Crouse Hinds Liquidtight Conduit Fittings Catalog Page

Liquidtight Conduit Fittings

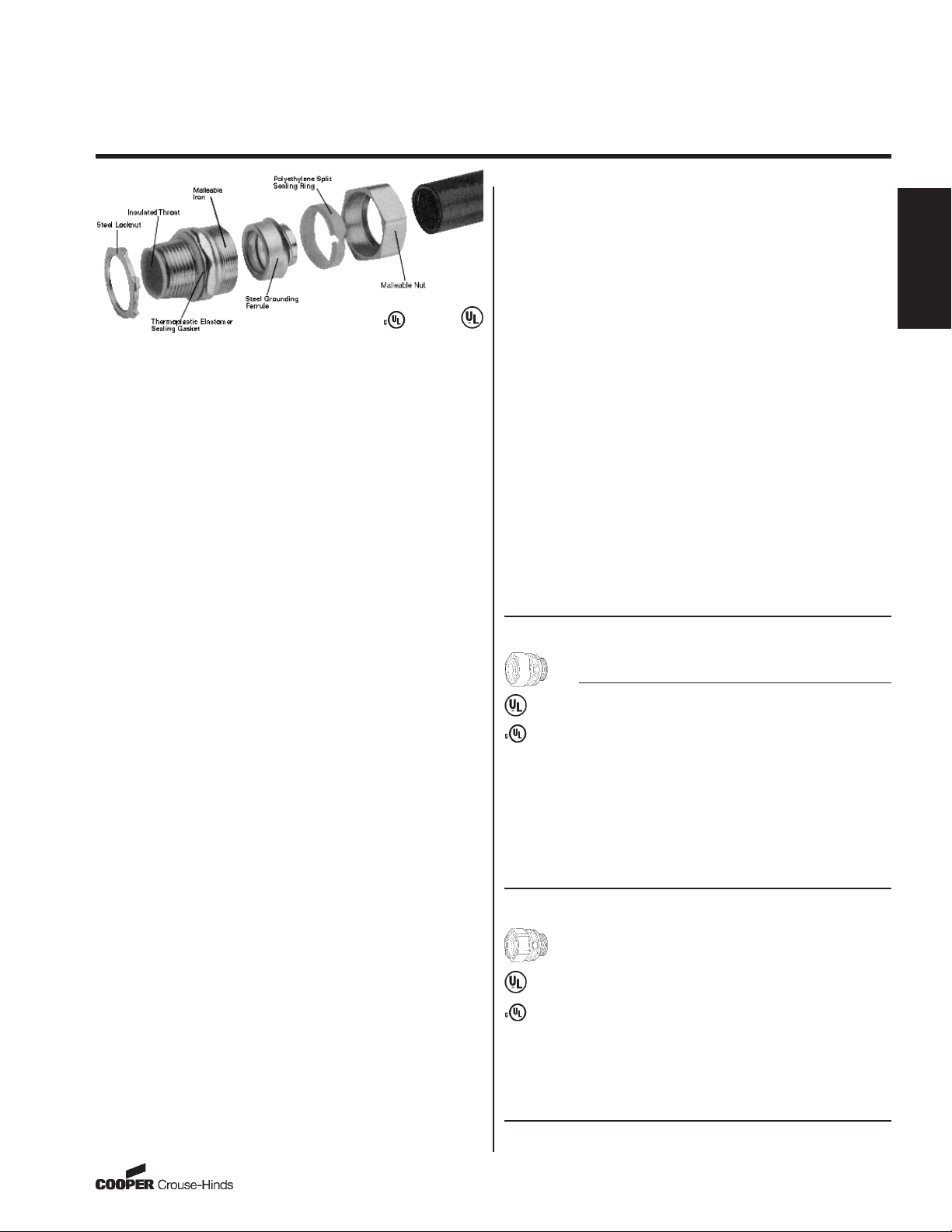

ɀ LiquidatorTMLiquidtight Flexible Metallic Conduit

Fittings

CP

UL File No. E-19189

Applications:

Typical applications for liquidtight conduit and the Liquidator include

the wiring of machine tools . . . motors . . . transformers . . . food

processing equipment . . . robotics . . . air conditioning units . . .

illuminated store front signs and billboards . . . etc. The flexible

metallic conduit and fittings protect conductors from mechanical

damage due to vibration and movement and seals out cutting oils,

coolants, water, dust, etc.

Applications such as these can be found in, but are not limited to,

industries such as:

ɀ machine tool manufacturers.

ɀ electric power generating plants.

ɀ waste treatment facilities.

ɀ paint manufacturing facilities.

ɀ automobile manufacturing facilities.

ɀ aerospace industries.

ɀ breweries.

ɀ food processing plants.

ɀ dairies.

ɀ pulp and paper mills.

ɀ petroleum refineries.

ɀ chemical and petrochemical plants.

Compliances:

ɀ NEC: Class I, Division 2

Class II, Divisions 1 and 2

Class III, Divisions 1 and 2

ɀ UL Standards: 514B, 467

ɀ CSA Standard: C22.2 No. 18

FEATURES AND BENEFITS:

Product Features

ɀ UL and cUL Listed

ɀ Provided protection in wet locations

ɀ Straight available in

3

⁄8⍯ through 4⍯ sizes.

3

⁄8⍯ through 6⍯ sizes; 45° and 90° available in

ɀ Malleable iron bodies and gland nuts with zinc electroplate; steel

ferrules and locknuts with zinc electroplate.

ɀ Cupped grounding ferrule is distortion-free and reusable.

ɀ Split polyethylene sealing ring is reversible.

ɀ Grooves inside sealing ring. Jacket of liquidtight conduit will cold

flow into grooves.

ɀ Reusable design.

ɀ Hex surfaces on gland nut and body.

ɀ Thermoplastic elastomer sealing gasket effectively seals out water,

oil, dust and dirt.

ɀ Steel locknut bites into box.

ɀ Available with or without insulated throats.

ɀ Insulated throat versions, 105°C rated nylon.

Standard Materials:

ɀ Body – Straight:

45° and 90°;

ɀ Gland nut – malleable iron or aluminum

ɀ Ferrule –

3

⁄8⍯ through 6⍯ – malleable iron or aluminum

3

⁄8⍯ through 4⍯ – malleable iron or aluminum

3

⁄8⍯ through 6⍯ – steel

ɀ Gland nut sealing ring – polyethylene

ɀ Sealing gasket – thermoplastic elastomer

ɀ Locknut – steel

Standard Finishes:

ɀ Steel and malleable iron – zinc electroplate

ɀ Polyethylene, thermoplastic elastomer, aluminum and die cast –

natural

User Benefits

ɀ Assurance of safe and reliable performance. End user peace of

mind.

ɀ Meets NEC and UL requirements for use in wet locations. Reduces

downtime and replacement costs.

ɀ Complete selection of styles and sizes. Easy selection from one

source, saves time and money.

ɀ High strength and excellent corrosion resistance. Long service life,

eliminates the need for replacement.

ɀ Provides excellent pullout strength and grounding for safety of

personnel and equipment.

ɀ Easy to install. Cannot be installed incorrectly. Saves labor.

ɀ Eliminates leakage, potential downtime and replacement costs.

Protection against vibration.

ɀ Can be disassembled and reused. Cost savings.

ɀ Easy wrenching, Fast, easy installation results in labor savings.

ɀ Eliminates leakage, potential downtime and replacement costs.

ɀ Provides a reliable ground and safety of personnel and equipment.

Won’t vibrate loose.

ɀ One-stop source to meet user needs. Saves time and money.

STRAIGHT CONNECTORS – NON-INSULATED – MALLEABLE

IRON

Cat. # Size Quantity Package 100

LT-38

LT-50

LT-75

LT-100 1⍯ 55045

LT-125 1

LT-150 1

LT-200 2⍯ 1 10 120

LT-250 2

LT-300 3⍯ 1 5 430

LT-350 3

Conduit Unit Standard Lbs. Per

3

⁄8⍯ 25 100 18

1

⁄2⍯ 25 100 20

3

⁄4⍯ 25 100 26

1

⁄4⍯ 52569

1

⁄2⍯ 22085

1

⁄2⍯ 1 5 340

1

⁄2⍯ 1 5 510

Weight

LT-400 4⍯ 1 5 600

LT-500† 5⍯ 1 1 800

LT-600† 6⍯ 1 1 1075

† Not UL Listed or CSA Certified

STRAIGHT CONNECTORS – INSULATED – MALLEABLE IRON

LTB-383⁄8⍯ 25 100 18

LTB-50

LTB-75

LTB-100 1⍯ 55045

LTB-125 1

LTB-150 1

LTB-200 2⍯ 1 10 120

LTB-250 2

LTB-300 3⍯ 1 5 430

LTB-350 3

1

⁄2⍯ 25 100 20

3

⁄4⍯ 25 100 26

1

⁄4⍯ 52569

1

⁄2⍯ 22086

1

⁄2⍯ 1 5 340

1

⁄2⍯ 1 5 510

LTB-400 4⍯ 1 5 600

LTB-500† 5⍯ 1 1 800

LTB-600† 6⍯ 1 1 1075

† Not UL Listed or CSA certified

ɀCP

Liquidtight

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

295

CP

Liquidtight Conduit Fittings

ɀ LiquidatorTMLiquidtight

Flexible Metallic Conduit Fittings

STRAIGHT CONNECTORS – NON-INSULATED – ALUMINUM

Conduit Unit Standard Lbs. Per

Cat. # Size Quantity Package 100

3

⁄8⍯ 25 100 12

1

⁄2⍯ 25 100 12

3

⁄4⍯ 25 100 14

1

⁄4⍯ 52534

1

⁄2⍯ 22048

1

⁄2⍯ 1 5 121

1

⁄2⍯ 1 5 245

Liquidtight

ɀCP

LT38-SA

LT50-SA

LT75-SA

LT100-SA 1⍯ 10 50 28

LT125-SA 1

LT150-SA 1

LT200-SA 2⍯ 11054

LT250-SA 2

LT300-SA 3⍯ 1 5 174

LT350-SA 3

LT400-SA 4⍯ 1 5 279

45° ANGLE CONNECTORS — NON-INSULATED – MALLEABLE

IRON

LT-3845

LT-5045

LT-7545

LT-10045 1⍯ 10 50 70

LT-12545 1

LT-15045 1

LT-20045 2⍯ 1 5 199

LT-25045 2

3

⁄8⍯ 25 100 27

1

⁄2⍯ 25 100 29

3

⁄4⍯ 10 50 41

1

⁄4⍯ 52593

1

⁄2⍯ 2 10 137

1

⁄2⍯ 1 1 600

LT-30045 3⍯ 1 1 925

1

LT-35045 3

⁄2⍯ 1 1 1150

LT-40045 4⍯ 1 1 1450

45° ANGLE CONNECTORS – INSULATED – MALLEABLE IRON

LTB-38453⁄8⍯ 25 100 27

LTB-5045

LTB-7545

LTB-10045 1⍯ 10 50 70

LTB-12545 1

LTB-15045 1

LTB-20045 2⍯ 1 5 195

LTB-25045 2

1

⁄2⍯ 25 100 29

3

⁄4⍯ 10 50 41

1

⁄4⍯ 52593

1

⁄2⍯ 2 10 137

1

⁄2⍯ 1 1 600

LTB-30045 3⍯ 1 1 925

1

LTB-35045 3

⁄2⍯ 1 1 1150

LTB-40045 4⍯ 1 1 1450

90° ANGLE CONNECTORS – NON-INSULATED – MALLEABLE

IRON

LT-3890

LT-5090

LT-7590

LT-10090 1⍯ 10 50 76

LT-12590 1

LT-15090 1

LT-20090 2⍯ 1 5 230

LT-25090 2

3

⁄8⍯ 25 100 31

1

⁄2⍯ 25 100 33

3

⁄4⍯ 10 50 48

1

⁄4⍯ 5 25 112

1

⁄2⍯ 2 10 155

1

⁄2⍯ 1 1 900

LT-30090 3⍯ 1 1 1383

1

LT-35090 3

⁄2⍯ 1 1 1875

LT-40090 4⍯ 1 1 2325

Weight

90° ANGLE CONNECTOR – INSULATED – MALLEABLE IRON

Weight

Conduit Unit Standard Lbs. Per

Cat. # Size Quantity Package 100

LTB-38903⁄8⍯ 25 100 30

LTB-5090

LTB-7590

LTB-10090 1⍯ 10 50 76

LTB-12590 1

LTB-15090 1

LTB-20090 2⍯ 1 5 230

LTB-25090 2

1

⁄2⍯ 25 100 33

3

⁄4⍯ 10 50 48

1

⁄4⍯ 5 25 112

1

⁄2⍯ 2 10 155

1

⁄2⍯ 1 1 900

LTB-30090 3⍯ 1 1 1380

1

LTB-35090 3

⁄2⍯ 1 1 1825

LTB-40090 4⍯ 1 1 2325

90° ANGLE CONNECTOR – NON-INSULATED – ALUMINUM

LT3890-SA3⁄8⍯ 25 100 19

LT5090-SA

LT7590-SA

LT10090-SA 1⍯ 10 50 40

LT12590-SA 1

LT15090-SA 1

1

⁄2⍯ 25 100 18

3

⁄4⍯ 10 50 24

1

⁄4⍯ 52548

1

⁄2⍯ 21061

LT20090-SA 2⍯ 1586

COMBINATION COUPLINGS FOR COUPLING LIQUIDTIGHT TO

THREADED RIGID/IMC CONDUIT

LTR-38*

LTR-50

LTR-75

LTR-100 1⍯ 55059

LTR-125 1

LTR-150 1

3

⁄8⍯ 25 100 17

1

⁄2⍯ 25 100 29

3

⁄4⍯ 25 100 33

1

⁄4⍯ 2 20 105

1

⁄2⍯ 2 20 105

LTR-200 2⍯ 1 10 160

3

⁄8⍯ Liquidtight to 1⁄2⍯ Rigid/IMC

* For

SELF RETAINING PVC GASKET WITH STEEL RING

UL File no. E-22133

Cat. # Size Quantity Package 100

Conduit Unit Standard Lbs. Per

SG1

SG2

3

⁄8⍯–1⁄2⍯ 100 100 1

3

⁄4⍯ 50 50 2

SG3 1⍯ 50 50 2

1

SG4 1

SG5 1

⁄4⍯ 25 25 2

1

⁄2⍯ 25 25 4

SG6 2⍯ 25 25 3

1

SG7 2

SG8 3⍯ 10 10 10

SG9 3

⁄2⍯ 10 10 5

1

⁄2⍯ 10 10 12

SG10 4⍯ 10 10 10

SG11 5⍯ 5515

SG12 6⍯ 5522

Weight

296

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

Loading...

Loading...