Crouse Hinds Conduit Outlet Bodies General Product Line Information

Condulet®Conduit Outlet Bodies

Gasket and Covers on page 7

1F

Application:

Conduit outlet bodies are installed in conduit

systems to:

ɀ act as pull outlets for conductors being

installed

ɀ provide openings for making splices and

taps in conductors

ɀ act as mounting outlets for lighting fixtures

and wiring devices

ɀ connect conduit sections

ɀ provide taps for branch conduit runs

ɀ make 90° bends in conduit runs

ɀ provide for access to conductors for

maintenance and future system changes

Features:

Conduit Outlet Bodies

ɀ Form 7 Condulet outlet bodies approach

conduit in size for neat, compact installations.

ɀ Form 8 and Mark 9 bodies provide more

room for heavier conductors

ɀ Many shapes and sizes are available for

rigid threaded conduit – see complete listings

on page 6.

ɀ Conduit hubs have tapered threads and

feature integral bushings for protection of

wire insulation.

ɀ Form 7 has exclusive snaptight and wedgenut cover attachment to provide clear,

unobstructed cover opening.

ɀ Built-in rollers on all Form 5 1

LB bodies to facilitate wire pulling.

ɀ Series 5 bodies available in optional

configuration with set screws on hubs for

EMT conduit (add suffix -MT to catalog

number).

Gaskets

Solid gaskets:

ɀ are used with blank covers

ɀ for Mark 9 and Form 5, can be converted to

open type gaskets by tearing out center

section along scored lines –

ɀ for Form 7 are used with all covers

Open gaskets:

ɀ for Form 8 –

ɀ for Mark 9 – 2

1

⁄2⍯ to 4⍯ sizes

1

⁄2⍯ to 4⍯ sizes

Blank Covers

Stainless steel cover screws are standard on

Form 7, Form 8, Mark 9, Series 5 and Form 5

covers.

ɀ Form 7

Wedge nut design facilitates installation and

removal. Nuts are held captive in cover.

Covers can be used with or without gaskets.

SNAPTIGHT

sealing gaskets are installed without the use

of screws, reducing installation time and

costs. Covers are reusable.

ɀ Form 8

Two cover screws provided on all sizes to

provide tight cover and gasket assembly.

Feraloy

for added strength and extra wiring room.

ɀ Mark 9

Self-retaining cover screws.

TM

Form 7 Covers with integral

iron alloy covers have dome shapes

1

⁄4⍯ to 4⍯ C and

1

⁄2⍯ to 2⍯ sizes

Standard Materials:

ɀ Form 7, Form 8 outlet bodies –

alloy

ɀ Mark 9 outlet bodies – copper-free

aluminum

ɀ Form 5 – malleable iron

ɀ Series 5 – die cast aluminum

Feraloy

iron

Standard Finishes:

ɀ Form 7, Form 8 outlet bodies –

electrogalvanized with aluminum acrylic paint

ɀ Mark 9 outlet bodies – natural

ɀ Form 5 – electrogalvanized with aluminum

acrylic paint

ɀ Series 5 – aluminum acrylic paint

Options:

Description Added to

Form 7 body and cover only:

Copper-free aluminum............... SA

Corro-free

powder coat............. add suffix S752

ɀ Series 5 in an EMT version with set screws

on all hubs .... add suffix -MT

ɀ Series 5 pre-packaged with neoprene

gasket and cover .... add suffix -CGN

TM

epoxy

Suffix to be

Cat. #

Certifications and

Compliances:

Outlet Bodies –

ɀ UL Standard: 514B

ɀ Fed. Spec.: W-C-586D

ɀ CSA Standard 22.2 No. 18

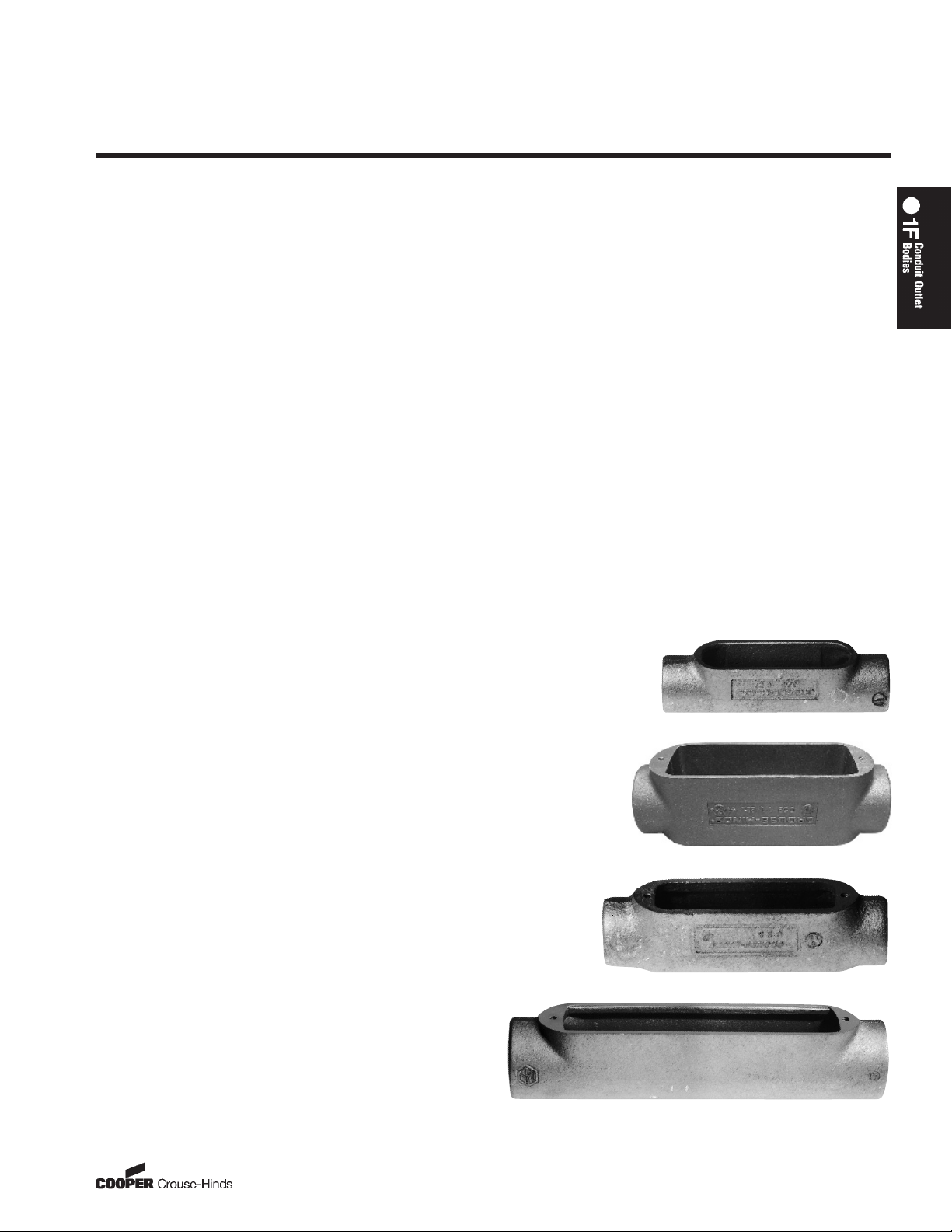

Size comparison of 1

7, Mark 9, Form 8, and Mogul

bodies. Round backs on Form

7 and Mogul; flat backs on

Form 8 and Mark 9. The round

back conduit body is a

registered trademark of Cooper

Industries, Inc.

ɀ Raintight (when installed

with cover and gasket)

1

⁄2⍯ Form

Mogul

Form 8

Form 7

Mark 9

®

®

©

2006 Cooper Crouse-Hinds

5US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

Loading...

Loading...