Crouse Hinds Circuit Breaking CPS Receptacles and CPP Plugs Catalog Page

2P

Arktite®Circuit Breaking CPS

Receptacles and CPP Plugs

Delayed Action

Factory Sealed

Cl. I, Div. 1 & 2, Groups C, D

Explosionproof

Wet Locations

Applications:

CPS receptacles, angle and straight types,

and CPP plugs are used:

• With portable electrically operated

devices such as motor-generator sets,

compressors, conveyors, portable tools,

lighting systems and similar equipment

• In locations which are hazardous due to

the presence of flammable vapors or

gases

• In damp or corrosive locations

• In petroleum refineries, chemical and

petrochemical plants, and other process

industry facilities where similar hazards

exist

Fig. 1

Fig. 2

2P

Fig. 3

Features:

• The delayed action feature permits the

plug to be used as an emergency pushpull switch

• CPS receptacles are equipped with a

rotating mechanism which prevents

complete withdrawal of the CPP plug in

one continuous movement. Details of

operation are illustrated and explained

below

Figure 1 shows a CPS angle type

receptacle assembly with CPP plug

fully engaged.

Figure 2 shows the plug withdrawn

until it is stopped by the delayed action

mechanism. In this position the circuit

has been broken and the arc has been

snuffed in the contact chambers.

To completely withdraw the plug as

shown in Figure 3, the delayed action

release lever must be rotated

counterclockwise. The time required to

actuate the mechanism permits

dissipation of the arc-generated heat

before contacts and arcing chambers

are opened to the atmosphere. When

inserting the plug, the reverse

procedure is followed.

• CPS receptacles are factory sealed to

simplify installation and wiring – external

seals are not required

• Series 152 receptacles have top hinged

cover design, with 45° downward angled

receptacle housing, to provide superior

environmental protection from

accumulations of dust, snow, ice, and

water

• Back boxes used for angle type

receptacles are standard EDS bodies.

Assemblies are listed with single and

two gang bodies and dead end or

through feed hubs –

• Back boxes used for straight type

receptacles are available with a variety of

hub arrangements in

• All receptacles and 30 ampere plugs are

provided with pressure terminals for

ease of field wiring. 20 ampere plugs

have solder terminals.

1

/2" to 1" sizes

1

/2" and 3/4" sizes

Certifications and

Compliances:

• NEC/CEC:

Class I, Division 1 and 2, Groups C, D

• UL Standard: 1203

• CSA Standard: C22.2 No. 30

Standard Materials:

• Receptacle housings – die cast copperfree aluminum

• EDS Back boxes – Feraloy

(U.S.)/Copper-free aluminum (Canada)

• Other back boxes – Feraloy iron alloy

• Plug exteriors – copper-free aluminum or

• Insulation – all receptacles and plugs –

• Pressure or solder contacts – brass

• Crimp/solder contacts – leaded red

®

Krydon

fiberglass-reinforced polyester

material (see listings)

Krydon fiberglass-reinforced polyester

material

brass

®

iron alloy

Standard Finishes:

• Copper-free aluminum – aluminum

acrylic paint

• Feraloy – electrogalvanized and

aluminum lacquer

• Fiberglass-reinforced polyester – natural

(red, white)

• Brass – natural

• Leaded red brass – electro-tin-plate

Electrical Rating Ranges:

• Angle type – 20 and 30 amperes; 125

and 250 VAC

• Straight type – 20 amperes; 125 and 250

VAC

Grounding:

• NEC Article 501 and CEC Part 1 Section

18 requires that metal frames or

exposed non-current-carrying metal

parts of portable devices used in

hazardous locations be grounded

through an extra conductor in the

portable cord

• CPS receptacles and CPP plugs are

provided with an extra grounding pole

• In plugs, provision is made for

attachment of the grounding wire to the

grounding pole. In addition, direct

connection is provided between plug

and receptacle housings and the

grounding pole. In the receptacle,

grounding is accomplished through the

conduit system

Interchangeability of Plugs

with Non-hazardous

Location Receptacles:

• 30 ampere CPP plugs can also be used

with standard 30 ampere AR Arktite

receptacles of the same style and

number of poles, thus permitting

portable devices suitable for use in

hazardous locations to be connected to

receptacles in both hazardous and nonhazardous areas

Note: Equipment to be used in hazardous areas must be

suitable for use in the specific hazardous location.

1344

Arktite®Circuit Breaking CPS

Cl. I, Div. 1 & 2, Groups C, D

2P

Explosionproof

Receptacles and CPP Plugs

Wet Locations

Delayed Action

Factory Sealed

Options:

The following special options are available from factory by adding suffix to Cat. #:

Description Suffix

Material: copper-free aluminum, natural finish, is available on certain back boxes. See listings.........................................................................

Receptacle interior rotated 22

Combination of receptacles and EFS/EFD or EDS series devices, such as pilot lights, switches, pushbutton stations, etc., can be

furnished using three, four and five gang bodies..........................................................................................................................................

Hub arrangements other than those listed can be supplied..........................................................................................................................

1

/2° to right (viewed from face) and plug changed to match. 30 ampere units only..............................................

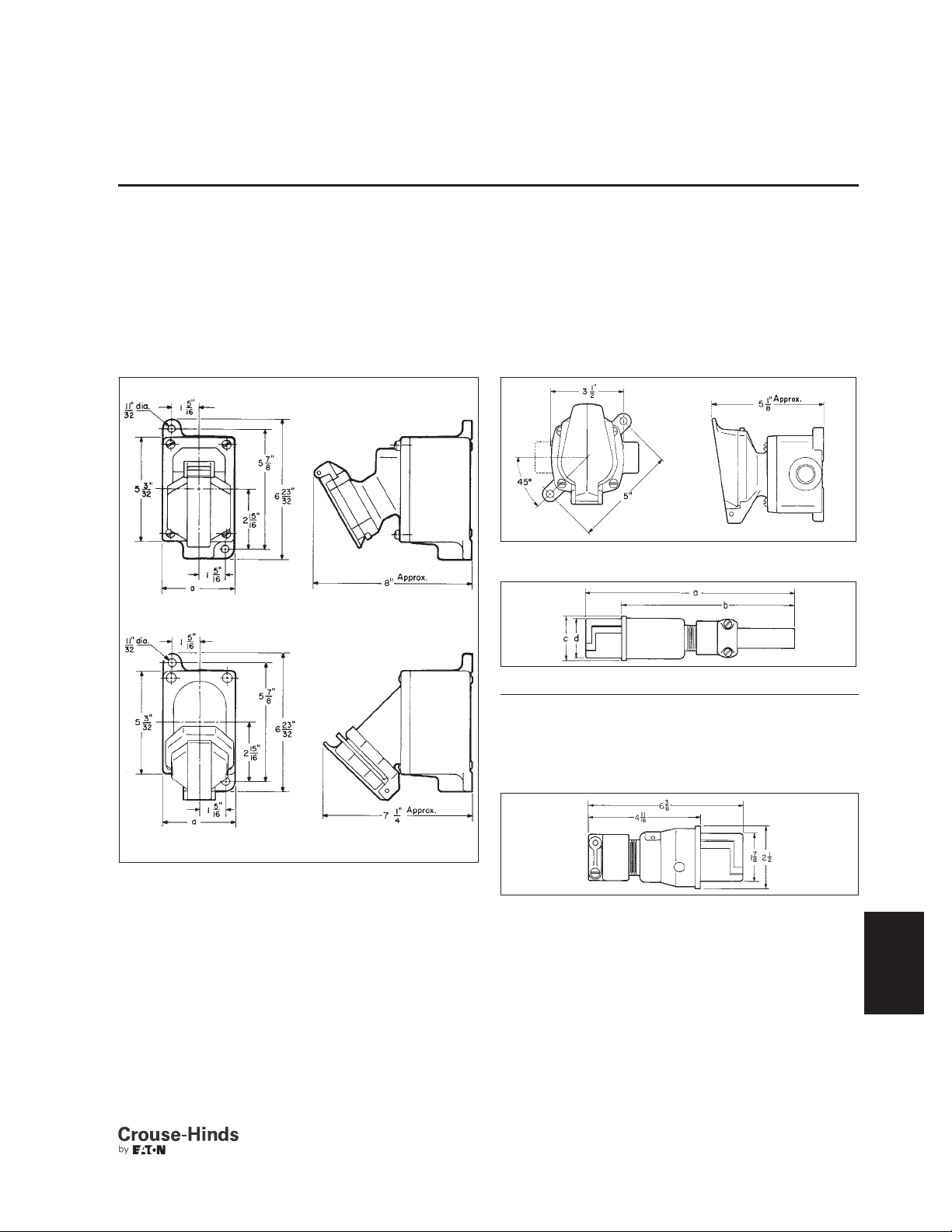

Dimensions

In Inches:

Angle Type Receptacles

Straight Type Receptacles

SA

S4

Specify

Specify

a

=3

1

/2 for single gang

3

7

/16 for two gang

Series 152

Series 532 and 732

20 Ampere Plugs

Cat. # a† b† c d

CPP516‡ 8

CPP512‡ 75

†These dimensions are approximate and vary with cable size.

‡ 20 amp plugs are furnished with solder terminations at standard, ground contacts have

pressure terminations.

3

/8 67/8 13/4 19/16

1

/2 13/4 19/16

30 Ampere Plugs

2P

1345

Loading...

Loading...