Crouse Hinds 4F Conduit Outlet Boxes Catalog Page

Condulet®Pull Boxes and

Outlet Bodies

Cl. I, Div. 1 & 2, Groups C,D

Cl. II, Div. 1, Groups E,F,G

Cl. II, Div. 2, Groups F,G

Cl. III

NEMA 7CD,9EFG

Explosionproof

Dust-Ignitionproof

4F

Application:

EKC series conduit outlet bodies

are installed in conduit systems

within hazardous areas to:

ɀ provide convenient opening in

conduit system for pulling or

splicing conductors

Features:

EKC bodies have:

ɀ accurately machined body and

cover mating surfaces to ensure

flametight joint when properly

assembled

ɀ extra long cover opening to

facilitate pulling and splicing of

conductors

ɀ taper threaded hubs and

integral bushing for rigid

threaded conduit

Standard Materials:

ɀ EKC bodies –

Feraloy

iron alloy

Standard Finishes:

ɀ

Feraloy

and aluminum acrylic paint

– electrogalvanized

Options:

ɀ EKC series:

Corro-free

– ..............add suffix S752

TM

epoxy powder coat

Size Ranges:

ɀ

EKC bodies – hub size – 1⍯ to 3⍯

Certifications and

Compliances:

ɀ NEC:

EKC 30 – 60

Class I, Division 1 & 2, Groups

C,D

Class II, Division 1, Groups E,F,G

Class II, Division 2, Groups F,G

Class III

EKC 70, 80

Class I, Division 1 & 2, Group D

Class II, Division 1, Groups E,F,G

Class II, Division 2, Groups F,G

Class III

ɀ UL Standard: 886

ɀ CSA Standard: C22.2 No. 30

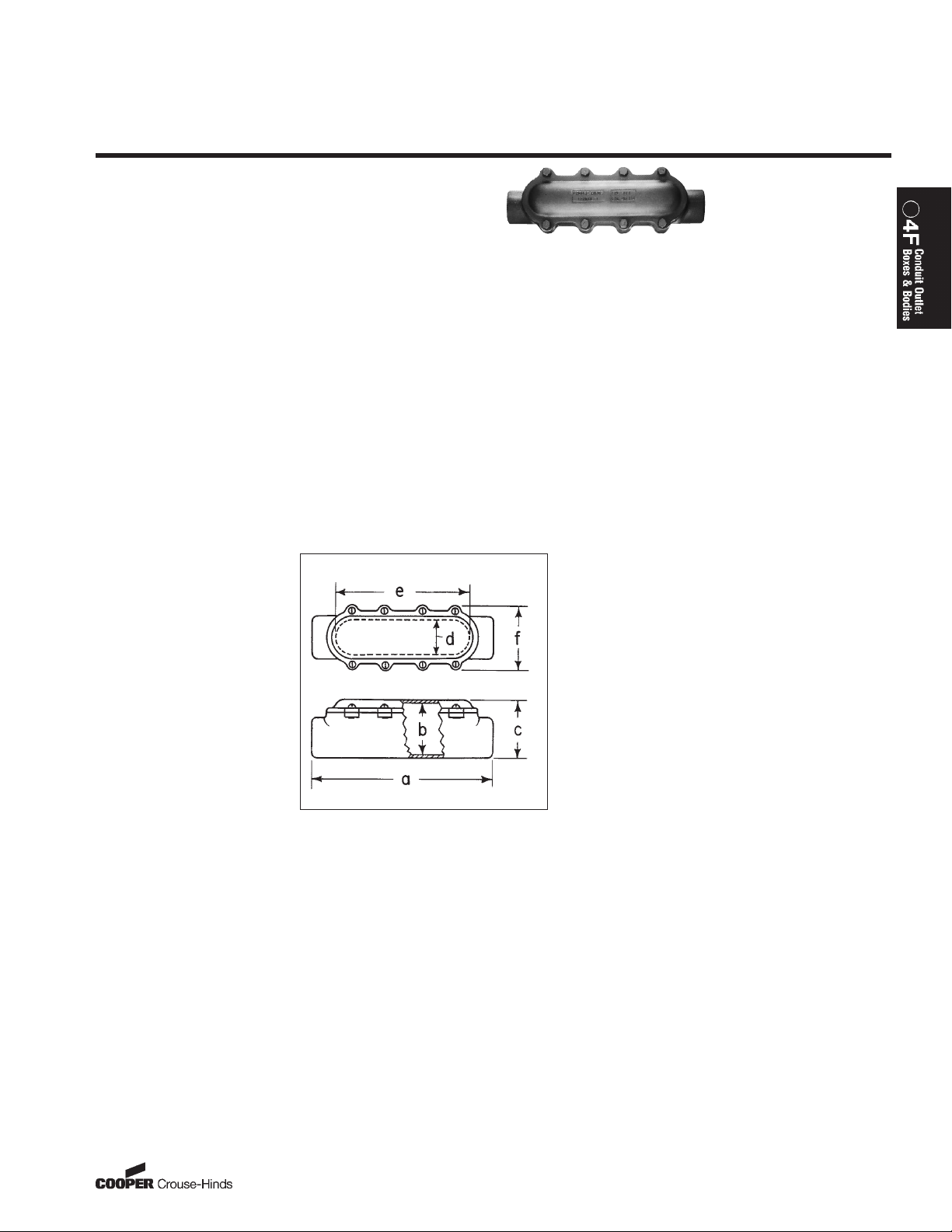

Dimensions

EKC

EKC

EKC Outlet

Bodies

Hub

Size Cat. #

1 EKC30

1

⁄4 EKC40

1

1

⁄2 EKC50

1

2 EKC60

1

⁄2 EKC70

2

3 EKC80

EKC

Size a b c d e f

1

⁄4 125⁄8 31⁄16 37⁄16 13⁄4 94

1 – 1

1

⁄2 – 2 1515⁄16 37⁄8 45⁄16 21⁄2 12 5

1

1

⁄2 – 3 213⁄4 51⁄2 63

2

3

⁄4 16 65⁄8

©

2006 Cooper Crouse-Hinds

57US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright

Loading...

Loading...