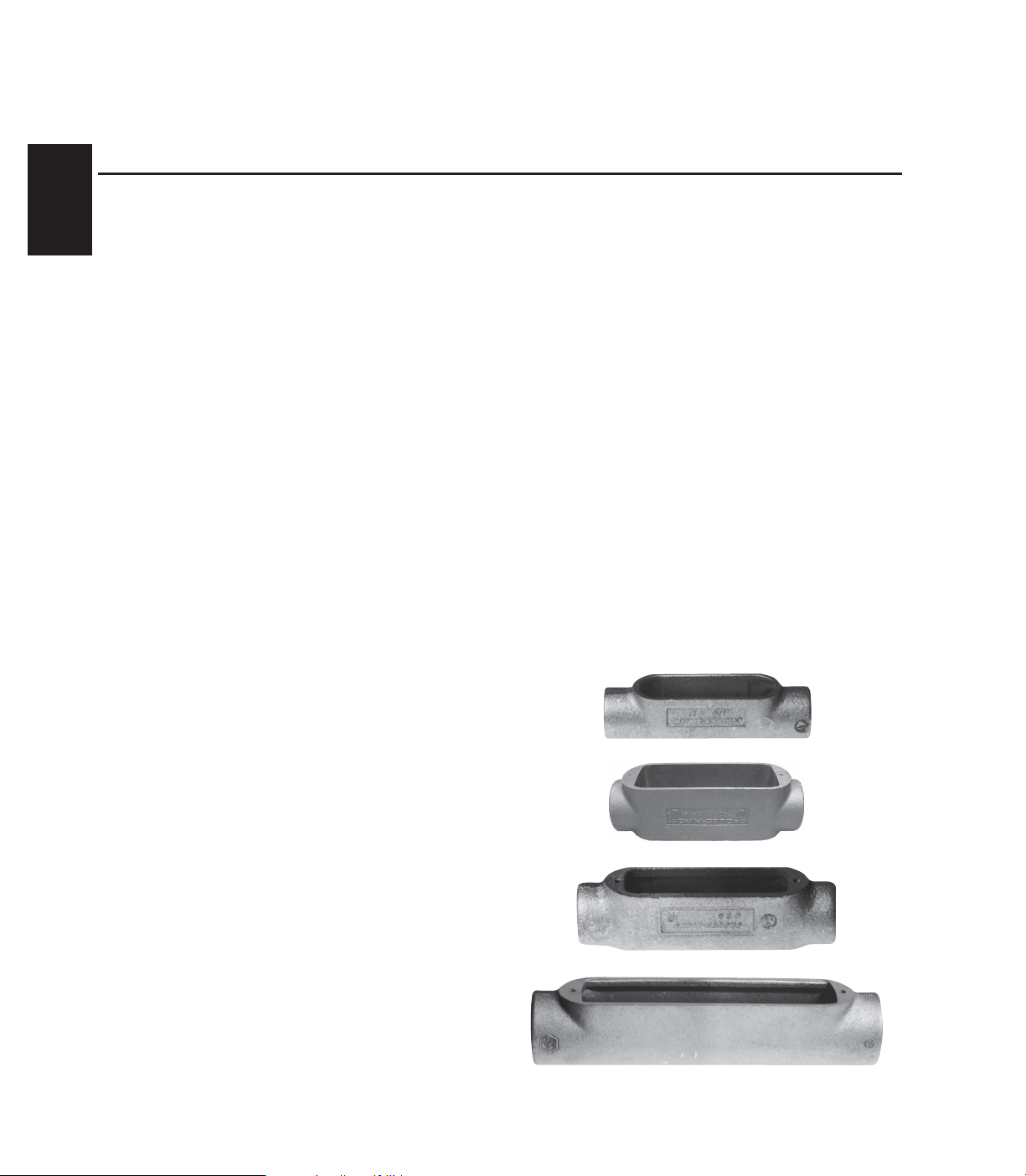

1F Condulet®Conduit Bodies -

Cast Iron or Aluminum

Gasket and Covers see page 8

Applications:

1F

Conduit outlet bodies are installed in conduit systems to:

• Act as pull outlets for conductors being installed

• Provide openings for making splices and taps in conductors

• Connect conduit sections

• Provide taps for branch conduit runs

• Make 90° bends in conduit runs

• Provide for access to conductors for maintenance and future

system changes

Features:

Conduit Outlet Bodies

• Form 7 Condulet outlet bodies approach conduit in size for neat,

compact installations

• Form 8 and Mark 9 bodies provide more room for heavier

conductors

• Many shapes and sizes are available for rigid threaded conduit –

for complete listings see pages 6–12

• Conduit hubs have tapered threads and feature integral bushings

for protection of wire insulation

• Form 7 has exclusive snaptight and wedgenut cover attachment to

provide clear, unobstructed cover opening

• Built-in rollers on all Form 5 1

facilitate wire pulling

• Series 5 bodies available in optional configuration with set screws

on hubs for EMT conduit (add suffix -MT to catalog number)

Gaskets

Solid gaskets:

• Are used with blank covers

• For Mark 9 and Form 5, can be converted to open type gaskets by

tearing out center section along scored lines –

• For Form 7 are used with all covers

Open gaskets:

• For Form 8 –

• For Mark 9 – 2

1

/2" to 4" sizes

1

/2" to 4" sizes

1

/4" to 4" C and LB bodies to

1

/2" to 2" sizes

Certifications and Compliances:

Outlet Bodies –

• UL Standard: 514B

• Fed. Spec.: W-C-586D

• CSA Standard 22.2 No. 18

• NEMA 3R Raintight (when installed with cover and gasket)

Standard Materials:

• Form 7, Form 8 outlet bodies – Feraloy iron alloy

• Mark 9 outlet bodies – copper-free aluminum

• Form 5 – malleable iron

• Series 5 – die cast aluminum

Standard Finishes:

• Form 7, Form 8 outlet bodies – electrogalvanized with aluminum

acrylic paint

• Mark 9 outlet bodies – natural

• Form 5 – electrogalvanized with aluminum acrylic paint

• Series 5 – aluminum acrylic paint

Options:

Description Suffix

Form 7 body and cover only:

Copper-free aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corro-free

Corro-free

Series 5 in an EMT version with set screws on all hubs . . . . . . .

Series 5 pre-packaged with neoprene gasket and cover . . . . . .

™

epoxy powder coat - external body only . . . . . . . . .

™

epoxy powder coat - internal and external . . . . . . .

Form 7

SA

S752

S753

MT

CGN

Blank Covers

Stainless steel cover screws are standard on Form 7, Form 8,

Mark 9, Series 5 and Form 5 covers.

• Form 7

Wedge nut design facilitates installation and removal. Nuts are held

captive in cover. Covers can be used with or without gaskets.

SNAPTIGHT

installed without the use of screws, reducing installation time and

costs. Covers are reusable.

• Form 8

Two cover screws provided on all sizes to provide tight cover and

gasket assembly. Feraloy iron alloy covers have dome shapes for

added strength and extra wiring room.

• Mark 9

Self-retaining cover screws.

™

Form 7 Covers with integral sealing gaskets are

Mark 9

Form 8

Mogul

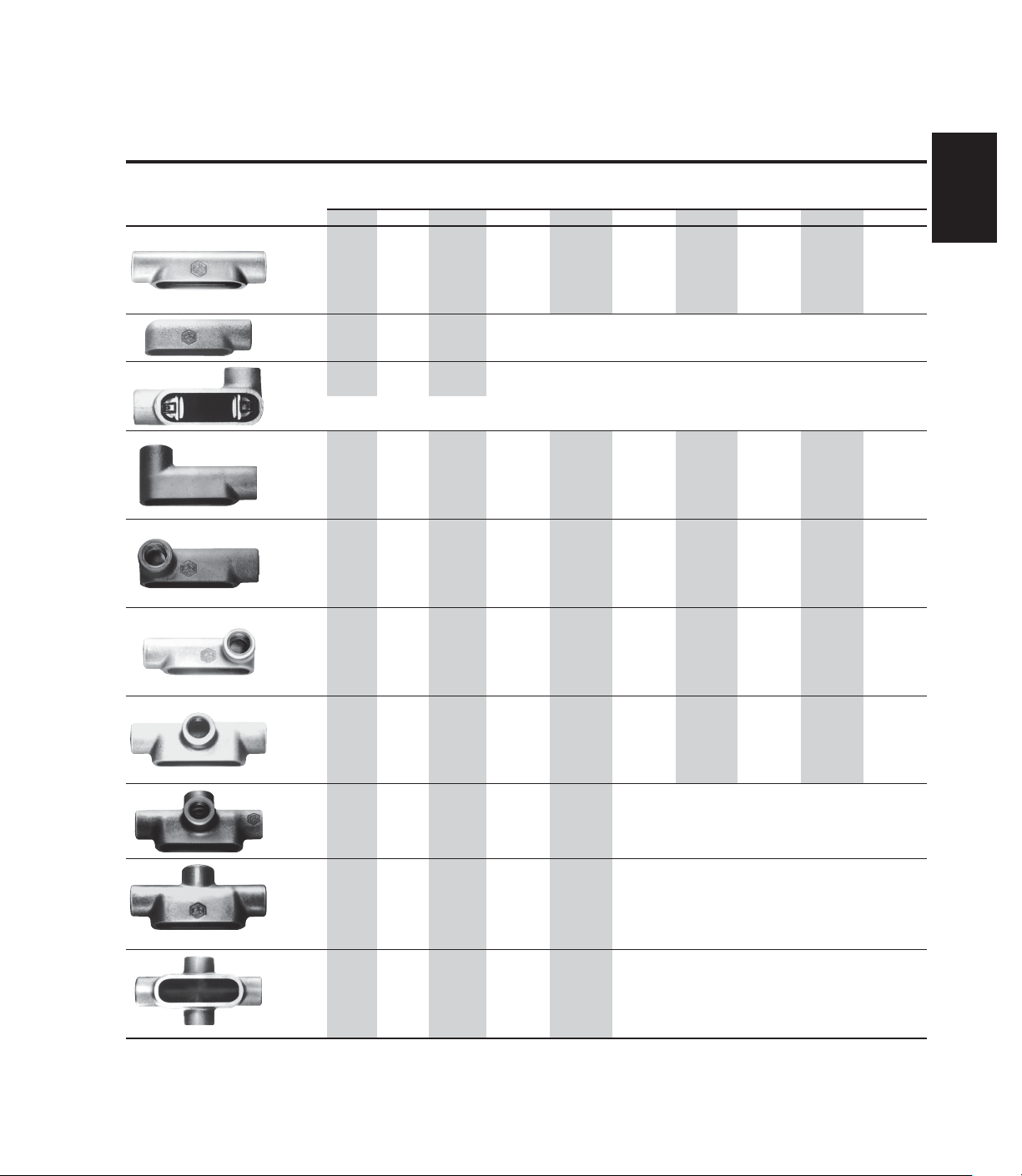

Condulet®Conduit Bodies Cast Iron or Aluminum

Dimensions Pgs. See pages 10–12 (Dimensions for Form 5 – see Section CP)

1F

Threaded Rigid Bodies

Shape

Style

C

Form 7 C17 C27 C37 C47 C57 C67 C77 C87

Form 8 C18 C28 C38 C448 C58 C68 C78 C88

Mark 9 C19 C29 C39 C49 C59 C69 C789 C889 C989 C1089

Form 5 C50M C75M C100M C125M* C150M* C200M* C250M* C300M* C350M* C400M*

Series 5 C15 C25 C35 C45 C55 C65 C75 C85 C95* C105*

E

Form 7 E17 E27 E37

L

Form 7 L17 L27 L37 L47 L57 L67

Double faced – may be used as LL or LR – has 2 openings, one of which is furnished with a blank sheet steel cover

LB

Form 7 LB17 LB27 LB37 LB47 LB57 LB67 LB777 LB87 LB97 LB107

Form 8 LB18 LB28 LB38 LB448 LB58 LB68 LB78 LB888 LB98 LB108

Mark 9 LB19 LB29 LB39 LB49 LB59 LB69 LB789 LB889 LB989 LB1089

Form 5 LB50M LB75M LB100M LB125M* LB150M* LB200M* LB250M* LB300M* LB350M* LB400M*

Series 5 LB15 LB25 LB35 LB45 LB55 LB65 LB75 LB85 LB95 LB105

LL

Form 7 LL17 LL27 LL37 LL47 LL57 LL67 LL777 LL87 LL97 LL107

Form 8 LL18 LL28 LL38 LL448 LL58 LL68 LL78 LL888

Mark 9 LL19 LL29 LL39 LL49 LL59 LL69 LL789 LL889 LL989 LL1089

Form 5 LL50M LL75M LL100M LL125M LL150M LL200M LL250M LL300M LL350M LL400M

Series 5 LL15 LL25 LL35 LL45 LL55 LL65 LL75 LL85 LL95 LL105

LR

Form 7 LR17 LR27 LR37 LR47 LR57 LR67 LR777 LR87 LR97 LR107

Form 8 LR18 LR28 LR38 LR448 LR58 LR68 LR78 LR888

Mark 9 LR19 LR29 LR39 LR49 LR59 LR69 LR789 LR889 LR989 LR1089

Form 5 LR50M LR75M LR100M LR125M LR150M LR200M LR250M LR300M LR350M LR400M

Series 5 LR15 LR25 LR35 LR45 LR55 LR65 LR75 LR85 LR95 LR105

T

Form 7 T17 T27 T37 T47 T57 T67 T77 T87 T97 T107

Form 8 T18 T28 T38 T448 T58 T68 T78 T88

Mark 9 T19 T29 T39 T49 T59 T69 T789 T889 T989 T1089

Form 5 T50M T75M T100M T125M T150M T200M T250M T300M T350M T400M

Series 5 T15 T25 T35 T45 T55 T65 T75 T85 T95* T105*

TA

Form 7 TA17 TA27 TA37 TA47 TA57 TA67

Hub Size

1

/2

3

/4 11

1

/4 11/2 22

1

/2 33

1

/2 4

1F

TB

Form 7 TB17 TB27 TB37 TB47 TB57 TB67

Form 8 TB18 TB28 TB38 TB448 TB58 TB68

Mark 9 TB19 TB29 TB39 TB49 TB59 TB69

Series 5 TB15 TB25 TB35 TB45 TB55 TB65

Form 5 TB50M TB75M TB100M TB125M TB150M TB200M

X

Form 7 X17 X27 X37 X47 X57 X67

Form 8 X18 X28 X38 X448 X58 X68

Mark 9 X19 X29 X39

Series 5 X15 X25 X35 X45 X55 X65

1

* 1

/4" - 4" Form 5 LB and C bodies are supplied with built-in rollers to facilitate wire pulling.

Form 5 X50M X75M X100M X125M X150M X200M

Loading...

Loading...