Page 1

Selection guide Temperature controllers

Number

Alarm

Action type

Heating

Input type

Resistance

temperature detector

PT 100 (2-wire)

Thermocouple J

Thermocouple K

Control type

Digital

or Proportional

derivative

of displays

Designation

- - Relay 5A

CT 48 A

Temperature

(-50 to +30°C)

(0 to +40°C)

(0 to +120°C)

(0 to +200°C)

(0 to +400°C)

(0 to +250°C)

(0 to +450°C)

(0 to +600°C)

(0 to +800°C)

(0 to +1200°C)

Output 1

Output 2

-

Supply

230 VAC

voltage

Page 210

CT 48 A

Universal configurable:

Resistance

temperature detector

PT 100 (2-3-wire)/

Thermocouples

J-K-R-S-L-N/Voltage

Heating

AND/

OR

Cooling

Resistance temperatu-

re detector

PT 100 (3-wire)/

Thermocouples

J-K-R-S-T-L-N/

Voltage/current

(1) Optional Modbus-Jbus RS 485 link on request for MIC 48 controllers

Heating

OR

Cooling

Resistance

temperature detector

PT 100 (3-wire)/

Thermocouples J-K-L-N

PID with

adaptive tune

PID with

adaptive tune

1

2

1

1

(4 digits)

2

(4 digits)

1

(3 digits)

2

(3 digits)

CTD 24

MIC 48

Without MODBUS

J.BUS RS 485

With MODBUS

J.BUS RS 485

(1)

MIC 48

(1)

CTD 43

CTD 46

link

link

Relay 3A

Solid

state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid state

Relay 3A

Solid

state

Relay 1A

Relay 1A

100 to 240 VAC

24 VAC/DC

100 to 240 VAC

24 VAC/DC

100 to 240 VAC

24 VAC/DC

100 to

240 VAC

24 VAC/DC

100 to

240 VAC

24 VAC/DC

100 to

240 VAC

24 VAC/DC

100 to

240 VAC

24 VAC/DC

Page 219

CTD 24

Page 212

MIC 48

Page 216

7

CTD 43

Heating

AND

Cooling

With this function, the controller performs initial auto tuning of the PID control parameters and performs adaptive tuning of these parameters during operation

For more information www.crouzet.com

Resistance

temperature detector

PT 100 (3-wire)/

Thermocouples J-K-L-N

PID with

adaptive tune

-

2

(3 digits)

CTH 46

Relay 3A

Solid state

Relay 3A

Solid state

Relay 1A

100 to

240 VAC

Page 216

24 VAC/DC

CTH 46

207

Page 2

COMMON FUNCTIONS FOR THE RANGE OF DIGITAL CONTROLLERS

Sommaire général

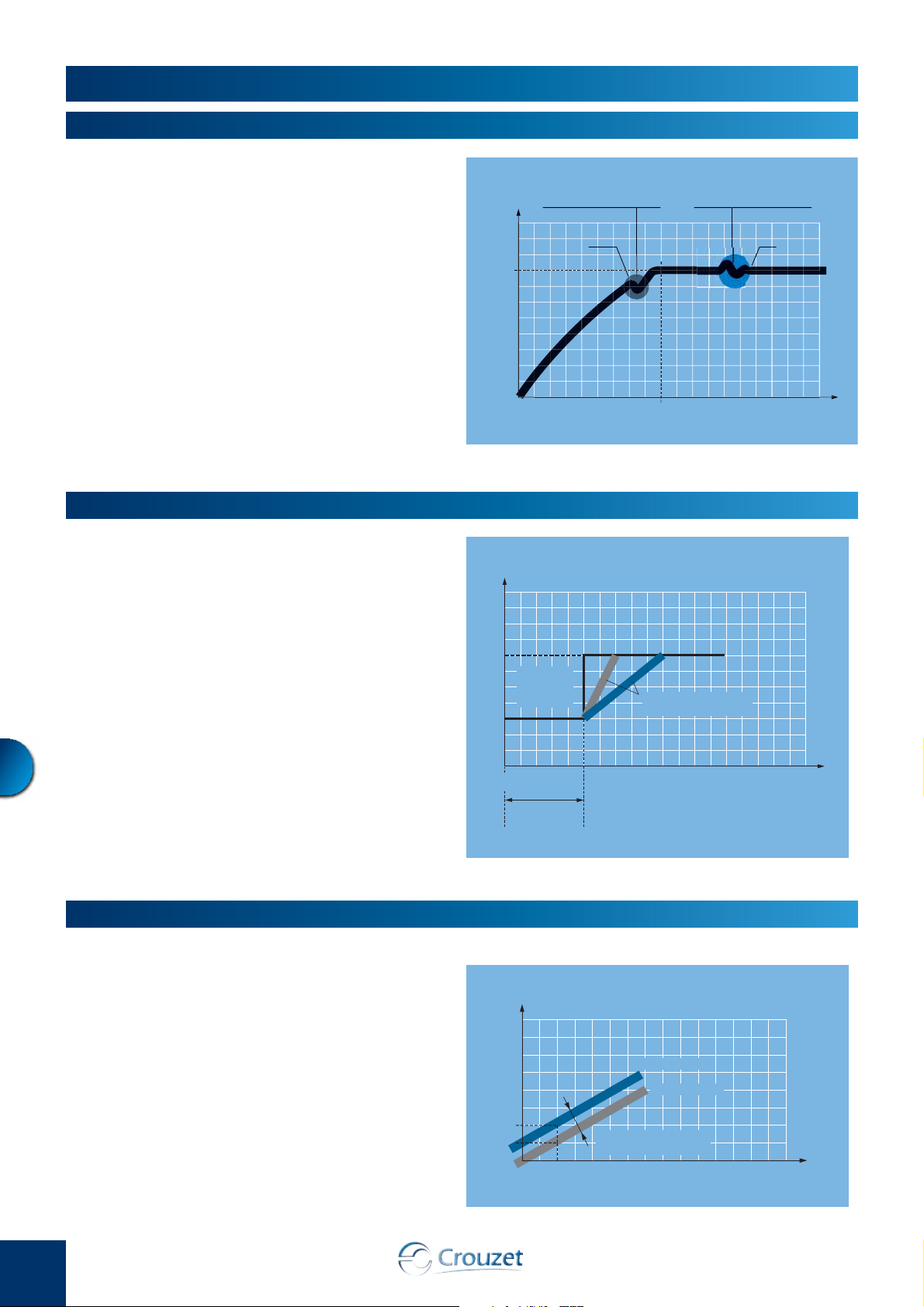

SMART function : auto-tune and adaptive tune

The entire range incorporates an algorithm known as SMART. This

algorithm calculates the PID control parameters automatically on starting (auto-tune) and during the process if any changes occur (adaptive

tune) without any user intervention.

Measurement

Starting period

During the process

➜ Starting period

The SMART function triggers its auto-tune action to calculate the PID

parameters.

This enables an optimum approach to reaching the setpoint.

➜ During the process

The SMART function triggers its adaptive tune action to recalculate the

PID parameters if there is a change in the setpoint or a modification to

the load.

SOFT-START function : gradual preheating

This function provides gradual preheating of the process.

This makes it possible to prolong the lifetime of the heating element and

avoid any thermal shocks.

If you require this function, simply set the required output power (OLH)

for preheating as well as its action time (t OL).

On starting, the inhibition function for the temperature threshold alarm

ensures that no fault indication will be acknowledged during preheating.

In addition, these controllers also offer the possibility of programming a

ramp to gradually increase power to further limit the risk of thermal

shocks.

Setpoint

Output power

100%

OLH

Adaptive tuneAuto-tune

Starting Control Time

Output power

limit threshold

Gradual power increase ramp (%/s)

7

OFFSET function : constant offset value

There are many applications where it is often difficult to install a

sensor in the most ideal location.

Indeed, in several cases, the sensor is installed quite far away from the

desired location.

Installing a sensor at such a distance can generate a measured value

which is not actually representative of the process value.

It is for this reason that our controllers offer the possibility of

programming a constant shift value known as an OFFSET. This

OFFSET is the difference between the actual temperature to be

measured and the temperature of the location where the sensor is

installed. Thus, the value read on the controller is that of the

temperature at the monitoring point and not the value at the sensor

installation point.

Starting

tOL

Output power

limit time

Display rea-

ding

12

10

8

6

4

2

0

24681012

with OFFSET

without OFFSET

constant programmed

deviation (known as OFFSET)

Time

Measurement

208

For more information www.crouzet.com

Page 3

1.

ADDITIONAL FUNCTIONS ONLY AVAILABLE ON THE MIC 48 AND CTD 24

Two independent ramps for switching from one setpoint to another.

Some processes require a ramp with a gradual increase in power to

reach a new setpoint value. In addition, this ramp may require a

different gradient in order to switch from one setpoint to another. This

second value may be higher or lower than the original.

For example, a process may require a rapid heating period and a slow

cooling period.

It is for this reason that the MIC offers these two options.Two ramps

can be programmed independently - one to rise from «SP A» to a

1

higher setpoint value «SP B» and the second to reduce to a lower

setpoint «SP C».

Note:

This function can also be applied to switching from SP to SP2.

SP : Normal operating temperature of the process

SP2 : Temperature when idle.

Setpoint

SP B

SP C

SP A

2 ramps which can be programmed independently to

switch from one setpoint to

another

1st setpoint change

2nd setpoint change

Switching device

Time

SP / SP2 are selected by an external

switch without needing to touch the MIC

48 controller, and via the keypad on the

CTD 24.

Heating element break monitoring function

This function continuously monitors current at the load.

It informs the user immediately of a break in the heating element.

MIC 48: Loads up to 100 A can be checked using an external current

transformer.

In addition, the load current can be monitored during the process.

Its value in amps can be read directly by pressing the F key.

CTD 24: The software integrates this function without a sensor.

Communication via the RS 485 serial link

compatible with C.BUS, MODBUS and

J.BUS protocol

Main MIC 48

output

F

MIC 48 load

break monitoring

input

Solid state relay

Load

Current

transformer

Load break alarm

output

7

Current

threshold

to be

checked

CY1

Time

For more information www.crouzet.com

operator console

RPX

PLC

DIAL 5

Main

output

Alarm

output

7192 / 7392 counter

MIC 48

MIC 48

controller

1

O

2

U

T

3

REM

°C

°F

ST

SP2

F

209

Loading...

Loading...