Page 1

| MICROSWITCHES | 1 | WWW.CROUZET-SWITCHES.COM

BASIC TECHNICAL CONCEPTS

INTRODUCTION

Our microswitches are high-precision, snap -action switches and these are the main features for which they are notable:

› Fast and reliable switching largely independent of actuating

speed

› High electrical ratings but small dimensions

› High repeat accuracy of switching points and forces

› Low operating force

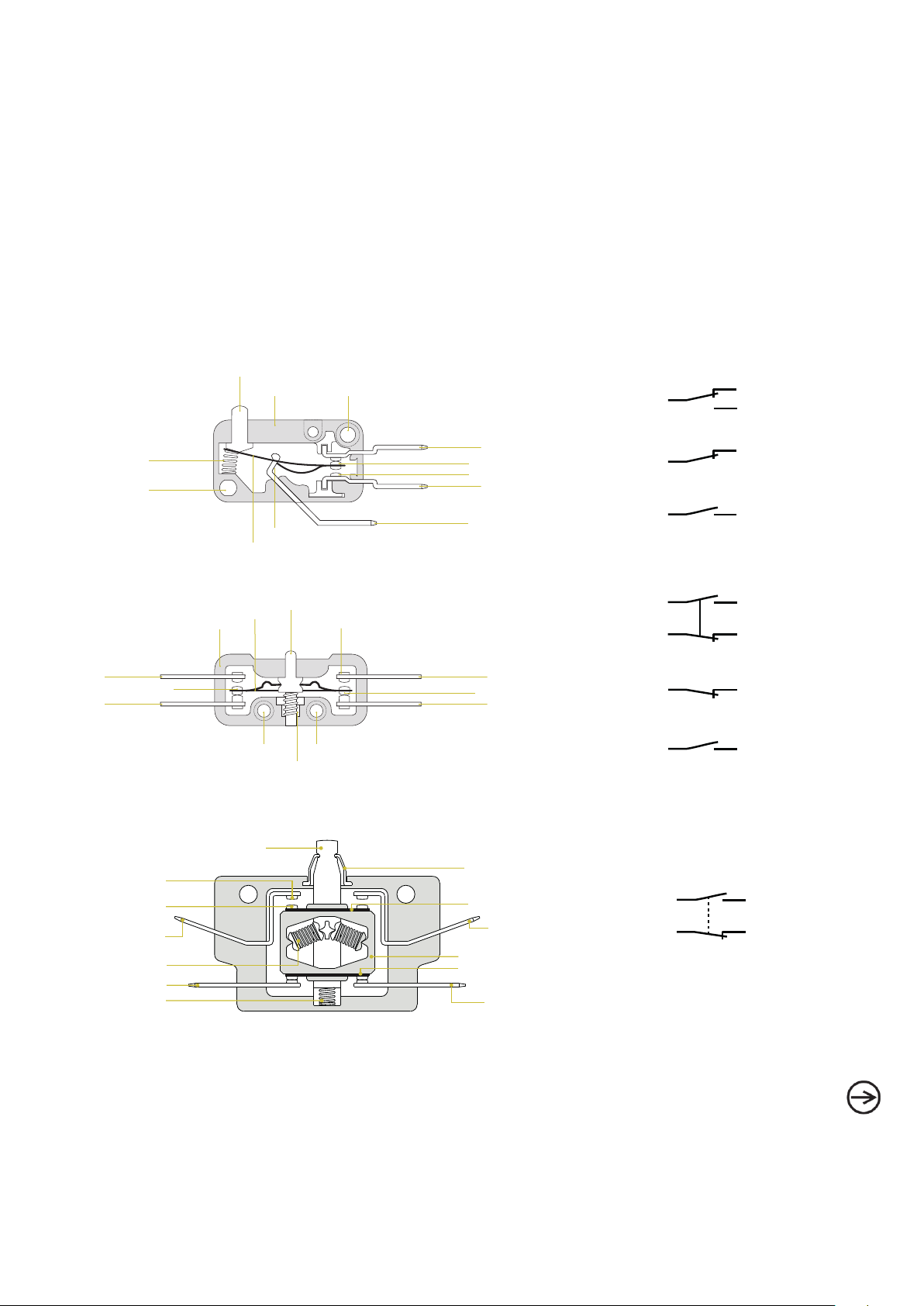

MICROSWITCH CONSTRUCTION - ELECTRICAL FUNCTIONS

› Single-break changeover SPDT Microswitch (e.g. V3 83161)

› Short pre-travel but large overtravel

› Very long service life

› Extensive range of connections, xing means and actuators for

easy adaptation to numerous applications.

| 05/2016

Operating device (Plunger)

Return

spring

Fixing hole

Housing

Conductive pivot point

Snap-acting blade

Fixing hole

NC terminal (2)

Mobile contact

Fixed contact

NO terminal (4)

Common terminal C (1)

› Double-break changeover SPDT Microswitch (e.g. 83132)

Housing

NO terminal (3)

Mobile contact

NC terminal (1)

Fixing hole Fixing hole

NO and NC circuits must be used at same polarity.

Operating device (Plunger)

Snapacting

blade

Return spring

Fixed contact

NO terminal (4)

Mobile c ontact

NC terminal (2)

Changeover SPDT (Form C)

1 (C)

Normally Closed SPST-NC (Form B)

1 (C)

Normally Open SPST-NO (Form A)

1 (C)

Changeover SPDT (Form Za)

3 (NO)

1 (NC) 2 (NC)

Normally closed SPST-NC (Form Y)

1 (NC) 2 (NC)

Normally open SPST-NO (Form X)

3 (NO)

› Double-break changeover SPDT Microswitch with separated circuits (e.g. PBX 8324)

2 (NC)

4 (NO)

2 (NC)

4 (NO)

4 (NO)

4 (NO)

Operating device

(Plunger)

4 xed contacts

4 mobile contacts

NO terminal (13)

Snap-action

springs

NC terminal (21)

Return spring

NO and NC circuits are electrically separated, and can be used at opposite polarities.

Sealing membrane

NO blade

NO terminal (14)

Insulated mobile bracket

NC blade

NC terminal (22)

Changeover SPDT (Form Zb)

13 (N O) 14 (NO)

21 (N C) 22 (NC)

› Positive (or direct) opening operation according to IEC 60947-5-1 Annex K (depending on models)

An additional internal mechanism, made of non-resilient parts,

forces the opening of NC contacts in case of accidental welding

(overload, short-circuit, …) or snap-action mechanism failure.

Models tted with this function are particularly suitable for safety

related applications according to ISO 13849-1 or EN 60204-1.

To ensure proper functioning of positive opening operation, the

operating device must be depressed up to the positive opening position.

› Maintained action / Bistable reset variants

Double-break microswitches (Form Za, X, Y and Zb) are particularly

suitable for achieving this kind of “mechanical memory” function.

Return spring is removed, and operating device has special shape

for push/pull actuation.

Typical applications are level regulation, manual reset and position

contacts for bistable electromagnets.

Page 2

| MICROSWITCHES | 2 | WWW.CROUZET-SWITCHES.COM

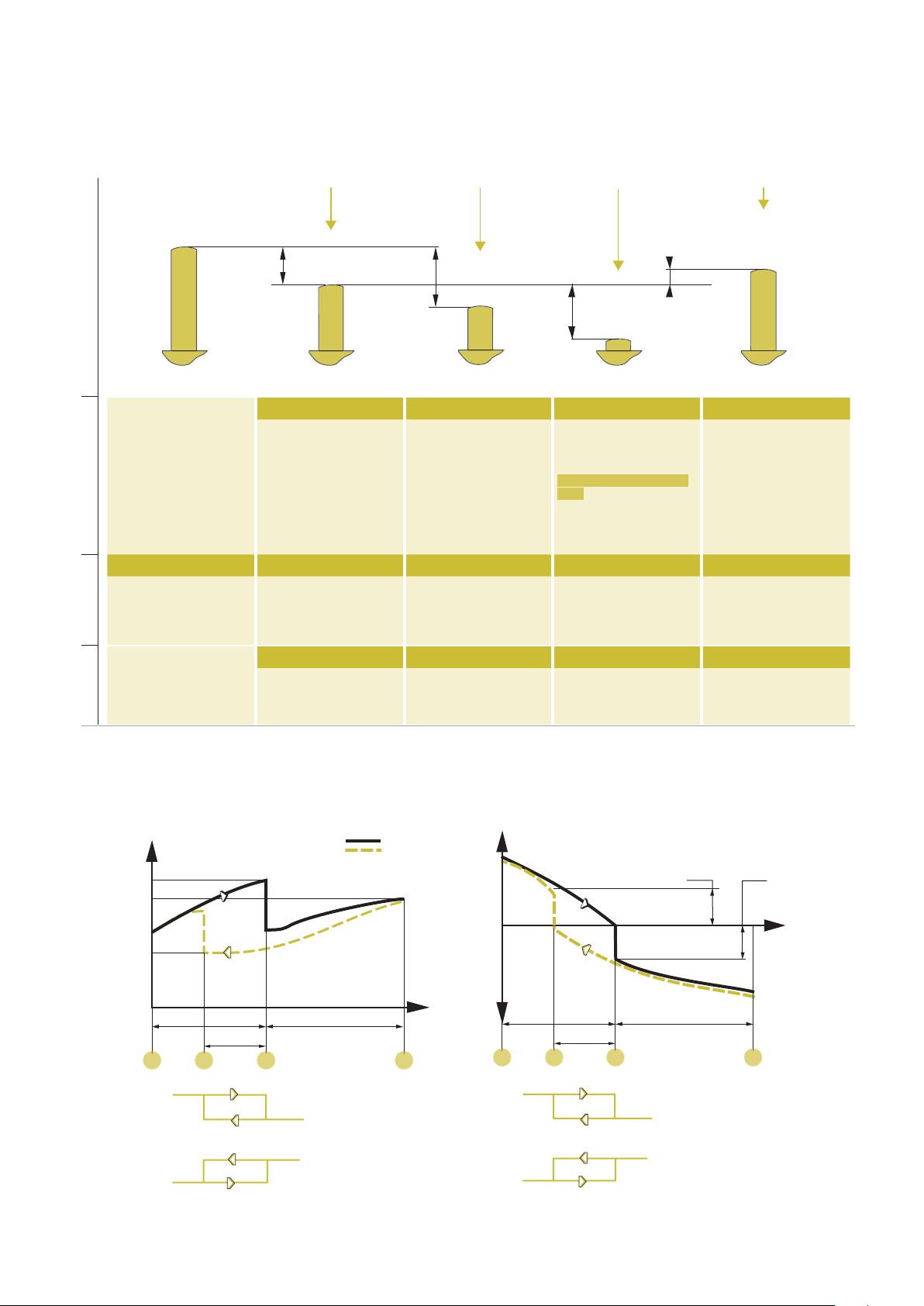

MECHANICAL CHARACTERISTICS

› Terminology: Forces - Positions - Travels

| 05/2016

PT

Actuation of operating device

*Depending on models

RP

OF Operating force

Force required to move

the operating device from

the rest position RP to the

operating position OP

Forces

RP Rest position OP Operating position

Position of the operating

device when no external

mechanical force is applied

Positions

Tra v els

Position of the operating

device at which the snapaction mechanism trips.

PT Pretravel

Distance between the

rest position RP and the

operating position OP

POF*

POT*

POF Positive opening force*

Force to be applied to the

operating device to achieve

the positive opening

operation

POP Positive opening position*

Position of the operating

device where the positive

opening of the NC contacts

is guaranteed

POT Positive opening travel*

Distance between the

rest position RP and the

positive opening position

POP

TTFOF

RF

DT

OT

TTPPOP*OP

TTF Total travel force RF Release force

Force required to reach total

travel position TTP (only

specified when higher than

operating force OF)

AOF Allowable overtravel

force

Maximum force which can

be applied to the operating

device without incurring

deterioration

TTP Total travel position RLP Release position

Position of the operating

device when the applied

force has moved it to the

effective end of the available

travel

OT Overtravel DT Differential travel

Distance between the

operating position OP and

the total travel position TTP

RLP

The level to which the

applied force must be

reduced to allow the snapaction mechanism to return

to its release position RLP

Position of the operating

device at which the snapaction mechanism trips back

to its original position

Distance between the

operating position OP and

the release position RLP

The reference po int for th e figur es given fo r travels an d forces i s a point F located on the top of th e plunger in the case of a plain microsw itch, or, generall y, 3 mm in from th e end of a

flat lever. The refere nce point for the po sitio ns is one of th e fixing h oles, unless oth erwis e indic ated.

› Force - Travel diagrams

On contactsOn operating device

N

OF

TTF

RF

RP RLP OP TTP

NC contact closed

open

NO contact closed

open

PT OT

DT

depression

return

mm

NC contact closed

NO contact closed

N

Force after tripping

return depression

NC

0

NO

PT OT

N

RP RLP OP TTP

DT

open

open

mm

Page 3

➛

➛

➛

➛

NC

NO

< 5 ms

0,3 0,5 12 51016

12

24

48

110

220

| MICROSWITCHES | 3 | WW W.CROUZET-SWITCHES.COM

| 05/2016

ELECTRICAL CHARACTERISTICSMECHANICAL CHARACTERISTICS

› Changeover time

This is the time taken by the mobile contact when moving from

one xed contact to another until it becomes fully stable (contact

bounce included). This time is a function of the contact gap, the

mechanical characteristics of the snap action and the mass of the

mobile element.

However, thanks to the snap-action mechanisms employed, the

time is largely independent of the speed of operation.

It is normally less that 20 milliseconds (including bounce time less

than 5 ms).

Bounce time

< 20 ms

Changeover time

› Actuating speed - Rate of operation

Our microswitches are suitable for actuating speeds varying over

a very wide range: typically from 1 mm/min to 0,5 m/s.

The maximum rate of operation with a low electrical load may be

as high as 10 cycles / second.

› Direct actuation on plunger

The plunger should preferably be actuated

along its axis (front actuation). However,

the majority of our microswitches can

accept lateral approach provided the angle

of actuation is not more than 45°.

› Max rating / Making & Breaking capacities

This is the max current the microswitch is capable of making and

breaking for at least 6000 cycles.

On DC current, the breaking capacity is extremely dependent

on the voltage, the contact gap and the nature of the load being

switched. There is a risk of prolonged or permanent arcing if the

following limits are exceeded:

Vdc

DC breaking capacity can be signicantly increased by using

different means, if necessary in combination:

– Arc reduction device (see «Electrical recommendations»)

– Double-break microswitch

– Microswitch with magnetic blow-out

– Use of several microswitches connected in series and operated

simultaneously

For making and breaking capacities according to utilization

categories AC12, AC13, AC14, AC15 and DC12, DC13,DC14

dened by IEC/EN 60947-5-1: refer to our datasheets.

For special applications, please consult us.

DC max breaking capacities

Resistive load

Inductive load L/R = 5 ms

3 mm contact gap

0.4 mm contact

gap

A

The actuating device shall not limit the

plunger travel to the operating position

(OP). It must always depress the plunger

through at least 0.5 times the dened

overtravel (OT), or up to the positive

must also be taken to ensure that it does not exceed the total

travel position (TTP) nor the allowable overtravel force (AOF).

opening position (POP) if applicable. Steps

› Operation by auxiliary actuator (lever)

When the roller lever is laterally

approached, force should preferably be

applied in the direction shown.

+

Where the movements involved are fast,

the ramp should be designed to ensure

that the operating device is not subjected

to any violent impact or abrupt release.

› Mechanical durability

This is an indicative value of the number

of possible operating cycles without an

electrical load.

It may be useful for evaluation purposes

in cases where the power levels involved

are very low and the electrical life is thus

close to the mechanical life.

› Nominal rating

This is the current the microswitch is capable of making and

breaking, for a given number of cycles (typically 100 000 cycles).

Nominal rating generally corresponds to the highest ampere rating

shown on the operating curve.

› Thermal rating

This is the amount of current the microswitch can withstand when

not being operated; for a terminal temperature rise of not more

than 60°C.

› Electrical durability

Operating curves indicate the electrical life of the microswitches,

under standard conditions (20°C, 1 cycle/2 seconds), by showing

the number of switching cycles that can be performed with varied

types of loads.

Note: for sealed products and/or for DC ratings, the rate of

operation is reduced to 1 cycle/6 seconds.

Example:

Number of

cycles

Resistive circuit

Inductive circuit

400

A

Page 4

c

500 V

µ

| MICROSWITCHES | 4 | WWW.CROUZET-SWITCHES.COM

| 05/2016

› Inuence of load type

Resistive load

This is the reference load that is used for

a resistive load, making and breaking, does not create specic

problem.

Inductive load

τ = L

R

M

In addition, in DC, the phenomenon of contact material relocation

is increased.

Ratings and / or life are reduced and special contacts may be

needed: please contact us.

Also refer to «Electrical recommendations».

Capacitive load and lamps

Breaking these loads is equivalent to that of a resistive load and

does not cause any particular problems.

Ratings and / or life are reduced and special contacts may be

needed: please contact us.

determining the nominal rating. Switching

Electromagnets or motors are typical

examples. They are characterized by a

cos φ <1 in AC or by a time constant

L / R> 0ms in DC.

Breaking these loads creates powerful

arcing that accelerates erosion of

contacts.

Making these loads of ten generates

inrush current up to 6 times the rated

current, which increases the risk of

contact welding.

Making these loads generates inrush

current up to 15 times the rated current,

which greatly increase the risk of contact

welding.

In addition, in DC, the phenomenon of

contact material relocation is strongly

accentuated.

› Contact resistance

This is the electrical resistance measured

at the terminals of the switch when the

contacts are closed. It consists of the

(variable) resistance of the contact point

and the (xed) resistance of the current

carrying parts.

plunger is in rest position or total travel position.

Near the operating or released positions, the contact force

decreases and the resistance may increase substantially.

It is generally less than 20 mΩ, when the

CONTACT MATERIALS

› Choice of contact material

To choose the best material for the contacts there are various

factors to be considered:

– Current and voltage levels

– Type of load

– Potential inrush current

– Number of cycles

– Rate of operation

– Environmental conditions

› Contacts for general use

Our microswitches are normally tted with silver or silver-nickel

contacts. These are suitable for the majority of applications and

provide the best compromise between electrical performance,

thermal performance and service life.

› Contacts for low-energy circuits

For applications at V <20V and/or I <100mA, especially if

P<0.3 VA, we recommend to use contacts with gold (or gold alloy)

coating, especially if the switching frequency is low

(e.g. <1 cycle / week), or in the presence of sulde atmosphere or

other corrosive environments.

The lower limits are not specically dened, but a proper

functioning can usually be assumed down to 4V 1mA. Below this

level, please consult us or refer to «Electrical recommendations».

› Contacts for special applications

We can supply special contacts suitable for various applications,

such as:

– AgSnO2 or AgCdO contacts for very high inrush current

– Gold plated AgNi contacts, possibly with a crossbar

arrangement, to cover a very wide operating range allowing a

single par t number to be used on dif ferent applications (dualcurrent models).

› Insulation resistance

The insulation resistance of our

microswitches is generally greater than

50 000 MΩ measured at 500 V DC.

› Dielectric withstand voltage

The dielectric withstand voltage of our

microswitches is generally higher than

values specied by IEC/EN 61058-1 for

250V rated voltage:

– 1500 volts between live parts and

ground (basic insulation)

– 1500 volts between open contacts for

contact gap >1.5mm (full disconnection)

– 500 volts between open contacts

for contact gap <1.5mm (micro disconnection “µ”)

Page 5

| MICROSWITCHES | 5 | WW W.CROUZET-SWITCHES.COM

| 05/2016

ELECTRICAL RECOMMENDATIONS

› Inductive circuits

To increase the life of contacts and the DC breaking capacity, the

arcing on contact opening can be reduced by using the following

protective circuits:

For DC

For DC or AC

› Very low-energy circuits

Switching very low energy circuits (I<1mA, V<4V) is highly

sensitive to environmental conditions like corrosive atmospheres

and pollutions.

In order to improve the contact reliability, the electrical circuit

should allow the passage of at least a few mA through the

contacts, and at least when the contacts are closing.

Also, the higher the voltage across open contacts, the better the

reliability when the contacts are closed.

Protection by fast diode

VR diode > V supply

IF diode ~ I inductive load

Protection by varistor

V varistor slightly higher than V supply

max

Energy to be dissipated = ½ L I

Protection by RC circuit

R and C values to be adjusted depending

on circuit characteristics

2

› Degree of protection

Degrees of protection provided

by enclosures against access to

hazardous parts, against ingress

of solid foreign objects and against

harmful ingress of water are dened

in IEC 60529 by an IP code followed

by two digits.

1st characteristic numeral

Protection of equipment

against ingress of solid

foreign objects

0 (not protected)

4 diameter ≥ 1 mm

5 dust-protected

6 dust-tight

2nd characteristic numeral

Protection of equipment

against ingress of water with

harmful effects

0 (not protected)

4 splashing

5 jetting

6 powerful jetting

7 temporary immersion

8 continuous immersion

9 high pressure and

temperature water jet

Under this classication, our microswitches mainly come within

the following categories:

– IP40 (with insulated connections): when no indication

– IP65, IP66, IP67, IP69: sealed microswitches, as indicated

Protection of persons

against access to hazardous

parts

(not protected)

1 mm Ø wire

1 mm Ø wire

1 mm Ø wire

INSTALLATION RECOMMENDATIONS

ENVIRONMENTAL CONDITIONS

› Operating temperature

The temperature range covered by our line of

microswitches extends from - 60°C to +250°C.

Operating limits are dened for each type of

microswitch. Within these limits, most of the mechanical

and electrical characteristics are preserved. However,

for cases of intensive use (e.g. numerous thermal cycles

with high electrical load) performance may be reduced.

For more information please contact us.

› Resistance to shock and vibration

Resistance to shock and vibration depends on the mass of the

moving parts and on the forces holding the contacts together. The

criterion of satisfactory performance is the absence of microopening of contacts.

Microswitches without auxiliary actuator

usually exceed the following levels when

plunger is in rest position or total travel

position:

– Vibration (sinusoidal): 10gn, 10 to 500Hz

– Shock: 50gn 11ms half-sine pulse

Further information on request.

› Mounting - Insulation

Our microswitches are built in accordance with the rules of

protection against electric shock dened by IEC/EN 60947-5-1 or

IEC/ EN 610 58-1.

Unless otherwise indicated, they are

intended for Class I devices and their

envelopes provide basic insulation.

Microswitches for Class I equipment are

also suitable for Class II equipment,with

appropriate installation conditions in the

equipment.

Class II microswitches can be used directly in Class II equipment

(and also Class 0, I, and III) without additional protection.

The integrator shall take appropriate measures to ensure

protection against electric shock (clearances and creepage

distances) after installation and connection in the application.

For example:

– An insulating pad may be required between the microswitch and

a conductive mounting surface, or between two microswitches

mounted side by side (optional accessory)

– Actuation of the operating device may require the use of an

intermediate part providing supplementary insulation

– Connections must be protected against direct contact

Please contact us for any additional information related to the

considered microswitch.

Page 6

| MICROSWITCHES | 6 | W WW.CROUZET-SWITCHES.COM

| 05/2016

› Fixing – Tightening torque

Unless otherwise indicated, the tightening torque of the xing

screws must conform to the following values:

Ø of fixing screw mm 2 2.5 3 3.5 4

Tightening torque max. 0.25 0.35 0.6 1 1.5

in N.m min. 0.15 0.25 0.4 0.6 1

› Processing

Silicone containing substances must be excluded from the close

environment of the microswitches because of their negative effect

on the contact resistance.

For the same reason, cyanoacrylate adhesives must be avoided or

carefully selected and tested prior to production run.

Also, grease and oil shall be avoided from the close environment

of the microswitches or shall be evaluated for chemical

compatibility with plastics.

Moreover, grease and oil shall never penetrate inside the

microswitches.

Ultrasonic welding process in the close environment of the

microswitches may affect the contacts and the mechanism.

Therefore, suitable tests and analysis shall be conducted prior to

production run.

Tin soldering must be carried out under an extractor hood in order

to avoid the penetration of solder vapors inside the microswitches,

that may have negative effect on the electric functioning.

STANDARDS, TESTING AND APPROVALS

Our microswitches are designed and tested according to

international standards like:

– EN/IEC 60947-5-1 for general industrial applications

– EN/IEC 61058-1 for household and similar appliances

– EN/IEC 60079 -1 for explosives atmospheres applications.

The Crouzet Switches laborator y is compliant with ISO/IEC 17025

and is cer tied to:

– SMT (Supervised Manufacturer’s Testing) by LCIE, for electrical

tests in accordance with EN/IEC 61058-1

– CTDP (Client Test Data Program) by UL, for electrical tests in

accordance with UL1054/UL61058-1.

Proof of compliance with these standards is demonstrated by:

– The manufacturer’s declaration of conformity (drafted in

accordance with ISO/IEC 17050), or

– Approvals granted by accredited bodies, like LCIE (for ENEC,

NF, ATEX, IECEx approvals), UL (for cURus, cULus approvals),

CQC (for CCC approvals)….

Approval certicates and declarations of conformity can be

obtained from www.crouzet-switches.com

Concerning machinery applications; EN/IEC 62061 and

EN/ISO 13849-1 standards for safety of machinery require the

component manufacturers to provide data allowing the equipment

manufacturers to calculate the Mean Time To Failure (MTTF) and

to determine the Safety Integrity Level (SIL) or the Performance

Level (PL) of the safety related par ts of their control systems.

Reliability data for switches according to EN/ISO13849-1 can be

obtained from www.crouzet-switches.com

Note: with appropriate wiring and monitoring system (like Crouzet

Control safety relays), safety related parts of control systems

containing switches, notably switches with positive opening

operation, can reach PL e / Category 4 according to EN/ISO

13849-1, and SIL 3 according to EN/IEC 62061.

QUALITY

Crouzet Switches undertakes a pro-active quality policy adapted

to our different markets of which the objectives are:

– To actively contribute to the success to our clients

– To ensure the perennial development of the company and

the brand by achieving global performance (social, economic,

product and service offer) in the eld of environment and

legislation.

This quality implies:

– Mobilization and dynamic behavior by the entire staff

– Achieving results and respecting our commitments

– Sharing our policies with our partners (clients, suppliers…).

This quality is based on a series of ongoing actions focusing on

the preventative:

– Quality starts from the understanding of the clients needs in

order to work out the specifications where Crouzet Switches

acts as expert advisor.

– Quality is pro-active in actions for progress

– Quality ensures the systematic exploitation of feedback

experience, methods and quality tools.

Our plants are certified to:

– ISO 9001: quality management systems

– ISO/TS 16949: particular requirements of quality management

systems for automotive production

– ISO/IEC 80079-34: application of quality systems for explosive

atmospheres equipment manufacture

– OHSAS 18 001: occupational health & safety management

systems.

Certicates can be obtained from www.crouzet-switches.com

RULES AND REGULATIONS

› EU directives

Our microswitches conform to:

– Low Voltage directive 2014/35/EU

– ROHS directive 2011/65/EU

– ATEX directive 2014/34/EU

when applicable.

In addition, they can be used within the framework of Machinery

directive 2006/42/EC.

Note about Electromagnetic Compatibility (EMC) directive

2014/30/EU:

– Microswitches, as electromechanical components and as

stated in EN/IEC 60947-1, are not sensitive to electromagnetic

disturbances and their emissions, generated only when

switching, are considered as par t of the normal electromagnetic

environment of low-voltage installations. Therefore, all of our

switches are compliant with the EMC directive.

› Environmental protection

Protection of the environment is an integral part of the

manufacturing process of our microswitches, from design to

packaging.

– ISO 14001: all of our plants are certied.

Certicates can be obtained from www.crouzet-switches.com

– REACH: Crouzet Switches takes into account any change of

the Reach regulation 1907/2006. None of our switches contain

substances from the authorisation list. For performance and

safety purposes, some switches have contacts containing

cadmium oxide which is currently in candidate list.

– WEEE: in order to comply with WEEE 2012/19/EU directive,

Crouzet Switches adheres to an accredited eco-organism.

Switches will come into the scope of WEEE from 2018.

Loading...

Loading...