Page 1

1 2 3

MRX-220N

OUTDOOR DOUBLE DUAL

MIRROR OPTICS

PASSIVE INFRARED &

MICROWAVE DETECTOR

ELECTRONIC ENGINEERING LTD.

INSTALLATION INSTRUCTIONS

P/N: 7101296 REV.A A.Y.

MRX–220N DESCRIPTION

The MRX-220N is a combination of DOUBLE

DUAL PIR with MIRROR optics & MW detectors,

specially designed for outdoor and harsh

environment applications.

The Mirror DOUBLE DUAL detector MRX-220N

uses varifocal mirror that improves the focus and

the level of energy received by the Pyro Sensor.

This combination assures “false alarm free”

operation.

The 16 position rotate switch changes the MW

and PIR sensitivity so that the effective pattern

will be scaled.

MRX–220N FEATURES

• DOUBLE DUAL PYRO sensor and full pattern

mirrors for outstanding detection performance

and elimination of false alarms.

• MW detection based on Doppler concept.

• FET based DRO with stripline antenna.

• VLSI based electronics with movement speed

spectrum analysis.

• N.O. & N. C. Relays switched at the same time.

• Height installation calibrations free from 1.5m to

3.0m (5ft to 10ft).

• Pet Immunity up to 10, 20, 30 or 40kg –

Selectable

• MW and PIR sensitivity adjustment.

• Environmental immunity.

• Temperature compensation.

MOUNTIN G THE DETECTOR

Choose a location most likely to intercept an

intruder. See detection pattern in FIG.: 7. The

DOUBLE DUAL high quality sensor detects

motion crossing the beam; it is less sensitive

detecting motion towards the detector.

The MRX-220N performs best when provided with

a constant and stable environment.

The bracket provides MRX-220N installation on

the wall and on the pole, allows changing the

installation angle (vertically and horizontally) in

wide range (FIG.2).

AVOID THE FOLLOWING LOCATIONS

∗ Facing direct sunlight.

∗ Facing areas subject to rapid temperature

changes.

∗ Areas with air ducts or substantial air flows.

∗ Facing metal doors.

NOTE

:

Recommended installation height is 2.4m.

FIG. 3 -

TERMINAL BLOCK CO NNE CTIONS

1 2 3 4 5 6 7 8 9

12V NC C NO EOL TAMPER EOL

RELAY

Terminal 1 - Marked “ - ” (GND)

Connect to the ground of the control panel.

Terminal 2 - Marked “ + ” (+12V)

Connect to a positive Voltage of 8.2 -16Vdc

source (usually from the alarm control unit)

Terminals 3,4 & 5 - Marked “ NC C NO ”

These are the output relay contacts of the

detector. Connect to a normally closed or

normally opened zone in the control unit.

Terminals 7 & 8 - Marked “ TAMPER ”

If a Tamper function is required connect these

Terminals to a 24-hour normally closed protective

zone in the control unit.

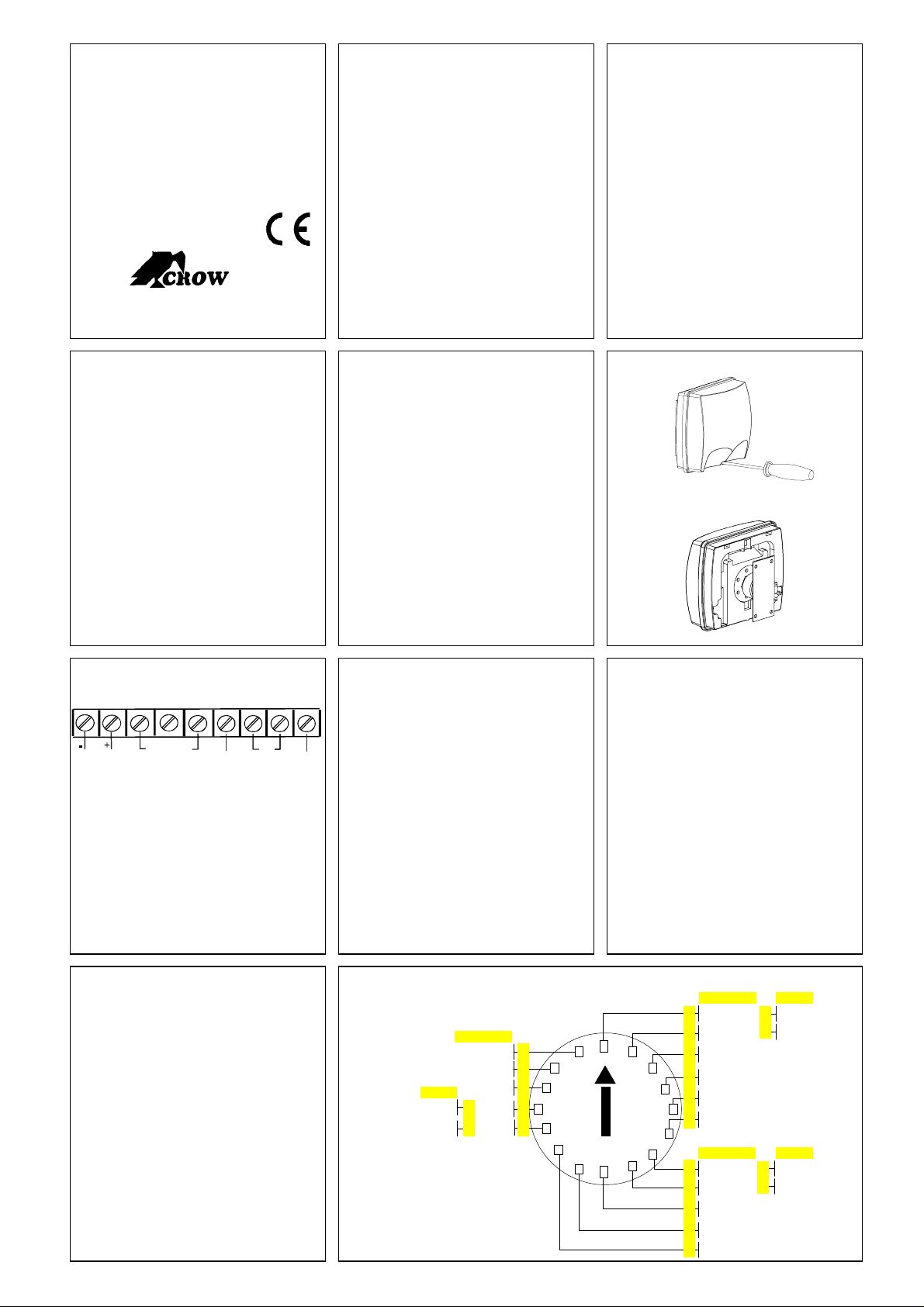

INSTALLING TH E DETECTOR

1. To remove the front cover, unscrew the

holding screw. Insert a screwdriver between

the front and the bottom and pull gently, until

the front cover is disengaged. (FIG 1)

2. Break out the desired holes for proper wiring

as per FIG 6.

3. Insert the wire through the wire access hole,

and mount the detector base to the wall with

the necessary number of screws.

4. Access for wiring connections is very easy

with the terminal block located on the PCB.

See FIG 3.

5. Replace the cover by inserting it back in the

appropriate closing, screw the holding screw.

If the front cover of the detector is opened, an

immediate alarm signal will be sent to the control

unit.

Terminals 6 & 9 - Marked “ EOL ”

End of line - options.

When an intruder is detected, alarm relays (N.O.

and N.C.) will switch for 1.8 sec.

WIRE SIZE REQUIREMENTS

Use #22 AWG or larger wires. Use the following

table to determine required wire gauge and length.

Wire Gauge: # 22 20 18 16

Wire Length: m 205 310 510 870

Ft. 800 1200 2000 3400

LED INDICATORS

YELLOW LED - MW detection, is blinking during

warm up period and self testing

GREEN LED - PIR detection

RED LED – Alarm

FIG. 1 - REMOVAL OF FRONT COVER

FIG. 2 – BRACKET ASSEMBLY

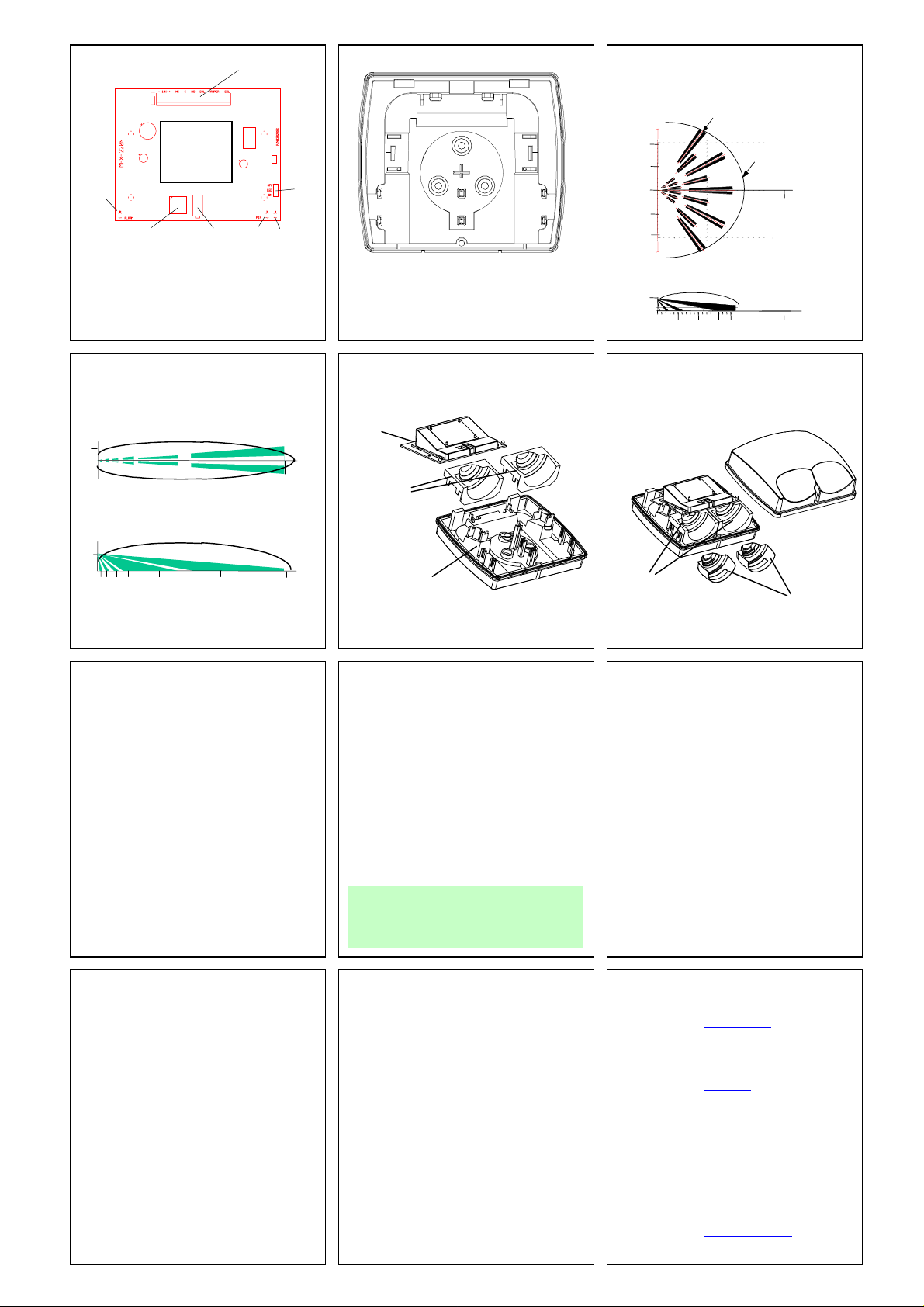

SENSITIVITY AND RANGE ADJUSTMENT

The calibration of range and sensitivity is

performed by single digital 16 positional rotary

switch.

There are 3 groups of switch setting according to

detection range.

Each group is devided to levels of sensitivity

according to installation environment.

The value of sensitivity level is changed according

to optic

For WA (Wide Angle ) mirror optic

Group A - positions 0 – 5 – set sensitivity for 21m

detection range

Group B - positions 6 – A – set sensitivity for15m

detection range

Group C - positions B – F – set sensitivity for 7m

detection range

For LR (Long Range ) mirror optic

Group A - positions 0 and 1 – set sensitivity for 40m

detection range

Group B - positions 6 and 7 – set sensitivity for28m

detection range

Group C - positions B and C – set sensitivity for

15m detection range

The 5 or 6 levels in each group are used to set up

the sensitivity according to environment.

Each range group includes 5 or 6 setting levels

according to environmental condition risk.

For example:

If detector is used for 15m range in open space with

sunlight – set switch to position 8 or 9.

FIG.4 - R OTARY SWITCH S ETTING

WA

Noise Area

Very High Risk

LR

High Risk

Low Risk

Installation Hight: 3m

Bracket Angle: 0°

15m

High Risk

Risk

Low Risk

7m

D

B

40m

Low Risk

28m

High Risk

LRWA

Low Risk

High Risk

LR

Low Risk

3

4C

5

Risk

High Risk

21m

Very High Risk

Noise Area

Extreme Noise Area

WA

Low Risk

Risk

High Risk

15m

Very High Risk

Noise Area

0

1F

E

A

9

8

2

6

7

Page 2

13 14 15

pp

FIG.5 - PCB LAYOUT

ANTENNA

DOPPLER

ALARM

LED

ROTARY

SWITCH

Double Dual Pyrosensors on opposite side

Tamper

BLOCK

CONNECTOR

PIR MW

LED LED

FIG. 6 - OPTIONAL HOLES

A

A

B

LED

Mode

Jumper

B

B

A. Wire access holes

B. Use for fl at wall mounting or for

mounting with the help of bracket

FIG. 7 - WA PIR + MW DETECTION

PATTERN

10m

5m

0m

5m

10m

2.4m

TOP VIEW

WA mirror 105 ° (PIR)

MW pattern

21m

`

SIDE VIEW

30m

30m 21m 10m 5m

FIG. 8 - LONG RANGE CURTAIN

PATTERN

1.5

1.5

2.4

m

m

0

m

m

m

0

m

1.5

TOP VIEW

m

m 5 m 3

10

m

40

m

25

m

40

SIDE VIEW

REPLACING MIRRORS (FIG.9)

1. Remove the front cover.

2. Pull out the PCB.

3. Pull out the old mirrors from slots.

4. Replace a new mirrors – insert mirror pins into

the slots; don’t touch the mirror from internal

side.

5. Replace the PCB.

6. Replace the front cover.

ASSEMBLY AND RE PLACING OF PET

IMMUNITY MASKS (SEE FIG.10)

1. Remove the front cover.

2. Put pet masks on the mirrors or replace them.

3. Replace the front cover.

FIG. 9 – REPLACING MIRRORS

PCB with

antenna

Do

ler

Mirrors

Plastic base

TEST PROCEDURES

Wait one-minute for warm-up time after applying

power.

Make the test at the protected area free of moving

people

LED should be in enable position.

.

Walk test

1. Start walking slowly across the detection zone.

2. Observe that the red LED lights whenever

motion is detected.

3. Allow 5 sec. between each test for the detector

to stabilize.

NOTE:

Walk tests should be done at least once a year to

confirm proper operation of the detector.

You must reset the detector from

Control Panel before the new

settings will take effect

FIG. 10 –ASSEMBLY OF PET

IMMUNITY MASKS

Mirrors

Pet masks

TECHNICAL SPECIFICATIONS

Detection Method DOUBLE DUAL element PIR & MW

Detection Speed 0.3 - 1.5 m/sec (1 - 5 ft/sec)

Maximum ripple 2.4Vdc peak to peak at 12Vdc

Power Input 8.2 to 16 Vdc

Current Draw Active : 27mA + 3mA

Standby: 17mA + 3mA

Bi Directional

Temperature YES

Alarm Period 1.8 sec

Alarm Output N.C 28Vdc 0.1 A with 10 Ohm

series protection resistors

N.O 28Vdc 0.1 A with 10 Ohm

series protection resistors

Tamper Switch N.C 28Vdc 0.1A with 10 Ohm series

Protection resistor - open when

cover is removed

Warm Up Period 30 sec

TECHNICAL SPECIFICATIONS (CONT.)

Operating Temperature -20°C to +50°C(-4°F to +122°F)

RFI Protection 30V/m 10 - 1000MHz

EMI Protection 50,000V of electrical

interference from lightning or

power through

Visible Light Protection stable against halogen light

2.4 m (8ft ) or reflected light

MW output power min + 13 dBm IERP

MW center frequency 10.525 GHz +/-3MHz

MW harmonic emission -7.3 dBm

Dimensions 154mm x 114mm x 74mm

(6.1” x 4.5” x 2.9”)

Weight 290gr. (10.23oz)

.

MRX220N

CROW reserves the rights to change

specifications without prior notice

CROW LIMITED WARRANTY

(Crow) warrants this product to be free from defects in mat erials and workmanship

under normal use and service f or a peri od of one year from t he last day of t he week

and year whose numbers are printed on the printed circuit board inside this product.

Crow’s obligation is lim ited to repairing or replaci ng this product, at its opti on, free of

charge for materials or labor, if it is proved to be defective in materials or

workmanship under normal use and service. Crow shall have no obl igat ion under thi s

Limited Warranty or otherwise i f the product is altered or improperly repaired or

serviced by anyone other then Crow.

There are no warranties, expressed or implied, of merchantability or fitness for a

particular purpose or otherwise, which extend beyond the description on the face

hereof. In no case shal l Crow be l iable to anyone f or any consequential or incident al

damages for breach of t his or any other warranty, expressed or implied, or upon any

other basis of liability whatsoever, even if the loss or damage is caused by Crow’s

own negligence or fault.

Crow does not represent that this product can not be compromised or circumvented;

that this product w i ll prevent any person injury or property loss or damage by burglary,

robbery, fire or otherwise; or that this product wil l in all cases provide adequate

warning or protection. Purchaser understands that a properly installed and maintained

product can only reduce the risk of burglary, robbery or other events occurring without

providing an alarm, but it is not insurance or a guarantee that such will not occur or

that there will be no personal injury or property loss or damage as a result.

Consequently, Crow shall have no liabili ty for any personal injury; property damage or

any other loss based on claim that this product fail ed to give any warning. However, if

Crow is held liable, whether directly or i ndirectly, for any loss or damage arising under

this limited warranty or otherwise, regardless of cause or origin, Crow’s maximum

liability shall not in any case exceed the purchase price of this product, which shall be

the complete and exclusive remedy against Crow.

CROW ELECTRONIC ENGINEERING LTD.

ISRAEL: 57 Hamelacha St., Holon 58855

Tel: 972-3-5569937 /8 /9

Fax: 972-3-5592981

E-mail: support@crow.co.il

USA: 2160 North Central Road,

Fort Lee, N.J. 07024

Tel: 1-800-GET CROW

or (201) 944 0005

Fax: (201) 944 1199

E-mail:

AUSTRALIA: 429 Nepean HWY Brighton East Vic 3187

Tel: 61-3-9596 7222

Fax: 61-3-9596 0888

E-mail:crow@crowaust.com.au

UK: Unit 5, Bradford on Avon Marina

Widbrook Bradford on Avon

Wiltshire BA15 1UD

Tel: 01225 863 138

Fax: 01225 863 171

POLAND: VIDICON 01-199 Warsaw

Ul. Leszno 34/36

Tel: 48 22 632 9666

Fax: 48 22 632 5543

crow@nis.net

E-mail: vidicon@medianet.com.pl

Loading...

Loading...