Page 1

iNSTALLATiON AND SERVICE MUST BE

PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL

iNSPECTOR'S USE. READ AND SAVE THESE

iNSTRUCTiONS FOR FUTURE REFERENCE.

• ALL RANGES

CAN TiP

• INJURYTO PERSONS

COULD RESULT

• iNSTALL ANTI-TIP

DEVICE PACKED WiTH

RANGE

• SEE iNSTALLATiON

INSTRUCTIONS

if the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

m Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

= WHAT TO DO iF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor's phone. Follow

the gas supplier's instructions.

• if you cannot reach your gas

supplier, call the fire department.

= Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Provide proper fuel type

Before proceeding: Your range is factory preset to

operate on natural gas. If L.P. conversion is needed,

contact your local L.P. Gas provider for assistance.

The L.P. conversion kit may be located on the lower rear

back panel of the range. If no L.P. kit is provided, contact

your product dealer to obtain the correct L.P. conversion kit.

for applicable agency

__ Refer to your serial plate

certifications

Important notes to the installer

• Read all instructions contained in these installation

instructions before installing range.

• Remove all packing material from the oven

compartments before connecting the gas and

electrical supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

Important notes to the consumer

• Keep these instructions with your Use & Care Guide

for future reference.

• Be sure your range is installed and grounded properly

by a qualified installer or service technician.

Special instructions for ap__pliancesinstalled in the State of

Massachusetts:

This appliance can only be installed in the State of

Massachusetts by a Massachusetts licensed plumber or

gas fitter. When using a flexible gas connector, it must not

exceed 3 feet (36 inches) in length. A "T" handle type

manual gas valve must be installed in the gas supply line to

this appliance.

IMPORTANT SAFETY INSTRUCTIONS

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code ANSI Z223. l--latest edition when installed in the

United States.

When installed in a manufactured (mobile) home,

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

[formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD (Part 280)] or, when

such standard is not applicable, the Standard for

Manufactured Home Installations,ANSI/NCSBCSA225.1,

or with local codes.

This range has been design certified by CSA International.

As with any appliance using gas and generating heat, there

are certain safety precautions you should follow. You will

find them in the Use & Care Guide, read it carefully.

1

p/n 316903001 (1005)

Page 2

iMPORTANT SAFETY iNSTRUCTiONS

Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA

No .70--latest edition when installed in the United

States. See Grounding Instructions on page 8.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat at

least 90°F above room temperature without

shrinking, warping or discoloring. Do not installthe

range over carpeting unless you place an insulating

pad or sheet of 1/4-inch thick plywood between the

range and carpeting.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may

become hot while the oven is in operation. This range

requires fresh air for proper burner combustion.

• Air curtain or other overhead range hoods, which

operate by blowing a downward air flow on to a range,

shall not be used in conjunction with gas ranges other

than when the hood and range have been designed,

tested and listed by an independent test laboratory for

use in combination with each other.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat control

was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly

turn the knob to the LITE position. Use extreme caution

when lighting burners this way.

Never leave children alone or

unattended in the area where an appliance is in use.

Teach children the proper, safe use of all appliances. Never

leave the oven door open when the range is unattended.

Stepping, leaning or sitting on the doors

or drawers of this range can result in serious injuries

and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• Reset all controls to the "OFF" position after using

a programmable timing operation.

• Unlike some gas ranges, the cooktop is not

removable. Do not attempt to remove the cooktop.

2

Page 3

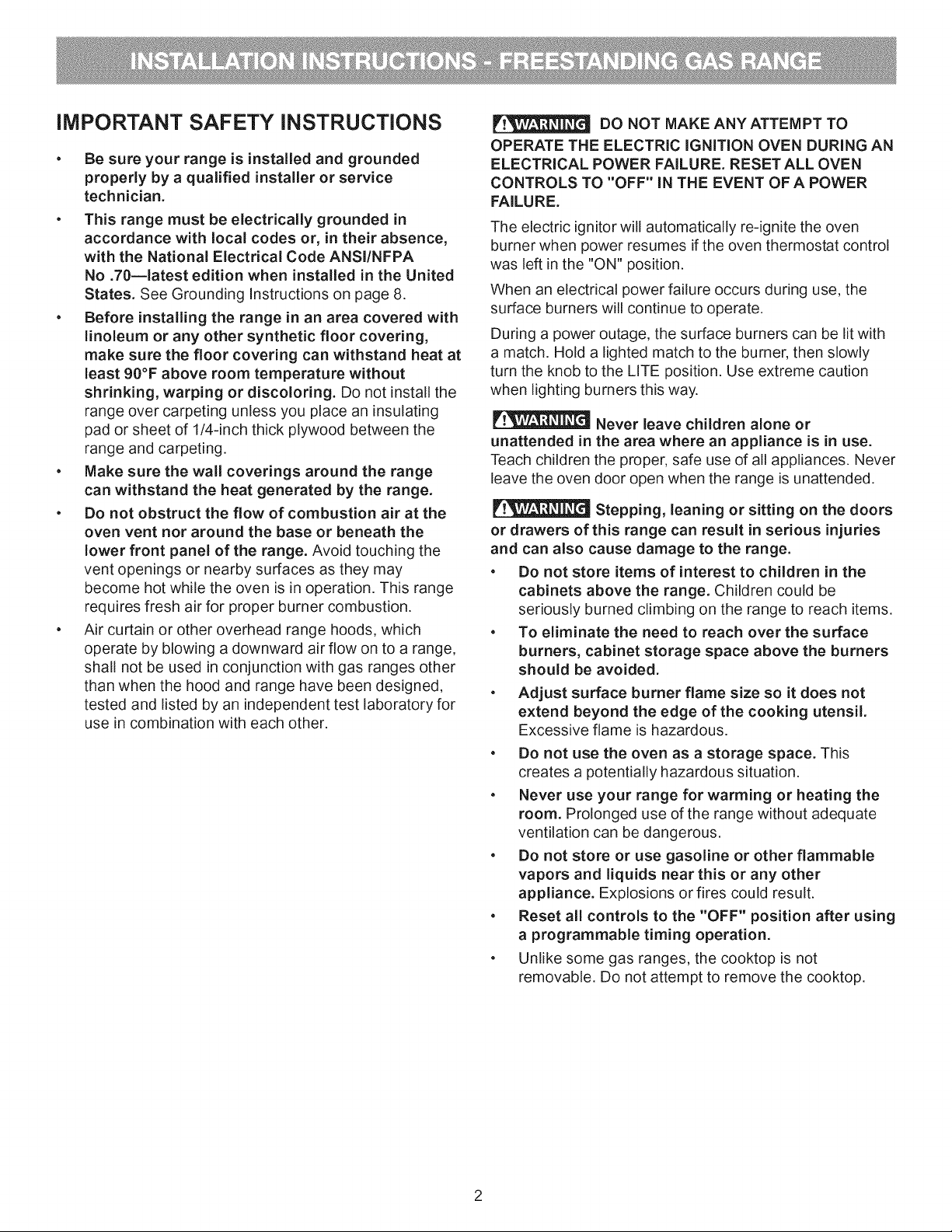

Tools you will need

(Wear safety glasses when using tools):

For leveling legs and Anti-Tip Bracket:

• Adjustable wrench or channel lock pliers (Fig. a)

• 5/16" Nutdriver or flat head screwdriver (Fig. b)

• Electric drill & 1/8" drill bit (3/16" Masonry drill bit if

installing in concrete) (Fig. c)

• Level (Fig. d)

For gas supply connection:

• Adjustable wrench and pipe wrench (Figs. a & e)

For burner flame adjustment:

• Phillips head and small flat-blade screwdrivers (Figs. f

&g)

Materials you will need:

• Pipe joint sealant that resists action of LP/Propane

gas (Fig. h)

• Gas line manual shut-off valve (Fig. i)

• A new flexible metal appliance conduit (1/2" NPT x

3/4" or 1/2" I.D.) must be design certified by CSA

International. Because solid pipe restricts moving the

range, we recommend using a new flexible conduit (4

to 5 foot length) for each new installation and

additional reinstallations. (Fig. j)

• Use new flare union adapters (1/2" NPT x 3/4" or 1/2"

I.D.) (Fig. k)

Materials supplied with appliance:

• Anti-Tip Template (Fig. I)

• Anti-Tip bracket; includes 2 mounting screws (Fig. m)

Tools

Materials

Fig. a

Fig. c

Fig. h

Fig. i

Fig. e

Fig. f

Fig. g

Fig. d

Fig. k

Fig. j

Materials supplied with appliance

Fig. I Fig. m

3

Page 4

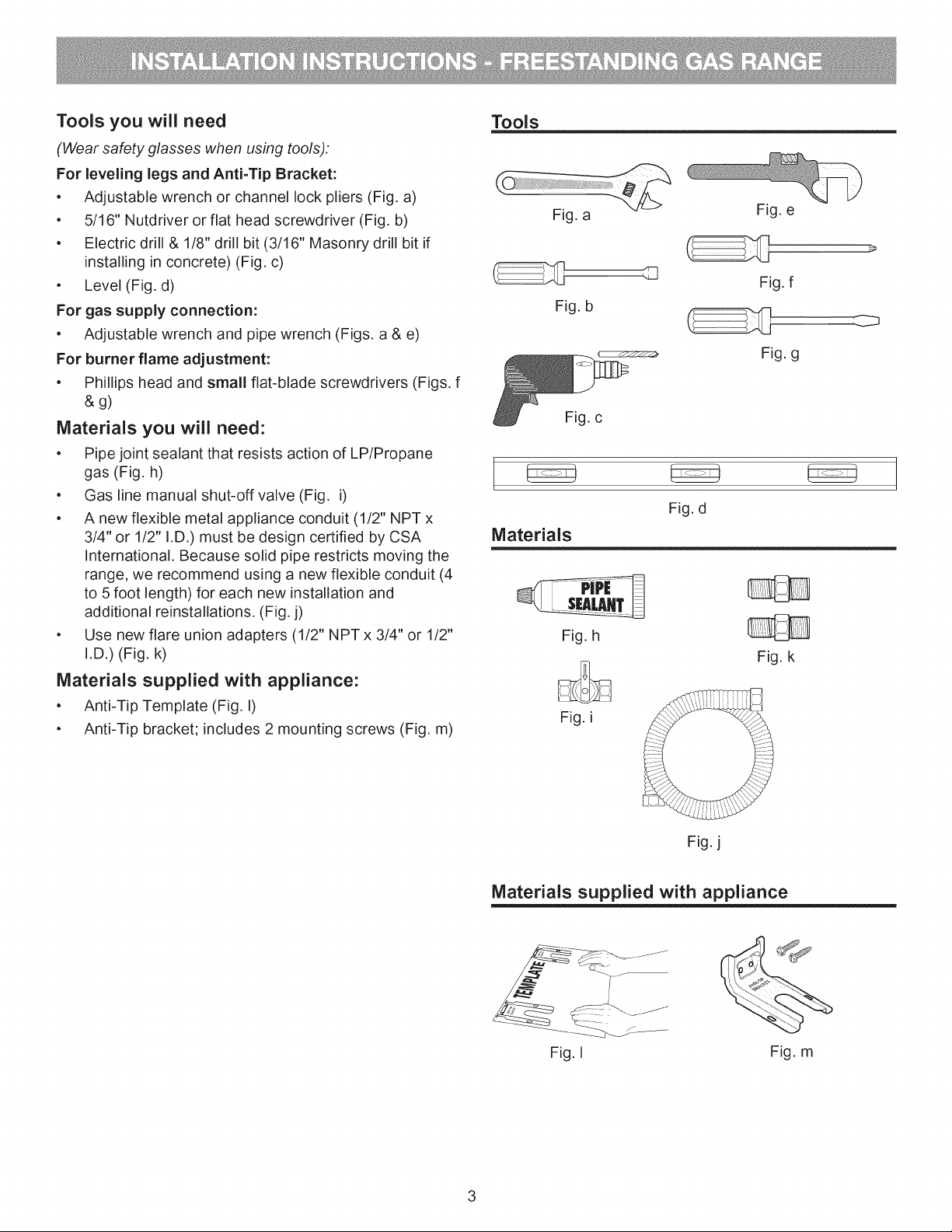

Installation with cabinets

Check location where the range will

be installed for proper electric and

gas supply, and stability of the floor.

The dimensions shown here must

be used and are minimal unless

otherwise stated. These

measurements do not allow for any

clearance below the cooking top or

at the rear of the range.

Contact surface must be solid and

level.

Things to remember:

• Do not seal the range to side

cabinets.

• Do not pinch the power supply

cord between the range and

rear wall.

If cabinet depth is greater than Std.

25", the oven front frame must |

extend beyond cabinet front by

1/2" minimum (See Fig. 1).

All openings in the wall or floor

where the range is to be

installed must be sealed.

Installation beside wall

If installing beside a wall, the

minimum distance to combustible

wall on either side of range above

36" height should be according to

the BTU of the largest burner (See

Fig 2).

36"

18" I 13"_ Min. height from I

Min. to cabinets on

either side of range

Recommended area for thru

the floor connection of gas

pipe stub and shut-off valve.

_Ma×. cooktop to cabinets

1'| ...............

30"

--q-___ _

30- /

I

"15"

* Models without self-clean feature

may have an additional 7 inches

clearance from the floor.

Fig. 1

25"

Recommended

area for 120V

outlet on rear of

wall and area for

thru the wall

connection of pipe

stub and shut-off

valve.

* 9500 BTU or less 2" h

10,000 - 16,999 BTU 3" |

Fig. 2

4

36+1/8"

(Adjustable)

29-1/4"

_l_max

door

closed

Fig. 3

Page 5

Install anti-tip bracket

IMPORTANT SAFETY WARNING !

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti=

tip bracket and screws packed with the range. Failure

to install the anti=tip bracket will allow the range to tip

over if excessive weight is placed on an open door or

if a child climbs upon it. Serious injury might result

from spilled hot liquids or from the range itself.

if range is ever moved to a different location, the anti=

tip bracket must also be moved and installed with the

range.

instructions are provided for installation in wood or

cement fastened to either the floor or wall. When

installed to the wall, make sure that screws completely

penetrate dry wall and are secured in wood or metal.

When fastening to the floor or wall, be sure that

screws do not penetrate electrical wiring or plumbing.

Anti-tip bracket installation instructions

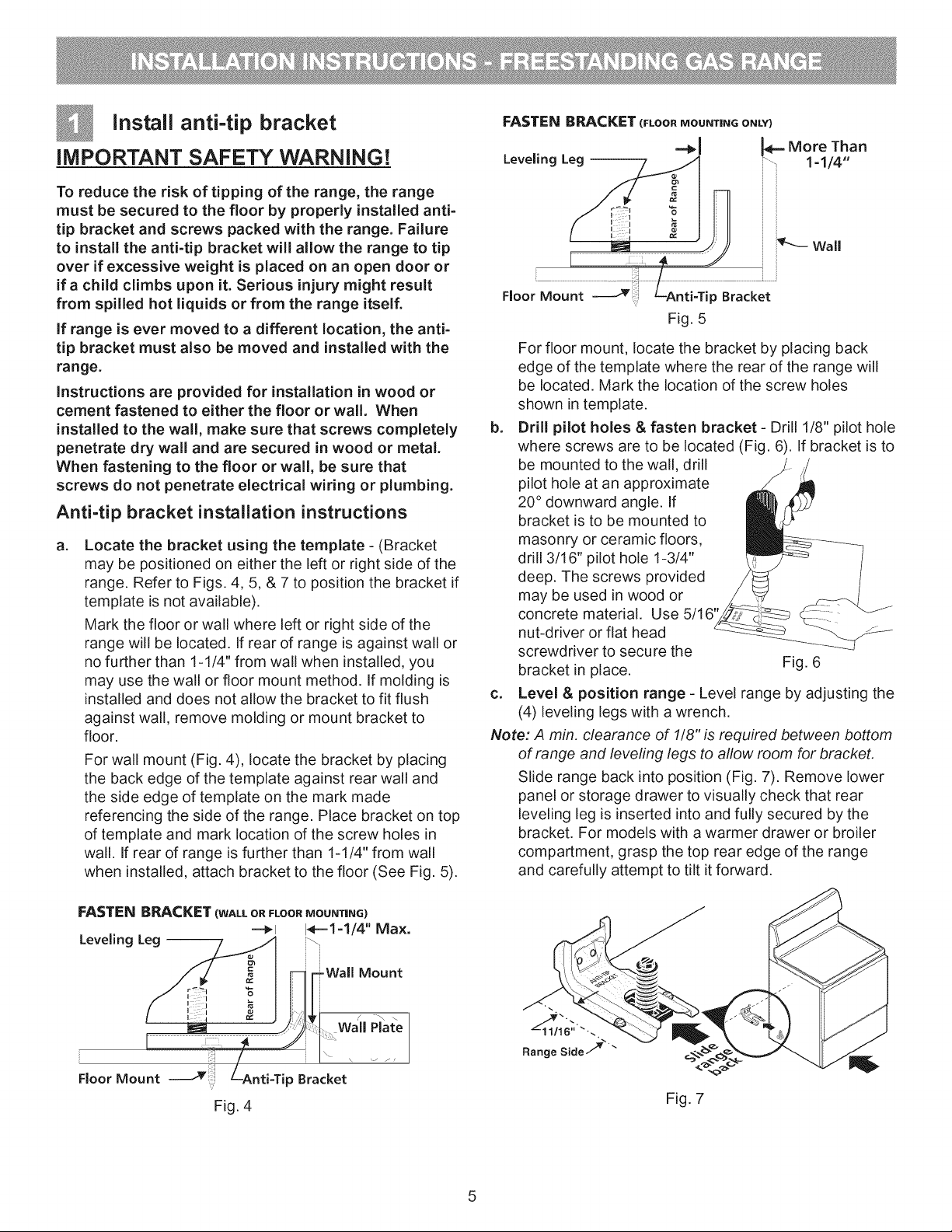

a.

Locate the bracket using the template - (Bracket

may be positioned on either the left or right side of the

range. Refer to Figs. 4, 5, & 7 to position the bracket if

template is not available).

Mark the floor or wall where left or right side of the

range will be located. If rear of range is against wall or

no further than 1-1/4" from wall when installed, you

may use the wall or floor mount method. If molding is

installed and does not allow the bracket to fit flush

against wall, remove molding or mount bracket to

floor.

For wall mount (Fig. 4), locate the bracket by placing

the back edge of the template against rear wall and

the side edge of template on the mark made

referencing the side of the range. Place bracket on top

of template and mark location of the screw holes in

wall. If rear of range is further than 1-1/4" from wall

when installed, attach bracket to the floor (See Fig. 5).

FASTEN BRACKET (FLOORMOUNTINGONLY)

Leveling Leg -- 1=1/4"

Floor Mount

-_1 _-- More Than

p Bracket

Fig. 5

For floor mount, locate the bracket by placing back

edge of the template where the rear of the range will

be located. Mark the location of the screw holes

shown in template.

b. Drill pilot holes & fasten bracket - Drill 1/8" pilot hole

where screws are to be located (Fig. 6). If bracket is to

be mounted to the wall, drill

pilot hole at an approximate

20° downward angle. If

bracket is to be mounted to

masonry or ceramic floors,

drill 3/16" pilot hole 1-3/4"

deep. The screws provided

may be used in wood or

concrete material. Use 5/16'

nut-driver or flat head

screwdriver to secure the

bracket in place. Fig. 6

c. Level & position range - Level range by adjusting the

(4) leveling legs with a wrench.

Note: A min. clearance of 118"is required between bottom

of range and leveling legs to allow room for bracket.

Slide range back into position (Fig. 7). Remove lower

panel or storage drawer to visually check that rear

leveling leg is inserted into and fully secured by the

bracket. For models with a warmer drawer or broiler

compartment, grasp the top rear edge of the range

and carefully attempt to tilt it forward.

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

Leveling Leg -- _,

---_1 14-=-1=1/4''Max.

: i

Fig. 4

Fig. 7

5

Page 6

Provide an adequate gas supply. Connect range to gas supply.

Please note: Operation at elevations above 2000 ft.,

appliance rating shall be reduced at the rate of 4 percent

for each 1000 ft. above sea level.

This appliance is pre-set to operate on 4" natural gas

manifold pressure. A convertible pressure regulator is

connected to the manifold and MUST be connected in

series with the gas supply line. If the LP/Propane

conversion kit has been used, follow instructions provided

with the kit for converting the pressure regulator to LP!

Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water

column pressure. The inlet pressure to the regulator must

be at least 1 inch greater than regulator manifold pressure.

Example: If regulator is set for natural gas 4 inch manifold

pressure, inlet pressure must be at least 5 inches; if

regulator has been converted for LP/Propane gas 10 inch

manifold pressure, inlet pressure must be at least 11

inches.

Leak testing of the appliance shall be conducted according

to the instructions in step 4g.

The gas supply line should be 112"or 314" I.D.

Seal wall openings.

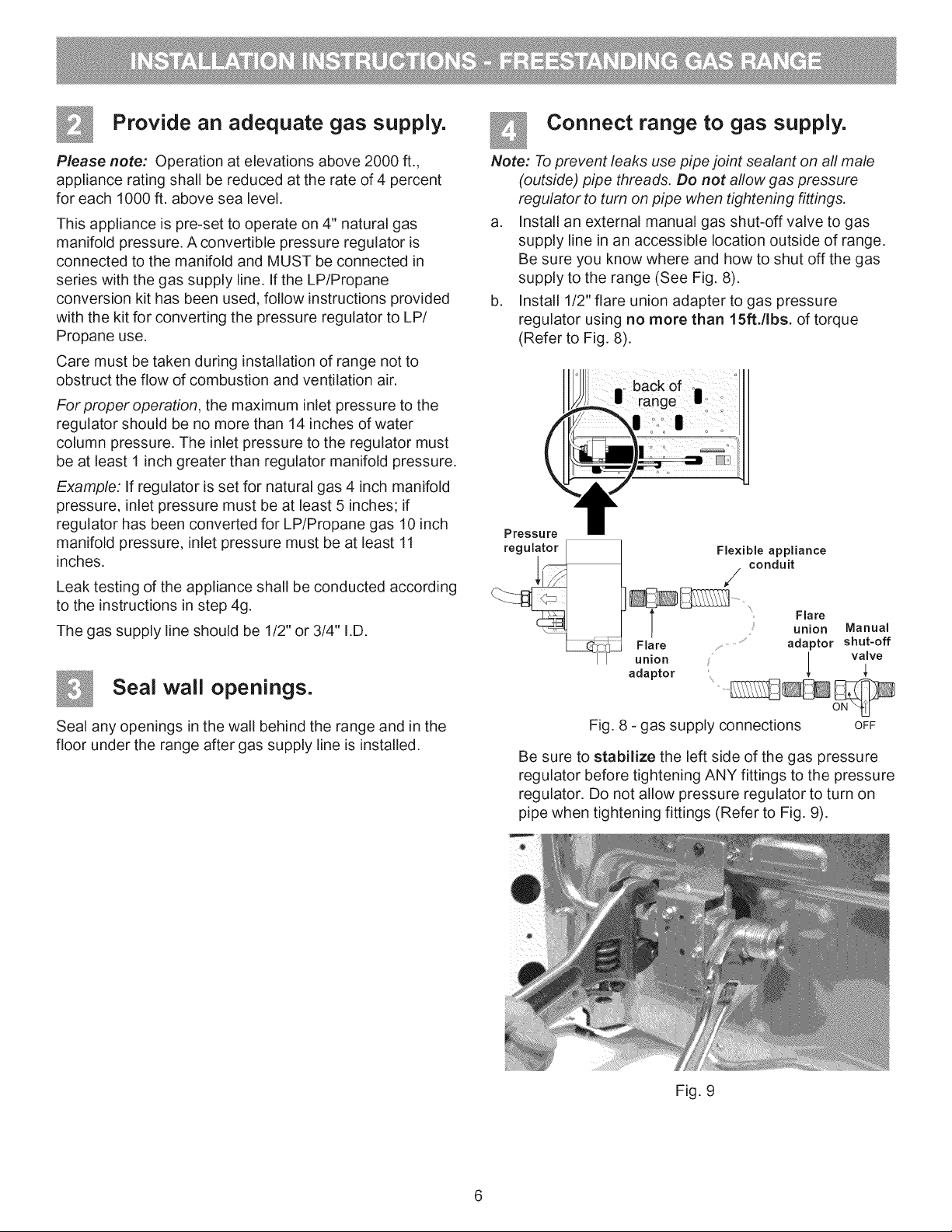

Note: To prevent leaks use pipe joint sealant on all male

(outside) pipe threads. Do not allow gas pressure

regulator to turn on pipe when tightening fittings.

a. Install an external manual gas shut-off valve to gas

supply line in an accessible location outside of range.

Be sure you know where and how to shut off the gas

supply to the range (See Fig. 8).

b. Install 112"flare union adapter to gas pressure

regulator using no more than 15ft./Ibs. of torque

(Refer to Fig. 8).

: back of ,

Pressure

regulator _ Flexible appliance

/ conduit

J _ ] Flare ................ P r shut-off

_]-I-- union / valve

adaptor _

Seal any openings in the wall behind the range and in the

floor under the range after gas supply line is installed.

Fig. 8 - gas supply connections OFF

Be sure to stabilize the left side of the gas pressure

regulator before tightening ANY fittings to the pressure

regulator. Do not allow pressure regulator to turn on

pipe when tightening fittings (Refer to Fig. 9).

Fig. 9

6

Page 7

C.

Tighten the gas supply fitting and/or appliance conduit

to flare union adaptor on the right side of the pressure

regulator (refer to Fig. 10) using NO MORE THAN

15ft./Ibs. of torque. Be sure to stabilize the 1/2" flare

union adapter with an adjustable wrench before

tightening the gas supply fitting and/or appliance

conduit.

Fig. 10

d. Install flare union adapter to external manual shut-off

valve (See Fig. 8).

e. Attach flexible appliance conduit to flare union adaptor

on shut-off valve (See Fig. 8).

f. Make sure the service shut-off valve on pressure

regulator is set to the ON position (See Fig. 11).

Checking manifold gas pressure

I_ Do not use flame to check for gas leaks.

Disconnect the range and its individual shut-off valve from

the gas supply piping system during any pressure testing of

that system at test pressures greater than 14" of water

column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 14" of water column

pressure (approximately 1/2" psig).

If it should be necessary to check the manifold gas

pressure, connect manometer (water gauge) or other

pressure device to the top burner right rear orifice. Using a

rubber hose with inside diameter of approximately 1/4," hold

tubing down tight over orifice. Turn burner valve on.

For an accurate pressure check have at least two (2) other

top burners burning. Be sure the gas supply (inlet) pressure

is at least one inch above specified range manifold

pressure. The gas supply pressure should never be over 14"

water column. When properly adjusted for Natural Gas the

manifold pressure is 4". For LP/Propane Gas the manifold

pressure is 10".

Pressure

regulator

Service shut-off

valve (shown in

ON position)

Fig. 11

g.

Check for gas leaks. Turn the gas supply on to the

range and use a liquid leak detector at all joints and

conduits to check for leaks in the system,

7

Page 8

Read the following electrical

connection details before

connecting electricity to range.

[_ Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric requirements:

A dedicated, properly grounded and polarized branch

circuit protected by a 15 amp. circuit breaker or time delay

fuse, See serial plate for proper voltage,

Extension cord precautions:

Because of potential safety hazards under certain

conditions, we strongly recommend against the use of any

extension cord. However, if you still choose to use an

extension cord, it is absolutely necessary that it be a UL

listed 3-wire grounding type appliance extension cord

and that the current carrying rating of the cord in amperes

be equivalent to or greater than the branch circuit rating.

Such extension cords are obtainable through your local

service organization.

[F_ Please read carefully! For personal

safety, this product must be properly grounded.

Do not, under any circumstances, cut or remove the third

(ground) prong from the power cord (See Fig. 12).

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and obligation

of the customer to have it replaced with a properly

grounded three-prong wall receptacle.

Preferred method

Grounding

type wall

receptacle

Do not, underany __

circumstances, cut,

remove or bypass the

grounding prong.

supply

cord with

3-prong

Power

grounding

plug

]

Check burner cap placement.

It is very important to be sure that all surface burner caps

and burner grates are properly installed and in the correct

locations before operating the appliance. Please note that

the burner heads are secured to the cooktop. The cooktop

is not removeable. Do not attempt to remove or lift the

cooktop.

To prevent flare-ups and avoid creation of

harmful by-products, do not use the cooktop without all

burner caps properly installed to insure proper ignition and

gas flame size.

Always keep the burner caps and burner heads in place

whenever the surface burners are in use. Do not allow

spills, food, cleaning agents or any other material to

enter the gas orifice holder openings.

Check and be sure the size of each burner cap matches

the size of the burner head. Check and be sure that all

round style burner caps are correctly in place on round

burner heads,

Check and be sure that all oval style burner caps are

correctly in place on oval burner heads (if equipped).

Check and be sure that all dual or twin style burner caps

are correctly in place on dual or twin burner heads (if

equipped).

On round style burners, the burner cap lip (See Fig. 13)

should fit snug into the center of burner head and be level.

Refer to Figs. 14 & 15 for correct and incorrect burner cap

placement.

Once in place, you may check the fit by gently sliding the

burner cap from side to side (Fig. 16) to be sure it is

centered and firmly seated. When the burner cap lip makes

contact inside the center of the burner head you will be

able to hear the burner cap click. Please note that the

burner cap should NOT move off the center of the burner

head when sliding from side to side.

BurRer cap

_Burnelr cap lip

Fig. 12

Grounding instructions:

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the

possibility of electric shock hazard from this appliance, The

customer should have the wall receptacle and circuit

checked by a qualified electrician to make sure the

receptacle is properly grounded and polarized,

Fig. 13

Fig. 16

8

Correct burner cap placement

Fig. 14

Incorrect burner cap placement

Fig. 15

Page 9

Check ignition of surface

burners.

Operation of electric igniters should be checked after range

and supply line connectors have been carefully checked for

leaks and range has been connected to electric power.

a. To check for proper ignition, push in and turn a

surface burner knob counterclockwise to the LITE

position. You will hear the igniter sparking.

b. The surface burner should ignite when gas is available

to the burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has a flame. Once the

burner ignites, the control knob should be turned out

of the LITE position.

d. Try each surface control knob separately until all

surface burners have been checked. Each burner

location is equipped with a separate electrode.

other surface burners

Fig. 17

Burner flame size _ 5/8"

Fig. 19

for Dual or Twin burner only

Fig. 18

Check ignition of oven burners.

J

Cooktop

Adjust the LOW setting of surface

burner valves (linear flow).

Test

to verify if LOW setting should be adjusted:

a.

Push in and turn control to LITE until burner ignites.

b.

Push in and quickly turn knob to lowest position.

C.

If burner goes out, reset control to OFF.

d.

Remove the surface burner control knob.

For all burner styles (except Dual or Twin burner):

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside, Flame size

can be increased or decreased with the turn of the

screw. Turn counterclockwise to increase flame size,

Turn clockwise to decrease flame size, (See Figs, 17

& 19).

Adjust flame until you can quickly turn knob from LITE

to lowest position without extinguishing the flame.

Flame should be as small as possible without

extinguishing.

For Dual or Twin burner style adjustment only:

e. The inner portion (Simmer) of the twin burner flame

size can be increased or decreased with the turn of

screw A. Use screw B to adjust the flame size of the

outer portion of the Twin Burner (See Fig. 18). Turn

the screw counterclockwise to increase flame size.

Turn clockwise to decrease flame size. Adjust flame

size until you can quickly turn the knob from LITE to

lowest position without extinguishing the flame.

Note: Air mixture adjustments are not required on surface

burners.

The operation of oven igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. Be sure all packing materials and

literature are removed from oven.

The oven burner is equipped with an electric control

system as well as an electric oven burner igniter. If your

model is equipped with an upper oven burner, it will also

have an electric burner igniter. These control systems

require no adjustment. When the oven is set to operate,

current will flow to the igniter. It will "glow" similar to a light

bulb. When the igniter has reached a temperature sufficient

to ignite gas, the electrically controlled oven valve will open

and flame will appear at the oven burner. There is a time

lapse from 30 to 60 seconds after the thermostat is turned

ON before the flame appears at the oven burner. When the

oven reaches the set temperature, the glowing igniter will

cycle off. The burner flame will turn off in 20 to 30 seconds

after the igniter turns off. To maintain any set oven

temperature, this cycle will continue as long as the oven

control is set to operate.

To check oven burner ignition:

a. Set oven to Bake at 300°F. See User's Manual for

operating instructions.

b. Within 60 seconds the oven burner should ignite.

Check for proper flame, and allow the burner to cycle

once. Reset control to OFF.

c. If your model is equipped with a waist-high broiler, set

oven to Broil. See User's Manual for operating

instructions.

d. Within 60 seconds the broil burner should ignite.

Check for proper flame. Reset control to OFF.

9

Page 10

Adjust air shutter - lower oven. Make sure range is level.

To determine if the oven burner flame is proper, remove the

oven bottom panel and lower burner baffle (Refer to Fig.

20) and set the oven to Bake at 300°F. The approximate

flame length of the lower oven burner should be 1 inch with

a distinct inner blue flame.

To remove the lower oven bottom, remove oven bottom

hold down screws at rear of oven bottom panel. Pull up at

rear, disengage front of oven bottom from oven front frame,

and pull the oven bottom out of the oven. Remove lower

burner baffle to observe oven burner flame.

If the flame is yellow in color, increase the lower oven air

shutter opening size. If the flame is a distinct blue, reduce

the air shutter opening size.

-'J Upper oven burner

(some models)

LJpper oven burr{er air

burner baffle (some models)

-- Lower oven

;_=== Lower oven bottom panel /

- burnerair !rem°vab e)I

shutter

Fig. 20 - oven burner locations

To adjust lower oven air shutter

Oven burner --

loosen lock screw (See Fig. 21),

reposition air shutter, and

tighten lock screw. When

finished adjusting replace

burner baffle and oven bottom

Lock screw-----! _

Air shutter--

Orifice hood --

panel.

Fig. 21 - typical oven

burner air shutter

Adjust air shutter - upper oven.

(some models).

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs or by placing

shims under the corners of the range as needed.

Note: After installation is complete, make sure all controls

are left in the off position.

Care, cleaning and maintenance

Refer to the User's manual for detailed cleaning

instructions. If removing the range is necessary for

cleaning or maintenance, shut off gas supply. Disconnect

the gas and electrical supply. If the gas or electrical supply

is inaccessible, lift the range slightly at the front and pull out

away from the wall. Pull out only as far as necessary to

disconnect the gas and electrical supply. Finish removing

the range for servicing and cleaning. Reinstall in reverse

order making sure to level the range and check gas

connections for leaks. Be sure to read and follow step 1 for

properAnti-tip installation.

Before you call for service

Read the "Before You Call" and operating instruction

sections in your Use & Care Guide. It may save you time

and expense. The list includes common occurrences that

are not the result of defective workmanship or materials in

this appliance.

Refer to the warranty in your Use & Care Guide for our toll-

free service number and address. Please call or write if you

have inquiries about your range product and/or need to

order parts.

Model and serial number location

The identification plate is located on the right-hand surface

of the oven front frame. To access this plate, open the

storage drawer (some models), warmer drawer (some

models) or broiler drawer (some models) (See Fig 22).

When ordering parts for or making inquires about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the identification

plate on your range. Your identification plate also tells you

the rating of the burners, the type of fuel and the pressure

the range was adjusted for when it left the factory.

The approximate flame length of the upper (broil) burner

should be 1 inch having a distinct inner, blue flame. To

determine if the upper broil burner flame is proper, set the

oven to Broil. If the flame is yellow, increase upper oven

air shutter opening size. If the flame is a distinct blue,

reduce the air shutter opening size.

To adjust the upper air shutter loosen lock screw (See Fig.

21), reposition air shutter, and tighten lock screw.

Fig. 22

10

Page 11

L'INSTALLATION ETL'ENTRETIEN DOiVENT ETRE

REALIS#S PAR UN INSTALLATEUR QUALIFI#.

iMPORTANT :CONSERVEZ CES iNSTRUCTiONS EN

PRl_VlSION D'UN USAGE #VENTUEL PAR

L'INSPECTEUR EN #LECTRICITE DE VOTRE LOCALITI e.

VEUILLEZ LIRE ET CONSERVER CES iNSTRUCTiONS

POURVOUS Y REPORTER ULT#RIEUREMENT.

* TUUTES LES CUISINli'=RES

PEUVENT SE RENVERSER

* CELA PEUT CAUSER DES

RLESSURES

* INSTALLEZ LE DISPUSITIF

ANTI-RENVERSEMENT INCLUS

AVEC CETTE CUISINI_:RE

o REPURTEZ-VUUS AUX

INSTRUCTIUNS

D'INSTALLATION

Si les directives

contenues darts ce guide ne sunt pas suivies &

la lettre, un feu uu une explosion pourrait se

pruduire et entrainer des dummages

mat6riels, des blessures, vuire la mort.

POURVOTRE SI CURITE "

-- Vous ne devez ni entreposer, ni utiliser

d'essence ou d'autres vapeurs ou liquides

inflammables _ pruximit6 de cet appareil

ou de tout autre appareil 61ectrom6nager.

-- QUE FAIRE SIVOUS DETECTEZ UNE

ODEURDEGAZ :

, Ne mettez pas d'appareil en marche.

. Ne touchez _ aucun cummutateur

61ectrique; ne vous servez pas du

t616phune de la maisun.

. En utilisant le t6i6phone d'un voisin,

appelez imm6diatement le fournisseur

de gaz. Suivez les directives donn6es

par vutre fuurnisseur de gaz.

. Si vous ne pouvez joindre vutre

fournisseur de gaz, appelez les pompiers.

-- L'installation et I'entretien de cet appareil

doivent 6tre r6aiis6s par un installateur

qualifi6, un technicien de service ou le

fuurnisseur de gaz.

Type de gaz appropri6

Avant de commencer : Votre cuisini_re est pr6r6gl6e en usine

pour fonctionner au gaz naturel. Si une conversion au GPL est

n6cessaire, communiquez avec votre foumisseur de GPL pour

obtenir de I'aide.

II se peut qu'un n6cessaire de conversion au GPL se trouve sur

le panneau du bas, _ I'arri_re de la cuisini_re. Si ce n6cessaire

de conversion n'est pas fourni, communiquez avec votre

marchand pour obtenir le n6cessaire appropri&

Reportez-vous _ la plaque

signal6tique pour connaftre

les certifications reconnues.

Remarques importantes pour rinstallateur

• Lisez toutes les instructions contenues dans ce guide avant

de proc6der _ I'installation de la cuisini_re.

• Retirez tout le mat6riel d'emballage des compartiments du

four avant de connecter la cuisini_re _ I'alimentation en gaz et

I'alimentation en 61ectricit&

• Respectez tousles codes et tous les r_glements.

• Assurez-vous de laisser ces instructions _ I'utilisateur.

Remarque importante pour I'utilisateur

• Conservez ces instructions avec le guide d'utilisation et

d'entretien pour vous y reporter ult6rieurement.

• Assurez-vous que votre cuisini_re est install6e et mise _ la

terre de fagon appropri6e par un installateur qualifi6 ou un

technicien de service.

Instructions particuli_res pour les appareils install6s dans

I'E_tatdu Massachusetts :

Cet appareil ne peut _tre install6 dans I'€:tat du Massachusetts

que par un plombier ou un monteur d'installations au gaz

qualifi6 de cet Etat. Si vous utilisez un raccord de gaz flexible,

celui-ci ne doit pas exc6der 0,91 m (3 pi) de Iongueur. Un

robinet de gaz manuel en <<T >>doit _tre install6 _ la conduite

de gaz qui est branch6e _ cet appareil.

MESURES DE SC:CURITE IMPORTANTES

L'installation de cette cuisini_re doit _tre faite conform6ment

aux codes Iocaux ou, si ce type de code n'existe pas, au code

national sur le gaz combustible ANSI Z223.1 (derni_re 6dition

si I'appareil est install6 aux E_tats-Unis).

Si la cuisini_re est install6e dans une maison pr6fabriqu6e

(maison mobile), I'installation doit _tre conforme _ la norme

Manufactured Home Construction and Safety Standard,

titre 24 CFR, partie 3280 (anciennement d_sign_e comme la

Federal Standard for Mobile Home Construction and Safety,

titre 24, HUD [partie 280]) ou, si cette norme ne s'applique pas,

I'installation doit _tre conforme _ la norme ANSI/NCSBCS

A225.1 de la Standard for Manufactured Home Installations,

ou aux codes Iocaux.

La conception de cette cuisini_re a _t_ approuv_e par CSA

International. Comme dans le cas de tousles appareils

fonctionnant au gaz et produisant de la chaleur, il est

n_cessaire de suivre certaines r_gles de s_curit& Vous les

trouverez dans le Guide d'utilisation et d'entretien. Lisez-les

attentivement.

p/n 316903001 (1005)

Page 12

IMPORTANTES MESURES DE S¢:CURITE

• Verifiez que votre cuisiniere est installee et raise & la terre

de fagon appropriee par un installateur qualifie ou un

technicien de service.

• Cette cuisini_re dolt _tre raise _ la terre conformement

aux codes Iocaux ou, en I'absence de tels codes,

conformement au National Electrical Code ANSI/NFPA n° 70

(derniere _dition Iorsque I'installation est faite aux Etats=

Unis). Reportez-vous aux instructions de raise _ la terre se

trouvant _ la page 8

• Avant d'installer la cuisini_re dans un endroit recouvert

de linoleum ou de tout autre type de rev_tement de sol

synth_tique, assurez=vous que ce rev_tement peut

supporter une chaleur se situant au moins _ 50 °C (g0 °F)

au-dessus de la temperature de la piece sans qu'il ne

r_tr_cisse, ne gauchisse ou ne se d_colore. N'installez pas

la cuisini_re sur de la moquette, _ moins que vous placiez

une plaque isolante en contreplaqu6 d'une 6paisseur de

0,6 cm (1/4 po) entre I'appareil et la moquette

• Assurez-vous que le rev_tement des tours qui se trouve

autour de la cuisiniere peut supporter la chaleur produite

par celle=ci.

• N'obstruez pas le d_bit d'air ni au niveau de I'event du four,

ni autour de sa base. Ne bloquez pas non plus le panneau

avant inferieur de la cuisiniere. E_vitezde toucher aux

ouvertures de 1'6vent ou _ la r6gion situ6e pros des surfaces,

car celles-ci peuvent devenir tr_s chaudes Iorsque le four

fonctionne. Cette cuisini_re n6cessite de I'air frais pour

permettre une bonne combustion des brGleurs.

• Les rideaux d'air ou autres hottes de cuisini_re en hauteur

qui projettent de I'air vers la cuisini_re en contrebas ne

doivent pas _tre utilis6s avec des cuisini_res _ gaz, sauf si la

hotte et la cuisini_re ont 6t6 congues, test6es et r6pertori6es

par un laboratoire d'essais ind6pendant et peuvent

fonctionner conjointement.

N'ESSAYEZ PAS DE FAIRE

FONCTIONNER LE FOUR AALLUMAGE I_LECTRIQUE

DURANT UNE PANNE D'I_LECTRICITI_. REMETTEZ TOUTES

LES COIVlMANDES DU FOURA LA POSITION _ OFF _

(ARRI_T) EN CAS DE PANNE D'I_LECTRICITI_.

L'allumeur 61ectrique rallumera automatiquement le brGleur

du four Iorsque 1'61ectricit_ reviendra, si les commandes du

thermostat du four ont _t_ laiss_es _ <<ON >>(marche).

Lorsqu'une panne d'_lectricit_ survient durant I'utilisation, les

brQleurs de surface continueront de fonctionner.

Durant une panne d'_lectricit_, les brOleurs de surface peuvent

_tre allum_s au moyen d'une allumette. Pour ce fake, tenez une

allumette allum_e pros du brOleur, puis faites tourner lentement

le bouton _ la position <<LITE >>(allumage). Faites preuve d'une

grande prudence Iorsque vous allumez les brOleurs de cette

fagon.

Ne laissez jamais un enfant seul ou

sans surveillance & proximit_ d'un appareil electromenager

en marche. Enseignez aux enfants la mani_re d'utiliser les

appareils _lectrom_nagers de fagon appropri_e et s_curitaire

Ne laissez jamais la porte du four ouverte Iorsque celui-ci est

laiss_ sans surveillance

Grimper, s'appuyer ou s'asseoir sur

les portes ou les tiroirs de la cuisini_re peut causer des

blessures graves aux personnes ainsi que des dommages

la cuisiniere.

• Ne rangez pas d'articles pouvant int_resser les enfants

darts les armoires se situant au=dessus de la cuisiniere.

En voulant atteindre ces articles, les enfants risqueraient de

se brOler gravement

• Pour eliminer le besoin d'avoir _ se pencher au=dessus des

br_leurs de surface, vous devriez _viter de ranger des

articles darts les armoires situ_es au=dessus des br_leurs.

• Reglez la flamme du br_leur de surface pour qu'elle ne

d_passe pas du bord de I'ustensile de cuisson. Les

flammes excessives sont dangereuses

• N'utilisez pas le four comme espace de rangement. Cela

pourrait crier une situation potentiellement dangereuse

• N'utilisezjamais votre cuisiniere pour r_chauffer ou

chauffer une piece. Une utilisation prolong_e de la

cuisini_re sans a_ration adequate peut s'av_rer dangereuse

• N'entreposez pas et n'utilisez pas d'essence ni d'autres

liquides et vapeurs inflammables pres de la cuisiniere ou

de tout autre appareil electromenager. Cela pourrait causer

des explosions ou des incendies

• Remettez toutes les commandes & la position <_OFF >>

(arr_t) apres avoir utilis_ la fonction de programmation de

la minuterie.

• Contrairement _ celle de certaines cuisini_res, la table de

cuisson n'est pas amovible. Ne tentez pas de retirer cette

table de cuisson.

Page 13

Outils n6cessaires

(Portez des lunettes de s6curit6 Iorsque vous utflisez les outils) :

Pour rajustement des pieds de raise _ niveau et rinstallation

du support anti=renversement :

• CI6 _ molette ou pince multiprise ordinaire (fig. a)

• Tournevis _ douille de 5/16 po ou tournevis _ lame plate (fig. b)

• Perceuse 61ectrique munie d'une m_che de 1/8 po

(si I'installation est faite dans le b6ton, utilisez une m_che

magonnerie de 3/16 po) (fig. c)

• Niveau (fig. d)

Pour le raccord d'alimentation en gaz :

• CI6 _ molette et cl6 _ tuyau (fig. a et e)

Pour le r_glage de la flarnrne du brQleur :

• Tournevis Phillips et petit tournevis _ lame plate (fig. f et g)

Materiel requis :

• P_te _ joint pour tuyau r6sistant au gaz propane/GPL (fig. h)

• Robinet d'arr_t manuel sur la conduite d'alimentation en gaz

(fig. i)

• Conduite flexible neuve en m6tal pour appareil

61ectrom6nager (1,3 cm [1/2 po] de NPT x 1,9 cm [3/4 po] ou

1,3 cm [1/2 po] de diam. int.) approuv6e par CSA International

I_tant donn6 que les tuyaux rigides emp_chent la cuisini_re

de bouger, nous recommandons I'utilisation d'une conduite

flexible neuve (mesurant de 121,9 cm _ 152,4 cm [4 pi _ 5 pi])

pour chaque nouvelle installation ou r6installation (fig. j).

• Utilisez des raccords-unions 6vas6s neufs

(1/2 po de NPT x 3/4 po ou 1/2 po de DI) (fig. k).

Materiel foumi avec I'appareil :

• Gabarit pour support anti-renversement (fig. I)

• Support anti-renversement avec deux vis de montage (fig. m)

Outils

Materiel

Fig. a

Fig. b

Fig. c

Fig. h

Fig. i

Fig. e

Fig. f

Fig. g

Fig. d

Fig. k

Fig. j

Materiel foumi avec I'appareil

.................... J_ ..........

Fig. I

Page 14

Installation avec des armoires

V6rifiez II'alimentation 61ectrique, I'alimentation

en gaz et la stabilit6 du plancher _ I'endroit oO

la cuisini_re sera install6e.

Sauf avis contraire, les dimensions indiqu6es

ici sont des dimensions minimales et doivent

_tre utilis6es. Ces mesures ne pr6voient

aucun d6gagement sous la surface ou

I'arri_re de la cuisini_re.

La surface qui supportera I'appareil dolt _tre

solide et de niveau.

N'oubliez pas :

• N'effectuez pas de joint entre la

cuisini_re et les armoires.

• Ne coincez pas le cordon

d'alimentation entre la cuisini_re

et lemur arri_re.

• Lorsque la profondeur des armoires

est sup6rieure _ 63,5 cm (25 po),

le cadre avant du four dolt

3_

Std

d6passer des armoires d'au

moins 1,3 cm (1/2 po) (voir fig. 1).

• Vous devez calfeutrer toutes les

ouvertures dans lemur ou le

plancher oQ sera install6e la

cuisini_re.

le plancher de la conduite d'alimentation en

Installation contre un tour

Si I'appareil est install6 contre un mur,

la distance minimale qui s6pare lemur

combustible d'une cuisini_re dot6e

d'une hauteur de 91,1 cm (36 po) et

plus d6pend de la capacit6 nominale

du plus grand brGleur (voir fig. 2).

Distance miuimale entre

les armoires, de chaque

recommand_ pour le raccordement

az et du robinet d'arr_t.

18 po Max.

cSt_ de macuisini_re.

14113 po

I

"15 po

30 po -____

Hauteur rain. de ma surface

de cuisson aux armoires

Un d_gagement additionnel de 17,8

(7 po) au-dessus du plancher peut 6tre

utilis_ avec les modules qui ne sont pas

munis de la fonetion d'autonettoyage.

30 po

30 po

10,1/2 pe' :

/

2 po

Fig. 1

Emplacement

recommand_ pour la

prise de 120 V sur le

tour artiste et

emplacement de ma

connexion murame du

tuyau et du robinet

d'arr6t manuel

1 po = 2,5 cm

ii

* 9 500 BTU ou moins

10 0OOa 16 999 BTU

.17 0OO BTU ou plus

Fig. 2

5,1 cm (2 po) "_

7,6 cm (3 po) |

12,7 cm (5 po!,,)

Fig. 3

29=1/4 po max.

porte ferm6e

46=5/8 po max.

porte ouverte

1 po = 2,5 cm

T

48-1/2 po

max,

Page 15

Installer le support anti-renversement

AVIS DE SECURITE IMPORTANT!

Afin de r_duire les risques de renversement, la cuisiniere dolt

_tre fix_e au plancher de fa_on appropriee au moyen du

support anti=renversernent et des vis fournis avec la cuisiniere.

Ne pas installer le support anti=renversement peut faire en

sorte que la cuisiniere bascule si un poids excessif est plac_

sur la porte ouverte ou si un enfant grimpe sur I'appareil. Des

blessures graves peuvent _tre caus_es par le renversement

de liquides chauds ou par la cuisiniere elle=m_rne.

Si vous devez changer I'emplacement de la cuisiniere, les

supports anti=renversement doivent _galement _tre installes

au nouvel endroit.

Des instructions sont fournies pour I'installation dans le bois

ou dans leciment, sur le plancher ou sur le tour. Lorsque vous

faites I'installation sur le tour, assurez-vous que les vis sont

bien enfonc_es dans la cloison seche et qu'elles sont fix_es

dans du bois ou du m_tal. Lorsque vous faites I'installation sur

le plancher ou sur le tour, assurez-vous que les vis ne

s'enfoncent pas dans des fils _lectriques ou de latuyauterie.

instructions d'installation du support

anti-renversement

a.

Installation du support & I'aide du gabarit (le support peut

_tre install6 sur le c5t6 gauche ou sur le c5t6 droit de la

cuisini_re. Reportez-vous aux figures 4, 5 et 7 pour

I'installation du support si aucun gabarit n'est fourni).

Faites une marque sur le plancher ou sur le tour _ I'endroit

o_ le c5t6 gauche ou le c5t6 droit de I'appareil se trouvera.

Si I'arri_re de la cuisini_re repose contre le tour ou se

trouve _ moins de 3,2 cm (1-1/4 po) de cehi-ci une fois

install6e, vous pouvez utiliser la m6thode de montage sur

le plancher ou sur le tour. S'il y a une mouhre et que celle-

ci emp_che d'appuyer compl_tement le support contre le

tour, enlevez-la ou montez le support sur le plancher.

Pour effectuer le montage sur le tour (fig. 4), installez le

support en pla;ant le bord artiste du gabarit contre le tour

qui se trouve _ I'arri_re de la cuisini_re et le bord lat6ral du

gabarit sur la marque servant de repute pour I'emplacement

du c5t6 de la cuisini_re. Placez le support sur le dessus du

gabarit et faites des marques sur le tour pour indiquer _ quel

endroit seront ins6r6es les vis. Si I'arri_re de la cuisini_re se

trouve _ plus de 3,2 cm (1-1/4 po) du mur Iorsqu'elle est

install6e, fixez le support au plancher (voir fig. 5).

FiXATiON DU SUPPORT

(SUR LE PLANCHER OU SUR LE MUR}

Pied de raise --

niveau

=---_I

3,2 cm (1-1/4 po)

max.

• Fixation sur

lemur

FiXATiON DUSUPPORT

(SUR LE PLANCHER SEULEMENT)

Pied de raise --

niveau

I

Fixation sur

le plancher

--4

Support anti-renversernent

= lus de

(t-tl4 po)

3,2 em

i

i

i

i'__ Mur

i

Fig. 5

Pour effectuer le montage sur le plancher, installez le

support en plagant le bord arri_re du gabarit _ I'endroit o_

I'arri_re de la cuisini_re se trouvera. Marquez les endroits

o_ les vis seront enfonc6es, tel qu'illustr6 sur le gabarit.

b.

Per_age d'avant-trous et fixation du support - Percez un

avant-trou de 0,3 cm (1/8 po) _ I'endroit o_ les vis seront

ins6r6es (fig. 6). Si le support doit _tre mont_ sur lemur,

percez les avant-trous dans un

angle descendant d'environ

20°. Si le support doit _tre

install_ sur un plancher en

b_ton ou en c_ramique, percez

des avant-trous de 0,5 cm

(3/16 po) et d'une profondeur

de 4,5 cm (1-3/4 po). Les vis

fournies peuvent _tre utilis_es

dans le bois ou dans le b_ton.

Servez-vous d'un tournevis

douille de 5/16 po ou d'un

tournevis _ lame plate pour

Fig. 6

viser le support.

c. Mise &niveau et positionnement de la cuisiniere - Mettez

la cuisini_re de niveau en r_glant les quatre (4) pieds de

raise _ niveau _ I'aide d'une cir.

Remarque : fl est n_cessaire de laisser un espace fibre d'au

moins 0,3 cm (1/8po) entre le bas de la cuisiniere

et les pieds de mise _ niveau pour le support.

Faites glisser la cuisini_re pour la remettre en

place (fig. 7). Retirez le panneau inf_rieur ou le tiroir

de rangement pour v_rifier si le pied de raise

niveau artiste est ins_r_ et solidement fix_ _ I'aide

du support. Dans le cas des modules comportant

un tiroir chauffant ou un tiroir-gril, agrippez le bord

sup_rieur arri_re de la cuisini_re et, avec

precaution, tentez de la pencher vers I'avant.

Fixationsur

le plancher :'

Support anti-renversement

Fig. 4

\

Montant

\ ,1/,

(11//16 pO) /,_'%

C6t_ de /

la euisiniere

Fig. 7

Page 16

Pr6voir une alimentation en gaz

adapt6e

Raccorder la cuisini re la conduite

d'alimentation en gaz

Remarque : Si I'altitude est sup6rieure _ 610 m (2 000 pi), les

caract6ristiques nominales de I'appareil doivent _tre r6duites

de 4 % pour chaque tranche de 305 m (1 000 pi) d'altitude au-

dessus du niveau de lamer.

Cette cuisini_re est pr6r6gl6e pour fonctionner au moyen d'une

pression au collecteur de 10,2 cm (4 po). Un d6tendeur

convertible est raccord6 au collecteur et DOlT _tre branch6 en

s6rie avec la conduite d'alimentation en gaz. Si vous utilisez le

n6cessaire de conversion au gaz propane/GPL, suivez les

instructions fournies dans ce n6cessaire pour faire la conver-

sion du d6tendeur.

Lors de I'installation de la cuisini_re, il est important de

s'assurer que le d6bit d'air n6cessaire _ la combustion et _ la

ventilation n'est pas obstru&

Pour assurer/e bon foncdonnement de/a cuidniOre, la

pression d'admission maximale allant vers le d6tendeur ne

dolt pas d6passer 35,6 cm (14 po) par rapport _ la colonne

d'eau. La pression d'admission allant vers le d6tendeur dolt

_tre sup6rieure d'au moins 2,5 cm (1 po) _ la pression au

collecteur du d6tendeur.

Exemple : Si le d6tendeur est r6g16 _ une pression au

collecteur de 10,2 cm (4 po) pour le gaz naturel, la pression

d'admission dolt _tre d'au moins 12,7 cm (5 po); si le

d6tendeur a 6t6 converti au gaz propane/GPL et est r6g16_ une

pression au collecteur de 25,4 cm (10 po), la pression

d'admission dolt _tre d'au moins 27,9 cm (11 po).

Veuillez proc6der _ la d6tection des fuites en suivant les

instructions de 1'6tape 4g.

La conduite d'alimentation en gaz dolt _tre d'un diam_tre

int6rieur de 1,3 cm (1/2 po) ou de 1,9 cm (3/4 po).

Remarque : Pour Oviter les fuites, utilisez de la pbte b joint pour

tuyau sur tousles raccords de tuyau de type mble

(vers I'extOrieur). Emp#chez le d#tendeur de gaz

de s'ouvrir Iorsque vous effectuez le serrage des

raccords.

a. Installez un robinet d'arret manuel externe sur la conduite

d'alimentation en gaz dans un endroit accessible situ6

I'ext6rieur de la cuisini_re. Assurez-vous de connaftre

I'endroit oQ se trouve le robinet d'arret ainsi que la fagon

d'arreter I'alimentation en gaz de la cuisini_re (voir fig. 8).

b. Installez un adaptateur _ raccord-union de 1,3 cm (1/2 po)

sur le d6tendeur sans setter _ plus de 15 pi/Ib (voir fig. 8).

Arri_re de la

ii'cuisini_re

D_tendeur _ Conduit flexible

po_ _lectrom_nager

Boucher les ouvertures qui se

trouvent clans le tour

Apr_s avoir install6 la conduite d'alimentation en gaz, bouchez

toutes les ouvertures qui se trouvent dans le mur situ6 derriere

la cuisini_re ainsi que ceux se trouvant dans la partie du

plancher situ6e sous la cuisini_re.

ARRET

Fig. 8 - Branchement de I'alimentation

Veillez _ stabiliser le c6t6 gauche du d6tendeur de gaz

avant de serrer TOUSles autres raccords qui lui sont

rattach6s. Empechez le d6tendeur de s'ouvrir Iorsque vous

effectuez le serrage des raccords (voir fig. 9).

Fig. 9

Page 17

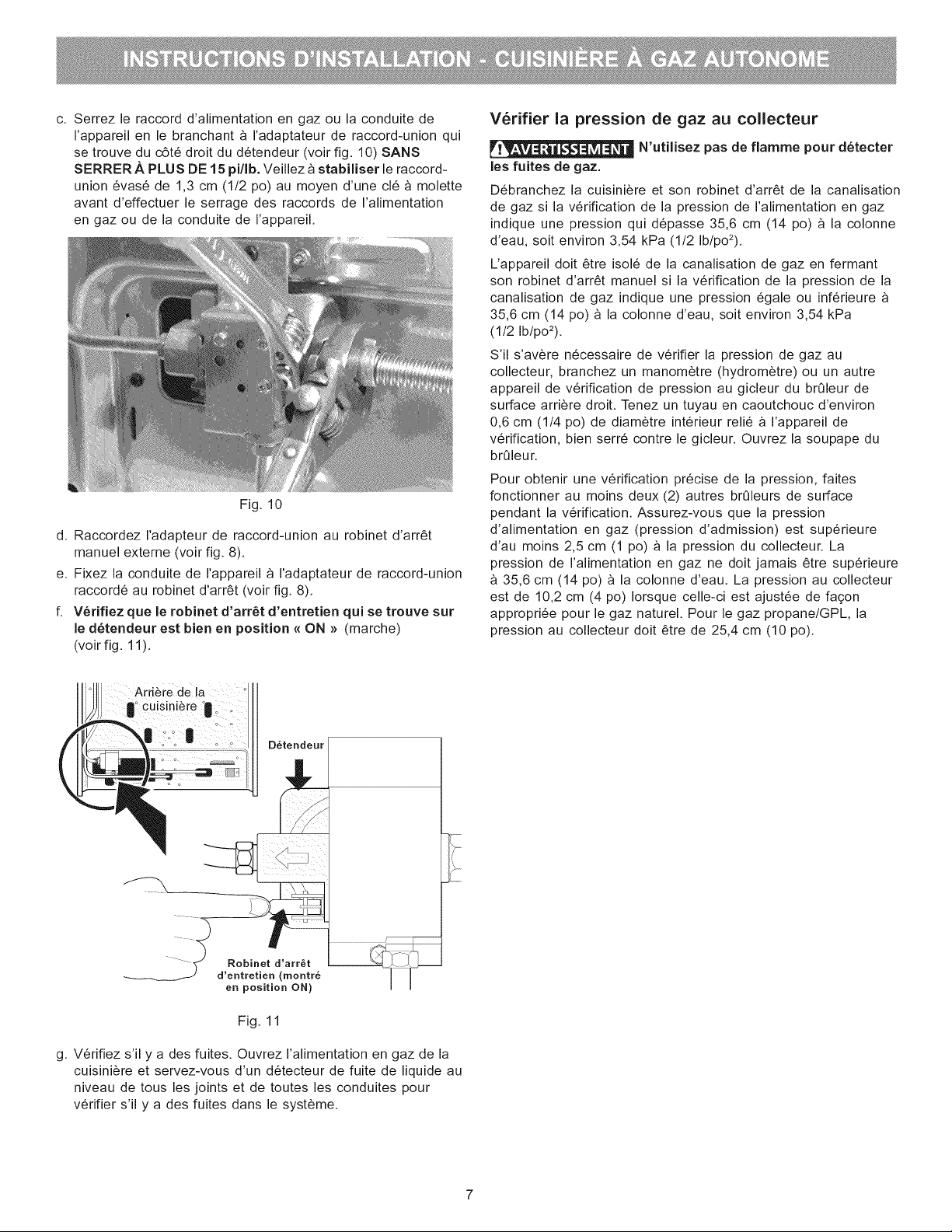

c.Serrezleraccordd'alimentationengazoulaconduitede

I'appareilenlebranchant_I'adaptateurderaccord-unionqui

setrouveduc6t6droitdud6tendeur(voirfig.10)SANS

SERRERAPLUS DE 15 pi/Ib. Veillez _ stabiliser le raccord-

union 6vas6 de 1,3 cm (1/2 po) au moyen d'une cl6 _ molette

avant d'effectuer le serrage des raccords de I'alimentation

en gaz ou de la conduite de I'appareil.

Fig. 10

d. Raccordez I'adapteur de raccord-union au robinet d'arr_t

manuel externe (voir fig. 8).

e. Fixez la conduite de I'appareil _ I'adaptateur de raccord-union

raccord6 au robinet d'arret (voir fig. 8).

f. V_rifiez que le robinet d'arr_t d'entretien qui se trouve sur

le d_tendeur est bJen en position <_ON _ (marche)

(voir fig. 11).

V6rifier la pression de gaz au collecteur

N'utilisez pas de flamme pour d_tecter

les fuites de gaz.

D6branchez la cuisini_re et son robinet d'arr_t de la canalisation

de gaz si la v6rification de la pression de I'alimentation en gaz

indique une pression qui d6passe 35,6 cm (14 po) _ la colonne

d'eau, soit environ 3,54 kPa (1/2 Ib/po2).

L'appareil dolt _tre isol6 de la canalisation de gaz en fermant

son robinet d'arr_t manuel si la v6rification de la pression de la

canalisation de gaz indique une pression 6gale ou inf6rieure

35,6 cm (14 po) _ la colonne d'eau, soit environ 3,54 kPa

(1/2 Ib/po2).

S'il s'av_re n6cessaire de v6rifier la pression de gaz au

collecteur, branchez un manom_tre (hydrom_tre) ou un autre

appareil de v6rification de pression au gicleur du brGleur de

surface arri_re droit. Tenez un tuyau en caoutchouc d'environ

0,6 cm (1/4 po) de diam_tre int6rieur reli6 _ I'appareil de

v6rification, bien serr6 contre le gicleur. Ouvrez la soupape du

brGleur.

Pour obtenir une v6rification pr6cise de la pression, faites

fonctionner au moins deux (2) autres brGleurs de surface

pendant la v6rification. Assurez-vous que la pression

d'alimentation en gaz (pression d'admission) est sup6rieure

d'au moins 2,5 cm (1 po) _ la pression du collecteur. La

pression de I'alimentation en gaz ne doit jamais _tre sup6rieure

35,6 cm (14 po) _ la colonne d'eau. La pression au collecteur

est de 10,2 cm (4 po) Iorsque celle-ci est ajust6e de fa£:on

appropri6e pour le gaz naturel. Pour le gaz propane/GPL, la

pression au collecteur doit _tre de 25,4 cm (10 po).

Arri_re de la

I _cuisiniere °l_,

/ ,IL

2. /

__ d'entretien {montr_

g. V6rifiez s'il y a des fuites. Ouvrez I'alimentation en gaz de la

cuisini_re et servez-vous d'un d6tecteur de fuite de liquide au

niveau de tousles joints et de toutes les conduites pour

v6rifier s'il y a des fuites dans le syst_me.

en position ON)

Fig. 11

Page 18

Life les consignes suivantes sur le

branchement 61ectriq ue

avant de brancher la cuisini re.

Avant d'effectuer une r_paration,

dbbranchez I'alimentation blectrique au niveau du

disjoncteur, du fusible ou du cordon d'alimentation.

Exigences concemant I'_lectricit_ :

Circuit de ddrivation sdpar6 mis _ la terre et polaris6

correctement protdg6 par un disjoncteur de 15 A ou un fusible

temporisd. Reportez=vous _ la plaque signal_tique pour

connaitre la tension appropri_e.

Prdcautions _ prendre concernant rutilisation

d'une rallon ege__:

En raison du danger potentiel que peuvent reprdsenter les

rallonges dans certaines situations, nous ddconseillons

fortement leur utilisation. Toutefois, si vous choisissez tout de

mdme d'utiliser une rallonge, il est absolument ndcessaire que

celle-ci soit une rallonge pour _lectrom_nagers _ trois

broches avec raise _ la terre homologu_e UL et que le courant

nominal de la rallonge soit 6quivalent ou supdrieur au courant

nominal du circuit de ddrivation. Ce type de rallonge est

disponible au service apr_s-vente de votre rdgion.

Veuillez life attentivement

instructions! Pour des raisons de sdcuritd, ce produit doit _tre

correctement mis _ la terre.

Ne coupez et ne retirez jamais, en aucune circonstance, la

troisi_me broche (mise _ la terre) du cordon d'alimentation

(voir fig. 12).

Si la prise murale ne poss_de que deux alvdoles, il vous revient

de la faire remplacer par une prise murale _ trois alvdoles mise

la terre correctement.

Methode recommand_e

---

Prise murale

avec raise a

la terre

__le e jamais couper, _'_

nlever ou mettre hors|

ircuit la broche de mise I

o

y

__ Cordon

ces

rre de cette fiche. )

d'alimentation

muni d'une

fiche _ trois

broches avec

raise a la terre

V rifier le positionnement du

chapeau de breleur

II est tr_s important de vdrifier que tousles chapeaux et toutes

les grilles des br_leurs de surface sont correctement installds

et se trouvent au bon endroit avant d'utiliser I'appareil. Veuillez

noter que les tdtes des br_leurs sont fixdes & la table de

cuisson. La table de cuisson n'est pas amovible. N'essayez

pas de soulever ou d'enlever la table de cuisson.

Pour 6viter les poussdes de flammes

ou la crdation de sous-produits dangereux, n'utilisez pas la

surface de cuisson si les chapeaux des brOleurs ne sont pas

bien installds, ceci afin d'assurer un allumage addquat et une

bonne dimension de la flamme.

Laissez toujours les chapeaux et les tdtes de br_leur en place

Iorsque les br_leurs de surface sont utilisds. Ne laissez pas de

renversements, de nourriture, de produits de nettoyage ni

d'autres produits p_n_trer darts I'ouverture du porte=gicleur.

V_rifiez que chaque brOleur est dot_ du chapeau appropri_.

Vdrifiez que tous les chapeaux de brOleur ronds sont bien

places sur des t_tes de brOleur rondes.

Vdrifiez que tous les chapeaux de brOleur ovales sont bien

places sur des t_tes de brOleur ovales (le cas 6ch_ant). Vdrifiez

que tous les chapeaux de brOleur doubles ou jumeau× sont

bien placds sur des t_tes de brOleur doubles ou jumelles

(le cas 6ch_ant).

Sur les brOleurs ronds, la I_vre du chapeau du brOleur (voir

fig. 13) doit s'adapter au gicleur au centre de la t_te de brOleur

et 6tre de niveau. Reportez-vous aux figures 14 et 15 pour le

positionnement correct et incorrect du chapeau du brOleur.

Vous pouvez v_rifier I'installation en faisant doucement glisser

lat_ralement le chapeau du brOleur (fig. 16) pour vous assurer

qu'il est bien centr_ et bien assis. Lorsque la 16vre du chapeau

du brOleur entre en contact avec le centre de la t_te du brOleur,

vous pourrez entendre un clic. Le chapeau du brOleur NE

DEVRAIT PAS sortir hors du centre de la t_te du brOleur lots du

d_placement lateral.

m

Chapeau de br=31eur

L_vre de chapeau

de br_leur

Fig. 12

Instructions de raise & la terre :

Le cordon d'alimentation de cet appareil est muni d'une fiche

trois broches (mise _ la terre) qui correspond aux prises

murales _ trois alvdoles qui rdduisent les risques de chocs

61ectriques causds par cet appareil. L'utilisateur devrait faire

vdrifier la prise murale et le circuit par un 61ectricien qualifi6

pour s'assurer que la prise est mise _ la terre et polarisde de

fagon appropride.

Fig. 13

Fig. 16

Chapeau de brr_leur bien

positionn_

Fig. 14

Chapeau de breleur real

positionn_

Fig. 15

Page 19

V6rifiez rallumage des br leurs de

surface.

Apr_s vous 6tre assur6 que la cuisini6re et les raccords de la

conduite d'alimentation ne pr6sentent aucune fuite, branchez la

cuisini_re _ I'alimentation en 61ectricit6 et v@ifiez le

fonctionnement des allumeurs 61ectriques.

a. Pour v@ifier I'allumage, poussez et tournez le bouton de I'un

des br_leurs de surface darts le sens contraire des aiguilles

d'une montre et mettez-le _ la position LITE (allumage). Vous

entendrez alors I'allumeur produire des 6tincelles.

b. Le brOleur de surface devrait s'allumer Iorsque le gaz se

rend _ son niveau. Faites sortir I'air qui se trouve dans les

conduites d'alimentation en laissant le bouton _ la position

LITE (allumage) jusqu'_ ce que le brOleur s'allume. Chaque

brOleur devrait s'allumer en I'espace de 4 secondes dans le

cas d'un fonctionnement normal apr_s avoir fait sortir I'air

qu'il y avait dans les conduites d'alimentation.

c. V@ifiez si le brOleur s'est allum6. Une lois que le brOleur

s'est allum6, le bouton de commande devrait 6tre retir6 de la

position <<LITE >>(allumage).

d. Essayez le bouton de chaque brOleur de surface jusqu'_ ce

que ces derniers aient tous 6t6 v@ifi6s. Chaque brOleur est

muni d'une 61ectrode distincte.

R6gler les soupapes des br leurs de

surface la position LOW (bas)

(d bit lin aire).

V_rifier si le r_glage faible <_LOW >>dolt _tre ajuste :

a. Appuyez sur le bouton de commande et tournez-le _ la position

<<LITE >>(allumage) jusqu'_ ce que le brOleur s'allume.

b. Appuyez sur le bouton de commande et tournez-le

rapidement _ la position la plus basse (<<LOW >>).

c. Si le brOleur s'6teint, remettez le bouton _ <<OFF >>(arr@).

d. Retirez le bouton de commande du brOleur de surface.

Pour tousles types de brQleurs (sauf doubles ou jumeaux) :

e. Ins@ez un tournevis _ lame 6troite dans la tige creuse du

robinet et tournez la vis _ I'int@ieur. La hauteur de la flamme

peut 6tre augment6e ou diminu6e par le r6glage de cette vis.

Tournez vers la gauche pour augmenter la hauteur de la

flamme. Tournez-la vers la droite pour la diminuer. (fig. 17 et 19).

Ajustez la flamme jusqu'_ ce que le bouton de commande

puisse 6tre tourn6 rapidement de la position <<LITE >>

(Allumage) _ la position la plus basse (<< LOW >>)sans que

la flamme s'6teigne. La flamme dolt 6tre aussi petite que

possible sans s'6teindre.

Pour le r_glage des brQleurs doubles ou jumeau× seulement :

e. La portion int@ieure (gicleur de mijotage) de la taille de la flamme

du brOleur double peut 6tre augment6e ou r6duite en tournant la

vis A. Utilisez la vis B pour r6gler la taille de la portion ext@ieure de

la flamme du brOleur double (voir fig. 18). Tournez la vis vers la

gauche pour augmenter la dimension de la flamme. Tournez-la

vers la droite pour la diminuer. Ajustez la taille de la flamme

jusqu'_ ce que le bouton de commande puisse @re tourn6

rapidement de la position <<LITE >>(allumage) _ la position la plus

basse sans que la flamme s'6teigne.

Remarque : Le r6glage du m_lange d'air n'est pas requis pour

les brOleurs de surface.

B

J

Autres br_31eurs de surface

Fig. 17

Dimension de la flamme du br=31eur _ 5/8 po

V rifier rallumage des breleurs du four

Apr_s avoir v_rifi_ que la cuisini_re et les raccords de la

conduite d'alimentation ne pr_sentent aucune fuite, branchez

la cuisini_re & I'alimentation en _Jectricit_ et v_rifiez le

fonctionnement des allumeurs _lectriques. V_rifiez que tous

les mat_riaux d'emballage et la documentation ont _t_ retires

du four.

Le brOleur du four est muni d'un syst_me de commande

61ectrique ainsi que d'un allumeur _lectrique. Si votre module

est muni d'un brOleur de four sup@ieur, votre appareil est aussi

6quip6 d'un allumeur 61ectrique. Ces syst_mes de commande

ne n6cessitent aucun r_glage. Lorsque le four est pr_t

fonctionner, le courant se rendra jusqu'_ I'allumeur. Celui-ci

<<brillera >>un peu comme une ampoule. Lorsque I'allumeur a

atteint une temp@ature suffisante pour permettre d'allumer le

gaz, la soupape du four _ commande 61ectrique s'ouvrira et fera

appara'itre une flamme au niveau du brOleur du four. II peut

s'_couler de 30 _ 60 secondes apr_s la mise en marche du

thermostat avant que la flamme apparaisse au niveau du

brOleur du four. Lorsque le four aura atteint la temp@ature

d_sir_e, I'allumeur s'_teindra. La flamme du brOleur s'_teindra

dans une p@iode allant de 20 _ 30 secondes apr_s que

I'allumeur se sera arr_t_. Afin de maintenir la temp@ature

d_sir_e, ce cycle continuera aussi Iongtemps que la

commande du four sera r_gl6e pour fonctionner.

Pour v_rifier I'allumage du br_leur du four :

a. R6glez le four sur Bake (cuisson au four) & une

temp&rature de 149 °C (300 °F). Pour conna'itre les instruc-

tions d'utilisation, reportez-vous au Guide de I'utilisateur.

b. Le brOleur du four devrait s'allumer en I'espace de

60 secondes. V@ifiez la qualit6 de la flamme, puis laissez le

brOleur effectuer un cycle. F!:teignez les commandes.

c. Si votre module est muni d'un brOleur de gril situ6 _ hauteur

de la taille, r_glez votre four _ Broil (gril). Pour conna'itre les

instructions d'utilisation, reportez-vous au Guide de

I'utilisateur.

d. Le brOleur du gril devrait s'allumer en I'espace de

60 secondes. V@ifiez la qualit_ de la flamme. F!:teignez les

commandes.

Breleur double ou jumeau

seulement

Fig. 18

Fig. 19

Page 20

R6gler robturateur d'air du br leur

inf6rieurdu four

Pour d6terminer si la flamme du brGleur du four est correcte,

enlevez la sole du four et le d6flecteur (voir fig. 20), puis r6glez

le four _ Bake (cuisson au four) _ une temperature de 149 °C

(300 °F). La flamme du brGleur inf6rieur du four dolt mesurer

environ 2,5 cm (1 po) (flamme int6rieure distincte de couleur

bleu franc).

Pour enlever la sole du four, retirez les vis de retenue qui se

situent _ I'arri_re de la sole du four. Tirez par I'arri_re vers le

haut, d6sengagez I'avant de la sole du four du cadre avant du

four, puis enlevez la sole du four. Enlevez le d6flecteur du bas

pour voir la flamme du brGleur du four.

Si la flamme est de couleur jaune, agrandissez I'ouverture de

I'obturateur d'air du bas. Si la flamme est de couleur bleu franc,

r6duisez I'ouverture de I'obturateur d'air.

Br_leur sup_rieur du four

Four inf_rieur Obturateur d'air du

D_flecteur "-. br_leur sup_rieur du four

(arnovible)

s -'y terrains modules)

Obturateur .... Four inf_rieur

- . - plaque de solel

;: _'alr ClU

_ brl_l,eur (amovib,e) I

inf_rieur

du four

(eertains rnod_les)

Fig. 20 - Emplacement des brGleurs du four

Pour r6gler I'obturateur d'air du

bas, desserrez la vis de blocage

(fig. 21), ajustez I'obturateur d'air,

puis resserrez la vis de blocage.

Une fois termin6, remettez le

d6flecteur et la plaque de sole du

four en place.

Vis de bloeag

Obturateur d'air-----_ L

T_te du gieleur

i

Fig. 21 - Obturateur

d'air du brGleur du four

R6gler robturateur d'air du br leur

sup6rieur du four (certains modules).

V6rifier que le four est de niveau

Mettez le four _ niveau en plagant un niveau _ I'horizontale sur une

grille du four. V6rifiez en diagonale de I'avant vers I'arri_re, puis mettez

la cuisini_re _ niveau soit en ajustant les pieds de mise _ niveau, soit

en plagant des cales au besoin sous les coins de la cuisini_re.

Remarque : Apr#s avoirtermin6 /'installation, assurez-vous que toutes

les commandes sont b la position _OFF _ (arr6t).

Nettoyage et entretien

Reportez-vous au Guide de I'utilisateur pour obtenir des instructions

de nettoyage d6taill6es. Si le d6placement de la cuisini_re est

n6cessaire pour effectuer le nettoyage et I'entretien, fermez

I'alimentation en gaz. D6branchez I'alimentation en gaz et en

61ectricit6.Si I'alimentation en gaz ou en 61ectricit6est inaccessible,

soulevez 16g_rementla cuisini_re par I'avant et tirez-la vers vous pour

1'61oignerdu mur. Tirez la cuisini_re seulement sur la distance

n6cessaire pour permettre de d6brancher I'alimentation en gaz et en

61ectricit6.Finissez de d6placer la cuisini_re pour effectuer I'entretien

et le nettoyage. R6installez I'appareil en suivant I'ordre inverse tout en

vous assurant de mettre le four _ niveau et de v6rifier si les raccords

d'alimentation en gaz presentent des fuites. Assurez-vous de lire et

de suivre I'_tape 1 pour bien installer le dispositif anti-renversement.

Avant de faire appel au service apr_s-vente

Lisez la section <<Avant de faire appel au service apr_s-vente >>

et les instructions d'utilisation qui se trouvent dans le Guide

d'utilisation et d'entretien. Cela pourrait vous faire _conomiser

temps et argent. Cette liste d_crit des situations courantes qui

ne sont caus_es ni par un d_faut de fabrication ni par un

mat_riau d_fectueux.

Consultez la page de garantie de votre Guide d'utilisation et

d'entretien pour connaftre notre num_ro sans frais et notre

adresse. Veuillez nous appeler ou nous _crire si vous avez des

questions _ propos de votre cuisini_re et/ou si vous d_sirez

commander des pi&ces.

Emplacement du num_ro de module et du

num_ro de s_rie

La plaque signal_tique se trouve sur le c6t_ droit du cadre

avant du four. Pour y acceder, ouvrez le tiroir de rangement (sur

certains modules), le tiroir r_chaud (sur certains modules) ou

le tiroir-gril (sur certains modules) (voir fig. 22).

Lorsque vous commandez des pi_ces ou que vous d_sirez

obtenir des renseignements _ propos de votre cuisini_re,

assurez-vous de toujours inclure le num_ro de s_rie et le

num_ro de module ainsi que la lettre ou le num_ro de lot,

inscrits sur la plaque signal_tique de votre cuisini_re. La

plaque signal_tique donne _galement de I'information sur la

capacit_ des brOleurs, le type de gaz _ utiliser et la pression

laquelle la cuisini_re a _t_ ajust_e _ la sortie de I'usine.

La flamme du brGleur sup6rieur du four dolt mesurer environ

2,5 cm (1 po) (flamme int6rieure distincte de couleur bleu franc).

Pour d6terminer si la flamme du brGleur sup6rieur du four est

correcte, allumez le gril. Si la flamme est jaune, agrandissez

I'ouverture de I'obturateur d'air du haut du four. Si la flamme est

de couleur bleu franc, r6duisez I'ouverture de I'obturateur d'air.

Pour r6gler I'obturateur d'air du haut, desserrez la vis de

blocage (fig. 21), ajustez I'obturateur d'air, puis resserrez la vis

de blocage.

I i

Fig. 22

10

Loading...

Loading...