Crouse Hinds 8F Seals & Breathers & Drains Catalog Page

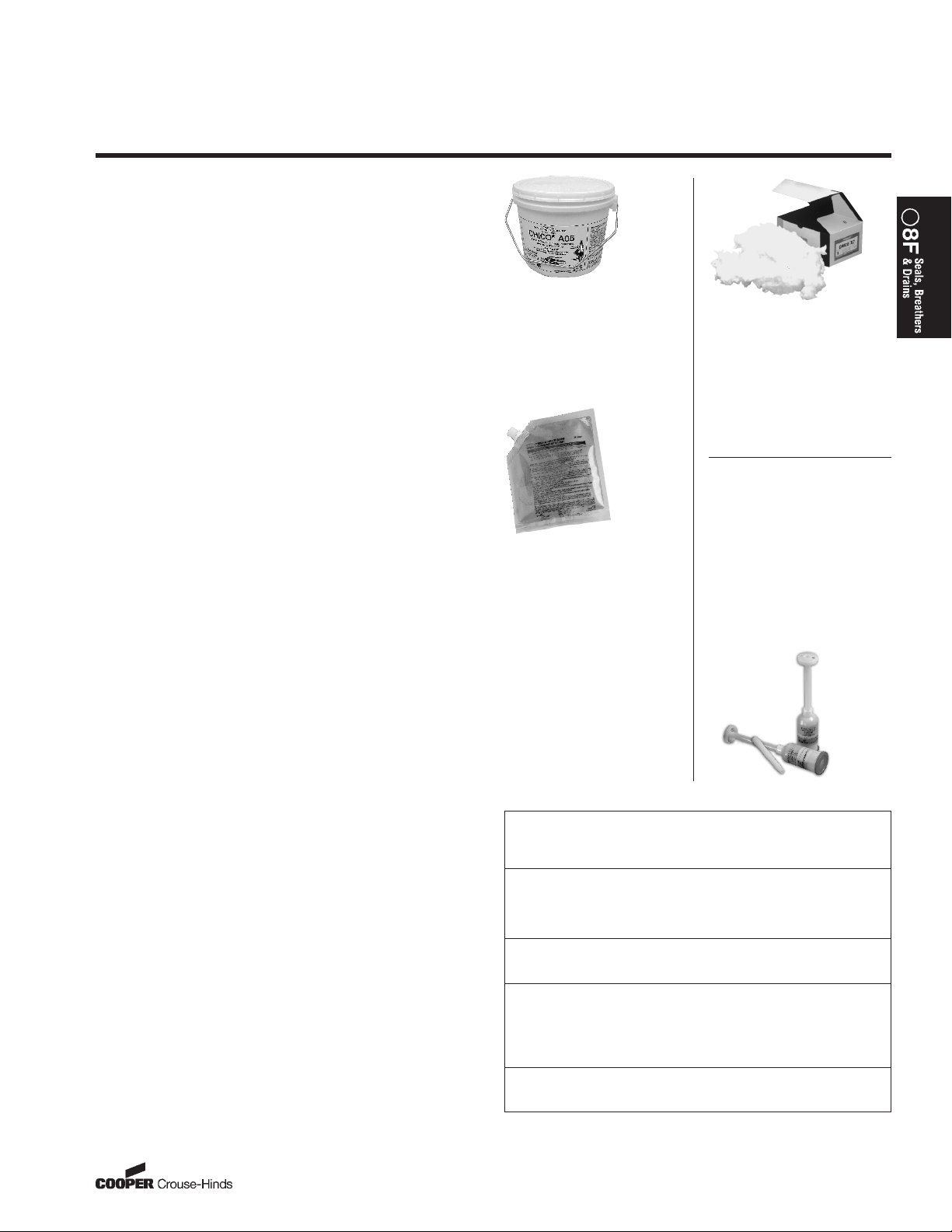

Chico®A and Chico®A-P Sealing Compound

®

Chico

Chico®SpeedSeal

For Sealing Fittings and Hubs

Application:

Chico X

ɀ forms a dam between the integral bushing of the sealing fitting and the

end of the conduit and around the electrical conductors entering the hub

Chico A

ɀ forms a seal around each electrical conductor and between them and

inside of the sealing fitting to restrict the passage of gases, vapors or

flames through the sealing fitting at atmospheric pressure and at normal

ambient temperatures

Chico®SpeedSealTMCompound:

ɀ

designed to separate and form an explosionproof seal around each

electrical conductor in Crouse-Hinds EYS and EYD sealing fittings.

ɀ restricts the passage of gasses, vapors or flames through the sealing fitting.

ɀ creates a seal for Class I, Division 1, Groups C & D and Class II, Division 1,

Groups E, F & G hazardous areas.

Features:

ɀ

Chico X

conductor

Chico A

ɀ

mixed and poured. The compound, unusually dense, expands slightly

when hardening and bonds to inner walls of sealing fittings. Compound

hardens in 60-70 minutes

ɀ Chico A cure time is 8 hours for class I, Group C and D applications and

72 hours for class I, Group A and B applications.

ɀ Chico A has a 1 year shelf life from date of manufacture.

ɀ Chico A ambient temperature range (after curing) is –40°F to +165°F.

ɀ

Chico A-P Intrapak®:

Packaged in two-compartment plastic pouch with precise amount of

water for mixing. No mixing or measuring implements required.

A hard squeeze of the water compartment forces the water into the

compartment containing the Chico compound. Mixing is completed by

kneading the pouch for one minute.

The mixed sealing compound is poured directly into the sealing fitting –

no funnel required. The package label indicates the size and quantity of

sealing fittings each pouch will properly fill. Compound hardens in 60-70

minutes.

Chico®SpeedSealTMCompound is a revolutionary material:

ɀ installs a reliable seal in five minutes -

ɀ hardens to a dense, strong mass that is suitable for Class I, Division 1,

Groups C & D and Class II, Division 1, Groups E, F & G hazardous

applications.

ɀ UL and cUL Listed for use with

fittings only.

ɀ packaged in a 2 oz. or 6 oz. pre-measured cartridge, eliminating the need

for measuring before mixing.

ɀ packaged with a screw-on nozzle for accurate dispensing.

ɀ expands four times its original size in the sealing fitting, eliminating the

need to separate the individual conductors with Chico X fiber.

ɀ Chico X fiber dams are not required in horizontal applications, reducing

installation times.

ɀ completely hardens in 20 minutes, simplifying use for OEMs.

ɀ suitable for cold temperature environments without the costly need to

build a temporary shelter around sealing fittings. All ice crystals must be

removed from inside the conduit seal before dispensing Chico SpeedSeal

compound. The Chico SpeedSeal compound should be kept above 10°C

(50°F) prior to mixing. The sealing fitting must be kept at or above 4°C

(40°F) during the 4 to 10 minute expansion/gel time of the compound.

ɀ one year shelf-life.

ɀ patent pending

Size Ranges:

ɀ

Chico A

compound)

Chico X

ɀ

Chico A-P

ɀ

compound.

ɀ

Chico SpeedSeal

NOTE: Cooper Crouse-Hinds sealing fitting are approved for use in

hazardous locations only when

Compound or

* A sixth pouch, containing an appropriate quantity of Chico X fiber, is included in these

cartons.

† Number of cubic inches this amount will fill when set. See internal volume requirements for

EYS, EZS, EYD, EZD and EYSR sealing fittings and ES sealing hubs (pages 184 to 191).

‡ Includes 1oz. Chico X fiber.

X Fiber

TM

fiber:

sealing compound:

fiber is a mineral wool that packs easily, forming around each

sealing compound is a water soluble powder, that can be easily

every time

1

⁄2⍯ to 2⍯ Copper Crouse-Hinds sealing

compound – 1 lb. to 5 lbs. (provides 23-115 cubic inches of

fiber – 2 oz. to 1 lb.

(5 pouches per carton) – provides 25 and 55 cubic inches of

- 2 oz. or 6 oz. cartridge

Chico X

Chico SpeedSeal

fiber and

are used to make the seal.

Chico A

Sealing

Chico A

Sealing Compound

Net Vol.

Weight Cu. In.† Cat. #

1 lb. 23 Chico A3

1 lb.‡ 23 Chico A4

5 lb. 115 Chico A05

Chico A-P Intrapak

(provided with Chico X

fiber)

Sealing Compound

and Water in Plastic

Mixing Pouch

Cu. In. No. of

Fill per Pouches Carton

Pouch† per Carton Cat. #

5 5 Chico A19-PX*

11 5 Chico A39-PX*

Chico SpeedSeal Ordering Information:

Sealing Fitting

Catalog Number

EYS1, EYS16; EYS11, EYS116

EYD1, EYD16, EYD11, EYD116

EYS2, EYS26, EYS21, EYS216

EYD2, EYD26, EYD21, EYD216

EYSX11, EYDX11

EYS3, EYS36, EYS31, EYS316

EYD3, EYD36, EYD31, EYD316

EYSX21, EYDX21

EYS41, EYS416, EYS4, EYS46

EYD4, EYD46, EYD41, EYD416

EYS51, EYS516, EYS5, EYS56

EYD5, EYD56, EYD51, EYD516

EYSX31, EYDX31

EYSX41, EYDX41

EYS61, EYS616, EYS6, EYS66

EYD6, EYD66, EYD61, EYD616

EYSX51, EYDX51

MSDS sheets are available at www.crouse-hinds.com

Chico X

Fiber

Net

Weight Cat. #

2 oz. Chico X4

8 oz. Chico X6

1 lb. Chico X7

Chart for Approximate

Amount of Fiber Per Hub

Hub

Size

1/2 1/32

3/4 1/16

1 1/8

1-1/4 1/4

1-1/2 1/2

®

21

2 1/2 1 1/2

32

3 1/2 3

4 4 1/2

57

610

Amount of

SpeedSeal Material

needed per fitting

(in ounces)

1 CHICO SS2

2 CHICO SS2

3 CHICO SS6

6 CHICO SS6

8F

Ozs.

Required

SpeedSeal

Catalog

Number

(2 oz. Cartridge)

(2 oz. Cartridge)

(6 oz. Cartridge)

(6 oz. Cartridge)

©

2006 Cooper Crouse-Hinds

193US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

Loading...

Loading...