Crouse Hinds 5F TERMINATOR Cable Fittings Catalog Page

5F

TERMINATORTMCable Fittings

for Metal Clad Cable and Tray Cable

TMC/TMCX Series

ɍ

†

Cl. I, Div. 1

Cl. II, Div. 1

Cl. III

, Groups A*,B,C,D

†

ɍ

, Div. 1†& 2

Wet Locations

, Groups F,G

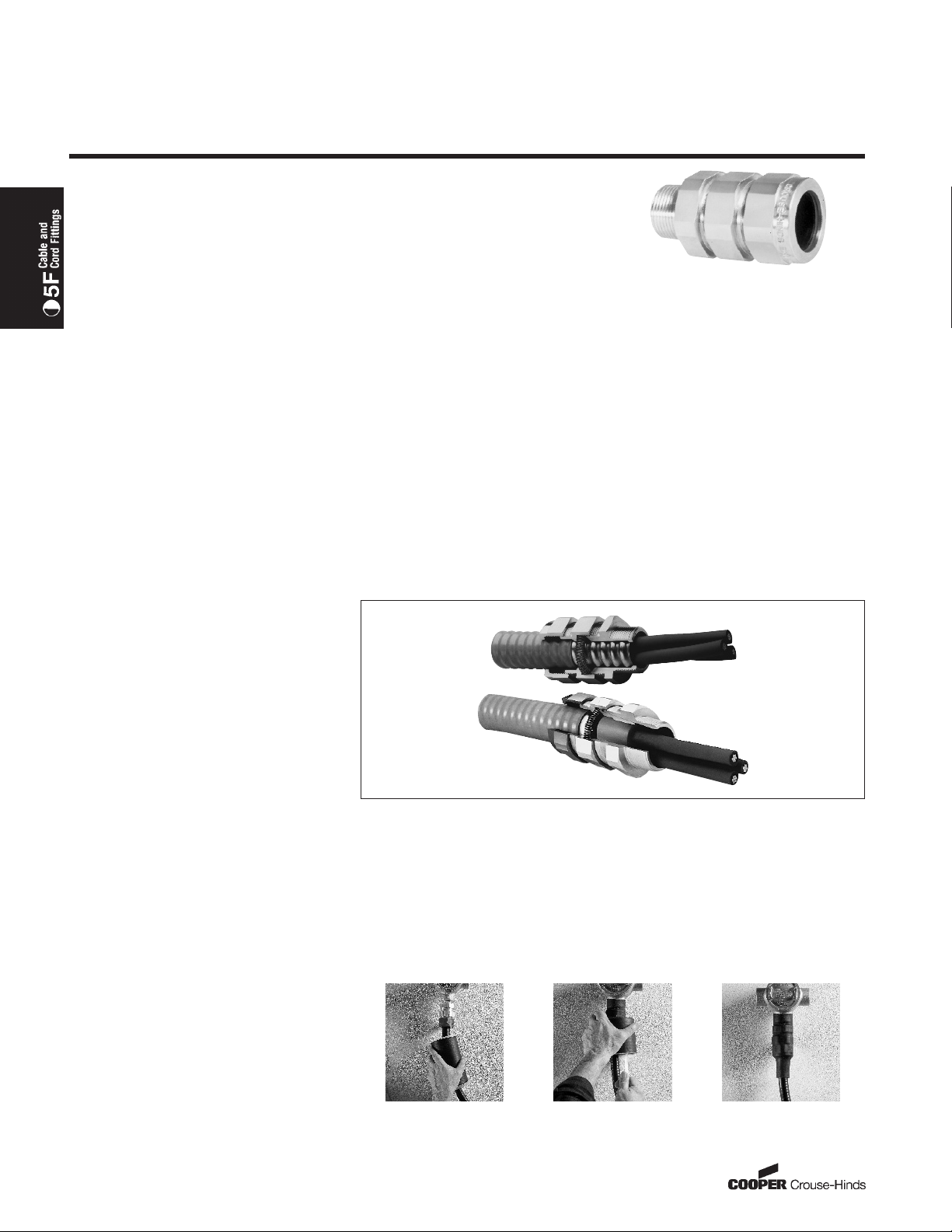

Application:

Terminator cable fittings are designed for use with

the following cables:

ɀ Type MC – corrugated aluminum, interlocked

aluminum and interlocked steel

ɀ Type TC Tray Cableɍ

Terminator cable fittings are installed:

ɀ to provide a means for terminating type MC and

TC cable at junction boxes, control centers,

panelboards and enclosures for motor control and

electrical distribution equipment

ɀ to form a mechanical watertight connection

ɀ to provide ground continuity of cable armor

ɀ indoors and outdoors in wet and dry locations

ɀ in vertical and horizontal cable runs

ɀ in non-hazardous and hazardous (classified)

locations. Both TMC and TMCX series can be used

in Class I and Class II, Division 2 locations. TMCX

series may be used in Division 1 locations and when

a seal is required.

Features:

ɀ Ten fittings cover cable O.D. range of .440⍯ to

4.020⍯, in

ɀ Quick and easy to install. No disassembly is

required for TMC installation.

ɀ Unique stainless steel grounding/retaining spring

with copper plate finish provides positive ground

continuity and superior pull-out resistance

exceeding that required by UL/CSA.

ɀ Neoprene bushing provides a watertight seal.

ɀ Lightweight, corrosion-resistant/copper-free

aluminum construction provides long, maintenancefree service life in industrial environments

ɀ Optional all brass construction available.

ɀ Hex design for easy wrenching.

ɀ Compact size for close nesting of cables.

ɀ TMCX fittings are furnished complete with epoxy

sealing compound.‡

ɀ TMCX fittings with sealing chamber have a red

colored gland nut for easy identification.

ɀ Hazardous location TMCX Terminators are

reusable. An integral union feature simplifies

installation on new construction and allows installed

TMCX Terminator cable fittings to be disassembled

and reused when performing repairs or replacement

of equipment.

ɀ Optional Cold-Shrink

protection against corrosive elements like salt water.

1

⁄2⍯ to 4⍯ NPT sizes.

®

Kit for extra corrosion

Standard Materials:

ɀ Body, intermediate body, gland nut, and armor

stop insert – copper-free aluminum

ɀ Bushing – neoprene

ɀ Grounding/retaining spring – stainless steel

ɀ Slip washer and armor stop reducer – nylon

ɀ Cold Shrink Kit — EPDM Rubber

Standard Finishes:

ɀ Copper-free aluminum – natural

ɀ Neoprene – natural

ɀ Stainless steel – copper flash

ɀ Nylon – natural

Options:

ɀ All brass construction .... add suffix -BR to

catalog number.

ɀ All brass construction with nickel plate

finish on entry threads .... add suffix -BR-NP

to catalog number.

Certifications and

Compliances:

ɀ NEC: Class I, Groups A*,B,C,D

Class II, Groups F,G

Class III, Div. 1 and 2 (except when

used with Tray Cable)

Article 334, 340, 501-4(b), 502-4(b),

503-3(a)

ɀ NEMA: FB1-1989

ɀ UL Standards: 514B, 886

ɀ Fed. Spec.: W-F-406B

NPT

Thread Size

1

⁄2 .440 to .650 TMC165 TMCX165ɍ TMC-K1

3

⁄4 .600 to .850 TMC285 TMCX285ɍ TMC-K2

1 .800 to 1.120 TMC3112 TMCX3112ɍ TMC-K3

1

⁄4 1.100 to 1.400 TMC4140 TMCX4140ɍ TMC-K4

1

1

⁄2 1.330 to 1.610 TMC5161 TMCX5161ɍ TMC-K5

1

2 1.570 to 2.060 TMC6206 TMCX6206ɍ TMC-K6

1

⁄2 1.930 to 2.470 TMC7247 TMCX7247ɍ TMC-K7

2

3 2.450 to 3.020 TMC8302 TMCX8302 TMC-K8

1

⁄2 2.950 to 3.520 TMC9352 TMCX9352 TMC-K9

3

Armor O.D.

Range

Non-Hazardous

Cat. #

4 3.500 to 4.020 TMC10402 TMCX10402 TMC-K10

刁 Hazardous location fittings are supplied with sealing compound for one termination. Additional compound may be

ordered separately. See following page.

† TMCX series is suitable for use in hazardous locations when installed in accordance with NEC articles 501-4(b), 501-5(e),

502-4(b), 502-5 and 503-3(a).

ɍ TMCX catalog numbers listed are suitable for use with Type TC tray cable in hazardous locations when installed in

accordance with NEC articles 501-5(e) and 502-5. TMCX series is not suitable for use in Class III locations when used with

tray cable.

‡ In Canada order separately Cat. # TSC1 - 1 oz. TSC4 - 4 oz.

* Terminators ordered in all brass construction (suffix – BR) are

environments.

TMC-K Corrosion Protection Kits

TMC-K Corrosion Protection Kits are specially designed for Cooper Crouse-Hinds TMC and TMCX fittings to provide

protection against corrosive elements like salt spray and moisture. The TMC-K kit is made of a Cold Shrink material that is

quick and easy to install on the fitting. The Cold Shrink material is made of EPDM rubber that contains no chlorides or

sulfurs.

ɀ CSA Standard C22.2 No. 18-M1987

Class I, A,B,C,D SL

Class II, E,F,G

Class III, Enc. 4 locations

Optional Cold

Hazardous

Cat. #刁

not

suitable for Class I, Group A hazardous area

Shrink

Cat. #

®

Kit

TMC6206

TMCX6206

74

The protection kit installs easily over the fitting

fitting. Just slide the kit over the fitting and pull out the inner core. The kit shrinks tightly over the fitting forming a watertight

seal. The Cold Shrink material can be removed easily from the fitting by simply cutting it off.

See ordering information for complete offering of TMC-K Cold Shrink kits for corrosion protection.

Cold Shrink is a registered trademark of the 3M Company.

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

without

the use of a heat source to shrink the material tightly over the

TERMINATORTMCable Fittings

for Metal Clad Cable and Tray Cable

TMC/TMCX Series

Accessories, Dimensions

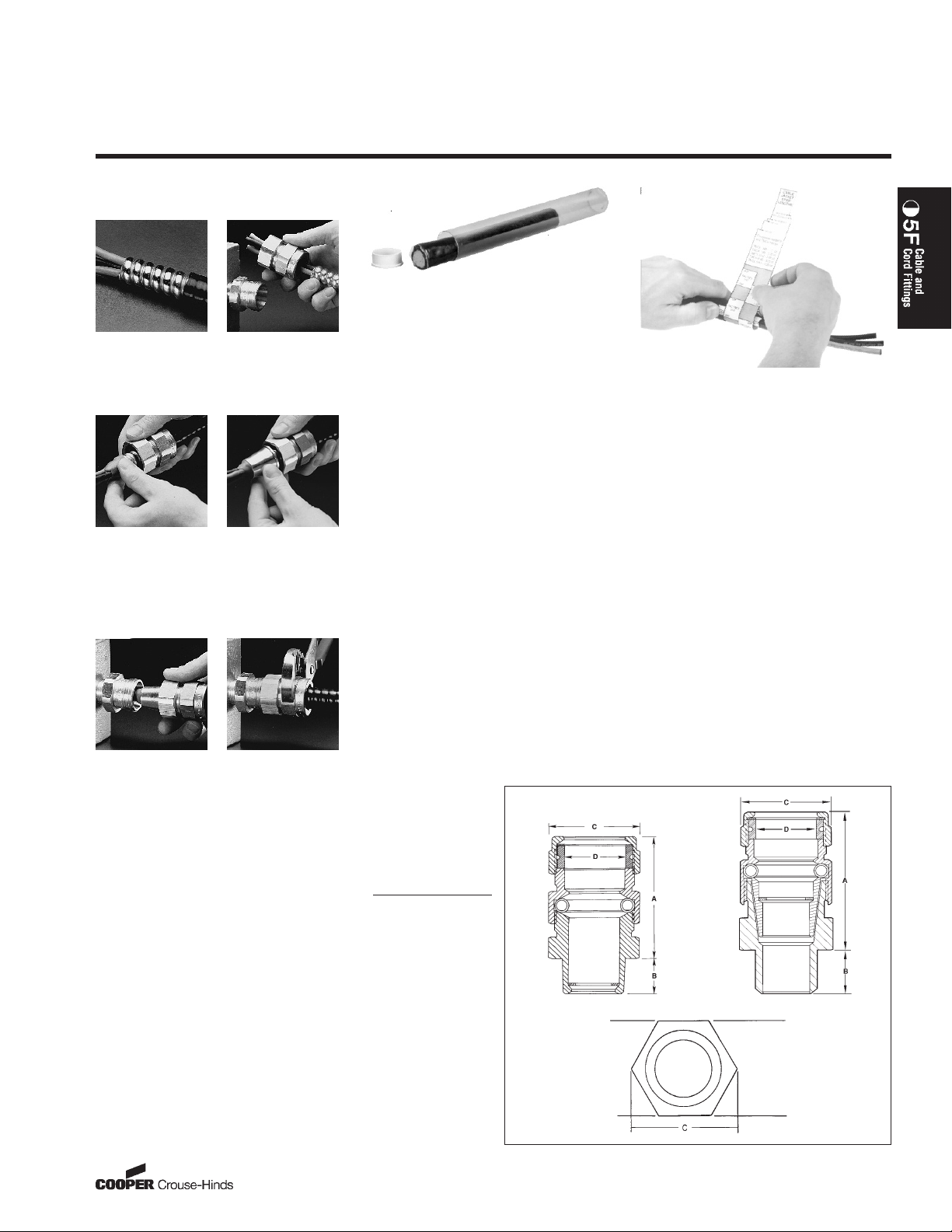

Installing a TMCX

Terminator

1. Prepare cable. 2. Install body into

3. Mix sealing com-

pound and pack

conductors over

armor.

5. Insert cable assembly into body.

enclosure. Slide

gland nut and intermediate body onto

cable.

4. Slide armor stop

insert over conductor

and sealing compound, then back

against armor. Pack

remaining sealing

compound.

6. Thread intermediate body with gland

nut onto body.

Tighten intermediate

body, then gland nut.

ɍ

TSC Epoxy Sealing

Compound

A two part epoxy sealing compound is used

to seal TMCX cable fittings. It is quick and

easy to measure, mix and install. The

compound is kneaded until a uniform color is

obtained. It is then packed around the

conductors and cable armor to effectively

seal the cable.

Each hazardous location fitting is supplied

with enough sealing compound for one

termination. Additional compound may be

ordered separately in one and four ounce

packages.

Std. Ctn.

Qty. Tube Size Cat. #**

10 0.5 oz TSC05

10 1.0 oz TSC1

5 4.0 oz. TSC4

Approximate Amount of Compound

Required to Seal Fittings

NPT

Size Cat. #

1

⁄2 TMCX165 0.25

3

⁄4 TMCX285 0.50

1 TMCX3112 0.70

1

⁄4 TMCX4140 1.50

1

1

⁄2 TMCX5161 1.85

1

2 TMCX6206 4.50

1

⁄2 TMCX7247 8.65

2

3 TMCX8302 15.75

1

⁄2 TMCX9352 25.55

3

4 TMCX10402 38.95

Cl. I, Div. 1

Cl. II, Div. 1

†

, Groups A,B,C,D

†

Cl. III, Div. 1

Wet Locations

, Groups F,G

†

& 2

Ounces

Required

5F

Cable Gauge and Sizer

TMC and TMCX cable fittings are supplied

with a cable gauge and sizer. This installation

tool is used:

ɀ to measure the cable armor and select the

proper cable fitting.

ɀ to determine how much cable jacket should

be removed to ensure proper installation,

eliminating any guesswork.

ɀ as a gauge of how much compound to

pack around the cable in order to meet UL

requirements and ensure a safe, proper

installation for TMCX fittings.

TMCX series is suitable for use in hazardous locations

†

when installed in accordance with NEC articles 501-4(b),

501-5(e), 502-4(b), 502-5 and 503-3(a).

ɍ TMCX catalog numbers listed are suitable for use with

Type TC tray cable in hazardous locations when installed in

accordance with NEC articles 501-5(e) and 502-5. TMCX

series is not suitable for use in Class III locations when used

with tray cable.

** Order quantity of one (1) TSC1 equals 10 1.0 oz. tubes;

one (1) TSC4 equals 5 4.0 oz. tubes.

Dimensions

TMC

Size

Cat. # A

1

⁄2 TMC165 23⁄8 TMCX165 25⁄83⁄4 13⁄825⁄32

3

⁄4 TMC285 25⁄8 TMCX285 27⁄8

1 TMC3112 2

11⁄4 TMC4140 23⁄4 TMCX4140 31⁄8

11⁄2 TMC5161 23⁄4 TMCX5161 33⁄8

2 TMC6206 41⁄2 TMCX6206 55⁄16 131⁄2 25⁄16

21⁄2 TMC7247 43⁄4 TMCX7247 61⁄16 17⁄16 4223⁄32

3 TMC8302 47⁄8 TMCX8302 61⁄16 17⁄16 47⁄8 39⁄32

31⁄2 TMC9352 53⁄8 TMCX9352 73⁄4 15⁄8 53⁄8 325⁄32

4 TMC10402 51⁄2 TMCX10402 85⁄16 15⁄8 57⁄8 49⁄32

(Dimensions also apply to brass product, suffix — BR)

TMCX

Cat. #

5

⁄8 TMCX3112 31⁄8

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

TMC/TMCXNPT

ABCD

25

⁄32 15⁄8 1

15

⁄16 215⁄16

31

⁄32 27⁄16 15⁄8

31

⁄32 23⁄4 125⁄32

TMC TMCX

75

Loading...

Loading...