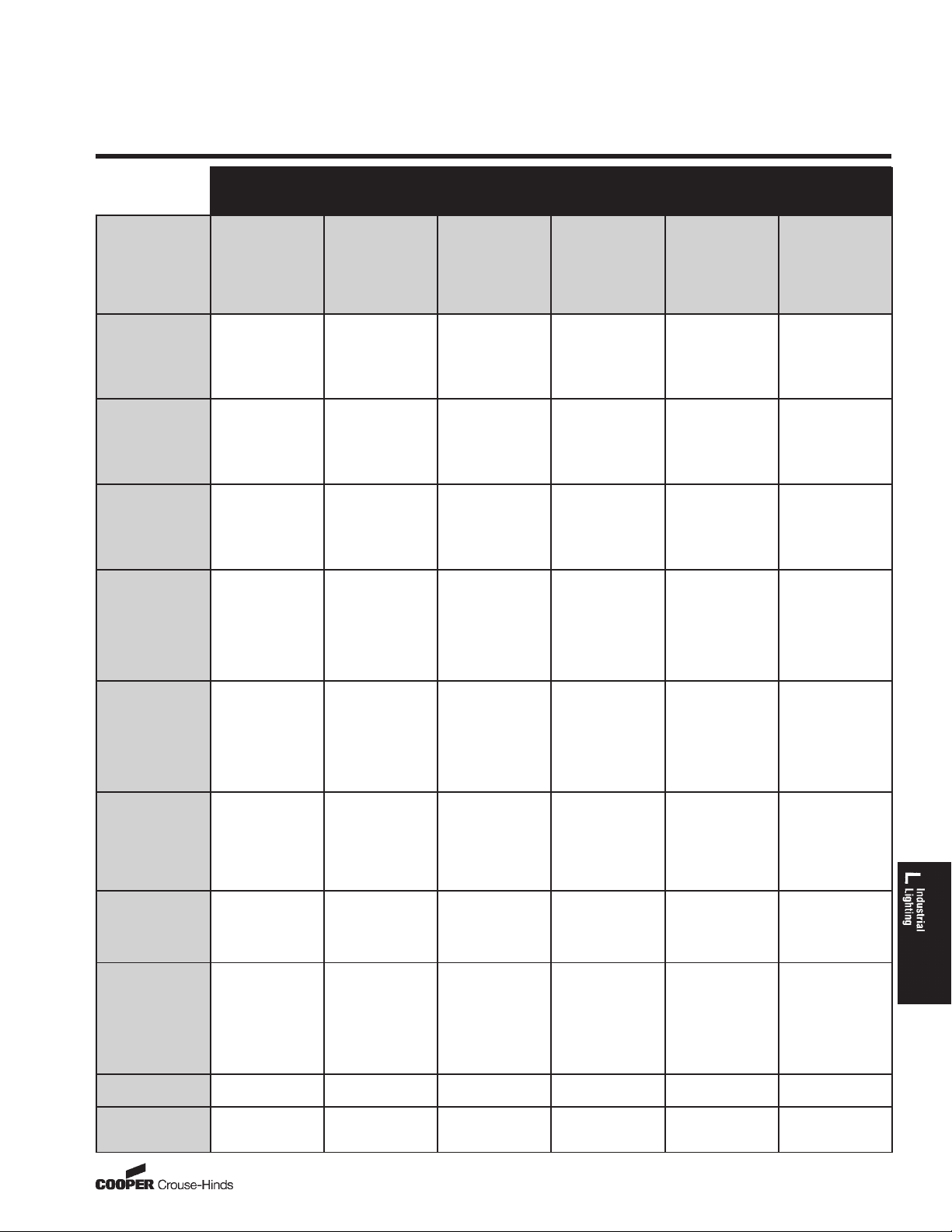

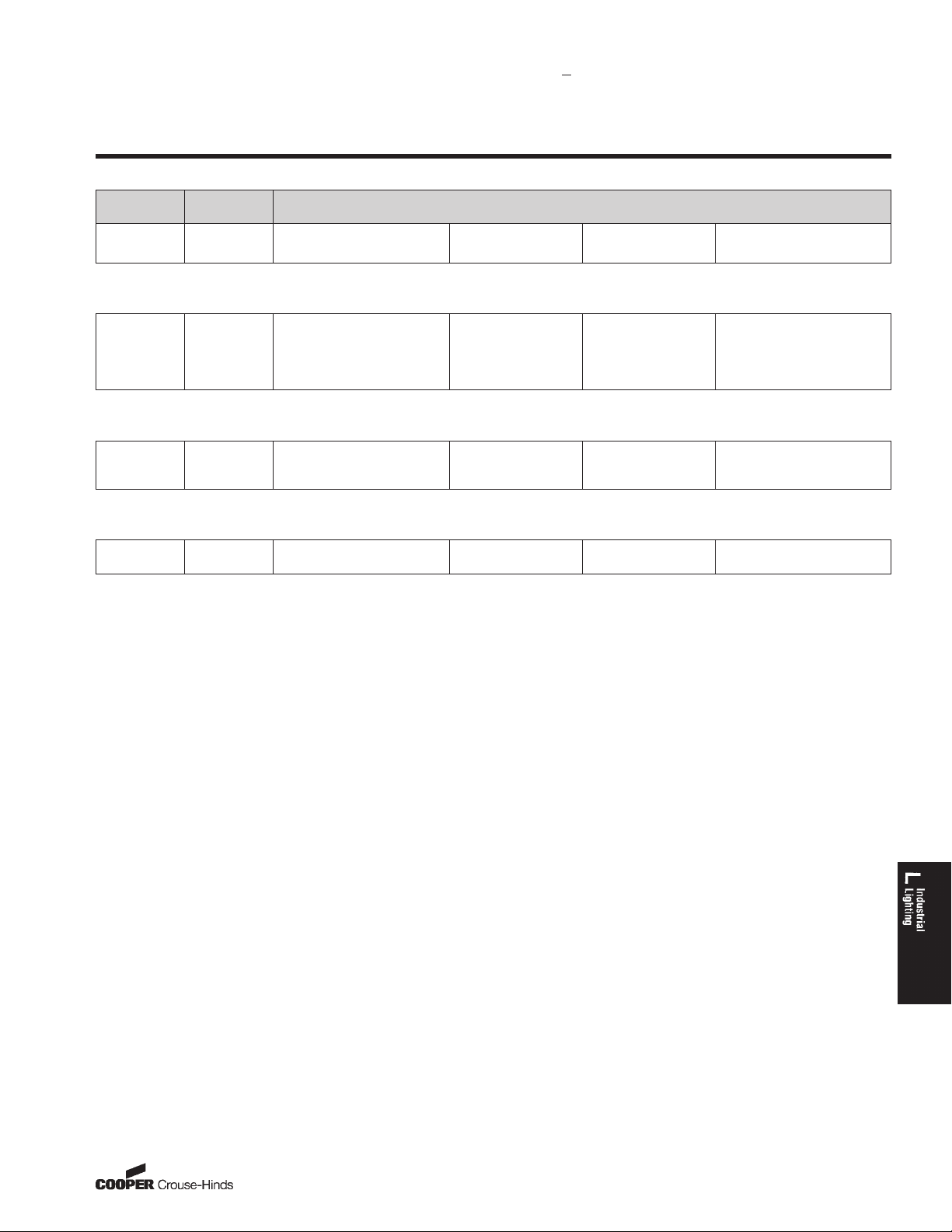

Crouse Hinds Industrial Lighting Products Quick Reference

Industrial Lighting Products

Quick Reference Chart

L

LIGHT SOURCE

Application

Environment

General Industrial Section 1L

Wet Locations Section 1L

Marine Locations

or 4X

Corrosive Section 1L

Class I, Div. 1 or

Zone 1

Class I, Div. 2 and

Zone 2

Restricted Breathing

ɀ Class I, Div 2

and Zone 2

ɀ Certified IEC

Zone 2

Class II

Class III

Simultaneous

Presence

Paint Spray Section 4L

Portables Section 9L

Incandescent H.I.D.

ɀ Pulse Start

Metal Halide

ɀ Metal Halide

ɀ High Pressure

Sodium

ɀ Mercury Vapor

Vaporgard

TM

, V

Series, NDA

Section 12L

V160 Tank light

Vaporgard

TM

, V

series, NDA

Section 3L

LMV, DMV, VMV,

N2MV Champ

Section 5L

Champ Induction

Section 3L

LMV, DMV, VMV,

N2MV Champ

Section 5L

Champ Induction

Section 1L

NDA

Section 3L

LMV, DMV, VMV,

N2MV Champ

Section 4L

EVLP Lo-Pro

EVM Hazard-Gard

Vaporgard

TM

, NDA

Section 3L

LMV, DMV, VMV,

N2MV Champ

Section 5L

Champ Induction

Section 2L

EV

Section 12L

Section 4L

EVLP Lo-Pro

EVM Hazard-Gard

EVTL, EVA160,

EVO, ELG

Section 1L

Vaporgard

NDA

TM

,

Section 3L

LMV, DMV, VMV,

N2MV Champ

Section 5L

Champ Induction

Section 3L

LMV, DMV, VMV,

N2MV Champ

Section 5L

Champ Induction

Section 2L

EV

Section 12L

EVTL, EVO

Section 3L

LMV, DMV, VMV,

N2NV Champ

Section 4L

EVLP Lo-Pro

EVM Hazard-Gard

Section 5L

Champ Induction

EVP

Section 9L

VS, EVH,

EVP

RCDER

®

®

®

®

®

®

®

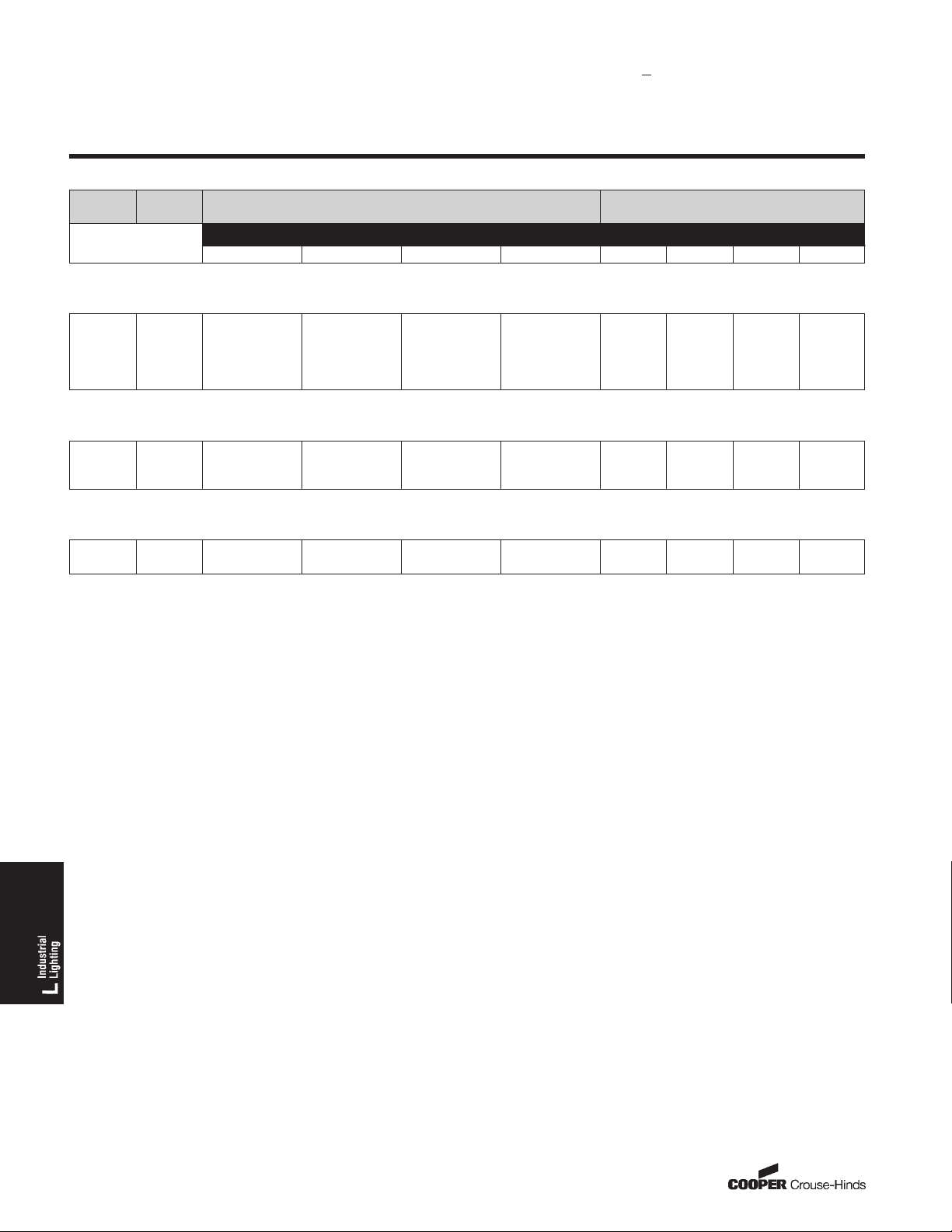

Fluorescent

ɀ Linear

ɀ Long Twin

Tube

ɀ Compact

Section 6L

VF Series, NFL,

FVN, FVS

DMVF, N2MVF

Section 6L

VF Series, NFL,

FVN, FVS, DMVF,

N2MVF

Section 6L

NFL, FVS, DMVF,

N2MVF, CPMVF

EVFDR,

EVFT Illuminator

Section 6L

NFL, N2MVF, FVS,

VF Series, DMVF,

CPMVF

Section 6L

EVF, EVFDR,

EVFT Illuminator

EVLPF, eLLK

Section 6L

VF Series, NFL,

nLLK, eLLK, FVN,

FVS, CPMVF,

DMVF, N2MVF

Section 6L

CPMVF, DMVF,

N2MVF

Section 6L

FVN, nLLK, eLLK,

FVS, DMVF,

N2MVF

EVF, EVFDR,

EVFT, EVLP

Section 6L

EVF, EVFT

Section 9L

EVH

Emergency

& Warning

ɀ Exit Signs

ɀ Emergency

Lighting

ɀ ‘‘Steady On’’

Beacons

ɀ Strobes

Section 10L

N2LPS Light-PakTM,

DMVFB, N2MVFB

Section 11L

VF ‘‘SO’’ Beacon

VDAS Strobe

Section 10L

DMVFB, N2MVFB,

N2LPS Light-PakTM,

Section 11L

VF ‘‘SO’’ Beacon

VDAS Strobe

Section 10L

DMVFB, N2MVFB,

Section 11L

VDAS Strobe

TM

Section 10L

DMVF-EXD exit,

N2MV-EXD exit,

N2LPS Light-Pak

N2MVFB, DMVFB

Section 11L

VF ‘‘SO’’ Beacon

VDAS Strobe

Section 10L

EXL exit,

®

,

EVLPF-EXD exit,

ELPS Light-Pak

EVLPFB

Section 11L

EV ‘‘SO’’ Beacon

EVAS Strobe

Section 10L

DMVF-EXD exit,

N2LPS Light-Pak

DMVFB, N2MVFB

Section 11L

VF ‘‘SO’’ Beacon

VDAS Strobe

Section 10L

DMVFB, N2MVFB

Section 10L

EXL,

N2LPS Light-Pak

DMVFB, N2MVFB

Section 11L

VF ‘‘SO’’ Beacon

VDAS Strobe

EVAS Strobe

WallPacks &

Floodlights

ɀ Pulse Start

Metal Halide

ɀ Metal Halide

ɀ High Pressure

Sodium

ɀ Mercury Vapor

ɀ Incandescent

Section 7L

F2MV, FMV,

FMV1000

Section 7L

F2MV, FMV,

FMV1000

Section 7L

CPMV, F2MV,

FMV, FMV1000

Section 7L

CPMV, F2MV,

FMV, FMV1000

TM

,

Section 7L

FZD, EVM-S812,

RCDE

TM

Section 7L

CPMV, F2MV,

TM

FMV, FMV1000

,

FZD

Section 7L

CPMV, F2MV,

FMV

Section 7L

CPMV

TM

,

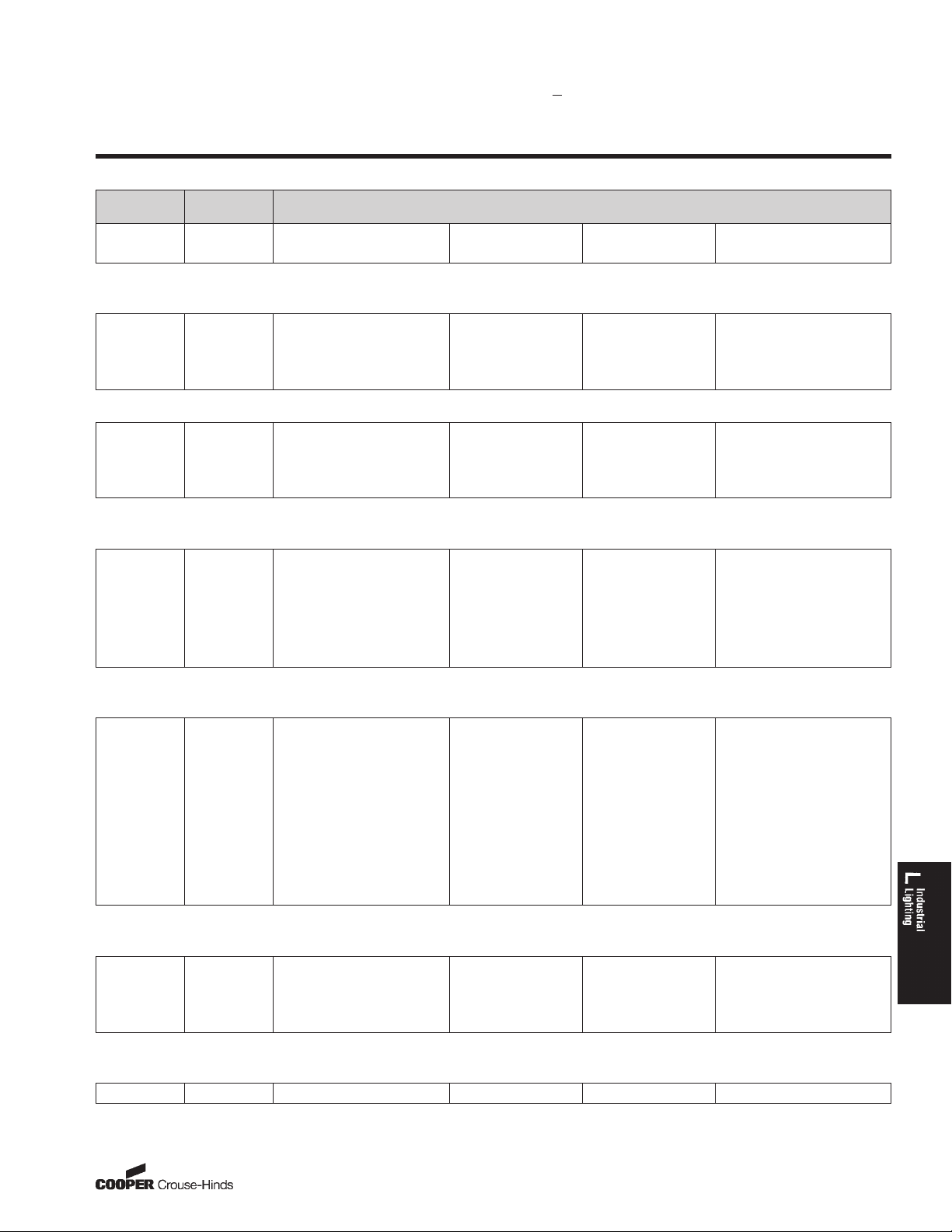

Luminaire

Hangers

Section 8L

AL, UNJ, FHM,

ARB, UNE, UNH,

CHS

Section 8L

AHG, ARB–21 series

Section 8L

EFHC-S752

ECHF-S758

ECF-S516

Section 8L

EAHC, EFHC,

ECHF, GUA, GUFX,

EFHX, CPS, UNR

Section 8L

AL, AHG, UNJ,

UNJC, ARB, UNE,

UNH, COUP

Section 8L

AL, AHG, UNH,

UNJC, ARB, UNE,

UNH, COUP

Section 8L

ECHF, GUA,

GUF,

GUJ. EAHC, EFHC,

AHG (Class II, Div 2)

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

663

L

New ideas in industrial lighting, translated

into modern equipment design, backed

technically by a nationwide sales force,

available worldwide through knowledgeable

electrical distributors – these are some of the

reasons you’ll be light-years ahead when you

look to Cooper Crouse-Hinds for industrial

lighting products.

This Lighting Selector Guide will help you

solve many of your lighting problems. For

additional assistance on complex projects,

call your Cooper Crouse-Hinds

representative or distributor. They can

provide detailed lighting layouts and

recommendations using the most advanced

computer and application engineering

facilities and techniques.

Industrial Lighting Products

Lighting Selector Guide

Below is a simple five-step procedure to help

you select the right equipment for a specific

job. Typical examples – with illustrations,

easy-to-read charts, and layouts – are

included to ensure correct results.

The five steps are:

1.) Determine Area

Lighting Needs

and Operational

Factors

Page 665

2.) Select

Type of Lamp

Page 666

3.) Select

Type of

Luminaire

Page 668

4.) Calculate

Number of

Luminaires

Required

Page 683

When known,

proceed to Step 2

When known,

proceed to Step 3

When known,

proceed to Step 4

When several light

sources or systems

seem suitable,

determine most

economical one

With LuxiconTMyou’ll be able to make

‘light’ work of analyzing the performance

of Cooper Crouse-Hinds broad line of

industrial luminaires.

From exterior/interior layouts to economic

performance data, you’ll be able to access

and evaluate information needed to design

and specify the most efficient and effective

lighting system possible.

TM

Luxicon

ɀ Online tutorial

ɀ Color output, either text or graphics

ɀ Exterior/interior layouts in one program

ɀ Daylight lighting analysis

ɀ Importing/exporting of any IES file

ɀ Importing/exporting of any .DXF CAD file

ɀ Detailed architectural feature calculations

ɀ Entire Cooper Crouse-Hinds and Cooper

Lighting line search

ɀ Economic performance/analysis

calculations

ɀ Database of customers and their projects

ɀ Professional output including summary

reports, luminaire schedules, calculation

results and renderings on multiple pages

ɀ Luminaire editing capabilities

ɀ Allowances of varying ambient temperature

levels

offers:

5.) Determine

Placement of

Luminaires and

Make Layout

Page 688

664

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

Industrial Lighting Products

1

Determine Area Lighting Needs and Operational Factors

L

The selection of the proper luminaire/lamp

combination and the determination of the

number of luminaires required is a function of

the desired quantity and quality of light

required, together with consideration of any

special factors arising from the nature of the

work operation.

Several aspects of this selection process are

discussed below. The conditions will vary

from job to job. It is important to consider

these conditions if the lighting system is to

yield optimum results.

A) Determine Illumination Quantity

Required

The Illuminating Engineering Society in the

current IES Lighting Handbook gives a

comprehensive listing of footcandle levels

recommended for all types of Industrial

Lighting. A condensed version of this listing is

given in Table I and is presented according to

the types of visual tasks encountered.

B) Determine Illumination Quality Required

Quality of illumination pertains to the

distribution of brightness in the visual

environment. Care must be taken to avoid

discomforting glare within the normal visual

field.

Luminaires normally selected for lower

mounting should be designed to limit

brightness below the 45° zone.

C) National Electric Code Compliance

The National Electric Code delineates some

areas as hazardous, depending on materials

or atmosphere within an area. The choice of

luminaire and lamp is therefore somewhat

restricted if the area is classified as

hazardous.

In hazardous areas, luminaire design and

operating temperature of both luminaire and

lamp must meet strict limitations. These

limitations are detailed under Step 3 of this

selection guide.

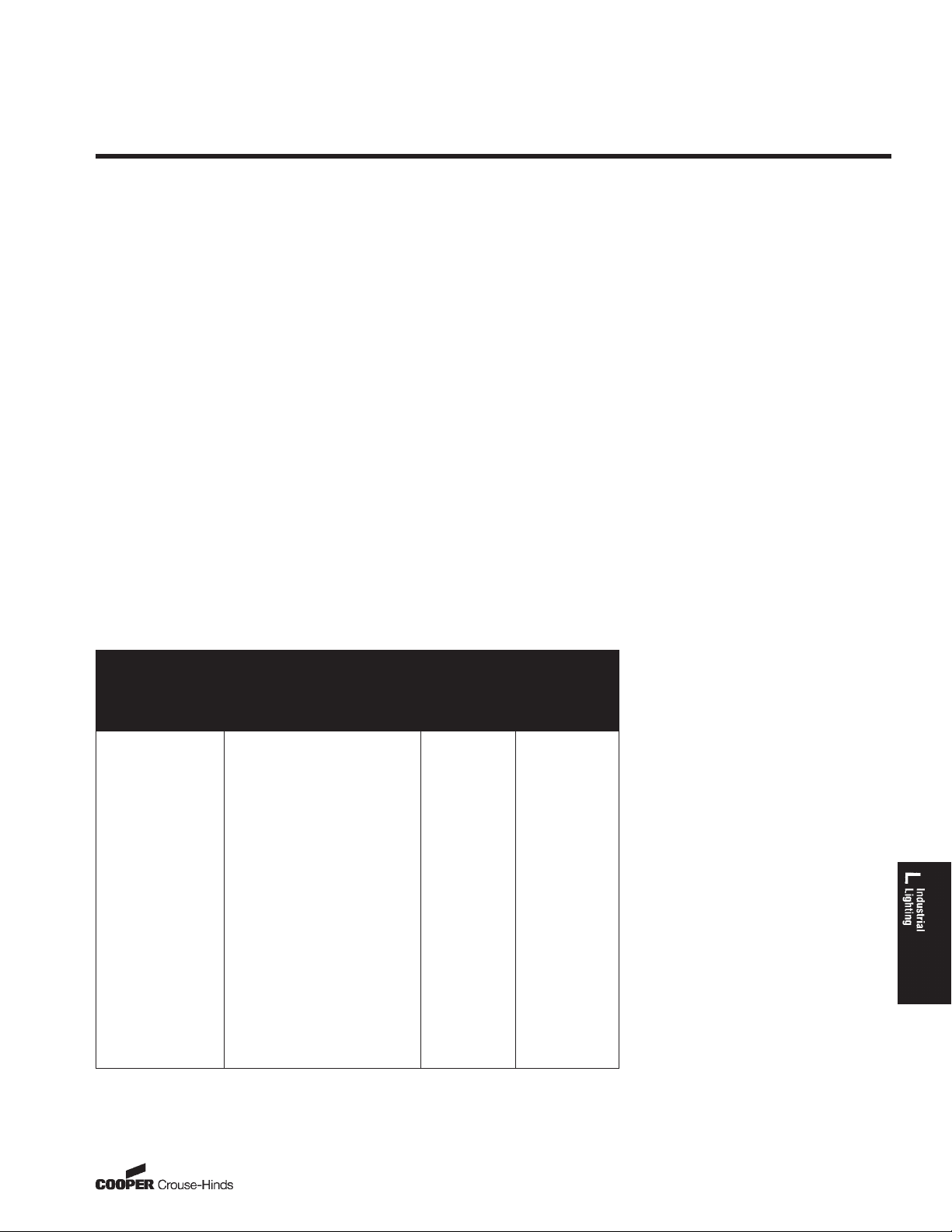

Table 1 / Recommended Levels of Illuminance

Seeing Task Typical Type of Work

Difficult Difficult assembly and

inspection, color coding, paper

manufacturing (Inspection and

Rewinder) finishing operations.

Moderate Moderately difficult assembly

and inspection, checking and

sorting, service garage repair

areas, medium bench work,

instrument panel (vertical

illumination).

Casual Simple assembly, rough bench

work, grinding, simple

inspection, wrapping, packing

and labeling, control house

general lighting.

Easy Rough active storage,

washrooms, dry lumber

warehouse, compressor

houses.

Limited Inactive storage, stairway B 5 to 10

NOTE: For other industrial footcandle levels such as petrochemical, refer to the Illuminating

Engineering Society’s Lighting Handbook (Application Volume) for more information.

Illuminance

Category Footcandles†

F 100 to 200

E 50 to 100

D 20 to 50

C 10 to 20

If the area is non-hazardous in nature, the

selection of the proper luminaire and lamp is

less restrictive and should be based on

general operational and environmental

conditions.

D) Maintenance Considerations

In order to insure optimum performance of

the lighting system at a reasonable cost,

some of the following related factors must be

introduced into the selection process:

ɀ Atmospheric Conditions: Luminaires for use

in extremely wet locations should be

enclosed and gasketed.

Luminaires for use in extremely dirty

locations should provide a minimum of light

depreciation under the anticipated

maintenance schedule (i.e., reflector with

open top and bottom should be used where

maintenance is infrequent). Luminaires for

use in extremely corrosive atmospheres

should have protection for the optical system

and have finishes to withstand the particular

corrosive agent (i.e., epoxy power finish;

enclosed Alzak reflector; Krydon

reinforced polyester reflector).

ɀ Accessibility: Since it may be necessary to

locate luminaires in inaccessible areas, the

luminaire and lamp selected should minimize

need for maintenance and maximize ease of

maintenance when required (i.e., high bay

open reflector with mercury lamp).

ɀ Area Usage: The selection of the proper

lamp/luminaire combination will depend

greatly on the required burning hours per

year. The anticipated usage should be a

major factor in lamp selection.

Values recommended are average maintained footcandles

†

at 30⍯ above floor (work plane).

TM

fiberglass

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

665

L

Industrial Lighting Products

2

Select Type of Lamp

After identification of the factors discussed in

Step 1, the following guide can be used in

selecting the proper lamp:

A) Illumination Level

High (30FC or more): high intensity

discharge (H.I.D.) lamps are generally the

most economic choice.

ɀ Exception: where luminaires must be

placed within an operator’s normal visual

span, a low brightness light source such as

fluorescent should be used.

Low (less than 30FC): all light sources can be

considered. Selection of best lamp is usually

based on other factors.

ɀ Exception: at medium to high mounting,

high intensity discharge is generally best.

B) National Electrical Code

Hazardous locations – all light sources can

be considered.

ɀ Exception: Article 500 of the National

Electrical Code classifies the various

categories of hazardous locations and

provides general rules for the application of

luminaires in these areas. (See Step 3 of

Selection Guide.)

ɀ Exception: where process must be shut

down for relamping, high intensity discharge

is best due to long lamp life. Non-hazardous

locations – all light sources.

®

C) Accessibility

High intensity discharge lamps should be

used where luminaires are relatively

inaccessible because of long life and the

need for infrequent relamping.

D) Area Usage (Burning Hours)

At more than 2,000 burning hours per year,

high intensity discharge and fluorescent

lamps generally yield the lowest system cost.

At less than 2,000 hours per year,

incandescent may be the best system

depending on the size of the area, mounting

height and illumination level required.

E) Other Considerations

ɀ Energy cost: where energy cost is high,

high intensity discharge lamps generally

prove most economical. H.I.D. lamps

produce more lumens per watt of electricity

than other lamp types.

ɀ Safety: due to warmup and restart

characteristics of high intensity discharge

lamps, auxiliary or emergency lighting should

be used in critical areas.

666

Continued

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

Industrial Lighting Products

2 (continued)

Select Type of Lamp

The following table of lamp characteristics

provides guidelines for choosing the best

lamp. If the decision is not obvious, contact

your Cooper Crouse-Hinds representative for

a computer analysis of the option desired.

Table II/Lamp Characteristics

Lamp Advantages Disadvantages

L

1. Induction Exceptionally long life – 100,000 hours.

Instant illumination upon start-up or warm

restart. Crisp, white light >80 color rending

index. Low operating cost.

2. High Pressure Sodium Good beam control. Long lamp life (24,000

hrs). Highest lamp output (lumens per watt).

Low operating cost. Shortest restart time of

H.I.D. lamps (instant with optional instant

restrike).

3. Metal Halide

Pulse Start

Improved lamp life (15,000- 30,000 hrs).

Increased lumen output over standard

metal halide (25 to 50%). Better lumen

maintenance (80%). Superior cold starting

-40°C. Improved color stability. Color shift

reduced by two-thirds. Improved lamp-tolamp color consistency. Warm up time 2

minutes. Restrike time 3-4 minutes.

4. Metal Halide Moderately long lamp life (7500 + hrs).

High light output (lumens per watt). Makes

colors look close to natural. Low operating

cost.

5. Mercury Long lamp life (24,000 hrs). High light

output per watt. Low operating cost.

Initial cost is higher than HID type luminaires.

High initial cost. Requires warmup period.

High initial cost. Requires warmup period. Does

not restart immediately after power outage.

High initial cost. Requires warmup period. Does

not restart immediately after power outage.

High initial cost. Requires warmup period. Does

not restart immediately after power outage.

6. Fluorescent Long lamp life (7500-24,000 hrs). High light

output per watt. Low operating cost. Low

brightness. Cool operation.

7. Incandescent Low initial cost. Good color rendition. Good

light control. Instant restart.

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

High initial cost. Poor light control. Output may

vary with ambient temperature.

Low light output (lumens per watt), short lamp life

(500-2000 hrs). High operating cost.

667

L

Industrial Lighting Products

3

Select Type of Luminaire

Choice of Reflector

The following list gives broad guidelines for selection of the proper reflectors.

Mounting Height

Above Floor Reflector

Up to 19′ Dome

20′ or more High bay

Where low footcandle levels will be provided, reflectors may be used at higher mounting heights than shown; where high footcandle levels will be

provided, reflectors may be used at lower mounting heights than shown in the table.

Quick Selector (Environment—Product)

Opposite the industrial environments listed below are the luminaires designed and approved to meet the requirements unique to each

environment. Where different types of light sources might be used, a choice is given.

Environment Type Description Cat. Sect. Pg. #

Corrosive Non Metallic

Explosive Vapors

(Class I, Div. 1)

Combustible Dusts

(Class II, Div. 1)

Moisture, Non-Combustible Dusts,

or Potential for Hazardous Vapors

Class I,

Div. 2

Non-Hazardous

Enclosed & Gasketed

Explosionproof

Dustignition-proof

Enclosed & Gasketed

Enclosed &

Gasketed

NDA

N2MV

N2MVF

N2MVFB

NFW

N2LPS

EV, EVI General—Incandescent 2L 709

EVLP, EVM HazardȿGard

EVF, EVFDR General—Fluorescent 6L 809

EVFT General—Fluorescent 6L 809

EVLPF General—Fluorescent 6L 809

RCDE/RCDER Flood—Incandescent 7L & 9L 865 & 913

ELPS Emergency—Halogen 10L 923

EVLPFB Emergency—Fluorescent 10L 923

EV Strobe—Incandescent 11L 939

EV

DMV

N2MV

DMVIG, VMVIG

DMVF, N2MVF

EVM HazardȿGard

FVN

FVS

DMVFB, N2MVFB

Vaporgard

CPMV

NDA General—Incandescent 1L 691

LMV

DMV

VMV

N2MV

FVN General—Fluorescent 6L 809

DMVF, N2MVF General—Fluorescent 6L 809

VF General—Fluorescent 6L 809

FVS General—Fluorescent 6L 809

FMV

SSFMV Voyager Flood—H.I.D. 7L 865

N2LPS Emergency—Halogen 10L 923

DMVFB, N2MVFB Emergency—Fluorescent 10L 923

NFL General—Fluorescent 6L 809

Champ

Champ

Champ

Champ

Champ

Champ

Champ

Champ

®

®

®

TM

®

®

®

®

®

®

General—Incandescent

General—H.I.D.

General—Fluorescent

Emergency—Fluorescent

General—Fluorescent

Emergency—Halogen

®

General—H.I.D. 4L 779

General—Incandescent

General—H.I.D.

General—H.I.D.

General—Induction

General—Fluorescent

General—H.I.D.

General—Fluorescent

General—Fluorescent

Emergency—Fluorescent

General—Incandescent 1L 691

General—H.I.D/Fluorescent 3L & 6L 721 & 809

General—H.I.D. 3L 721

General—H.I.D. 3L 721

General—H.I.D. 3L 721

General—H.I.D. 3L 721

Flood—H.I.D. 7L 865

1L

3L

6L

10L

6L

10L

2L

3L

3L

5L

6L

4L

6L

6L

10L

691

721

809

923

809

923

709

721

721

801

809

779

809

809

923

668

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

Lamps Used With

Cooper Crouse-Hinds

Luminaires

H.I.D. Medium Base

Series - LMV, EVLP

1

L

LAMP ANSI

WATTS Ballast

GE

High Pressure Sodium

35 S76 LU35/MED LU35/MED C35S76/M

50 S68 LU50/MED LU50/MED C50S68/M

70 S62 LU70/MED LU70/MED C70S62/M

100 S54 LU100/MED LU100/MED C100S54/M

150 S55 LU150/MED LU150/MED C150S55/M

Metal Halide

70 M98 MXR70/U/MED MP70/U/MED MHC70/U/M/3K MH70W/U

100 M90 MXR100/U/MED MP100/U/MED MHC100/U/M/3K MH100W/U

175 M57 MVR175/U/MED M175/U/MED MH175/U/M

Pulse Start Metal Halide

150 M102 MXR150/U/MED MP150/U/MED MH150W/U/PS

175 M137 MXR175/VBU/MED/PA MS175W/BU/MED/PS

MANUFACTURER

Osram/

Sylvania

Phillips Venture

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

669

L

Lamps Used With

H.I.D. Medium Base

Series - LMV, EVLP

1

Cooper Crouse-Hinds

Luminaires

LAMP ANSI

WATTS Ballast

GE O/S Ph Venture GE O/S PH Venture

High Pressure Sodium

35 S76 2250/16K 2250/16K 2250/24K B17 E17 ED17

50 S68 4000/24K 4000/24K 4000/24K B17 E17 ED17

70 S62 6400/24K 6300/24K 6300/24K B17 E17 ED17

100 S54 9500/24K 9500/24K 9500/24K B17 E17 ED17

150 S55 16000/24K 15800/24K 16000/24K B17 E17 ED17

Metal Halide

70 M98 5500/12K 5200/15K 6200/10K 5600/15K BD17 E17 ED17 ED17

100 M90 9000/15K 8500/15K 9300/12.5K 9000/15K BD17 E17 ED17 ED17

175 M57 13600/10K 14400/10K 13500/10K BD17 ED17 ED17

Pulse Start Metal Halide

150 M102 12500/15K 13300/15K 14000/15K BD17 E17 ED17

175 M137 17700/15K 17500/15K BD17 E17 ED17

MANUFACTURER MANUFACTURER

Lumens/Life (hrs) Bulb

670

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

Lamps Used With

Cooper Crouse-Hinds

Luminaires

H.I.D. Mogul Base

Series - DMV, VMV, CPMV,

FMV, F2MV, EVLP

0, FZD

L

LAMP ANSI

WATTS Ballast

GE

High Pressure Sodium

50 S68 LU50 LU50 C50S68

70 S62 LU70 LU70 C70S62

100 S54 LU100 LU100 C100S54

150 S55 LU150/55 LU150/55 C150S55

150 (100V) S56 LU150/100 LU150/100 C150S56

200 S66 LU200 LU200 C200S66

250 S50 LU250 LU250 C250S50

310 S67 LU310 LU310 C310S67

400 S51 LU400 LU400 C400S51

1000 S52 LU1000 LU1000 C1000S52

Metal Halide

70 M98 MH70W/U/ED28

100 M90 MH100W/U/ED28

175 M57 MVR175/U M175/U MH175/U

250 M58 MVR250/U M250U MH250/U

400 M59 MVR400/U M400/U MH400/U

400 M59 MVR400/U/ED28 M400/U/BT-28 MH400/U/ED28

1000 M47 MVR1000/U M1000/U MH1000/U

1500 M48 MVR1500/HBD M1500/BD MH1500/BD

MANUFACTURER

Osram/

Sylvania

Phillips Venture

Pulse Start Metal Halide (Base up+–15%) (Base up+–15%)

150 M102 MH150W/U/ED28/PS

175 M137 MXR175/VBU/PA MS175/BU/PS MS175W/BU/PS

200 M136 MH200W/U/PS

250 M138 MXR250/VBU/PA MS250/BU/PS MH250W/HBU/PS

320 M132 MXR320/VBU/PA MS320/PS/BU-ONLY MS320W/BU/PS MH320W/U/ED28/PS

350 M131 MH350W/U/PS

400 M135 MXR400/VBU/PA MS400/PS/BU-ONLY MS400/BU/PS MH400W/HBU/PS

1000 M141

Mercury Vapor

100 H38 HR100A38 H38HT-100 H38HT-100

175 H39 HR175A39 H39KB-175 H39KB-175

250 H37 HR250A37 H37KB-250 H37KB-250

400 H33 HR400A33 H33CD-400 H33CD-400

1000 H36 HR1000A36 H36GV-1000 H36GV-1000

HID Double Contact Metal Halide for EVP Series

70W CMH70/TD/830/R7S HQI-DE 70/WDX CDM70/TD/830

M138 MH250W/HBD/PS

M131 MH350W/U/ED28/PS

M135 MH400W/HBD/PS

M135 MH400W/HBU/ED28/PS

M135 MH400W/HBD/ED28/PS

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

671

Loading...

Loading...