Pump control

HPC

Part numbers

Product adaptations

Accessories

➜ 3-phase and single phase pump control relay - 35 mm

■ Allows control and monitoring of single phase and 3-

phase pumps

■ Monitors phase sequence and phase failure

■ Checks for undercurrent to protect against running

dry

■ Checks for overcurrent to protect against overload

■ Digitial inputs for operation control logic

■ True RMS current measurement

Type Measurement ranges Nominal voltage (V) Code

HPC 1 A

➞ 10 A in DC

208

➞ 480 V

230 V

■ Customisable colours and labels

■ Fixed or adjustable time delay

■ Fixed threshold in the generic range

a

a

monophase

3-phase

84874200

Description Code

Removable sealable cover for 35 mm casing

84800001

66

www.crouzet.com

General characteristics

Supply

Supply voltage Un

208 V

230 V

Voltage supply tolerance -12% / +10%

Operating range

a

supply voltage frequency

183

➞ 528 V

50/60 Hz ± 10%

Galvanic isolation of power supply/measurement No

Power consumption at Un

5 VA in

Immunity from micro power cuts 500 ms

Inputs and measuring cicuit

Measurement ranges

1

➞ 10 A

E1-L2: 1 ➞ 10 A

Input resistance E1-L2: 0.01 Ω

Permanent overload at 25°C E1-L2: 11 A

Pulse overload < 1 sec at 25°C E1-L2: 50 A

Frequency of measured signal 50 / 60 Hz: ± 10%

Max. measuring cycle time 150 ms/True RMS measurement

Adjustment of upper threshold 0.1

Adjustment of lower threshold 0.1

➞ 10 A

➞ 10 A

Fixed hysteresis 5% of displayed threshold

Display precision ±10% of full scale

Repetition accuracy with constant parameters ± 0.5%

Measuring error with voltage drift < ± 1% across the whole range

Measuring error with temperature drift ± 0.05% / °C

Timing

Delays on power up (Ti) 1

Delay on threshold crossing 0.1

➞ 60 s (0, + 10%)

➞ 10 s (0, + 10%)

Repetition accuracy with constant parameters ± 1%

Reset time 2 s

Y2 minimum reset time 300 ms

Delay on pick-up 500 ms

Alarm on delay time max. 300 ms

Output

Type of output 1 single pole changeover relay

Type of contacts No cadmium

Maximum breaking voltage

Max. breaking current

Min. breaking current

Electrical life (number of operations)

Breaking capacity (resistive)

250 V

z

5 A

10 mA / 5 V

5

1 x 10

1250 VA

Maximum rate 360 operations/hour at full load

Operating categories acc. to IEC 60947-5-1 AC 12, AC 13, AC 14, AC 15, DC 12, DC 13

Mechanical life (operations)

DC 14, 30 x 10

Insulation

Nominal insulation voltage IEC 60664-1 400 V

Insulation coordination (IEC 60664-1 / 60255-5) Overvoltage category III: degree of pollution 3

Rated impulse withstand voltage IEC 60664-1/60255-5 4 kV (1.2 / 50 µs)

Dielectric strength IEC 60664-1/60255-5

Insulation resistance IEC 60664-1 / 60255-5

a

2 kV

> 500 MΩ 500 V

a

➞ 480 V

a

monophase

a

a

a

z

c

a

6

50 Hz 1 min

3-phase *

c

67

General characteristics

Pump control

General characteristics

Principles

Display power supply Green LED

Display relay Yellow LED

"Fault" indication Yellow LED

Casing 35 mm

Mounting On 35 mm symmetrical DIN rail, IEC/EN 60715

Mounting position All positions

Material: enclosure plastic type VO to UL94 standard Incandescent wire test according to IEC 60695-2-11 & NF EN 60695-2-11

Protection (IEC 60529) Terminal block: IP 20

Weight 100 g

Connecting capacity IEC 60947-1

Max. tightening torques IEC 60947-1 0.6

Operating temperature IEC 60068-2 -20

Storage temperature IEC 60068-2 -40

Casing: IP 30

Rigid: 1 x 4

1 x 11 AWG - 2 x 14 AWG

Flexible with ferrules: 1 x 2.5

1 x 14 AWG - 2 x 16 AWG

2

- 2 x 2.52 mm2

➞ 1 Nm / 5.3 ➞ 8.8 Lbf.In

➞ +50°C

➞ +70°C

2

- 2 x 1.52 mm

2

Humidity IEC 60068-2-30 2 x 24 hr cycle 95% RH max. without condensation 55°C

Vibrations according to IEC/EN60068-2-6 10

➞ 150 Hz, A = 0.035 mm

Shocks IEC 60068-2-6 5 g

Standards

Marking CE (LVD) 73/23/EEC - EMC 89/336/EEC

Product standard NF EN 60255-6 / IEC 60255-6 / UL 508 / CSA C22.2 N°14

Electromagnetic compatibility Immunity EN 61000-6-2/IEC 61000-6-2

Certifications UL, CSA, GL

Emission EN 61000-6-4/EN 61000-6-3

IEC 61000-6-4/IEC 61000-6-3

Emission EN 55022 class B

pending

Conformity with environmental directives RoHS, WEEE

Comments

* 3-phase mains with earth

HPC

Overview

The pump controller can operate on a single phase or 3-phase network. It provides 3 functions in one unit:

●

Checking current,

●

Checking phase presence (in 3-phase mode),

●

Checking phase sequence (in 3-phase mode).

It has two operating modes whose purposes is to control a pump based on two external signal inputs (Y1 Y2).

These two signals are controlled by volt-free contacts.

Faults are signalled via LEDs, distinguishing the origin of the fault.

Operating principle

Selecting the operating mode

A rotary switch on the front is used to select:

- single control mode,

- dual control mode,

- single-phase or 3-phase network.

The position of this selector switch is only taken into account when the unit is powered up.

If the switch position changes while the unit is operating, all the LEDs flash but the product continues to work normally with the mode selected on

energisation prior to the change of position.

The LEDs return to their normal state if the switch is reset to its initial position defined before the last energisation.

HPC - Single control mode This mode is for controlling a pump based on one external signal (Y1).

The relay output is closed when the signal is present at Y1 (contact closed).

U

Y1

Y2

1

2

Ti

Current fault

B

Relay

C

Fault monitoring inhibit time on pump start-up (Ti)

D

Delay timing in case of fault (Tt)

E

3 4

Tt

Tt

Ti

Tt

Ti

After a fault the relay remains open (even if the current returns to normal) and the module can be

reclosed in two different ways:

- By a reset: cutting of power supply,

- Or by a reset through pressing an external contact (pushbutton for example) entering the

second control input (Y2).

68

Principles

www.crouzet.com

HPC - Dual control mode This mode is for controlling a pump based on two external signals (Y1 and Y2).

U

Y1

Y2

1

2

Current fault

B

Relay

C

Fault monitoring inhibit time on pump start-

D

Ti

3 4

Tt

Tt

Ti

Ti

Ti

The output relay closes when both input signals are present (Y1 and Y2 closed).

It will open as soon as either of these two signals is absent.

If the controller is configured in single phase, it monitors the current drawn by the pump.

If the controller is configured in 3-phase, it monitors current, phase sequence and phase failure.

If a phase fault is detected, the output relay opens immediately.

On energisation, the output relay cannot be closed if there is a phase fault or phase failure.

up (Ti)

Delay timing in case of fault (Tt)

E

HPC - Overcurrent control Current control

U

1

2

3

Ti

Tt

4 5

Overcurrent

B

Hysteresis

C

Relay

D

Fault monitoring inhibit time on pump start-

E

Tt

Ti

The under and overcurrent values are set by two independent potentiometers graduated from 1

to 10 A.

In case of a control error (low threshold higher than high threshold), the output relay opens and all

the

LEDs flash to signal the error.

I

If a current fault occurs (under or overcurrent) the relay opens if the fault persists

beyond the preset threshold delay. When the current returns to a correct value, the output relay

remains open. It can only be closed by a reset: either by de-energisation or by closing on

external contact Y2 (in single control mode)

An inhibit delay (Ti) on energisation allows current peaks due to start-up of the motor to be

disregarded.

up (Ti)

Delay timing in case of fault (Tt)

F

HPC - Undercurrent control

U

1

1

2

3

Ti

Tt

4 5

Undercurrent

B

Hysteresis

C

Relay

D

Fault monitoring inhibit time on pump start-

E

Tt

up (Ti)

Delay timing in case of fault (Tt)

F

I

Ti

69

HPC

Pump control

Dimensions (mm)

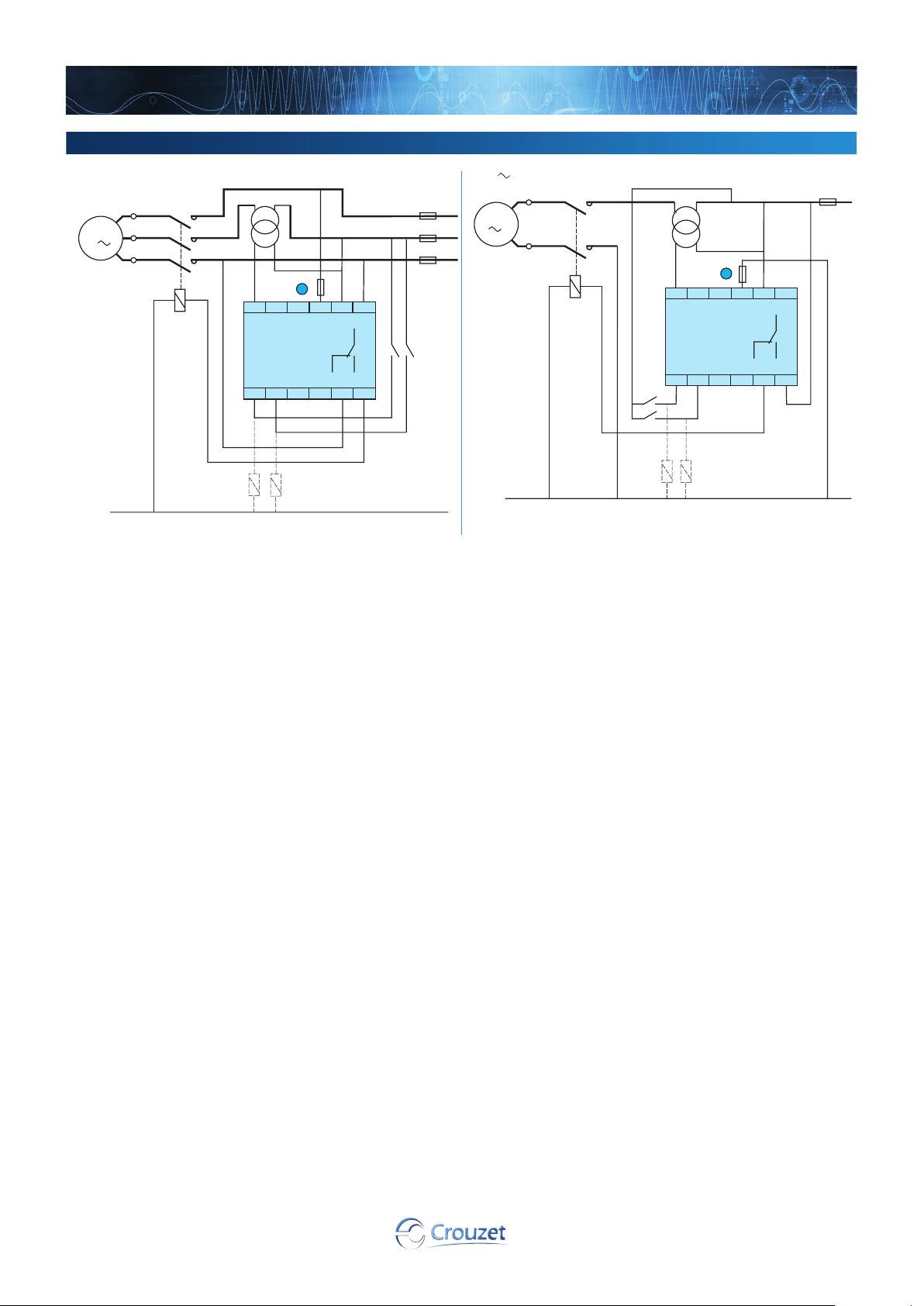

Connections

M

3

L1

L2

L3

KM1

U1

W1

V1

N

L1

L2

L3

E1

Y1 Y2 1112 14

11

12

14

R

F1

1

M

U

V

KM1

N

L1

L2

L3

E1

Y1 Y2 1112 14

11

12

14

Ph

R

F1

1

L1

L2

L3

E1

Y1 Y2 1112 14

60

44

23,2

3,5

35

45

67,5

3 ph < 10 A

90

2,6

5,5

a

230 V < 10 A

1 ph

100 mA fast-blow fuse or cut-out

B

70

100 mA fast-blow fuse or cut-out

B

Connections

www.crouzet.com

3 ph > 10 A

U1

KM1

V1

M

3

W1

100 mA fast-blow fuse or cut-out

B

T.I.

1

F1

E1

Y1 Y2 1112 14

L2

L1

11

R

14

12

a

230 V > 10 A

1 ph

L1

M

L2

L3

L3

KM1

U

V

T.I.

1

F1

E1

Y1 Y2 1112 14

L2

L1

11

R

14

12

L3

Ph

N

N

100 mA fast-blow fuse or cut-out

B

71

Loading...

Loading...