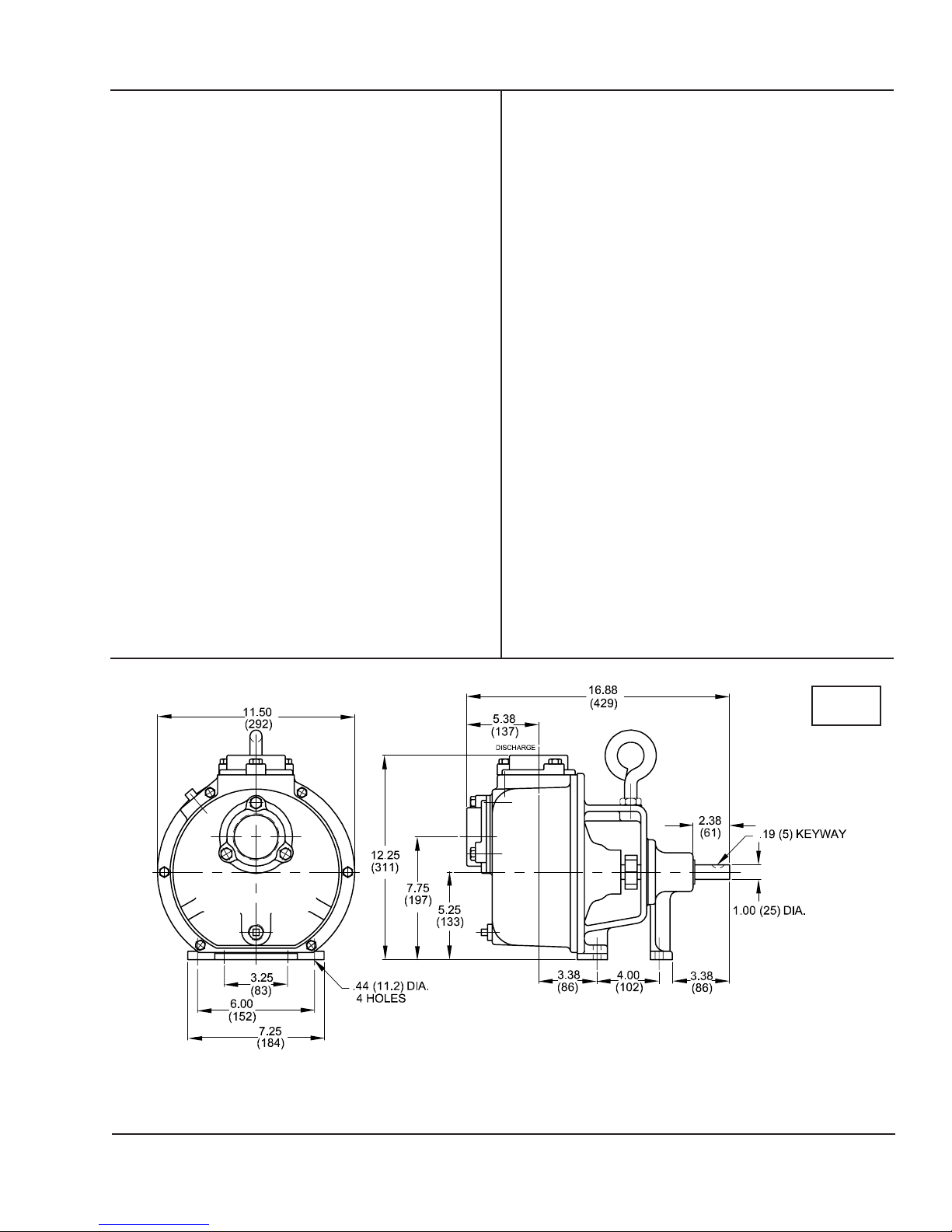

SECTION: A - PUMP SPECIFICATIONS: B12, SB12, BH7, SBH7

SUCTION/DISCHARGE ........... 2" X 2" NPT Female

LIQUID TEMPERATURE ......... 160°F (71°C) Continuous

VOLUTE/WEARPLATE

B & BH ......................... Cast Iron ASTM A-48, Class 30

SB & SBH .........................316 Stainless Steel, Replaceable

CASE B & B H ......................... Cast Iron ASTM A-48, Class 30

SB & SBH ................... 316 Stainless Steel

PEDESTAL ......................... Cast Iron ASTM A-48, Class 30

IMPELLER:

Design B12 & SB12 ... Open Type, Passes 1/2" Solids

Design BH7 & SBH7 ... Open Type, Passes 1/4" Solids

Material B & BH ...........Cast Iron ASTM A-48, Class 30

SB & SBH ..... 316 Stainless Steel

Dynamically Balanced,

ISO G6.3

IMPELLER SHAFT ................ Stainless Steel

LOCKING COLLAR ................. Stainless Steel. Serves as

Shaft Slinger

SQUARE RINGS ..................... B & BH - Buna-N

SB & SBH - Viton®

HARDWARE

B & BH ...................... Corrosion Resistant Steel

SB & SBH ................... Stainless Steel

PAINT B & BH ...................... Air Dry Enamel

SB & SBH ................... Two Part Epoxy

SEAL:

B & BH Design ...................... Single Mechanical

Lubrication ...................Grease, with Self-Feeding

Lubricator

Material ...................... Rotating Faces - Carbon

Stationary Faces - Ceramic

Elastomer - Buna-N

Hardware - 300 Series Stainless

SB & SBH

Design ...................... Single Mechanical

Lubrication ...................Pumped Fluid

Material ...................... Rotating Faces - Carbon

Stationary Faces - Ceramic

Elastomer - Viton

Hardware - 300 Series Stainless

BEARING:

Design ...................... Single Row, Ball

Lubrication ...................Grease

Load ...................... Radial & Thrust

CHECK VALVE:

Material ...................... B & BH - Valve Flap

Neoprene

SB & SBH - Valve Flap

Viton

Weight-Cast Iron ASTM A-48,

Class 30

OPTIONAL EQUIPMENT ......... Seal Material, Case Heater,

Stainless Hardware; High Temperature Control; Flex Coupled

Assy., with Base & OSHA Guard; Right Hand V-Belt Drive

Assy., Left Hand V-Belt Drive Assy., and In-Line Vertical

V-Belt Drive Assy., with Base, Motor Adjusting Base & OSHA

Guard.

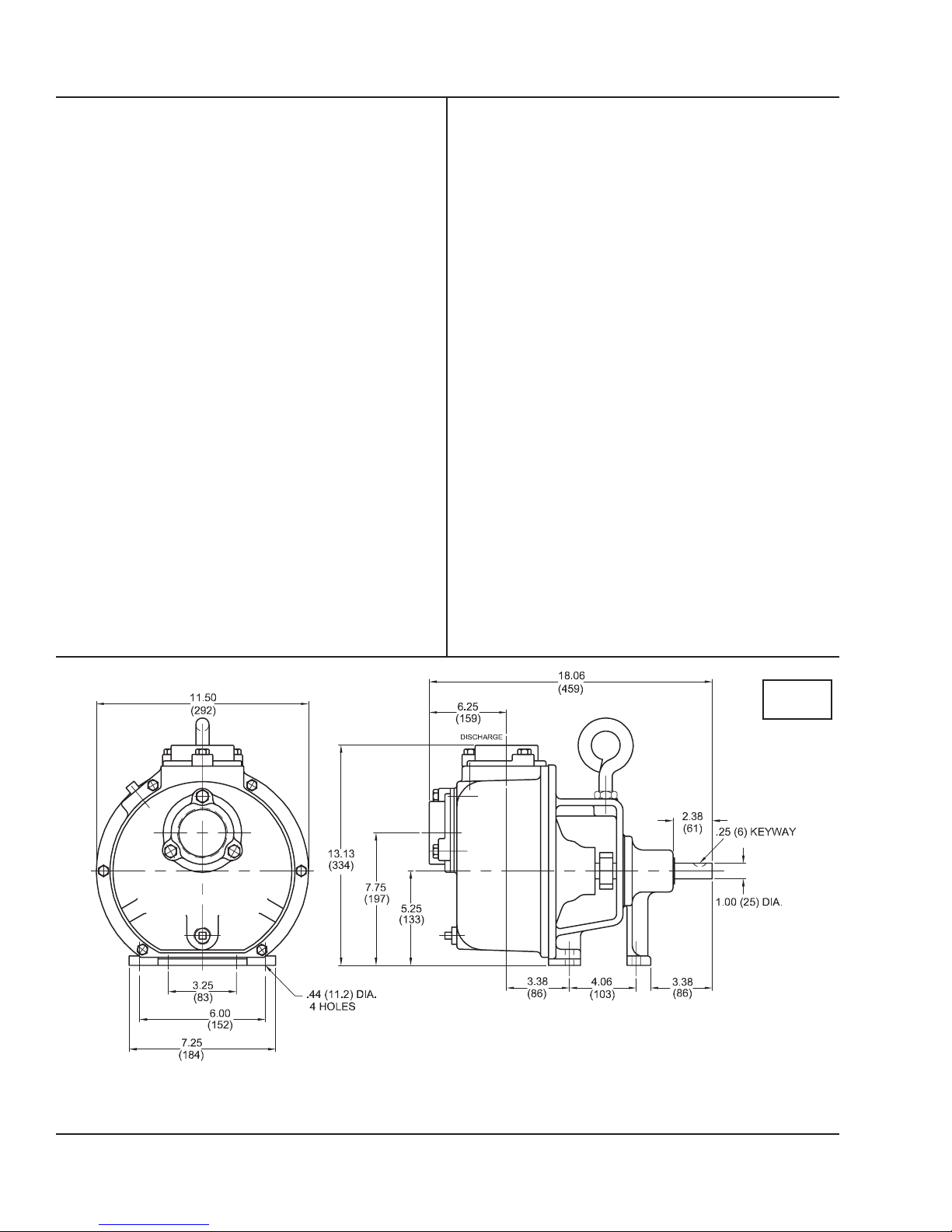

inches

(mm)

IMPORTANT !

1.) DO NOT USE FOR PUMPING FLUIDS WITH A FLASH POINT OF LESS THAN 100°F.

2.) MAKE CERTAIN THAT PUMP AND/OR MOTOR ASSEMBLY AND CONTROLS HAVE THE APPROPRIATE RATINGS FOR THE GIVEN APPLICATION

AREA CLASSIFICATION. (ie DIVISION I, AGENCY LISTING ETC.)

5

Page 6

SECTION: A - PUMP SPECIFICATIONS: B19, SB19, B21, SB21

SUCTION/DISCHARGE .........3" X 3" NPT Female

LIQUID TEMPERATURE .......160°F (71°C) Continuous

VOLUTE/WEARPLATE

B .......................Cast Iron ASTM A-48, Class 30

SB .....................316 Stainless Steel,

Replaceable

CASE B .......................Cast Iron ASTM A-48, Class 30

SB .....................316 Stainless Steel

PEDESTAL .............................Cast Iron ASTM A-48, Class 30

IMPELLER: Design ...............Open Type, Passes 3/4" Solids

Material

B .......................Cast Iron ASTM A-48, Class 30

SB .....................316 Stainless Steel

Dynamically Balanced, ISO G6.3

IMPELLER SHAFT ..............Stainless Steel

LOCKING COLLAR ..............Stainless Steel. Serves as

Shaft Slinger

SQUARE RINGS ...................B - Buna-N

SB - Viton®

HARDWARE ..........................B - Corrosion Resistant Steel

SB - Stainless Steel

PAINT ....................................B - Air Dry Enamel

SB - Two Part Epoxy

SEAL: B Design ..............Single Mechanical

Lubrication ........Grease, with Self-Feeding

Lubricator

Material .............Rotating Faces - Carbon

Stationary Faces - Ceramic

Elastomer - Buna-N

Hardware - 300 Series Stainless

SB Design ..............Single Mechanical

Lubrication ........Pumped Fluid

Material .............Rotating Faces - Carbon

Stationary Faces - Ceramic

Elastomer - Viton

Hardware - 300 Series Stainless

BEARING:

B19 & SB19 Design ..............Double Row, Ball

B21 & SB21 Design ..............Single Row, Ball

Lubrication ........Grease

Load ..............Radial & Thrust

CHECK VALVE:

Material ............B - Valve Flap-Neoprene

SB - Valve Flap - Viton

Weight-Cast Iron ASTM A-48,

Class 30

OPTIONAL EQUIPMENT .......Seal Material, Case Heater,

Stainless Hardware; High Temperature Control; Flex Coupled

Assy., with Base & OSHA Guard; Right Hand V-Belt Drive

Assy., Left Hand V-Belt Drive Assy., and In-Line Vertical V-

Belt Drive Assy., with Base, Motor Adjusting Base & OSHA

Guard.

inches

(mm)

IMPORTANT !

1.) DO NOT USE FOR PUMPING FLUIDS WITH A FLASH POINT OF LESS THAN 100°F.

2.) MAKE CERTAIN THAT PUMP AND/OR MOTOR ASSEMBLY AND CONTROLS HAVE THE APPROPRIATE RATINGS FOR THE GIVEN APPLICATION

AREA CLASSIFICATION. (ie DIVISION I, AGENCY LISTING ETC.)

6

Page 7

SECTION B: GENERAL INFORMATION

B-1) To the Purchaser:

Congratulations! You are the owner of one of the fi nest

pumps on the market today. Crown® Pumps are products

engineered and manufactured of high quality components.

Over one hundred years of pump building experience along

with a continuing quality assurance program combine to

produce a pump which will stand up to the toughest pumping

projects.

This pump manual will provide helpful information concerning

installation, maintenance, and proper service guidelines.

Locate the pump on a fi rm footing to make sure the pump

will not move due to vibration. Flex coupled and V-belt

driven units should be permanently grouted onto a cement

foundation. The pumps should be level to provide favorable

operating conditions. In addition, the fl exible coupling should

be realigned after grouting in order to eliminate excessive

wear on the coupling.

Allow a minimum of 18 inches in front of the pump case cover

or hatch cover to permit easy removal and access to the

interior of the pump. On belt driven units, allow a minimum

of 10 inches at the shaft end to permit easy removal of the

pedastal or rotating cartridge.

B-2) Receiving:

Upon receiving the pump, it should be inspected for

damage or shortages. If damage has occurred, fi le a claim

immediately with the company that delivered the pump. If the

manual is removed from the crating, do not lose or misplace.

B-3) Storage:

Short Term - Crown Pumps are manufactured for effi cient

performance following long inoperative periods in storage.

For best results, pumps can be retained in storage, as factory

assembled, in a dry atmosphere with constant temperatures

for up to six (6) months.

Long Term - Any length of time exceeding six (6) months, but

not more than twenty four (24) months. The units should be

stored in a temperature controlled area, a roofed over walled

enclosure that provides protection from the elements (rain,

snow, wind blown dust, etc.), and whose temperature can be

maintained between +40 deg. F and +120 deg. F.

If extended high humidity is expected to be a problem, all

exposed parts should be inspected before storage and all

surfaces that have the paint scratched, damaged, or worn

should be recoated with a water base, air dry enamel paint.

All surfaces should then be sprayed with a rust-inhibiting oil.

B-4) Service Centers:

For the location of the nearest Crown Service Center, check

your representative or Crane Pumps & Systems, Inc., in

Piqua, Ohio, telephone (937) 778-8947 or Crane Pumps &

Systems Canada, Bramton, Ontario, (905) 457-6223.

C-2) Suction:

It is advisable to use a suction line of the same size as the

pump port size. All horizontal suction lines should slope up to

the pump to avoid trapped air pockets. An adjustable stand,

pipe clamp or fl oor fl ange must be installed to support the

weight of the suction line. On suction lifts less than 5 feet, it is

sometimes possible to increase capacity slightly by oversizing

the suction line, but oversized suction pipe on high suction

lifts will create priming problems. Using a smaller suction line

than the pump port size can cause internal damage to the

pump.

The suction line must not have holes, even small holes. The

smallest air leak in the suction line may prevent the pump

from priming. Coat all threaded connections in the suction

line with pipe thread compound to insure an air tight joint. In

addition, suction fl anges should be pulled up tight to prevent

air leaks. Where fi ber gaskets are used, coat them with

grease.

Use a strainer on suction line to prevent the entrance of

oversize solids. This strainer should be submerged deep

enough to prevent air from being drawn into the suction line,

thus reducing the pump’s capacity and pressure.

CAUTION! - This pump should not be operated

without a strainer on the end of the suction line

to prevent sticks, stones, rags and other foreign

matter from being drawn into the impeller. The

strainer should be cleaned regularly to insure full

fl ow.

SECTION C: INSTALLATION RECOMMENDATIONS:

C-1) Location:

Locate the pump as close to the source of supply as possible.

Although the pump will operate on suction lifts of 25 feet, it is

desirable to keep the suction lift less than 15 feet, if possible.

The closer the pump can be located to the source of supply,

the faster the pump will prime and a greater capacity can be

pumped.

All pump units rotate clockwise when looking from the motor

end (driven end) of the pump. Also, rotation arrows are

located on the pump. On three phase units with threaded

suction/discharge connections the impellers are threaded on

the shaft and it is necessary to slide one half of the fl exible

coupling back when checking rotation in order to eliminate

the possibility of unscrewing the impeller and damaging the

pump. NOTE: Where impellers thread on pump shaft, never

check the direction of electric motor rotation without fi rst

disconnecting fl exible coupling.

C-3) Discharge:

Connect discharge hose or pipe to discharge on pump.

If Discharge hose is used, protect it from being driven over.

Do not use quick closing check valves.

SECTION D: OPERATION RECOMMENDATIONS:

1. Fill the pump case with liquid prior to starting the pump. A

self priming pump does require the case to be at least 2/3 full

of liquid in order to self prime. Operate at suffi cient speed to

prime pump. Generally speaking, the pump will prime faster if

it is operated at a fast speed.

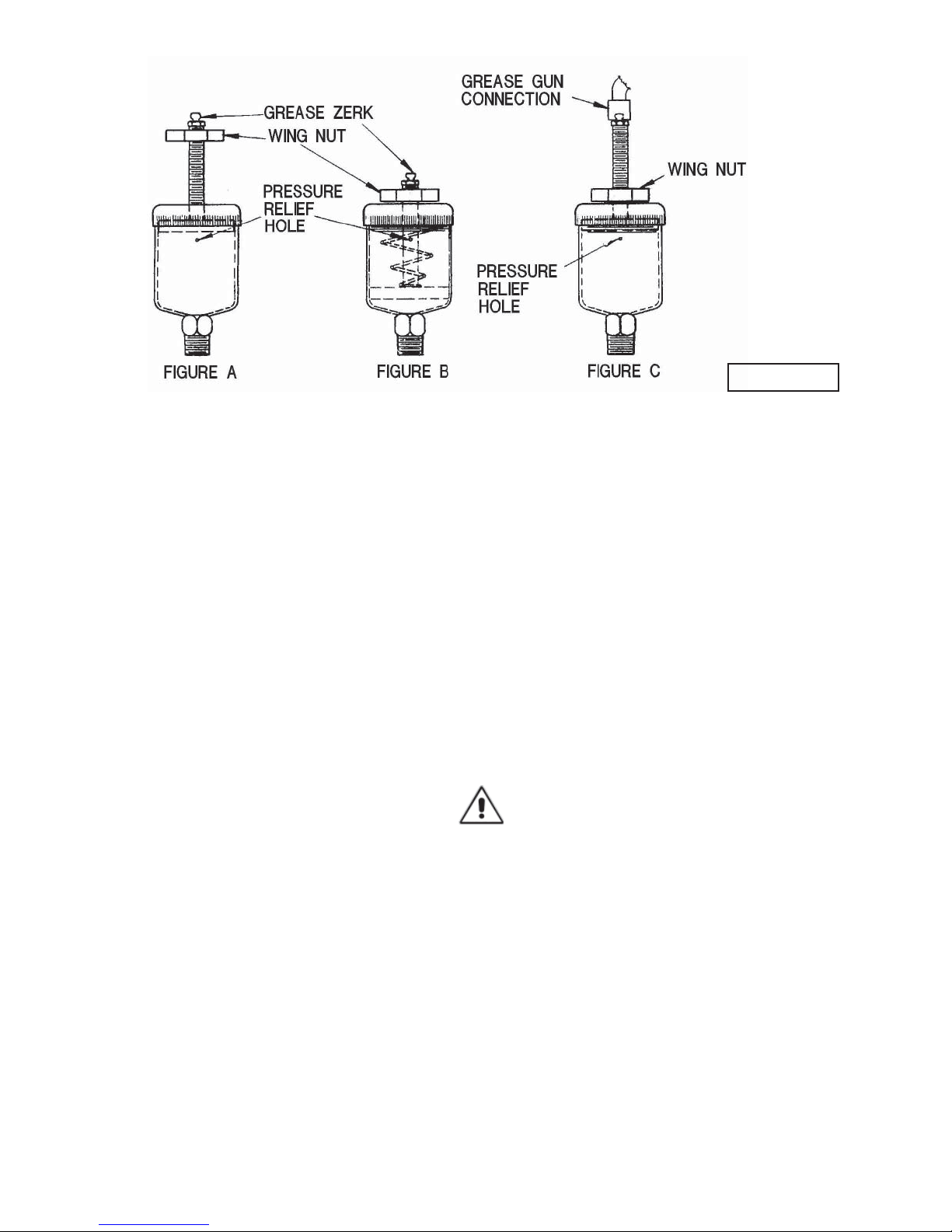

2. Place the self-feeding grease lubricator in operation by

turning the wing nut on the threaded plunger shaft counter

clockwise as far as it will go. Do not force the plunger into the

grease cup as this can cause a seal failure. See Maintenance

Recommedations, Paragraphs 1 and 2 for instructions on

fi lling the grease cup.

7

Page 8

FIGURE 1

3. In cold weather operation, the pump will not freeze as

long as it is running. However, it may freeze if it is not drained

while standing idle. To drain the pump, remove the drain plug

at the bottom of the pump case and rotate the impeller at

least once to assure removal of all the water.

4. The discharge of a self priming centrifugal pump may be

closed briefl y without damaging the pump. However, the wa-

ter will soon heat up and this can damage to the pump seal.

5. It is not desirable to run the pump without liquid in the

pump case. If the pump must be run in order to check the

operation of the engine or motor, fi ll the case with suffi cient

water to keep the rotating seal wet. This will eliminate damage to the seal and other pump parts.

6. If the pump has been idle for some time, the impeller may

appear to be stuck or locked in place. This is usually caused

by a fi lm of rust or dirt between the impeller and volute. A little

extra force on the crank may break it loose. If not, the pump

must be dismantled.

SECTION E: MAINTENANCE RECOMMENDATIONS:

E-1) Seal Lubrication:

A self-feeding lubricator is provided to supply grease to the

shaft seal of the pump. The grease cup is empty when the

wing nut, positioned at the outer end of the threaded plunger

shaft, recedes to the cap of the grease cup. To refi ll the

grease cup, rotate the wing nut clockwise as far as it will

go, attach a zerk gun to the zerk fi tting, then fi ll until grease

oozes from the relief hole on the side of the cup. For operation, return the wing nut to the end of the plunger. Never

force the plunger into the grease cup as this can cause seal

failures. (See Fig. 1)

A #1 grease is normally recommended. However, where high

ambient temperatures are encountered, such as in direct

sunlight, a #2 grease can be used. Use a water resistant,

nonfi berous grease. Lithium base greases are excellent and

molydisulphide is acceptable. Normally, the sodium soap

base greases are the only non-water resistant types that are

not acceptable for mechanical seal lubrication.

If the pump is inoperative for a long period of time, or appears

not to use any grease, remove and clean the cup thoroughly.

Caked grease in the cup can create a problem of

non-lubrication to the seal. Under normal conditions, a grease

cup full of grease will last three to four months. If a grease

seal requires grease every day, and it is not leaking past the

outer lip seal it indicates that the seal is wearing out. The

internal pressure of the pump will often force the cup plunger

out when the seal leaks badly.

E-2) Shaft Seal Replacement:

All parts of the pump are easily dismantled by simply

removing nuts and screws. Rotating parts of the shaft seal

grip the shaft by friction and may be frozen to the shaft

through long usage.

If the mechanical shaft seal is not leaking and it is necessary

to dismantle part of the pump for inspection or cleaning DO

NOT disturb the shaft seal other than its spring if the impeller

is removed. Once a shaft seal has been in operation it cannot

be removed and replaced without leaking.

CAUTION ! - Handle parts with extreme care.

Do not scratch or mar lapped surfaces.

It is recommended to remove the pump side from the support

bracket. After the pump has been disassembled make sure

that the shaft and seat areas in the pump side are as clean

as possible. The shaft must not be sharp, but neatly rounded

and polished to a 1/32” radius. This radius and the shaft, on

which the rubber bellows grips, must be polished with 180 to

240 grit emery cloth. The seal will install relatively easy if the

shaft is properly polished.

Install the seat assembly (1 and 2 or 1A and 2A, see Figure

2) in pump side adapter (12) using SAE# 10 oil on the rubber

parts. They may install easier by fi rst inserting the rubber part

and then sliding the seat part into the rubber. All of this must

be done with the fi ngers only .

8

Page 9

FIGURE 2

1 - Ni-Resist Stationary Seat

1A - Ceramic Stationary Seat

2 - Buna-N Seat Ring

2A - Buna-N Seat Cup

3 - Stainless Retainer

4 - Stainless Drive Band

5 - Stainless Spring

6 - Stainless Springholder

7 - Cran-Carb® Mating Ring

7A - Carbon Mating Ring

8 - Buna-N Bellows

Cross SEction of SEals.

Two Styles Shown

Now assemble the spring and rotating portion of the seal

onto the impeller shaft (19). Lubricate the impeller shaft (19)

and the inside of the bellows each with 2 or 3 drops of SAE#

10 oil. Install this assembly into adapter (12), this may take

several minutes, therefore, oscillate the seal back and forth

on the shaft to make sure it does not stick to the shaft until

gage pin is in place and the clamp tightened.

If for any reason the gage pin does not give proper clearance,

quickly adjust the impeller clearance before the rubber

bellows seats on the shaft.

E-3) Impeller:

These pumps have their impellers threaded on with right

hand threads.

The clearance between an open faced impeller and its wear

surface in the volute is set at the factory at approximately

.015 inches. This clearance is re-adjustable by relocating

the shaft at the clamping arrangement. In cases where

much sand is being pumped, close clearances may bind

the impeller and volute and overload the motor. It may be

necessary to provide extra clearance on these.

When reassembling a dismantled pump, clean all parts and

especially areas where gaskets and o-rings are located.

Grease all gaskets and o-rings and areas where o-rings must

slide when assembling.

FIGURE 3

9

Page 10

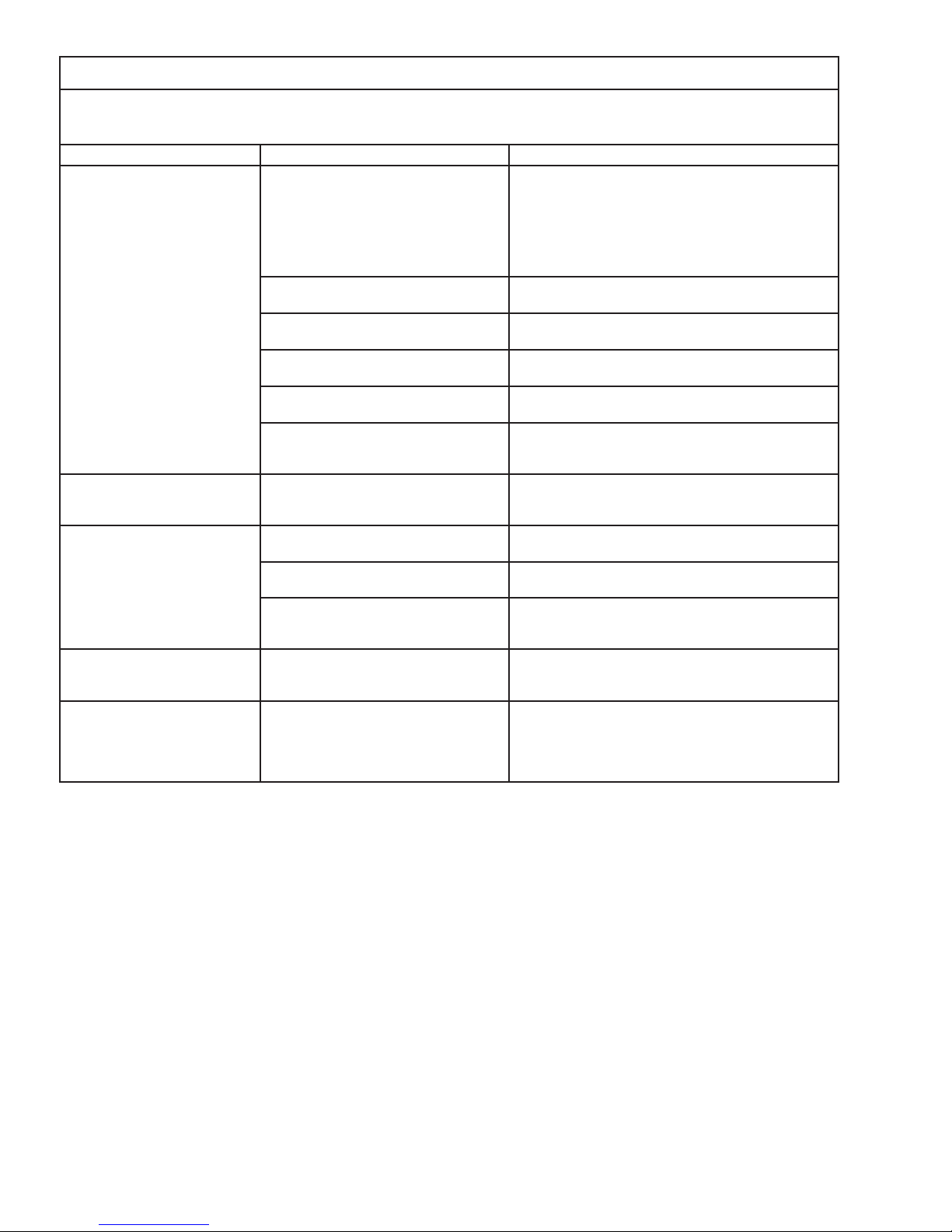

TROUBLE SHOOTING

CAUTION ! Always disconnect the pump from the electrical power source before handling.

If the system fails to operate properly, carefully read instructions and perform maintenance recommendations.

SYMPTOM POSSIBLE CAUSE(S) CHECK

1. Air leak in suction side of system. a. Threaded joints in suction line for tight fi t

2. Air bleed line blocked, or Air bleed valve

A. Pump not primed - Vacuum

gauge reading less than normal

B. Pump not priming - Vacuum

gauge reads more than normal 1. Suction side of system clogged

C. Pump primes - Vacuum gauge

reads normal, discharge gauge

reads lower than normal

D. Pump primes - Vacuum gauge

reads near normal, Discharge

gauge reads higher than normal

E. Pump looses prime when shut

off - Vacuum gauge recedes to

zero

closed.

3. Insuffi cient liquid in case

4. Operating speed to low

5. Plugged pump

6. Mechanical defects

1. Small air leak in suction side of system

2. Pump speed too slow

3. Mechanical defects

1. Plugged discharge

1. Check valve leaking

b. Gasket in suction line for tight fi t

c. O-rings in case cover for nicks or cuts

d. Mechanical seal for air leaks

e. Bottom drain plug for air leaks

f. O-rings in pump side for nicks or cuts

g. Vacuum gauge may be leaking internally

a. Check line or valve

a. Pump case for water level

b. Suction check valve for obstructions or deterioration

a. Belts for proper tension

b. Motor for low voltage

a. Impeller for lodge foreign material

b. Vent line for stoppage

a. Impeller - volute for proper clearance

b. Impeller and volute for damage

c. Pump for worn parts

a. End of suction line for obstructions

b. Suction pipe for obstructions

c. Suction check valve for obstructions

a. For excessive air in discharge line

b. Refer to A-1, a through g

a. Belts for proper tension

b. Motor for low voltage

a. Impeller - volute for proper clearance

b. Impeller and volute for damage

c. Pump for worn parts

a. Discharge line for obstructions

b. Discharge valves to insure proper operation

a. Check valve for obstructions or deterioration

b. Leak in suction pipe threads or fl anges

c. Water level bubbler control line too close to suction pipe

d. The infl uent liquid for chuming air into the sump and

entering the suction pipe

10

Page 11

TROUBLE SHOOTING

CAUTION ! Always disconnect the pump from the electrical power source before handling.

If the system fails to operate properly, carefully read instructions and perform maintenance recommendations.

SYMPTOM POSSIBLE CAUSE(S) CHECK

1. Drawdown too great a. Automatic cut-off control for failure

F. Pump loose prime during operation - vacuum gauge recedes

to zero

G. Pump primed and pumping,

but too noisy

H. Motor runing too hot

I. Motor will not run

2. Pump taking air

1. Loose foundation

2. Air leaks a. Refer to A-1, a through g

3. Cavitation

4. Bearings

5. Misalignment

6. Vibration

1. Low voltage a. Voltage at motor terminals when loaded

2. Overload

1. Overload relay kicked out

2. Three phase motor hums but will not

rotate

3. Automatic sump control failure

a. Suction line for leak between cut-out and cut-off

b. End of suction line for vortexing to suction pipe

c. Water level bubbler control line too close to suction pipe

d. The infl uent liquid for chuming air into the sump and

entering the suction pipe

a. Foundation bolts for looseness

b. Grouting

c. For cracks

a. Drawdown too great

b. Capacity too great

c. Unit not operating in proper NPSH rang

d. If reducing capacity quiets pump, then (c) above is

cause, close discharge valve partially

a. Balls for wear

b. Oil reservoir for lubrication

a. Coupling for proper alignment

b. Check base, not properly bolted down

a. Impeller for partial obstruction

b. Operating in cavitation range

c. Misalignment of coupling

a. Amps at motor terminals when loaded

b. Trash lodged in pump impeller

c. Motor not large enough

a. For one or more blown fuses

b. Fuses for proper size

c. For low voltage

a. For one of 3 blown fuses

a. Float rod for corrosion

b. Air bubbling pump not working

c. Air line for stoppage

SECTION K: REPLACEMENT PARTS

K-1 ORDERING REPLACEMENT PARTS:

When ordering replacement parts, ALWAYS furnish the following information:

1. Pump serial number and date code.

2. Pump model number.

3. Pump part number.

4. Part description.

5. Item part number.

6. Quantity required.

7. Shipping instructions.

8. Billing Instructions.

IMPORTANT ! When Ordering Parts, ALWAYS Provide

The Complete Part Number, Serial Number and Model

Number. Information Subject To Change Without Notice.

11

Page 12

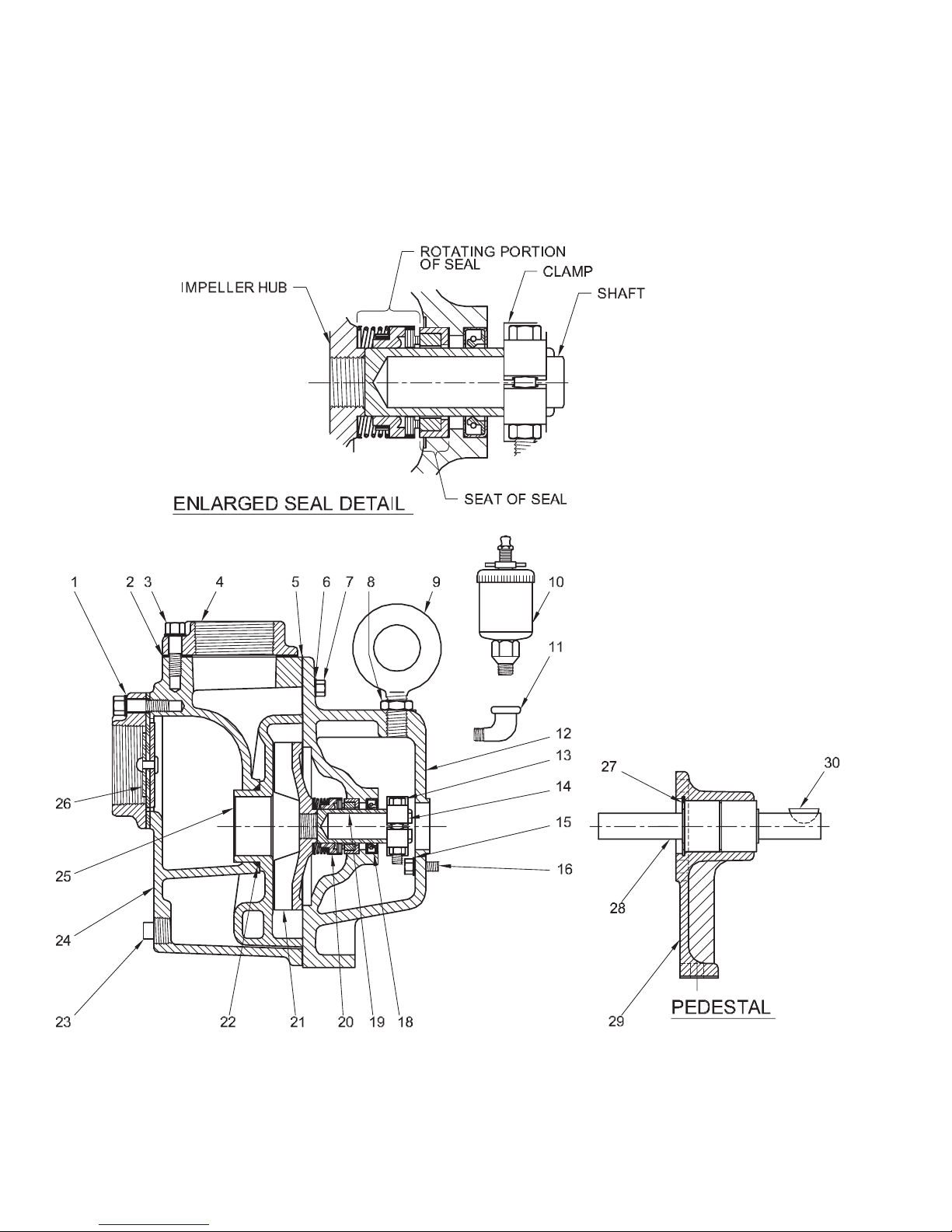

MODEL: B4, B6, B9

12

Page 13

MODEL: B4, B6, B9

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-14-1 Washer, Lock, Split, 3/8”, Stainless

2 1 MT-8650 Gasket, Flange

3 6 1-36-1 Screw, Hex Hd. 3/8-16 x 1.25”Lg, Stainless

4 2 FP-4487 Flange 1-1/2” (B4, B6)

2 FP-4488 Flange 2” (B9)

5 1 T-28700 Gasket, Pump Case

6 6 20-22-1 Washer, Lock, Split 5/16”, Stainless

7 6 1-156-1 Screw, Hex Hd. 5/16-18 x 1.00”Lg, Stainless

8 1 15-22-6 Nut, Hex, Jam 5/8-11, Zinc Plated

9 1 M-5087 Bolt, Eye 5/8-11, Steel

10 1 M-3415 Cup, Grease

11 1 625-01179 Elbow, Street 1/4”, Galv.

12 1 FP-4446-A Adapter, Side, Pump

13 2 1-135-1 Screw, Hex Hd. 5/16-18 X 1.75”, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

14 2 PSS-4476 Clamp, Impeller

15 4 20-22-6 Washer, Lock, Split 5/16”, Zinc Plated

16 4 1-129-6 Screw, Hex Hd. 5/16-18 X .75”, Zinc Plated

18 1 M-8759 Seal, Lip

19 1 TS-29790 Hub, Impeller Stainless

20 1 M-4292-F Seal, Mechanical 1.00”

21 1 FP-4300-A Impeller (B4)

1 FP-4126-D Impeller (B6, B9)

22 1 M-5291 O-Ring

23 1 525-00157 Plug, Pipe 1/2” NPT, Nylon

24 1 FP-4486 Case, Pump

25 1 FP-4097 Volute (B4)

1 FP-4097-A Volute (B6, B9)

26 1 A-6064 Check Valve Assembly

27 1 625-02840 Ring, Retaining

28 1 T -29373 Shaft And Bearing Assembly

29 1 FP-4417 Pedastal

30 1 M-7313 Key, Woodruff

1 T-25856 Spacer, Pump Foot (Not Shown)

1 510-00234 Guard, Left, (Not Shown)

1 510-00235 Guard, Right, (Not Shown)

1 625-01652 Plug, Pipe 1” NPT, C.I. (Not Shown)

13

Page 14

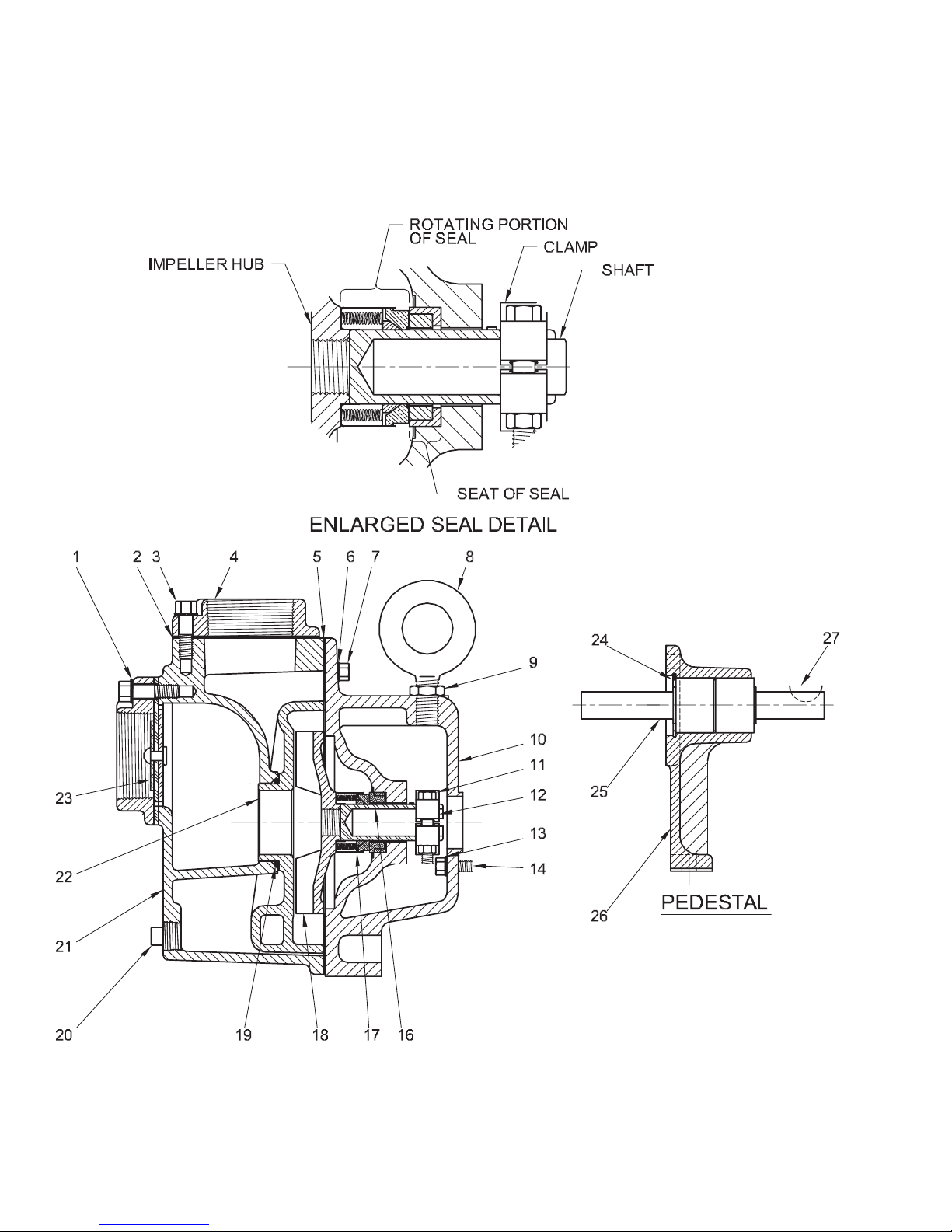

MODEL: SB4, SB6, SB9

14

Page 15

MODEL: SB4, SB6, SB9

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 1-36-1 Screw, Hex Hd 3/8-16 x 1.25”Lg, Stainless

2 1 M-9597 Gasket, Flange Viton

3 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

4 2 FSS-4487 Flange 1-1/2” (SB4, SB6)

2 FSS-4488 Flange 2”, (SB9)

5 1 M-9595 Gasket, Pump Case Viton

6 6 1-156-1 Screw, Hex Hd. 5/16-18 x 1.00”Lg, Stainless

7 6 20-22-1 Washer, Lock, Split 5/16”, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 1 FSS-4446-B Adapter, Side, Pump

11 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75”, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

12 2 PSS-4476 Clamp, Impeller

13 4 20-22-6 Washer, Lock, Split 5/16”, Zinc Plated

14 4 1-129-6 Screw, Hex Hd. 5/16-18 x .75”, Zinc Pltd.

16 1 TS-29790-A Hub, Impeller Stainless

17 1 525-00298-001 Seal, Mechanical 1.00”

18 1 FSS-4300-A Impeller (SB4)

1 FSS-4126-C Impeller (SB6, SB9)

19 1 M-9431 O-Ring Viton

20 1 625-02786 Plug, Pipe 1/2” NPT, Stainless

21 1 FSS-4486 Case, Pump

22 1 FSS-4097 Volute

23 1 A-7913 Check Valve Assembly

24 1 625-02840 Ring, Retaining

25 1 T -29373 Shaft And Bearing Assembly

26 1 FP-4417 Pedestal

27 1 M-7313 Key, Woodruff

1 T-25856 Spacer, Pump Foot (Not Shown)

1 510-00234 Guard, Left (Not Shown)

1 510-00235 Guard, Right (Not Shown)

1 625-02787 Plug, Pipe 1.00” NPT, Stainless (Not Shown)

15

Page 16

MODEL: B12

16

Page 17

MODEL: B12

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-15-1 Washer, Lock, Split 1/2”, Stainless

2 6 1-68-1 Screw, Hex Hd. 1/2-13 x 1.25”Lg, Stainless

3 2 FP-4498 Flange 2”

4 1 MT-8655 Gasket, Flange

5 1 T-28699 Gasket, Pump Case

6 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

7 6 1-34-1 Screw, Hex Hd. 3/8-16 x 1.00”Lg, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 1 M-3415 Cup, Grease

11 1 625-01188 Elbow 1/4” NPT, 90 Deg., Galv.

12 1 625-02835 Nipple, Pipe 1/4” NPT x 2.00”Lg, Steel

13 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75”Lg, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

14 2 PSS-4477 Clamp, Impeller

16 4 1-34-6 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Zinc Plated

4 20-14-6 Washer, Lock, Split 3/8”, Zinc Plated

17 1 FP-4113-A Adapter, Side, Pump

18 1 M-3649 Seal, Lip

19 1 TS-24907 Hub, Impeller Stainless

20 1 M-3957-F Seal, Mechanical 1.25”

21 1 FP-4127-A Impeller

22 1 M-5352 O-Ring

23 1 525-00157 Plug, Pipe 1/2” NPT, Nylon

24 1 FP-4497 Case, Pump

25 1 FP-4502 Volute

26 1 A-6089 Check Valve Assembly

27 1 510-00048 Shaft

28 1 525-00011 Ring, Retaining

29 2 525-00009 Bearing

30 1 501-00003 Pedestal

31 1 625-02816 Zerk Fitting, Grease

32 1 625-02805 Key, Woodruff

1 510-00236 Guard, Left (Not Shown)

1 510-00237 Guard, Right (Not Shown)

1 625-01652 Plug, Pipe 1” NPT, C.I. (Not Shown)

17

Page 18

MODEL: SB12

18

Page 19

MODEL: SB12

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-15-1 Washer, Lock, Split 1/2”, Stainless

2 6 1-68-1 Screw, Hex Hd. 1/2-13 X 1.25”Lg, Stainless

3 2 FSS-4498 Flange 2”

4 1 M-9596 Gasket, Flange Viton

5 1 M-9594 Gasket, Pump Case

6 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

7 6 1-34-1 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75” Lg, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

11 2 PSS-4477 Clamp, Impeller

13 4 1-34-6 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Zinc Plated

4 20-14-6 Washer, Lock, Split 3/8”, Zinc Plated

14 1 FSS-4113-B Adapter, Side, Pump

15 1 TS-24907-B Hub, Impeller Stainless

16 1 525-00299-001 Seal, Mechanical 1.25”

17 1 FSS-4127-A Impeller

18 1 M-9430 O-Ring Viton

19 1 625-02786 Plug, Pipe 1/2” NPT, Stainless

20 1 FSS-4497 Case, Pump

21 1 FSS-4502 Volute

22 1 A-7912 Check Valve Assembly

23 1 510-00048 Shaft

24 1 525-00011 Ring, Retaining

25 2 525-00009 Bearing

26 1 501-00003 Pedestal

27 1 625-02816 Zerk, Fitting, Grease

28 1 625-02805 Key, Woodruff

1 625-02787 Plug, Pipe 1.00” NPT, Stainless (Not Shown)

1 510-00236 Guard, Left (Not Shown)

1 510-00237 Guard, Right (Not Shown)

19

Page 20

MODEL: BH7

20

Page 21

MODEL: BH7

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-15-1 Washer, Lock, Split 1/2”, Stainless

2 6 1-68-1 Screw, Hex Hd. 1/2-13 x 1.25” Lg, Stainless

3 2 FP-4498 Flange 2”

4 1 MT-8655 Gasket, Flange

5 1 T-28699 Gasket, Pump Case

6 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

7 6 1-34-1 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 1 M-3415 Cup, Grease

11 1 625-01188 Elbow 1/4” NPT, 90 Deg., Galv.

12 1 625-02835 Nipple, Pipe 1/4” NPT x 2.00” Lg, Steel

13 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75” Lg, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

14 2 PSS-4477 Clamp, Impeller

16 4 1-34-6 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Zinc Plated

4 20-14-6 Washer, Lock, Split 3/8”, Zinc Plated

17 1 FP-4113-A Adapter, Side, Pump

18 1 M-3649 Seal, Lip

19 1 TS-24907 Hub, Impeller Stainless

20 1 M-3957-F Seal, Mechanical 1.25”

21 1 FP-4268-A Impeller

22 1 M-5352 O-Ring

23 1 525-00157 Plug, Pipe 1/2” NPT, Nylon

24 1 FP-4497 Case, Pump

25 1 FP-4269-B Volute

26 1 A-6089 Check Valve Assembly

27 1 510-00048 Shaft

28 1 525-00011 Ring, Retaining

29 2 525-00009 Bearing

30 1 501-00003 Pedestal

31 1 625-02816 Zerk Fitting, Grease

32 1 625-02805 Key, Woodruff

1 510-00236 Guard, Left (Not Shown)

1 510-00237 Guard, Right (Not Shown)

1 625-01652 Plug, Pipe 1” NPT, C.I. (Not Shown)

21

Page 22

MODEL: SBH7

22

Page 23

MODEL: SBH7

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-15-1 Washer, Lock, Split 1/2”, Stainless

2 6 1-68-1 Screw, Hex Hd. 1/2-13 X 1.25” Lg, Stainless

3 2 FSS-4498 Flange 2”

4 1 MT-8655 Gasket, Flange

5 1 T-28699 Gasket, Pump Case

6 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

7 6 1-34-1 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75” Lg, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

11 2 PSS-4477 Clamp, Impeller

13 4 1-34-6 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Zinc Plated

4 20-14-6 Washer, Lock, Split 3/8”, Zinc Plated

14 1 FSS-4113-B Adapter, Side, Pump

15 1 TS-24907-B Hub, Impeller Stainless

16 1 525-00299-001 Seal, Mechanical 1.25”

17 1 FSS-4268-A Impeller

18 1 M-9430 O-Ring Viton

19 1 625-02786 Plug, Pipe 1/2” NPT, Stainless

20 1 FSS-4497 Case, Pump

21 1 FSS-4269-B Volute

22 1 A-6089 Check Valve Assembly

23 1 510-00048 Shaft

24 1 525-00011 Ring, Retaining

25 2 525-00009 Bearing

26 1 501-00003 Pedestal

27 1 625-02816 Zerk, Fitting, Grease

28 1 625-02805 Key, Woodruff

1 625-02787 Plug, Pipe, 1.00” NPT, Stainless (Not Shown)

1 510-00236 Guard, Left (Not Shown)

1 510-00237 Guard, Right (Not Shown)

23

Page 24

MODEL: B19, B21

24

Page 25

MODEL: B19, B21

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-15-1 Washer, Lock, Split 1/2”, Stainless

2 6 1-71-1 Screw, Hex Hd. 1/2-13 x 1.75” Lg, Stainless

3 2 FP-4499 Flange 3”

4 1 MT-8655 Gasket, Flange

5 1 T-28699 Gasket, Pump Case

6 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

7 6 1-34-1 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 1 M-3415 Cup, Grease

11 1 625-01188 Elbow 1/4” NPT, 90 Deg., Galv.

12 1 625-02835 Nipple, Pipe, 1/4” NPT x 2.00”, Steel

13 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75” Lg, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

14 2 PSS-4477 Clamp, Impeller

16 4 1-34-6 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Zinc Plated

4 20-14-6 Washer, Lock, Split 3/8”, Zinc Plated

17 1 FP-4113-A Adapter, Side, Pump

18 1 M-3649 Seal, Lip

19 1 TS-24907 Hub, Impeller Stainless

20 1 M-3957-F Seal, Mechanical 1.25”

21 1 FP-4128-A Impeller (B19)

1 FP-4169-D Impeller (B21)

22 1 M-5352 O-Ring

23 1 525-00157 Plug, Pipe 1/2” NPT, Nylon

24 1 FP-4497 Case, Pump

25 1 FP-4117 Volute (B19)

1 FP-4117-A Volute (B21)

26 1 A-6089 Check Valve Assembly

27 1 510-00048 Shaft

28 1 525-00011 Ring, Retaining

29 2 525-00009 Bearing

30 1 501-00003 Pedestal

31 1 625-02816 Zerk Fitting, Grease

32 1 625-02805 Key, Woodruff

1 510-00236 Guard, Left (Not Shown)

1 510-00237 Guard, Right (Not Shown)

1 625-01652 Plug, Pipe 1” NPT, C.I. (Not Shown)

25

Page 26

MODEL: SB19, SB21

26

Page 27

MODEL: SB19, SB21

PARTS LIST

ITEM QTY. PART NO DESCRIPTION

1 6 20-15-1 Washer, Lock, Split 1/2”, Stainless

2 6 1-71-1 Screw, Hex Hd. 1/2-13 X 1.75” Lg, Stainless

3 2 FSS-4499 Flange 3”

4 1 M-9596 Gasket, Flange Viton

5 1 M-9594 Gasket, Pump Case

6 6 20-14-1 Washer, Lock, Split 3/8”, Stainless

7 6 1-34-1 Screw, Hex Hd. 3/8-16 x 1.00”, Stainless

8 1 M-5087 Bolt, Eye 5/8-11, Steel

9 1 15-22-6 Nut, Hex 5/8-11, Zinc Plated

10 2 1-135-1 Screw, Hex Hd. 5/16-18 x 1.75” Lg, Stainless

2 20-22-1 Washer, Lock, Split 5/16”, Stainless

2 15-19-1 Nut, Hex 5/16-18, Stainless

11 2 PSS-4477 Clamp, Impeller

13 4 1-34-6 Screw, Hex Hd. 3/8-16 x 1.00” Lg, Zinc Plated

4 20-14-6 Washer, Lock, Split 3/8”, Zinc Plated

14 1 FSS-4113-B Adapter, Side, Pump

15 1 TS-24907-B Hub, Impeller Stainless

16 1 525-00299-001 Seal, Mechanical 1.25”

17 1 N515-00211 Impeller (SB19)

1 N515-00212 Impeller (SB21)

18 1 M-9430 O-Ring Viton

19 1 625-02786 Plug, Pipe 1/2” NPT, Stainless

20 1 FSS-4497 Case, Pump

21 1 FSS-4117 Volute (SB19)

1 FSS-4117-A Volute (SB21)

22 1 A-7912 Check Valve Assembly

23 1 510-00048 Shaft

24 1 525-00011 Ring, Retaining

25 2 525-00009 Bearing

26 1 501-00003 Pedestal

27 1 625-02816 Zerk, Fitting, Grease

28 1 625-02805 Key, Woodruff

1 625-02787 Plug, Pipe 1.00” NPT, Stainless (Not Shown)

1 510-00236 Guard, Left (Not Shown)

1 510-00237 Guard, Right (Not Shown)

27

Page 28

Limited 24 Month Warranty

Crane Pumps & Systems warrants that products of our manufacture will be free of defects in material and workmanship

under normal use and service for twenty-four (24) months after manufacture date, when installed and maintained

in accordance with our instructions.This warranty gives you specifi c legal rights, and there may also be other rights

which vary from state to state. In the event the product is covered by the Federal Consumer Product Warranties Law

(1) the duration of any implied warranties associated with the product by virtue of said law is limited to the same

duration as stated herein, (2) this warranty is a LIMITED WARRANTY, and (3) no claims of any nature whatsoever

shall be made against us, until the ultimate consumer, his successor, or assigns, notifi es us in writing of the defect,

and delivers the product and/or defective part(s) freight prepaid to our factory or nearest authorized service station.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply.

THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF ANY AND ALL WARRANTIES WITH RESPECT TO ANY

PRODUCT SHALL BE TO REPLACE OR REPAIR AT OUR ELECTION, F.O.B. POINT OF MANUFACTURE OR

AUTHORIZED REPAIR STATION, SUCH PRODUCTS AND/OR P ARTS AS PROVEN DEFECTIVE. THERE SHALL BE

NO FURTHER LIABILITY, WHETHER BASED ON WARRANTY, NEGLIGENCE OR OTHERWISE. Unless expressly

stated otherwise, guarantees in the nature of performance specifi cations furnished in addition to the foregoing material

and workmanship warranties on a product manufactured by us, if any, are subject to laboratory tests corrected for

fi eld performance. Any additional guarantees, in the nature of performance specifi cations must be in writing and such

writing must be signed by our authorized representative. Due to inaccuracies in fi eld testing if a confl ict arises between

the results of fi eld testing conducted by or for user, and laboratory tests corrected for fi eld performance, the latter

shall control. RECOMMENDATIONS FOR SPECIAL APPLICATIONS OR THOSE RESULTING FROM SYSTEMS

ANALYSES AND EVALUATIONS WE CONDUCT WILL BE BASED ON OUR BEST AVAILABLE EXPERIENCE AND

PUBLISHED INDUSTRY INFORMATION. SUCH RECOMMENDATIONS DO NOT CONSTITUTE A WARRANTY OF

SATISFACTORY PERFORMANCE AND NO SUCH WARRANTY IS GIVEN.

This warranty shall not apply when damage is caused by (a) improper installation, (b) improper voltage (c) lightning

(d) excessive sand or other abrasive material (e) scale or corrosion build-up due to excessive chemical content. Any

modifi cation of the original equipment will also void the warranty. We will not be responsible for loss, damage or labor

cost due to interruption of service caused by defective parts. Neither will we accept charges incurred by others without

our prior written approval.

This warranty is void if our inspection reveals the product was used in a manner inconsistent with normal industry practice

and\or our specifi c recommendations. The purchaser is responsible for communication of all necessary information

regarding the application and use of the product. UNDER NO CIRCUMSTANCES WILL WE BE RESPONSIBLE FOR

ANY OTHER DIRECT OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO TRAVEL EXPENSES,

RENTED EQUIPMENT, OUTSIDE CONTRACTOR FEES, UNAUTHORIZED REPAIR SHOP EXPENSES, LOST

PROFITS, LOST INCOME, LABOR CHARGES, DELA YS IN PRODUCTION, IDLE PRODUCTION, WHICH DAMAGES

ARE CAUSED BY ANY DEFECTS IN MATERIAL AND\OR WORKMANSHIP AND\OR DAMAGE OR DELAYS IN

SHIPMENT. THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTY,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No rights extended under this warranty shall be assigned to any other person, whether by operation of law or otherwise,

without our prior written approval.

A Crane Co. Company

420 Third Street 83 West Drive, Brampton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com

28

Page 29

IMPORTANT!

WARRANTY REGISTRATION

Your product is covered by the enclosed Warranty.

To complete the Warranty Registration Form go to:

http://www.cranepumps.com/ProductRegistration/

If you have a claim under the provision of the warranty, contact your local

Crane Pumps & Systems, Inc. Distributor.

RETURNED GOODS

RETURN OF MERCHANDISE REQUIRES A “RETURNED GOODS AUTHORIZATION”.

CONTACT YOUR LOCAL CRANE PUMPS & SYSTEMS, INC. DISTRIBUTOR.

Products Returned Must Be Cleaned, Sanitized,

Or Decontaminated As Necessary Prior To Shipment,

To Insure That Employees Will Not Be Exposed To Health

Hazards In Handling Said Material. All Applicable Laws

And Regulations Shall Apply.

29

Page 30

A Crane Co. Company

Pump Owner’s Name: __________________________________________________________

Address: ____________________________________________________________________

Location of Installation: _________________________________________________________

Contact Person: __________________________________Phone: _______________________

Purchased From: _____________________________________________________________

Pump Model #: ___________________ Serial #: _____________________________________

Part #: __________________________ Impeller Diameter: ____________________________

Voltage: _________Phase: _____ Ø Hertz: ____________Horsepower: _______________

Full Load Amps: ___________________ Service Factor Amps: __________________________

Motor Manufacturer: ___________________________________________________________

Control panel manufacturer: _____________________________________________________

Model/Part number: ____________________________________________________________

Number of pumps operated by control panel: ________________________________________

Short circuit protection? YES___ NO___ Type: _________________________________

Number and size of short circuit device(s): ___________ Amp rating: ___________________

Overload Type: _____________ Size: ______________ Amp rating: ___________________

Do protection devices comply with pump and motor Amp rating? YES___ NO___

Are all electrical and panel entry connections tight? YES___ NO___

Is the interior of the panel dry? YES___ NO___

Liquid level Control Brand and Model: ______________________________________________

START-UP REPORT

General Information

Nameplate Data

Controls

Pre-Startup

All Pumps

Type of equipment: NEW___ REBUILT___ USED___

Condition of equipment at Start-Up: DRY___ WET___ MUDDY___

Was Equipment Stored? YES___ NO___ Length of Storage: ______________________

Liquid being pumped: __________________ Liquid Temperature: _____________________

Supply Voltage/Phase/Frequency matches nameplate? YES___ NO___

Shaft turns freely? YES___ NO___

Direction of rotation verifi ed for 3Ø motors? YES___ NO___

Debris in piping or wet well? YES___ NO___

Debris removed in your presence? YES___ NO___

Pump case/wet well fi lled with liquid before startup? YES___ NO___

Is piping properly supported? YES___ NO___

Non-Submersible Pumps

Is base plate properly installed / grouted? YES___ NO___ N/A___

Coupling Alignment Verifi ed per I&O Manual? YES___ NO___ N/A___

Grease Cup/Oil Reservoir Level checked? YES___ NO___ N/A___

30

Page 31

Submersible Pumps

Resistance of cable and pump motor (measured at pump control):

Red-Black:_______Ohms(Ω) Red-White:_______Ohms(Ω) White-Black:_______Ohms(Ω)

Resistance of Ground Circuit between Control Panel and outside of pump: __________Ohms(Ω)

MEG Ohms check of insulation:

Red to Ground: _________ White to Ground: __________ Black to Ground: ____________

Operational Checks

Is there noise or vibration present? YES___ NO___ Source of noise/vibration: ___________

Does check valve operate properly? YES___ NO___ N/A___

Is system free of leaks? YES___ NO___ Leaks at: ______________________________

Does system appear to operate at design fl ow rate? YES___ NO___

Nominal Voltage: _____________________Phase: 1Ø 3Ø (select one)

Voltage Reading at panel connection, Pump OFF: L1, L2 _____ L2, L3 ____ L1, L3 _____

Voltage Reading at panel connection, Pump ON: L1, L2 ______ L2, L3 ____ L1, L3 _____

Amperage Draw, Pump ON: L1 ____________ L2 _____________ L3 _____________

Submersible Pumps

Are BAF and guide rails level / plumb? YES___ NO___

Is pump seated on discharge properly? YES___ NO___

Are level controls installed away from turbulence? YES___ NO___

Is level control operating properly? YES___ NO___

Is pump fully submerged during operation? YES___ NO___

Follow up/Corrective Action Required

YES___ NO___

Additional Comments:

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

Startup performed by: _____________________ Date: ______________________________

Present at Start-Up

( ) Engineer: ____________________________ ( ) Operator: ________________________

( ) Contactor: ____________________________ ( ) Other: ___________________________

All parties should retain a copy of this report for future trouble shooting/reference

A Crane Co. Company

420 Third Street 83 West Drive, Brampton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com

Page 32

Notes

Loading...

Loading...