Crouse Hinds 5F TWDC SERIES, 5F TBDC SERIES Catalog Page

5F

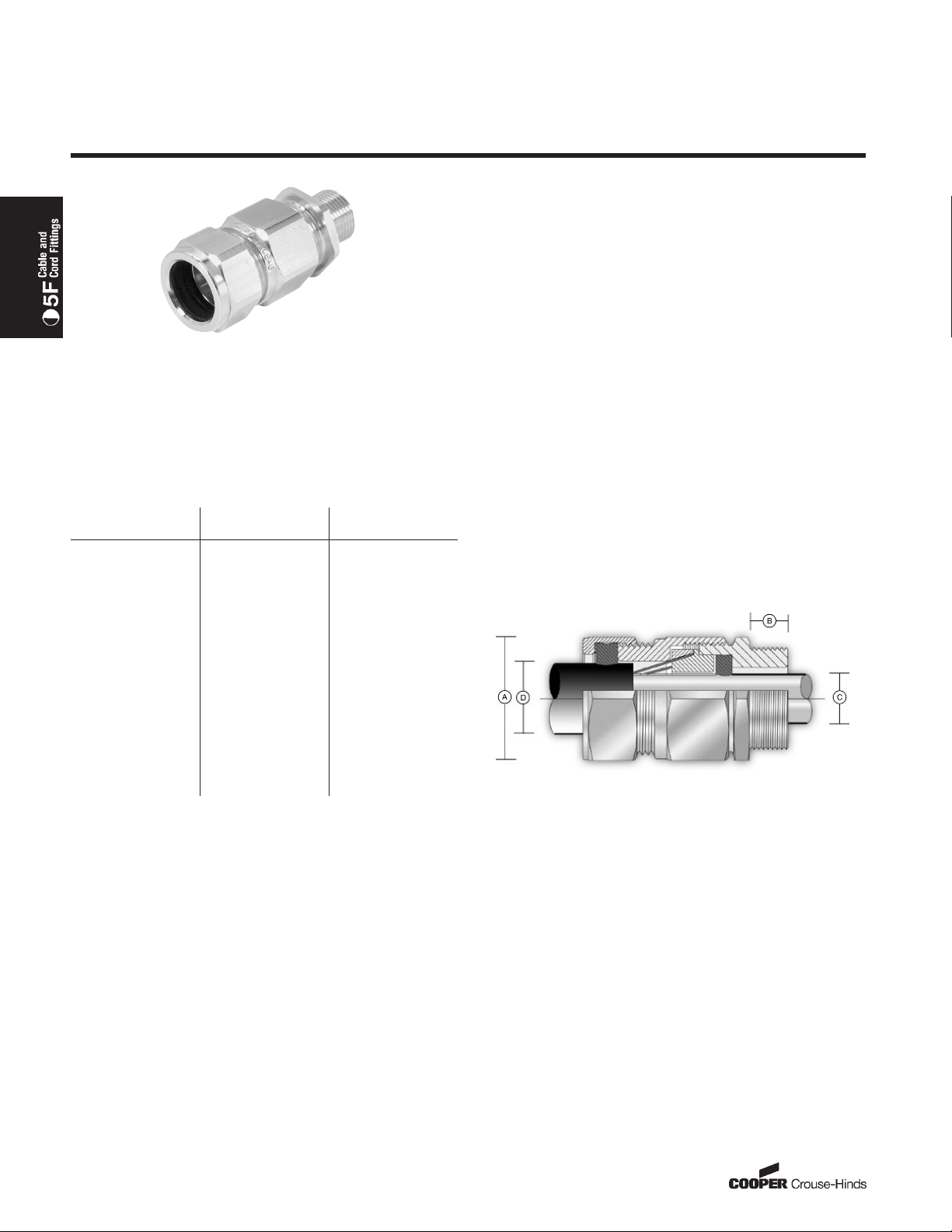

TWDC/TBDC SERIES

ATEX and CENELEC Range

for Steel Wire Armour or Steel Wire

Braid Cable

Certifications and Compliances

ɀ ATEX E Exd IIC/E Exe II with SIRA 03ATEX2078X

ɀ Standards EN50014:1998, EN50018:2000,

EN50019:2000 and EN50281-1-1:1998

ɀ IP66 and IP67

GOST R - Exd IICU/Exe IIU

Design Data (millimeters)

Gland

Size

16 25.5 16.0

20S 26.5 16.0

20 33.0 16.0

25 41.4 16.0

32 50.6 16.0

40 60.5 16.0

50S 71.5 16.0

50 71.5 16.0

63S 88.0 19.0

63 88.0 19.0

75S 99.0 19.0

75 99.0 19.0

80 115.2 25.0

80H 115.2 25.0

85 115.2 25.0

90 125.7 25.0

90H 125.7 25.0

100 125.7 25.0

A

(across corners) B

ATEX and CENELEC Dual E Exd IIC/E Exe II

Zone 1 or 2 Hazardous Areas

IP66/67

Application

For use in Zone 1 or 2 hazardous areas with ATEX/CENELEC certified

equipment and armoured or braided cable.

Features

All TWDC and TBDC glands offer:

ɀ a flameproof or increased safety seal on the inner sheath of the

cable

ɀ mechanical clamping, providing retention of armour or braid

ɀ a weatherproof seal to the outer sheath of the cable

ɀ brass construction (optional stainless steel)

ɀ optional nickel-plate finish

ɀ metric or NPT threads

TW3DC/TB3DC cable glands offer a zero halogen version for extreme

high and low temperature applications (-60°C to +180°C).

78 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

©

2006 Cooper Crouse-Hinds

TWDC/TBDC Brass Cable Glands

EEx d IIC

EEx e II

for Steel Wire Armour or

Steel Wire Braid Cable

Zone 1 and 2

IP 66/67

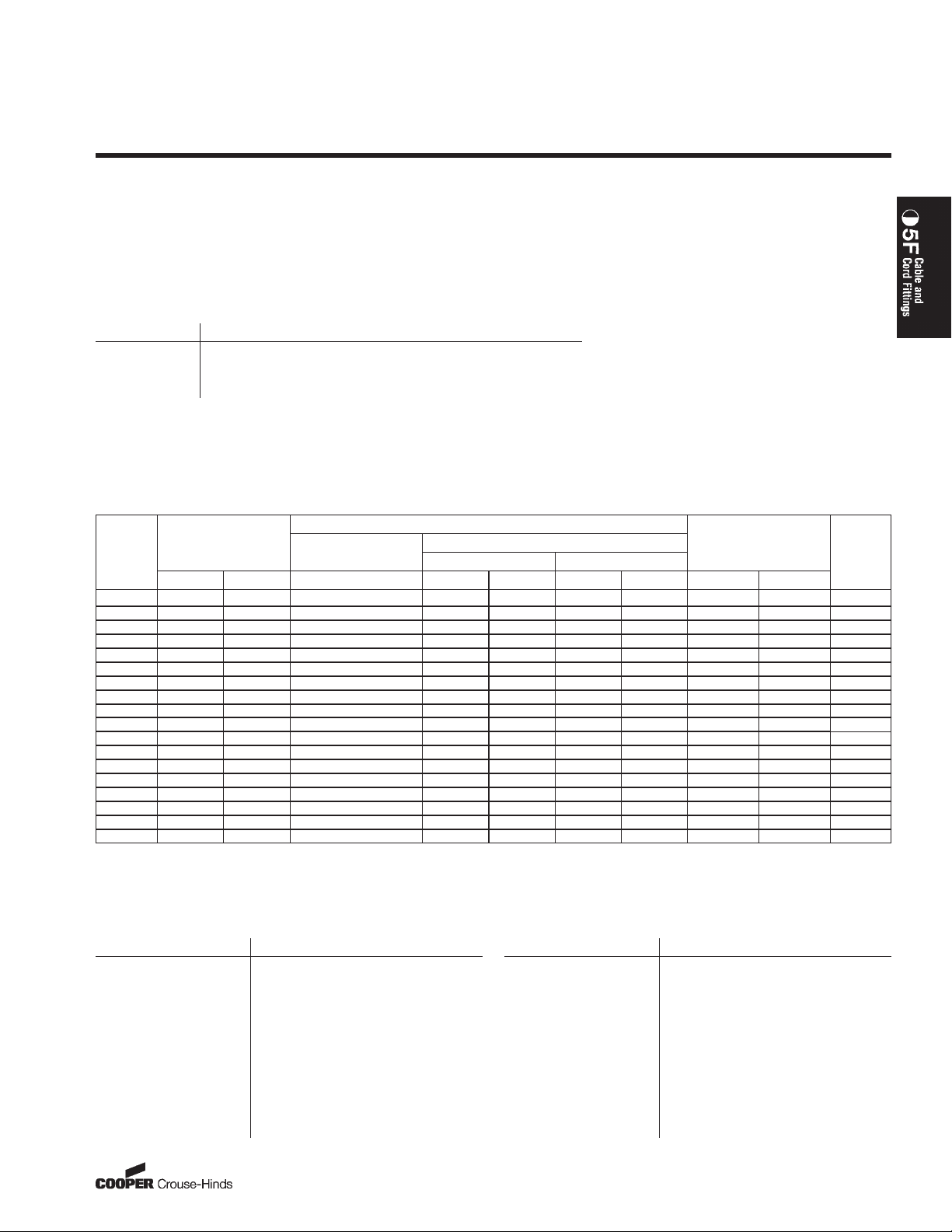

Ordering Information

Build your catalog number from the information below. All catalog numbers consist of three main sections:

1. Select the Gland Type based on cable type and seal required (i.e., TW1DC)

2. Select the Gland Size based on cable specifications (i.e., 20S)

3. Specify Thread Size (i.e., 075NPT)

Step 1 – Select Gland Type from Table below:

Ordering example:

TW1DC/NP/20S/075NPT

Gland Types

Gland Type Description

TW1DC For steel wire armour with neoprene seal.

TW3DC For steel wire armour with silicone seal for extreme temperatures.

TB1DC For braided cable with neoprene seal.

TB3DC For braided cable with silicone seal for extreme temperatures.

For optional nickel-plate finish add suffix/NP after Gland Type (i.e., TW1DC/NP).

For reduced bore gland add ‘‘R’’ at the end of Gland Type (i.e., TW1DCR).

For optional poly-bagged kit including gland, brass locknut, brass earth tag, sealing washer and PCP shroud, add ‘‘K1’’ at the end of Gland Type (i.e. TW1DCK1).

For stainless steel construction add ‘‘S’’ at the end of Gland Type (i.e., TW1DCS).

Step 2 – Select Gland Size based on Cable Size from Table below:

Cable Sizes

(Dimensions are all in millimeters)

5F

Gland Seal Range

Available Cable Inner Cable Outer Sheath [D] Armour

Gland Entry Threads Sheath [C] Standard Reduced Acceptance Range Shroud

Size Metric NPT Min Max Min Max Min Max SWA Braided Size†

16 M20

20S M20

20 M20

25 M25

32 M32 1⍯ or 11⁄4⍯ 19.0 26.3 26.7 34.0 23.2 30.5 1.60 – 2.00 0.15 – 0.55 L46

40 M40 11⁄4⍯ or 11⁄2⍯ 25.0 32.2 33.0 40.6 28.6 36.2 1.60 – 2.00 0.20 – 0.60 L55

50S M50 11⁄2⍯ or 2⍯ 31.5 38.2 39.4 46.7 34.8 42.4 2.00 – 2.50 0.20 – 0.60 L65

50 M50 2⍯ 36.5 44.1 45.7 53.2 41.1 48.5 2.00 – 2.50 0.30 – 0.80 L65

63S M63 2⍯ or 21⁄2⍯ 42.5 50.1 52.1 59.5 47.5 54.8 2.50 0.30 – 0.80 L80

63 M63 21⁄2⍯ 49.5 56.0 58.4 65.8 53.8 61.2 2.50 0.30 – 0.80 L80

75S M75 21⁄2⍯ or 3⍯ 54.5 62.0 64.8 72.2 60.2 68.0 2.50 0.30 – 1.00 L90

75 M75 3⍯ 60.5 68.0 71.1 78.0 66.5 73.4 2.50 0.30 – 1.00 L90

80 M80 × 23⍯ or 31⁄2⍯ 62.2 72.0 77.0 84.0 --- --- 3.15 0.45 – 1.00 L104

80H M80 × 23⍯ or 31⁄2⍯ 62.2 72.0 79.6 90.0 --- --- 3.15 0.45 – 1.00 L104

85 M85 × 23⍯ or 31⁄2⍯ 69.0 78.0 79.6 90.0 75.0 85.4 3.15 0.45 – 1.00 L104

90 M90 × 231⁄2⍯ or 4⍯ 74.0 84.0 88.0 96.0 --- --- 3.15 0.45 – 1.00 L114

90H M90 × 231⁄2⍯ or 4⍯ 74.0 84.0 92.0 102.0 --- --- 3.15 0.45 – 1.00 L114

100 M100 × 231⁄2⍯ or 4⍯ 82.0 90.0 92.0 102.0 87.4 97.4 3.15 0.45 – 1.00 L114

† For PVC or PCP shrouds see Accessories, page 93.

1

⁄2⍯or 3⁄4⍯ 3.5 8.4 8.4 13.5 4.9 10.0 0.90 0.15 – 0.35 L24

1

⁄2⍯or 3⁄4⍯ 8.0 11.7 11.5 16.0 9.4 12.5 0.90 – 1.25 0.15 – 0.35 L24

1

⁄2⍯or 3⁄4⍯ 6.7 14.0 15.5 21.1 12.0 17.6 0.90 – 1.25 0.15 – 0.50 L30

3

⁄4⍯or 1⍯ 13.0 20.0 20.3 27.4 16.8 23.9 1.25 – 1.60 0.15 – 0.50 L38

Step 3 – Specify Thread Size from Table below:

Metric Thread Sizes

Thread Size Add to Catalog Number

M16 M16

M20 M20

M25 M25

M32 M32

M40 M40

M50 M50

M63 M63

M75 M75

M80 M80

M85 M85

M90 M90

M100 M100

NPT Thread Sizes

Thread Size Add to Catalog Number

1

⁄2⍯ NPT 050NPT

3

⁄4⍯ NPT 075NPT

1⍯ NPT 100NPT

1

⁄4⍯ NPT 125NPT

1

1

⁄2⍯ NPT 150NPT

1

2⍯ NPT 200NPT

1

⁄2⍯ NPT 250NPT

2

3⍯ NPT 300NPT

1

⁄2⍯ NPT 350NPT

3

4⍯ NPT 400NPT

––

––

©

2006 Cooper Crouse-Hinds

79US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

Loading...

Loading...