Crouse Hinds 5F TACF Series Barrier Gland Catalog Page

5F

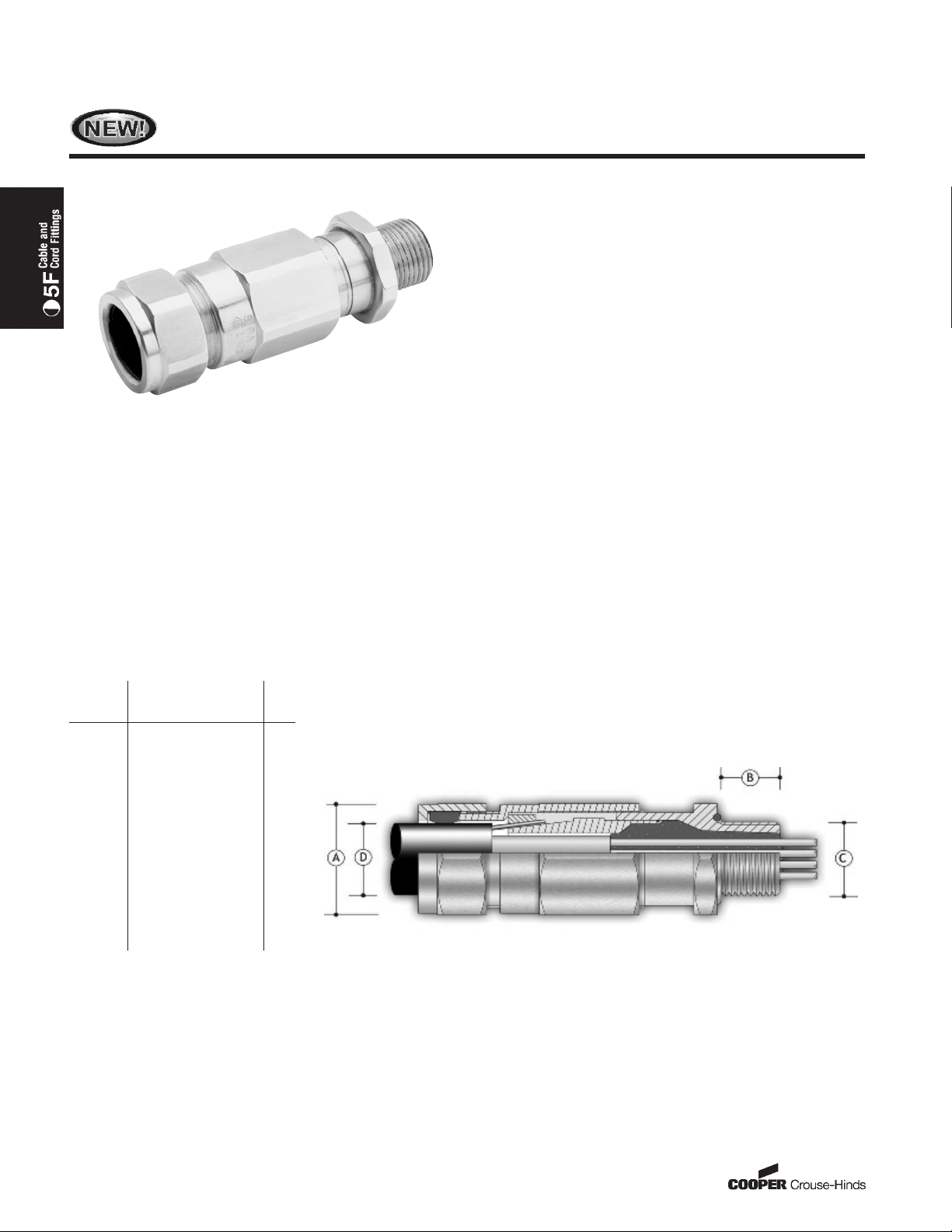

TACF Series Barrier Gland

Atex and CENELEC Range

TACF

Certifications and Compliances

ɀ ATEX E Exd I & IIC with SIRA 03ATEX1552X

ɀ Standards EN50014, EN50018 and EN50281-1-1:1998

ɀ IP66 and IP68 at 100 meters

ɀ DTS01 1991 deluge

ɀ CSA Exd I & IIC

ɀ Type 4X

ɀ Zone 1 and Zone 2

ɀ Ignitable dusts, Zones 21 and 22

ɀ GOST R-Exd I & IICU

ɀ Mining Equipment Group I, M2

ATEX and CENELEC E Exd & IIC ATEX I M2 II 2 GD

Ignitible dusts, Zones 21 and 22 CSA Exc I IIC

Class I, Zone 1 or 2 Hazardous Areas

Type 4X, IP66/88

DTS01 1991 Deluge

Application

The TACF series is a flameproof E Exd compound filled barrier cable

gland for use in Zone 1 or 2 hazardous areas with ATEX/CENELEC

equipment and steel wire armoured, steel wire braided, steel tape

armoured and unarmoured cables. Also, for use in Exd and Exe

hazardous areas with CSA equipment and braided and marine

shipboard cable. The TACF series will maintain the flameproof Exd

integrity of any volume enclosure with an internal ignition source for all

gas groups when used with any armoured or unarmoured cable types.

Features:

All TACF Cable glands:

ɀ are available in all brass or all stainless steel construction.

ɀ offer a universal armour clamp for all armoured cable types (steel

wire, steel braid, steel tape, marine shipboard) and unarmoured cable.

ɀ are provided with sealing compound that cures in 4 hours at 21°C.

ɀ come with no reversible components, eliminating installer error.

ɀ maintain Flameproof Exd and Increase Safety Exe methods of

explosion protection.

ɀ provide a seal on the outer sheath offering IP66/68 and Type 4X

protection.

ɀ provide an entry thread seal (metric threads only).

ɀ meet DTS01 1991 deluge requirements.

ɀ may be terminated 1 hour after creation of seal.

ɀ may be energized 4 hours after creation of seal.

ɀ incorporate anti-twist assembly reducing the amount of cable twist

during installation.

ɀ are available with metric or NPT threads.

ɀ are available with optional nickel-plate finish.

ɀ are provided with silicone seals, temperature range -60°C to +85°C.

Design Data (millimeters)

Gland A B

Size (across corners)

16 28.0 16

20S 28.0 16

20 33.0 16

25 41.4 16

32 50.6 16

40 60.5 16

50S 71.5 16

50 71.5 16

63S 88.0 19

63 88.0 19

75S 99.0 19

75 99.0 19

80 115.2 25

85 115.2 25

90 125.7 25

100 125.7 25

82

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

TACF Series Barrier Gland

ATEX and CENELEC E Exd & IIC ATEX I M2 II 2 GD

Ignitible dusts, Zones 21 and 22 CSA Exc I IIC

Class I, Zone 1 or 2 Hazardous Areas

Atex and CENELEC Range

Type 4X, IP66/88

DTS01 1991 Deluge

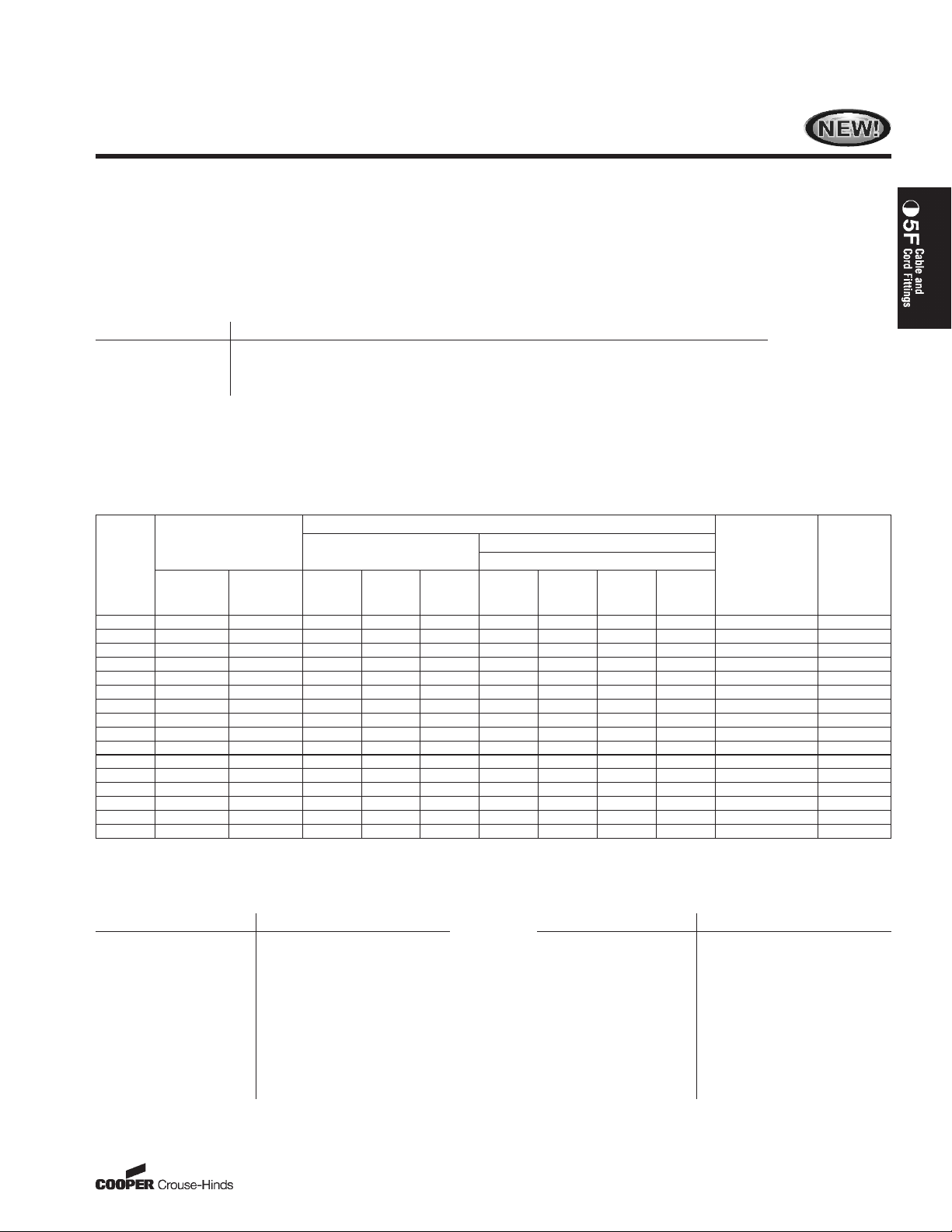

Ordering Information

Build your catalog number from the information below. All catalog numbers consist of three main sections:

1. Select the Gland Type based on material required (i.e., TACFB)

2. Select the Gland Size based on cable specifications (i.e., 20S)

3. Specify Thread Size (i.e., 075NPT) (Available sizes listed in step 2)

Ordering example:

TACFB/20S/075NPT

Step 1: Select Gland Type from Table below:

Gland Types

Gland Type Description

TACFB Compound filled universal gland for steel wire, steel braid & steel tape w/ silicone seal -

TACFS Compound filled universal gland for steel wire, steel braid & steel tape w/ silicone seal -

For optional nickel-plate finish on brass glands add suffix /NP after Gland Type (i.e., TACFB/NP).

For reduced bore gland add ‘‘R’’ at the end of Gland Type (i.e., TACFBR).

For optional poly-bagged kit including gland, locknut, earth tag, sealing washer and PVC shroud, add ‘‘K1’’ at the end of Gland Type (i.e., TACFBK1).

Brass construction

Stainless steel construction

Step 2: Select Gland Size based on Cable Size from Table below:

5F

Cable Sizes

Gland No. of Over Inner Acceptance Shroud

Size Metric NPT Cores Cores Sheath Min Max Min Max Range Size

16 M20

20S M20

20 M20

25 M25

32 M32 1⍯ or 11⁄4⍯ 50 23.5 26.3 26.7 34.0 23.2 30.5 0.15 - 2.00 EL46

40 M40 11⁄4⍯ or 11⁄2⍯ 80 28.8 32.2 33.0 40.6 28.6 36.2 0.20 - 2.00 EL55

50S M50 2⍯ 100 34.2 38.2 39.4 46.8 34.8 42.4 0.20 - 2.50 EL65

50 M50 2⍯ 100 39.4 44.1 45.7 53.2 41.1 48.5 0.20 - 2.50 EL65

63S M63 21⁄2⍯ 120 44.8 50.1 52.1 59.5 47.5 54.8 0.30 - 2.50 EL80

63 M63 21⁄2⍯ 120 50.0 56.0 58.4 65.8 53.8 61.2 0.30 - 2.50 EL80

75S M75 3⍯ 140 55.4 62.0 64.8 72.2 60.2 68.0 0.30 - 2.50 EL90

75 M75 3⍯ 140 60.8 68.0 71.1 78.0 66.5 73.4 0.30 - 2.50 EL90

80 M80 x 2 3⍯ or 31⁄2⍯ 160 64.4 72.0 77.0 84.0 — — 0.45 - 3.15 L104

85 M85 x 2 3⍯ or 31⁄2⍯ 180 69.8 78.0 79.6 90.0 75.0 85.4 0.45 - 3.15 L104

90 M90 x 2 31⁄2⍯ or 4⍯ 200 75.1 84.0 88.0 96.0 — — 0.45 - 3.15 L114

100 M100 x 2 31⁄2⍯ or 4⍯ 220 80.5 90.0 92.0 102.0 87.4 97.4 0.45 - 3.15 L114

(Dimensions are all in millimeters)

GLAND SEAL RANGE

Available Cable Inner

Entry Threads Sheath/Cores [C] Standard Reduced

Max Max Max Armour

1

⁄2⍯ or 3⁄4⍯ 7 9.0 11.7 9.0 13.5 6.7 10.3 0.15 - 1.25 L24

1

⁄2⍯ or 3⁄4⍯ 8 10.4 11.7 11.5 16.0 9.4 12.5 0.15 - 1.25 L24

1

⁄2⍯ or 3⁄4⍯ 14 12.5 14.0 15.5 21.1 12.0 17.6 0.15 - 1.25 EL30

3

⁄4⍯ or 1⍯ 25 17.8 20.0 20.3 27.4 16.8 23.9 0.15 - 1.60 EL38

Cable Outer Sheath [D]

Step 3: Specify Thread Size from Table below:

Metric Thread Sizes

Thread Size Add to Catalog Number

M16 M16

M20 M20

M25 M25

M32 M32

M40 M40

M50 M50

M63 M63

M75 M75

M80 M80

M85 M85

M90 M90

M100 M100

NPT Thread Sizes

Thread Size Add to Catalog Number

1

⁄2⍯ NPT 050NPT

3

⁄4⍯ NPT 075NPT

1⍯ NPT 100NPT

1

⁄4⍯ NPT 125NPT

1

1

⁄2⍯ NPT 150NPT

1

2⍯ NPT 200NPT

1

⁄2⍯ NPT 250NPT

2

3⍯ NPT 300NPT

1

⁄2⍯ NPT 350NPT

3

4⍯ NPT 400NPT

——

——

US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright©2006 Cooper Crouse-Hinds

83

Loading...

Loading...