Page 1

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

RV Freestanding

Gas Ranges and

Gas Cooktops

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

ALY1680BD*

ALY2280BD*

ALY2289BD*

ALZ8580AD*

ALZ8589AD*

ALZ8590AD*

CG11000AD*

CLY1610BD*

CLY1620BD*

CLY1628BD*

CLY2210BD*

CLY2220BD*

CLY2260BD*

CPL1110AD*

YPL1110AD*

16023515

April 2005

©2005 Maytag Services

Page 2

Important Information

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime a product may require service. Products should be serviced only by a qualified service

technician who is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

Important Notices for Servicers and Consumers

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

WARNING

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM................................................ 1-800-843-0304

WWW.MAYTAG.COM ............................................. 1-800-688-9900

CAIR Center in Canada ........................................... 1-800-688-2002

Amana Canada Product ........................................... 1-866-587-2002

Recognize Safety Symbols, Words, and Labels

DANGER!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION!

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16023515 ©2005 Maytag Services

Page 3

Table of Contents

Important Information ................................................... 2

Important Safety Information

Safety Practices for Servicer .................................... 4

Servicing .................................................................. 4

Receiving Oven ........................................................ 5

Using the Oven ........................................................ 5

Baking, Broiling, and Roasting ................................. 6

Connecting Range to Gas ........................................ 6

Product Safety Devices ........................................... 6

General Information

Cooking Nomenclature ............................................. 7

Specifications .......................................................... 8

Placement of Oven or Cooktop ................................ 8

Do Not Block Air Vents ............................................ 8

Location of Model Number ....................................... 8

Model Identification .................................................. 8

Service .................................................................... 8

Parts and Accessories............................................. 8

Extended Service Plan ............................................. 8

Range Description ................................................... 9

Troubleshooting Procedures ....................................... 10

Testing Procedures .................................................... 12

Disassembly Procedures

Replacing Range/Cooktop ..................................... 14

Replacing Open Surface Burner (Select Models) .. 14

Replacing Sealed Surface

Burner (Select Models). ...................................... 14

Replacing Sealed Surface Burner Orifice.............. 14

Replacing Maintop Assembly ................................. 15

Replacing Manifold Assembly ................................ 15

Replacing Surface Burner Valve Control

Assembly (Select Models) ................................... 15

Replacing Igniter Assembly (Select Models) .......... 15

Replacing Control Panel Assembly ........................ 15

Replacing Regulator ............................................... 15

Replacing Flashtube Assembly (Select Models) ..... 15

Replacing Oven Control Valve (Select Models) ...... 15

Replacing Oven/Safety Valve (Select Models) ....... 16

Replacing Bake Burner (Select Models) ................ 16

Replacing Oven Pilot Burner (Select Models) ........ 16

Replacing Oven Bottom Plate (Select Models) ....... 16

Replacing Elbow Block Assembly (Select Models) . 16

Replacing Thermostat Sensor (Select Models) ...... 16

Replacing Oven Flue Box

Assembly (Select Models) ................................... 16

Replacing Main Back ............................................. 17

Replacing Side Trim .............................................. 17

Oven Door Removal (Select Models) ...................... 17

Replacing Oven Door Handle (Select Models) ....... 17

Replacing Oven Door Hinge (Select Models) ......... 17

Oven Door Disassembly (Select Models) ............... 18

Replacing Spark Module (Model ALZ8590AD*) ..... 18

Appendix A: Installation Instructions

All Models except ALZ8590AD*, CG11000AD*,

CPL1110AD*, YPL1110AD* .............................. A-2

Model ALZ8590AD* .............................................. A-5

Models CG11000AD*, CPL1110AD*,

YPL1110AD* ..................................................... A-8

Appendix B: Use and Care Information

Use and Care Information, Gas Range ................. B-2

Cleaning Information, Gas Range ......................... B-6

Use and Care Information, Gas Cooktop .............. B-8

Cleaning Information, Gas Cooktop .................... B-10

Appendix C: LP Conversion Instructions

Model CG11000AD*, CPL1110AD*

YPL1110AD* ..................................................... C-2

©2005 Maytag Services 16023515 3

Page 4

Important Safety Information

As with all appliances, there are certain rules to follow

for safe operation. Verify everyone who operates the

oven or cooktop is familiar with the operations and with

these precautions.

Use appliance only for its intended purpose as

described. Pay close attention to the safety sections of

this manual. Recognize the safety section by looking for

the symbol or the word safety.

Recognize this symbol as a safety precaution.

!

WARNI NG

!

If the information in this manual is not followed exactly,

a fire or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

• Extinguish any open flame.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call fire

department.

WARNI NG

!

This gas appliance contains or produces a chemical

or chemicals which are known to the state of

California to cause cancer, birth defects, or other

reproductive harm. To reduce the risk from substances

in the fuel or from fuel combustion make sure this

appliance is installed, operated and maintained

according to the instructions in this manual.

Due to the nature of cooking, fires can occur as a

result of overcooking or excessive grease. Although a

fire is unlikely, if one occurs proceed as follows:

Oven Fires

1. Do not open the oven door.

2. Turn all controls to OFF.

3. As an added precaution turn off the electricity at

the main circuit breaker or fuse box and the gas

at the main supply valve.

4. Allow the food or grease to burn itself out in the

oven.

If smoke or fire persists, call the local fire department.

To avoid the risk of property damage or personal

injury, do not obstruct the flow of combustion or

ventilation air to the oven.

To avoid the risk of electrical shock, serious personal

injury or death: Make sure your oven has been

properly grounded and always disconnect the

electrical supply before servicing this unit.

Installation and service must be performed by an

authorized installer, service agency or gas supplier.

!

WARNI NG

To avoid risk of electrical shock, property damage,

personal injury, or death, verify wiring is correct, if

components were replaced. Verify proper and

complete operation of unit after servicing.

4 16023515 ©2005 Maytag Services

NOTE: The maximum gas supply pressure for these

models must not exceed 14 inches W.C.P.

Safety Practices for Servicer

Safe and satisfactory operation of gas ranges depends

upon its design and proper installation. However, there is

one more area of safety to be considered:

Servicing

Listed below are some general precautions and safety

practices which should be followed in order to protect

the service technician and consumer during service and

after service has been completed.

1. Gas smell—Extinguish any and all open flames and

open windows.

2. Turn gas off—Service range with gas turned off

unless testing requires gas.

Page 5

Important Safety Information

3. Checking for gas leaks—Never check for leaks with

any kind of open flame. Soap and water solution

should be used for this purpose. Apply solution to

suspected area and watch for air bubbles which

indicates a leak. Correct leaks by tightening fittings,

screws, connections, applying approved compound,

or installing new parts.

4. Using lights—Use a hand flashlight when servicing

ranges or checking for gas leaks. Electric switches

should not be operated where leaks are suspected.

This will avoid creating arcing or sparks which could

ignite the gas. If electric lights are already turned on,

they should not be turned off.

5. Do not smoke—Never smoke while servicing gas

ranges, especially when working on piping that

contains or has contained gas.

6. Check range when service is completed—After

servicing, make visual checks on electrical

connections, and check for gas leaks. Inform

consumer of the condition of range before leaving.

7. Adhere to all local regulations and codes when

performing service.

Receiving Oven or Cooktop

• Installer needs to show consumer location of the range

gas shut-off valve and how to shut it off. Cooktop units

are not equipped with a shut-off valve.

• Authorized servicer must install the range or cooktop

in accordance with the Installation Instructions.

Adjustments and service should be performed only by

authorized servicer.

• Insure all packing materials are removed from the

range or cooktop before operating it, to prevent fire or

smoke damage should the packing material ignite.

• Ensure range or cooktop is correctly adjusted by a

qualified service technician or installer for the type of

gas (Natural or LP). Some ranges can be converted

for use with Natural or LP gas.

• With prolonged use of a range, high floor

temperatures could result. Many floor coverings will not

be able to withstand this kind of use. Never install

range over vinyl tile or linoleum that cannot withstand

high temperatures. Never install range directly over

carpeting.

Using the Oven or Cooktop

• Do not leave children alone or unattended where a

range or cooktop is hot or in operation. They could be

seriously burned.

• Do not allow anyone to climb, stand or hang on the

oven door. They could damage the range and cause

severe personal injury.

• Wear proper apparel. Loose fitting or hanging

garments should never be worn when using range or

cooktop. Flammable material could ignite if brought in

contact with flame or hot oven surfaces which may

cause severe burns.

©2005 Maytag Services 16023515 5

• Never use range for warming or heating a room. This

may cause burns, injuries, or a fire.

• Do not use water on grease fires.

• Do not let grease or other flammable materials collect

in or around range or cooktop.

• Do not repair or replace any part of range or cooktop

unless it is recommended in this manual.

• Use only dry potholders. Moist or damp potholders

used on hot surfaces may result in a burn from steam.

• Do not let a potholder touch the flame. Do not use a

towel or a bulky cloth as a potholder.

• Never leave range or cooktop unattended while

cooking. Boilovers can cause smoking and may ignite.

• Only certain types of glass/ceramic, earthenware, or

other glazed utensils are suitable for oven use.

Unsuitable utensils may break due to sudden

temperature change.

• Use care when opening oven door. Let hot air or steam

escape before removing or replacing food.

• Do not heat unopened food containers in oven.

Build-up of pressure may cause a container to burst

and result in injury.

• Keep range vent ducts unobstructed.

• Place oven racks in desired location while oven is

cool. If a rack must be moved while oven is hot, use a

dry potholder.

• Do not use aluminum foil to line oven bottom or racks.

Aluminum foil can cause a fire will seriously affect

baking results, and damage to porcelain surface's.

• Do not touch interior surfaces of oven during or

immediately after use. Do not let clothing or other

flammable materials come in contact with bake or broil

burners.

• Other areas of the range can become hot enough to

cause burns, such as vent openings, window, oven

door and oven racks.

• To avoid steam burns, do not use a wet sponge or

cloth to wipe up spills on hot cooking area.

• Do not store combustible or flammable materials, such

as, gasoline or other flammable vapors and liquids

near or in range or cooktop.

• Do not clean oven door gasket located on back of the

door. Gasket is necessary to seal the oven and can be

damaged as a result of rubbing or being moved.

• Do not drape towels or any materials on oven door

handles. These items may ignite causing a fire.

!

CAUTI ON

Do not store items of interest to children in cabinets

above range or cooktop. Children may climb on oven

to reach these items and become seriously injured.

Page 6

Important Safety Information

Baking, Broiling, and Roasting

• Do not use oven area for storage.

• Stand back from range when opening door of a hot

oven. Hot air or steam can cause burns to hands,

face, and eyes.

• Do not use aluminum foil anywhere in the oven. This

could result in a fire hazard and damage the range.

• Use only glass cookware appropriate for use in gas

ovens.

• Always remove broiler pan from oven when finished

broiling. Grease left in pan can catch fire if oven is

used without removing grease from the broiler pan.

• When broiling, meat that is close to the flame, may

ignite. Trim any excess fat to help prevent excessive

flare-ups.

• Make sure broiler pan is placed correctly to reduce

any possibility of grease fires.

• Should a grease fire occur in the broiler pan, turn off

oven, and keep oven door closed until fire burns out.

Connecting Range to Gas

Install manual shut-off valve in gas line for easy

accessibility outside range. Be aware of the location of

the shut-off valve. This does not apply to cooktops.

Product Safety Devices

Safety devices and features have been engineered into

the product to protect consumer and servicer. Safety

devices must never be removed, bypassed, or altered in

such a manner as to defeat the purpose for which they

were intended.

Listed below are various safety devices together with the

reason each device is incorporated in the gas ranges.

Pressure Regulator Maintains proper and

steady gas pressure for

operation of oven

controls.

Regulator must be set

for the type of gas being

used Natural or LP.

After servicing regulator,

make certain it is set

properly before

completing service.

Gas Burner Orifices Universal orifices are

used on most valves.

They must be adjusted

for the type of gas being

used Natural

After servicing a valve

or orifice verify it is

adjusted properly before

completing service.

or LP.

Oven Safety Valve Oven valve is designed

to be a safety valve. Two

basic designs are used

in gas ranges:

Hydraulic and Electric

Both types are safety

valves because they are

indirectly operated by

the oven thermostat,

which controls a pilot

flame or electric ignitor,

to open and close the

oven valve.

Cooktops are not

equipped with an oven

shut-off valve.

Grounded Oven Frame Ground prong on power

cord is connected to the

frame, usually a green

lead fastened by a

screw. In addition, any

part or component

capable of conducting

an electric current is

grounded by its

mounting.

If any ground wire,

screw, strap, nut, etc. is

removed for service, or

any reason, it must be

reconnected to its

original position with

original fastener before

the appliance is put into

operation again.

Failure to do so can

create a possible shock

hazard.

6 16023515 ©2005 Maytag Services

Page 7

General Information

This manual provides basic instructions and suggestions

for handling, installing and servicing gas ranges and

cooktops.

The information and warnings in this manual were

developed from experience with, and careful testing of

the product. If the unit is installed according to this

This manual contains information needed by authorized

service technicians to install and service gas ranges and

cooktops. There may be, however, some parts which

need further explanation. Refer to the Installation

Instructions, Use and Care, Technical Sheets or the tollfree technical support line.

manual, it will operate properly and will require minimal

servicing. A unit in proper operating order ensures the

consumer all the benefits provided by clean gas cooking.

Cooking Nomenclature

A L Y 2 2 8 0 A D S

Color

A Almond on Almond

Brand

A Amana

C Magic Chef

G Graffer &

Sattler

H Hardwick

J Jenn-Air

M Maytag

N Norge

U Universal

Y Crosley

Fuel

B Butane

D Dual Fuel

E/J Electric

G Gas, Natural

L Liquid Propane

M Microwave

P Standing Pilot

X No Fuel

W Warming Drawer

Product Type

A Accessory/Cartridge

C Cooktop Updraft/Countertop

D Downdraft Cooktop or Warming Drawer

E Eyelevel Range

G Grill

L Range (20")

M Range (36")

P Drop In (24")

Q Wall Oven (27")

R Range, Free-Standing (30")

S Slide-In (30")

T Range Hood

V OTR

W Wall Oven

Y RV Range

Z RV Top

©2005 Maytag Services 16023515 7

B Black

C Brushed Chrome

H Traditional White

L Traditional Almond

P Prostyle

Q Monochromatic Bisque

S Stainless

T Traditional Bisque

W White on White

F Frost White (True Color White)

N Natural Bisque (True Color Bisque)

Listing

A UL/AGA

C CSA/CGA/CUL

D Dual Listed

G 220-240 V / 50-60 Hz

M Military Model

P PSB Approved

(Singapore)

X Export 120 V / 60 Hz

Production Code

This identifies the

production version.

Feature Content

1000-3999 Brands

4000-6999 Maytag/Amana

7000-9999 Jenn Air

Page 8

General Information

Specifications

Refer to individual Technical Sheet for specification

information.

Placement of the Oven or Cooktop

The freestanding range or cooktop must be placed in the

kitchen or comparable room. All safety guidelines must

be followed and free air flow around the range is

essential (see Chapter 2).

Do Not Block Air Vents

All air vents must be kept clear during cooking. If air

vents are covered during operation, the oven may

overheat. If this occurs, a sensitive, thermal safety device

automatically removes power to the oven, rendering the

oven inoperable. The oven will remain in this state until it

has sufficiently cooled.

Location of Model Number

To request service information or replacement parts, the

service center will require the complete model, serial, and

manufacturing number of your freestanding range or

cooktop. The number can be found under the cooking

surface. Tilt the cooktop up to view the data.

Underside

of Cooking

Surface

Model

Number

Gas

Burners

Model Identification

Complete enclosed registration card and promptly return.

If registration card is missing:

• For Amana product call 1-800-843-0304 or visit the

Web Site at www.amana.com

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.maytag.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Manufacturing Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Dealer’s name and address: ___________________

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an authorized

servicer:

• For Amana product call 1-800-628-5782 or visit the

Web Site at www.amana.com

• For Maytag product call 1-800-462-9824 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Site at www.maytag.com

Warranty service must be performed by an authorized

servicer. We also recommend contacting an authorized

servicer, if service is required after warranty expires.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• For Amana product call 1-877-232-6771 or visit the

Web Site at www.amana.com

• For Maytag product call 1-800-688-9900 or visit the

Web Site at www.maytag.com

• For product in Canada call 1-866-587-2002 or visit the

Web Sites at www.maytag.com

8 16023515 ©2005 Maytag Services

Extended Service Plan

We offer long-term service protection for this new oven

and cooktop.

• Dependability PlusSM Extended Service Plan is

specially designed to supplement Maytag’s warranty.

This plan covers parts, labor, and travel charges.

Call 1-800-925-2020 for information.

Page 9

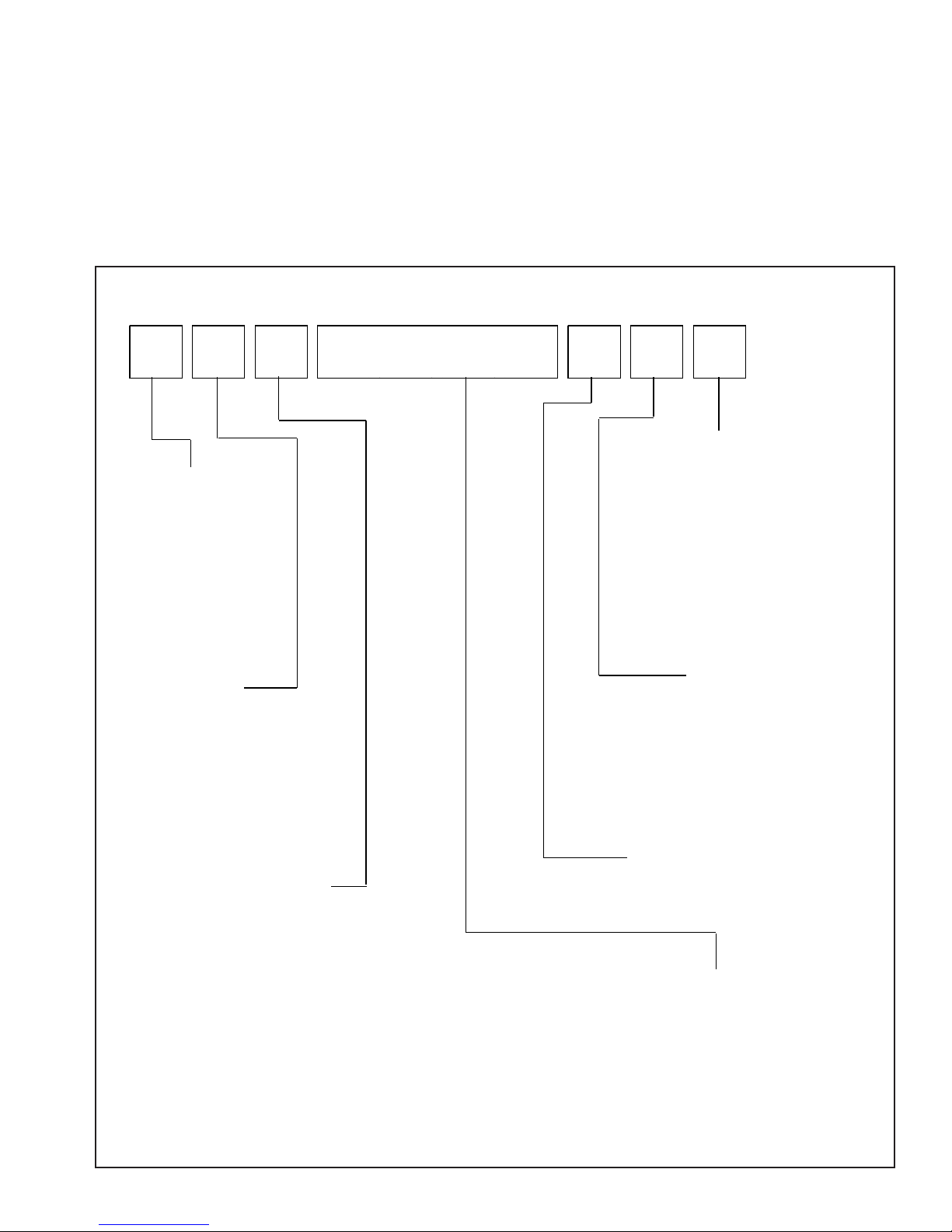

Range Description

Surface

Burner

Surface

Burners

Grates

Surface Burner

Control Knobs

Oven Burner

Control Knob

Oven Pilot

Door Hinge

Surface Burner

Control Knobs

Oven Rack

Oven Bottom Panel

Bake and

Broil Burner

Door Hinge

Oven Door

Door Handle

©2005 Maytag Services 16023515 9

Page 10

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury, or death, disconnect power and gas before servicing, unless

testing requires power and/or gas.

WARNING

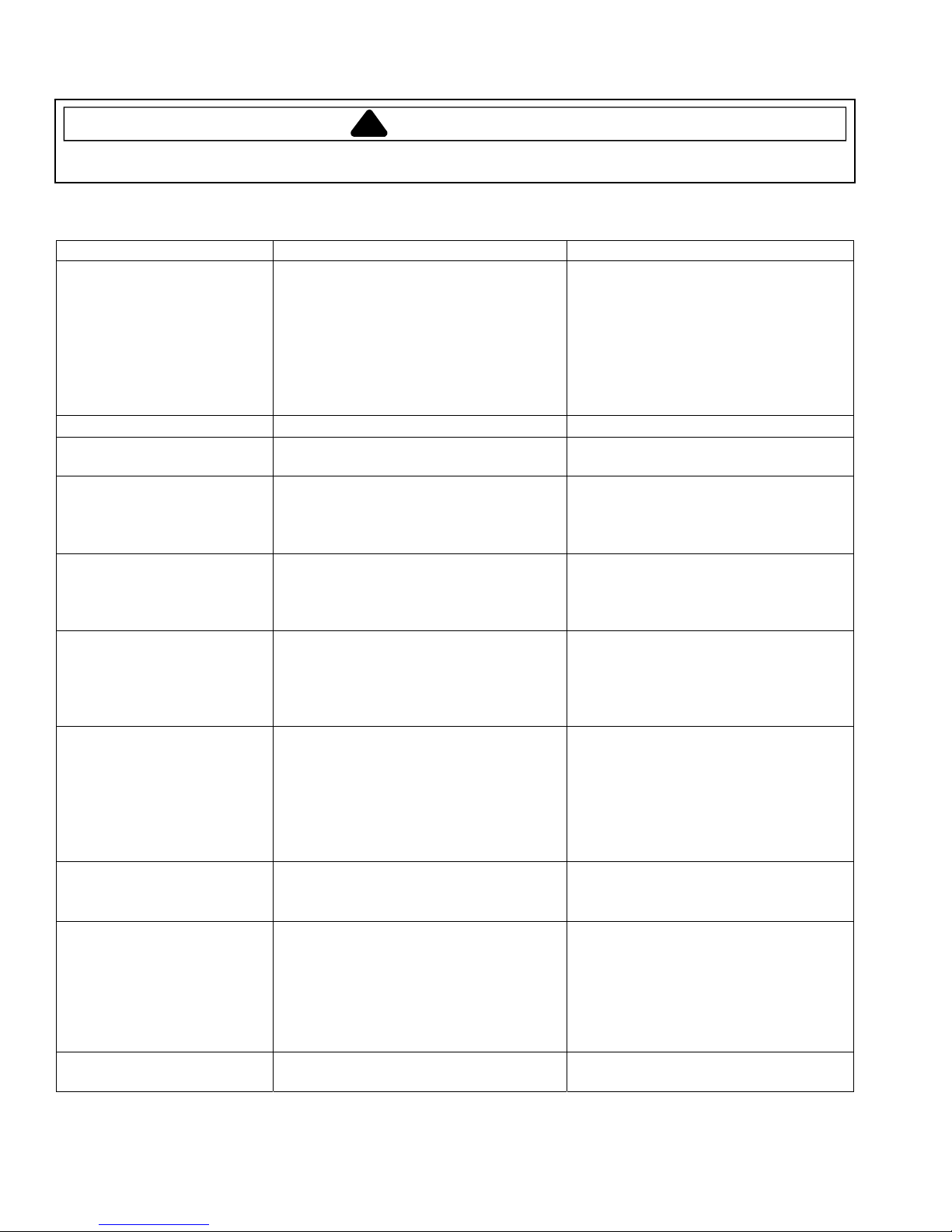

Troubleshooting Chart

Problem Possible Cause Correction

Surface burner fails to light.

Burner flame is uneven.

Surface burner flame lifts off

port or is yellow in color.

Oven burner fails to light.

Popping sound heard when

burner extinguishes.

Moisture condensation on

oven window (if equipped)

when oven is in use.

Baking results are not

satisfactory.

Oven smokes excessively

during broil.

Oven pilot will not light or

stay lit.

Oven smokes/odor first few

times of usage.

Clogged burner port(s) .............................

Surface control not completely turned to

the LITE position, or turned too quickly

from the LITE position ..............................

Damaged, wet or soiled burner ................

Clogged burner port(s) .............................

Air/gas mixture .........................................

Oven pilot not lit........................................

Improper oven control setting...................

This is a normal sound that occurs with

some types of gas when a hot burner is

turned off ..................................................

Moisture in oven .......................................

Moisture in oven window..........................

Oven not preheated or set to correct

temperature ..............................................

Oven thermostat sensing device not

inserted into clips......................................

Oven bottom panel incorrectly installed ...

Oven temperature set too high.................

Broil pan, broil area or oven soiled...........

Pilot tubing................................................

Gas pressure regulator.............................

Oven knob ................................................

Normal ......................................................

• Clean burner ports.

• Continue to turn the LITE control in

the direction indicated until the

burner ignites.

• Clean and/or dry burner, replace

burner if damaged.

• Clean burner ports.

• Adjust burner flame (some yellow

tipping with LP gas is acceptable).

• Light oven pilot. (See “Lighting Pilot

Burner,” page C-4.)

• Push in and turn oven control to

desired temperature.

• This is not a safety hazard and will

not damage the appliance.

• Leave oven door ajar for one or two

minutes to allow moisture to escape.

• Use a damp cloth to clean window to

prevent excess water from seeping

between the panels of glass.

• Preheat oven 10 to 15 minutes, or

set oven temperature to correct

temperature.

• Reinstall thermostat sensing device.

• Replace oven bottom correctly.

• Lower oven temperature.

• Clean broiler pan, broiler area or

oven.

• Pilot tubing may be clogged, kinked

or leaking at the fitting.

• Test pressure regulator, see Chapter

5, "Testing Procedures."

• Knob must be in PILOT ON position.

(See “Lighting Pilot Burner,”

page C-4.)

• Minor smoking and/or odor is normal

the first few times of oven usage.

10 16023515

©2005 Maytag Services

Page 11

Troubleshooting Procedures

.

.

.

!

To avoid risk of electrical shock, personal injury, or death, disconnect power and gas before servicing, unless

testing requires power and/or gas.

WARNING

Problem Possible Cause Correction

Gas odor.

Oven slow to heat, poor

baking results, poor burner

ignition, pilot won’t stay lit,

carbon on pilot shield, flame

too high or too low.

Gas leak ...................................................

Loose fittings ............................................

Pressure regulator....................................

• Check all gas connections for leaks

(see note below).

• Check all gas fittings for leaks.

• Test pressure regulator, see Chapter

5, "Testing Procedures."

NOTE: Due to vibrations that occur when traveling in a recreational vehicle, gas connections may loosen.

Periodically check all gas connections and gas fittings for leaks.

Never test for gas leaks using an open flame.

TESTING FOR GAS LEAKS: To test for a gas leak, apply a non-corrosive leak detection fluid to all joints and

fittings in the gas connection between the supply line, shut-off valve, and range or

cooktop. Include gas fittings and joints in the range or cooktop if connections were

disturbed during installation. Bubbles appearing around fittings and connections

indicates a leak. If a leak is present, turn off supply line gas shut-off valve, tighten

connections, turn on the supply line gas shut-off valve, and retest for leaks. When

finished, wipe off all residue.

©2005 Maytag Services 16023515 11

Page 12

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing, unless

testing requires power and/or gas.

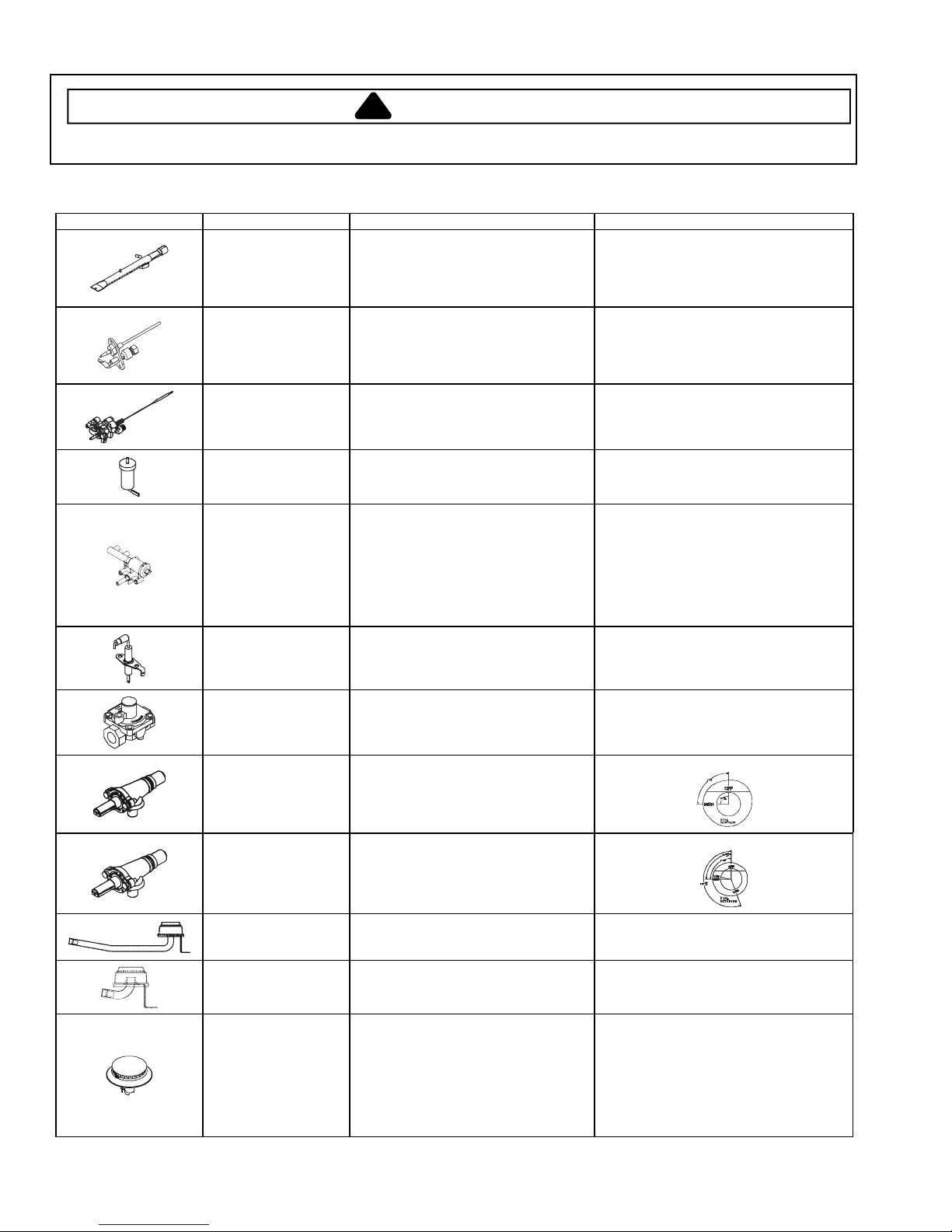

Component Testing Procedures

Illustration Component Test Procedure Results

Burner, bake

(Not applicable to

cooktop models.)

Burner, pilot

(Not applicable to

cooktop models.)

Thermostat, gas

Verify gas is supplied.

Check for obstructions, contamination

in ports or damage .................................

Verify gas is supplied.

Check for obstructions, contamination

in ports or damage .................................

Verify gas is supplied ............................. Gas is supplied.

(Copreci)

(Not applicable to

Spark ignitor, top

burners

Measure resistance from tip of spark

ignitor to wire terminal ............................ Continuity.

cooktop models.)

Ignitor, Piezo

(All models except

ALZ8590AD*,

Verify operation by rotating dial in the

direction indicated on the knob............... Ignitor clicks and top burner spark ignitor

CG11000AD*,

CPL1110AD*,

YPL1110AD*,

CLY2210BD*,

CLY1610BD*)

Electrode, top burner

electrode

(Models

Measure resistance from tip of

electrode to wire terminal ....................... Continuity.

ALZ8580AD*,

ALZ8589AD*)

Regulator, pressure Verify gas pressure (WCP).....................

Air shutter opening: .438" to .498".

Blue flame with some yellow tipping is

normal (burner should not soot).

Replace if punctured or torn.

Orifice diameter: .0078" to .0086".

Blue flame with some yellow tipping is

normal (burner should not soot).

Replace if punctured or torn.

emits a spark.

10" LP/Propane.

Valve, top burner

Verify gas is supplied ............................. Gas is supplied.

(6.5K burners)

Valve, top burner

Verify gas is supplied ............................. Gas is supplied.

(9.1K burner)

Burner, top rear,

sealed (6.5K burners)

Burner, top front,

sealed (9.1K burner)

Burner, top, sealed

(Models

ALY1680BD*,

Verify gas is supplied .............................

Check for obstructions or

contamination in burner ports.................

Verify gas is supplied .............................

Check for obstructions or

contamination in burner ports.................

Verify gas is supplied .............................

Check for obstructions or

contamination in burner ports.................

Gas is supplied.

Clean/remove any foreign objects.

Gas is supplied.

Clean/remove any foreign objects.

Gas is supplied.

Clean/remove any foreign objects.

ALY2280BD*,

ALY2289BD*,

ALZ8580AD*,

ALZ8589AD*,

ALZ8590AD*)

12 16023515

©2005 Maytag Services

Page 13

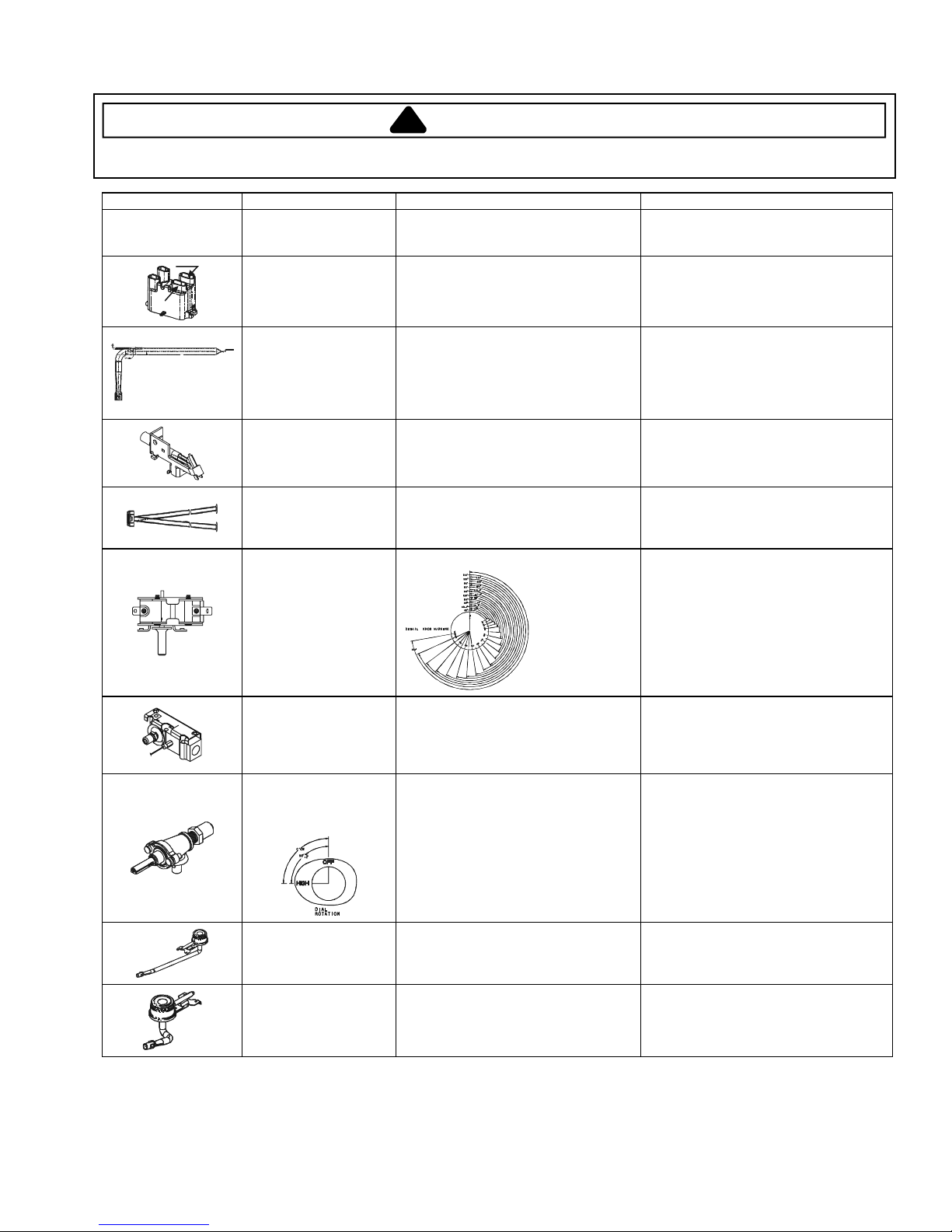

Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing, unless

testing requires power and/or gas.

Illustration Component Test Procedure Results

B

Switch, lighter

(Model ALZ8590AD*)

Module, spark

(Model ALZ8590AD*)

A

Burner, bake

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Lighter, pilot

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Burner, pilot

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Thermostat, gas

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Verify operation by rotating dial in the

direction indicated on the knob .............. Ignitor clicks and top burner spark

ignitor emits a spark.

Test for voltage at terminals A and B .....

Check polarity and ground .....................

Verify gas is supplied.

Verify air shutter adjustment ..................

Verify proper orifice installed-Nat or LP..

Check for obstructions, contamination

in ports or damage .................................

Verify gas pressure (WCP) ....................

12 VDC.

See schematic drawing.

Air shutter opening: .349" to .411".

Refer to LP/Nat. conversion instructions.

Blue flame with some yellow tipping is

normal (burner should not soot).

Replace if punctured or torn.

" Natural

4

" LP/Propane

10

Verify pilot selector cartridge is set to

the proper gas........................................ LP or Natural

Verify gas is supplied .............................

Gas is supplied.

Safety valve, oven,

Verify gas supply is turned on ................ Gas is turned on.

shut-off

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Valve, top burner

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Verify gas is supplied .............................

Orifice adjusted for Natural or LP ...........

Gas is supplied.

Refer to LP/Nat. conversion

instructions.

Adjust set screw for simmer control.

Burner, open, top rear

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Burner, open, top front

(Models CPL1110AD*,

YPL1110AD*,

CG11000AD*)

Verify gas is supplied .............................

Verify air shutter adjusted properly.........

Gas is supplied.

Air shutter opening: .420" to .460"

Verify gas is supplied .............................

Verify air shutter adjusted properly.........

Gas is supplied.

Air shutter opening: .420" to .460"

©2005 Maytag Services 16023515 13

Page 14

Disassembly Procedures

b

To avoid risk of electrical shock, personal injury or

death; disconnect power and gas before servicing.

Replacing Range/Cooktop

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

NOTE: To avoid countertop damage, do not move

range forward or cooktop up until raised enough

to clear all cabinetry.

3. Pull the range forward out of the cabinet opening, or

pull the cooktop up and out of the installation location.

4. Replace the range/cooktop using the installation

instructions and anti-tip bracket(s).

Replacing Open Surface Burner (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove surface grates and lift cooking surface.

4. Remove burner flashtube extender from burner.

5. Remove screw securing burner to chassis.

6. Remove burner gas tubing from burner control valve.

7. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

4. Place Burner Wrench removal and installation tool

(Part Number 8312D075-60) over sealed burner (see

wrench label for proper alignment).

5. Once the wrench is placed properly on the burner,

turn wrench counterclockwise with steady and even

pressure. Turn the burner no more than two inches

to loosen.

NOTE: Some minor crunching or grinding sounds may

be heard. This is normal. Be careful not to chip

the finish in visible areas.

6. Once loose, lift the burner straight up and out of the

mounting hole.

7. Disconnect ignitor wire.

8. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

This gap

fits over

the ignitor.

Ignitor

Flashtube

Assembly

Ignitor

Front Open

Burner

Burner Control

Valv e

Burner Control

Knobs

Oven Control

Valv e

Manifold

Assembly

Regulator

Ignitor Control

Knob

Grates

Maintop

Rear Open

Burner

Gas

Fitting

Ignitor Control

Open Burner Surface Gas Controls

Replacing Sealed Surface Burner (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove surface grates from cooking surface.

Sealed

Burner

Oven Control

Val ve

Burner Control

Knobs

Front Burner

Orifice

Burner Control

Val ve

Manifold

Assembly

Grates

Maintop

Pressure

Regulator

Rear Burner

Orifice

Gas Fitting

Ignitor Control

Ignitor Control

Kno

Sealed Burner Surface Gas Controls

Replacing Sealed Surface Burner Orifice

(Select Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

14 16023515 ©2005 Maytag Services

Page 15

Disassembly Procedures

To avoid risk of electrical shock, personal injury or

death; disconnect power and gas before servicing.

3. Remove maintop assembly, see "Replacing Maintop

Assembly" procedure.

4. Remove screws securing burner orifice assembly to

burner box.

5. Disconnect orifice assembly from burner control

valve.

6. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

Replacing Maintop Assembly

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Lift left side of top up and slide top off guide pin.

4. Slide right side of top toward the left and off guide pin.

5. Set maintop assembly in a safe location.

6. Reverse procedures to reassemble.

Replacing Manifold Assembly

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove maintop assembly, see "Replacing Maintop

Assembly" procedure.

4. Remove gas supply line from pressure regulator.

5. Remove surface burners. Depending on model, see

either "Replacing Open Surface Burner" procedure or

"Replacing Sealed Surface Burner Assembly"

procedure.

6. Remove gas valve control knobs from control panel.

7. Disconnect all gas lines from oven control valve.

8. Remove screws securing manifold to chassis.

9. Open oven door and remove thermostat sensor from

retaining clip.

10.Gently slide sensor up and out of oven cavity using

the installation hole located in the top of the oven

cavity.

11. Slide manifold assembly from burner box.

12.Reverse procedures to reassemble.

Replacing Surface Burner Valve Control

Assembly

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove manifold assembly, see "Replacing Manifold

Assembly" procedure.

4. Remove screw securing surface burner control valve

to manifold.

5. Slide surface burner control valve from manifold

assembly.

6. Reverse procedures to reassemble.

(Select Models)

Replacing Igniter Assembly (Select Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove ignitor control knob.

4. Remove screws securing assembly to control panel.

5. Remove wire to electrode.

6. Slide igniter assembly from control panel/burner box.

7. Reverse procedures to reassemble.

Replacing Control Panel Assembly

1. Remove unit from installation position, see “Replacing

Range/Cooktop” procedure.

2. Remove maintop, see "Replacing Maintop Assembly"

procedure.

3. Remove valve control knobs.

4. Remove ignitor control knob (select models).

5. Remove screws securing control panel to chassis.

6. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

Replacing Regulator

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Disconnect gas supply lines from regulator.

4. Remove manifold assembly, see "Replacing Manifold

Assembly" procedure.

5. Remove regulator from manifold assembly.

6. Reverse procedures to reassemble.

NOTE: When reconnecting supply line to regulator, use

pipe dope compound to seal the connection.

Once connected, perform gas leak test.

Replacing Flashtube Assembly (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Lift up on maintop assembly to access burner box.

4. Disconnect flashtube extensions from burners.

5. Disconnect ignitor wire.

6. Remove screws securing flashtube assembly to

chassis.

7. Slide flashtube assembly from burner box.

8. Reverse procedures to reassemble.

NOTE: Perform gas leak test.

Replacing Oven Control Valve (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove manifold assembly, see "Replacing Manifold

Assembly" procedure.

4. Remove screw securing oven control valve to

manifold.

5. Slide oven control valve from manifold assembly.

6. Reverse procedures to reassemble.

©2005 Maytag Services 16023515 15

Page 16

Disassembly Procedures

y

Thermostat

Sensor

Burner Baffle Plate

Oven/Safety Valve or

Elbow Block Assembl

Bake Burner

Pilot Burner

Assembly

To avoid risk of electrical shock, personal injury or

death; disconnect power and gas before servicing.

6. Disconnect gas lines to oven and pilot burners.

7. Remove screws securing burner holder to oven

chassis.

8. Remove screws securing pilot burner assembly to

bake burner.

9. Gently slide pilot assembly toward the front of the

oven to remove.

10.Reverse procedures to reassemble.

Replacing Oven Bottom Plate (Select

Models)

1. Turn oven off.

2. Open oven door and remove baking racks.

3. Push oven bottom plate in, slide up, then pull plate

toward the front of the oven once the plate has

cleared the guide pins.

4. Slide oven bottom plate out of oven cavity.

5. Reverse procedures to reassemble.

Oven Cavity Gas Controls

Replacing Oven/Safety Valve (Select Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door and remove baking racks.

4. Remove oven bottom plate, see "Replacing Oven

Bottom Plate" procedure.

5. Disconnect gas supply lines from oven/safety valve.

6. Remove screws securing oven/safety valve to rear

wall of oven cavity.

7. Remove oven/safety valve from oven cavity.

8. Reverse procedures to reassemble.

Replacing Bake Burner (Select Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door and remove baking racks.

4. Remove oven bottom plate, see "Replacing Oven

Bottom Plate" procedure.

5. Remove screw securing baffle to burner.

6. Disconnect gas lines to oven and pilot burners.

7. Remove screws securing burner holder to oven

chassis.

8. Remove screws securing pilot burner assembly to

bake burner. Gently slide pilot assembly out.

9. Slide bake burner toward front of oven and remove.

10.Reverse procedures to reassemble.

Replacing Elbow Block Assembly (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door and remove baking racks.

4. Remove oven bottom plate, see "Replacing Oven

Bottom Plate" procedure.

5. Disconnect gas supply line from elbow block

assembly.

6. Remove screws securing elbow block assembly to

rear wall of oven cavity.

7. Remove elbow block assembly from oven cavity.

8. Reverse procedures to reassemble.

Replacing Thermostat Sensor (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove manifold assembly, see "Replacing Manifold

Assembly" procedure.

4. Remove screw securing oven control valve to

manifold.

5. Slide oven control valve from manifold assembly.

6. Reverse procedures to reassemble.

NOTE: The individual sensor cannot be replaced. The

complete oven control valve assembly must be

replaced.

Replacing Oven Pilot Burner (Select Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door and remove baking racks.

4. Remove oven bottom plate, see "Replacing Oven

Bottom Plate" procedure.

5. Remove screw securing baffle to burner.

16 16023515 ©2005 Maytag Services

Replacing Oven Flue Box Assembly (Select

Models)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door and remove baking racks.

4. Remove screws securing bottom of oven flue box

assembly to rear wall of oven cavity.

Page 17

Disassembly Procedures

g

g

To avoid risk of electrical shock, personal injury or

death; disconnect power and gas before servicing.

5. Slide vent up and out to remove flue box.

6. Reverse procedures to reassemble.

Oven Hin

Flue Box

Main Back

e Sprin

Burner Box Bottom

Side Trim

Control Panel

Oven Rack

Oven Cavi ty

Oven Bot tom

Range Components, Oven and Frame

Replacing Main Back

1. Remove unit from installation position, see “Replacing

Range/Cooktop” procedure.

2. Remove maintop, see "Replacing Maintop Assembly"

procedure.

3. Remove screws securing main back to chassis.

4. Reverse procedures to reassemble.

Replacing Side Trim

1. Remove unit from installation position, see “Replacing

Range/Cooktop” procedure.

2. Remove maintop, see "Replacing Maintop Assembly"

procedure.

3. Remove screws securing maintop guide pins to side

trim.

4. Remove bolt and nut securing side trim to chassis.

5. Remove screws securing side trim to chassis.

6. Slide side trim up and toward the front to remove.

7. Reverse procedures to reassembly.

4. Remove screws securing door panel to inner door

(also glass panel on select models).

5. Remove screws securing bottom oven door bracket

to oven chassis.

6. Remove screws securing inner door to hinge

receptacles.

7. Pull and slide hinge spring arms away from hinge

receptacles.

8. Hook spring arms into oven chassis hinge slots until

reassembly.

9. Reverse procedures to reassemble.

Replacing Oven Door Handle (Select Models)

WARNI NG

!

To avoid risk of personal injury or property damage,

do not lift oven door by the handle.

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door.

4. Remove screws securing door panel to inner door

(also glass panel on select models).

5. Remove screws securing oven door handle to oven

door (also glass panel on select models).

6. Reverse procedures to reassemble.

Replacing Oven Door Hinge (Select Models)

WARNI NG

!

To avoid risk of personal injury or property damage,

do not lift oven door by the handle.

1. Remove oven door, see "Oven Door Removal"

procedure.

2. Slide hinge out from inner door assembly.

3. Reverse procedures to reassemble.

Oven Door Removal (Select Models)

WARNI NG

!

To avoid risk of personal injury or property damage,

do not lift oven door by the handle.

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Open oven door.

©2005 Maytag Services 16023515 17

Page 18

Disassembly Procedures

y

To avoid risk of electrical shock, personal injury or

death; disconnect power and gas before servicing.

Oven Door Disassembly (Select Models)

1. Remove oven door, see "Replacing Oven Door" procedure.

2. Remove oven door handle, see "Replacing Oven Door Handle" procedure.

3. Reverse procedure to reassemble oven door.

Door

Lining

Glass

Door

(select models)

Door

Handle

Glass Clip

Door

Panel

Door

Insulation

Replacing Spark Module (Model ALZ8590AD*)

1. Turn off and remove power from unit (if electric unit).

2. Turn off and remove gas supply from unit.

3. Remove maintop, see "Replacing Maintop Assembly" procedure.

4. Remove screws securing spark module to chassis.

5. Slide spark module up to remove.

6. Reverse procedures to reassemble.

Hinge Spring

Door Hinge

Grate

Sealed

Burner

Drip

Bowl

Ta p e

Seal

To p / G la s s

Assembly

Burner

Control

Knob

18 16023515 ©2005 Maytag Services

Burner

Bottom

Glass

Grommet

Burner

Orifice

Box

Ignitor

Regulator

Switch

Manifold

Assembl

Burner Control

Valve

Cooktop Model ALZ8590AD* Components

Page 19

Appendix A

©2005 Maytag Services 16023515 A – 1

Page 20

Installation Instructions (All models except ALZ8590AD*, CPL1110AD*,

YPL1110AD*, CG11000AD*)

For RV Cooktop s

6.

INSTALLATION

1. Cut opening in accordance with diagram shown below.

2. Align the 3/8" gas supply line with the hole provided in

burner box so it will slide into place when the range is

placed into the opening.

3. Place the range in position and fasten down with four

wood screws through holes provided in the side trim.

4. Connect gas supply line.

5. Check all gas connections for leaks with non-corrosive

leak detection fluid.

checking gas leaks.

Do not use open flames for

CAUTION:

GASSUPPLYLINEMUSTHAVEAL.P.GAS

PRESSURE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

P.S.I.) INLET PRESSURES IN EXCESS OF 0.5 P.S.I.

CAN DAMAGE THE APPLIANCE PRESSURE

REGULATOR AND OTHER GAS COMPONENTS IN

THIS APPLIANCE AND CAN RESULT IN A GAS

LEAK.

WARNING:

fused to metal. It is thoroughly inspected and will give

good service if carefully handled, but it is breakable and

cannot be guaranteed. Like all glass or porcelain articles,

we cannot replace enamel parts that are damaged after

delivery to carriers except at customer’s expense.

LIQUIFIED PETROLEUM (L.P.)/PROPANE

Porcelain enamel is glass which has been

Min. Vertical

Back Wall 7/8

11/2 Min.

to Vertical

Side Wal l

43/8

Front Cut-out

NOTE:

Clearance spaces shall be framed in or

7

21 7/16

20 1/2

18 9/16

23/4

If countertop has overhang, it must be

notched to suit 21 7/16 dimension.

Countertop overhang in excess of 1 will

require radius return to tri m of range.

Min. Distance

to side wall 1 1/16

Front Cut-out 4 3/8

guarded to prevent storage space within the

clearance specified. Cabinet enclosures shall

be designedto prevent drafts that will affect pilot

stability.

Minimum clearances zero from intergral

casing spacers below countertop.

21 3/8

Dottedlineindicates

top trim

7

20 1/2

11/16

23/4

Service

Pipe

Opening

Min. distance to back wall

18 9/16

7/16

Range to be supported

on countertop only

Top T ri m

Overlap

7/8

41/2

A – 2 16023515 ©2005 Maytag Services

Page 21

Installation Instructions (All models except ALZ8590AD*, CPL1110AD*,

YPL1110AD*, CG11000AD*)

For RV Ranges

INSTALLATION

1. Cut opening as shown below (range can be suspended

from top flange; no other support is necessary.)

2. Range equipped with a 120 volt light in the oven will

require the installation of a 120V three prong grounded

receptacle directly behind the range (for correct

location see sketch below.) On range with BX cable

and marked for 12 volt DC power supply connect 12

volt DC power to the tagged wires.

3. Place range in opening and fasten in place. Six screw

holes that are provided are located at points AA and

BB. A minimum of four screws must be used to fasten

range. Recreational vehicle manufacturers may use

appropriate holes as found necessary to suit the

application. Use No. 8 flat head wood screws.

4. Make gas connections and check for leaks with non

corrosive leak detection fluid.

with open flame.

Do not check for leaks

5.

CAUTION:

GASSUPPLYLINEMUSTHAVEAL.P.GAS

PRESSURE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

P.S.I.) INLET PRESSURES IN EXCESS OF 0.5 P.S.I.

CAN DAMAGE THE APPLIANCE PRESSURE

REGULATOR AND OTHER GAS COMPONENTS IN

THIS APPLIANCE AND CAN RESULT IN A GAS

LEAK.

WARNING:

fused to metal. It is thoroughly inspected and will give

good service if carefully handled, but it is breakable and

cannot be guaranteed. Like all glass or porcelain articles,

we cannot replace enamel parts that are damaged after

delivery to carriers except at customer’s expense.

LIQUIFIED PETROLEUM (L.P.)/PROPANE

Porcelain enamel is glass which has been

NOTE:

Clearance spaces shall be framed

in or guarded to prevent storage space

within the clearance specified. Cabinet

enclosures shall be designed to prevent

drafts that will affect pilot stability.

MODEL

16

22

©2005 Maytag Services 16023515 A – 3

CUTOUT HT.

16 3/8

21 13/16

PIPE LOC.

17/8

25/8

Page 22

Installation Instructions (All models except ALZ8590AD*, CPL1110AD*,

YPL1110AD*, CG11000AD*)

OVEN SECTION

1. The oven thermostat in this range will enable you to turn

off the Oven Constant Pilot by simply turning the

thermostat dial to the “OFF” position. To light oven pilot,

push the Control knob and rotate counter clockwise to

the “OVEN PILOT ON” position. Push and hold the

control knob while lighting the oven standing pilot.

2. The air shutter has been adjusted at the factory,

however, it may require some additional adjustment

when used at high altitudes.

3. To adjust, open the air shutter to the full open position

where you will have a blowing condition. Begin closing

the shutter slowly, when you reach the correct

adjustment the blowing will stop and the burner should

have a sharp blue flame approximately 3 inches long.

4. There is no oven pilot adjustment on the thermostat, the

control has been factory preset for use on LP gas, no

field adjustment necessary.

RECOMMENDED GROUNDING METHOD

ELECTRICAL REQUIREMENTS AND GROUNDING

INSTRUCTIONS FOR 120V 60HZ AC,

if equipped.

FIGURE 1

NOTE:

electrically grounded in accordance with National Electric

Code. ANSI/NFPA No. 70-1990. In Canada CAN/CSA C22.2 Electrical Code.

A unit having an external electrical supply must be

WIRING DIAGRAM FOR MODELS WITH

EXTERNAL ELECTRICAL SUPPLY

Observe all governing codes and ordinances. All ranges

requiring electrical supply must be grounded.

If this appliance is factory equipped with a power supply

cord it has a three-pronged grounding plug. It must be

plugged into a mating grounding type receptacle in

accordance with National Electrical Code and applicable

local codes and ordinances. If the circuit does not have a

grounding type receptacle, it is the responsibility and

obligation of the customer to change the existing

receptacle to a proper grounded receptacle in accordance

with the National Electrical Code and applicable local

codes and ordinances.

PRONGSHOULDNOT,UNDERANY

CIRCUMSTANCES, BE CUT OR REMOVED as it

provides protection against shock hazard.

THE THIRD GROUNDING

A – 4 16023515 ©2005 Maytag Services

Page 23

Installation Instructions (Model ALZ8590AD*)

Note To Installer

Always check with local and state codes before

installation. Requirements beyond those as shown may

affect these instructions, for which the manufacturer is not

responsible.

The installation of appliances designed for recreational

vehicles must conform with state or provincial codes, or in

the absence of such codes, with the latest edition of the

Standard for Recreational Vehicles ANSI/NFPA No.

501C.

CUL appliance must be installed in accordance with

CAN/CSA Z240.4 Series Standards, “Gas equipped

recreational vehicles and mobile homes” and/or local

codes having jurisdiction. Minimum clearance from

countertop to combustible ceiling as approved by U.L. is

24 , CUL is 19 .

Rating Plate Location

The rating plate is located under the cooktop. The

following information is listed on this plate:

The model and serial numbers.

When inquiring about your appliance be sure to include

these numbers with your inquiry.

For your convenience please record these numbers in the

space provided below.

1. Model number:

2. Serial number:

WIRING DIAGRAM FOR MODELS WITH EXTERNAL ELECTRICAL SUPPLY

©2005 Maytag Services 16023515 A – 5

Page 24

Installation Instructions (Model ALZ8590AD*)

Installation For RV Cooktops

1.

CAUTION:

LIQUIFIED PETROLEUM (L.P.)/PROPANEGASSUPPLYLINEMUSTHAVEAL.P.GAS

PRESSURE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

P.S.I.) INLET PRESSURES IN EXCESS OF 0.5 P.S.I.

CAN DAMAGE THE APPLIANCE PRESSURE

REGULATOR AND OTHER GAS COMPONENTS IN

THIS APPLIANCE AND CAN RESULT IN A GAS

LEAK.

3

20

15

2. Cut opening in accordance with figure 1 shown below.

3MIN.TO

REAR WALL

3 MIN. TO SIDE WALLS

3. Place the cooktop upside down on a protected surface

and place the 1/2 x 1/2 foam strip on the underside of

the glass around the perimeter of cooktop to seal

between cooktop and counter. (See figure 2).

4. Place the cooktop in position and fasten down with

screws and mounting brackets. (See figure 2).

FOAM

GASKET

Ar t #: 9215- 188

MOUNTING BRACKET

MOUNTING SCREW

Figure 2

PRIOR TO STEPS 5 & 6, MAKE SURE BOTH KNOBS

ARE IN THE “OFF

”POSITION.

5. Connect ignition wires to 12 VOLT DC power source,

as shown in figure 3. (Black to negative and Red to

positive).

6. Connect gas supply line to .625-18UNF-2A nipple at

back of unit. (See figure 3).

NOTE:

If local codes and ordinances permit, A.G.A.

design certified, new flexible metal tubing is recommended for connecting cooktop to the gas supply line.

7. Check all gas connections for leaks with non corrosive

leak detection fluid.

Do not use open flames for

checking gas leaks.

FLEXIBLE CONNECTOR

SHUTOFF

20 15

VALV E

Figure 1

FLEXIBLE CONDUIT

BLACK TO (-) NEGATIVE

RED TO (+) POSITIVE

POWER SOURCE: 9 TO 12 VDC

Figure 3

A – 6 16023515 ©2005 Maytag Services

Page 25

Installation Instructions (Model ALZ8590AD*)

WARNING:

Porcelain enamel is glass which

has been fused to metal. It is thoroughly inspected

and will give good service if carefully handled, but

it is breakable and cannot be guaranteed. Like all

glass or porcelain articles, we cannot replace

enamel parts that are damaged after delivery to

carriers except at customer’s expense.

CHECK THESE POINTS BEFORE YOU CALL FOR SERVICE

PROBLEM

CAUSE

Insertion And Removal Of SqueezeGrate

Press on two grate fingers on both sides of expansion gap

and insert or remove squeeze grate from burner bowl.

(See figure 4).

EXPANSION GAP

PRESS HERE

GRATE

FINGER

BURNER

BOWL

PRESS HERE

Ar t #: 9215- 189

Figure 4

CORRECTION

Surface burner fails to light.

Burner flame is uneven.

Surfaceburner flamelifts off port

or is yellow in color.

Popping sound heard when

burner extinguishes.

Gas odor

a. Clogged burner port(s).

b. Surface control not completely turned

to the LITE position or turned too

quickly from the LITE position.

c. Burner will not light if the ignitor is

damaged, soiled, wet or if the port

directly below the ignitor is blocked.

Clogged burner port(s).

Air/gas mixture not proper.

NOTE:

is normal and acceptable.

This is a normal sound that occurs with some types of gas when a hot burner is

turned off. The popping sound is not a safety hazard and will not damage the

appliance.

Possible leak or loose fittings.

Some yellow tipping with LP gas

a. Clean ports with straight pin.

b. Turn control to the LITE position

until the burner ignites, then turn

control to desired flame size.

c. Clean and dry burner head. If

broken or damaged, call a

serviceman.

Clean ports with straight pin.

Call serviceman to adjust burner.

NOTE:

adjusted range at time of installation.

See boxed statements on front cover.

Because of vibrations due to travel,

connections on a recreational vehicle

may loosen. Therefore, periodically

check all connections for leaks.

See the installation instructions for

proper procedures on leak testing.

NEVER use a match or flame to

check for leaks.

Be sure installer properly

©2005 Maytag Services 16023515 A – 7

Page 26

Installation Instructions (Models CG11000AD*, CPL1110AD*,

YPL1110AD*)

INSTALLATION DRAWINGS

A – 8 16023515 ©2005 Maytag Services

Page 27

g

Installation Instructions (Models CG11000AD*, CPL1110AD*,

YPL1110AD*)

BACKGUARD INSTALLATION

(if not installed)

The backguard fits on the range as shown in figure 1 and

is secured with a bracket, 2 bolts and nuts on each side.

Set the backguard on the rear of the range. Bolt the

backguard to the end panel flanges.

FIGURE 1

CONNECTING THE RANGE

Electric Supply

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code,

ANSI/NFPA 70.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1.

ELECTRICAL SUPPLY CONNECTION:

The range requires 120 volts, 60 cycle alternating current

from an outlet capable of supplying 15 amperes.

User may experience occasional circuit tripping if Ground

Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

Electrical Grounding Instructions

This appliance is equipped with a (three-prong)

grounding plug for your protection against shock hazard

and should be plugged directly into a properly grounded

receptacle. Do not cut or remove the grounding prong

from this plug.

DISCONNECT ELE CTRICAL POWER TO

AVOID SHOCK HAZARD.

CLEARANCE DIMENSIONS

All free-standing ranges can be installed with the back

against (0 inches) a vertical combustible wall, and the

sides below the cooking surface against (0 inches)

combustible base cabinets. For complete information in

re

ard to the installation of wall cabinets above the range

and clearances to combustible surfaces see the

installation drawings and/or the model number plate on

the range. For

a range in any combustible cabinetry which is not in

accord with the installation drawings and the clearance

given on the range Model Number Plate.

SAFETY CONSIDERATIONS

do not install

LOCA TING THE RANGE

Do not set range over holes in the floor or other locations

where it may be subject to strong drafts. Any opening in

the wall behind the range and in the floor under the range

should be sealed. Make sure the flow of

cooling/ventilation air is not obstructed below the range.

NOTE:

A range should

kitchen carpeting.

NOT

be installed directly over

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING THE APPLIANCE.

©2005 Maytag Services 16023515 A – 9

Page 28

Installation Instructions (Models CG1100AD*, CPL1110AD*,

YPL1110AD*)

Gas Supply

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition.

In Canada the range must be installed in accordance with

the current CGA Standard CAN/CGA-B149 - Installation

Codes for Gas Burning Appliances and Equipment and/or

local codes.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or

gas fitter when installed within the Commonwealth of

Massachusetts.

A “T” handle type manual gas valve must be installed in

the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a

length of three (3) feet / 36 inches.

GAS SUPPLY CONNECTION: (see figure 4)

A QUALIFIED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the

instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL

GAS SERVICE REGULATOR. INL ET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

POUNDS PER SQUARE INCH (P.S.I.) LIQUEFIED

PETROLEUM (L.P.)/PROPANE GAS SUPPLY LINE

MUST HAVE A L.P. GAS PRESSURE REGULATOR.

INLET PRESSURE TO THIS APPLIANCE SHOULD BE

REDUCED TO A MAXIMUM OF 14 INCHES WATER

COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

PRESSURE REGULATOR AND OTHER GAS

COMPONENTS IN THIS APPLIANCE AND CAN

RESULT IN A GAS LEAK.

a. A GAS CUTOFF VALVE SHOULD BE PUT IN AN

ACCESSIBLE LOCATION IN THE SUPPLY LINE

AHEAD OF THE RANGE, FOR TURNING ON AND

TURNINGOFFGASSUPPLY.Ifrangeistobe

connected to house piping with flexible or semi-rigid

metal connectors for gas appliance, CONNECTOR

NUTS MUST NOT BE CONNECTED DIRECTLY TO

PIPE THREADS. THE CONNECTOR MUST BE

INSTALLED WITH ADAPTORS PROVIDED WITH

THE CONNECTOR.

b. The house piping and/or range connector used to

connect the range to t he main gas supply must be

clean, free of metal shavings, rust, dirt and liquids (oil

or water). Dirt, etc. in the supply lines can work its way

into the range manifold and in turn cause failure of the

gas valves or controls and clog burners and/or pilot

orifices.

CAUTION: DO NOT LIFT OR MOVE RANGE BY

DOOR HANDLES, OR BACKGUARD.

e. Before connecting range, apply pipe thread compound

approved for LPG to all threads.

FIGURE 4

APPLIANCE PRESSURE REGULATOR &

ALTERNATE CONNECTORS

*

THE APPLIANCE PRESSURE REGULATOR

ON YOUR RANGE MAY DIFFER FROM THIS

ILLUSTRATI ON.

f. Connect range to gas supply. Use a backup wrench

when twisting on end of manifold. CAUTION: MAKE

SURE THE CONNECTION DOES NOT SHIFT THE

MANIFOLD PIPE OUT OF POSITION. THIS COULD

CAUSE THE VALVE HANDLES AND KNOBS TO

BIND.

g. Turn on main gas valve at meter, and relight pilots at

other gas appliances.

h. Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the supply

line shut-off valve and the range. Include gas fittings

and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles appearing

around fittings and connections will indicate a leak. If a

leak appears, turn off supply line gas shut-off valve,

tighten connections, turn on the supply line gas shut

off valve, and retest for leaks.

CAUTION: NEVER CHECK FOR LEAKS WITH A

FLAME.

WHEN LEAK CHECK IS COMPLETE, WIPE OFF

ALL RESIDUE.

i. Remove shipping screw from ALL top burners. (See

figure 5). This is to hold the burners in place on the

burner bracket for shipping purposes only.

j. Adjust burner air shutter to the widest opening that will

not cause the flame to lift or blow off the burner when

cold.

REMOVE

SHIPPING

SCREW

c. Turn off all pilots and main gas valve of other gas

appliances.

d. Turn off main gas valve at meter.

A – 10 16023515 ©2005 Maytag Services

FIGURE 5

Page 29

Appendix B

©2005 Maytag Services 16023515 B – 1

Page 30

Use and Care Information, Gas Range

USING THE COOKTOP

IGNITION SYSTEM

The surface burners will feature either

Piezo pilotless

OFF position before supplying gas to the appliance. Be sure

gas supply to appliance is on before lighting burner.

ignition. Be sure all control knobs are in the

HOW TO LIGHT SURFACE BURNER

To prevent damage to the cooktop or pan:

S

Never operate the surface burner without a pan in

place.

S

Never allow a pan to boil dry.

S

Never operate a surface burner on HIGH for

extended periods of time.

CAUTION:

seconds or if the flame should go out during cooking, turn

the burner off. If gas has accumulated and a strong gas

odor is detected, open a window and wait 5 minutes for

the gas odor to disappear before relighting the burner.

If the burner does not light within about 4

matchlit

ignition or

To light surface burner with Piezo ignition:

1. Place a pan on the burner grate.

2. Push in and turn the surface

burner control knob to the LITE

position.

IMPORTANT:

surface burner at a time.

3. Immediately, rotate the TOP

BURNER IGNITOR knob to the

right (clockwise) several clicks

until the burner lights. The burner

should light within 6 clicks or one

full rotation of the knob.

4. When the burner lights, adjust the surface burner

control knob between HI and LOW to select the desired

flame size.

Only light one

If the appliance has not been operated for a period of time,

the surface burner may be difficult tolight due to air in the gas

line.

To bleed off air from the line:

1. Hold a lighted match next to the burner.

2. Turn the surface burner control knob to the LITE position.

3. When the burner lights, turn the knob back to the OFF

position.

4. Proceed as directed below.

To light surface burner with matchlit ignition:

1. Place a pan on the burner grate.

2. Hold a lighted match next to the desired surface burner

head.

CAUTION:

to escape before lighting the match.

3. Push in and turn the surface

burner control knob to the LITE

position.

4. When the burner lights, adjust

the knob between HI and LOW to

select the desired flame size.

Do not turn the control knob on and allow gas

5. After cooking, turn the surface burner control knob to the

OFF position.

To operate burner if the Piezo ignitor is not functional:

1. Be sure all controls are in the OFF position.

2. Hold a lighted match to the desired surface burner head.

CAUTION:

to escape before lighting the match.

3. Push in and turn the surface burner control knob to the

LITE position.

4. When the burner lights, adjust the knob between HI and

LOW to select the desired flame size.

5. After cooking, turn the knob to the OFF position.

Do not turn the control knob on and allow gas

SHUTDOWN INSTRUCTIONS

When the recreational vehicle is not in use or while traveling,

turn all knobs to the OFF position and turn off the main gas

supply.

5. After cooking, turn the surface burner control knob to the

OFF position.

B – 2 16023515 ©2005 Maytag Services

Page 31

Use and Care Information, Gas Range

USING THE COOKTOP

SELECTING FLAME SIZE

Use a HIGH flame setting to quickly bring liquids to a boil or

to begin a cooking operation. Then reduce to a lower setting

to continue cooking.

using a HIGH flame setting.

Flame adjusted for HIGH setting.

An intermediate flame size is used to continue a cooking

operation.

flame setting is used than needed to maintain a gentle

boil

whether boiling gently or vigorously.

Use LOW to simmer or keep foods at serving temperatures.

Food will not cook any faster when a higher

. Remember, water boils at the same temperature

Never leave food unattended when

ADJUSTING THE FLAME

Adjust the flame size so it

does not extend beyond

the edge of the cooking

utensil. This is for

personal safety and to

prevent possible damage

to the appliance, pan, or

cabinets above the

appliance. This also improves cooking efficiency.

COOKWARE CONSIDERATIONS

Cookware which extends more than one inch beyond the

grate, rests on two grates, or touches the cooktop will cause

a build up of heat and result in damage to the the burner

grate, burner and cooktop.

CAUTION:

To prevent damage to the cooktop and the burner valves,

do not use canners or oversized cookware. The pan

should not be more than one inch larger than the burner

grate.

Cookware, such as a wok with a support ring, which restricts

air circulation around the burner will cause heat to build up