Page 1

Page 2

Crouzet Touch Soft User Manual

Table of contents

Crouzet Touch Soft Installation and Startup Guide............................................................... 1-1

1.1. Installation Requirements............................................................................................. 1-1

1.2. Steps to Install Crouzet Touch Soft ............................................................................... 1-2

Utility Manager ..................................................................................................................... 2-1

2.1. Overview ....................................................................................................................... 2-1

2.2. HMI IP, Password .......................................................................................................... 2-3

2.3. Editing Tools .................................................................................................................. 2-4

2.4. Transfer ......................................................................................................................... 2-5

2.5. Simulation ..................................................................................................................... 2-7

2.6. Pass-Through ................................................................................................................ 2-8

Create an Crouzet Touch Soft Project ................................................................................... 3-1

3.1. Overview ....................................................................................................................... 3-1

3.2. Create a New Project File ............................................................................................. 3-1

3.3. Save and Compile the Project File ................................................................................ 3-4

3.4. Run On-Line or Off-Line Simulation .............................................................................. 3-4

3.5. Download the Project File to HMI ................................................................................ 3-5

3.6. Upload the Project File from HMI ............................................................................... 3-10

Hardware Settings ................................................................................................................. 4-1

4.1. Overview ....................................................................................................................... 4-1

4.2. I/O Ports ........................................................................................................................ 4-1

4.3. LED Indicators ............................................................................................................... 4-1

4.4. System Reset ................................................................................................................. 4-2

4.5. System Toolbar .............................................................................................................. 4-3

4.6. EasySystemSetting ........................................................................................................ 4-6

System Parameter Settings ................................................................................................... 5-1

5.1. Overview ....................................................................................................................... 5-1

5.2. Device ........................................................................................................................... 5-1

5.3. Model ............................................................................................................................ 5-9

5.4. General ....................................................................................................................... 5-11

5.5. System Setting ............................................................................................................ 5-13

5.6. Security ....................................................................................................................... 5-16

5.7. Font ............................................................................................................................. 5-19

5.8. Extended Memory ...................................................................................................... 5-20

5.9. Printer / Backup Server ............................................................................................... 5-22

Crouzet Touch Soft

Page 3

Crouzet Touch Soft User Manual

5.10. Time Sync./DST ........................................................................................................... 5-23

5.11. e-Mail .......................................................................................................................... 5-24

5.12. Recipes ........................................................................................................................ 5-27

5.13. Cellular Data Network ................................................................................................ 5-29

Window Operations .............................................................................................................. 6-1

6.1. Overview ....................................................................................................................... 6-1

6.2. Window Types .............................................................................................................. 6-1

6.3. Create, Set, and Delete a Window ................................................................................ 6-3

Event Log ............................................................................................................................... 7-1

7.1. Overview ....................................................................................................................... 7-1

7.2. Event Log Management ................................................................................................ 7-1

7.3. Creating a New Event Log ............................................................................................. 7-4

Data Sampling ....................................................................................................................... 8-1

8.1. Overview ....................................................................................................................... 8-1

8.2. Data Sampling Management ........................................................................................ 8-1

8.3. Creating a New Data Sampling ..................................................................................... 8-1

Object General Properties .................................................................................................... 9-1

9.1. Overview ....................................................................................................................... 9-1

9.2. Selecting PLC and Setting Read/Write Address ............................................................ 9-1

9.3. Using Shape Library and Picture Library ....................................................................... 9-2

9.4. Setting Label Text .......................................................................................................... 9-5

9.5. Adjusting Profile Size .................................................................................................... 9-7

User Password and Object Security .................................................................................... 10-1

10.1. Overview ..................................................................................................................... 10-1

10.2. User Password and Operable Object Classes ............................................................. 10-1

10.3. Enhanced Security Mode and Control Address .......................................................... 10-2

10.4. Enhanced Security Mode Usage ................................................................................. 10-6

10.5. Object Security Settings ............................................................................................ 10-11

10.6. Example of Object Security Settings ......................................................................... 10-13

10.7. Protecting Password Settings from Unauthorized Editing ....................................... 10-16

Index Register ..................................................................................................................... 11-1

11.1. Overview ..................................................................................................................... 11-1

11.2. Examples of Index Register ......................................................................................... 11-2

Keyboard Design and Usage ............................................................................................... 12-1

12.1. Overview ..................................................................................................................... 12-1

12.2. Steps to Design a Popup Keyboard ............................................................................. 12-1

12.3. Steps to Design a Keyboard with Direct Window ....................................................... 12-4

12.4. Steps to Design a Fixed Keyboard on Screen .............................................................. 12-5

Crouzet Touch Soft

Page 4

Crouzet Touch Soft User Manual

12.5. Steps to Design a UNICODE Keyboard ........................................................................ 12-6

Objects ................................................................................................................................ 13-1

13.1. Bit Lamp ...................................................................................................................... 13-1

13.2. Word Lamp ................................................................................................................. 13-3

13.3. Set Bit .......................................................................................................................... 13-7

13.4. Set Word ..................................................................................................................... 13-9

13.5. Function Key ............................................................................................................. 13-17

13.6. Toggle Switch ............................................................................................................ 13-21

13.7. Multi-State Switch .................................................................................................... 13-23

13.8. Slider ......................................................................................................................... 13-26

13.9. Numeric .................................................................................................................... 13-30

13.10. ASCII .......................................................................................................................... 13-44

13.11. Indirect Window ....................................................................................................... 13-47

13.12. Direct Window .......................................................................................................... 13-50

13.13. Moving Shape ........................................................................................................... 13-54

13.14. Animation ................................................................................................................. 13-58

13.15. Bar Graph .................................................................................................................. 13-62

13.16. Meter Display ............................................................................................................ 13-67

13.17. Trend Display ............................................................................................................ 13-72

13.18. History Data Display .................................................................................................. 13-77

13.19. Data Block Display .................................................................................................... 13-83

13.20. XY Plot ....................................................................................................................... 13-91

13.21. Alarm Bar and Alarm Display .................................................................................... 13-97

13.22. Event Display ........................................................................................................... 13-102

13.23. Data Transfer (Trigger-based) ................................................................................. 13-111

13.24. Backup .................................................................................................................... 13-113

13.25. Media Player ........................................................................................................... 13-119

13.26. Data Transfer ........................................................................................................... 13-125

13.27. PLC Control ............................................................................................................. 13-129

13.28. Scheduler ................................................................................................................ 13-136

13.29. Option List ............................................................................................................... 13-145

13.30. Timer ....................................................................................................................... 13-153

13.32. System Message ..................................................................................................... 13-157

13.33. Recipe View ............................................................................................................ 13-159

13.34. Flow Block ............................................................................................................... 13-165

13.35. Operation Log ......................................................................................................... 13-169

13.36. Combo Button......................................................................................................... 13-181

13.37. Circular Trend Display ............................................................................................. 13-184

Crouzet Touch Soft

Page 5

Crouzet Touch Soft User Manual

13.38. Picture View ............................................................................................................ 13-193

13.39. File Browser ............................................................................................................ 13-196

13.40. Import/Export ......................................................................................................... 13-199

13.41. Pie Chart ................................................................................................................. 13-203

13.42. 2D Barcode Display ................................................................................................. 13-205

13.43. String Table ............................................................................................................. 13-207

13.44. Dynamic Scale ......................................................................................................... 13-209

13.45. Dynamic Drawing .................................................................................................... 13-212

13.46. Table ........................................................................................................................ 13-217

13.47. VNC Viewer ............................................................................................................. 13-219

13.48. Contact Editor ......................................................................................................... 13-223

Shape Library and Picture Library ....................................................................................... 14-1

14.1. Overview ..................................................................................................................... 14-1

14.2. Building Shape Library ................................................................................................ 14-1

14.3. Building Picture Library ............................................................................................... 14-8

Label Tag Library and Multi-Language ................................................................................ 15-1

15.1. Overview ..................................................................................................................... 15-1

15.2. Label Tag Library Manager .......................................................................................... 15-1

15.3. Steps to create Label Tag Library ................................................................................ 15-2

15.4. Using Label Tag Library ............................................................................................... 15-3

15.5. Settings of Multi-Language ......................................................................................... 15-4

Address Tag Library ............................................................................................................. 16-1

16.1. Overview ..................................................................................................................... 16-1

16.2. Building Address Tag Library ....................................................................................... 16-1

16.3. Using Address Tag Library ........................................................................................... 16-3

Transferring Recipe Data ..................................................................................................... 17-1

17.1. Overview ..................................................................................................................... 17-1

17.2. Steps to Update Recipe Data with Ethernet or USB Cable ......................................... 17-1

17.3. Steps to Update Recipe Data with SD Card or USB Disk ............................................. 17-2

17.4. Transferring Recipe Data ............................................................................................. 17-3

17.5. Saving Recipe Data Automatically .............................................................................. 17-4

Macro Reference ................................................................................................................. 18-1

18.1. Overview ..................................................................................................................... 18-1

18.2. Instructions to use the Macro Editor .......................................................................... 18-1

18.3. Configuration .............................................................................................................. 18-7

18.4. Syntax .......................................................................................................................... 18-8

18.5. Statement ................................................................................................................. 18-13

18.6. Function Blocks ......................................................................................................... 18-18

Crouzet Touch Soft

Page 6

Crouzet Touch Soft User Manual

18.7. Built-In Function Block .............................................................................................. 18-21

18.8. How to Create and Execute a Macro ........................................................................ 18-81

18.9. User Defined Macro Function................................................................................... 18-86

18.10. Some Notes about Using the Macro ........................................................................ 18-99

18.11. Use the Free Protocol to Control a Device ............................................................. 18-100

18.12. Compiler Error Message ......................................................................................... 18-105

18.13. Sample Macro Code ................................................................................................ 18-110

18.14. Macro TRACE Function ........................................................................................... 18-115

18.15. Example of String Operation Functions .................................................................. 18-119

18.16. Macro Password Protection .................................................................................... 18-127

Configure HMI as a MODBUS Server .................................................................................. 19-1

19.1. Overview ..................................................................................................................... 19-1

19.2. Steps to Create a MODBUS Server ............................................................................. 19-1

19.3. Steps to Access a MODBUS Server ............................................................................. 19-4

19.4. Changing MODBUS Server Station Number Online.................................................... 19-6

19.5. MODBUS Address Type ............................................................................................... 19-6

How to Connect a Barcode Reader ..................................................................................... 20-1

20.1. Overview ..................................................................................................................... 20-1

20.2. Steps to Connect a Barcode Reader ........................................................................... 20-1

Ethernet Communication and Multi-HMI Connection ....................................................... 21-1

21.1. Overview ..................................................................................................................... 21-1

21.2. HMI to HMI Communication ...................................................................................... 21-2

21.3. PC to HMI Communication ......................................................................................... 21-3

System Registers ................................................................................................................. 22-4

22.1. Overview ..................................................................................................................... 22-4

22.2. The Address Ranges of Local HMI .............................................................................. 22-5

22.3. System Registers ......................................................................................................... 22-6

HMI Supported Printers ...................................................................................................... 23-1

23.1. The Supported Printer Types ...................................................................................... 23-1

23.2. Steps to Add a New Printer and Start Printing ........................................................... 23-4

Recipe Editor ....................................................................................................................... 24-1

24.1. Overview ..................................................................................................................... 24-1

24.2. Recipe / Extended Memory Editor Setting ................................................................. 24-1

24.3. Recipe Records Setting ............................................................................................... 24-3

EasyConverter ..................................................................................................................... 25-1

25.1. Overview ..................................................................................................................... 25-1

25.2. Converting Data Log File to Excel File ......................................................................... 25-1

25.3. Converting Event Log File to Excel File ....................................................................... 25-3

Crouzet Touch Soft

Page 7

Crouzet Touch Soft User Manual

25.4. Converting Operation Log File to Excel File ................................................................ 25-4

25.5. Converting Multiple Files ............................................................................................ 25-6

25.6. Scaling Function .......................................................................................................... 25-7

25.7. Batch File .................................................................................................................... 25-8

EasyPrinter .......................................................................................................................... 26-1

26.1. Overview ..................................................................................................................... 26-1

26.2. Using EasyPrinter as a Printer Server ......................................................................... 26-2

26.3. Using EasyPrinter as a Backup Sever .......................................................................... 26-5

26.4. EasyPrinter Operation Guide ...................................................................................... 26-9

26.5. Convert Batch File ..................................................................................................... 26-14

EasySimulator...................................................................................................................... 27-1

27.1. Overview ..................................................................................................................... 27-1

27.2. Steps to setup EasySimulator ..................................................................................... 27-1

Multi-HMI Communication (Master Slave Mode) .............................................................. 28-1

28.1. Overview ..................................................................................................................... 28-1

28.2. Steps to Create a Project of Master HMI .................................................................... 28-1

28.3. Steps to Create a Project of Slave HMI ....................................................................... 28-2

Project Protection ............................................................................................................... 29-1

29.1. Overview ..................................................................................................................... 29-1

29.2. EXOB Password ........................................................................................................... 29-1

29.3. Decompilation is Prohibited ....................................................................................... 29-2

29.4. Disable EXOB Upload Function ................................................................................... 29-3

29.5. Project Key .................................................................................................................. 29-3

29.6. EMTP Password .......................................................................................................... 29-4

Memory Map ...................................................................................................................... 30-1

30.1. Overview ..................................................................................................................... 30-1

30.2. PIN Settings ................................................................................................................. 30-1

30.3. Communication Flowchart ......................................................................................... 30-2

30.4. Address Types ............................................................................................................. 30-3

30.5. Settings ....................................................................................................................... 30-6

FTP Server Application ........................................................................................................ 31-1

31.1. Overview ..................................................................................................................... 31-1

31.2. Steps to Log in FTP Server .......................................................................................... 31-1

31.3. Backup History Data and Update Recipe Data ........................................................... 31-2

EasyDiagnoser ..................................................................................................................... 32-1

32.1. Overview ..................................................................................................................... 32-1

32.2. Configuration .............................................................................................................. 32-1

32.3. EasyDiagnoser Settings ............................................................................................... 32-3

Crouzet Touch Soft

Page 8

Crouzet Touch Soft User Manual

32.4. Error Code ................................................................................................................... 32-9

32.5. Window Adjustment ................................................................................................. 32-10

EasyWatch ........................................................................................................................... 33-1

33.1. Overview ..................................................................................................................... 33-1

33.2. Configuration .............................................................................................................. 33-2

33.3. Monitor Settings ......................................................................................................... 33-3

33.4. Macro Settings ............................................................................................................ 33-8

33.5. HMI Manager .............................................................................................................. 33-9

33.6. Object List ................................................................................................................. 33-11

Administrator Tools ............................................................................................................. 34-1

34.1. Overview ..................................................................................................................... 34-1

34.2. User Accounts ............................................................................................................. 34-2

34.3. USB Security Key ......................................................................................................... 34-6

34.4. e-Mail SMTP Server Settings ...................................................................................... 34-9

34.5. e-Mail Contacts ......................................................................................................... 34-10

EasyDownload ..................................................................................................................... 35-1

35.1. Overview ..................................................................................................................... 35-1

35.2. Configuration .............................................................................................................. 35-1

Data Security ....................................................................................................................... 36-1

36.1. Overview ..................................................................................................................... 36-1

36.2. Configuration .............................................................................................................. 36-1

Crouzet Touch Soft

Page 9

Crouzet Touch Soft Installation and Startup Guide

1-1

Crouzet Touch Soft Installation and Startup Guide

This chapter explains how to install Crouzet Touch Soft.

1.1. Installation Requirements

Software:

Download Crouzet Touch Soft from USB KEY or visit Crouzet website at

http://www.crouzet.com. The language versions include Simplified Chinese, Traditional

Chinese, English, Japanese, German, Italian, Korean, Spanish, Russian, French, and Turkish. The

latest upgraded files can be downloaded too.

Hardware (Recommended):

CPU: INTEL Pentium II or higher

Memory: 256MB or higher

Hard Disk: 2.5GB or higher (Disc space available at least 500MB)

Display: 1024 x 768 resolution or greater

Keyboard and Mouse

Ethernet: for project downloading/uploading

USB Port 2.0: for project downloading/uploading

RS-232 COM: for on-line simulation

Printer

Operating System:

Windows XP / SP3

Windows Vista

Windows 7 (32bit / 64bit)

Windows 8 (32bit / 64bit)

Windows 8.1 (32bit / 64bit)

Windows 10 (32bit / 64bit)

Crouzet Touch Soft

Page 10

Crouzet Touch Soft Installation and Startup Guide

1-2

1.2. Steps to Install Crouzet Touch Soft

1. Insert the UB Key your PC. Select the folder “Crouzet Touch Soft Vxx”and run

“Setup_Crouzet_Touch_Soft_Vxx.exe”.

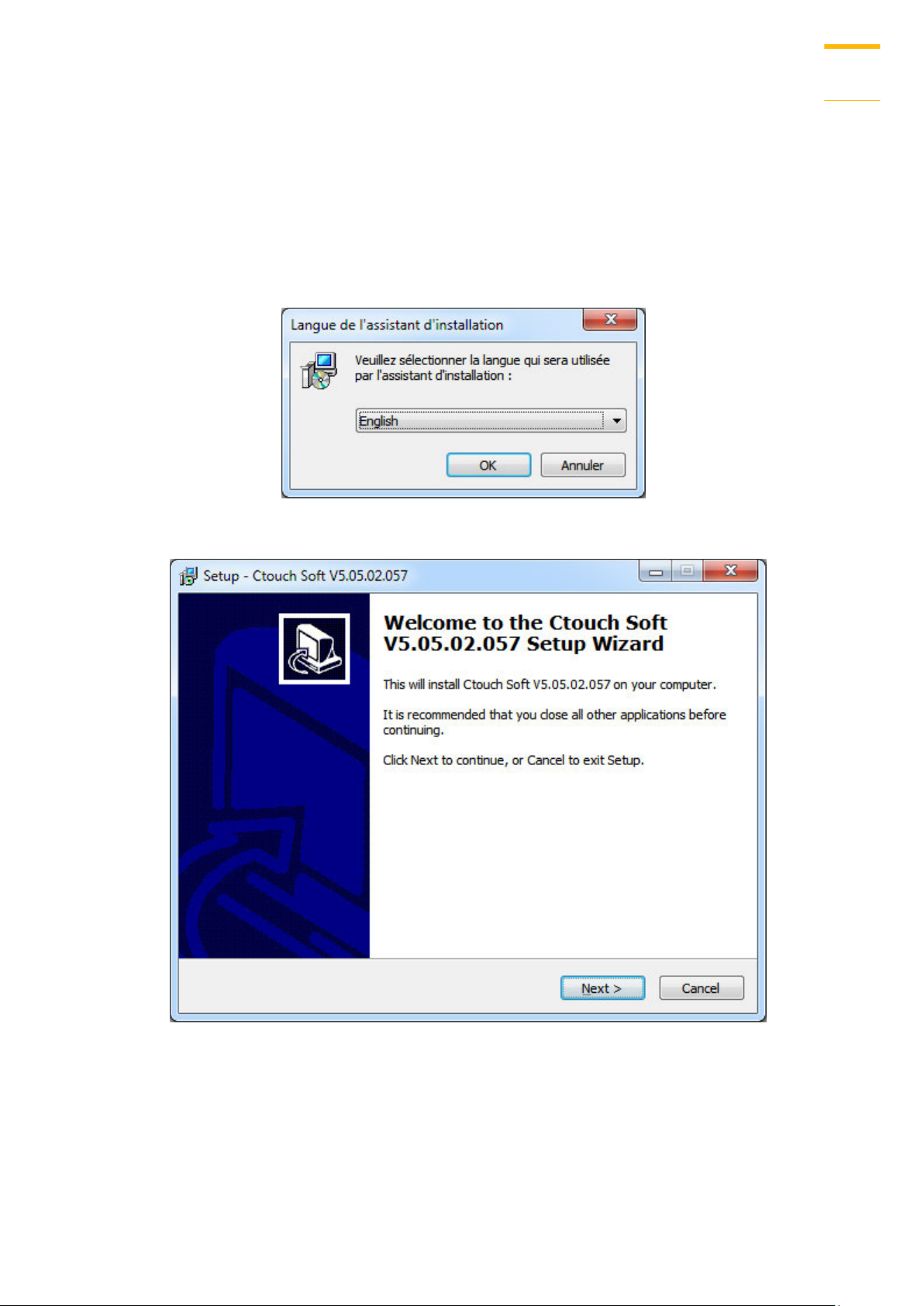

2. The installation screen is shown as the following figure.

3. Click [Install] and select the language for the installation process, and then click [Next].

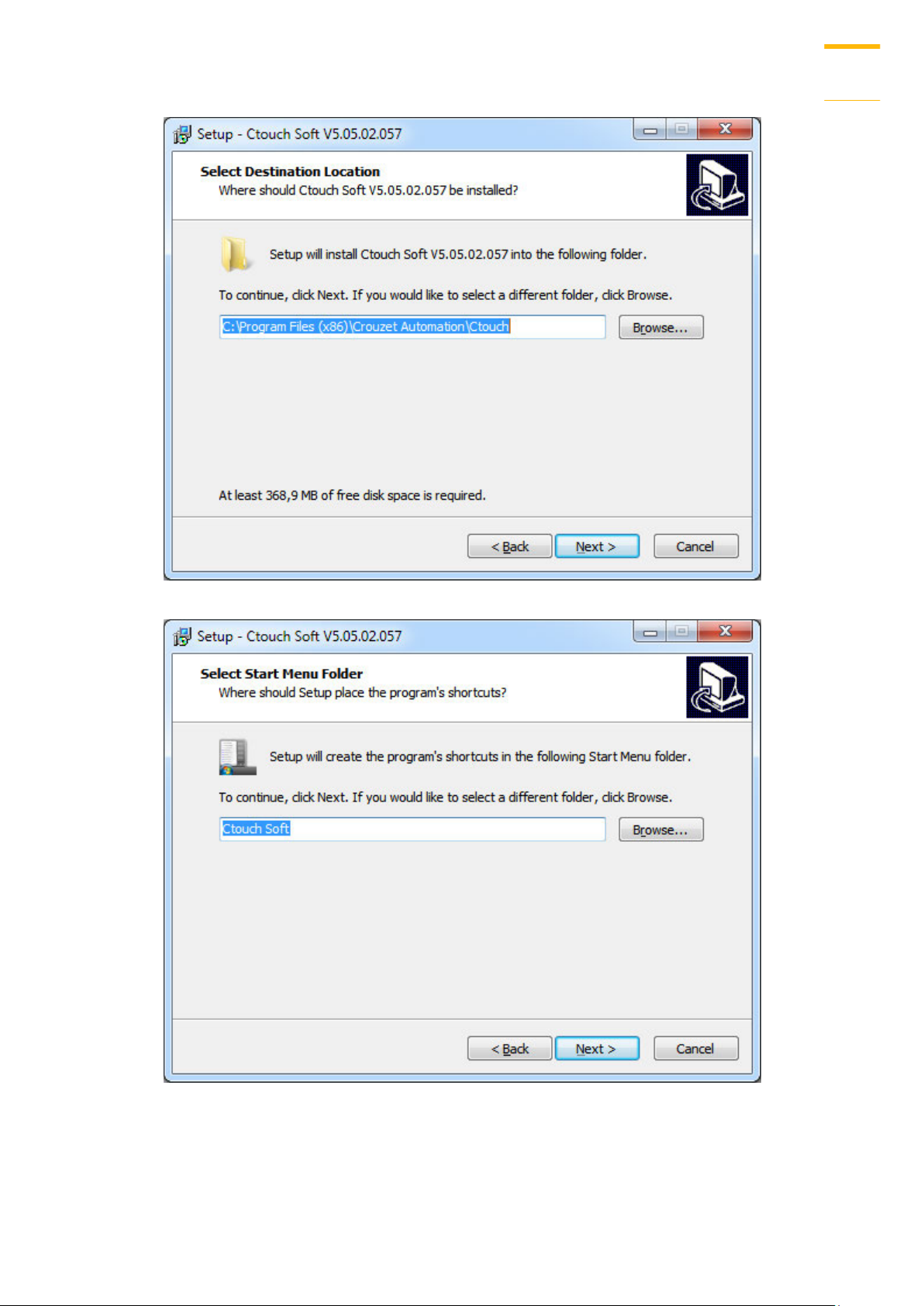

4. If there is a previous version of Crouzet Touch Soft on the PC, please remove it before

installation.

5. Select a folder for Crouzet Touch Soft installation, or use the default folder. Click [Next].

Crouzet Touch Soft

Page 11

Crouzet Touch Soft Installation and Startup Guide

1-3

6. Select a start menu folder, or use the defulat folder. Click [Next].

Crouzet Touch Soft

Page 12

Crouzet Touch Soft Installation and Startup Guide

1-4

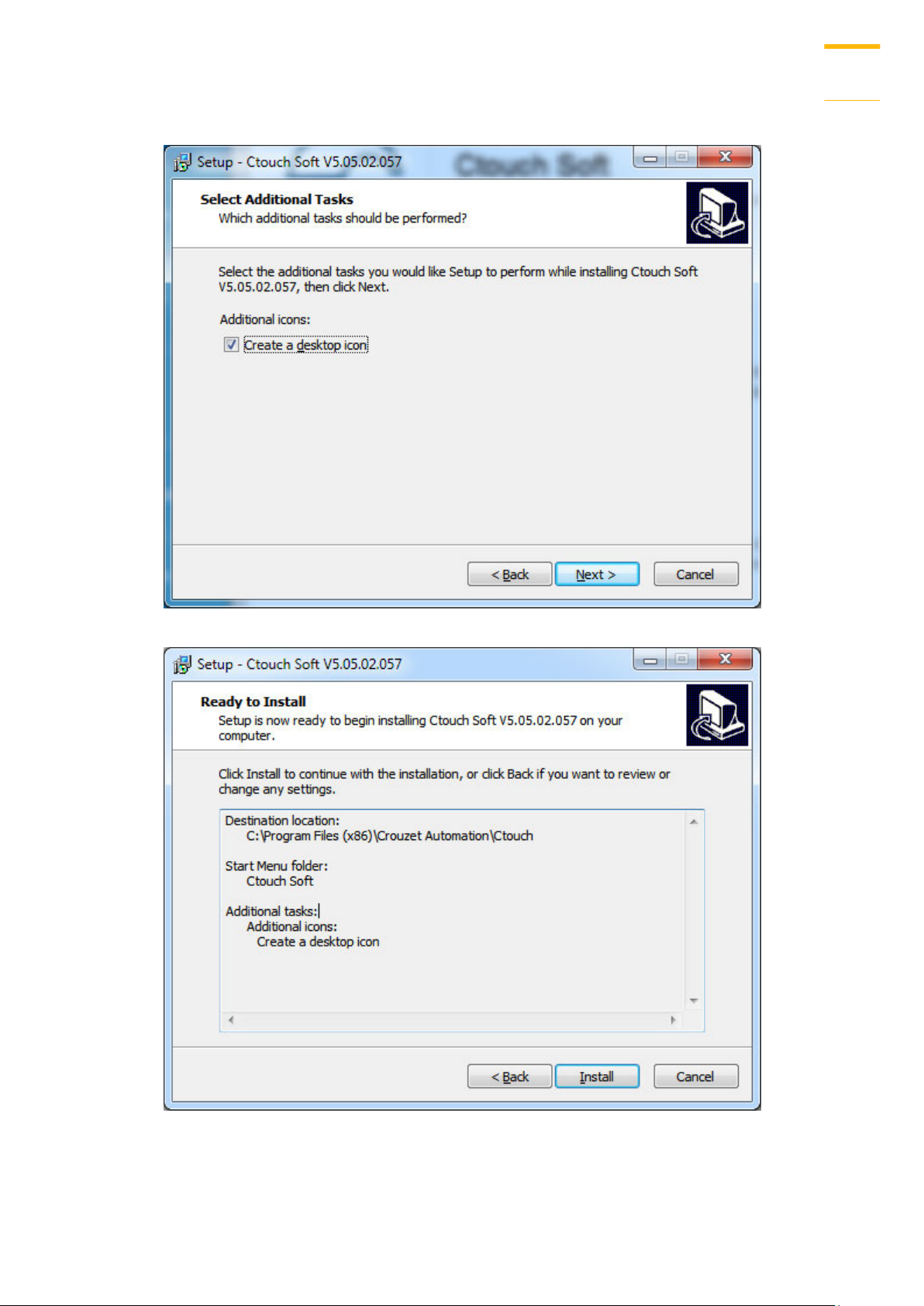

7. Select additional tasks, for example: [Create a desktop icon]. Click [Next].

8. Confirm all setting. To change the setting, click [Back]. To start installation, click [Install].

Crouzet Touch Soft

Page 13

Crouzet Touch Soft Installation and Startup Guide

1-5

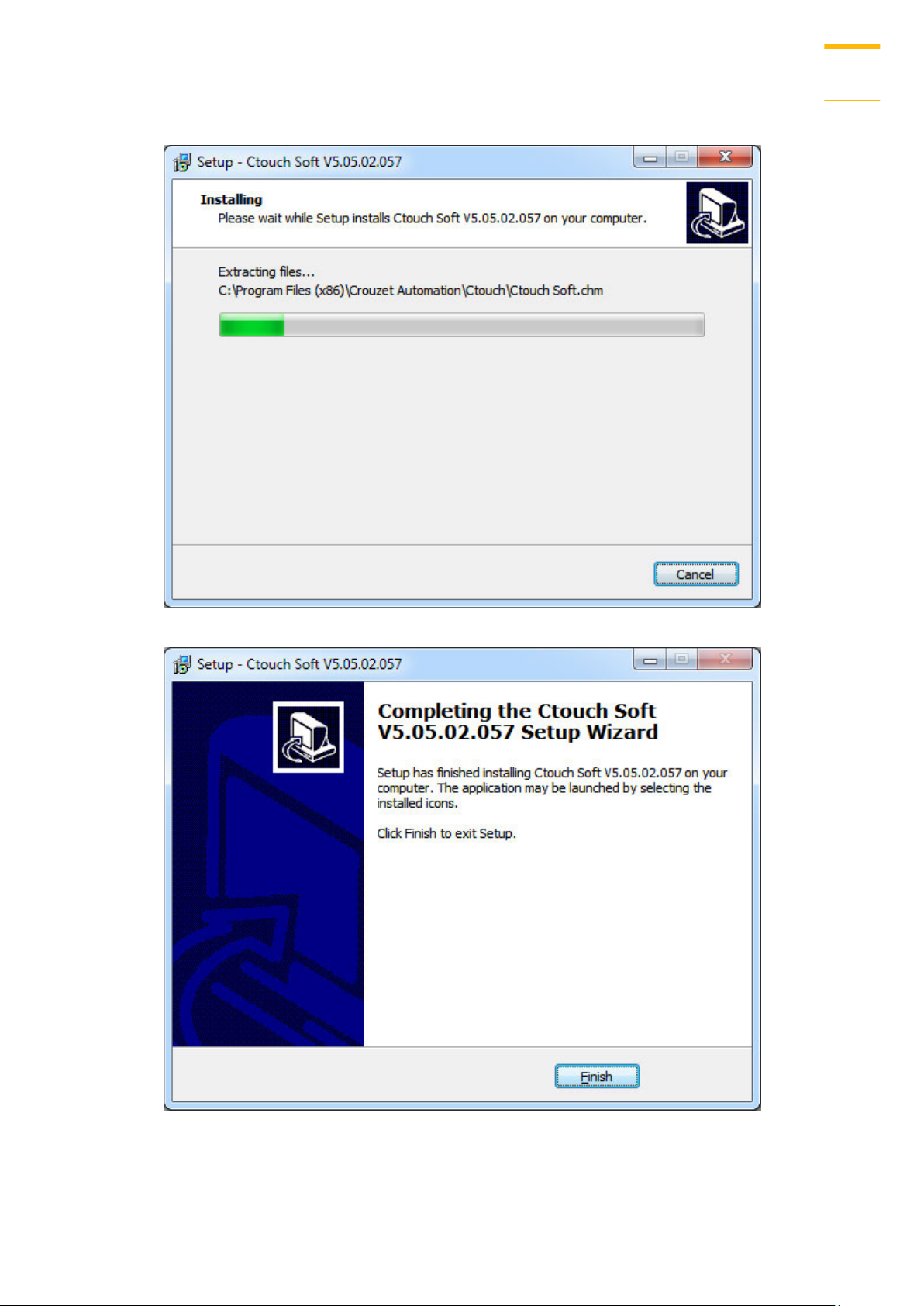

9. Installation progress.

10. Click [Finish] to complete the installation.

Crouzet Touch Soft

Page 14

Crouzet Touch Soft Installation and Startup Guide

1-6

Installed file

Description

Administrator Tools

Saves the data of User Accounts, USB Security Key,

e-Mail SMTP Server Setting, e-Mail Contacts to USB

disk and import to HMI.

Crouzet Touch Soft

Crouzet Touch Soft project editor.

EasyConverter

Conversion tool for Data Sampling and Event Log.

EasyDiagnoser

Monitoring and debugging tool operated on HMI.

EasyPrinter

Remote screen hardcopy and backup server.

EasySimulator

Executes simulation.

EasySystemSetting

Allows updating hardware system settings by using

SD card or USB drive.

EasyWatch

On PC to monitor or set HMI and PLC address value.

Recipe Editor

Tool for setting the format of Recipe data. Users can

open Recipe data or data in the External Memory.

Release Note

Software release notes.

Structure Editor

Supports AB TAG and improve the flexibility to read /

write an object.

Uninstall Crouzet

Touch Soft

Utility Manager

Crouzet Touch Soft management tool.

11. The Crouzet Touch Soft shortcut can be found in [Start] » [All Programs] » [Crouzet Touch

Soft].

The description of each item in Crouzet Touch Soft menu:

Note

HMI supports downloading/uploading projects via USB cable. After installing

Crouzet Touch Soft, the USB driver will be automatically installed. A message saying

“Windows can’t verify the publisher of this driver” may show, please continue anyway.

After installing the USB driver, open [Computer Management] » [Device Manager] to

check if installation succeeded.

Crouzet Touch Soft

Page 15

Utility Manager

2-1

Utilities

Description

Select Model

Select your HMI model. Please note that if the model is incorrect,

certain features may not work correctly.

Design

Crouzet Touch Soft: Launch Crouzet Touch Soft to edit projects.

EasyAddressViewer: Review the address ranges and formats of

supported PLCs.

Simulation: Simulate a HMI on PC by On-line Simulation (with

Utility Manager

This chapter explains how to use Utility Manager.

2.1. Overview

After installing Crouzet Touch Soft, double click [UtilityManagerEx] shortcut on the desktop to

start. Utility Manager is for launching several utilities and it is a stand-alone program.

Crouzet Touch Soft

Page 16

Utility Manager

2-2

PLC) or Off-line Simulation (without PLC).

Analysis & Testing

EasyDiagnoser: On-line monitoring and debugging tool. Diagnose

the connection status between PC/HMI and PLC.

See “33 EasyDiagnoser”.

EasyWatch: Allows users to monitor HMI or PLC address values

via Ethernet on PC.

See “35 EasyWatch”.

Reboot HMI: Restart a HMI to its initial condition by Ethernet or

USB connection.

Pass-Through: Allows PC applications to control PLC via HMI. In

this case the HMI is an adaptor.

See “29 Pass-through”.

Publish

Download: Download project file to HMI via Ethernet.

Upload: Upload files on HMI to PC via Ethernet.

Build Download Data for SD/USB Disk:

Build the data to be saved in SD card / USB drive and then insert

the device to HMI to download the data.

Maintenance

EasyPrinter, Backup/Printer Server: A backup/printer server on

PC, which receives backups from HMI and run a defined batch to

convert, or HMI screenshots to print out on PC.

Administrator Tools: Allows storing the data of [User Accounts],

[USB Security Key], [e-Mail SMTP Server Settings], and [e-Mail

Contacts] to USB.

See “36 Administrator Tools”.

Data/Event log Information: Connect with HMI via USB cable or

Ethernet to check the number of history files in HMI.

Data Conversion

Database Editor: Used to edit recipe data.

Click the icon to download the document about Recipe

Database.

Easy Converter: Reads the data sampling file (.dtl) and event log

file (.evt) in HMI and convert the files to Excel (.xls) format.

See “25 EasyConverter”.

Recipe Editor: Used to create, view, and edit recipe data.

See “24 Recipe Editor”.

Minimize the window.

Crouzet Touch Soft

Page 17

Utility Manager

2-3

Close the window.

Add the frequently used utilities to the toolbar at the bottom of

the window.

Run

Run the selected utility on the toolbar.

Edit

Delete the selected utility on the toolbar.

2.2. HMI IP, Password

Settings

When operating HMI via Ethernet or USB cable, please set the password for HMI to protect

against unauthorized access.

Set the download password. To use masking password, select [Mask] check box.

Note

Please remember the password, otherwise, while restoring HMI default settings, the

project files and data in HMI will be completely erased.

Reboot HMI

Reboot the HMI without unplugging. After reboot, the system returns to the initial state. Set

the correct IP address when rebooting HMI via Ethernet.

Data/Event Log File Information

After setting, connect with HMI to check the number of history files in HMI.

Crouzet Touch Soft

Page 18

Utility Manager

2-4

2.3. Editing Tools

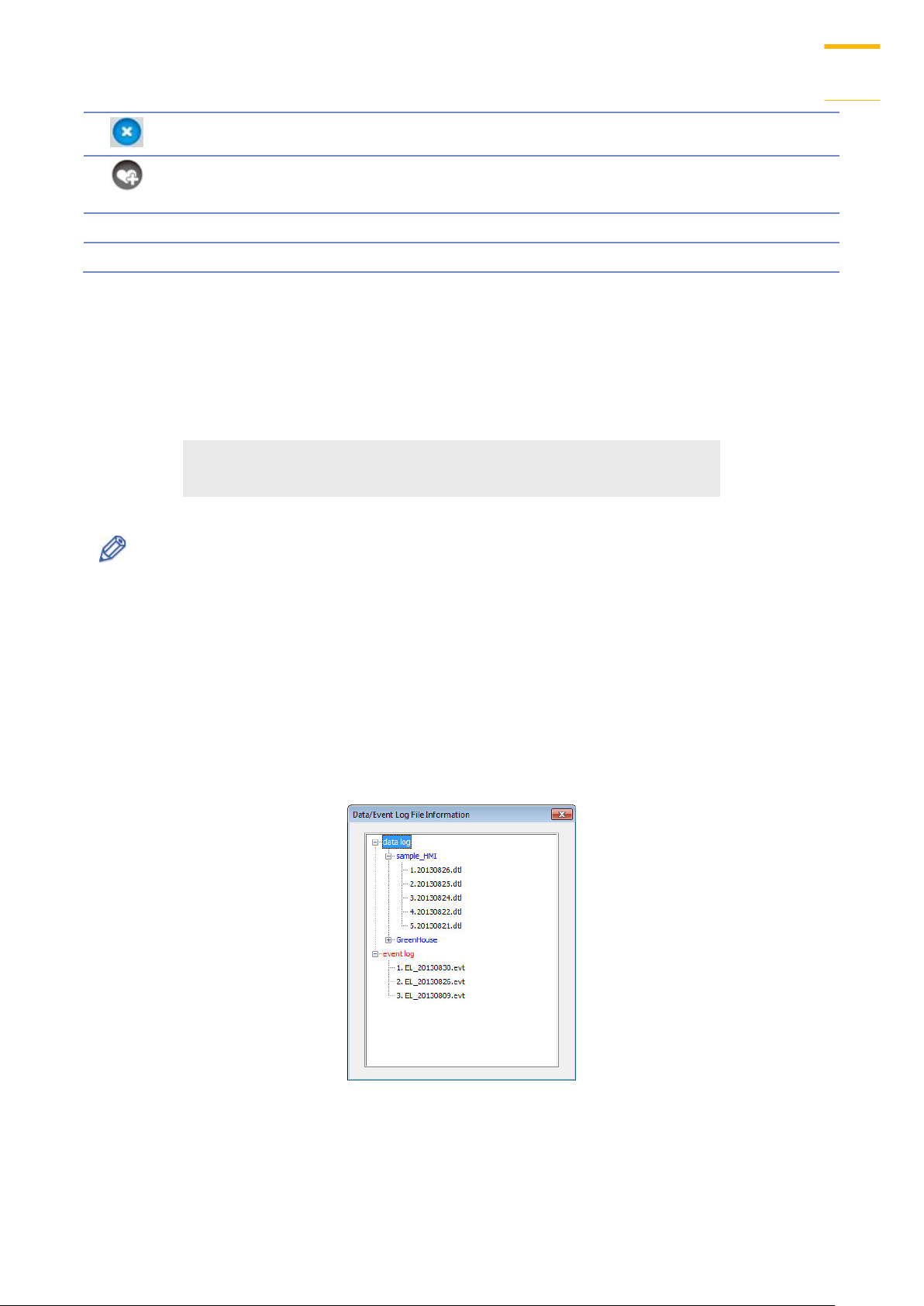

Build Download Data for SD/USB Disk

1. Insert an external device (SD card or USB drive) to PC.

2. Assign the directory to store data.

3. Select the directory of the source file.

4. Click [Build] to create files for downloading.

Files will then be store to the inserted device for users to download to HMI without connecting

via a USB cable or Ethernet.

Steps to Download Project to HMI via USB Disk or SD Card

Assume we will download data in the folder named “123” (K:\123) on an USB disk.

1. Insert USB (in which the project is saved) to HMI.

2. In [Download / Upload] dialog box select [Download].

3. Enter Download Password.

4. In [Download Settings] dialog box, select [Download project files] and [Download history

files] check boxes.

5. Press [OK].

6. In [Pick a Directory] dialog box, select directory: usbdisk\disk_a_1\123.

7. Press [OK].

Project will then be updated.

Crouzet Touch Soft

Page 19

Utility Manager

2-5

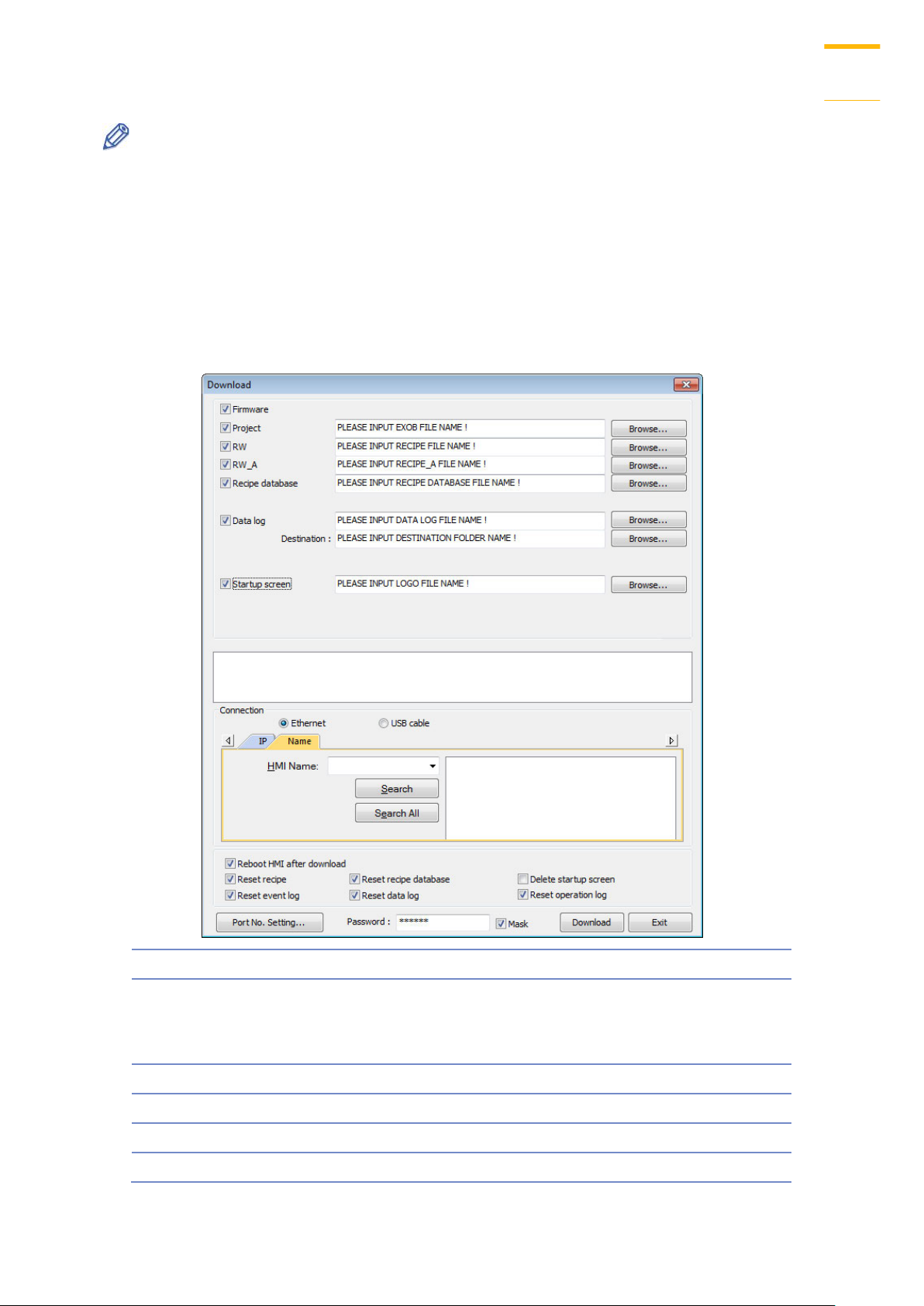

Setting

Description

Firmware

Update HMI kernel programs. The firmware

must be downloaded at the first time

downloading data to HMI.

Project

Select an .exob project file.

RW / RW_A

Select a .rcp recipe file.

Recipe database

Select a .db file of Recipe Database.

Data log

Select the data sampling folder in HMI and then

Note

If only the history files are downloaded, it is necessary to reboot HMI to update files.

2.4. Transfer

Download

Download files to HMI via Ethernet or USB cable.

Crouzet Touch Soft

Page 20

Utility Manager

2-6

select a .dtl file.

Startup screen

Download a .bmp bitmap file to HMI. After HMI

is rebooted, this .bmp file will be shown before

project starts.

Reboot HMI after

download

Automatically reboot after download.

Port No. Setting

Select the port by which to download the

project file via Ethernet.

Reset recipe / recipe

database / event log /

data log / operation log

/ Delete startup screen

Erase the selected files in HMI before download.

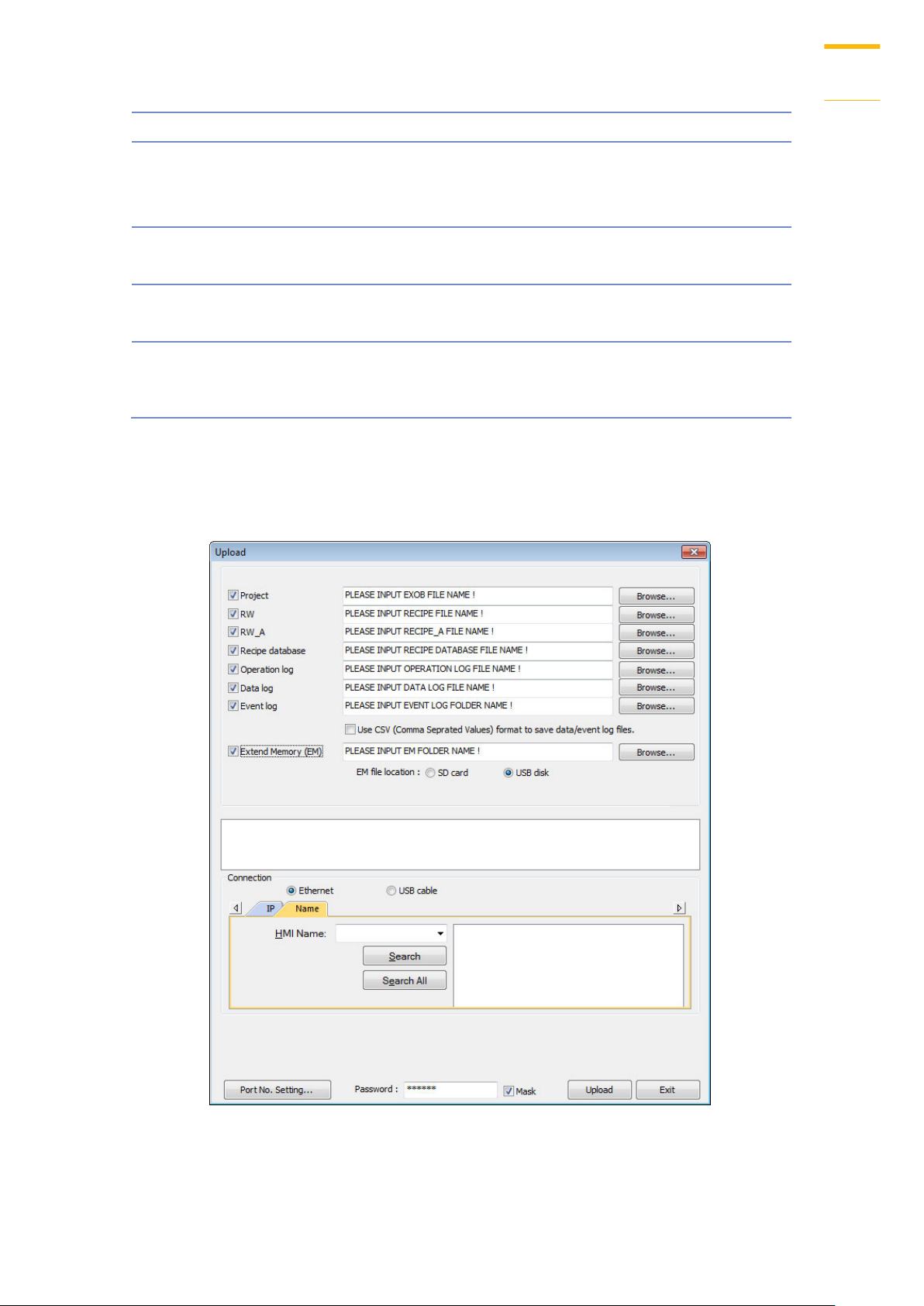

Upload

Upload files from HMI to PC via Ethernet or USB cable. Click [Browse] and assign the file path

before uploading.

Crouzet Touch Soft

Page 21

Utility Manager

2-7

Setting

Description

Event log

Upload the .evt file in HMI to PC.

Extended Memory

(EM)

Upload the .emi file saved in SD card or USB disk

to PC.

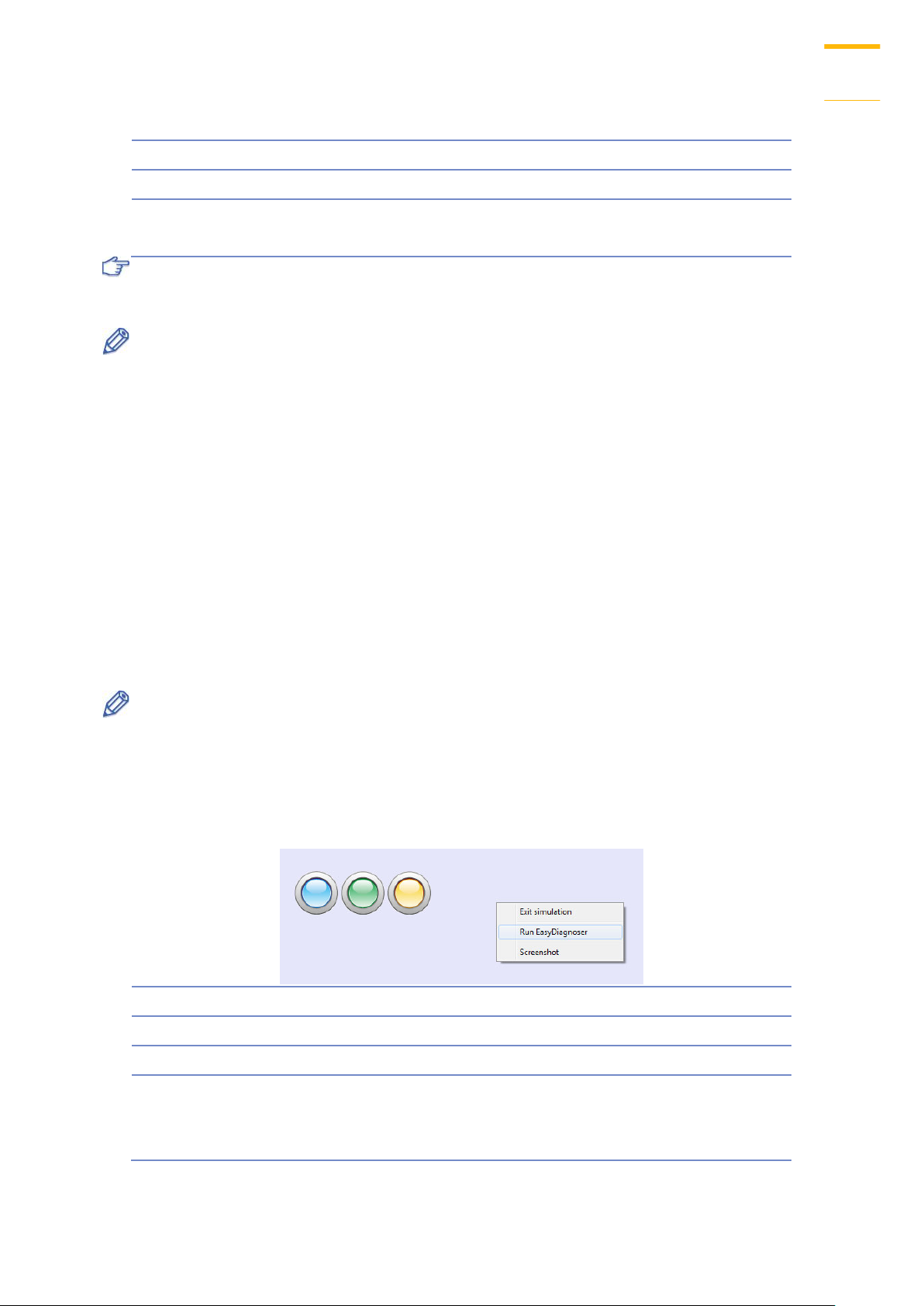

Setting

Description

Exit simulation

Stop simulating.

Run EasyDiagnoser

To monitor current communication status.

Screenshot

Capture and save current screen image as a

picture file in the screenshot folder under the

installation directory.

For information about [Project], [RW / RW_A], [Recipe database] or [Data log], see “2.4.1

Download” in this chapter.

Note

The file will be uploaded to PC in .exob format. Please decompile it into editable .emtp file

first and open the .emtp file in Crouzet Touch Soft.

To upload the historical files saved in the external device, please use FTP. See “32 FTP

Server Application” for more information.

2.5. Simulation

Off-line Simulation / On-line Simulation

Off-line simulation: Simulate project operation on PC without any connection.

On-line simulation: Simulate project operation on PC and PLCs are directly connected with PC.

Note

When using [On-line simulation] on PC, if the target device is a local PLC (the PLC directly

connected to PC), there is a 10 minutes simulation limit.

Before executing On-line/Off-line Simulation, please select the source .exob file.

When executing On-line/Off-line Simulation, right click to use these functions:

Crouzet Touch Soft

Page 22

Utility Manager

2-8

2.6. Pass-Through

This function allows the PC application to connect PLC via HMI. In this case, the HMI works like a

converter.

Pass-through provides two modes: [Ethernet] and [COM port].

When using [Ethernet], please install the virtual serial port driver first.

For more detail, please refer to “Chapter 29 Pass-Through Function”.

Crouzet Touch Soft

Page 23

Create an Crouzet Touch Soft Project

3-1

Create an Crouzet Touch Soft Project

This chapter explains the basic steps to create an Crouzet Touch Soft project.

3.1. Overview

The following is the process of creating a project.

1. Create a new project file.

2. Save and compile the project file.

3. Run On-line or Off-line simulation.

4. Download the project file to HMI.

The following describes each process.

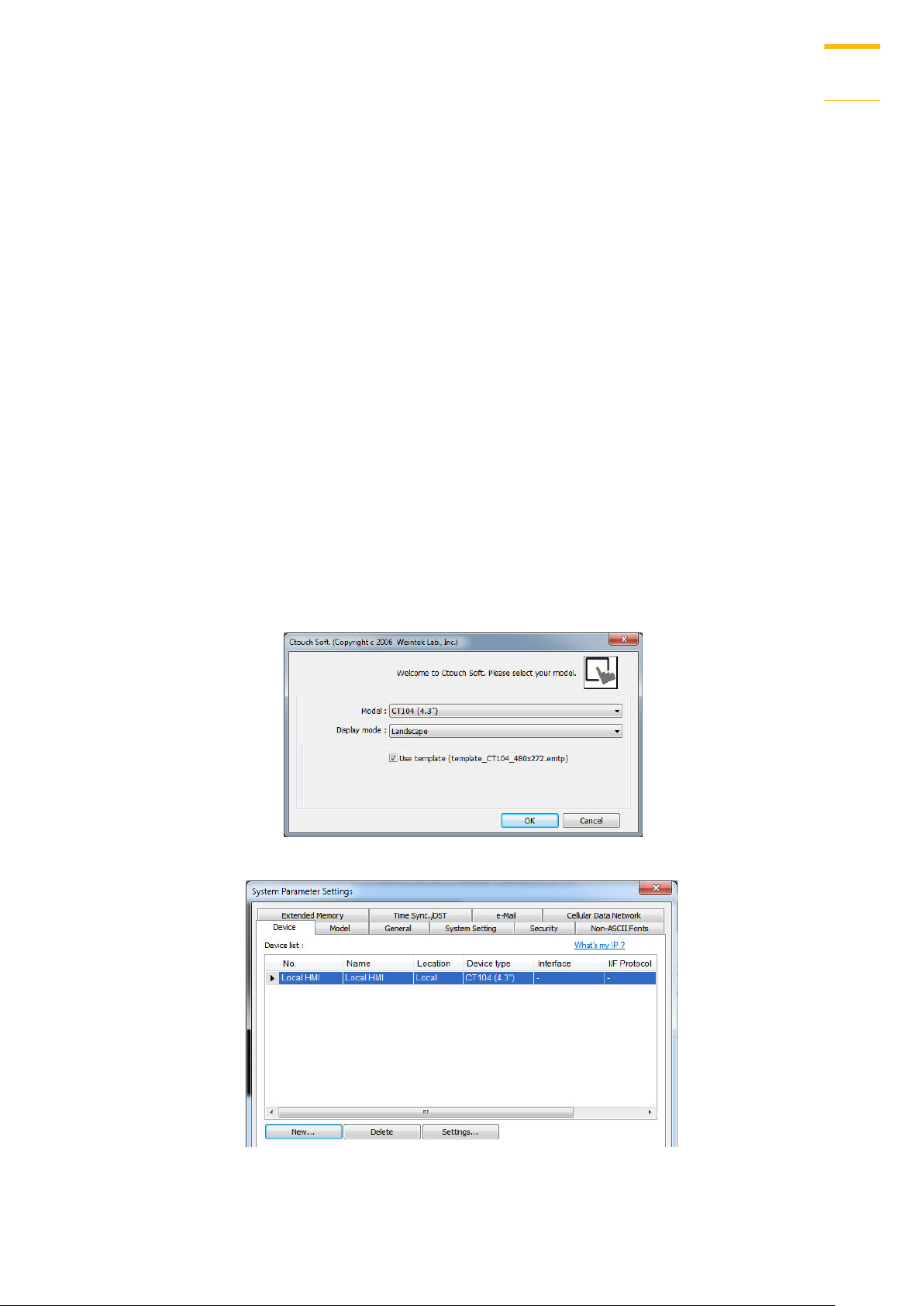

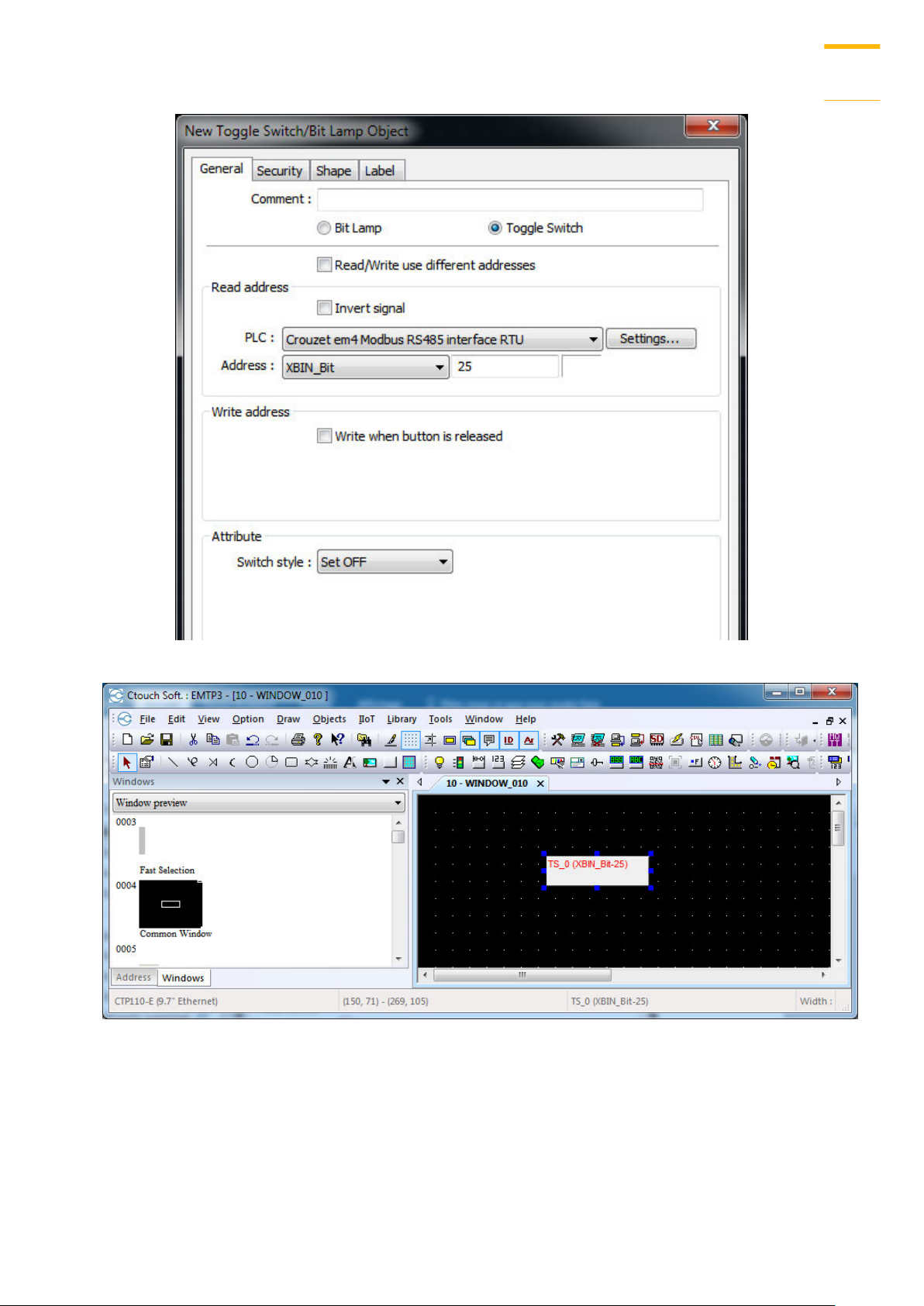

3.2. Create a New Project File

1. Launch Crouzet Touch Soft and open a new file.

2. Select [Model] and select [Use template] check box. Cilck OK

3. Click [New] to add a device.

Crouzet Touch Soft

Page 24

Create an Crouzet Touch Soft Project

3-2

4. Configure parameters.

5. A new device is added to the [Device List].

6. Create an object, take Toggle Switch as an example, and set the address.

Crouzet Touch Soft

Page 25

Create an Crouzet Touch Soft Project

3-3

7. Place the object in the edit window. A project is now created.

Crouzet Touch Soft

Page 26

Create an Crouzet Touch Soft Project

3-4

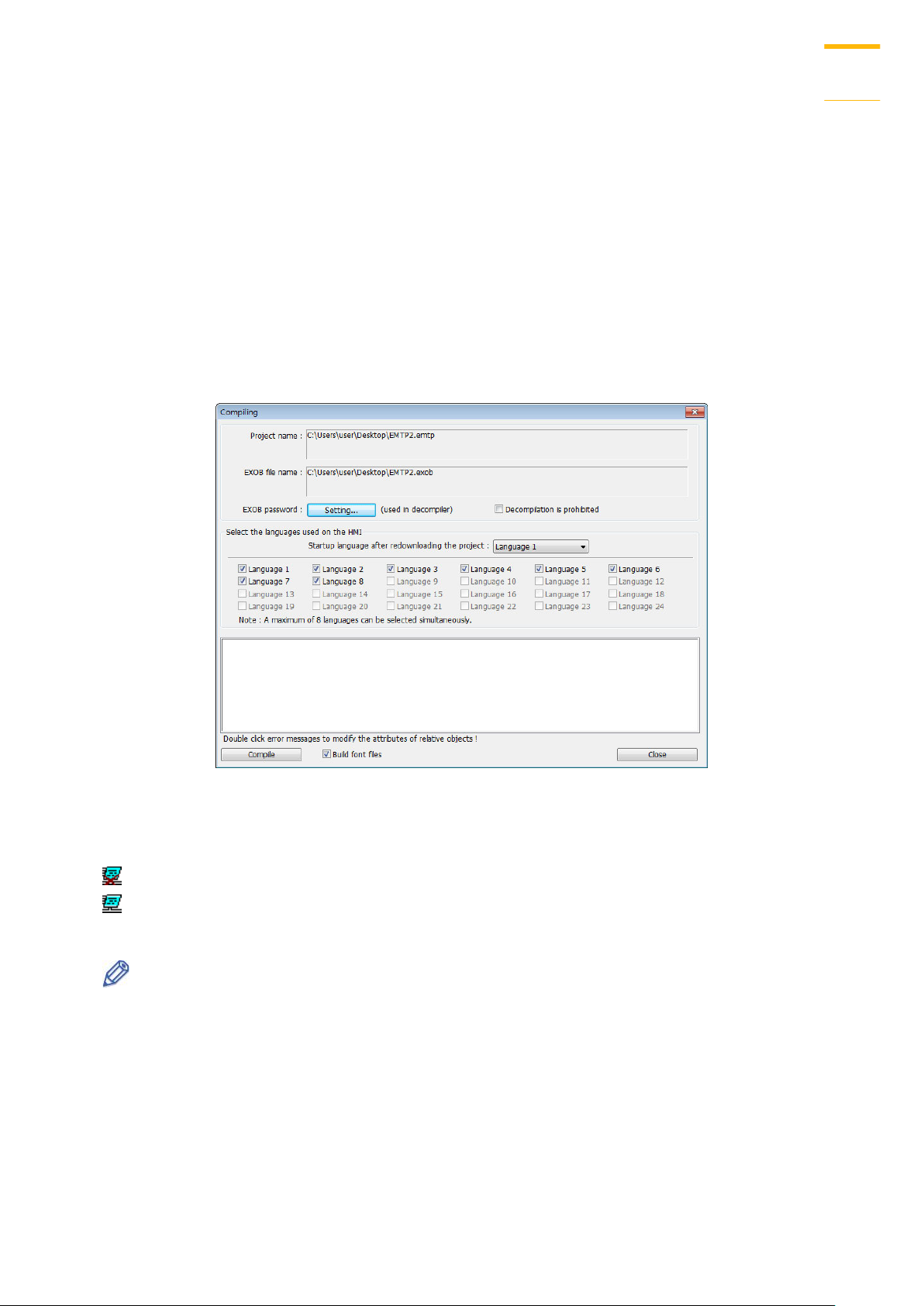

3.3. Save and Compile the Project File

1. In Crouzet Touch Soft toolbar click [File] » [Save] to save the .emtp file.

2. In Crouzet Touch Soft toolbar click [Tools] » [Compile] to compile .emtp file as .exob file,

which could be downloaded to HMI. This also checks if the project can run correctly.

3. To use multiple languages, all languages must be configured in Label Tag Library first.

When downloading the project to HMI, select the needed languages only. A successful

compilation is shown in the following figure.

3.4. Run On-Line or Off-Line Simulation

Off-line simulation: Simulate project operation on PC without connecting any device.

On-line simulation: Simulate project operation on PC without downloading the project to

HMI. The PLC is connected to PC, please set correct parameters.

Note

When using On-line Simulation on PC, if the target device is the PLC directly connected to

PC, there is a 10-minute simulation limit.

Crouzet Touch Soft

Page 27

Create an Crouzet Touch Soft Project

3-5

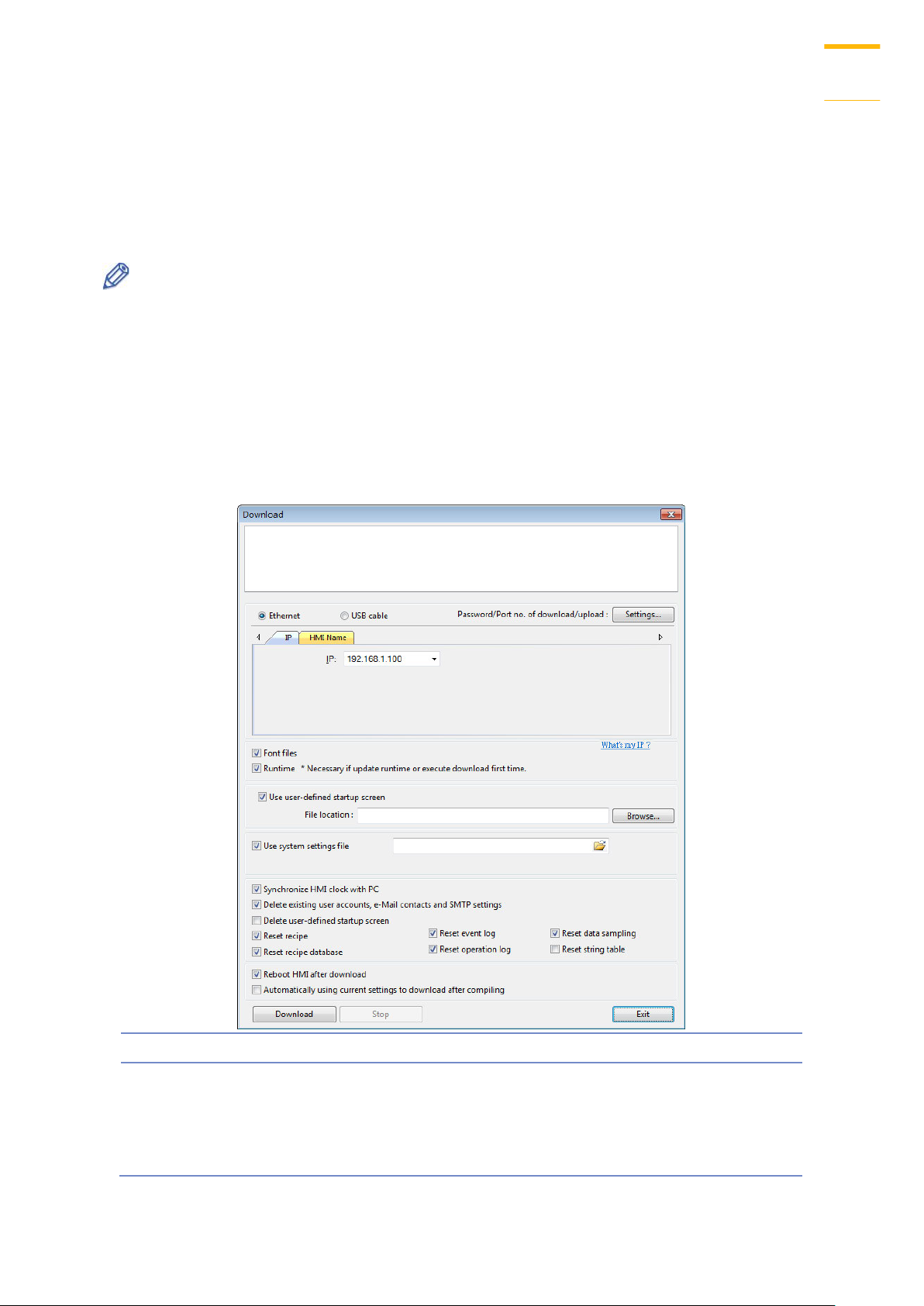

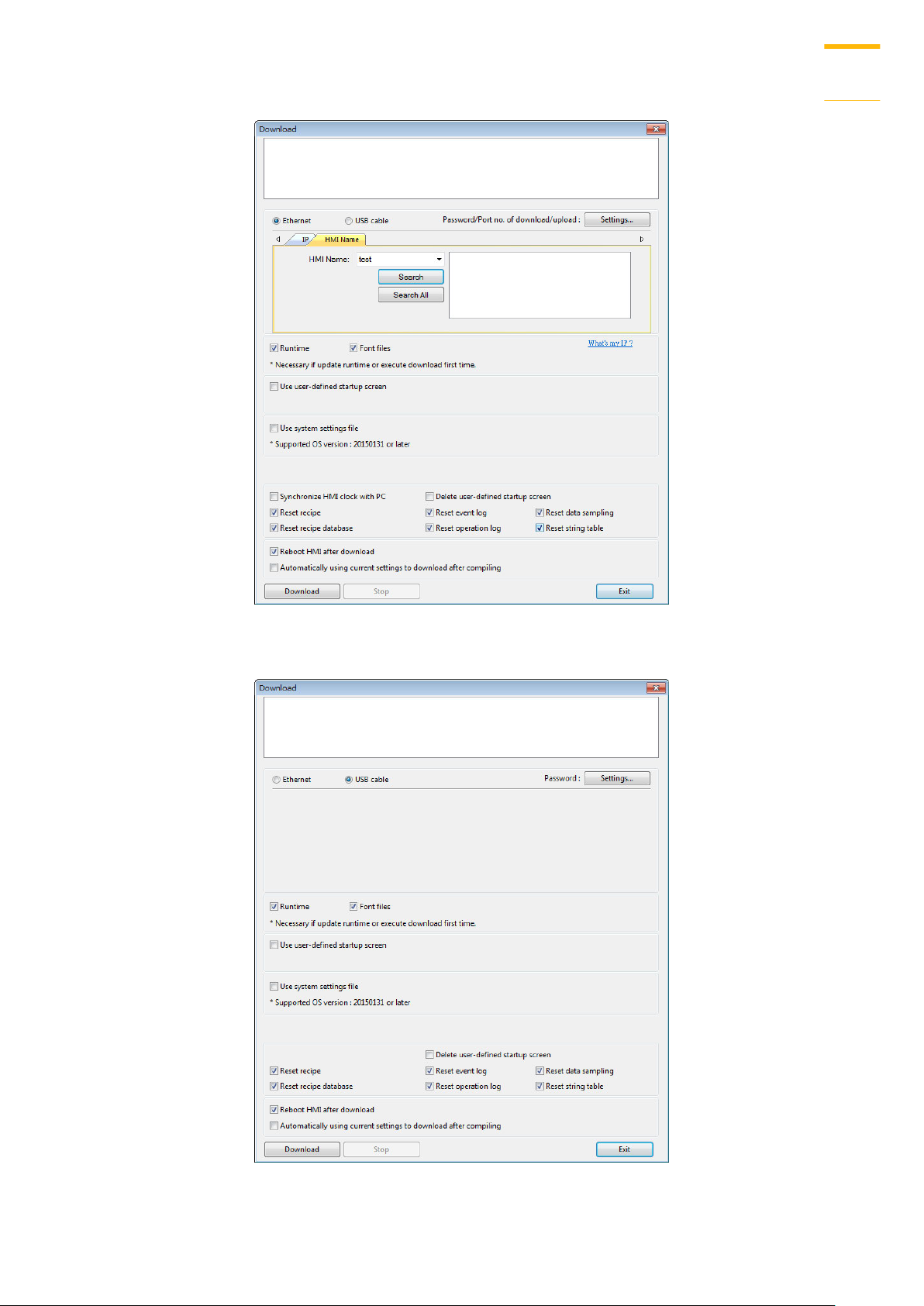

Setting

Description

Runtime

Select the check box to update the HMI kernel programs.

If this is the first time downloading file or Crouzet Touch

Soft version is updated, please download the firmware

before downloading files to HMI.

3.5. Download the Project File to HMI

The following explains four ways to download the project file to HMI.

Note

When download project file to HMI using mini USB cable, please do not connect PLC

simultaneously, in order to avoid noise from PLC interfering with HMI.

Configure in Crouzet Touch Soft

1. In Crouzet Touch Soft toolbar, click [Tools] » [Download]. Make sure that all the settings

are correct.

2. Select [Ethernet], set password and HMI IP.

Crouzet Touch Soft

Page 28

Create an Crouzet Touch Soft Project

3-6

Font files

Download the font used in the project.

Use user-defined

startup screen

Use the picture selected by user as the startup screen.

The picture format must be .bmp.

Use system

settings file

Download the system settings file to update hardware

settings.

Synchronize HMI

clock with PC

Synchronize HMI time with PC time when downloading

project file.

Delete existing

user accounts, eMail contacts

and SMTP

settings

Select the check box to delete existing user accounts, e-

Mail contacts or SMTP settings before downloading the

project. This setting is only effective when one of the

following settings is enabled:

1. [System Parameter Settings] » [Security] » [Enhanced

security mode] » [Use existing user accounts on HMI

first (if existed), Othrewise, use settings below].

2. [System Parameter Settings] » [e-Mail] » [Use existing

user accounts on HMI first (if existed), Othrewise, use

settings below].

Reset recipe/

event log/

data sampling/

recipe database/

operation log/

string table/

user-defined

startup screen

The selected files will be erased before downloading.

Reboot HMI

after download

HMI will reboot after the downloading process is done.

Automatically

using current

settings to

download after

compiling

The system will compile the project and download it to

the latest target HMI. The way to enable this function is

described in the following part.

Note

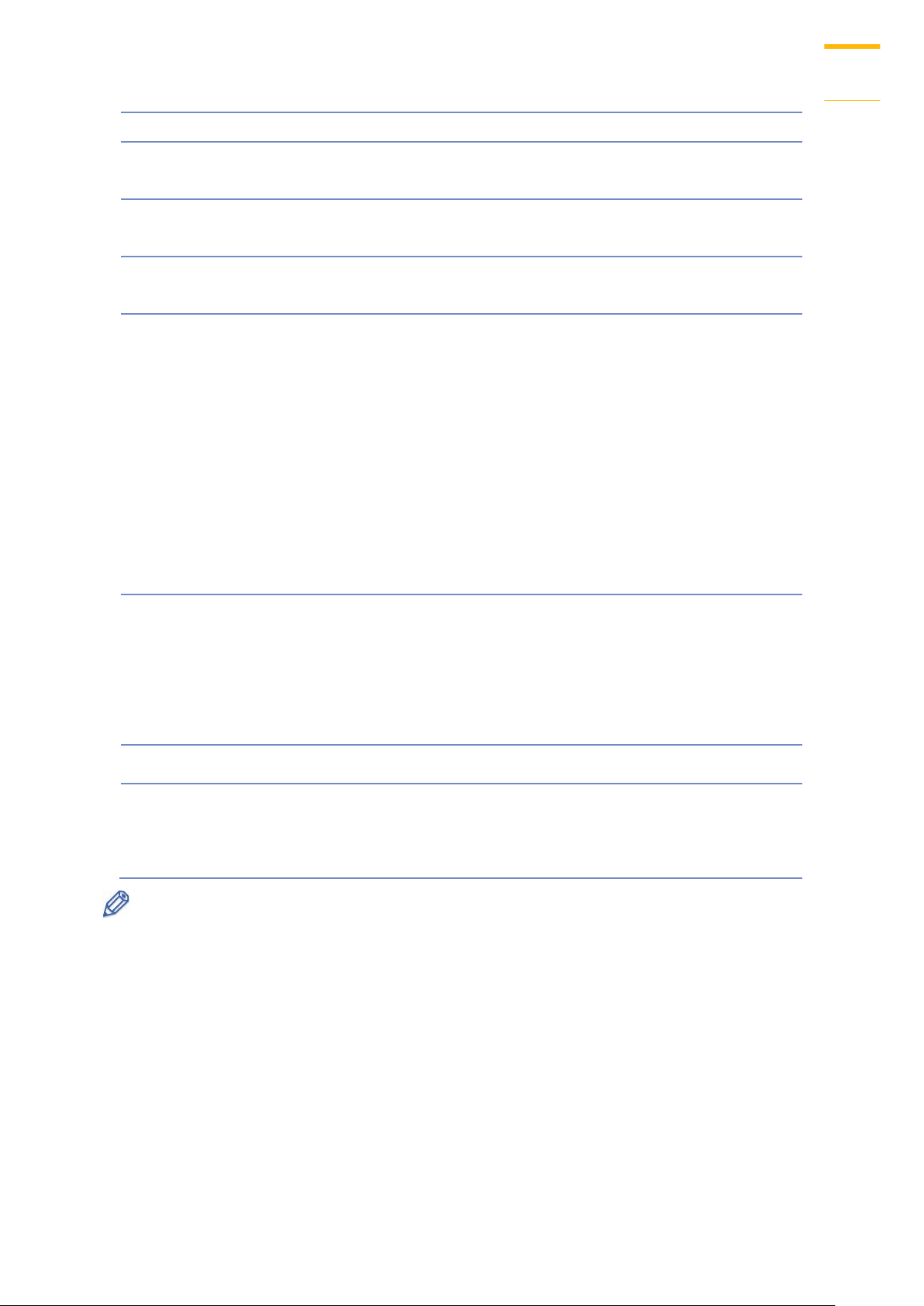

1. In Crouzet Touch Soft toolbar, click [Option] » [Preferences].

2. Select [Automatic save and compile when download and simulate] check box.

Crouzet Touch Soft

Page 29

Create an Crouzet Touch Soft Project

3-7

3. In Crouzet Touch Soft toolbar, click [Save] and then [Download].

4. In the dialog box, select [Automatically using current settings to download after

compiling] check box.

5. Click [Download].

6. When finished, next time when [Download] is clicked, Crouzet Touch Soft will

automatically compile and download the project to the latest target HMI.

Use HMI Name

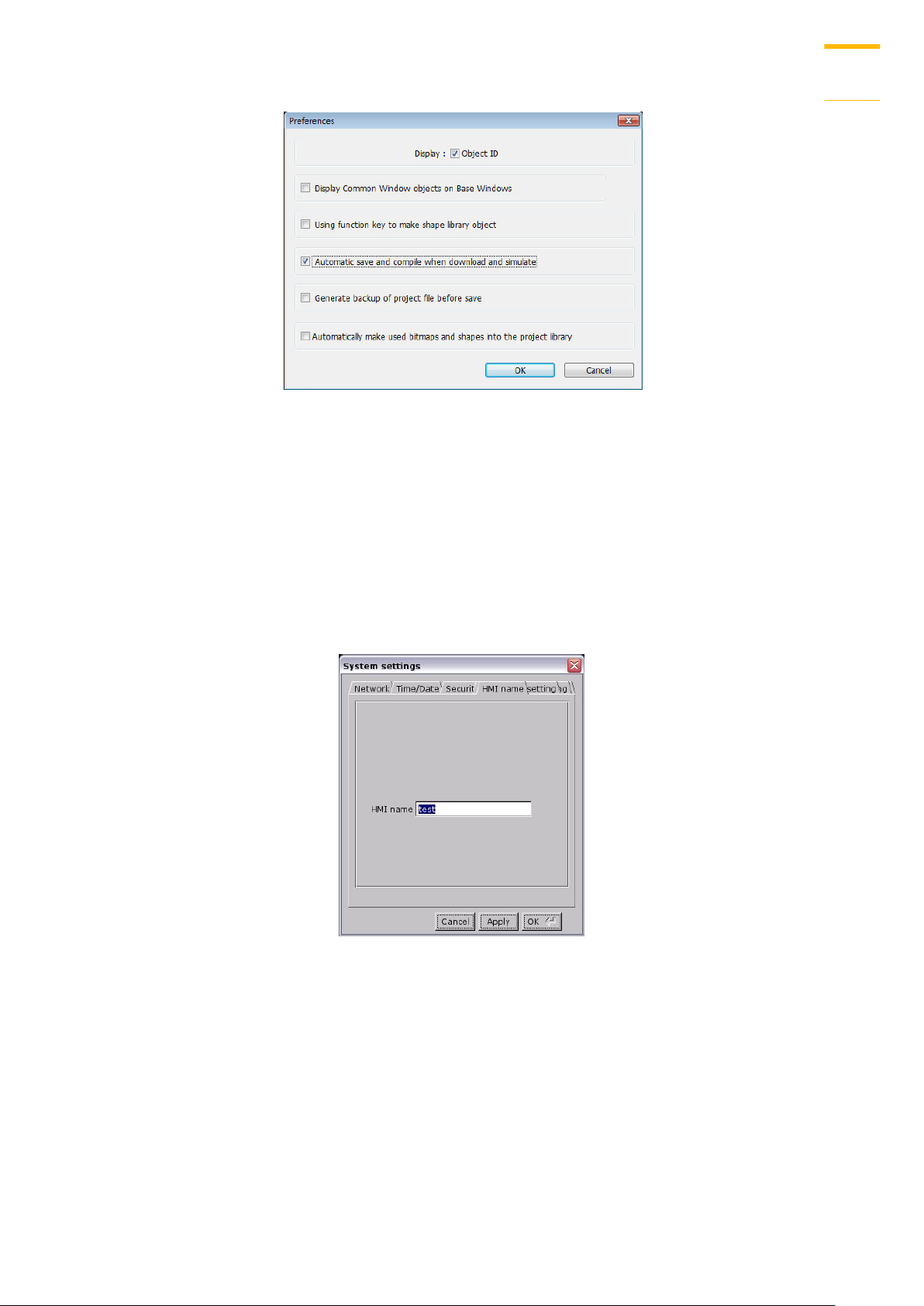

1. Go to [System settings] on HMI and then set HMI name first.

2. On PC, select the HMI name and start downloading. To use [Search], enter the HMI name

first to search for the HMI. [Search all] searches for all HMIs in the same subnet network.

Crouzet Touch Soft

Page 30

Create an Crouzet Touch Soft Project

3-8

Use USB cable

Crouzet Touch Soft

Page 31

Page 32

Create an Crouzet Touch Soft Project

3-10

5. Select the directory that contains project, and then click [OK] to start downloading.

Note

Please select the parent directory of the generated files when downloading. For the

structure above, please select disk_a_1, not CTP104.

You may click [System Settings] to save the hardware settings configured in Crouzet Touch

Soft into SD card or USB disk, and then download the settings file to HMI. See “4

Hardware Settings” for more information.

3.6. Upload the Project File from HMI

1. On Crouzet Touch Soft toolbar click [Tools] » [Upload].

2. Set HMI IP, HMI model, project location and project name, and then click [Upload].

Crouzet Touch Soft

Page 33

Create an Crouzet Touch Soft Project

3-11

Crouzet Touch Soft

Page 34

Hardware Settings

4-1

LED

Description

PWR (Orange)

Indicates power status.

CPU (Green)

Indicates CPU status. If it blinks or goes out, there may be a CPU

error.

COM

(Blue/Red)

Indicates communication status, blinks during communication.

Hardware Settings

This chapter explains HMI settings.

4.1. Overview

This chapter discusses the HMI settings.

4.2. I/O Ports

The I/O ports are different from one HMI type to another; please see the relevant datasheet

for more information.

The I/O Ports include:

SD card slot: Download / Upload project via SD card, including recipe transfer, event log,

data log…etc and to backup or record history data.

COM Port: Connects PLC or other peripheral devices. The type of serial port include: RS-

232, RS-485 2W, RS-485 4W, and CAN Bus.

Ethernet: Download / Upload project including recipe transfer, event log, data log…etc.

Connects to Ethernet devices, such as PLC, laptop.

USB Host: Supports USB devices, such as mouse, keyboard, USB disk, printer, or barcode

device.

USB Client: Download / Upload project including recipe transfer, event log, and data

log…etc.

For the first time operating HMI, please complete the following system settings. When

finished, the project files designed using Crouzet Touch Soft can be used on HMI.

4.3. LED Indicators

The LED indicators on the HMI indicate:

Crouzet Touch Soft

Page 35

Page 36

Hardware Settings

4-3

Network

When downloading project file to HMI via Ethernet,

set the correct IP of the target HMI. You can obtain

an IP address automatically or enter the IP address

manually. To use Email, please set correct DNS

address.

Time / Date

Set HMI local time/date.

4.5. System Toolbar

After rebooting HMI, you can set the system with [System Toolbar] at the bottom of the screen.

Normally, this bar is hidden automatically. Only by touching the arrow icon at the bottom-right

corner of the screen will the System Toolbar pop up. From left to right the icons are: System

Settings, System Information, Text Keyboard, and Number Keyboard.

How to hide HMI System Setting Toolbar:

When [DIP Switch 2] is set ON, the system setting toolbar is disabled. When set OFF; the

system setting toolbar is enabled. Please restart HMI to enable/disable the toolbar.

System register [LB-9020] can also enable/disable system setting toolbar. When [LB-9020]

is set ON, the toolbar is displayed, and set OFF to hide the toolbar.

System Setting

Set or modify system parameters. Confirm password for security first. The factory default

password is 111111.

Crouzet Touch Soft

Page 37

Hardware Settings

4-4

Security

Password protection, the default is 111111. Please

click the buttons to set the passwords, and finish

password confirmation.

[Password for entering system]

[Password for uploading project]

[Password for downloading project]

[Password for uploading history data]

History

Clears history data in HMI.

HMI name

Set HMI name to be used when download/upload

project.

Firmware setting

[Upgrade OS]

Upgrade firmware. Please do not turn off or unplug

HMI during OS upgrade process. For more details,

see the instruction about OS upgrade of the model

used.

[Portrait Mode]

Set screen orientation mode. After changing the

mode, reconnect HMI to power supply, for the

setting to take effect. That is, disconnect all power

from HMI, and then connect again. If portrait mode

Crouzet Touch Soft

Page 38

Hardware Settings

4-5

is used (90 or 270 degree), the project must be

designed for portrait mode, otherwise it cannot be

correctly displayed.

VNC server

Remote HMI monitoring and controlling via

Ethernet.

[Start VNC single-connection]

Allows connection with one VNC client.

[Start VNC multi-connection]

Allows connection with multiple VNC clients.

Connecting more VNC clients may slow down the

communication speed.

Please see the settings steps in the later part.

Miscellaneous

Rotary switch for adjusting LCD brightness.

[Popup download window]

If selected, after inserting USB disk or SD card to

HMI, the Upload / Download dialog box is displayed.

[Restart after download/upload]

If selected, restarts HMI automatically after

uploading / downloading project.

Misc 2

[Hide mouse cursor]

If selected, the mouse cursor will be hidden.

[Enable [Reset HMI to default] button in calibration

mode]

If selected, when the operator presses and holds

anywhere on the screen for more than 2 seconds

during HMI startup, the touch screen calibration

mode will start. After calibration, [Reset HMI to

default] option shows.

[FTP client can modify USB/SD data]

If selected, USB/SD data can be modified using FTP.

[Modify HMI ports]

Change the port number for Upload/Download and

FTP.

Crouzet Touch Soft

Page 39

Hardware Settings

4-6

Setting

Description

General

[HMI name] Enter HMI name.

[Back light] Adjust LCD backlight brightness.

[Time offset] Set the HMI RTC with offset.

For example, if the current RTC time is 15:00:00, and

System Information

Network: Displays network information & HMI IP.

Version: Displays HMI firmware version and model type.

4.6. EasySystemSetting

EasySystemSetting allows updating hardware system settings by using SD card or USB drive.

The feature is available for HMI OS version 20131106 or later.

Crouzet Touch Soft

Page 40

Hardware Settings

4-7

the time offset is set to -3, the updated time will be

12:00:00.

[Protrait mode] Set the display mode.

Import

Import and edit an existing .conf file.

Export

Export the configured data to a .conf file.

Default

Restore default.

The following explains how to update HMI IP address by using SD card or USB drive.

1. On Crouzet Touch Soft toolbar click [Tools] » [Build Download Data for SD / USB Disk], and

then select [Use system setting] check box.

2. Click [System Settings] button to open [System Setting] Editor dialog box. Specify HMI

network information as shown in the following figure.

3. Click [Export] to generate a “systemsetting.conf” file.

4. Click [Exit] to leave EasySystemSetting.

5. Click [Build] button in [USB Disk/CF Card/SD Card Data] dialog box to generate the file for

download by using SD card or USB disk.

Crouzet Touch Soft

Page 41

Hardware Settings

4-8

6. Insert the storage device that stores the download file to HMI and the Download/Upload

dialog box appears.

7. Press [Load System setting] and then the [Download Config Settings] message appears.

The project file will be updated after finishing system settings.

Crouzet Touch Soft

Page 42

System Parameter Settings

5-1

System Parameter Settings

This chapter introduces the system parameter settings.

5.1. Overview

Launch Crouzet Touch Soft, in the main menu select [Edit] » [System Parameters] to open the

[System Parameter Settings] dialog box. System Parameter Settings are divided into several

tabs as shown in the following figures. These tabs will be introduced respectively in this

chapter.

5.2. Device

Parameters in this tab determine the attributes of each device connected with HMI. The device

can be a Local / Remote HMI / PLC. When creating a new project file, there is a default device

"Local HMI" which indicates the HMI that will be updated and programmed. To change the

relevant device settings, click [System Parameter Settings] » [Settings] to open [Device

Properties] dialog box.

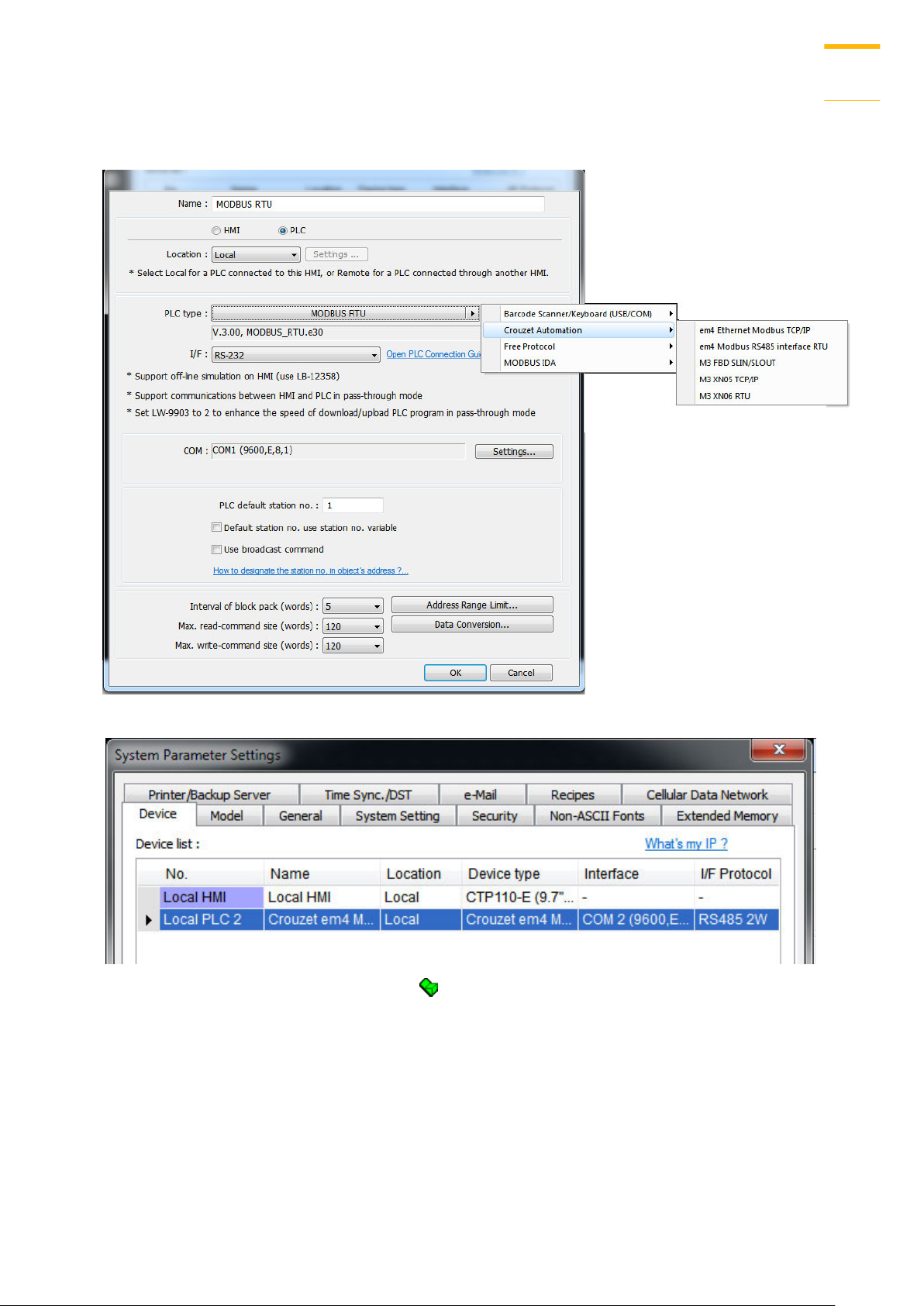

How to Control a Local PLC

“Local PLC” means the PLC is connected to the local HMI. To control/connect a Local PLC, add

this type of device first. Click [System Parameter Settings] » [New] to open [Device Properties]

dialog box. For example, when connecting MODBUS RTU as a Local PLC:

Crouzet Touch Soft

Page 43

System Parameter Settings

5-2

Setting

Description

Name

The name of the device.

HMI / PLC

In this example the device used is a PLC, so select [PLC].

Location

Select [Local] or [Remote]. In this example the PLC is

connected to the Local HMI, so select [Local].

PLC type

Select the type of the PLC.

PLC I/F

The available PLC interface: [RS-232], [RS-485 2W], [RS-485

4W], [Ethernet], [USB], and [CAN Bus].

If the interface used is [RS-232], [RS-485 2W], or [RS-

485 4W], configure communication parameters by

clicking [Device Properties] » [Settings] and then

[Com Port Settings] dialog box opens.

Timeout

If the communication has been disconnected for more

Crouzet Touch Soft

Page 44

System Parameter Settings

5-3

than preset time limit configured in [Timeout] (in sec),

Window No. 5 will pop up and show “PLC No Response”

message.

Turn around delay

While sending the next command to PLC, HMI will delay

the sending according to the time interval set in [Turn

around delay]. This may influence the efficiency of the

communication between HMI and PLC. Default value is

“0”.

If the interface used is [Ethernet], click [Device

Properties] » [Settings] and the [IP Address Settings]

dialog box opens. Please set correct PLC IP address

and port number.

If the interface is [USB], no further setting is

required. Please check the settings in [Device

Properties].

If the interface is [CAN (Controller Area Network)

Bus], please see “PLC Connect Guide” for “CANopen”

and import the .eds device file.

PLC default

station no.

The default station number for PLC address if the PLC

station number is not included in the address. PLC station

no. can be set in PLC address. The address format:

ABC#DEFGH

ABC stands for PLC station number and ranges from 0 to

255. DEFGH stands for PLC address. And the “#” sign

separates the station number and the address. As shown

in the following figure, the data is read from PLC station

number 1, and address 0x-20.

Crouzet Touch Soft

Page 45

System Parameter Settings

5-4

Default

station no.

use station

no. variable

Use the station number variables as the default PLC

station number. Select one from LW-10000 to LW-10015

(var0 to var15) as the station number variables. If the

station no. is not specified in PLC address, the station

number will be determined by the station no. variable.

For example, if var3 is set for default station no:

The followings demonstrate some examples:

The PLC station number is “5”.

The PLC station number is determined by var7 (LW-

10007)

PLC address is set to “111”, since PLC station no. is

not specified, and the default station no. is var3, the

PLC station no. is determined by var3 (LW-10003).

Use

broadcast

When [Use broadcast command] check box is selected,

please fill in [Broadcast station no.] according to the

Crouzet Touch Soft

Page 46

System Parameter Settings

5-5

command

broadcast station number defined by PLC. When HMI

sends a broadcast command to the station number set

here, PLC will only receive the command and not reply to

HMI.

As shown in the following figure:

When HMI sends a command to address 255#200, all the

PLCs will receive this command and will not reply.

Only PLCs that support broadcast command can use this

feature.

Interval of

block pack

(words)

If the interval between read addresses of different

commands is less than this value, the commands can be

combined to one. The combining function is disabled if

this value is set to “0”.

For example, the interval value is set to “5”, to read 1 word

from LW-3 and 2 words from LW-6 respectively (read from

LW-6 to LW-7), since the interval of addresses between

LW-3 and LW-6 is less than 5, these two commands can be

combined to one. The result is to read 5 consecutive words

from LW-3 to LW-7.

Note: The maximum size of command combination data

must be less than [Max. read-command size].

Max. read -

command

size (words)

The maximum data size to read from the device at one

time. Unit: word

Max. write command

size (words)

The maximum data size to write to the device at one time.

Unit: word.

After all settings are completed, a new device named “Local PLC 1” is added to the [Device list].

Crouzet Touch Soft

Page 47

System Parameter Settings

5-6

Setting

Description

HMI or PLC

In this example, the device used is a PLC, so select [PLC].

Location

Select [Local] or [Remote]. In this example the PLC is

connected to Remote HMI, so select [Remote]. Set the IP

address and port number of the Remote HMI by clicking

[Settings] next to [Remote].

How to Control a Remote PLC

“Remote PLC” is a PLC being connected to a remote HMI. To control a remote PLC, add this

type of device first. Please click [System Parameter Settings] » [New] to open [Device

Properties] dialog box. For example, use MODBUS RTU as the Remote PLC:

Crouzet Touch Soft

Page 48

System Parameter Settings

5-7

PLC Type

Select the type of the PLC.

PLC I/F

The interface used for Remote PLC. If the remote PLC uses a

COM port, select [RS-232], [RS-485 2W], or [RS485 4W].

COM

Set the correct COM port used by the Remote PLC.

PLC default

station no.

Set the station number of Remote PLC.

Setting

Description

HMI or PLC

In this example, the device used is a HMI, so select [HMI].

Location

Select [Local] or [Remote]. In this example Remote HMI is

After all settings are completed, a new device named “Remote PLC 1” is added to the [Device

list].

How to Control a Remote HMI

“Remote HMI” is the HMI other than “Local HMI”, and PC is also a “Remote HMI”. To control a

Remote HMI, add this type of device first. Click [System Parameter Settings] » [New] to open

[Device Properties] dialog box as shown in the following figure:

Crouzet Touch Soft

Page 49

System Parameter Settings

5-8

used, select [Remote]. Set the IP address and port number

of the Remote HMI by clicking [Device Properties] »

[Settings].

After all settings are completed, a new device named “Remote HMI 1” is added to the [Device

list].

Crouzet Touch Soft

Page 50

System Parameter Settings

5-9

Setting

Description

HMI model

Select the HMI model to use.

If the HMI model is changed, the [Resize pop-up windows /

objects] dialog box will pop up. Select required adjustment

and click [OK]. In most cases, select all options.

HMI station

no.

Set the station number of current HMI. The default value is

“0”.

Port no.

Set the port number of current HMI. It is also used in MODBUS

5.3. Model

Configure the [HMI model], [Timer], [Printer] and [Scroll bar] settings.

Crouzet Touch Soft

Page 51

System Parameter Settings

5-10

server. The default value is “8000”.

Timer

Clock source

Set the source device of the clock/time information. It is used

by [Data Sampling], [Event Log], etc.

If [HMI RTC] is selected, the time information comes from

the internal clock of the HMI.

If [External device] is selected, the time information

comes from an external device. The address of the

source device must set correctly. As shown below, the

time information is from “TV” address type of the “Local

PLC”. The addresses of “TV” start from 0 and contain 6

consecutive words and each of them store the following

information:

TV 0 → Second (range: 0~59)

TV 1 → Minute (range: 0~59)

TV 2 → Hour (range: 0~23)

TV 3 → Day (range: 1~31)

TV 4 → Month (range: 1~12)

TV 5 → Year (range: 1970~2037)

Printer

Type

A printer can be connected with the HMI. The HP PCL Serie

printer is connected through USB interface while other

printers through a COM port.

For more information, see “23 HMI Supported Printers”.

If the printer is connected through [COM], configure the

parameters correctly. If the printer type is [SP-M, D, E, F], the

[pixels of width] has to be set accurately, i.e. the set pixel(s)

Crouzet Touch Soft

Page 52

System Parameter Settings

5-11

cannot exceed printer’s default setting, or the HMI will fail to

print data.

Scroll bar

Set the width of Scroll Bar, when the size of the object is too

small to display the contents, a scroll bar is displayed in the

object. This feature can be applied to objects that allow

scrolling, such as Alarm Display, Event Display, History Data

Display, and Option List.

Pass through

Set the port number for Pass-through communication.

Setting

Description

Fast

selection

button

This setting is applicable for CTP Series.

Setting the attributes for fast selection button for Window

No. 3. To use the fast selection button, create Window No.

5.4. General

Configure the properties related to screen display.

Crouzet Touch Soft

Page 53

System Parameter Settings

5-12

3 first.

Attribute

Enable or disable fast selection window. Select [Enable] and

click [Settings] to set the attributes, including color and text

of the button.

Position

Select the button position on the screen. If [Left] is chosen,

the button will show up in at bottom left side of the screen;

if [Right] is chosen, the button will show at the bottom

right side of the screen.

Settings

Set the shape and label font of the Fast Selection Button.

Hide button when HMI starts

The Fast Selection Button will be hidden, calling it out

requires system registers LB-9013~LB-9015.

Screen saver

Back light saver

If the screen is left untouched and reaches the time limit

set here, the back light will be turned off. The unit is

minute. Back light will be on again once the screen is

touched. If [none] is set, the back light will always be on.

Screen saver

If the screen is left untouched and reaches the time limit

set here. The current screen will automatically switch to a

window assigned in [Saver window no.].The setting unit is

minute. If [none] is set, this feature is disabled.

Saver window no.

To assign a window for screen saver.

Option

Startup window no.

Designate the window shown when start up HMI.

Common window

The objects in the common window (Window No. 4) will be

shown in each base window. This determines that the

objects in common window are placed above or below the

objects in the base window.

Object layout

If [Control] mode is selected, when operating HMI,

[Animation] and [Moving Shape] objects will be displayed

above other kinds of objects neglecting the sequence that

the objects are created. If [Nature] mode is selected, the

display will follow the sequence that the objects are

created, the first created will be displayed first.

RW_A enabled

Enable or disable recipe data RW_A. Enable this, the

Crouzet Touch Soft

Page 54

System Parameter Settings

5-13

objects can then control RW_A .The size of RW_A is 64K.

Event

Extra no. of events

The default number of the events in the system is 1000. For

additional number of events, modify this setting. The

maximal is 10000.

Keyboard

The window number in which the keyboard is placed.

When using Numeric Input or ASCII Input objects, the type

of keyboards can be selected. Up to 32 keyboards can be

added. To design a keyboard, a window should be

designated for creating it. Press [add] after creating, and

add the window to the list.

See “12 Keyboard Design and Usage”.

External keyboard layout

Applicable for CTP series.

The available USB keyboard layouts are QWERTY and

AZERTY. System register LW-9199 allows switching keyboard

layouts on HMI.

Caret color / Select color

This setting is applicable for CTP Series.

Set the color of caret that appears when entering data in

Numeric Input and ASCII Input objects, or change the

selection color.

Project

protection

Projects can be restricted to be executed by a specific HMI.

See “30 Project Protection”.

5.5. System Setting

[System Setting] is used to configure different features of Crouzet Touch Soft.

Crouzet Touch Soft

Page 55

System Parameter Settings

5-14

Setting

Description

Startup language after

redownloading the

project

Set the language to use when HMI starts after

the project is re-downloaded.

Execute init. MACRO

when power on

Designate the macro to be executed when HMI

power on.

Auto logout

If leaving HMI untouched for longer than the

set time, the objects protected by security

classes will not be able to operate. The user ID

and password must be entered again to unlock

Some features are duplicated from system registers, such as, [Hide system setting bar (LB-

9020)], [Hide mouse cursor (LB-9018)], [Disable buzzer (LB-9019)], [Prohibit remote HMI

connecting to this machine (LB-9044)], and [Disable upload function (LB-9033)]. Users can also

set these features via system tag.

To select a system tag, select [Address] » [System tag] check box when adding a new object and

then select the [Device Type].

To browse all the system tags, Select [Library] » [Tag] » [System] from the main menu of

Crouzet Touch Soft.

Crouzet Touch Soft

Page 56

System Parameter Settings

5-15

it.

Hide system setting bar

Hide the system setting bar in the bottom right

corner of the HMI screen.

Hide mouse cursor

Hide the mouse cursor in HMI screen.

Mouse cursor size

Set mouse cursor size.

Sound control

With each touch on a button, a sound is

emitted: A sound is emitted when touching a

button.

With Each operation from a button, a sound is

emitted: When the [Min. press time] is

specified, there may be a time gap between

touching the object and the action of the

object. This setting can control the timing to

emit a sound.

Disable sound output: Mute HMI.

Prohibit remote HMI

connecting to this

machine

Prohibit the connection with a remote HMI.

The remote HMI will not be able to control the

local HMI.

Disable upload function

(effective after rebooting

HMI) (or set LB9033 ON)

Disable HMI to upload project, after

downloading, HMI must be rebooted to

disable uploading project.

Prohibit password

remote-read operation

(or set LB9053 ON)

Prohibit Remote HMI to read Local HMI.

Prohibit password

remote-write operation

(or set LB9054 ON)

Prohibit Remote HMI to write Local HMI.

Use a disconnection icon

or relative objects when

PLC communication fails

If selected, displays a

disconnection icon on relevant

objects when failing to

communicate with PLC.

This icon will be shown in the

lower right corner of the

object.

Enable watch dog (LB-

9049)

Watchdog automatically reboots the system

after the HMI stops functioning for a specified

period of time.

VNC Server

If [Password free] check box is selected, the

client can connect with HMI via VNC without

entering the password.

Crouzet Touch Soft

Page 57

System Parameter Settings

5-16

If [Monitor mode] check box is selected, the

HMI connected via VNC can only be monitored

but not controlled.

If [Password from project] check box is

selected, set the password for VNC login.

LW protection

RW protection

If select [Disable LW/RW remote-write] check

boxes and set the protect range in [LW/RW

range], values within the protected range

cannot be adjusted using Remote HMI.

5.6. Security

Parameters in this tab configure the user passwords and security classes. There are two

authentication modes: General Mode and Enhanced Security Mode.