Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

FOR YOUR SAFETY:

m Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do nottouch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

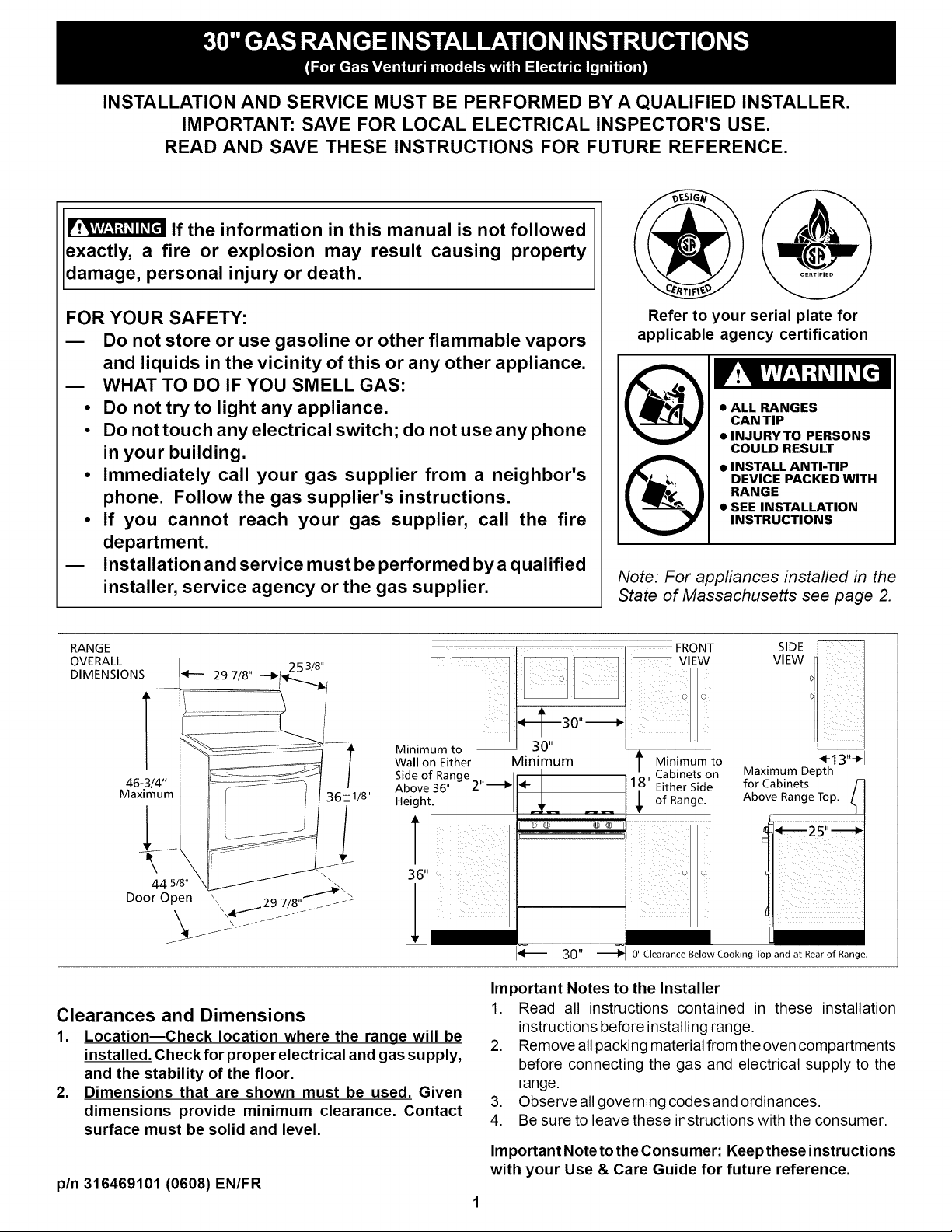

RANGE

OVERALL

DIMENSIONS

Minimum to

46-3/4" l

Maximum 36 + 1/8"

Wall on Either Minimum T Minimum to

Above 36" 2"_ Either Side

Side of Range _ 1_" Cabinets on

Height. of Range.

Refer to your serial plate for

applicable agency certification

• ALL RANGES

CAN TIP

• INJURYTO PERSONS

COULD RESULT

• INSTALL ANTI-TIP

DEVICE PACKED WITH

RANGE

• SEE INSTALLATION

INSTRUCTIONS

Note: For appliances instafled in the

State of Massachusetts see page 2.

SIDE

VIEW

............

A

Maximum Depth

for Cabinets

Above Range Top.

1_-13"-_1

Clearances and Dimensions

1. LocationmCheck location where the range will be

installed. Check for proper electrical and gas supply,

and the stability of the floor.

2. Dimensions that are shown must be used. Given

dimensions provide minimum clearance. Contact

surface must be solid and level.

p/n 316469101 (0608) EN/FR

30"

_1_ 0" Clearance Below Cooking Top and at Rear of Range.

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove allpacking material from the oven compartments

before connecting the gas and electrical supply to the

range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer: Keep these instructions

with your Use & Care Guide for future reference.

Page 2

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes or, in

the absence of local codes, with the National Fuel Gas Code

ANSI Z223.1--1atest edition when installed in the United

States. When installed in Canada, installation must conform

with CAN/CGA-B 149.1 and CAN/CGA-B 149.2.

This range has been design certified by CSA International. As

with any appliance using gas and generating heat, there are

certain safety precautions you should follow. You will find them

in the Owner's Guide, read it carefully.

• Be sureyour range is installed and grounded properly

by a qualified installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No .70m

latest edition when installed in the United States.

When installed in Canada, this range must be electrically

grounded in accordance with CSA Standard C22.1,

Canadian Electrical Code, Part 1. (Read the Grounding

Instructions on pages 5 and 6).

• The installation of appliances designed for manufactured

(mobile) home installation must conform with Manufactured

Home Construction and Safety Standard, title 24CFR,

part 3280 [Formerly the Federal Standard for Mobile Home

Construction and Safety, title 24, HUD (part 280)] orwhen

such standard is not applicable, the Standard for

Manufactured Home Installation 1982 (Manufcatured Home

Sites, Communities and Set-ups), ANSI Z225.1/NFPA

501A--latest edition, or with local codes when installed in

the United States. When installed inCanada, installation

must conform with CAN/CSA-Z240 MH.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering, make

sure the floor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not install the range over

carpeting unless you place an insulating pad or sheet of

1/4-inch thick plywood between the range and carpeting.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the oven

vent nor around the base or beneath the lower front

panel of the range. Avoid touching thevent openings or

nearby surfaces as they may become hot while the oven

is in operation. This range requires fresh air for proper

burner combustion.

Stepping, leaning or sitting on the doors or

drawers of this range can result in serious injuries and

can also cause damage to the range.

Never leave children alone or unattended

in the area where an appliance is in use. As children grow,

teach them the proper, safe use ofall appliances. Never leave

the oven door open when the range is unattended.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This creates

a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

• Reset all controls to the "off" position after using a

programmable timing operation.

• Air curtain or other overhead range hoods, which

operate by blowing a downward air flow on to a

range, shall not be used in conjunction with gas

ranges other than when the hood and range have

been designed, tested and listed by an

independent test laboratory for use in combination

with each other.

Before Proceeding:

Your range has been preset at the factory for use with Natural

Gas. This appliance may be converted for LP/Propane Gas by

installing the supplied LP Kit located on the backside of the

appliance.

Special instructions for appliances installed in the State of

Massachusetts: This appliance can only be installed in the

State of Massachusetts by a Massachusetts licensed

plumber or gas fitter. When using a flexible gas connector, it

must not exceed 3 feet (36 inches) in length. A "T" handle

type manual gas valve must be installed in the gas supply

line to this appliance.

[;"iV-'la#l=_L_'lDO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING AN

ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes ifthe oven thermostat control

was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During apower outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly turn

the knob to the LITE position. Use extreme caution when

lighting burners this way.

Page 3

Before Starting

Tools You Will Need

For leveling legs and Anti-Tip Bracket:

Adjustable wrench or channel lock pliers

5/16" Nutdriver or Flat Head Screw Driver

Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry Drill Bit

if installing in concrete)

For gas supply connection:

• Pipe wrench

For burner flame adjustment:

• Phillips head and

blade-type screwdrivers

Additional Materials You Will Need

• Gas line shut-off valve _

• Pipe joint sealant that resists action of LP/Propane gas

A new flexible metal appliance conduit (1/2" NPT x 3/4" or 1/

2"1.D.) must be design certified by CSA International. Because

solid pipe restricts moving the range we recommend using

a new flexible conduit (4 to 5 foot length) for each new

installation and additional reinstallations.

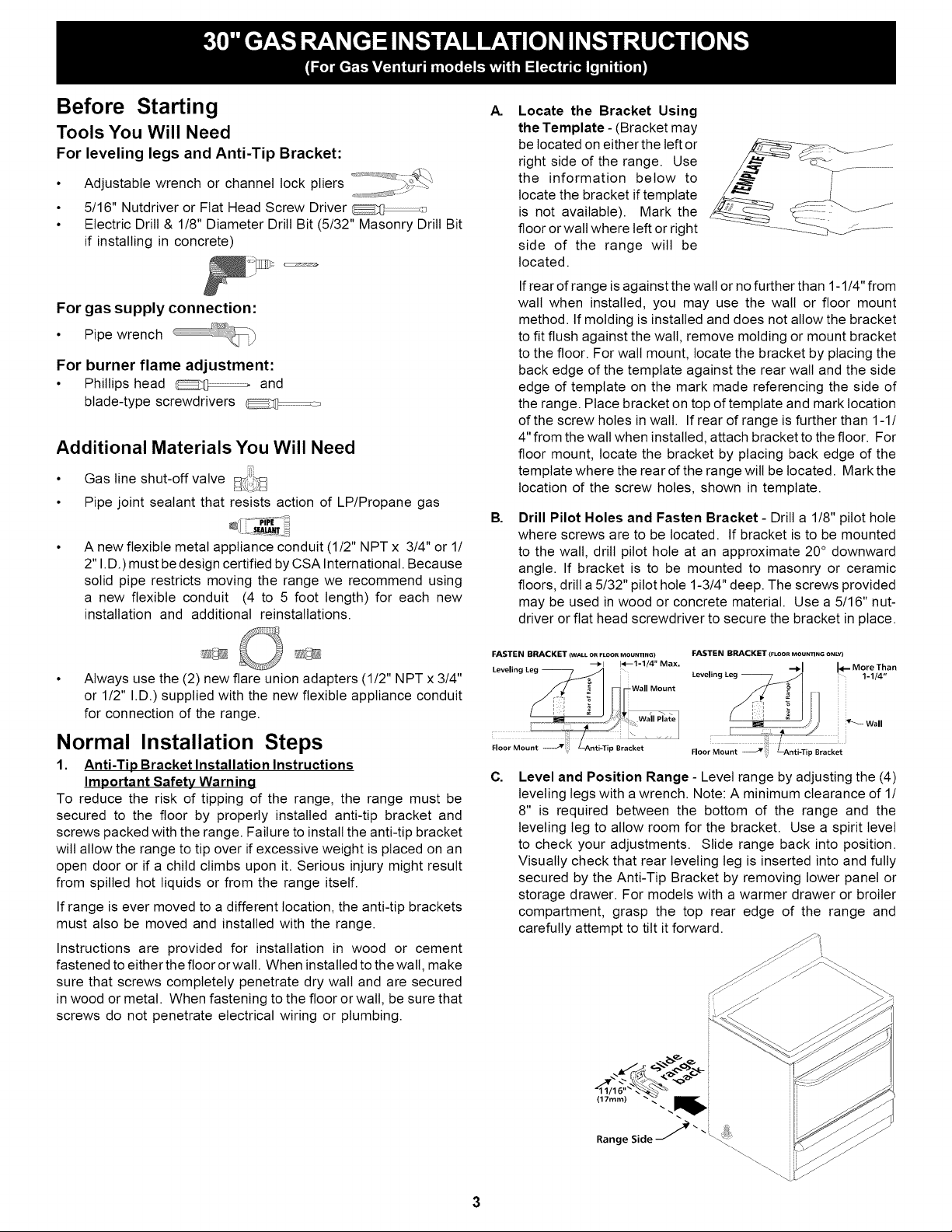

A.

Locate the Bracket Using

the Template - (Bracket may

be located on either the left or

right side of the range. Use

the information below to

locate the bracket if template

is not available). Mark the

floor or walt where left or right

side of the range will be

located.

Ifrear of range is against the walt or no further than 1-1/4" from

walt when installed, you may use the walt or floor mount

method. If molding is installed and does not allow the bracket

to fit flush against the walt, remove molding or mount bracket

to the floor. For walt mount, locate the bracket by placing the

back edge of the template against the rear wall and the side

edge of template on the mark made referencing the side of

the range. Place bracket on top of template and mark location

of the screw holes in walt. If rear of range is further than 1-1/

4" from the wall when installed attach bracket to the floor. For

floor mount, locate the bracket by placing back edge of the

template where the rear of the range wilt be located. Mark the

location of the screw holes, shown in template.

B.

Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot hole

where screws are to be located. If bracket is to be mounted

to the walt, drill pilot hole at an approximate 20 ° downward

angle. If bracket is to be mounted to masonry or ceramic

floors, drill a 5/32" pilot hole 1-3/4" deep. The screws provided

may be used in wood or concrete material. Use a 5/16" nut-

driver or flat head screwdriver to secure the bracket in place.

• Always use the (2) new flare union adapters (1/2" NPT x 3/4"

or 1/2" I.D.) supplied with the new flexible appliance conduit

for connection of the range.

Normal Installation Steps

1. Anti-Tip Bracket Installation Instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range must be

secured to the floor by properly installed anti-tip bracket and

screws packed with the range. Failure to install the anti-tip bracket

will allow the range to tip over ifexcessive weight is placed on an

open door or if a child climbs upon it. Serious injury might result

from spilled hot liquids or from the range itself.

If range is ever moved to a different location, the anti-tip brackets

must also be moved and installed with the range.

Instructions are provided for installation in wood or cement

fastened to either the floor or wall. When installed to the walt, make

sure that screws completely penetrate dry walt and are secured

in wood or metal. When fastening to the floor or walt, be sure that

screws do not penetrate electrical wiring or plumbing.

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

Leveling Leg _ ,_--1-1/4" Max.

Floi: Mii!nt _i_i "- "p cket

C.

Level and Position Range - Level range by adjusting the (4)

FASTEN BRACKET (FLOOR MOUNTING ONLy)

Leveling Leg

Floor Mount

-- 1-1/4"

_1 I_-- More Than

Bracket

leveling legs with awrench. Note: A minimum clearance of 1/

8" is required between the bottom of the range and the

leveling leg to allow room for the bracket. Use a spirit level

to check your adjustments. Slide range back into position.

Visually check that rear leveling leg is inserted into and fully

secured by the Anti-Tip Bracket by removing lower panel or

storage drawer. For models with a warmer drawer or broiler

compartment, grasp the top rear edge of the range and

carefully attempt to tilt it forward.

Wall

Page 4

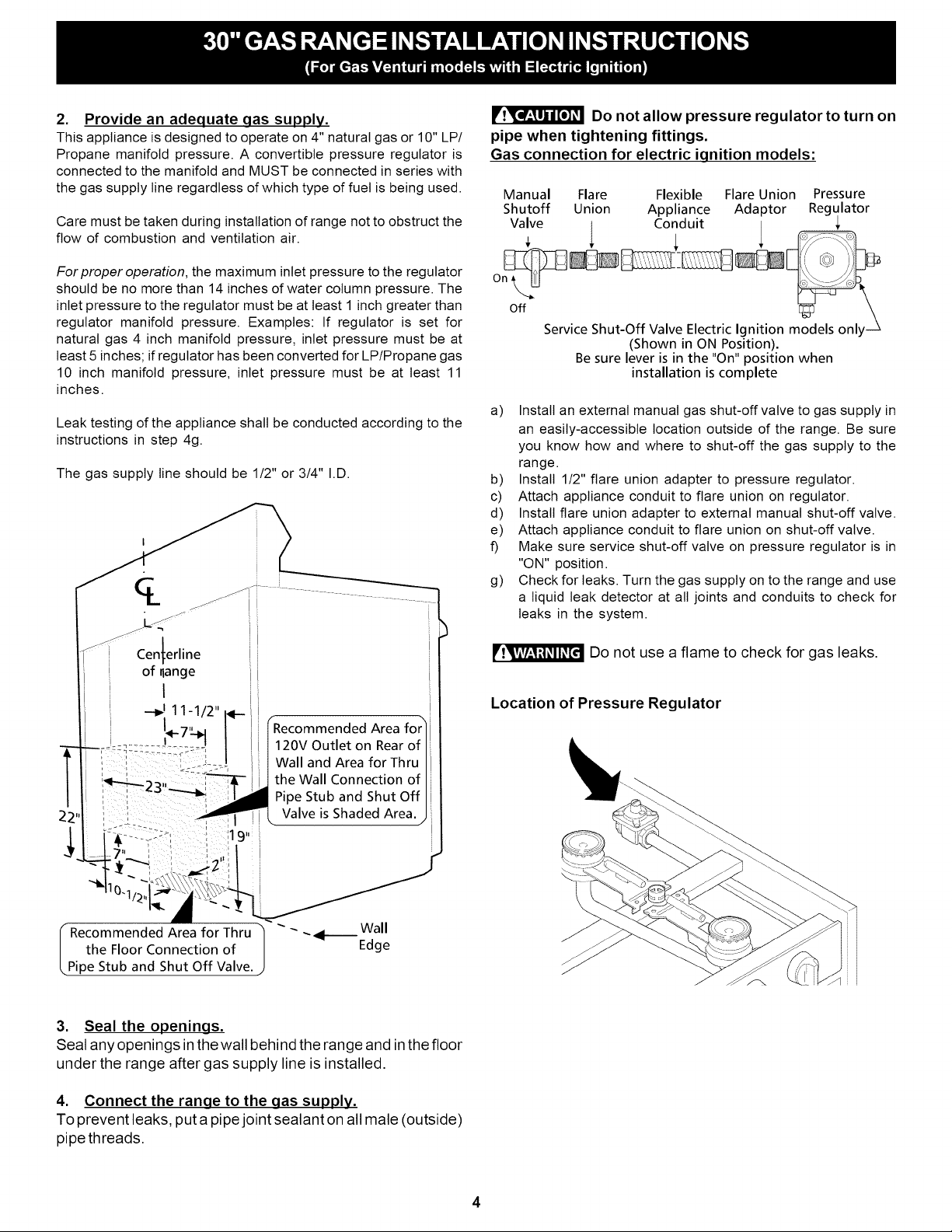

2. Provide an adequate qas supply.

This appliance is designed to operate on 4" natural gas or 10" LP/

Propane manifold pressure. A convertible pressure regulator is

connected to the manifold and MUST be connected in series with

the gas supply line regardless of which type of fuel is being used.

Care must be taken during installation of range not to obstruct the

flow of combustion and ventilation air.

Forproper operation, the maximum inlet pressure to the regulator

should be no more than 14 inches of water column pressure. The

inlet pressure to the regulator must be at least 1 inch greater than

regulator manifold pressure. Examples: If regulator is set for

natural gas 4 inch manifold pressure, inlet pressure must be at

least 5 inches; if regulator has been converted for LP/Propane gas

10 inch manifold pressure, inlet pressure must be at least 11

inches.

Leak testing of the appliance shall be conducted according to the

instructions in step 4g.

The gas supply line should be 1/2" or 3/4" I.D.

Do not allow pressure regulator to turn on

pipe when tightening fittings.

Gas connection for electric iqnition models:

Manual Flare Flexible Flare Union Pressure

Shutoff Union Appliance Adaptor Regulator

Valve _ Conduit !

off Service Shut-Off Valve Electric Ignition models only --x

(Shown in ON Position).

Be sure lever is in the "On" position when

installation is complete

a) Install an external manual gas shut-off valve to gas supply in

an easily-accessible location outside of the range. Be sure

you know how and where to shut-off the gas supply to the

range.

b) Install 1/2" flare union adapter to pressure regulator.

c) Attach appliance conduit to flare union on regulator.

d) Install flare union adapter to external manual shut-off valve.

e) Attach appliance conduit to flare union on shut-off valve.

f) Make sure service shut-off valve on pressure regulator is in

"ON" position.

g) Check for leaks. Turn the gas supply on to the range and use

a liquid leak detector at all joints and conduits to check for

leaks in the system.

of _ange ' i

I

_Recommended Area for_

120V Outlet on Rear of I

Wall and Area for Thru|

the Wall Connection of I

Pipe Stub and Shut Off I

Valve is Shaded Area./I

Area for Thru "_ _ "4-- Wall

the Floor Connection of _ Edge

Pipe Stub and Shut Off Valve.

3. Seal the openings.

Seal any openings inthe wall behind the range and inthe floor

under the range after gas supply line is installed.

4. Connect the ranqe to the gas supply.

To prevent leaks, put a pipe joint sealant on all male (outside)

pipe threads.

Do not use a flame to check for gas leaks.

Location of Pressure Regulator

Page 5

Checking Manifold Gas Pressure

Disconnect the range and its individual shut-off valve from the gas

supply piping system during any pressure testing of that system

at test pressures greater than 14" of water column pressure

(approximately 1/2" psig).

If it should be necessary to check the manifold gas pressure,

connect manometer (water gauge) or other pressure device to the

top burner right rear orifice. Using a rubber hose with inside

diameter of approximately 1/4," hold tubing down tight over orifice.

Turn burner valve on.

For an accurate pressure check have at least two (2) other top

burners burning. Be sure the gas supply (inlet) pressure is at least

one inch above specified range manifold pressure. The gas

supply pressure should never be over 14" water column. When

properly adjusted for Natural Gas the manifold pressure is 4." (For

LP/Propane Gas the manifold pressure is 10.")

6. Operation of Surface Burners

Operation of electric igniters should be checked after range and

supply line connectors have been carefully checked for leaks and

range has been connected to electric power.

Check Surface Burners

To check for proper lighting, push in and turn a surface burner knob

to the LITE position. Each burner should light within four (4)

seconds in normal operation. Once the burner lights, the knob

should be rotated out of the LITE position. Try each knob separately

until all burner valves have been checked.

Air Shutter _

5. Read electrical connection details below and connect

electricity to range.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric Requirements: A dedicated, properly grounded and

polarized branch circuit protected by a 15 amp. circuit breaker or

time delay fuse. See serial plate for proper voltage.

Extension Cord Precautions:

Because of potential safety hazards under certain conditions, we

strongly recommend against the use of any extension cord.

However, if you still elect to use an extension cord, it is absolutely

necessary that it be a UL listed 3-wire grounding type appliance

extension cord and that the current carrying rating of the cord in

amperes be equivalent to or greater than the branch circuit rating.

Such extension cords are obtainable through your local service

organization.

PLEASE READ CAREFULLY! For personal

safety, this product must be properly grounded.

Grounding Instructions

The power cord of this appliance is equipped with a 3-prong

(grounding) plug which mates with a standard 3-prong grounding

walt receptacle to minimize the possibility of electric shock hazard

from this appliance. The customer should have the walt receptacle

and circuit checked by a qualified electrician to make sure the

receptacle is properly grounded and polarized.

Where a standard two-prong walt receptacle is encountered, it is

the personal responsibility and obligation of the customer to have

it replaced with a properly grounded three-prong wall receptacle.

DO NOT, UNDERANY CIRCUMSTANCES, CUT OR REMOVE THE

THIRD (GROUND) PRONG FROM THE POWERCORD.

Preferred Method

_1 Any Circumstances, I

_F"I or Bypass the J

Grounding Prong.,,,/

._ Power Supply

/fDo Not, Under "_

ICut, Remove, /

IlI Cord with

_w 3-Prong

|| Grounding

Plug

Grounding

Type

Wall

Receptacle

13;

adjustment

7. Air adjustment

The air shutter (adjustment) for each of the four top burners is

located at the open end of the venturi tube and sets on the hood

of the valve.

Should the air shutter need adjusting, rotate the air shutter to allow

more or less air into the burner tubes as needed.

If the air is properly adjusted, the flame will be steady, relatively

quiet, and have approximately 1/2" sharp blue cone. (Usually

about the center of air shutter's ajustment.)

Ifthe flame is yellow in color, increase air shutter opening size. If

the flame is a distinct blue, but lifting away from the burner, reduce

the air shutter opening size.

8. Oven Burner Adjustments

Operation of electric igniters should be checked after range and

supply line connectors have been carefully checked for leaks and

range has been connected to electric power.

The oven burner is equipped with an electric control system as

well as an electric oven burner igniter.

These control systems require no adjustment. When the oven is

set to operate, current wilt flow to the igniter. It will "glow" similar

to a light bulb. When the igniter has reached a temperature

sufficient to ignite gas, the electrically controlled oven valve will

open and flame wilt appear at the oven burner. There is a time

lapse from 30 to 60 seconds after the thermostat is turned ON

before the flame appears at the oven burner. When the oven

reaches the dial setting, the glowing igniter wilt go off. The burner

flame wilt go "out" in 20 to 30 seconds after the igniter goes "OFF."

To maintain any given oven temperature, this cycle will continue

as tong as the dial (or display) is set to operate.

After removing all packing materials and literature from the oven:

a) Set oven to BAKE at 300°F. See Owner's Guide for operating

instructions.

b) Within 60 seconds the oven burner should ignite. Check for

proper flame, and allow the burner to cycle once. Reset

controls to off.

c) Within 60 seconds the broil burner should ignite. Check for

proper flame. Reset controls to off.

Page 6

1" Flame

Oven

Burner

Tube

Burner

Baffle

Model andSerial Number Location

The serial plate is located under the lift-up cooktop. When

ordering parts for or making inquires about your range, always

be sure to include the model and serial numbers and a lot

number or letter from the serial plate on your range. Your serial

plate also tells you the rating of the burners, the type of fuel

and the pressure the range was adjusted for when it left the

factory.

BeforeYou Call for Service

Check to make sure the house fuses or circuit breakers for

your range are not blown or open. Refer to the Avoid Service

Checklist and operating instructions in your Owner's Guide. It

may save you time and expense. The list includes common

occurrences that are not the result of defective workmanship

or materials in this appliance.

Refer to the warranty in your Owner's Guide for our

toll-free service number and address. Please call or

write ifyou have inquiries about your range product and/

or need to order parts.

Orifice

Hood

I I

I I I I

9. AirShutter-Oven Burner

The approximate flame length of the oven burner is 1 inch

(distinct inner, blue flame).

To determine if the oven burner flame is proper, remove the

oven bottom and burner baffle and set the oven to bake at

300°F.

To remove the oven bottom, remove oven hold down screws at

rear of oven bottom. Pull up at rear, disengage front of oven

bottom from oven front frame, and pull the oven bottom out of

the oven. Remove burner baffle so that the burner flame can be

observe.

Ifthe flame isyellow in color, increase air shutter opening size.

If the flame is a distinct blue, reduce the air shutter opening

size.

To adjust loosen lock screw, reposition air shutter, and tighten

lock screw. Replace oven bottom.

10. Make Sure Range is Level.

Level the range by placing a level horizontally on an oven rack.

Check diagonally from front to back, then level the range by

either adjusting the leveling legs or by placing shims under the

corners of the range as needed.

Care, Cleaning and Maintenance

Refer to the Owner's Guide for operating and cleaning

instructions.

Ifremoving the range is necessary for cleaning or maintenance,

shut offgas supply. Disconnect the gas and electrical supply.

Ifthe gas or electrical supply is inaccessible, lift the appliance

slightly at the front and pull out away from the wall. Pull only

as far as necessary to disconnect the gas and electrical

supply. Finish removing the unit for servicing and cleaning.

Reinstall in reverse order making sure to level the range and

check gas connections for leaks. See Anti-Tip Instructions for

properanchoring instructions.

11. After installation is complete, make sure all controls are

left in the OFF position.

Page 7

L'INSTALLATION ET L'ENTRETIEN DOIVENT I_TRE RI_ALISI_S PAR UN INSTALLATEUR QUALIFII_.

IMPORTANT: CONSERVEZ CES INSTRUCTIONS EN PRI_VISION D'UN USAGE I_VENTUEL

PAR L'INSPECTEUR EN I_LECTRICITI_ DEVOTRE LOCALITI_.

VEUILLEZ LIRE ET CONSERVER CES INSTRUCTIONS POURVOUSY REPORTER ULTI_RIEUREMENT.

_!_r:\,A_:_eF,l,l_,a_inn Si les directives contenues dans ce guide ne

sont pas suivies & la lettre, un feu ou une explosion pourrait se

produire et entrainer des dommages mat6riels, des blessures ou

m_me la mort.

POUR VOTRE SI_CURITI_ :

-- Vous ne devez ni entreposer, ni utiliser d'essence ou d'autres

vapeurs ou liquides inflammables & proximit6 de cet appareil

Reportez-vous a la plaque

signaletique pour connaitre les

certifications reconnues.

ou de tout autre appareil 61ectrom6nager.

-- QUE FAIRE SI VOUS DI_TECTEZ UNE ODEUR DE GAZ :

• Ne mettez pas d'appareil en marche.

• Ne touchez & aucun commutateur 61ectrique; ne vous servez

pas du t616phone dans le b_timent.

• En utilisant le t616phone d'un voisin, appelez imm6diatement

le fournisseur de gaz. Suivez les directives donn6es par

votre fournisseur de gaz.

• Si vous ne pouvez joindre votre fournisseur de gaz, appelez

les pompiers.

PEUVENT SE RENVERSER

• CELA PEUT CAUSER

] • TOUTES LES CUISINII:RES

DES BLESSURES

• INSTALLEZ LE DISPOSITIF

INCLUS AVEC CETTE

CUISINIERE

• REPORTEZ-VOUS

AUX INSTRUCTIONS

1 ANTI-RENVERSEMENT

D'INSTALLATION

-- L'installation et I'entretien doivent _tre r6alis6s par un

installateur qualifi6, un technicien de service ou le

fournisseur de gaz.

Remarque : Pour les appareils installOs

dans I'Etat du Massachusetts, reportez-

vous a la page 2.

DIMENSIONS

HORS TOUT DE 64,5cm

LA CUlSINI¢:RE _-- (7_5"90'_-/L_-._po_ 1254'8po/

....... /

! ......... .......

maximum

I | 1,4!0++om

] /36-+t,+

t 13,3 cm (44-6/8 po) ,9 cm ...._..._\\

porte euverte (29-7/8 pe)t _ _ _ _ _

\ \_i- ....

D6gagements et dimensions

1. Emplacement-- Verifiez I'emplacement ou sera installee

la cuisiniere. Verifiez s'ily aune source d'electricite et une

source de gaz appropriees, ainsi que la stabilite du

plancher.

2. Les dimensions donnees sur I'image doivent _tre

respectees. Les dimensions donnees procurent un

degagement minimal. La surface qui supportera I'appareil

doit _tre solide et de niveau.

p/n 316469101 EN/FR (0609)

_IIC6CI _DEIACE LATI2RALE U

_uU_lem9_le m _Jpon_ "-_ _- I (18po) dechaquec6te au-dessusde /t-

t,4cm/36 e/o

VUE VUE

76,2 cm (30 po) A Profondeur i i

minimum T D stance m n ma e maximale. I,_1-_-_-_--_1

I 45,7 cm entre les armoires, des armolres (13 po)

/ / de la cuJsJnJere, la su[fac.e de /

_ 76,2 cm _ De_a_m_nt de 0 cm (0 po) sous la surface de cuisson

(30 po) et a rarrier_ de la cui$inier_.

Remarques importantes pour I'installateur

1. Lisez toutes les instructions contenues dans ce guide avant

de proceder & l'instaltation de ta cuisiniere.

2. Retirez tout te materiel d'emballage des compartiments du

four avant de connecter la cuisiniere a l'alimentation en gaz

eta t'alimentation en electricite.

3. Respectez tousles codes et toutes tes ordonnances.

4. Assurez-vous de laisser ces instructions a l'utilisateur.

Remarque importante pour I'utilisateur : Conservez ces

instructions avec leguide d'utilisation et d'entretien pour vous

y reporter ulterieurement.

la CUlSlnlere.(36 po) de hauteur, oooo_=_ ................. "1

Page 8

MESURES DE S¢CURIT¢

IMPORTANTES

L'instaltation de cette cuisiniere dolt 6tre faite conformement aux

codes locaux ou, si ce type de code n'existe pas, au code national

sur te gaz combustible ANSI Z223.1 (derniere edition si t'appareit

est instalte aux €:tats-Unis). Lorsque ta cuisiniere est instaltee au

Canada, t'installation dolt 6tre conforme aux normes CAN/CGA-

B149.1 et CAN/CGA-B149.2.

La conception de cette cuisiniere a ete approuvee par CSA

International. Comme dans te cas de tousles appareits

fonctionnant au gaz et produisant de ta chaleur, it est necessaire

de suivre certaines regles de securit& Vous les trouverez dans

le Guide de l'utilisateur. Lisez-les attentivement.

• Assurez-vous que votre cuisiniere est installee et mise &

la terre de fa_on appropriee par un installateur qualifie ou

un technicien de service.

• Cette cuisiniere doit _tre mise a la terre conform6ment aux

codes Iocaux ou, en I'absence de tels codes, conformement

au National Electrical Code ANSI/NFPA n° 70 (derniere

edition Iorsque I'installation est faite aux I_tats-Unis). Lorsque

la cuisiniere est installee au Canada, celte-ci dolt 6tre mise

& ta terre conformement &ta norme C22.1 de la CSA, Code

canadien de t'etectricite, partie 1. (Veuitlez lire tes instructions

de mise & la terre se trouvant aux pages 5 et 6.)

• L'instaltation des appareits congus pour les maisons

prefabriquees (maisons mobiles) dolt 6tre conforme & ta

norme Manufactured Home Construction and Safety

Standard, titre 24 CFR, partie 3280 (anciennement designee

comme ta Federal Standard for Mobile Home Construction

and Safety, titre 24, HUD [partie 280]) ou, si cette norme ne

s'applique pas, l'instaltation dolt 6tre conforme & ta norme

ANSI Z225.1/NFPA 501A de ta Standard for Manufactured

Home Installations 1982, derniere edition, ou aux codes

locaux s'ils sont installes aux €:tats-Unis. Lorsque les

appareits sont instaltes au Canada, t'installation dolt 6tre

conforme a ta norme CAN/CSA-Z240 MH.

• Avant d'installer la cuisiniere dans unendroit recouvert de

linoleum ou de tout autre type de rev_tement de sol

synthetique, assurez-vous que ce rev_tement peut

supporter une chaleur se situant au moins a 32,2 °C (90 °F)

au-dessus de la temperature de la piece sans qu'il ne

r6trecisse, ne gauchisse ou ne se decolore. N'instaltez pas

la cuisiniere sur de la moquette, a moins que vous placiez

une plaque isolante en contreplaque d'une epaisseur de

0,6 cm (1/4 po) entre l'appareil et la moquette.

• Assurez-vous que le rev_tement des murs qui se trouve

autour de la cuisiniere peut supporter la chaleur produite

par celle-ci.

• N'obstruez pas le debit d'air niau niveau de I'event du four,

ni autour de sa base. Ne bloquez pas non plus le panneau

avant inferieur de la cuisiniere. #vitez de toucher aux

ouvertures de t'event ou a ta region situee pres des surfaces,

car celles-ci peuvent devenir tres chaudes lorsque te four

fonctionne. Cette cuisiniere necessite de l'air frais pour

permettre une bonne combustion des br01eurs.

[!_:\vi_:til,'_,l_V_l_ill Grimper, s'appuyer ou s'asseoir sur

les portes ou les tiroirs de la cuisiniere peut causer des

blessures graves aux personnes ainsi que des dommages a la

cuisiniere.

_!V_,\v_q;ilk}lq_V_lq_ttil Ne laissez jamais un enfant seul ou

sans surveillance aproximite d'un appareil electromenager en

marche. Lorsque les enfants grandissent, enseignez-leur la

fagon d'utitiser les appareils etectromenagers de fagon appropriee

et securitaire. Ne laissez jamais ta porte du four ouverte lorsque

celui-ci est laisse sans surveillance.

• Ne rangez pas d'articles pouvant interesser les enfants

dans les armoires se situant au-dessus de la cuisiniere. En

voulant atteindre ces articles, les enfants risqueraient de se

br01er gravement.

• Pour eliminer le besoin d'avoir &se pencher au-dessus des

brQleurs de surface, vous devriez eviter de ranger des

articles dans les armoires situees au-dessus des brQleurs.

• Reglez la flamme du brQleur de surface pour qu'elle ne

depasse pas du bord de I'ustensile de cuisson. Lesflammes

excessives sont dangereuses.

• N'utilisez pas le four comme espace de rangement. Cela

pourrait creer une situation potentieltement dangereuse.

• N'utilisezjamais votre cuisiniere pour rechauffer ou chauffer

une piece. Une utitisation prolongee de la cuisiniere sans

aeration adequate peut s'averer dangereuse.

• N'entreposez pas et n'utilisez pas d'essence ni d'autres

liquides et vapeurs inflammables pres de la cuisiniere ou

de tout autre apparei l electromenager. Cela pourrait causer

des explosions ou des incendies.

• Remettez toutes les commandes & la position _<OFF _>

(arr_t) apres avoir utilise la fonction de programmation de

la minuterie.

• Les rideaux d'air ou les hottes de cuisinieres en hauteur,

qui projettent de I'air vers la cuisiniere en contrebas, ne

doivent pas _tre utilises avec des cuisinieres a gaz sauf si

la hotte et la cuisiniere ont ete con_ues, testees et

repertoriees par un laboratoire d'essai independant pour

pouvoir fonctionner conjointement.

Avant de commencer :

Votre cuisinJere a ete prereglee & I'usine pour fonctionner au gaz

naturel. Cet electromenager peut 6tre converti au gaz propane/

GPL gr&ce & t'installation du necessaire de conversion au GPL

fourni qui se trouve & l'arriere de l'appareil.

Instructions particuli#res pour les appareils instafl#s dans I'Etat

du Massachusetts " Cet appareil ne peut etre instafl# dans I'Etat

du Massachusetts que par un plombier ou un monteur

d'installations au gaz qualifi#s de cet Etat. Si vous utilisez un

raccord de gaz flexible, celui-ci ne dolt pas exc#der 0,91 m (3 pi)

de Iongueur. Un robinet de gaz manuel en _ T _ dolt etre install#

b la conduite de gaz qui est branch#e b cet apparefl.

N'ESSAYEZ PAS DE FAIRE

FONCTIONN ER LEFOURAALLUMAGE I_LECTRIQUE DURANT

UNE PANNE D'C:LECTRICIT¢:. REMETTEZ TOUTES LES

COMMANDES DU FOURA LA POSITION <<OFF >>(ARRI_T) EN

CAS DE PANNE D'I_LECTRICIT¢:.

L'allumeur etectrique raltumera automatiquement te brQleur

du four torsque t'etectricite reviendra, sites commandes du

thermostat du four ont ete laissees & <<ON >>(marche).

Lorsqu'une panne d'electricite survient durant t'utilisation, les

br01eurs de surface continueront de fonctionner.

Durant une panne d'electricite, tes br01eurs de surface peuvent

6tre altumes au moyen d'une altumette. Tenez une altumette

altumee pres du br01eur, puis faites tourner tentement te

bouton & ta position <<LITE >>(allumage). Faites preuve d'une

grande prudence lorsque vous allumez les br01eurs de cette

fagon.

Page 9

Avant de commencer

Outils n6cessaires

Pour I'ajustement des pieds de mise a niveau et I'installation du

support anti-renversement :

une cle a molette ou une pince multiprise ordinaire

un tournevis a douille de 5/16 po ou un tournevis a t6te plate

une perceuse electrique munie d'une meche de 1/8 po de diametre

(si I'installation est faite dans le beton, utilisez une meche a ma£onnerie

de 5/32 po)

Pour le raccord d'alimentation en gaz :

• une cle a tuyau .....

Pour I'ajustement de la flamme du br_leur :

• un tournevis Phillips _ et un tournevis a lame

plate (__

Autres articles dont vous aurez besoin :

• un robinet d'arr6t pour conduite de gaz _._'_

• de la p_te a joint pour tuyau resistante au gaz propane/GPL

P,_TEA_,Oi.T

_ ,ouR,u','AolL

• une conduite flexible en metal pour appareil electromenager neuve

(1/2 po de N PT x 3/4 po ou 1/2 po de D 1)qui doit 6tre approuvee par

CSA International. En raison du fait que les tuyaux rigides restreignent

le deplacement de la cuisiniere, nous recommandons I'utilisation

d'u ne conduite flexible neuve (mesurant de 122,9 cm a 152,4 cm [4 pi

5 pi]) pour chaque nouvelle installation ou reinstallation.

pour installer le support sile gabarit n'est pas disponible.) Faites une

marque sur le plancher ou sur lemur a I'endroit or3le c6te gauche ou

le c6te droit de I'appareil se trouvera.

Si I'arriere de la cuisiniere repose contre lemur ou nese situe pas

plus de 3,2 cm (1-1/4 po) de celui-ci Iorsqu'elle est installee, vous

pouvez utiliser soit la methode de montage surle plancher, soit la

methode de montage sur lemur. S'il y a une moulure et que celle-ci

emp_che d'appuyer completement le support contre lemur, enlevez-

la ou montezlesupport surle plancher. Poureffectuerle montage sur

lemur, installez lesupport en pla£ant le bord arriere du gabarit contre

lemur qui se trouve a I'arriere de la cuisini@e et le bord lateral du

gabarit surla marque servant de repere pour I'emplacement du cSte

de la cuisini@e. Placez le support sur le dessus du gabarit et faites

des marques sur lemur pour indiquer a quel endroit seront inserees

les vis. Si I'arriere de la cuisiniere se situe a plus de 3,2 cm (1- 1/4 po)

du mur Iorsqu'elle est installee, fixez le support au plancher. Pour

effectuer le montage sur le plancher, installez le support en plagant

le bord arriere du gabarit a I'endroit or3I'arriere de la cuisini@e se

trouvera. Faites des marques pour indiquer a quel endroit les vis

seront enfoncees, tel que montre sur le gabarit.

B,

Pergage d'avant-trous et fixation du support- Percez un avant-

trou de 0,3 cm (1/8 po) a I'endroit or3 les vis seront ins@ees. Sile

support dolt 6tre monte sur lemur, percez les avant-trous dans un

angle descendant d'environ 20 °. Sile support dolt 6tre monte sur un

plancher en beton ou en c@amique, percez des avant-trous de

0,4 cm (5/32 po) d'une profondeur de 4,5 cm (1-3/4 po). Les vis

fournies peuvent 6tre utilisees dans le bois ou dans le beton. Servez-

vous d'un tournevis a douille de 5/16 po ou d'un tournevis a t6te plate

pour fixer le support en place.

FIXATION DU SUPPORT (SUR LE pLANCHER OU SUR LE MUR) FIXATION DU SUPPORT (SUR LE PLANCHER SEULEMENT)

niveau (1-1/4 po) _<'-- 3,2PlUSomde

I_ 3,2 cm 14"

(1-1/4po)

Utilisez toujours les (2) raccords-unions a evasement neufs (1/2 po

de NPT x 3/4 po ou 1/2 po de D l) fournis avec la nouvelle conduite

flexible pour appareil electromenager afin d'effectuer le raccordement

de la cuisiniere.

I tapes asuivre pour uneinstallation normale •

1. Instructions d'installation du support anti-renversement

Avis de securite important

Afin de reduire les risques de renversement, la cuisini@e dolt 6tre fixee

au plancher de fagon appropriee au moyen du support anti-renversement

et des vis fournis avec la cuisiniere. Ne pas installer le support anti-

renversement peut faire en sorte que la cuisiniere bascule si un poids

excessif est place sur la porte ouverte ou si un enfant grimpe su rI'appareil.

Des blessures graves peuvent 6tre causees par le renversement de

liquides chauds ou par la cuisiniere elle-m6me.

Si vous devez changer I'emplacement de la cuisiniere, les supports anti-

renversement doivent egalement 6tre installes au nouvel endroit.

Des instructions sont fournies pour I'installation dans le bois ou dans le

ciment, surle plancher ou sur lemur. Lorsque vous faites I'installation sur

lemur, assurez-vous que les vis sont bien enfoncees dans la cloison

seche et qu'elles sont fixees dans du bois ou d umetal. Lorsq ue vous faites

I'installation sur le plancher ou sur le mur, assurez-vous que les vis ne

s'enfoncent pas dans des ills electriques ou de la tuyauterie.

I'aide du gabarit - (Le support

A. Installation du support a ____-_ii ......

gauche ou sur le c6te droit de la

cuisiniere. Servez-vous de

peut 6tre installe sur le c6te

I'information fournie ci-dessous

Fixation sur _ Fixation sur _ ;; Support anti-renversement

le plancher le plancher

C,

Mise a niveau et positionnement de la cuisini_re - Mettez la

cuisini@e a niveau en ajustant les 4 )ieds de mise a niveau a I'aide

d'une cle. Remarque " 11est necessaire de laisser un espace de

degagement d'au moins 0,3 cm (1/8 po) entre la partie inf@ieure de

la cuisini@e et le pied de mise a niveau pour disposer d'un espace

suffisant pour le support. Servez-vous d'un niveau a bulle pour

verifier vos ajustements. Faites glisser la cuisiniere pour la remettre

en place. Enlevez le panneau inf@ieur de la cuisini@e ou le tiroir de

rangement et effectuez une v@ification visuelle pour vous assurer

que le pied de mise a niveau arri@e est bien insere dans le support

anti-renversement. Dans le cas des modeles comportant un tiroir

chauffant ou un tiroir-gril, agrippez le bord sup@ieur arri@e de la

cuisini@e et, avec precaution, tentez de la pencher vers I'avant.

Mur

Page 10

2. Fournir une alimentation en gaz appropriee.

Get appareil 6]ectrom6nager est con_u pour fonctionner a I'aide d'une

pression au co]lecteurde 10,2 cm (4 po)]orsque ceHe-ci est ajustee pour

le gaz nature], et de 25,4 cm pour le gaz propane/GPL Un detendeur

convertible est raccorde au coHecteur et DOlT 6tre branche en s@ie avec

la concluite d'a]imentation en gaz quel que soit le type de gaz utilis&

Durantl'installation de lacuisiniere, il est important de s'assurer que le debit

d'air necessaire a la combustion eta la ventilation ne soit pas obstrue.

Pour assurer lebon fonctionnement dela cuisiniere , la pression d'admission

maximale allant vers le detendeur ne dolt pas 6tre superieure a 35,6 cm

(14 po)a la colonne d'eau. La pression d'admission allant vers le detendeur

doit 6tre superieure d'au moins 2,5 cm (1 po) a la pression au collecteur

du detendeur. Exemples : Si le detendeur est regl6 a une pression au

collecteurde 10,2 cm (4 po) pour le gaz naturel, la pression d'admission

doit 6tre d'au moins 12,7 cm (5 po); si le detendeur a 6te converti au gaz

propane/GPL et est regl6 a une )ression au collecteur de 25,4 cm (10 po),

la pression d'admission doit 6tre d'au moins 27,9 cm (11 po).

Veuillez proceder a la detection des fuites en suivant les instructions de

I'etape4g.

La conduite d'alimentation en gaz dolt 6tre de 1/2 po ou de 3/4 po DI.

de lacuisini@re

I_'_=J'_ N'ouvrez pas le detendeur Iorsque vous

effectuez le serrage des raccords.

Raccord de qaz pour les modules a allumaqe electrique :

Robinet Raccord- Conduite flexible Adaptateur de Detendeur

d'arr6t union pour appareil raccord-union |

manuel | 61ectromenager |

March_ _ _-!_ _ _

Arret _,_,_ -_,l_trlnl _ i_

Robinet d'arr6t d'entretien, modeles & allumage electrique

seulement (en position de marche). Assurez-vous que le levier

est & la position ,, On ,, (marche) une fois I'installation completee.

a) Installez un robinet d'arr6t manuel externe surla conduite d'alimentation

en gaz dans un endroit facilement accessible situe a I'exterieur de

la cuisini@e. Assurez-vous de connaftre I'endroit oQ se trouve le

robinet d'arr6t ainsi que la fa£on d'arr6ter I'alimentation en gaz de la

cuisiniere.

b) Installez un raccord-union a evasement de 1/2 po sur le detendeur.

c) Branchezla conduite de I'appareil au raccord-union a evasement du

detendeur.

d) Branchez le raccord-union a evasement au robinet d'arr6t manuel

externe.

e) Fixez la conduite de I'appareil au raccord-union a evasement au

moyen du robinet d'arr6t.

f) Assurez-vous que le robinet d'arr6t d'entretien qui se trouve sur le

detendeurest a la position <_ON >>(marche).

g) V6rifiezs'ilyadesfuites. Ouvrezralimentationengazdelacuisiniere

et servez-vous d'un detecteur de fuite de liquide au niveau de tous

les joints et de toutes les cond uites pour verifier s'il y a des fuites dans

le systeme.

29,2 cm

)o)

L'emplacement recommande

de laprise de 120 Vsur le

mur arriereet I'emplacement

de laconnexion murale du

tuyau et du robinet d'arr_t

55,9 cm

(22 po)

(10-i/2 po)

manuel correspondent

la zone ombragee.

/

Emplacement recommandepour la q _ _ Bord du mur

connexionpar le plancher du tuyau

etdu robinetd'arr_t manuel.

3. Boucher les ouvertures.

Apres avoir installe la conduite d'alimentation en gaz, bouchez toutes les

ouvertures qui se trouvent dans lemur situe derriere la cuisiniere ainsi que

ceux se trouvant dans la partie du plancher situee sous la cuisini@e.

4. Raccorder la cuisini_re a la conduite d'alimentation en gaz.

Pour eviter les fuites, mettez de la p_te a joint pour tuyau sur tousles

raccords de tuyau de type m_le (vers I'ext@ieur).

_'!_!'_,\viq_il/k$1q_Vilq_lil N'utilisez pas de flamme pour detecter

les fuites de gaz.

Emplacement du detendeur

Page 11

Verification de la pression de gaz au collecteur

Debranchez la cuisiniere et son robinet d'arr6t de la canalisation de gaz

si laverification de la pression de I'alimentation en gaz indique une pression

qui depasse 35,6 cm (14 po) a la colonne d'eau, soit environ 3,54 kPa

(1/2 Ib/po2).

S'il s'av@e necessaire de verifier la pression de gaz au collecteur,

branchez un manometre (hydrometre) ou un autre appareil de verification

de pression au gicleur du brQleur de surface arriere droit. Tenez un tuyau

en caoutchouc d'environ 0,6 cm (1/4 po) de diametre interieur relie

I'appareil de verification, bien serre contre le gicleur. Ouvrez la soupape

du brOleur.

Pour obtenir une v6rification precise de la pression, faites fonctionner au

moins deux (2) autres br01eurs de surface pendant la verification.

Assurez-vous que la pression d'alimentation en gaz (pression d'admission)

est superieure d'au moins 2,54 cm (1 po) a la pression du collecteur. La

pression de I'alimentation en gaz ne doitjamais 6tre superieure a 35,6 cm

(14 po)a la colonne d'eau. La pression au collecteurest de 10,2 cm (4 po)

Iorsque celle-ci est ajustee de fagon appropriee pour le gaz naturel. (Pour

le gaz propane/GPL, la pression au collecteur doit 6tre de 25,4 cm [10 po].)

5. Lisez d'abord les details ci-dessous concernant les

connexions electriques, puis branchez la cuisini_re a une

source d'alimentation electrique.

_.vV-'\Vl=l_il/k_l=l_V_l=l_llll Avant d'effectuer une reparation,

debranchez I'alimentation electrique au niveau du disjoncteur,

du fusible ou du cordon d'alimentation.

Exigences concernant 1'61ectricite :Circuit de derivation s6pare mis a la

terre et polarise correctement proteg6 par un disjoncteur de 15 A ou un

fusible temporise. Reportez-vous a la plaque signaletique pour connaftre

la tension appropriee.

Precautions a prendre concernant I'utilisation d'une rallonge :

En raison du danger potentiel que peuvent representer les rallonges dans

certaines situations, nous deconseillons fortement leur utilisation. Toutefois,

si vous choisissez tout de m6me d'utiliser une rallonge, il est absolument

necessaire que celle-ci soit une rallonge pour 61ectromenagers a trois

broches avec mise a la terre homologuee UL et que le courant nominal de

la rallonge soit equivalent ou superieur au courant nominal du circuit de

derivation. Ce type de rallonge est disponible aupres du service apres-

vente de votre region.

_!_±\vlqlt/k_!qlVilq_iil VEUILLEZ LIRE ATTENTIVEMENT CES

INSTRUCTIONS! Pour des raisons de securite, ce produit dolt 6tre

correctement mis a la terre.

Instructions de mise a la terre

Le cordon d'alimentation de cet appareil est muni d'une fiche a trois

broches (mise a la terre) qui correspond aux prises murales a trois

alveoles qui reduisent les risques de chocs electriques causes par cet

appareil. L'utilisateur devrait faire v@ifier la prise murale et le circuit par

un electricien qualifie pour s'assurer que la prise est mise a la terre et

polarisee de fagon appropriee.

Si la prise murale ne possede que deux alveoles, il vous revient de la faire

remplacer par une prise murale a trois alveoles correctement mise a la

terre.

NE COUPEZ JAMAIS, EN AUCUN E ClRCONSTANCE, LA TROISII_ME

BROCHE (MISEA LA TERRE) DU CORDON D'ALIMENTATION.

M_thode recommand_e

fNe jamais couper, _'_

_enlever ou mettre |

_hors circuit la broche I

L _de mise _ la terre J

de cette fiche. ._

d'alimentation

muni d'une

Prise murale fiche _ trois

avec mise broches avec

__ Cordon

la terre / mise _ la terre

6. Fonctionnement des br_leurs de surface

Apres vous 6tre assure que la cuisini@e et les raccords de la conduite

d'alimentation ne presentent aucune fuite, branchez la cuisini@e

I'alimentation en electricite et v@ifiez le fonctionnement des allumeurs

electriques.

Verification des br_leurs de surface

Pour verifier I'allumage, poussezet tournez le bouton de I'un des br01eurs

de surface et mettez-le a la position LITE (allumage). S'il fonctionne

normalement, chaque brOleur devrait s'allumer en l'espace de 4 secondes.

Une fois que le br01eur s'est allume, le bouton de commande devrait 6tre

retire de laposition <<LITE >>(allumage). Essayez chaque bouton separement

jusqu'a ce que tousles robinets des br01eurs aient ete v@ifies.

R6glage de _]_

I'obturateur d'air

7. Recllage du debit d'air

L'obturateur d'air (reglage) de chacun des 4 brQleurs de surface se trouve

I'extremite ouverte du tube de venturi et repose sur la t6te du robinet.

Si I'obturateur d'air doit 6tre regle, tournez-le pour permettre d'ajuster au

besoin le debit d'air qui entre dans les tuyaux des brQleurs.

Si le d6bit d'air est regl6 de fa£on appropriee, la flamme sera constante,

relativement silencieuse et aura un c6ne d'un bleu vif d'environ 1,3 cm

(1/2 po). (Habituellement, I'obturateur d'air doit 6tre ajuste au centre.)

Si laflamme est de couleurjaune, agrandissez I'ouverture de I'obturateur

d'air. Si la flamme est d'un bleu franc, mais qu'elle s'eloigne du brQleur,

reduisez I'ouverture de I'obturateur d'air.

8. Reglages du br_leur du four

Apres vous 6tre assure que la cuisini@e et les raccords de la conduite

d'alimentation ne presentent aucune fuite, branchez la cuisini@e

I'alimentation en electricite et v@ifiez le fonctionnement des allumeurs

electriques.

Le brQleur du four est muni d'un systeme de commande electrique ainsi

que d'un allumeur electrique.

Ces systemes de commande ne necessitent aucun reglage. Lorsque le

fourest pr6t a fonctionner, le courant se rendrajusqu'a I'allumeur. Celui-

ci <<brillera >>un peu comme une ampoule. Lorsque I'allumeura atteint une

temperature suffisa nte pour permettre d'allu merle gaz, la soupape du four

commande electriq ue s'ouvrira et fera apparaftre une flam me au niveau

du brQleur du four. tl peut s'ecouler de 30 a 60 secondes apres la mise en

marche du thermostat avant que la flamme apparaisse au niveau du brQleur

du four. Lorsq ue le four aura atteint le reglage desire, I'allumeur s'eteindra.

Laflamme du brQleurs'eteindra dans une periode allant de 20 a 30 secondes

apres que I'allumeur se sera arr6t& Afin de maintenir la temp@ature du

four, ce cycle continuera aussi Iongtemps que le cadran (ou I'afficheur)

sera regle pour fonctionner.

Apres avoir retire tousles mat@iaux d'emballage et la documentation se

trouvant dans le four :

a) Reglez le four a BAKE (cuisson) a une temp@ature de 300 °F

(150 °C). Reportez-vous au Guide de I'utilisateur pour obtenir des

instructions.

b) Le brQleur du four devrait s'allumer en I'espace de 60 secondes.

V@ifiez la qualite de la flamme, puis laissez le brQleur effectuer un

cycle. Eteignez les commandes.

c) Le brQleur du gril devrait s'allumer en I'espace de 60 secondes.

V@ifiez la qualite de la flamme. Eteignezles commandes.

Page 12

Flamme

de2,5cm

(1po)

Deflecteur

Tube

dubrQleur

dufour

Emplacement du numero de module et du numero de serie

La plaque signaletique se trouve sous la table de cuisson relevable.

Lorsque vous commandez des pieces ou que vous desirez obtenir des

renseignements apropos de votre cuisini@e, assurez-vous de toujours

inclure le num@o de s@ie et le num@o de modele ainsi que la lettre ou le

num@o de lot, inscrits sur la plaque signaletique de votre cuisini@e. La

plaque signaletique donne egalement de I'information surla capacite des

brQleurs, le type de gaz a utiliser et la pression a laquelle la cuisini@e a

ete ajustee a la sortie de I'usine.

Avant de faire appel au service apr6s-vente

V@ifiez si les fusibles ou les disjoncteurs de votre maison destines a votre

cuisini@e ne sont pas grilles ou declenches. Reportez-vous a la liste de

v@ification et aux instructions d'utilisation contenues dans le Guide de

I'utilisateur. Cela pourrait vous faire economisertemps et argent. Cette liste

decrit des situations courantes qui ne sont causees ni par un defaut de

fabrication ni parun mat@iau defectueux.

Consultez la page de garantie de votre Guide de I'utilisateur pour

connaitre notre numero sans frais et notre adresse. Veuillez

nous appeler ou nous ecrire si vous avez des questions a propos

de votre cuisini_re et/ou si vous desirez commander des pi_ces.

Visdereglage

deI'obturateur

d'air

Obturateurd'air

T6tedu

I W I gicleur

9. Obturateur d'air du brQleur du four

La fiamme du brQleur du four mesure environ 2,5 cm (1 po) (fiamme

int@ieure distincte de couleur bleu franc).

Pour determiner si lafiamme du brQleur du four est correcte, enlevez la

sole du four et le deflecteur, puis reglez le four a BAKE (cuisson) a une

temp@ature de 300 °F (150 °C).

Pour enlever la sole du four, retirez les vis de retenue qui se situent

I'arriere de la sole du four. Tirez par I'arri@e vers le haut, desengagez

I'avant de la sole du four du cadre avant du four, puis enlevez la sole du

four. Enlevez le defiecteur pour pouvoir examiner la flamme.

Si lafiamme est de couleurjaune, agrandissez I'ouverture de I'obturateur

d'air. Si la flamme est de couleur bleu franc, reduisez I'ouverture de

I'obturateurd'air.

Pour ajuster la fiamme, desserrez la vis de blocage, ajustez I'obturateur

d'air, puis resserrez lavis de blocage. Remettez lasole du four en place.

10. Assurez-vous que le four est de niveau.

Mettez le four a niveau en pla£ant un niveau a I'horizontale sur une grille

du four. V@ifiez en diagonale de I'avant vers I'arriere, puis mettez la

cuisini@e a niveau soit en ajustant les pieds de mise a niveau, soit en

pla£ant des cales au besoin sous les coins de la cuisini@e.

Nettoyage et entretien

Reportez-vous au Guide de I'utilisateur pour connaftre les instructions

d'utilisation et d'entretien.

Si le deplacement de la cuisini@e est necessaire pour effectuer le

nettoyage et I'entretien, fermez I'alimentation en gaz. Debranchez

I'alimentation en gaz et en electricit& Si I'alimentation en gaz ou en

electricite est inaccessible, soulevez legerement I'appareil par I'avant et

tirez-le vers vous pour I'eloigner du mur. Tirez la cuisiniere seulement sur

la distance necessaire pour permettre de debrancher I'alimentation en gaz

et en electricit& Finissez de deplacer I'appareil pour effectuer I'entretien

et lenettoyage. Reinstallez I'appareilen suivant I'ordre inverse tout en vous

assurant de mettre le four a niveau et de v@ifier si les raccords

d'alimentation en gaz presentent des fuites. Reportez-vous aux instructions

concernant ledispositif anti-renversement pour connaTtre les instructions

permettant d'effectuer un ancrage appropri&

11. Apr_s avoir termine I'installation, assurez-vous que toutes

les commandes sont a la position {<OFF >_(arr_t).

Page 13

Loading...

Loading...