Crouzet SMI22 CANopen, SQ75 CANopen 80350, SQ75 CANopen 80360, SQ75 CANopen 80370, SMI22 CANopen Series Product User Manual

...Page 1

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 1/24

September 3rd, 2018

PRODUCT USER MANUAL

SMI22 CANopen

Important Notes

• This manual is part of the product.

• Read and follow the instructions in this manual.

• Keep this manual in a safe place.

• Give this manual and any other documents relating to the product to anyone that uses the product.

• Read and be sure to comply with all the safety instructions and the section "Before you Begin -

Safety-Related Information" in the document “Safety User Manual”

• Please consult the latest catalogue to find out about the product's technical specifications.

• We reserve the right to make modifications without prior notification.

Page 2

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 2/24

September 3rd, 2018

Table of Contents

1. Introduction ................................................................................................................................................ 5

1.1. Motor Family ..................................................................................................................................... 5

1.2. Characteristics .................................................................................................................................. 5

1.3. Identification Label ............................................................................................................................ 5

1.4. Product Coding ................................................................................................................................. 6

1.5. Standards and concepts ................................................................................................................... 7

2. Options and Accessories ........................................................................................................................... 8

2.1.1. Holding brake ........................................................................................................................... 8

2.1.2. Gearboxes ................................................................................................................................ 8

2.1.3. Other ......................................................................................................................................... 8

2.1.4. Starter Kit .................................................................................................................................. 8

3. Precautions for use concerning the mechanics ......................................................................................... 9

3.1. Data specific to the motor shaft ........................................................................................................ 9

3.2. USB Connector ............................................................................................................................... 10

3.3. Fixings ............................................................................................................................................. 11

4. Product overview ..................................................................................................................................... 11

4.1. Description of the Product ............................................................................................................... 11

4.2. SMI22 CANopen Control Electronics .............................................................................................. 12

4.3. "DCmind-Soft + CANopen" PC Parameter-Definiti on S of tware ...................................................... 13

5. Technical Specifications .......................................................................................................................... 14

5.1. Electrical Data ................................................................................................................................. 14

5.2. Generic Data ................................................................................................................................... 14

5.3. Logic M16 connector ....................................................................................................................... 15

5.4. Power Supply M16 connector ......................................................................................................... 16

5.5. CAN communication M12 connector .............................................................................................. 16

6. Motor electrical connection ...................................................................................................................... 18

6.1. Power Connection ........................................................................................................................... 18

6.1.1. Ballast Circuit .......................................................................................................................... 18

6.1.2. EMC Protection ...................................................................................................................... 19

6.1.3. Earth connection ..................................................................................................................... 19

6.2. Protection ........................................................................................................................................ 20

6.2.1. Voltage Protection .................................................................................................................. 20

6.2.2. Temperature Protection .......................................................................................................... 21

6.2.3. Current Limiting ...................................................................................................................... 21

6.3. Input/Output Connection ................................................................................................................. 22

6.3.1. Equivalent Input Diagram ....................................................................................................... 22

6.3.2. Equivalent Output Diagram .................................................................................................... 23

6.4. Terminology and Abbreviations....................................................................................................... 24

Page 3

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 3/24

September 3rd, 2018

Page 4

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 4/24

September 3rd, 2018

About This Manual

This manual applies to SQ75 CANopen brushless products:

• 80350,

• 80360,

• 80370,

And all gearboxes adaptation.

Reference source for manuals

The manuals can be downloaded from our website at the following address:

http://www.crouzet-motors.com/

Units

SI units are the default values.

Risk Categories

In this manual, safety instructions are identified by warning symbols.

Depending on how serious the situation is, the safety instructions are split into 3 risk categories.

DANGER

DANGER indicates a directly dangerous situation which, if the

instructions are not followed, will inevitably lead to a serious or fatal

accident.

WARNING

WARNING indicates a possibly dangerous situation which, if the

instructions are not followed, will in some cases lead to a serious or

fatal accident or cause damage to equipment.

CAUTION

CAUTION indicates a potentially dangerous situation which, if the

instructions are not followed, will in some cases lead to an accident or

cause damage to equipment.

Page 5

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 5/24

September 3rd, 2018

1. INTRODUCTION

1.1. Motor Family

SQ75 brushless motors are brushless DC motors, with a control circuit board integrated in the motor.

1.2. Characteristics

SQ75 brushless motor s are intelligent servomotors for speed, pos ition and torqu e control appl ications. They

can be configured via a Human-Machine Interface (HMI) with CANopen or USB communication bus.

They are equipped with 3 i ndustria l c onnec tors, 1 for po wer, 1 for the contr ol signals and 1 f or th e CANo pen

communication.

1.3. Ide nti fication Label

The label contains the following data:

Page 6

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 6/24

September 3rd, 2018

1.4. Product Coding

Three

firsts

digits

4th digit 5th digit 6th digit 7th digit 8th digit

803 5 = Rotor 37,5mm

0 : direct motor

IP69

0 : with integrated drive

0 à 3: SMi22 CAN (if 6th digit = 0 ou 1)

from 0 to 9

6 = Rotor 50mm D : P72 1 : with integrated drive + brake

4 à 6: SMi22 (without CAN) (if 6th digit = 0 ou 1)

7 = Rotor 75mm E : P81 4 : hall effects

2 : RAD20 5 : Hall effects + brake

Page 7

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 7/24

September 3rd, 2018

1.5. Standards and concepts

The product is ROHS confirmed following European Directive 2011/65/CE. Following this confirmation, the

product is CE marked.

The electrical design follows the IEC 60335-1 and IEC 60950-1 standards.

Page 8

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 8/24

September 3rd, 2018

2. OPTIONS AND ACCESSORIES

The motors can be supplied with options, such as:

• Different gearboxes

• A failsafe holding brake

• Different motor output shaft versions

2.1.1. Holding brake

SQ75 brushless motors can be equipped as standazromechanical brake.

The holding brake is designed to lock the motor shaft in a de-energized state.

The holding brake is not a safety function.

A motor with a holding brake needs a corresponding c ontrol logic which releases the ho lding brake at the

start of the rotation movement, locking the motor shaft in time when the motor stops.

Nota : Outputs are able to drive the electromechanical brake.

Nota : Motor has to be completely stopped before activation of the brake.

2.1.2. Gearboxes

SQ75 brushless motors can be equipped with different types of gearbox.

The gearboxes off ered as standard in the c atalogue are planetar y gearboxes which com bine compact si ze

and robust design, and worm gearboxes that allow a shaft output at right-angles to the motor shaft.

2.1.3. Other

Other types of adaptation are possible on request, please contact the sales department.

2.1.4. Sta rter Kit

This kit consists of:

- a 2-meter long micro USB B to USB A (MOLEX 68784-0003) connecting cable 27 526 005

- a power cable : this cable can be obtained by ordering part number 79 298 664

- an I/O cable : this cable can be obtained by ordering part num ber 79 5 13 106

- a CAN cable M12 M/F : this cable can be obtained by ordering part number 27 358 015

- a bus terminating resistor : this resistor can be obtained by ordering part number 27 358 014

- a D-Sub bus connector 27 358 017

- an USB to CAN converter (PEAK System reference IPEH-002021) 27 358 016

- an USB stick containing the "DCmind Soft + CANopen Interface" parameter-definition software and

installation drivers for this HMI.

- A T (F-M/F) CAN connector 27 358 020

This starter kit can be obtained by ordering part number 79 5 13 105

Page 9

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 9/24

September 3rd, 2018

3. PRECAUTIONS FOR USE CONCERNING THE MECHANICS

3.1. Data specific to the motor shaft

WARNING

MOTOR MECHANISM

Exceeding the maximum permissible forces on the shaft leads to rapid

bearing wear, a broken shaft or damage to any accessories (encoder,

brake, etc.)

• Never exceed the maximum axial and radial forces.

• Protect the shaft from any impact.

• When press-fitting components, do not exceed the maximum

permissible axial force.

Failure to comply with these precautions can result in death,

serious injury or damage to equipment.

Radial load on the shaft

The application point X of the radial force F depends on the motor size.

This information appears in the motor technical data sheet.

The maximum axial and radial loads must not be applied simultaneously.

F

x

Page 10

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 10/24

September 3rd, 2018

3.2. USB Connector

The motor is equipped with a micro USB conn ector, which can be acc essed by removing the s topper from

the housing.

The stopper prevents penetration of foreign bodies or fluids inside the motor.

The stopper prevents fingers or any inappropriate object making contact with the micro USB connector.

For any other connector, when not used, stoppers have to be mounted.

WARNING

UNEXPECTED MOVEMENT DUE TO ELECTROSTATIC DISCHARGES

Electrostatic discharges (ESD) on the micro USB connector can, in

some cases, lead to deterioration or destruction of some system

components and generate unexpect ed motor operation.

• Never touch the connector with your fingers or any inappropriate

object.

Failure to comply with these precautions can result in death,

serious injury or damage to equipment.

CAUTION

LOSS OF SEALING

The stopper ensures the motor is sealed.

• Replace it after completing parameter definition.

• Make a visual check to ensure it is in place.

Failure to comply with these precautions can result in injury or

damage to equipment.

Housing

USB stopper

Page 11

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 11/24

September 3rd, 2018

3.3. Fixings

Fixing of the product has to be done by using 4 M6 screws with a screwing torque of 7N.m.

4. PRODUCT OVERVIEW

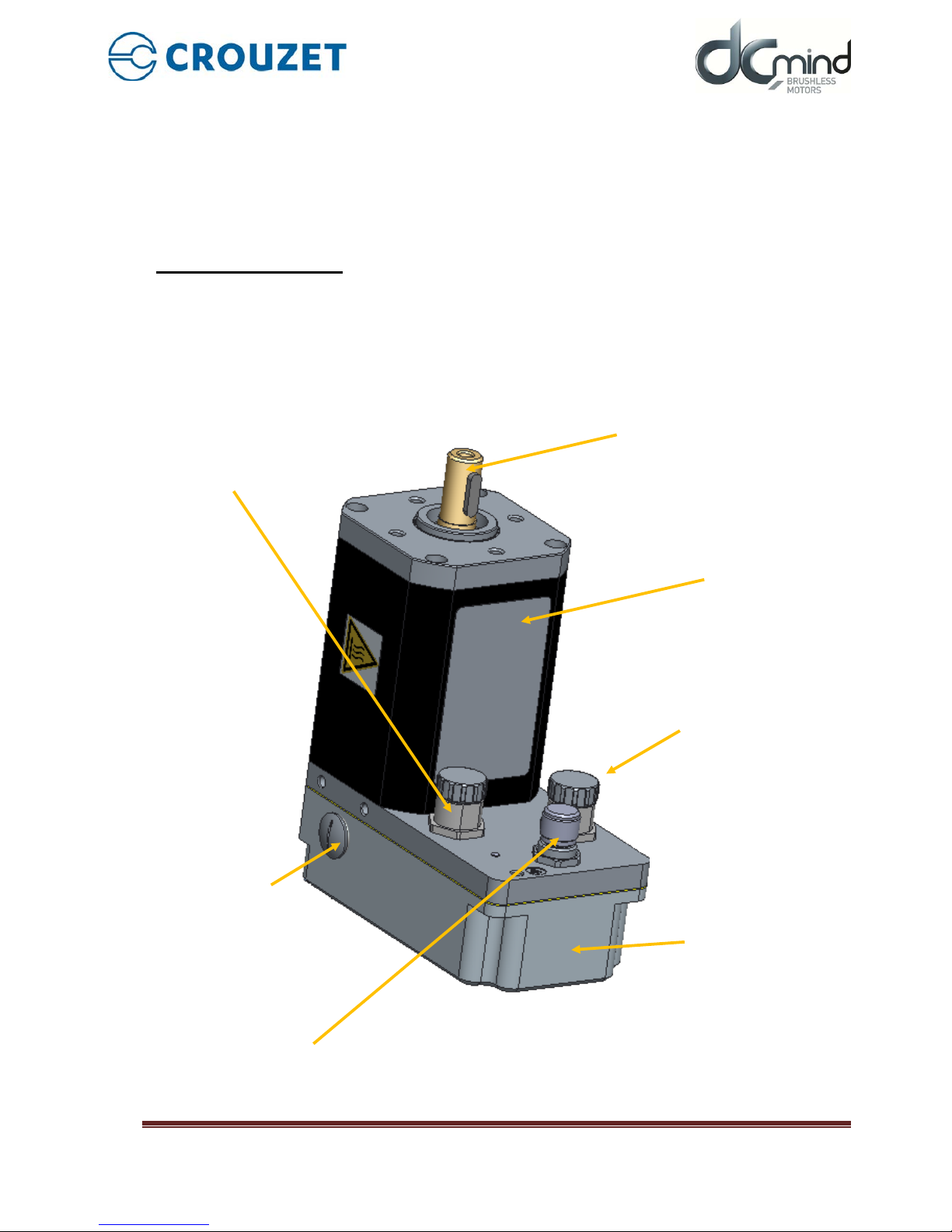

4.1. Description of the Product

Label

18-pin logic M16 connector

(Inputs/Outputs)

3-pin power supply M16

connector

Output shaft

CAN communication

M12 connector

SMI22 CANopen integrated

electronics

USB-B micro-connector

(Parameter definition via HMI)

Page 12

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 12/24

September 3rd, 2018

4.2. SMI22 CANopen Control Electronics

The SQ75 CANopen electronic control board contains the control electronics for a brushless motor,

integrated in the motor body.

This electronics is used for:

• Power switching of the motor in sine mode (field-oriented control (FOC)) or trapezoidal mode.

• Position-Speed-Torque and Current control algorithms.

• CANopen CiA 301 standard – Application layer and communication profile

• CANopen CiA 402 standard – Drive and motion control device profile

• Use of preconfigured programs which can perform numerous routine applications (DCmind programs).

• Management of different types of operation:

o "Stand-alone" motor without external PLC.

o Use with other motors incorporating SMI22 or SMI21 electronics.

o Use with a programmable controller, with the SMI22 simplifying motor management.

• The interface with parameter-definition software installed on the PC:

o Easy to use, even by a laym an, thanks to simplified application pro grams that are quick to

get up and running.

o Wide choice of expert programs covering a wide range of applications.

o CAN connection via a commercially-available standard cable (can be supplied on request).

o USB connection via a commercially-available standard cable (can be supplied on request).

• Management of 6 inputs,4 outputs and 2 STO inputs (for safety) to control the motor:

o 2 inputs that can be configured for 0-10 V 10-bit analog or PWM or digital control

o 4 digital inputs

o 2 isolated differential STO inputs (4 leads)

o 1 output that can be configured as PWM or frequency or digital

o 1 output that can be configured as PWM or digital

o 2 digital outputs

As standard, the motors have an internal encoder with 4096 points per revolution that can reach high

positioning and control resolutions.

Note : For res et the motor by CANOpen (e.g. when Bootload er mode is requir ed), index 0x2FF F sub index

0x00 has to be set at value=0x64747372.

Page 13

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 13/24

September 3rd, 2018

4.3. "DCmind-Soft + CANopen" PC Parameter-Definition Software

This software can be downloaded from the Internet at the following address: http://www.crouzet-motors.com/

It can also be supplied as a kit, see "Starter Kit" section.

This "DCmind-Sof t + CANopen" s oftware is needed th e first time the m otor is used and for debuggi ng if you

don’t have a CANopen master.

It is used for:

• Selecting the motor operating program:

o Position

o Speed

o Torque

o Homing

o Quick and easy starting using preprogrammed applications.

o Use of "expert" programs that provide access to all settings.

• The various settings needed for the application to work correctly.

• Updating the "firmware" motor program using the bootloader function.

For more information, see the HMI user manual dedicated for the “DCmind Soft + CANopen”

Page 14

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 14/24

September 3rd, 2018

5. TECHNICAL SPECIFICATIONS

5.1. Electrical Data

Maximum Product Specifications

Parameters

Value

Unit

Supply voltage V

DC_MAX

75

V

Maximum current I

DC_MAX (2seconds)

75

A

Maximum input voltage V

IN_MAX

90

V

Maximum output voltage V

OUT_MAX

24

V

Maximum output current I

OUT_MAX

10

mA

Operating Specifications

Parameters

Min

Typical

Max

Unit

Supply voltage VDC

9

24 / 32 / 48

75

V

Current IDC

-

15 - A

Motor consumption when stopped without holding

W0

- 1 - W

Input Specifications

Parameters

Min

Typical

Max

Unit

Input impedance In1 to In4

-

200 - kΩ

Input impedance AN5 to AN6

-

107.2

-

kΩ

Low logic level on inputs In1 to In4

-90 - 2.4

V

High logic level on inputs In1 to In4

4.5 - 90

V

Low logic level on inputs AN5 to AN6

-90 - 2

V

High logic level on inputs AN5 to AN6

4.6 - 90

V

Low logic level on STO1 & 2

-2 - 4

V

High logic level on STO1 & 2

4.6 - 75

V

CAN Low level

0.5

1.5

2.25

V

CAN High level

2.75

3.5

4.5

V

Output Specifications

Parameters

Min

Typical

Max

Unit

Low logic level on outputs Out1 to Out4 V

OL

RL = 4 K7Ω, VDC = 24 V

- 5 10 mV

High logic level on outputs Out1 to Out4 V

OL

RL = 4 K7Ω, VDC = 24 V = voltage supply added from

eventual rejective voltage

- - 24 V

5.2. Generic Data

General Specifications

Parameters

Value

Unit

Ambient motor temperature

-30 to +70

°C

Insulation class (compliant with directive IEC 60085)

E

/

Ingress protection (excluding output shaft)

IP67 + IP69

/

CANopen compliance

CiA DS 301 and CiA DS 402

/

Page 15

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 15/24

September 3rd, 2018

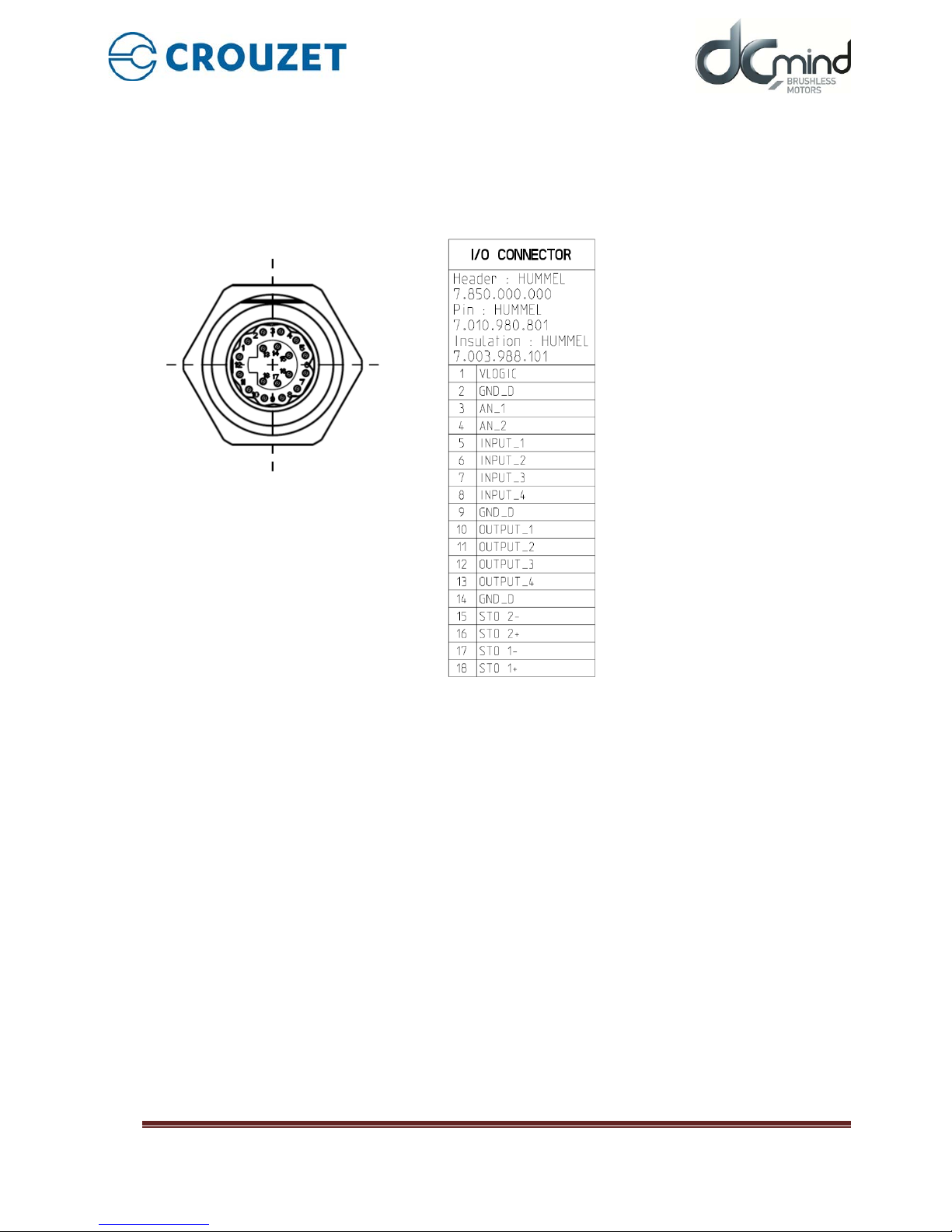

5.3. Logic M16 connector

It’s a M16 18-pin industrial male connector

Recommended AWG for the associated cable: AWG24 for wires inside a shielded cable.

(See part “Starter Kit” of this document).

With cables more than 3 m long, tests must be performed in situ.

Page 16

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 16/24

September 3rd, 2018

5.4. Power Supply M16 connector

It’s a M16 3-pin industrial male connector.

Recommended AWG for the associated cable: AWG14 for wires inside a shielded cable.

(See part “Starter Kit” of this document).

With cables more than 3 m long, tests must be performed in situ.

5.5. CAN communication M12 connector

It’s a M12 5-pin industrial male connector with standard pinout according to CiA 303-1 recommendations.

Recommended AWG for the associated cable: AWG24 for wires inside a shielded cable.

(See part “Starter Kit” of this document).

Note that the maximum baud rate depends of the cable length.

Page 17

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 17/24

September 3rd, 2018

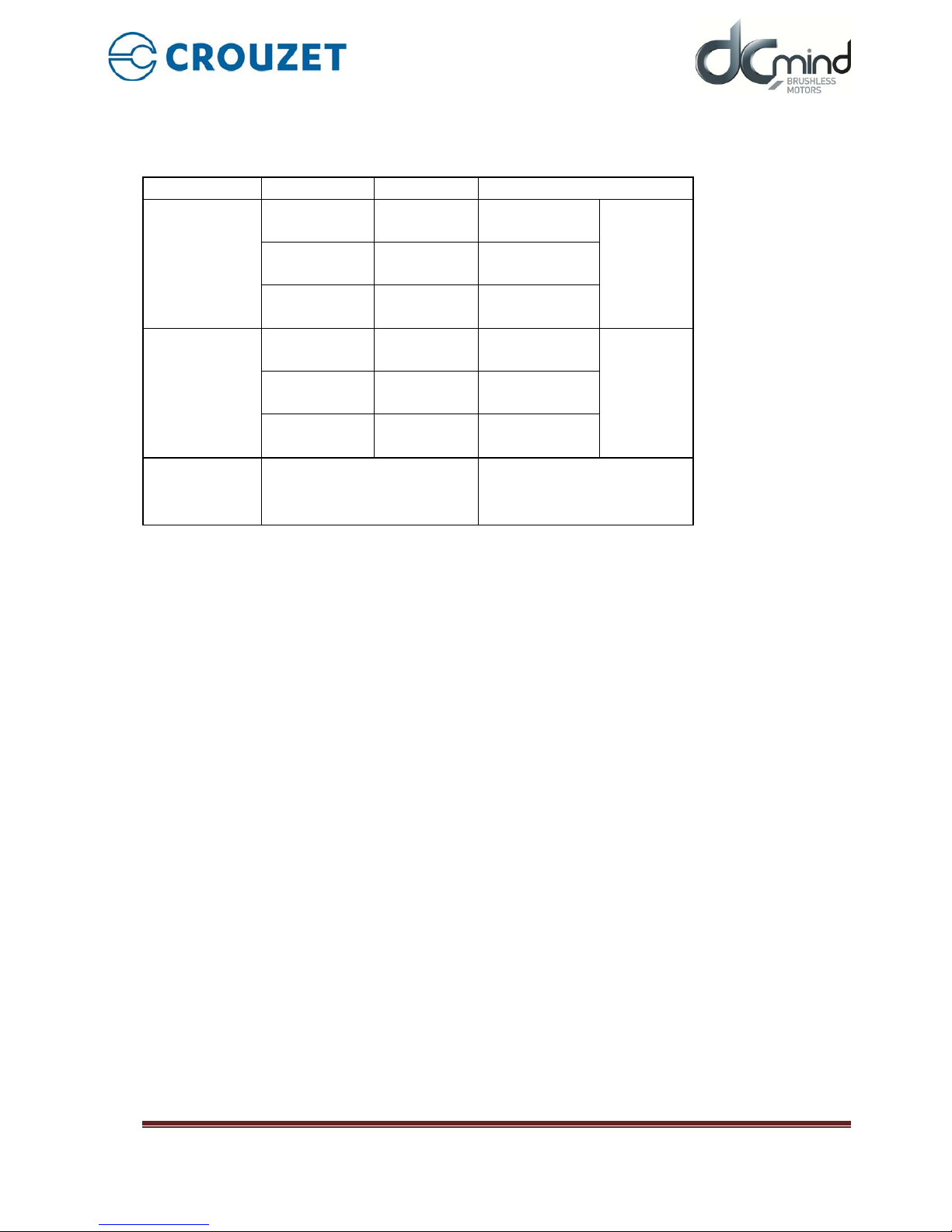

5.6. Connectors part numbers

MOTOR

CABLE

I/O

connector

Panel

connector

HUMMEL

7.850.000.000

All HUMMEL

M16

AWG24

cable

Insert

HUMMEL

7.003.988.101

HUMMEL

7.003.988.102

Contact

HUMMEL

7.010.980.801

HUMMEL

7.010.980.802

Supply

connector

Panel

connector

HUMMEL

7.850.000.000

AWG14

cable

Insert

HUMMEL

7.003.983.101

HUMMEL

7.003.983.102

Contact

HUMMEL

7.010.982.001

HUMMEL

7.010.982.002

CAN connector MOLEX M12/PG9 1200708205

any compatible connectors

(i.g : Weidmüller SAIL-

M12GM12G-5S3.0U)

Page 18

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 18/24

September 3rd, 2018

6. MOTOR ELECTRICAL CONNECTION

These motors are not intended to be directly connected to the line supply.

It is the responsibility of the installer to define the electrical protections to be implemented according to the

regulations applicable to the end product range of application.

We recommend the use of fuses in accordance with UL248-5 Test 1.3 & 5.

Supply power must be a stabilized power supply with double electrical insulation.

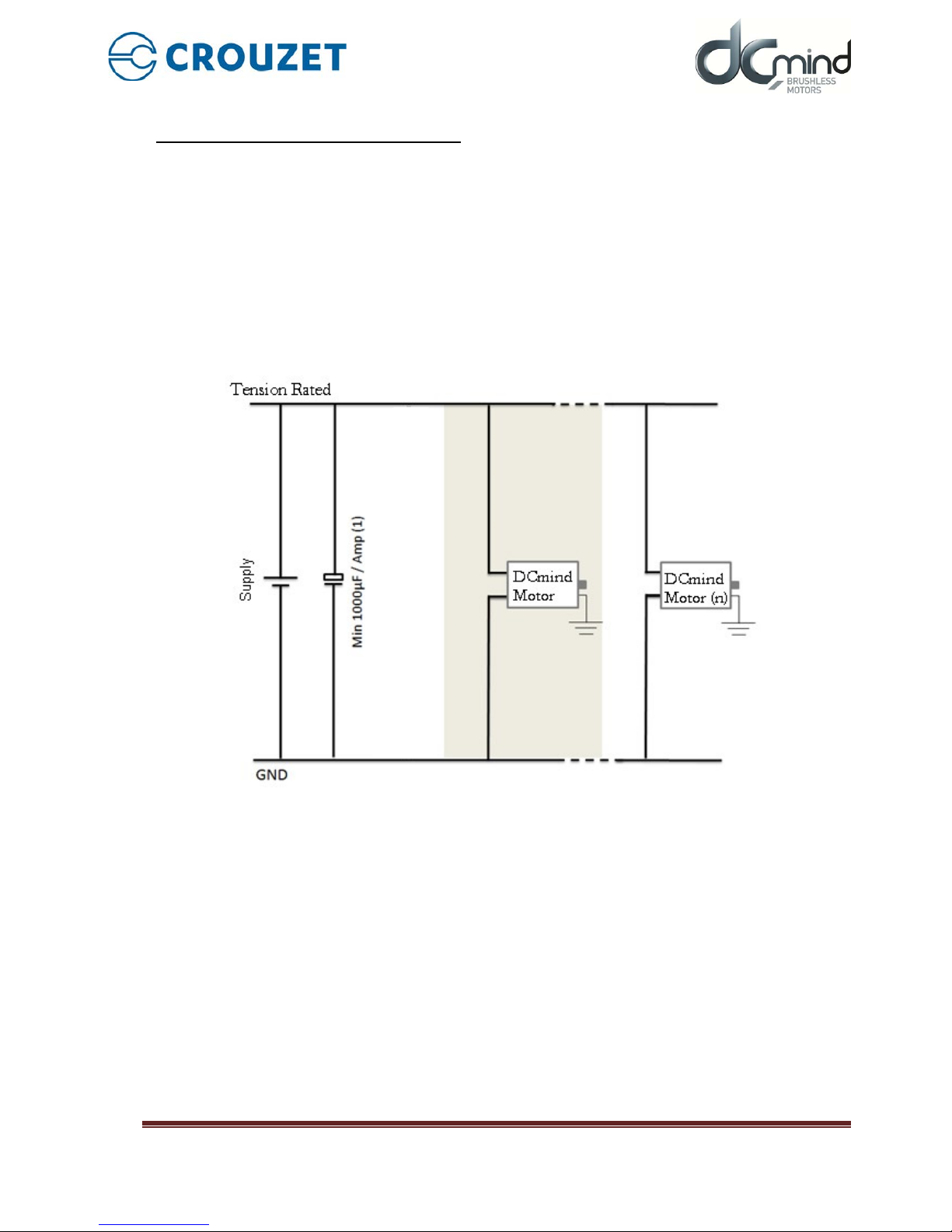

6.1. Power Connection

We recommend grounding the motor housing.

Power connection diagram.

(1)

Include capacitors to smooth out inrush currents. Recommended value 1000 µF/A drawn.

6.1.1. Balla s t Circuit

When the motor brakes, the kinetic energy stored in the inertias during rotation is returned to the power

supply and generates a vo ltage surge. This voltage surge can be destructi ve for the motor or for devices

connected to the power supply.

In the event of frequent brak ing, an ext ernal ball ast resistor must be u sed, all the cir cuitr y is integrated in

the product. Ballast parameters are available through CANopen communication.

For more information, see the HMI user manual dedicated for the “DCmind Soft + CANopen”

It is always necessary to conduct tests to check what size it should be.

Page 19

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 19/24

September 3rd, 2018

6.1.2. EMC Protection

In order to ensure that the product is compatible with EMC standards IEC 61000-6-1, IEC 61000-6-2, IEC

61000-6-3, IEC 61000-6-4, EN55022 Class B we recommend:

- Connecting the motor to ground while limiting length of the grounding strip,

- Adding capacitors on the main power supply.

We recommend 1000 µF per amp drawn.

-

6.1.3. Earth connection

A taped hole on the housing is dedicated to the earth connection. Use M5x6mm screw class 8.8 to connect

product with a screwing torque of 4N.m±15%. Use AWG12 gauge lead for earth connection.

Page 20

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 20/24

September 3rd, 2018

6.2. Protection

DANGER

PROTECTION

The product has in ternal protection de vices that switch off the

motor power suppl y when activated. As the motor is no longer

controlled, driving loads can decrease.

• The system manufac tur er is res pons ib le f or c om pl ying w ith all

the applicable safety rules in the event of product failure.

Failure to comply with these precautions will result in

death or serious injury.

6.2.1. Voltage Protection

The product incorporates protection against voltage surges and undervoltages.

Protection against voltage sur ges :

The voltage surge threshold can be set in the HMI.

When the supply voltage exceeds the threshold, the product automatically switches to ERROR mode. In

ERROR mode the motor is no longer controlled.

To reset the motor:

- The supply voltage must be at least 1 V below the threshold value.

- It is necessary to pass in DISABLE mode then ENABLE mode.

Protection against undervol tages :

The under voltage threshold can be set in the HMI.

When the supply volta ge falls below this threshold, the pro duct automaticall y switches to ERRO R mode. In

ERROR mode the motor is no longer controlled.

To reset the motor:

- The supply voltage must be at least 1V higher than the threshold value

- It is necessary to pass in DISABLE mode then ENABLE mode.

Page 21

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 21/24

September 3rd, 2018

6.2.2. Temperature Protection

• The product incorpora tes a first temperature protec tion in the form of a tem perature sensor on the

motor pilot control card.

Temperature protection:

The under and over temperature thresholds can be set in the HMI (set at -40°C and +110°C by default).

In this case, when the internal temperature exceeds 110°C (or is below than -40°C), the product

automatically switches to ERROR mode. In ERROR mode the motor is no longer controlled.

To reset the motor:

- The temperature must be between the 2 thresholds.

- The motor inputs must be set to DISABLE mode then ENABLE mode.

• The product incorporates second temperature protection with 3 thermistors into the stator coils.

Temperature protection:

In this case, when the stator temperature exceeds 120°C, the product automatically switches to ERROR

mode. In ERROR mode the motor is no longer controlled.

To reset the motor:

- The temperature must be under 120°C.

- The motor inputs must be set to DISABLE mode then ENABLE mode.

- .

6.2.3. Current Limiting

The product incorporates internal current limiting. This limiting directly affects the motor in terms of hardware.

If this limit is reached, it results in a loss of motor performance.

This product is not designed to operate continuously with this limiting (see the "Electrical Data" section).

Page 22

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 22/24

September 3rd, 2018

6.3. Input/Output Connection

6.3.1. Equivalent Input Diagram

Page 23

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 23/24

September 3rd, 2018

6.3.2. Equivalent Output Diagram

Page 24

SMI22 CANopen

C.MO.SAV.00022.FR_V3 Page 24/24

September 3rd, 2018

6.4. Terminology and Abbreviations

Encoder

Mounted on the motor, the angular position sensor provides frequency pulses proportional to the motor

speed.

Degree of protection

The degree of protection is a standard definition used for electrical equipment that aims to describe the

protection against penetration of solids and liquids inside the motor casing (for example IP54M). The M

indicates that the tests are conducted with the motor running.

This value cannot take account of the seal around the output shaft, for which the installer must take

responsibility.

Axial forces

Longitudinal traction or compression forces affecting the shaft.

Radial forces

Radial forces affecting the shaft.

Direction of rotation

Positive or negative direction of rotation of the motor shaft. The positive direction of rotation is clockwise

rotation of the motor shaft, when looking at the motor from the output shaft.

Nominal speed

Motor speed of rotation when nominal torque is applied.

Nominal current

Current drawn by the motor when nominal torque is applied.

Nominal torque

Maximum applicable torque in continuous duty on the motor shaft.

Firmware

Control software embedded in the motor.

Bootloader

Function available in the HMI which can be used to update the firmware.

Commonly used abbreviati ons:

HMI: Human-Machine Interface

SMI22: Trade name of the new CROUZET brushless range

Homing: Initialization phase for finding the limits

AON: Type of digital inputs/outputs (All Or Nothing)

PWM: Pulse Width Modulation

FWD: Forward

REV: Reverse

NO: Normally Open

NC: Normally Closed

EMC: Electromagnetic Compatibility

Loading...

Loading...