02 / 26 / 2014

LAUNCH NOTE

NEW LEVEL & PHASE

CONTROL RELAYS

Level Control

Phase Control

New Level & Phase Control Relays

Launch Note - New Level & Phase Control Relays

3

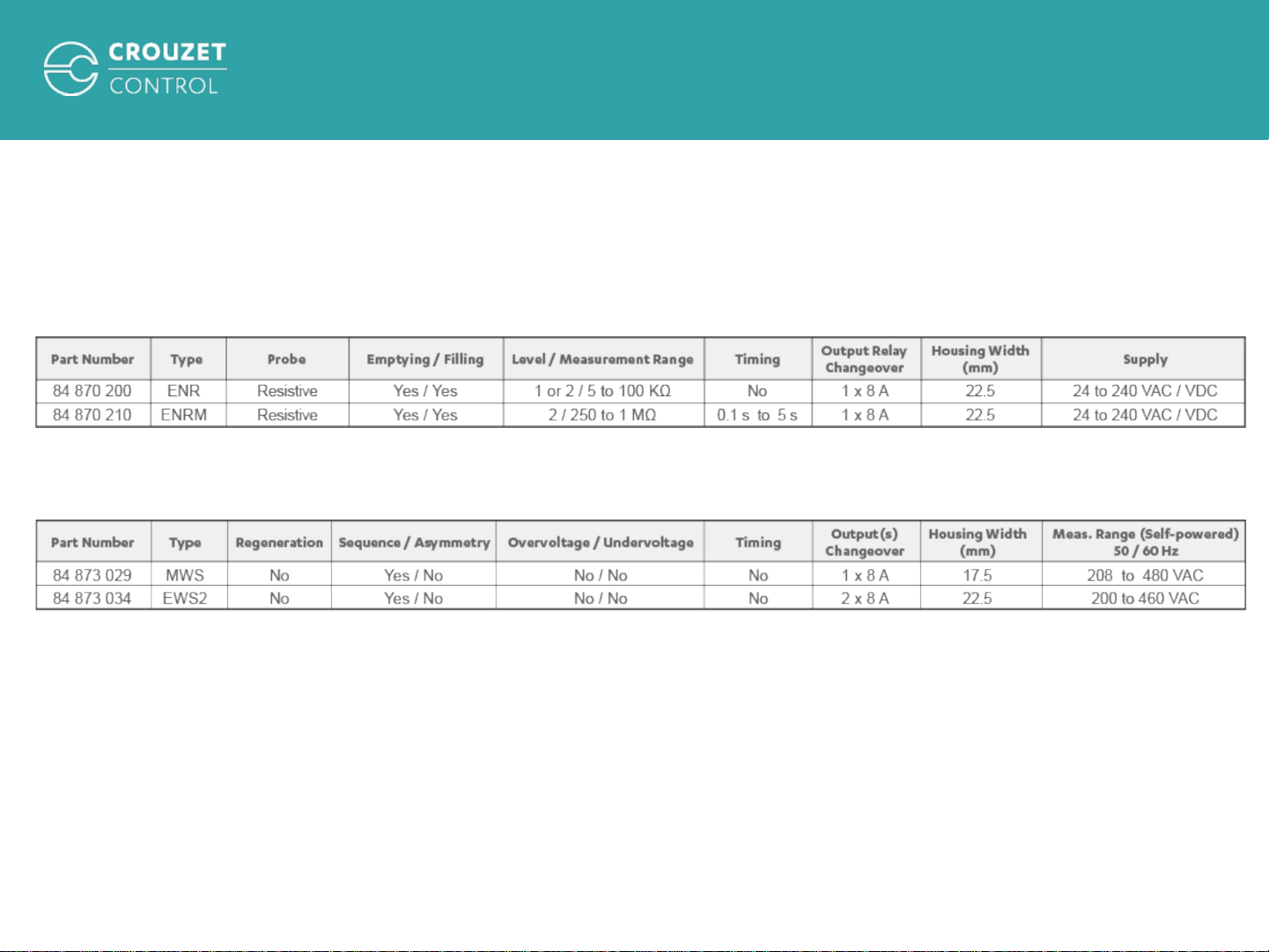

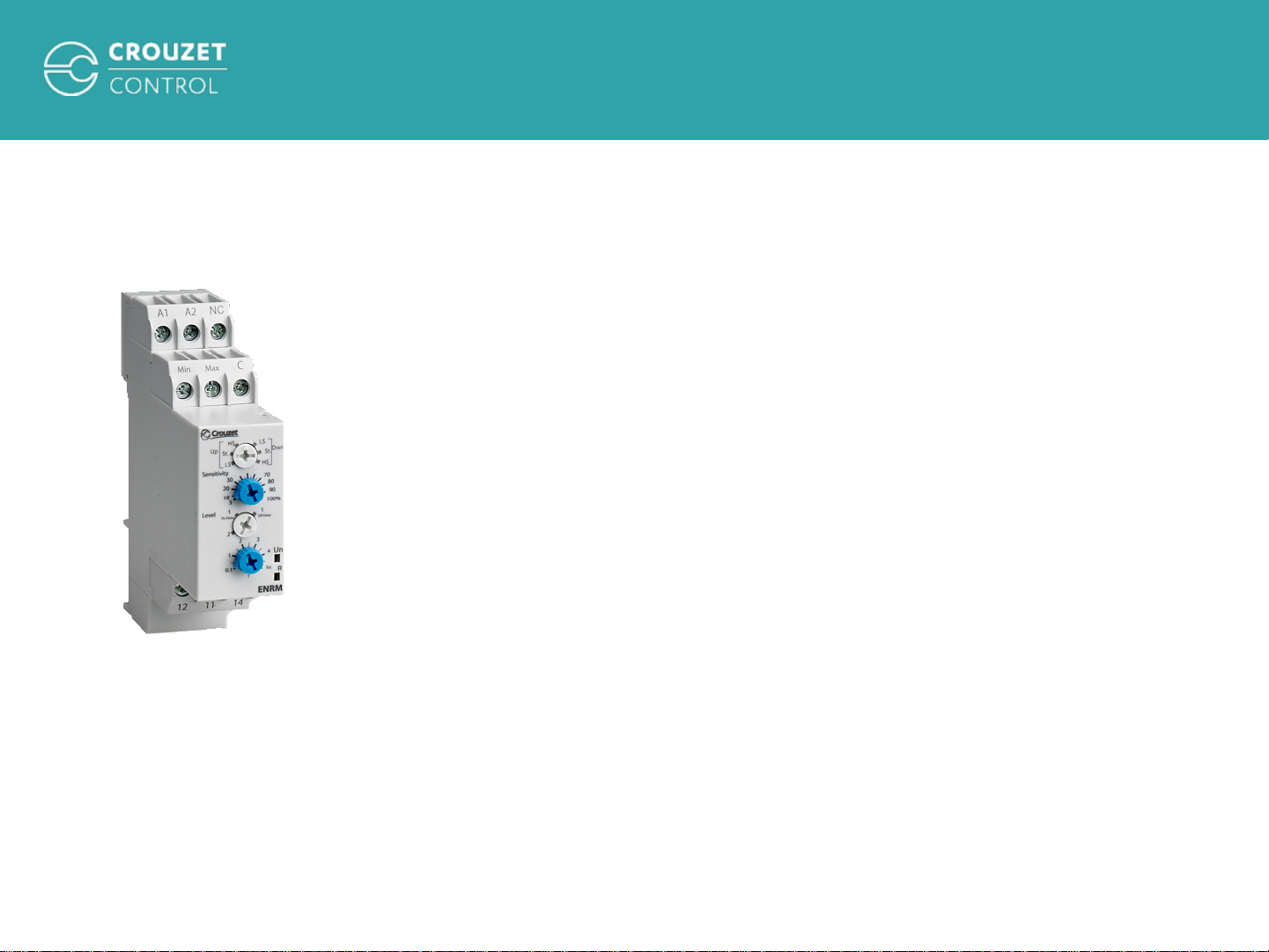

New Level Control Relays

ENR & ENRM- 22.5 mm

• 2 New part numbers will replace 8 existing part

numbers featuring:

– Filling or emptying function: E NR

– Filling or emptying with adjustable time delay: ENRM

– Multi-voltage (24 to 240 VAC/DC)

– Screw terminals

Launch Note - New Level & Phase Control Relays

– LED status indicators

4

Product Specifications: ENR

U

Down

Up

1

2

3

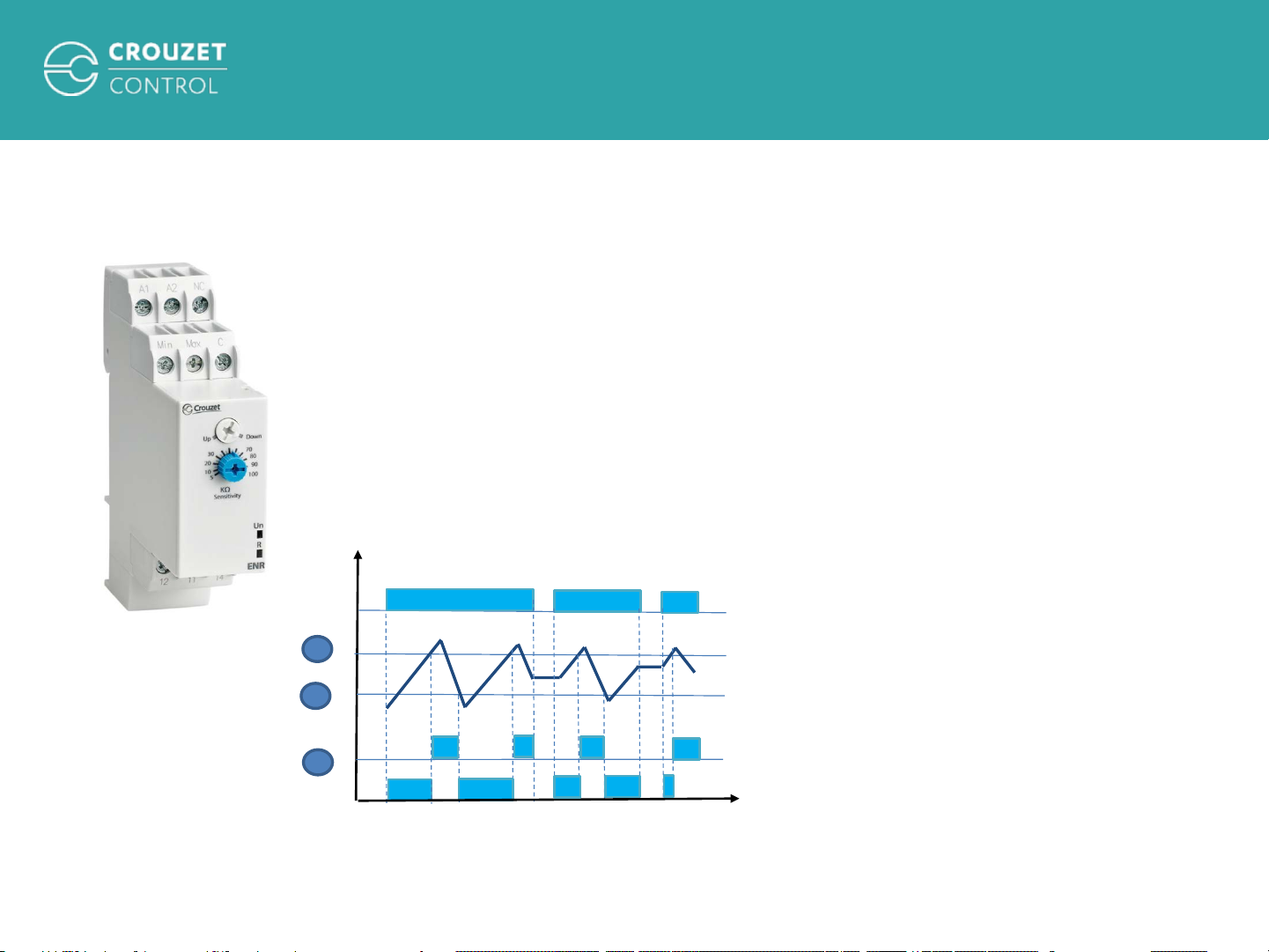

• Monitoring filling or emptying

• Rated supply voltage: 24 to 240 VAC/DC

• Output: 1 relay 250 VAC/ 8 A resistive -

250 VDC / 0.3 A resistive

• CE, C-UL-US, CSA

– Maximum level

– Minimum level

– Output relay : Down or Up

Launch Note - New Level & Phase Control Relays

5

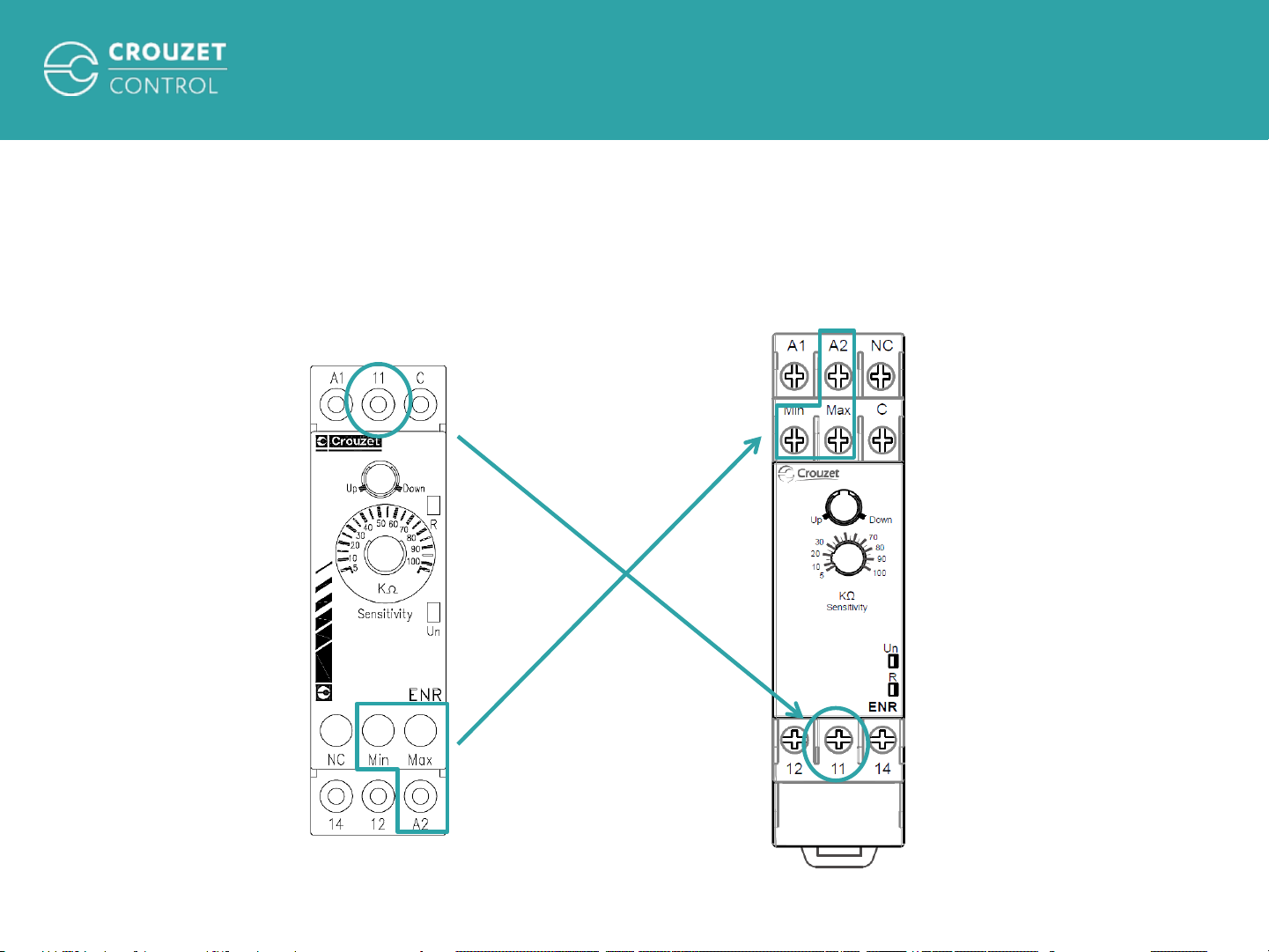

Product Specifications: ENR

• LEDs & connections are at different places

Old P/N 84 870 20X New P/N 84 870 200

New ENR has

increased height

and decreased

Launch Note - New Level & Phase Control Relays

depth

6

Product Specifications: ENR M

• Monitoring filling or emptying with adjustable time delay

• Casing width: 22.5mm

• Rated supply voltage: 24 to 240 VAC/DC

• Output: 1 relay 250 VAC/ 8 A resistive -

250 VDC / 0.3 A resistive

• CE, C-UL-US, CSA

Launch Note - New Level & Phase Control Relays

7

ENRM Functions

Monitoring filling or emptying

with adjustable time delay

Monitoring a level, emptying

function, deactivation time

Monitoring a level, emptying

function, activation time

Monitoring two levels,

emptying function

Monitoring a level, filling

function, deactivation time

Monitoring two levels,

filling fun ction

Launch Note - New Level & Phase Control Relays

8

Product Specifications : ENRM

• LEDs & connections are at different places

Old P/N 84 870 21X New P/N 84 870 210

New ENRM has

increased height

and decreased

Launch Note - New Level & Phase Control Relays

depth

9

New Phase Control Relay

MWS - 1 7. 5 m m

• The new MWS features:

– 8A changeover output relay

– Multi-voltage

– Screw terminals

– LED status indicators

Launch Note - New Level & Phase Control Relays

• The new MWS will replace existing:

– 17.5mm Phase sequence or phase failure

MWS (5A)

– 22.5mm Phase sequence or phase failure

EWS (8A)

10

Product Specifications: New MWS

Monitoring phase sequence and phase failure

• Improved Rated supply voltage: 3 x 208 to 480 VAC (3 x 230 to 440 VAC

for old EWS)

• Output: 1 relay 250 VAC/ 8 A resistive - 250 VDC / 0.3 A resistive

• Agency approvals include CE, C-UL-US, CSA and GL

• Simple to install: MWS control relays use the controlled main supply for their

own power supply voltage. Simply install MWS phase control relay and

without any adjustment it monitors the loss or inversion of one of the phases

Launch Note - New Level & Phase Control Relays

11

Product Specifications: New MWS

Tr

Tr Tr

Off

On

0%

0%

0%

100%

100%

100%

Tr

R

L1

L2

L3

L2

L3

Td Td Td Td

Tr

Tr Tr

Off

On

0%

0%

0%

100%

100%

100%

Tr

R

L1

L2

L3

L2

L3

TdTd TdTd TdTd TdTd

Operating Principle

Phase failure

Phase sequence

Typical Wiring Diagram

Launch Note - New Level & Phase Control Relays

12

Product Specifications: New MWS

Phase Sequence Monitoring

A change of the phase sequence during operation or an incorrect phase

sequence that is applied at start-up can cause a three-phase motor to

run with reverse rotation. Certain motors when operated in the reverse

direction cause severe damage to connected loads such as pumps,

compressors and fans. Specially for portable equipment, such as

construction machinery, phase sequence detection prior to the start-up

process is highly recommended.

Phase Failure Monitoring

In case of a phase loss, undefined states of the installation are likely to

occur. E.g. the startup process of motors is disturbed. Crouzet phase

control relays detect a phase loss as soon as the voltage of one phase

drops below 100VAC.

Launch Note - New Level & Phase Control Relays

13

New Phase Control Relay

EWS2 - 22.5 mm

• The new phase sequence or phase failure relay

EWS2 features:

– 2 x 8A changeover relays

– Multi-voltage

– Screw terminals

Launch Note - New Level & Phase Control Relays

– LED status indicators

• Direct replacement of existing EWS2

14

Product Specifications: EWS 2

• Monitoring phase sequence and phase failure

• Casing width: 22.5mm

• Improved Rated supply voltage: 3 x 230 to 440 VAC (3 x 230 to 415 VAC

for old EWS2)

• Output: 2 relays 250 VAC / 8 A resistive - 250 VDC / 0.3 A resistive

• Agency approvals include CE and C-UL-US

• Simple to install: EWS2 control relays use the controlled main supply for

their own power supply voltage. Simply install EWS2 phase control relay

and without any adjustment it monitors the loss or inversion of one of the

phases

• Same operative principle as the MWS phase control relay but with 2

changeover output relays

Launch Note - New Level & Phase Control Relays

15

Product Specifications: EWS 2

Front face & connections display only minor changes

Old P/N 84 873 004 New P/N 84 873 034

Launch Note - New Level & Phase Control Relays

16

Product Comparison

P/N

Output

Width

Rated

Supply

voltage

Old Offer

EMWS

(Essential)

84 903 020 84 873 020 84 892 299

5 A / 3 A 5 A 8 A

17.5 mm 17.5 mm 22.5 mm

3 x 208…

480VAC

MWS EWS

3 x 208…

480VAC

3 x 230…

440 VAC

New Offer

EMWS

(Essential)

P/N

Output

Width

Rated

Supply

voltage

84 903 020 84 873 029

5 A / 3 A 8 A

17.5 mm 17.5 mm

3 x 208…

480VAC

New MWS

3 x 208…

480VAC

Launch Note - New Level & Phase Control Relays

17

Product Characteristics: New MWS

Front face & connections display NO change

New NWS

EWS

Old P/N 84 892 299

Old P/N 84 873 020

New P/N 84 873 029

MWS

Launch Note - New Level & Phase Control Relays

18

Typical Level Control Applications

• They are used to detect the presence of liquid (e.g. seal failure) or to

control the liquid level between 1 or 2 levels.

• When controlling the level of liquid between 2 levels on a container there

are 2 possible modes: Pump Up (filling), and Pump Down (emptying).

• The most common type uses probes to measure the apparent resistance

(in kΩ) of the liquid. These are for conductive, non flammable liquids only.

• Other types can use float switches or discrete sensors.

Typical applications for Liquid Level Control Relays:

• Water treatment facilities

• Pumping stations

• Beverage vending machines

• Industrial washing machines

• Milk tanks

• Fountains

Launch Note - New Level & Phase Control Relays

19

Typical Phase Control Applications

• T hey are used to monitor 3-phase networks.

• T hey det ect when there is a phase m i s sing or when the sequence of the

phases is incorrect.

Typical applications for Phase Control Relays:

• Prot ec tion of motors against the risk of start i ng in reverse (pumps,

compressors, generators )

• Prot ecti on of motors against phas e loss or imbalance (lif ts and cranes,

pumps, elevators, c onveyors, etc.)

• Water and sewage lift st ations

• HVAC and refrigeration

Launch Note - New Level & Phase Control Relays

20

High Volume Applications (EMWS & MWS)

Phase control in Industrial Air Compressors and HVAC (Industrial

Chillers)

• Phase Control Relays are normally integrated in control panels of

medium / large size compressors.

• The function of the Phase Control Relay is to monitor the presence

and correct sequence of the 3 phases before starting the

compressor. If the compressor motor starts rotating in the wrong

direction we have the risk of damaging the compressor.

Launch Note - New Level & Phase Control Relays

21

Loading...

Loading...