Crouse Hinds 5F TECK TERMINATOR Cable Fittings Catalog Page

5F

TECK TERMINATORTMCable

Fittings

for Teck Cable

Cl. II, Division 1, Groups E,F,G

Cl. II, Division 2, Groups F,G

Cl. III

IP56

Wet Locations

Application:

TECK TERMINATORS have a wide array of

applications in pulp and paper mills,

chemical and petrochemical plants,

petroleum refineries, waste treatment

facilities, coal mines, electric power

generating plants, grain handling and

storage facilities, and many other industrial

applications.

TECK TERMINATORS are CSA Certified for

use with TECK armoured cable:

ɀ to provide a means to terminate at junction

boxes, control centers, panelboards, and

enclosures for motor control and electrical

distribution equipment

ɀ to form a watertight (Encl 4/IP 56) seal

around cable and at enclosure entry

ɀ to provide ground continuity of cable

armour

ɀ to provide excellent cable pullout protection

exceeding CSA requirements

ɀ indoors or outdoors, in wet and dry

locations

ɀ in vertical or horizontal cable runs; and

ɀ with TMC-K Series Cold Shrink

protection kits to protect fitting from corrosive

elements like salt water

TM

corrosion

Features:

ɀ CSA Certified for ordinary and hazardous

locations assuring a safe and reliable

termination in adverse environments

ɀ No disassembly required, resulting in a

quick-and-easy installation and lower labour

costs

ɀ Available in aluminum, steel, stainless steel

and PVC-coated aluminum construction for

almost any type of corrosive environment

ɀ Unique stainless steel grounding spring

provides 360° positive grounding and

superior pullout resistance

ɀ Neoprene bushing creates a watertight

seal to protect electrical equipment

ɀ Neoprene O-ring on connector provides an

environmental seal when fitting is installed

in knockout

ɀ Hex surfaces provide a large wrenching

area for easy installation

ɀ Hex surfaces on aluminum fittings have

slots for screwdriver tightening/loosening

ɀ Compact design allows close spacing of

connectors

ɀ Available in

application flexibility

1

⁄2⍯ to 4⍯ trade sizes for

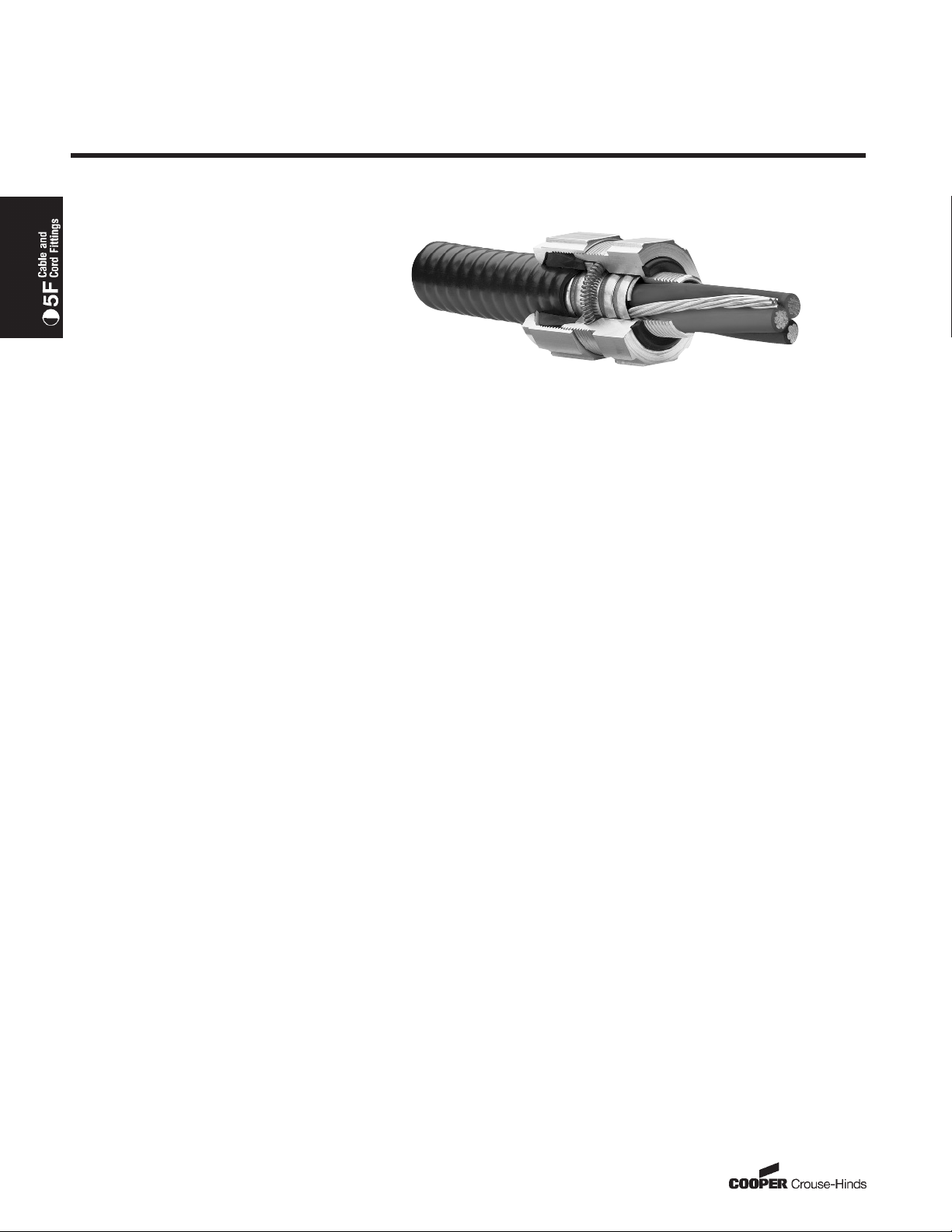

Assembly Detail Shown with

TECK Cable Installed

Standard Materials/Finishes:

ɀ Body, Gland Nut – aluminum/natural, steel/zinc electrogalvanized,

electrogalvanized, stainless steel/natural

ɀ Drive Washer – aluminum/natural, steel/electrogalvanized, stainless steel/natural

ɀ Bushing, O-ring – neoprene/natural

ɀ Grounding Spring – stainless steel/copper-plated

ɀ Cold Shrink Corrosion Protection Kit – EPDM rubber

ɀ Slip Washer – nylon/natural

Feraloy

®

/zinc

Certifications and Compliances:

ɀ CEC: Class II, Division 1 and 2

Groups E, F and G

Class III

ɀ CSA Standard: C22.2 No. 18

ɀ Encl 4/IP 56

76 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

©

2006 Cooper Crouse-Hinds

TECK TERMINATORTMCable

Fittings

for Teck Cable

Cl. II, Division 1, Groups E,F,G

Cl. II, Division 2, Groups F,G

Cl. III

IP56

Wet Locations

Ordering Information:

Range Over Jacket Range Over Armour

Hub Size Aluminum Cat. # Steel Cat. # Stainless Steel Cat. # PVC Cat. # Min. Max. Min. Max.

1

⁄2⍯ TECK050-1 TECK050-1S TECK050-1SS TECK050-1PVC 0.525 0.650 0.415 0.570

1

⁄2⍯ TECK050-2 TECK050-2S TECK050-2SS TECK050-2PVC 0.600 0.760 0.490 0.680

1

⁄2⍯ TECK050-3 TECK050-3S TECK050-3SS TECK050-3PVC 0.725 0.885 0.615 0.805

1

⁄2⍯ TECK050-4 TECK050-4S TECK050-4SS TECK050-4PVC 0.825 0.985 0.715 0.905

3

⁄4⍯ TECK075-5 TECK075-5S TECK075-5SS TECK075-5PVC 0.880 1.065 0.770 0.985

3

⁄4⍯ TECK075-6 TECK075-6S TECK075-6SS TECK075-6PVC 1.025 1.205 0.915 1.125

1⍯ TECK100-7 TECK100-7S TECK100-7SS TECK100-7PVC 1.187 1.375 1.077 1.295

1

⁄4⍯ TECK125-8 TECK125-8S – TECK125-8PVC 1.350 1.625 1.240 1.545

1

1

⁄4⍯ TECK125-9 TECK125-9S – TECK125-9PVC 1.500 1.625 1.390 1.545

1

1

⁄4⍯ TECK125-10 TECK125-10S – TECK125-10PVC 1.600 1.875 1.490 1.795

1

1

⁄2⍯ TECK150-11 TECK150-11S – TECK150-11PVC 1.700 1.965 1.590 1.885

1

1

⁄2⍯ TECK150-12 TECK150-12S – TECK150-12PVC 1.900 2.187 1.790 2.107

1

2⍯ TECK200-13 TECK200-13S – TECK200-13PVC 1.900 2.187 1.790 2.107

2⍯ TECK200-14 TECK200-14S – TECK200-14PVC 2.100 2.375 1.990 2.280

2⍯ TECK200-15 TECK200-15S – TECK200-15PVC 2.300 2.565 2.190 2.485

2⍯ TECK200-16 TECK200-16S – TECK200-16PVC 2.500 2.750 2.390 2.656

1

⁄2⍯ TECK250-17 TECK250-17S – TECK250-17PVC 2.380 2.640 2.240 2.560

2

1

⁄2⍯ TECK250-18 TECK250-18S – TECK250-18PVC 2.580 2.840 2.440 2.750

2

3⍯ TECK300-19 TECK300-19S – TECK300-19PVC 2.790 3.060 2.640 2.970

3⍯ TECK300-20 TECK300-20S – TECK300-20PVC 3.000 3.270 2.870 3.190

3⍯ TECK300-21 TECK300-21S – TECK300-21PVC 3.210 3.480 3.042 3.390

1

⁄2⍯ TECK350-22 TECK350-22S – TECK350-22PVC 3.420 3.690 3.270 3.590

3

1

⁄2⍯ TECK350-23 TECK350-23S – TECK350-23PVC 3.610 3.870 3.440 3.770

3

4⍯ TECK400-24 TECK400-24S – – 3.810 4.030 3.600 3.930

4⍯ TECK400-25 TECK400-25S – – 3.965 4.185 3.755 4.065

4⍯ TECK400-26 TECK400-26S – – 4.120 4.340 3.910 4.220

5F

Optional Cold Shrink Corrosion

Protection Kits

Trade Size Cat. # Trade Size Cat. #

1

⁄2⍯ TMC-K1 2⍯ TMC-K6

3

⁄4⍯ TMC-K2 21⁄2⍯ TMC-K7

1⍯ TMC-K3 3⍯ TMC-K8

1

⁄4⍯ TMC-K4 31⁄2⍯ TMC-K9

1

1

⁄2⍯ TMC-K5 4⍯ TMC-K10

1

Dimensions (inches)

Cat. # A - Throat Dia. B - Overall C - Max.

TECK050-1 0.395 2.16 1.34

TECK050-2 0.485 2.24 1.47

TECK050-3 0.612 2.20 1.61

TECK050-4 0.612 2.24 1.61

TECK075-5 0.819 2.37 2.14

TECK075-6 0.819 2.42 2.14

TECK100-7 1.039 2.42 2.41

TECK125-8 1.184 3.42 3.20

TECK125-9 1.375 3.34 3.20

TECK125-10 1.375 3.34 3.20

TECK150-11 1.577 3.81 3.60

TECK150-12 1.600 3.81 3.72

TECK200-13 1.715 4.14 4.20

TECK200-14 1.995 4.06 4.20

TECK200-15 2.063 3.84 4.40

TECK200-16 2.063 3.92 4.40

TECK250-17 2.250 5.15 4.79

TECK250-18 2.437 5.10 4.79

TECK300-19 2.630 4.91 4.89

TECK300-20 2.875 4.97 5.30

TECK300-21 3.032 4.97 5.30

TECK350-22 3.260 5.12 5.90

TECK350-23 3.437 5.25 5.90

TECK400-24 3.594 4.90 6.53

TECK400-25 3.750 4.90 6.53

TECK400-26 3.900 4.90 6.53

©

2006 Cooper Crouse-Hinds

77US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

Loading...

Loading...